Thermoplastics type plastic carrier band recycling splicing using device and work method thereof

A thermoplastic, carrier tape technology, applied in applications, belts, household appliances, etc., can solve the problems of large investment, can only be regarded as waste, not in line with the company's interests, etc., to achieve the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

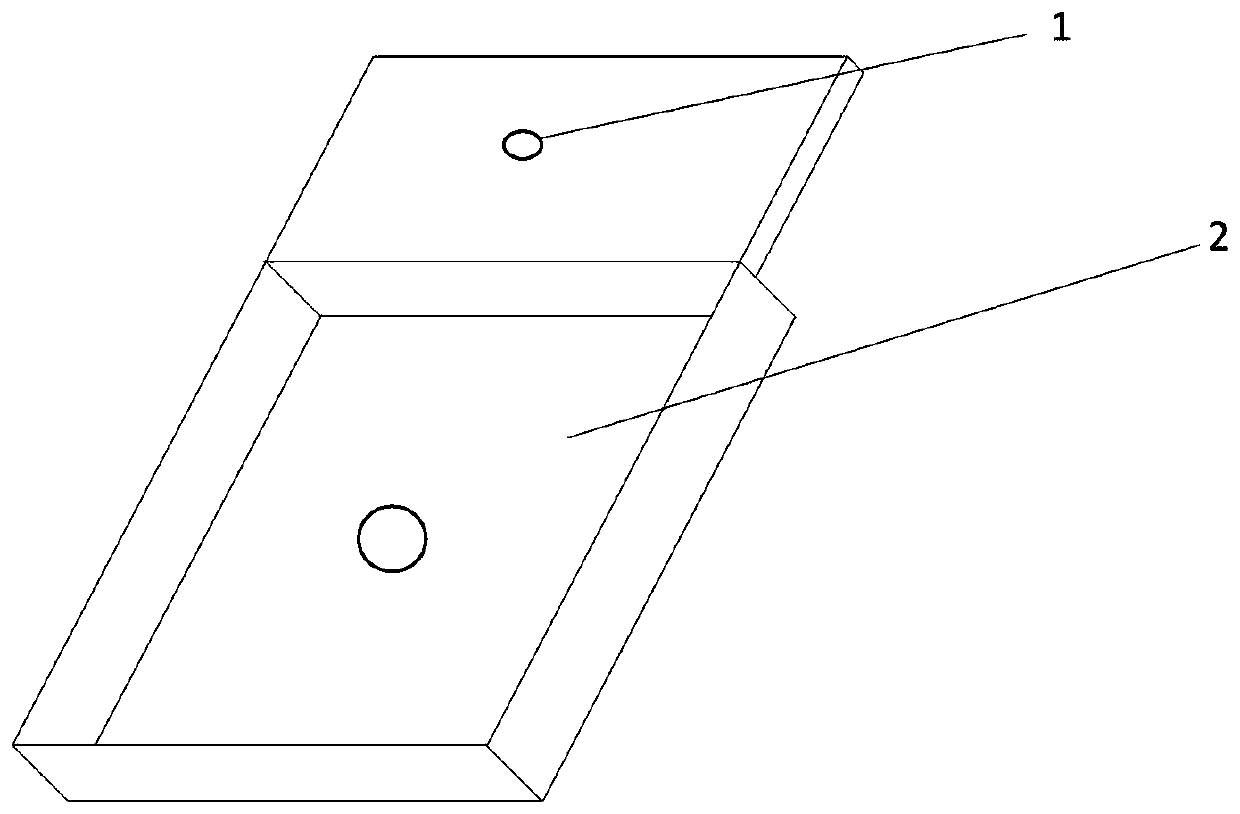

[0028] Such as figure 1 As shown, the carrier tape is composed of several chip packages, and the chip package includes a chip card slot 2 and a counting hole 1; the bottom surface of the chip card slot 2 is provided with holes; on flat surface.

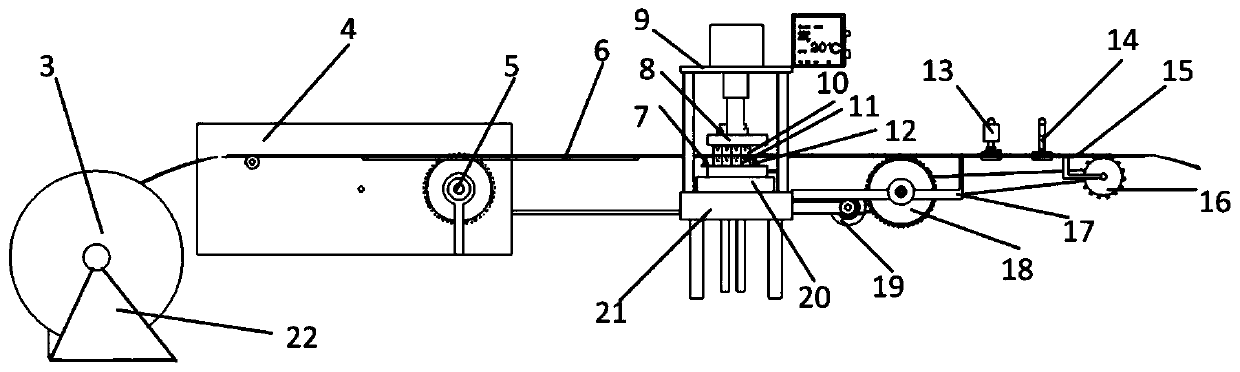

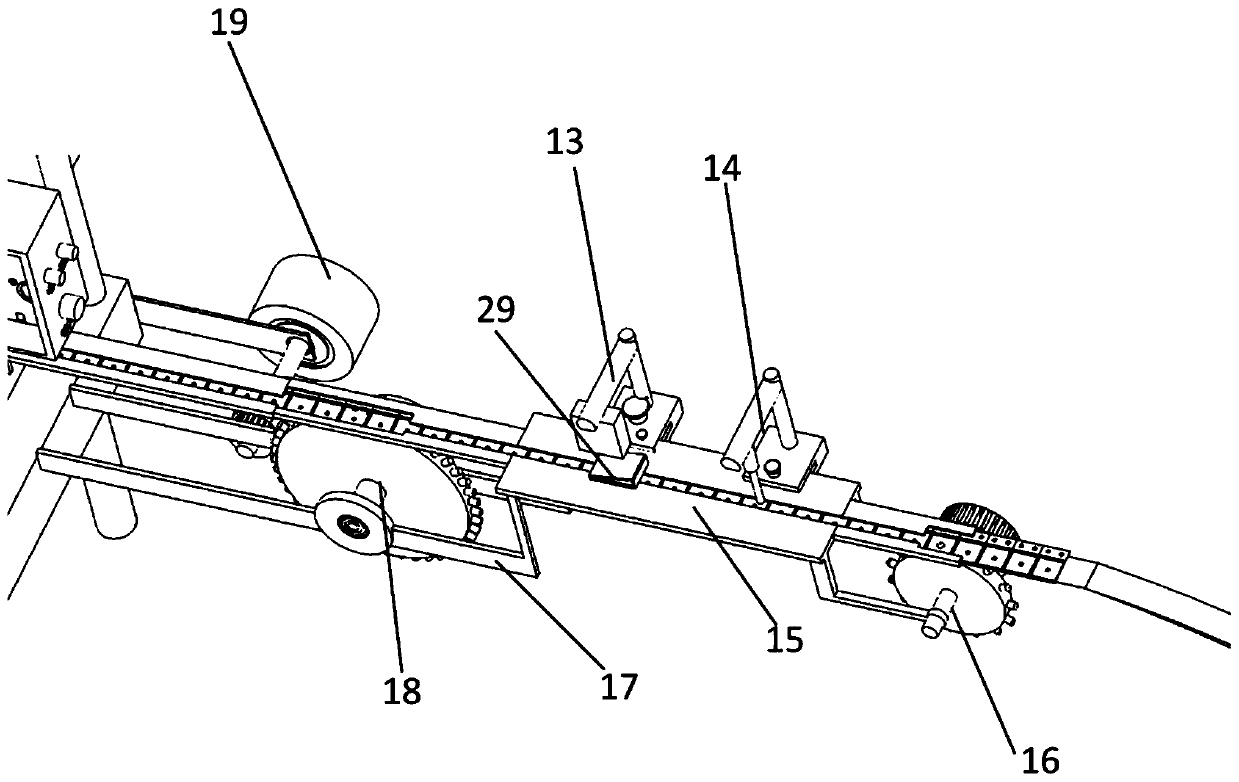

[0029] Such as figure 2 As shown, a thermoplastic carrier tape recycling and splicing utilization device includes a power supply system, a bracket 21, a plastic carrier tape and a control system, and also includes: an injection molding device installed on the bracket 21, fixedly connected with the bracket 21, and connected to the power supply The system is electrically connected and communicated with the control system; the supercharging device is installed on the support 21, fixedly connected with the support 21, electrically connected with the power supply system, and communicated with the control system; the winding device is installed on the support 21 and connected with the support 21 is fixedly connected, electrically connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com