Crack splicing method in bridge quality detection

A bridge and quality technology, applied in the field of crack splicing, can solve the problems of time-consuming and labor-intensive, human error of direct reading by technicians, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and specific conditions.

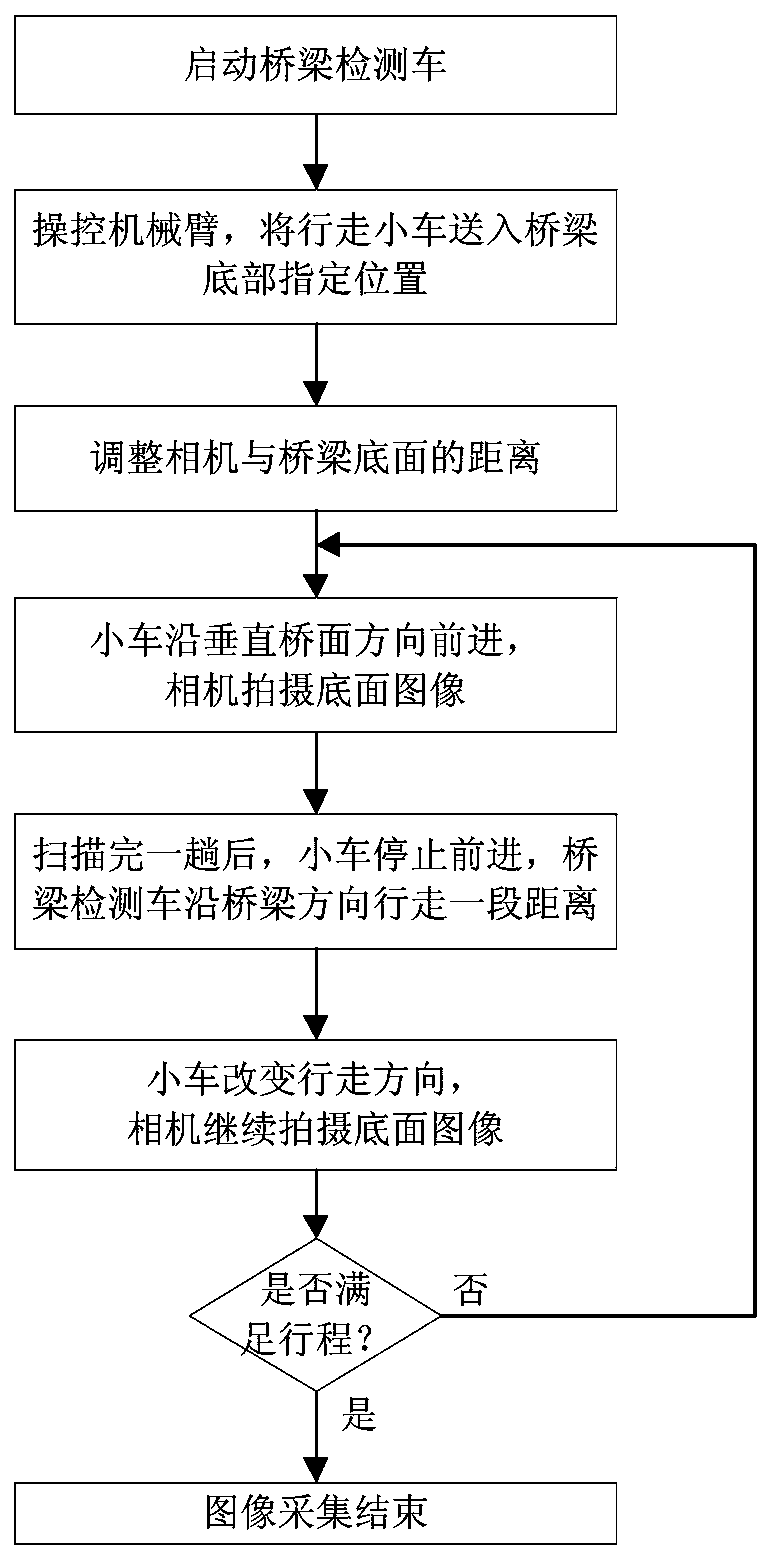

[0082] In the specific implementation of the present invention, a method for splicing cracks in bridge quality inspection comprises the following steps:

[0083] (1) Installation equipment:

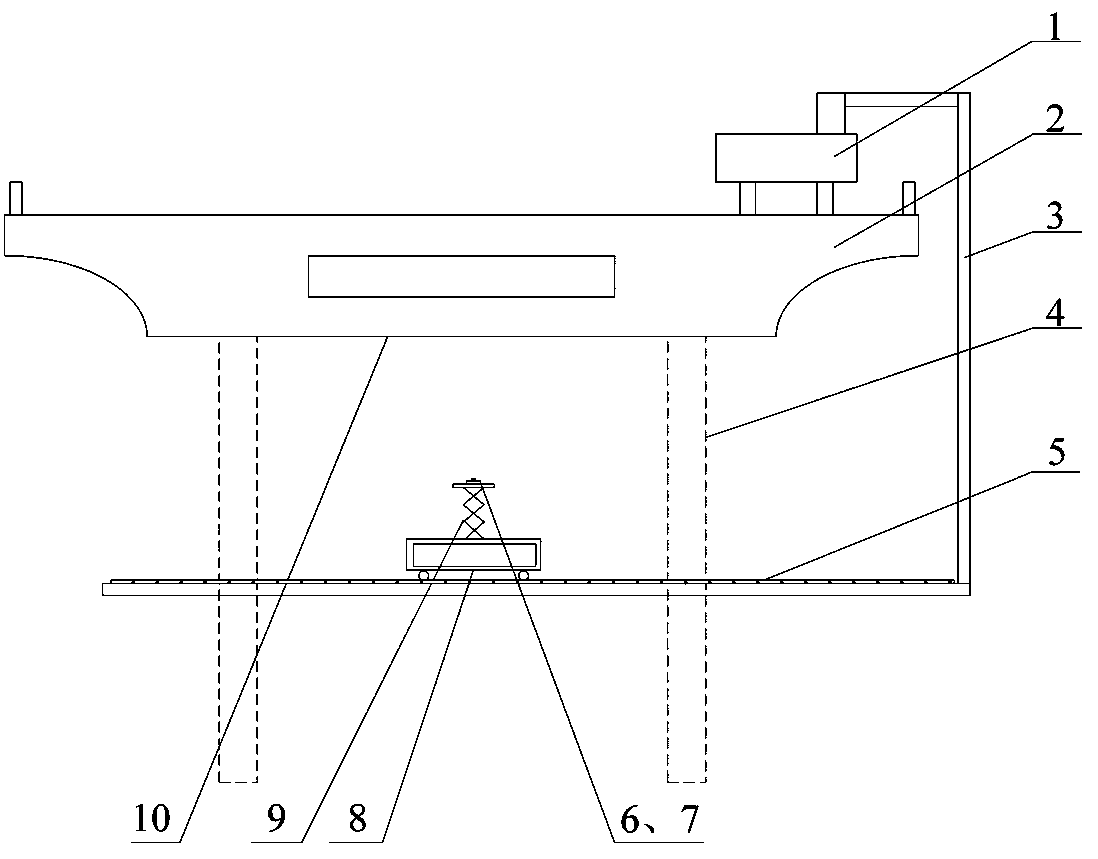

[0084] Depend on figure 1 As shown, the detection vehicle 1 is driven to the top of the area to be detected on the bridge 2, and the downward mechanical arm 3 is installed on the detection vehicle 1, and the linear track 5 parallel to the bridge to be tested part 10 is installed on the lower part of the mechanical arm 3. The track 5 is fixed on the pier 4, and the traveling trolley 8 is installed on the linear track 5, so that the traveling trolley 8 reciprocates along the linear guide rail 5, and the traveling trolley 8 is connected with the control host (optional, not shown in the figure), and the The annular LED light s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com