Automatic yarn replacing, twisting and connecting machine for yarn of multiple colors

A yarn and yarn twisting technology is applied in the field of multicolor yarn automatic yarn changing and splicing machine, which can solve the problems of high labor cost, low work efficiency and high production cost, and achieves eliminating cleaning steps, improving splicing efficiency, The effect of high splicing success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

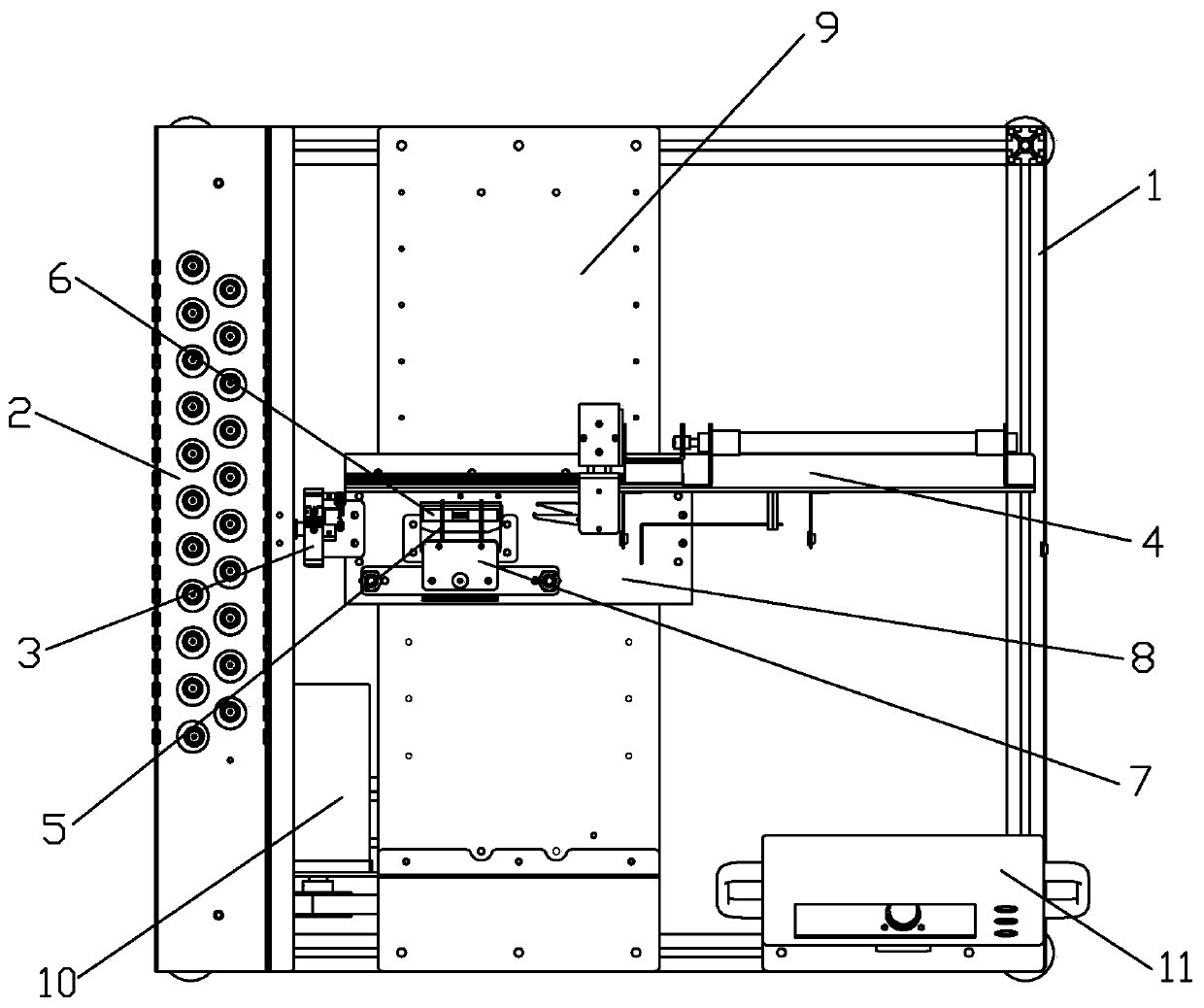

[0025] Such as figure 1 As shown, the multi-color yarn line automatic yarn-changing splicing machine of the present invention comprises a splicing machine frame 1, and a yarn arrangement mechanism 2, a second guide rail 9, a motor 10, and a computer display screen are arranged on the splicing machine frame 1 11. The second guide rail 9 is movably connected with a moving base plate 8, on which a thread cutting and clamping mechanism 3, a yarn gripping mechanism 4, a thread pressing mechanism 5, a splicer 6 and a cleaning mechanism 7 are installed.

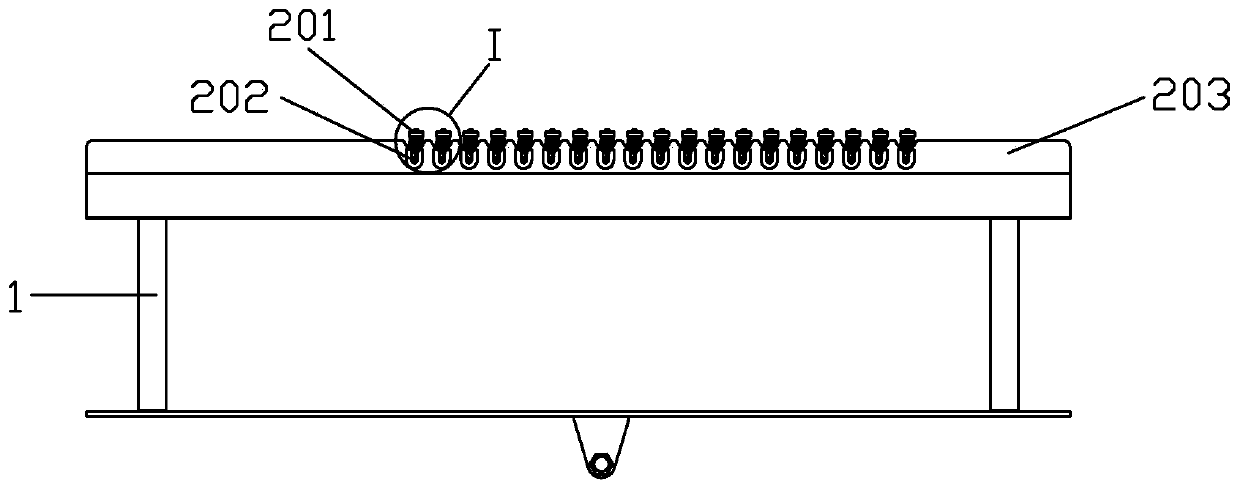

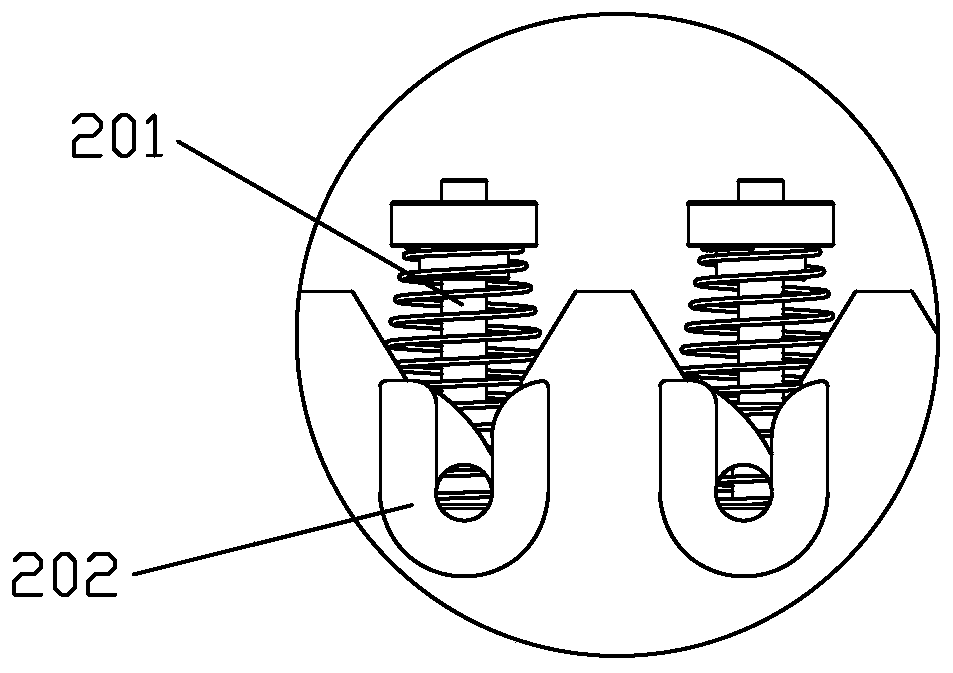

[0026] Such as figure 2 and image 3 As shown, the yarn arrangement mechanism 2 includes a tensioner 201, a magnetic part 202, and a yarn arrangement plate 203. Several tensioners 201 are regularly arranged on the yarn arrangement plate 203 according to a certain gap, and the ceramic parts 202 are arranged on the yarn arrangement plate 203. sides. The tensioner 201 makes the yarn meet certain tension requirements during winding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com