Elastic band connecting machine

A technology of elastic and elastic bands, which is applied in the direction of cloth feeding mechanism, sewing machine components, textiles and papermaking, etc., can solve the problems of cumbersome operation steps, low processing efficiency, and high requirements for operators to operate proficiency, and achieve high structural compactness , high processing efficiency and short feeding stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

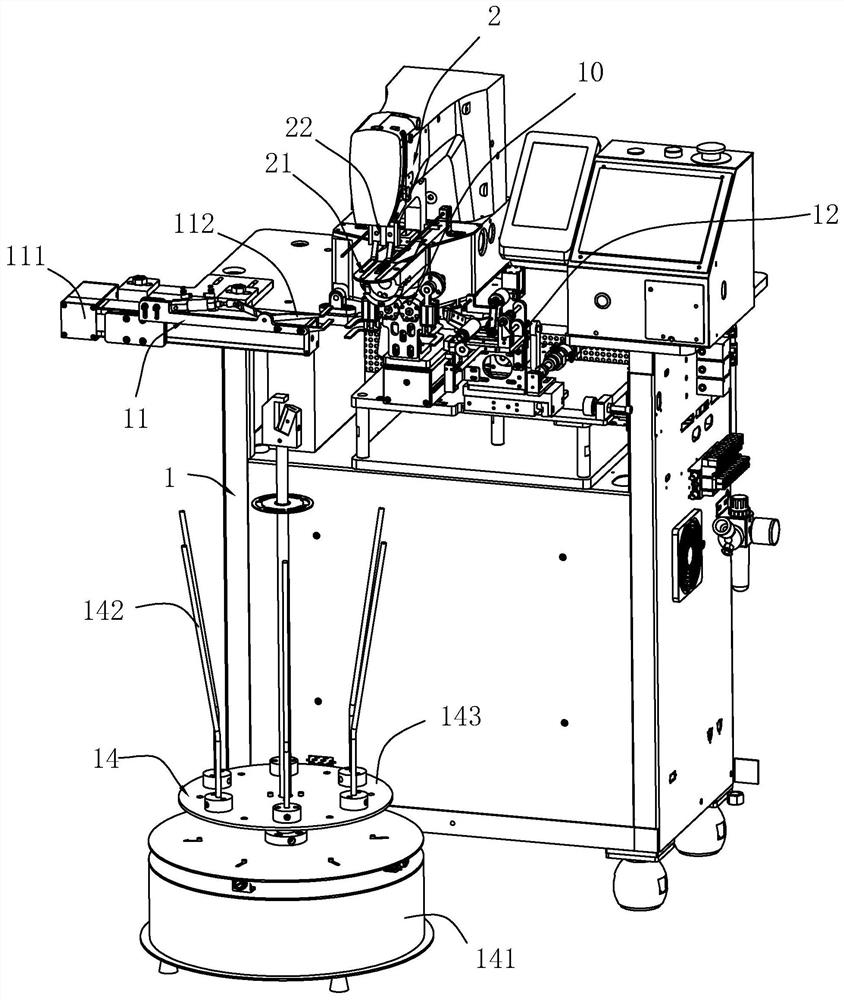

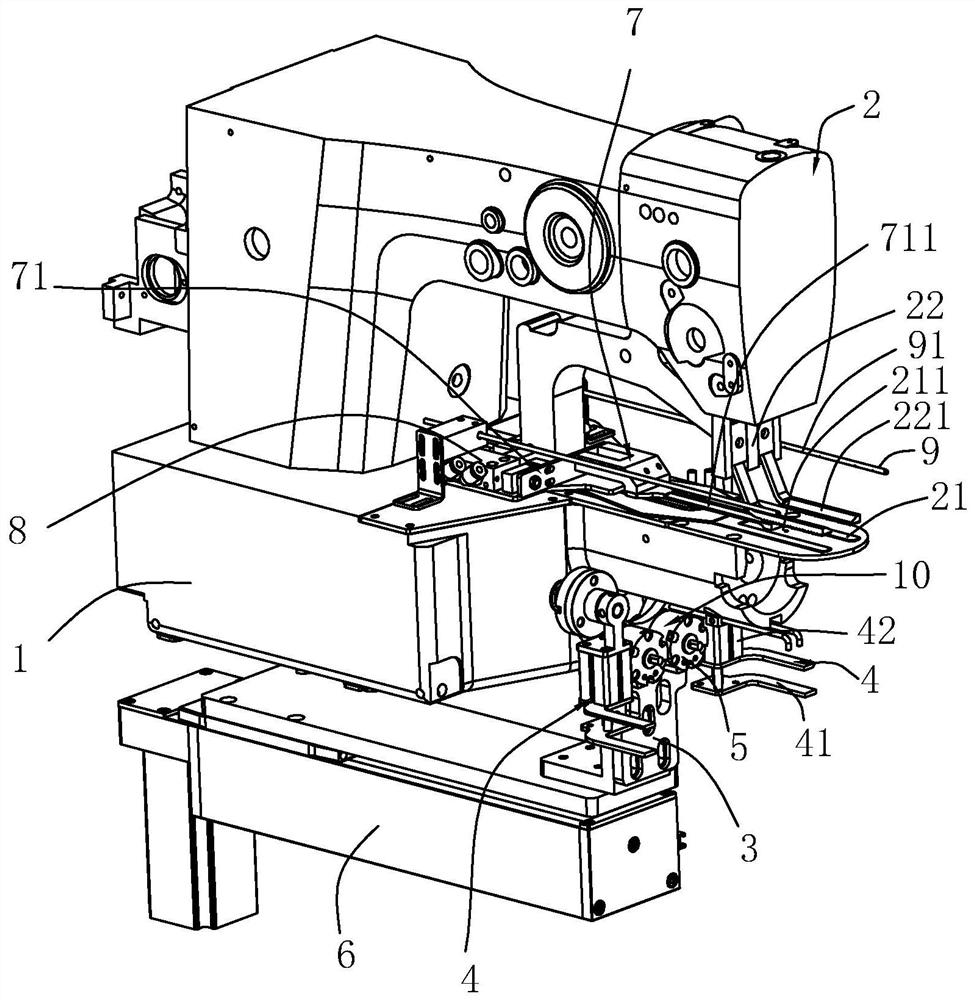

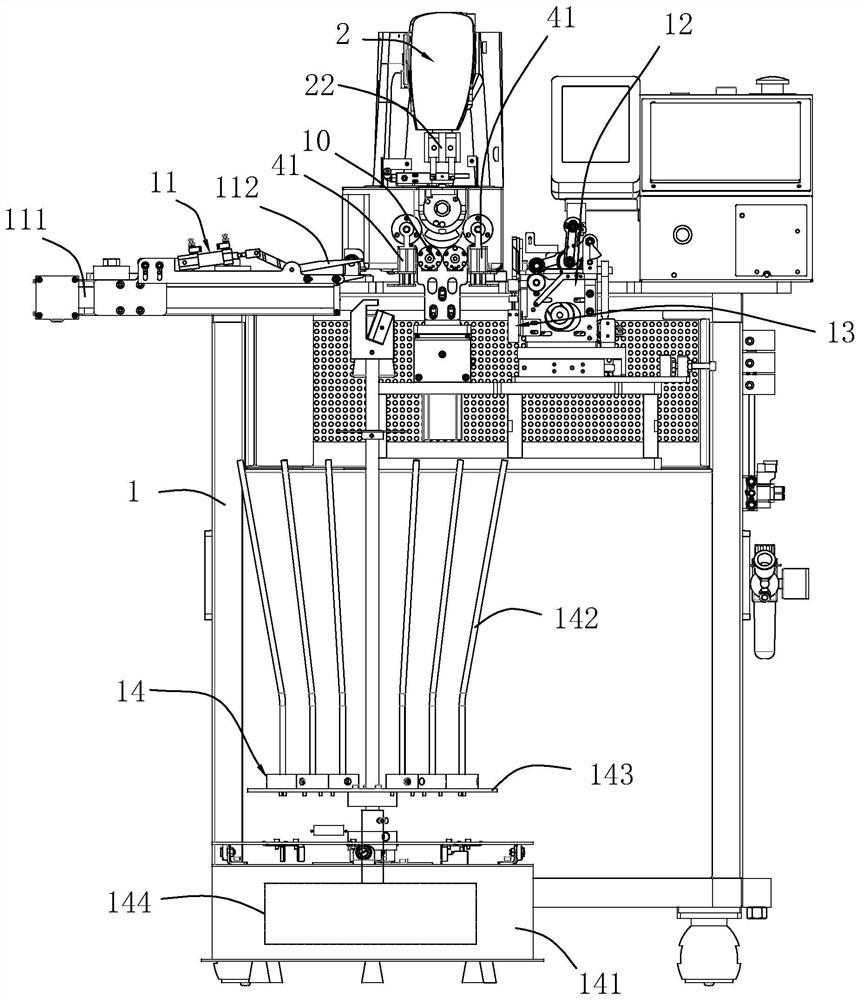

[0045] A kind of elastic machine, see figure 1 as well as figure 2 , including a frame 1, a sewing machine main body 2 is installed on the frame 1, the sewing machine main body 2 includes a seaming platform 21 and a seaming head 22, and the seaming head 22 is used to sew the elastic band on the seaming platform 21. The seaming head 22 includes a seaming presser foot 221 for pressing the elastic band on the seaming platform 21 tightly.

[0046] see figure 1 as well as image 3 , The frame 1 is provided with a material clamping mechanism 11, a material turning mechanism 10, and a material cutting mechanism 12 from left to right.

[0047] Among them, see figure 1 as well as figure 2 , the turning mechanism 10 is located below the sew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com