Device for replacing steel needle with Z-direction steel needle three-dimensional fabrics and buckling fibers

A technology of three-dimensional fabrics and locking devices, which is applied in the direction of braided fabrics, textiles, and papermaking, can solve the problems that manual weaving of three-dimensional fabrics cannot meet market demand, expensive labor costs, and high labor intensity, etc., so as to facilitate popularization and use, The effect of improving product consistency and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]The present invention will be further described in detail below in combination with specific embodiments.

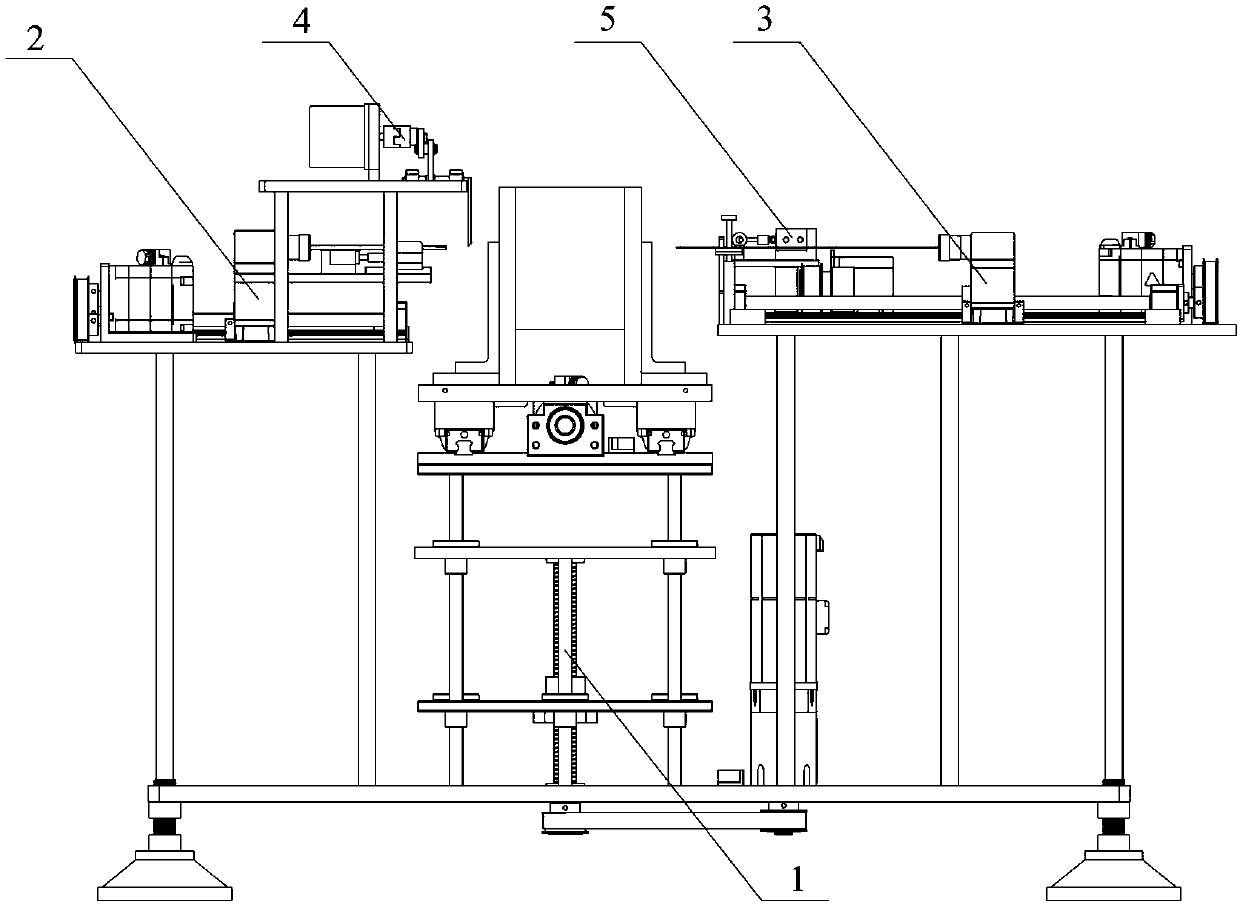

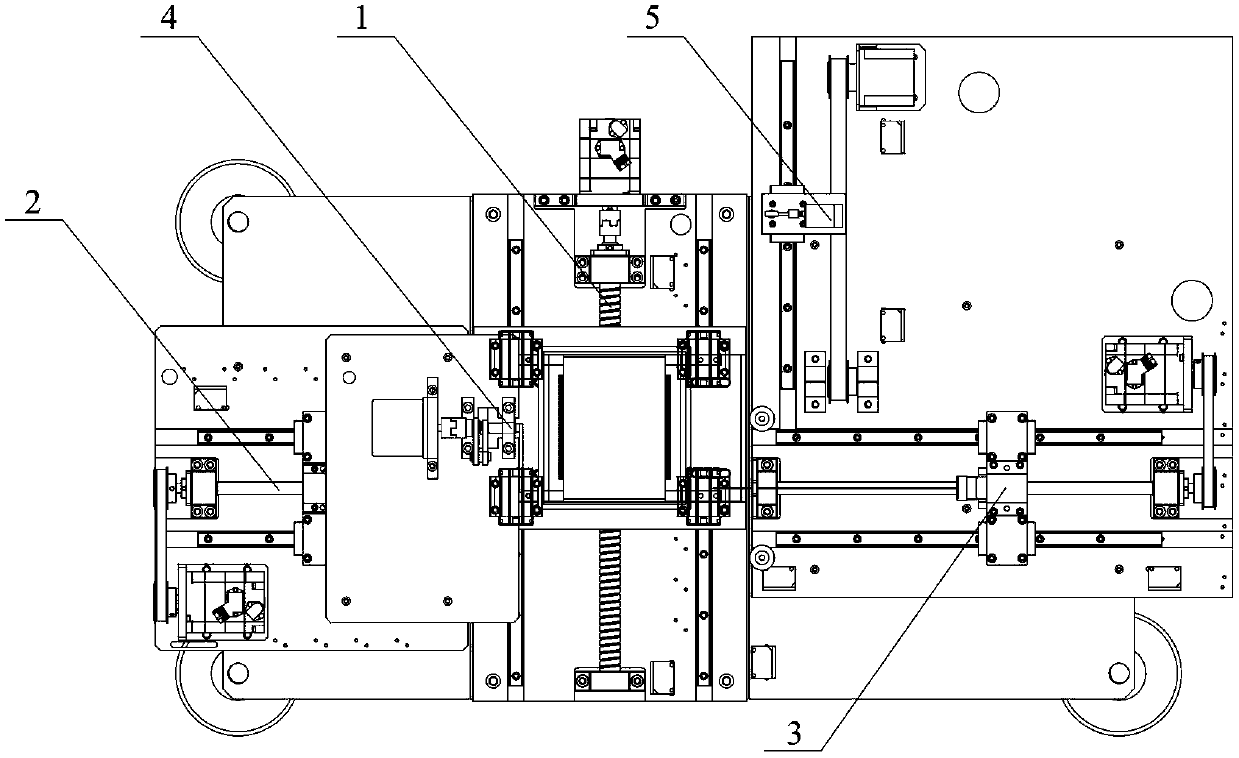

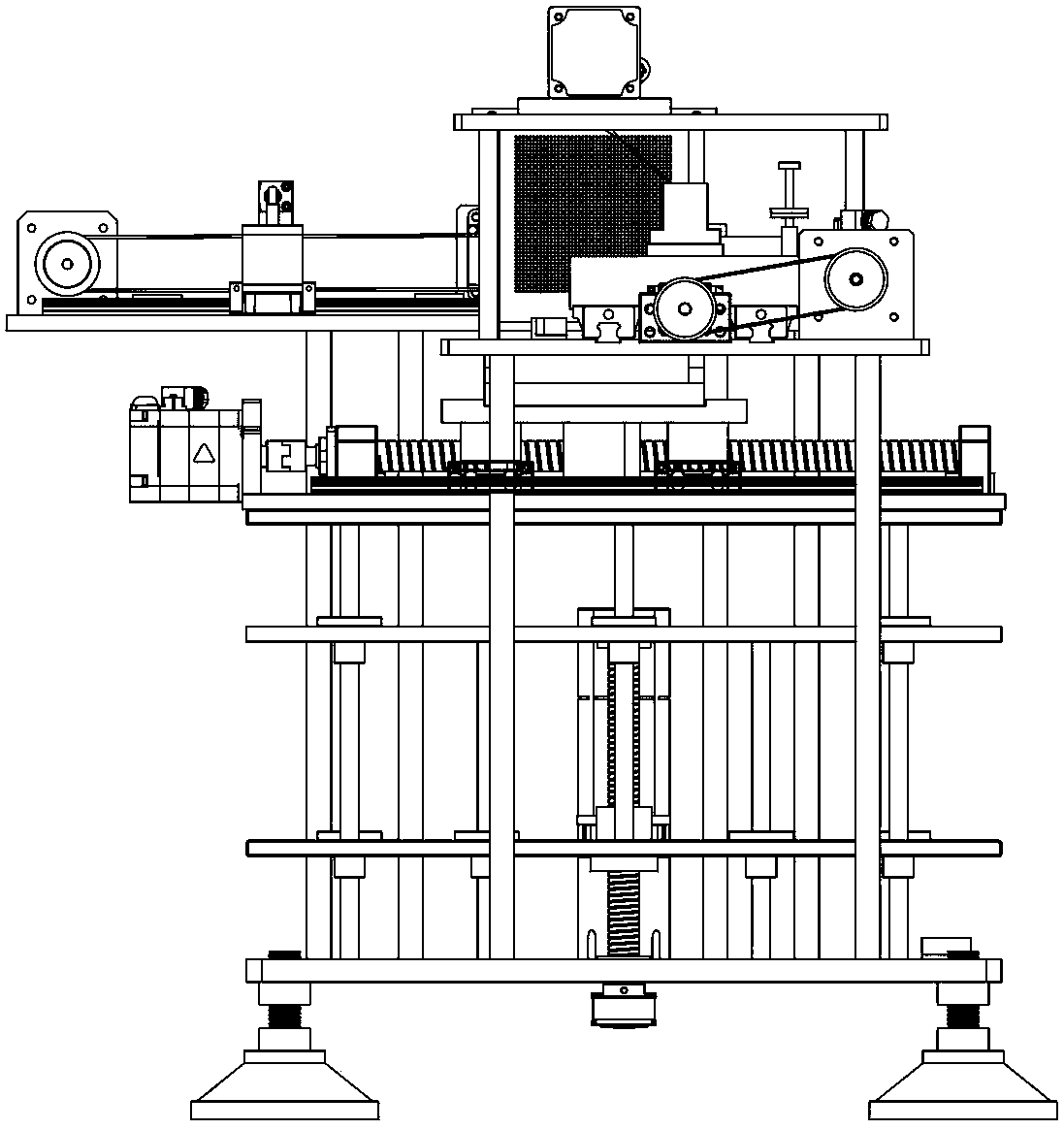

[0049] Such as Figure 1 to Figure 12 As shown, a three-dimensional fabric steel needle replacement and fiber locking device containing Z-direction steel needles includes a mobile workbench 1, a steel needle replacement mechanism 2, a wire feeding mechanism 3, a locking mechanism 4 and a tension control mechanism 5. The mobile worktable 1 includes a Z-direction mobile platform I 104 and a Y-direction mobile platform II 106, which are driven by a servo motor, and a three-dimensional fabric clamping device 1010 containing Z-direction steel needles is fixed on the mobile workbench; the steel needle replacement mechanism 2 is composed of The servo motor III 201 drives the special steel needle holder 203 to move in the X direction to complete the needle taking and clamping of the steel needle; the thread feeding mechanism 3 is driven by the servo motor IV 301 to move th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com