Full-automatic unlimited lengthening machine

A fully automatic technology of lengthening machine, which is applied in the jointing of wooden veneers, wood processing equipment, other plywood/plywood equipment, etc. It can solve the problems affecting the quality of splicing, degumming or dislocation, and high labor costs, and achieve mobile High speed, flat and smooth incision, and reduced processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

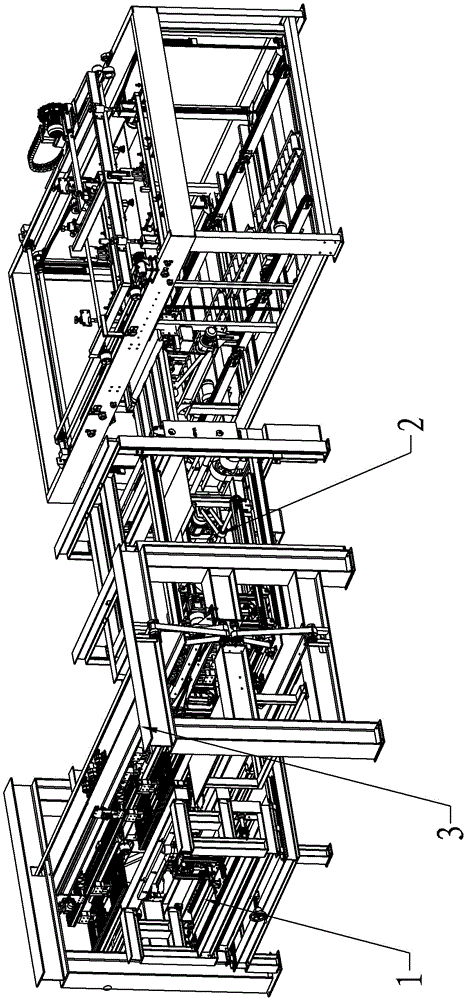

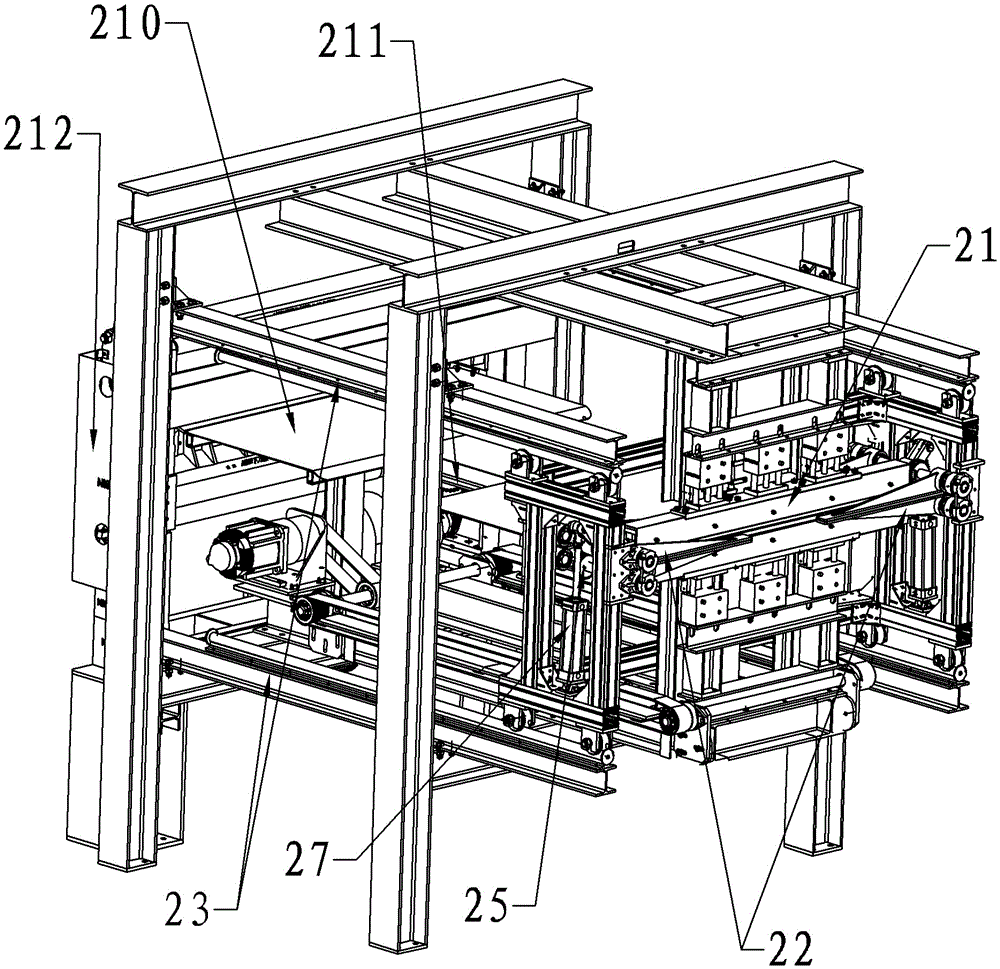

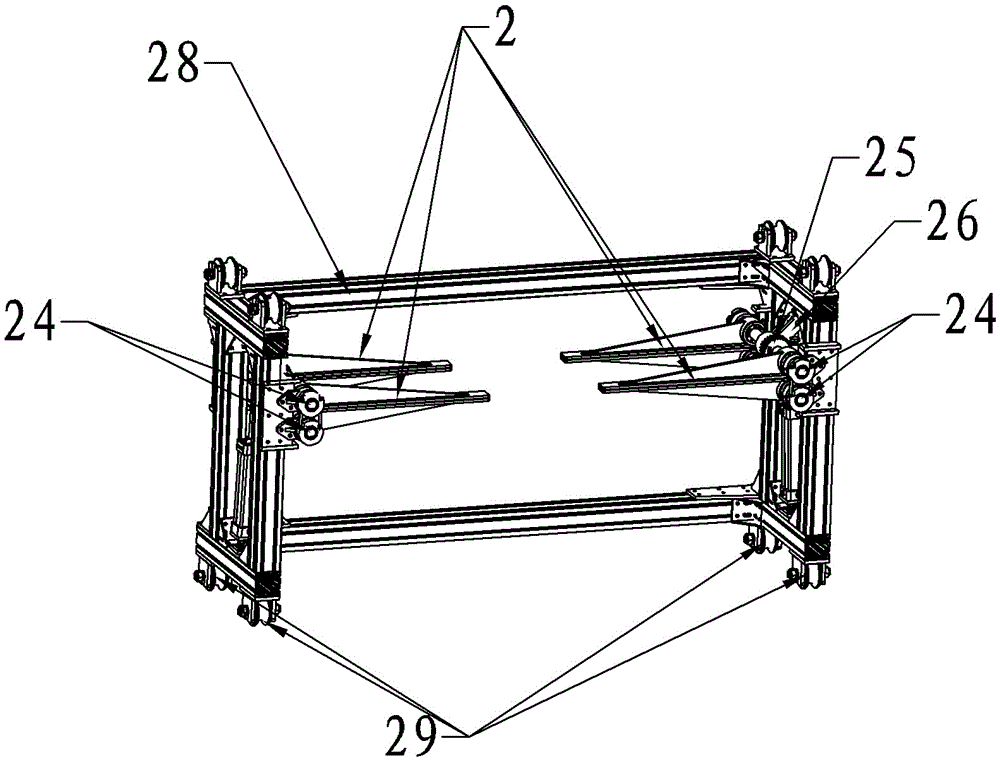

[0023] refer to Figure 1 to Figure 6 , a fully automatic infinite lengthening machine, at least including a plate cutting and chamfering mechanism 1, a plate infinite lengthening mechanism 2 and a double-station plate transmission mechanism 3; the plate cutting and chamfering mechanism 1 includes a frame 11 and is installed on the frame 11 The chamfering cutting assembly on the top, the chamfering cutting assembly consists of at least a cutting tool 12, the cutting tool 12 is installed on the movable tool rest 13, and the movable tool rest 13 moves along the edge of the plate, and the cutting tool 12 cuts the chamfer to the edge of the plate; The plate infinite splicing mechanism 2 includes a pressure splicing mechanism and a plate conveying mechanism, wherein the pressure splicing mechanism is composed of a pressure gate 21 and a driving mechanism of the pressure gate 21, and the driving mechanism drives the pressure gate 21 to apply pressure to the splicing part of the plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com