Patents

Literature

48results about How to "Not prone to wear and tear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

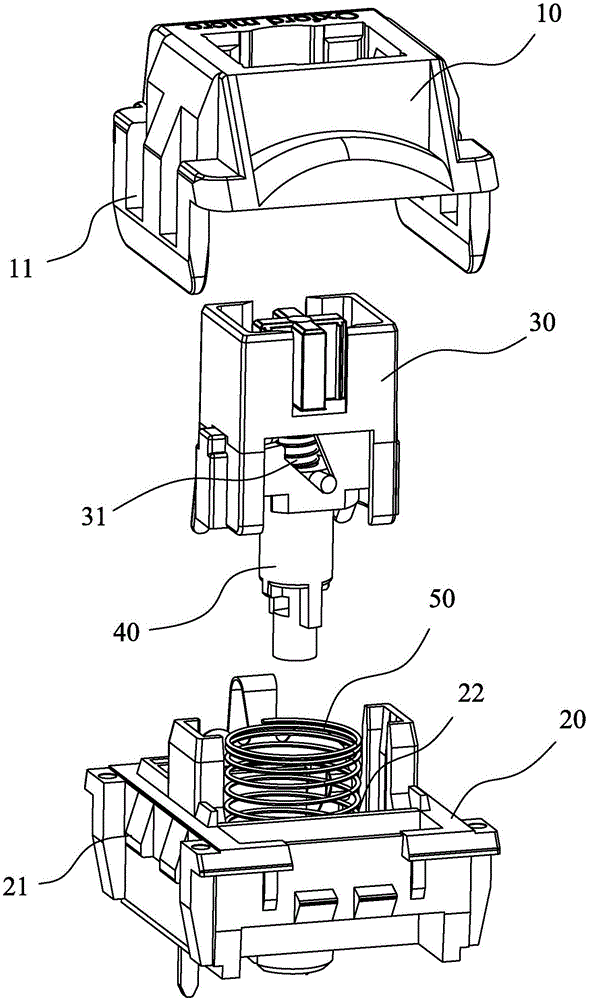

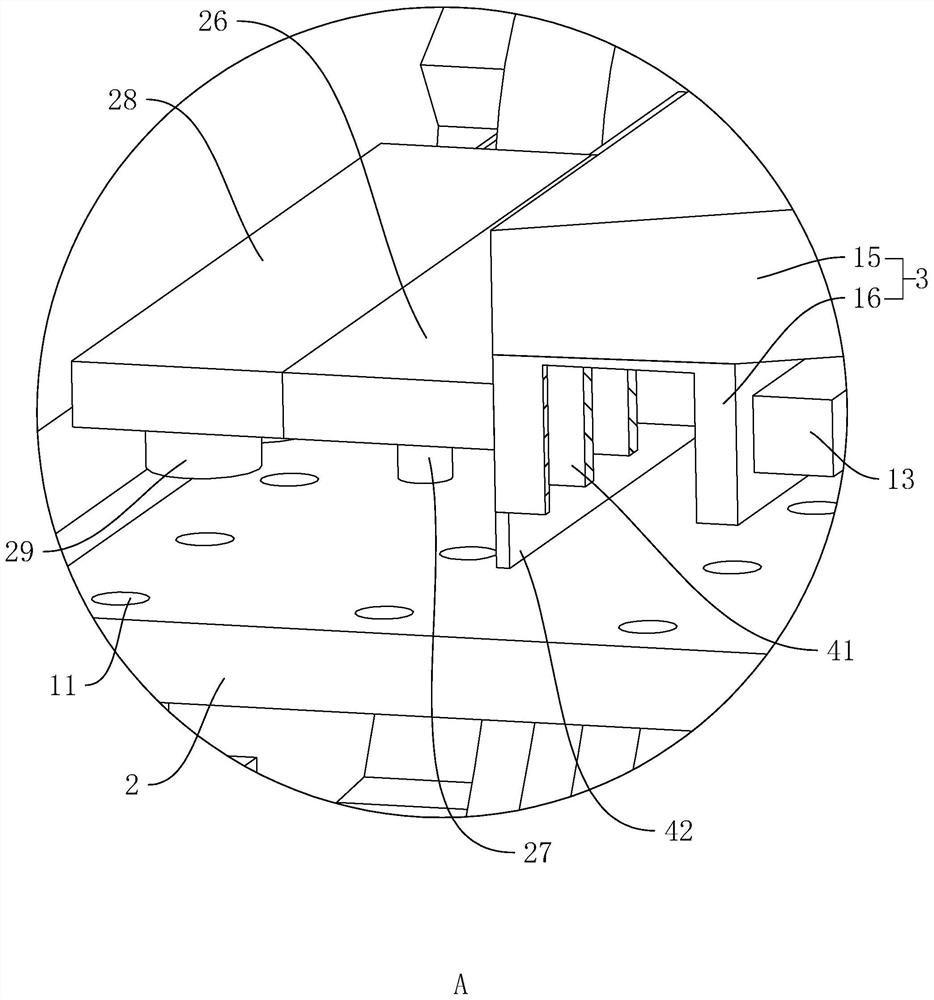

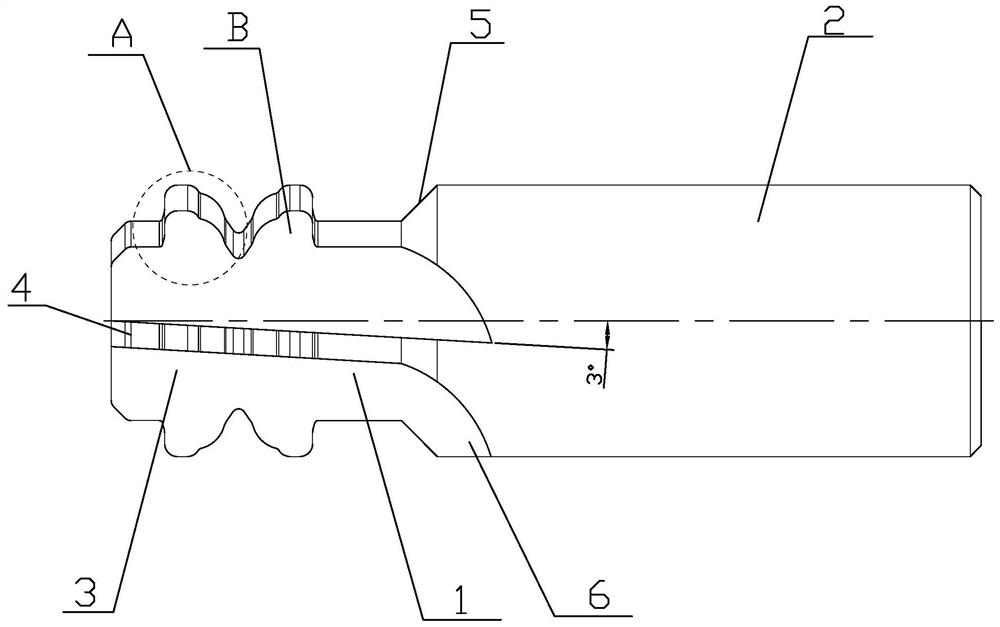

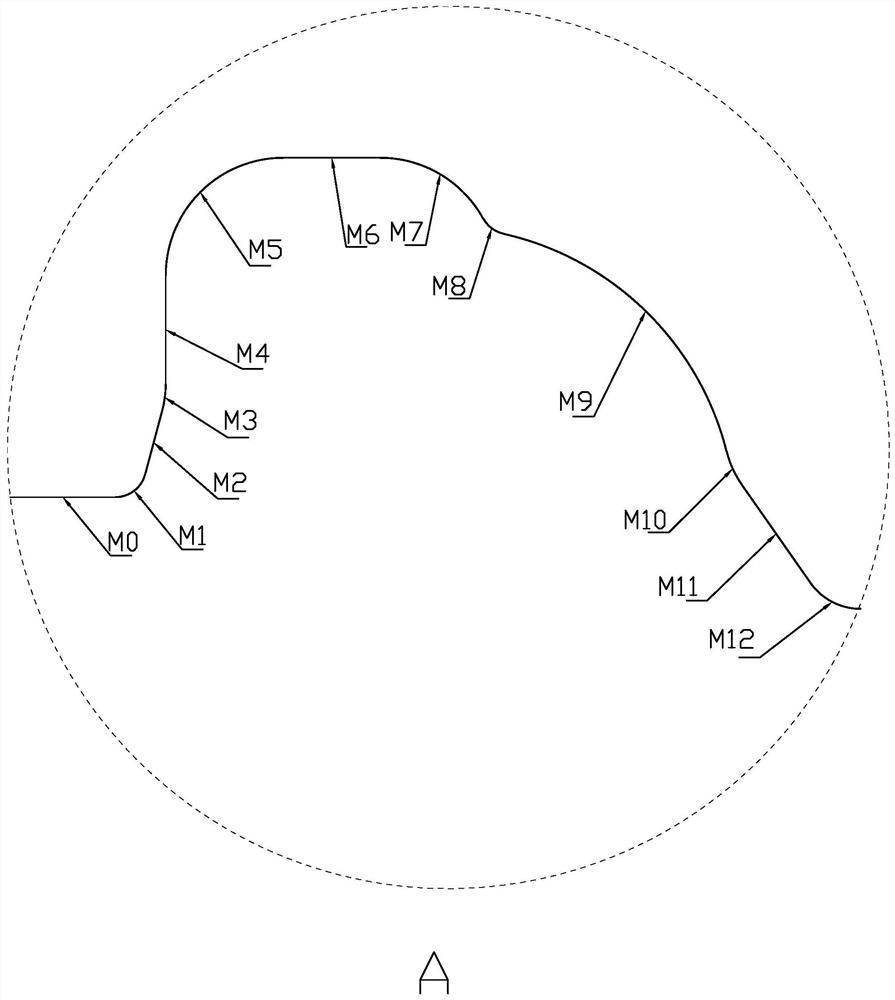

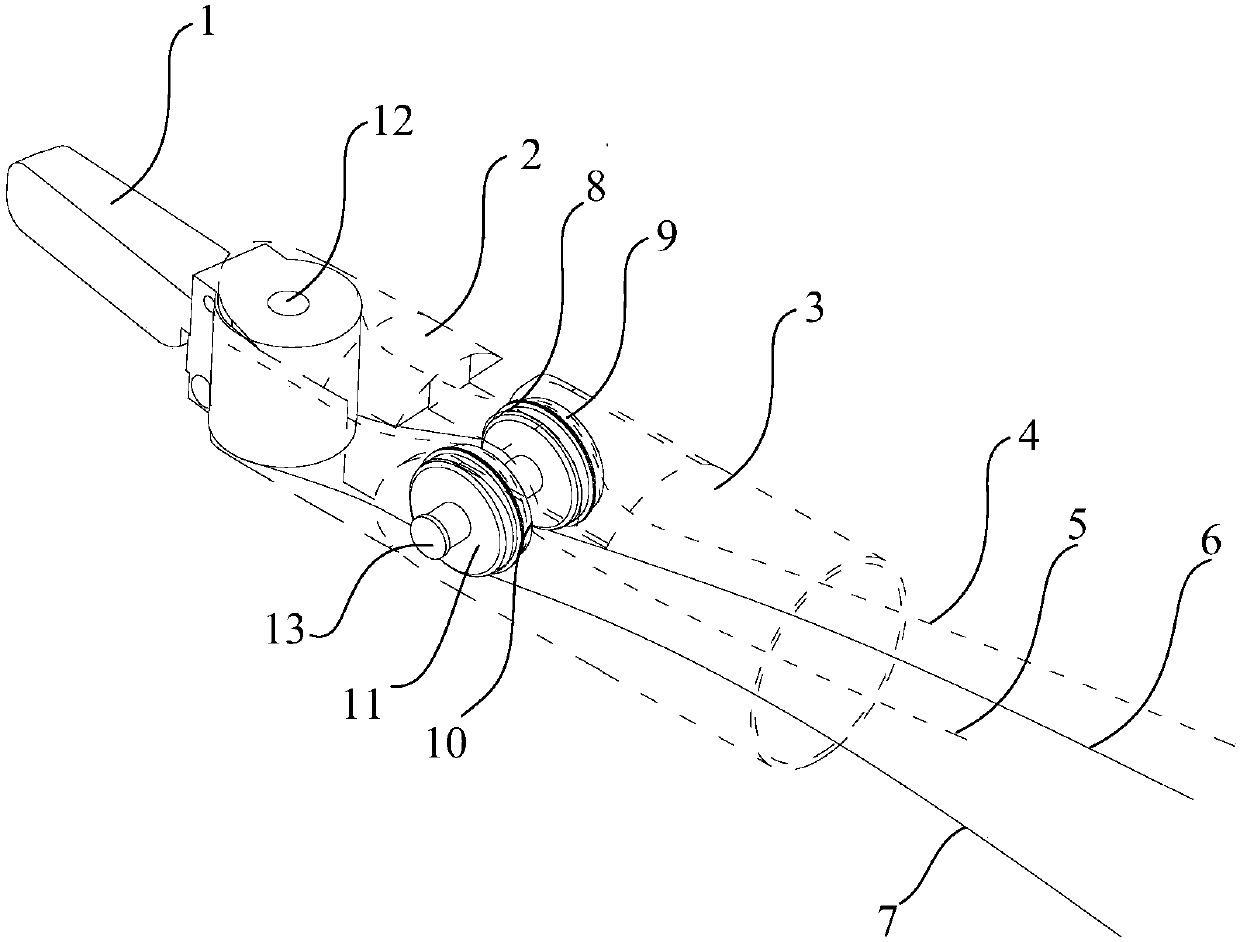

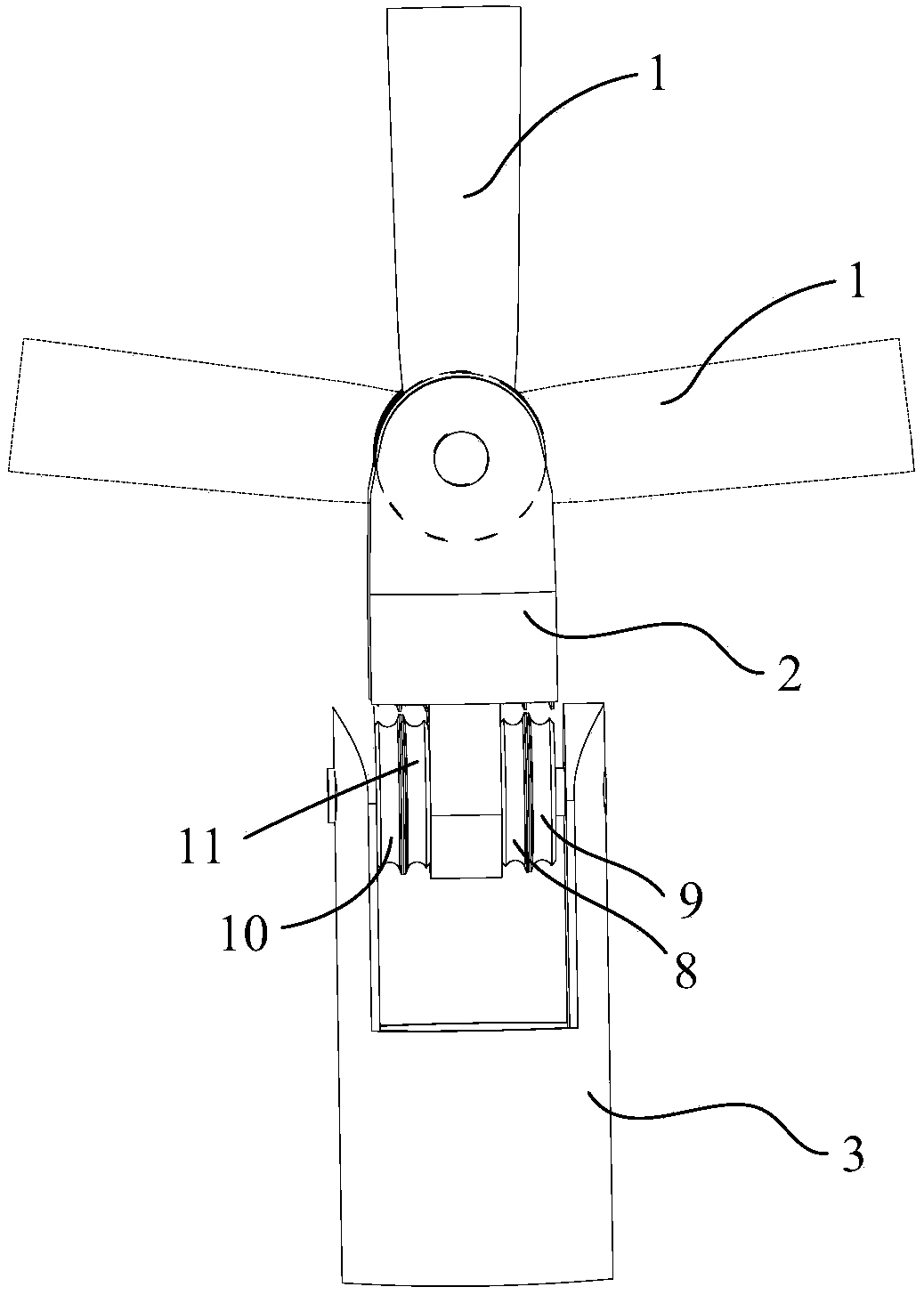

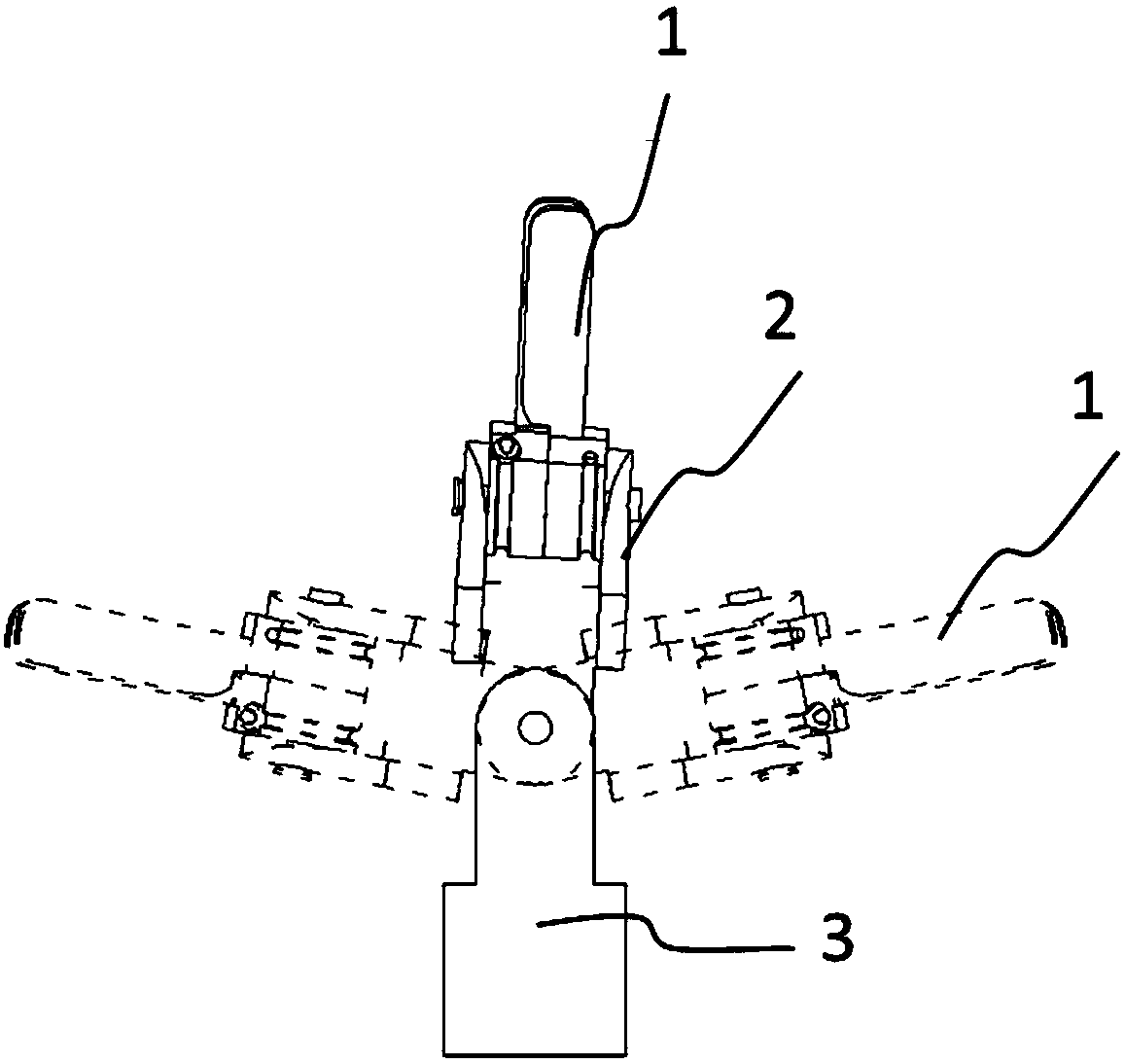

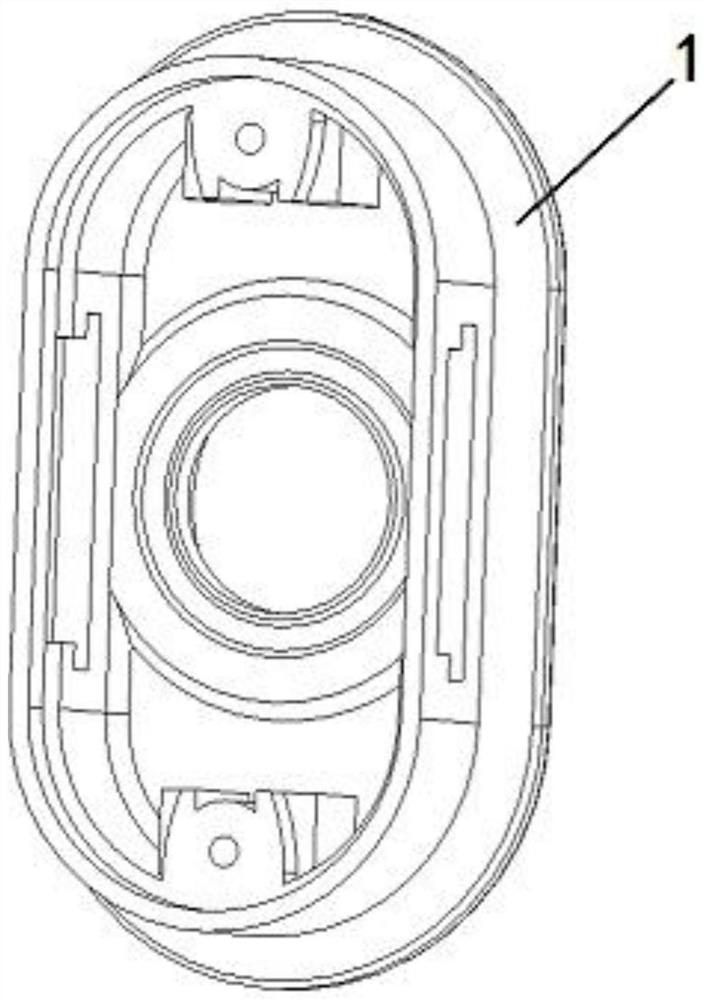

Surgical instrument and surgical robot adopting same

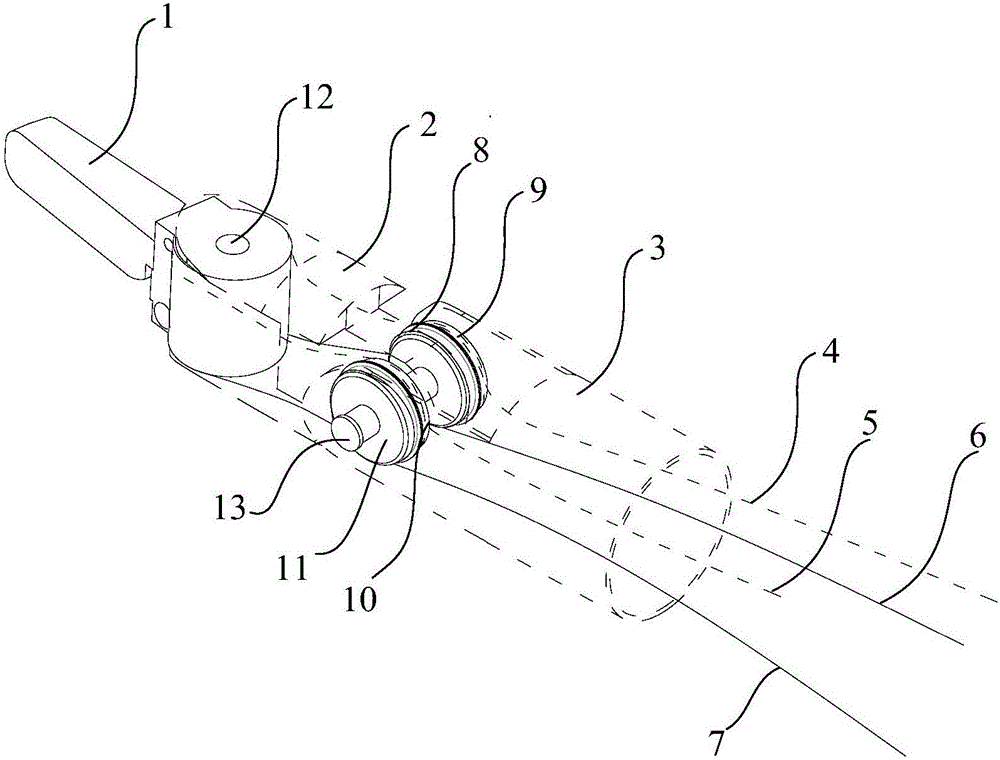

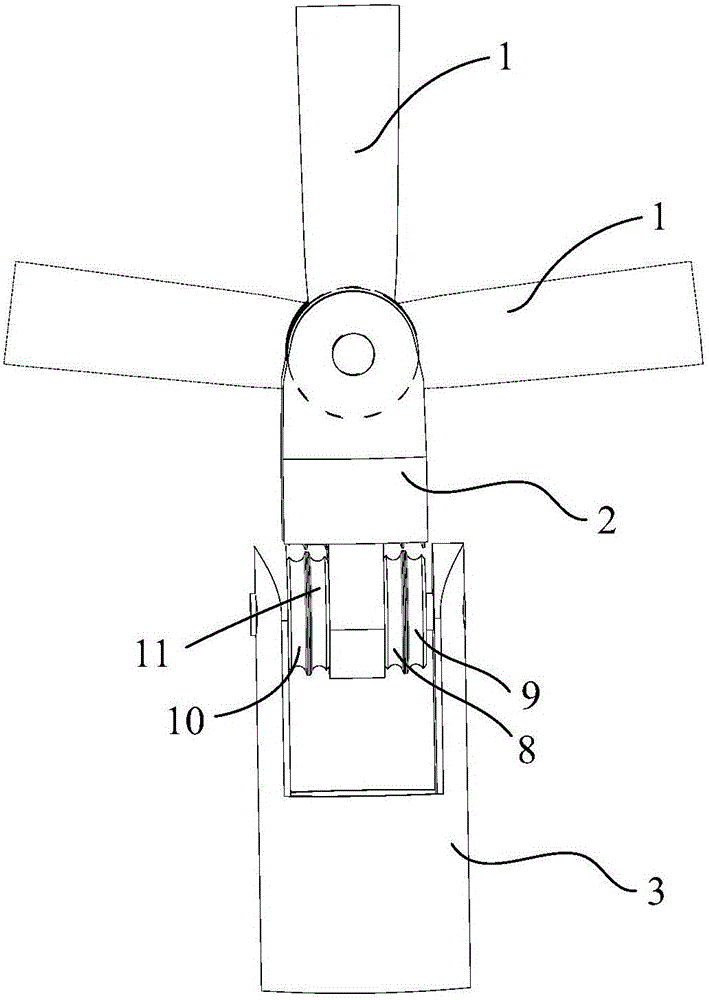

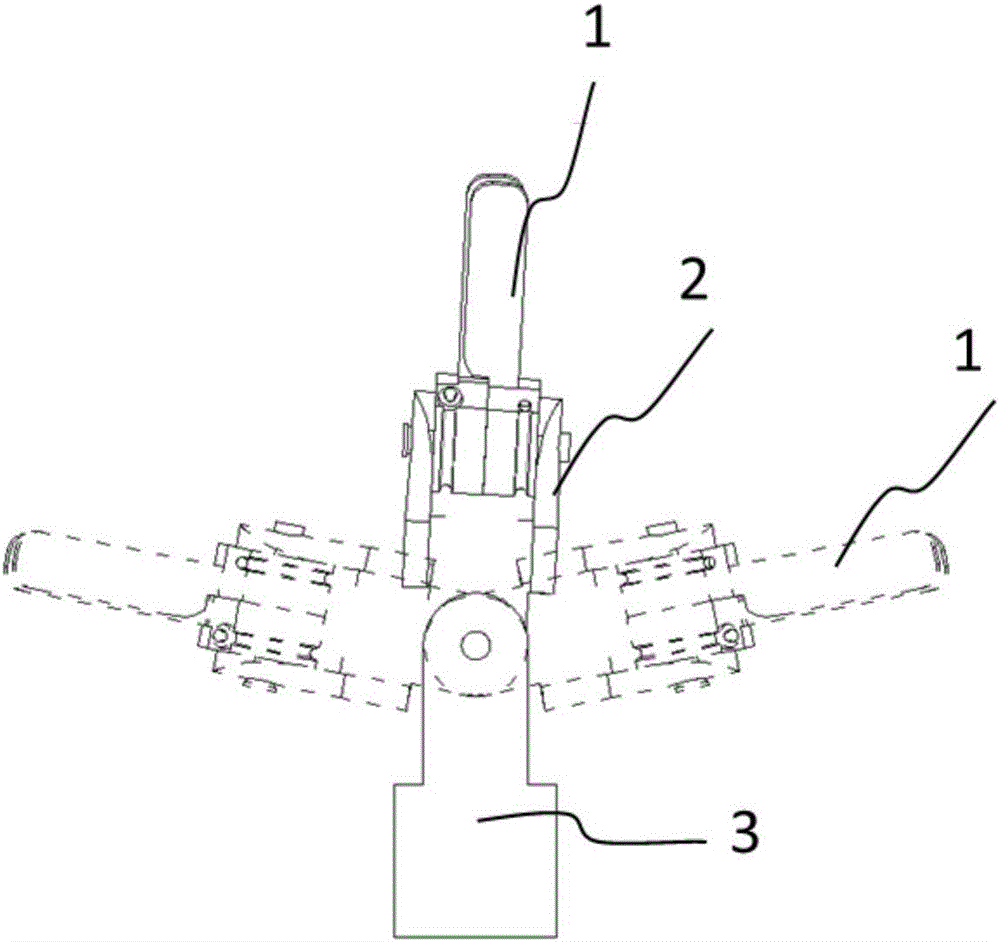

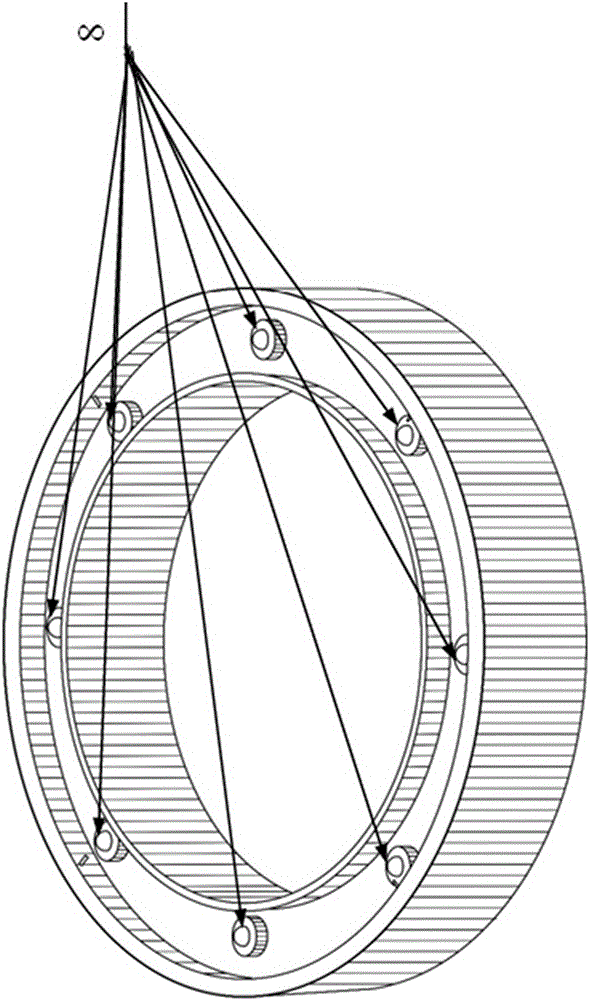

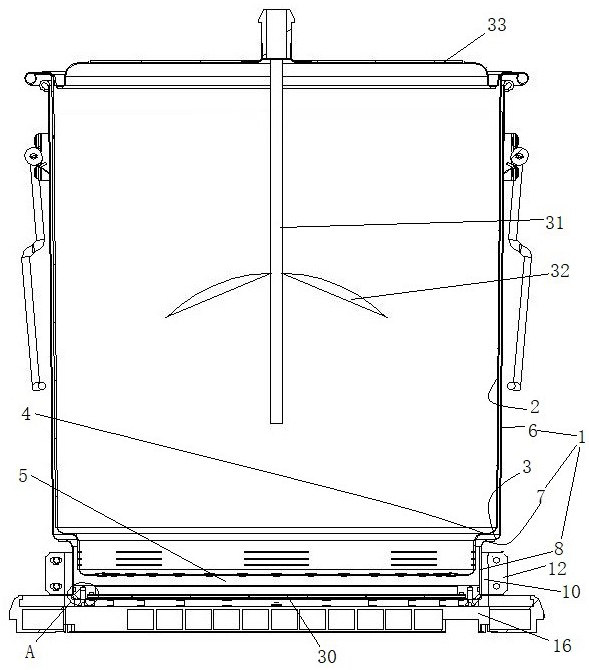

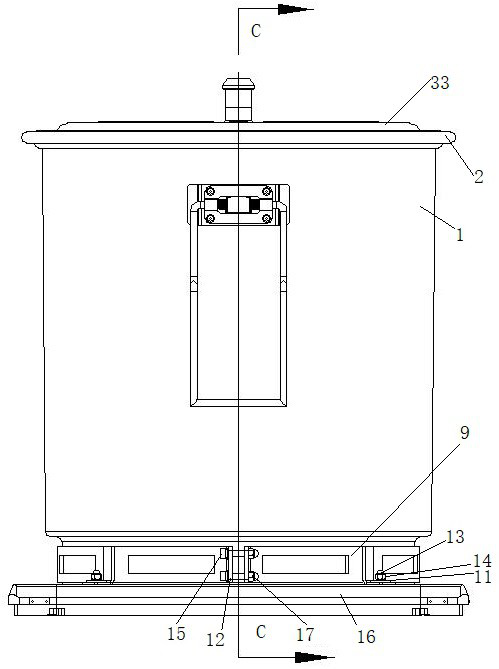

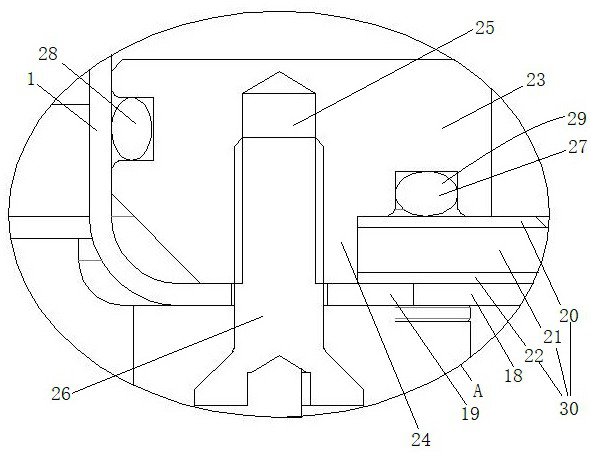

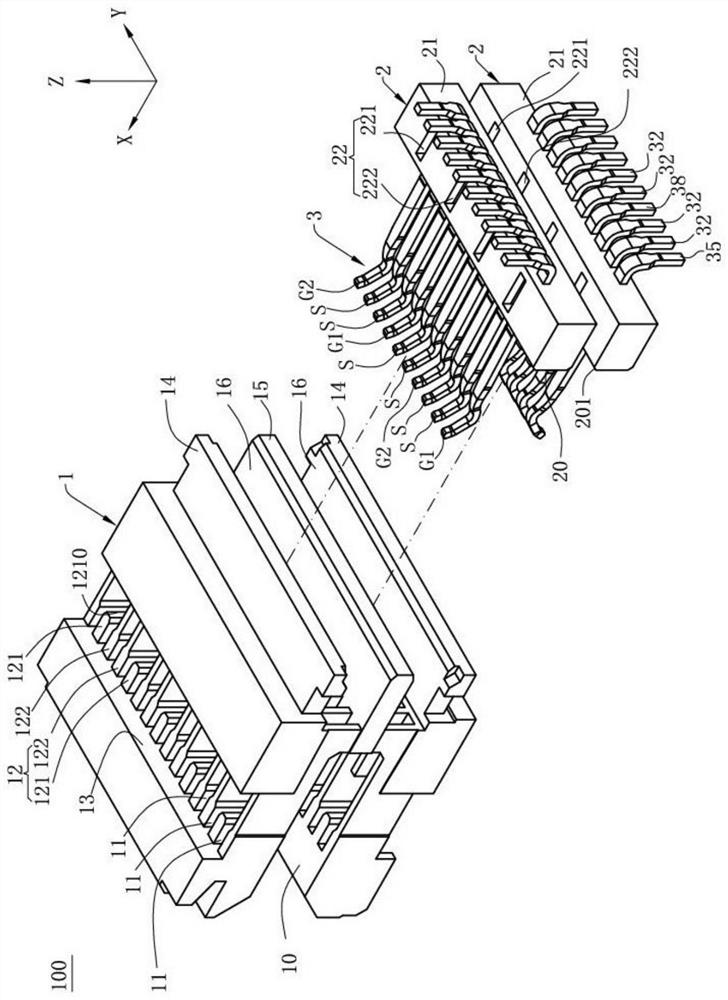

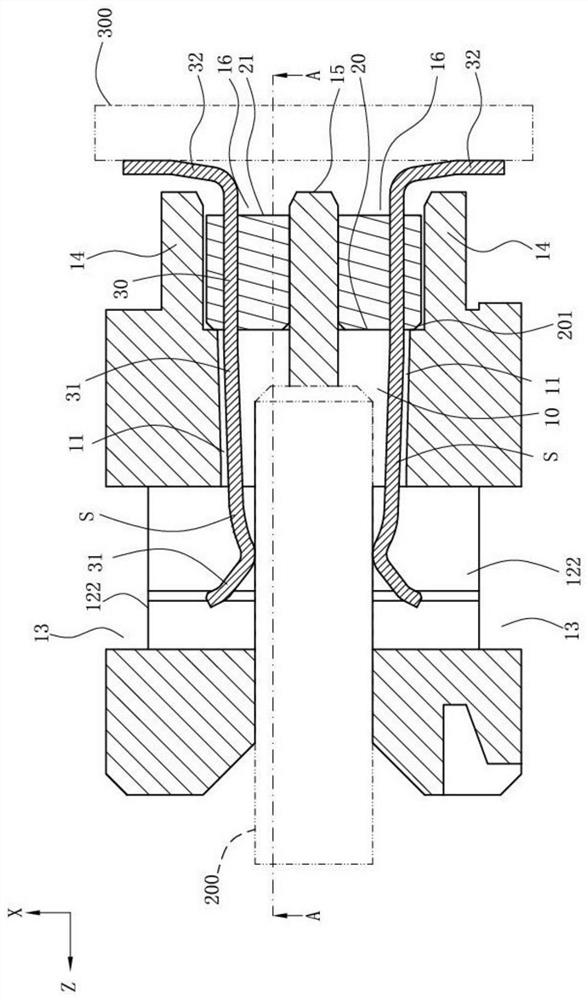

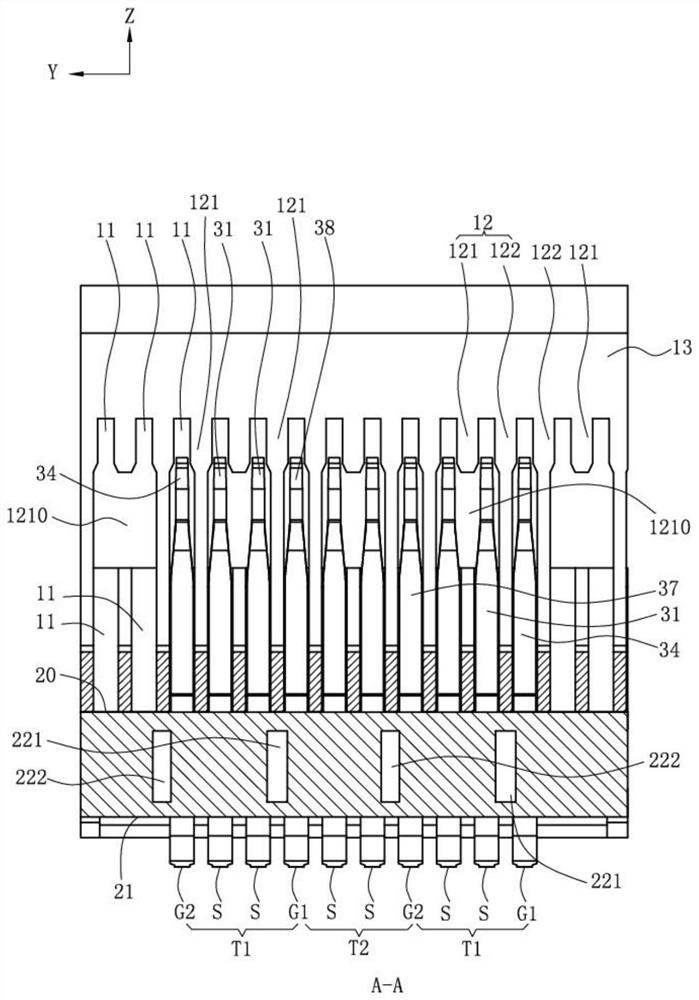

The invention provides a surgical instrument and a surgical robot adopting the surgical instrument. The surgical instrument comprises a front end, a wrist part, a foundation base, a guide mechanism and a traction unit, wherein the front end is rotatably connected with the wrist part and a first rotation axis is formed, the wrist part is rotatably connected with the foundation base and a second rotation axis is formed, and the first rotation axis and the second rotation axis are non-coplanar and are vertical to each other; the traction unit comprises a first traction body, a second traction body, a third traction body and a fourth traction body; the four traction bodies surround and are partially fixedly connected with the front end, extend, are restrained by the guide mechanism, and then are connected with an external mechanism; the second traction body surrounds the front end in the direction opposite to that of the first traction body, and the fourth traction body surrounds the front end in the direction opposite to that of the third traction body; the first traction body and the second traction body are distributed on one side of the second rotation axis, and the third traction body and the fourth traction body are distributed on the other side of the second rotation axis.

Owner:SHANGHAI MICROPORT MEDBOT (GRP) CO LTD

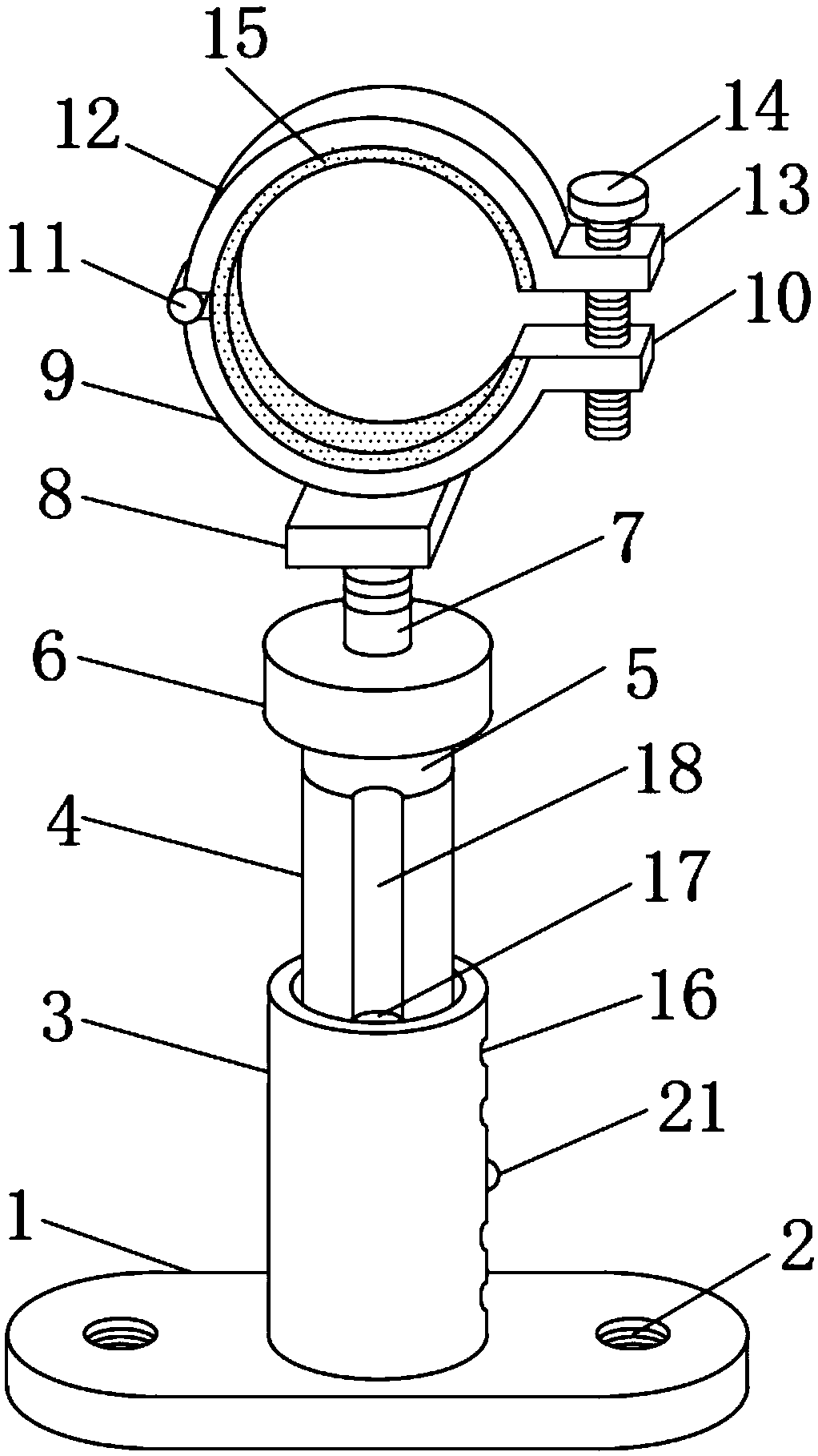

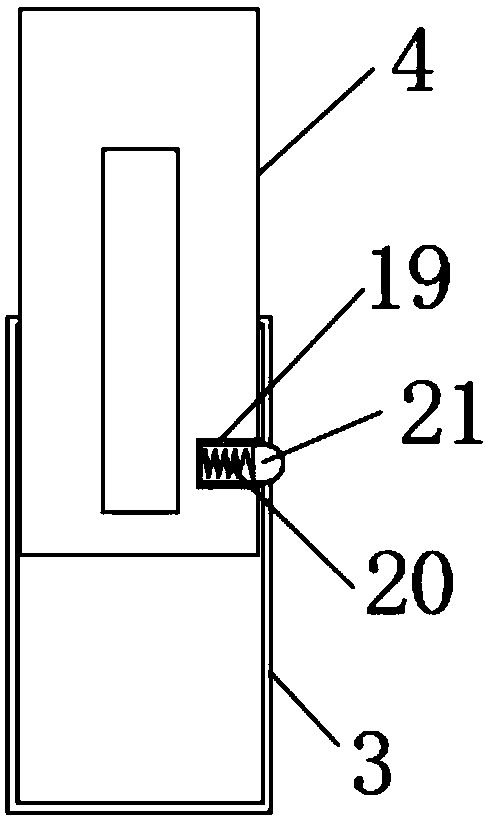

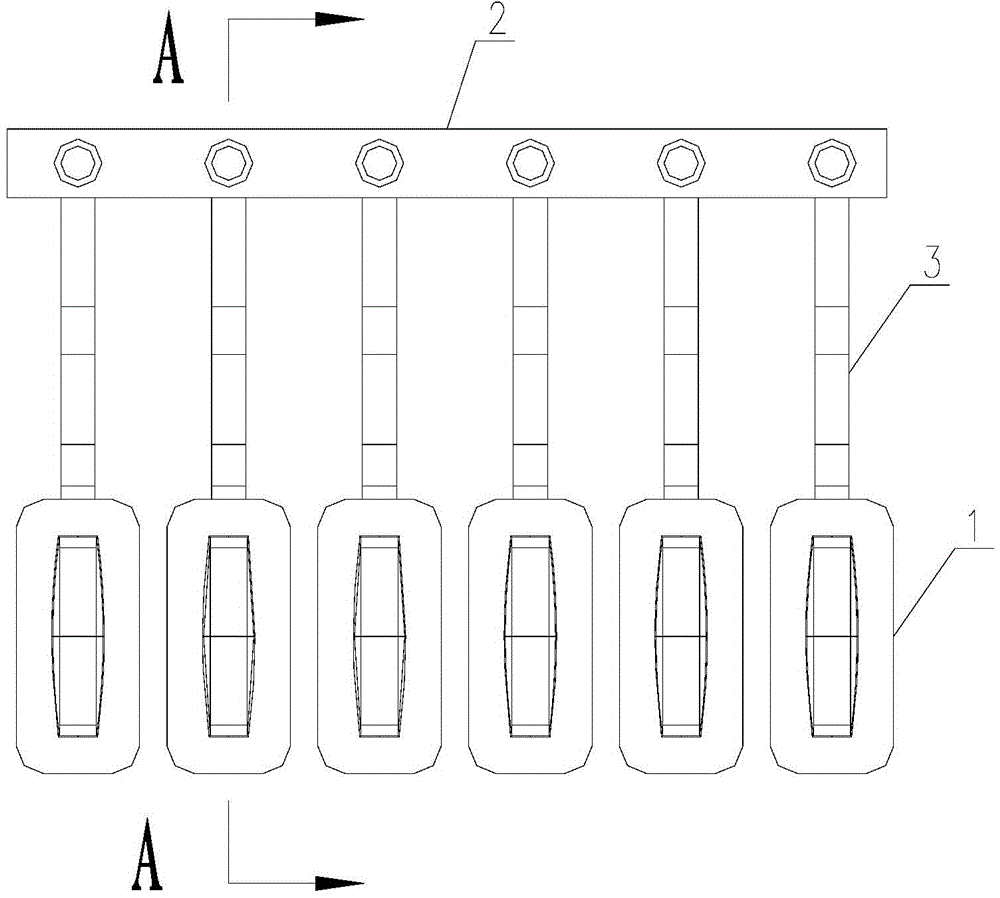

Fiber cable fixing device

ActiveCN109541767AAdjustable spacingNot prone to wear and tearElectrical apparatusFibre mechanical structuresFiberComputer engineering

The invention discloses a fiber cable fixing device which comprises a base. Two sides of top of the base are provided with fixing holes. The middle position of top of the base is provided with a sleeve. The sleeve is internally connected with a sleeve rod. The top end of the sleeve rod is provided with a fixed shaft. The top of the fixed shaft is rotatably connected with a turntable. The top of the turntable is provided with a screw. According to the fiber cable fixing device, the sleeve and the sleeve rod are arranged; and a plurality of sets of through holes are arranged outside the sleeve;the bottom end of one side of the sleeve rod is provided with a recessed hole; the recessed hole is internally provided with a spring; one end of the spring is connected with a projection; the sleeverod performs upward or downward movement in the sleeve; the projection contacts with the inner wall of the sleeve; the spring is in a compressed state; when the projection corresponds with the throughhole, the spring is elongated, the projection outwards projects through the function of the spring and is snapped with the through hole. the projection can be snapped with different through holes according to an actual requirement, thereby adjusting the distance between the fiber cable and the wall or the ground.

Owner:衡阳市光纤技术产学研管理有限公司

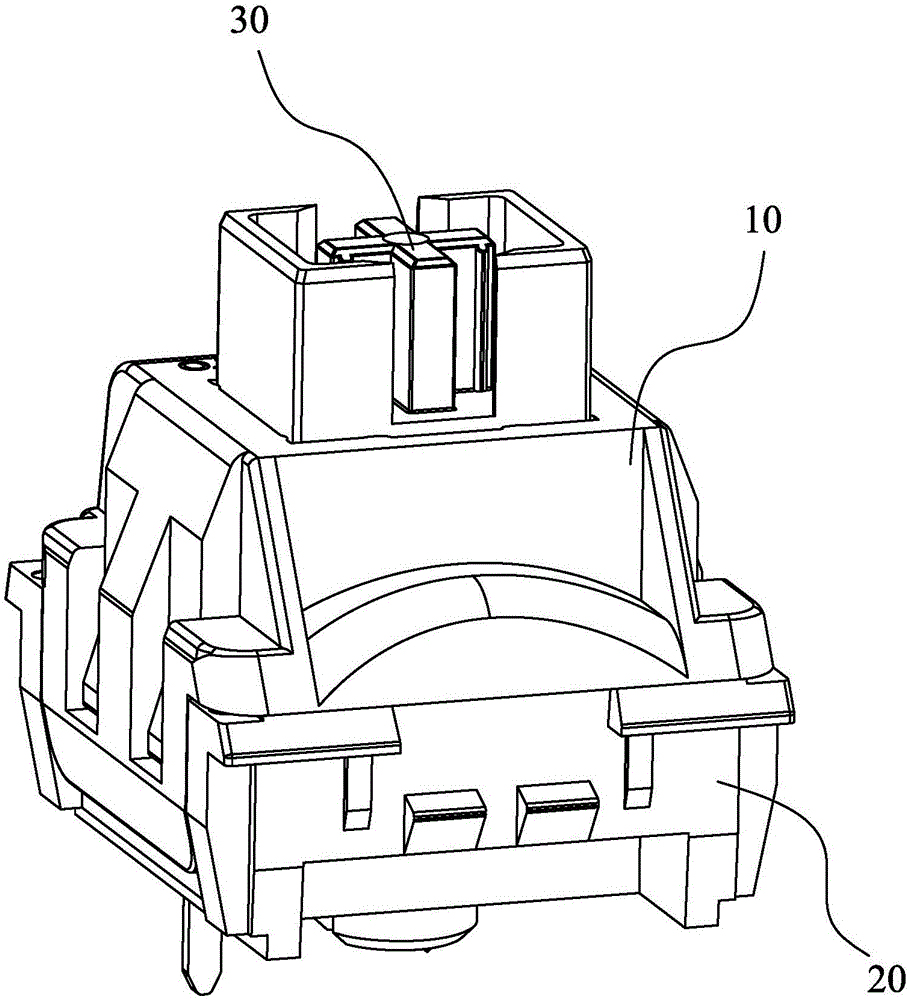

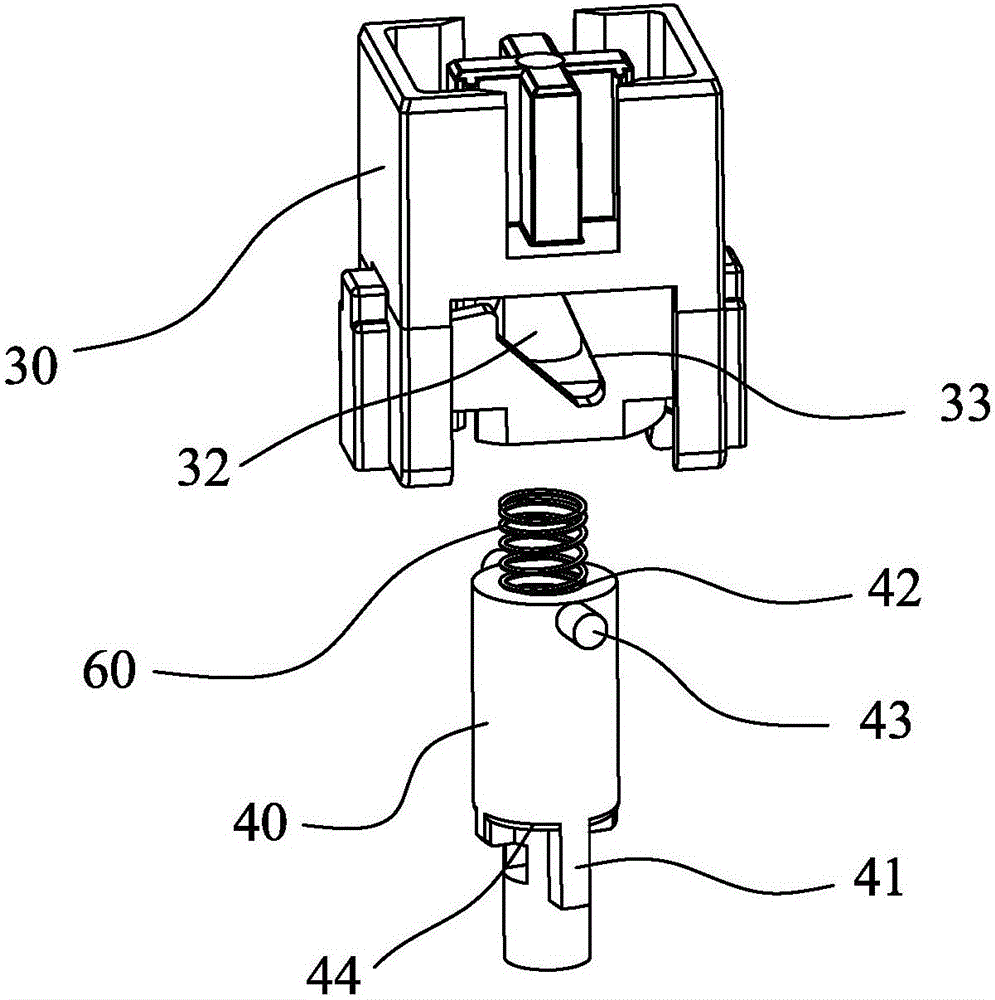

Sound production structure of keyboard switch

InactiveCN106847595ACrisp knocking soundNot prone to wear and tearElectric switchesSound productionEngineering

The invention discloses a sound production structure of a keyboard switch. The sound production structure comprises a shell and a pressing assembly movably installed in the shell, wherein the pressing assembly comprises a key cap and a pressing rod, the lower end of the key cap is provided with an accommodating groove with an opening facing downwards, the side surface of the accommodating groove is provided with an oblique groove penetrating through the inner side and the outer side of the accommodating groove, the upper end of the pressing rod is provided with a limiting rod corresponding to the oblique groove, the upper end of the pressing rod is movably installed in the accommodating groove, the limiting rod is clamped in the oblique groove, a first return element used for enabling the pressing rod to always have a downward extending trend is arranged in the accommodating groove, a through hole which is used for the pressing rod to extend downwards is formed in the shell, the lower end side surface of the pressing rod is provided with a limiting convex block, two sides of the limiting convex block are avoidance grooves, and the inner side lower end of the through hole is provided with a stop block corresponding to the limiting convex block. By adopting the sound production structure, the abrasion situation of the keyboard switch is unlikely to occur, the blockage and oxidation phenomena are unlikely to occur, a stable working state can be maintained, and the produced sound is clear.

Owner:东莞市集贤电子有限公司

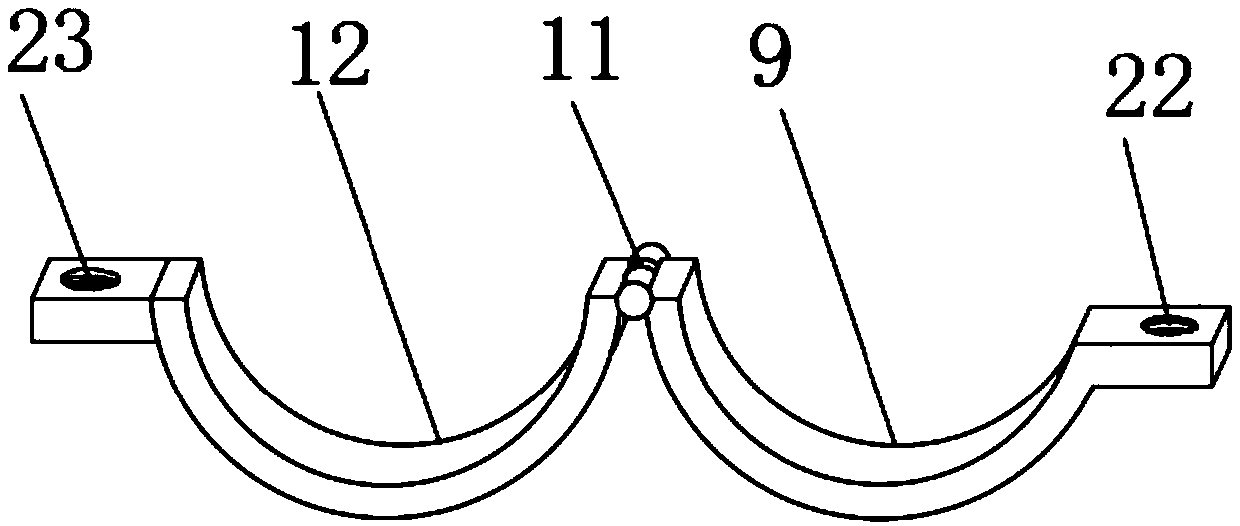

Multi-cantilever button and controller

InactiveCN104409264AEven by forceNot easy to wearElectric switchesDomestic articlesEngineeringTouch switch

The invention relates to the technical field of operation buttons, and in particular relates to a multi-cantilever button and a controller. The multi-cantilever button comprises a pressing part and a fixing part, wherein the pressing part is fixed to the fixing part through a plurality of symmetrically-distributed elastic cantilevers. The invention also provides a controller employing the multi-cantilever button. The multi-cantilever button and the controller have the advantages that two symmetrically-distributed elastic cantilevers are used for fixing the pressing part, the pressing part is in parallel contact with a contact surface of touch switches during being pressed, and the button can uniformly bear the force during pressing, thus greatly avoiding wearing and breaking, and as a result, the service life of the button can be prolonged, and the reliability in use can be improved.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

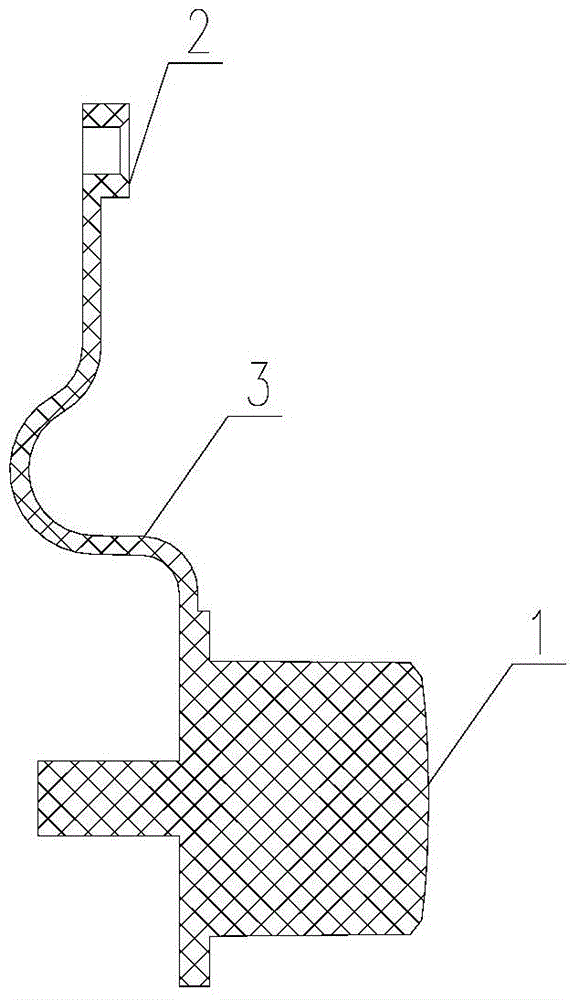

Scotching structure

The invention provides a scotching structure. The scotching structure can adjust the scotching speed of a scotching device and enables the scotching speed to keep pace with the transmission speed of the fabric, and therefore the folding is avoided and the quality of the fabric is ensured. The scotching structure comprises a roll shaft. The shaft surface of the roll shaft is a threaded face. The scotching structure further comprises a motor. The roll shaft comprises a driving roll shaft, a driven roll shaft. The motor drives the driving roll shaft through a coupler. The driving roll shaft is connected with the driven roll shaft through a meshing gear. The driving roll shaft and the driven roll shaft are respectively installed on a bearing seat. The threaded face is divided into two sections and the direction of spiral is opposite. The direction of rotation of the driving roll shaft ensures that the friction force obtained by threaded faces to the fabric enables the fabric to open towards two ends when the fabric passes the surface of the roll shaft, wherein the threaded faces are arranged at two ends of the driving roll shaft. The scotching structure is characterized in that the bearing seat is provided with a sensing roll shaft. The sensing roll shaft is provided with a velocity transducer. The motor is the stepping motor. The velocity transducer is connected with the stepping motor.

Owner:WUXI YAQING MACHINERY

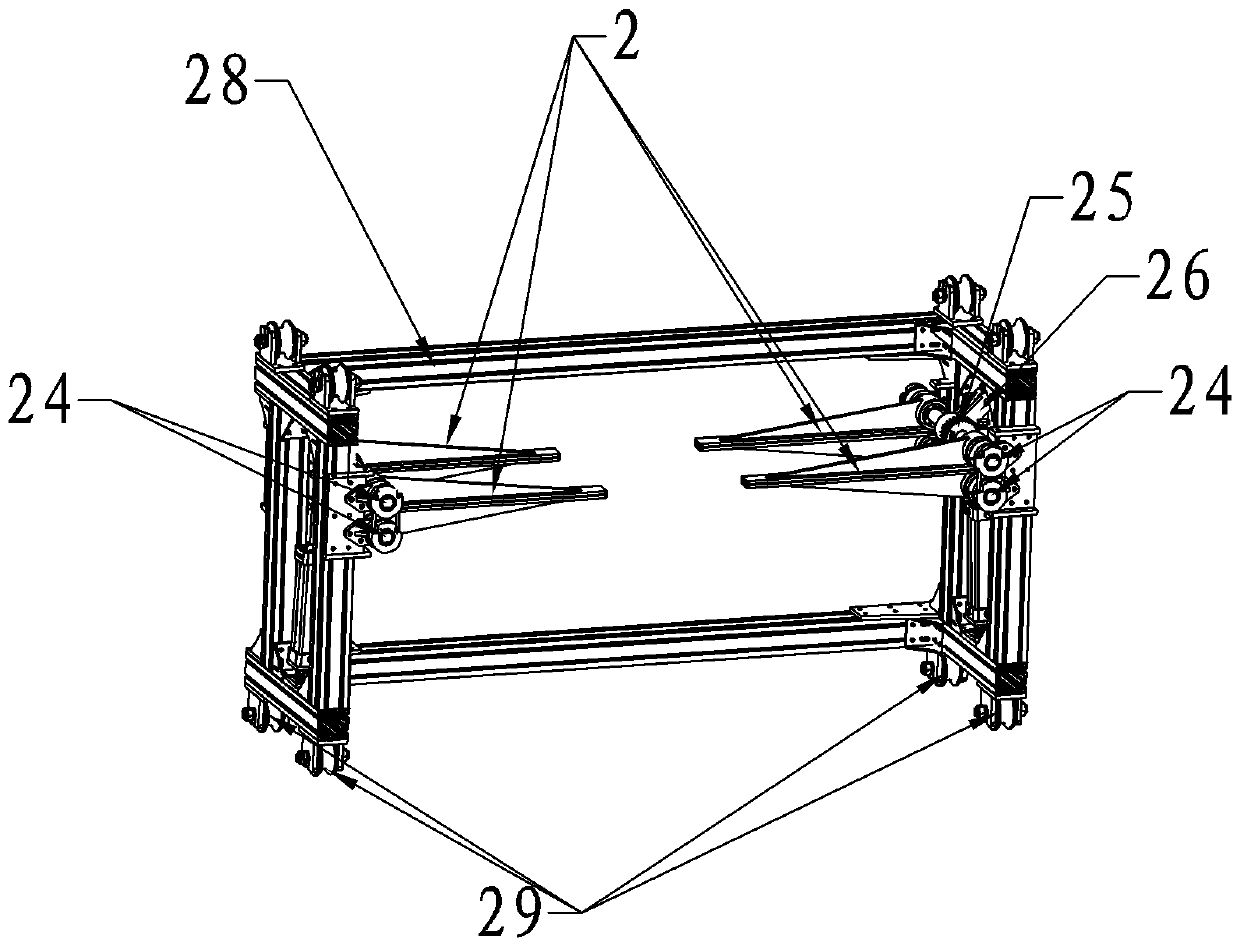

Power cable laying device

InactiveCN106451240ANot prone to wear and tearNot prone to folding problemsApparatus for laying cablesHydraulic cylinderPower cable

Discloses in the invention is a power cable laying comprising a base plate and a central shaft arranged above the base plate. Two upper beams perpendicular to each other are arranged on the upper end of the central shaft; and the middle parts of the two upper beams are fixedly connected to the central shaft. Chutes are formed in the lower end surfaces of the upper beams; sliding rods that can slide along the chutes are arranged at the inner sides of the chutes; and vertical rollers are arranged on the sliding rods. Besides, a hydraulic cylinder is arranged on the central shaft; one end of the hydraulic cylinder is connected with the central shaft; and the other end of the hydraulic cylinder is connected the sliding rods. Limiting grooves corresponding to the chutes are formed in the base plate; and the lower ends of the sliding rods can slide along the limiting grooves. According to the power cable laying device provided by the invention, line laying can be realized conveniently; breaking and wearing of the cable during the cable laying process can be avoided; and thus the service life of the cable can be prolonged.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO LONGKOU POWER SUPPLY CO

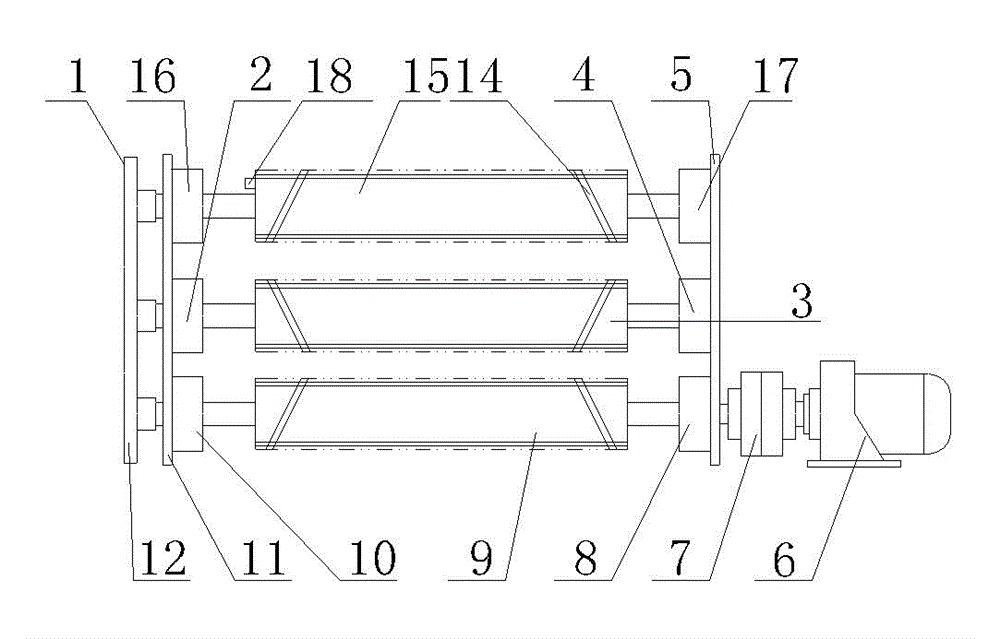

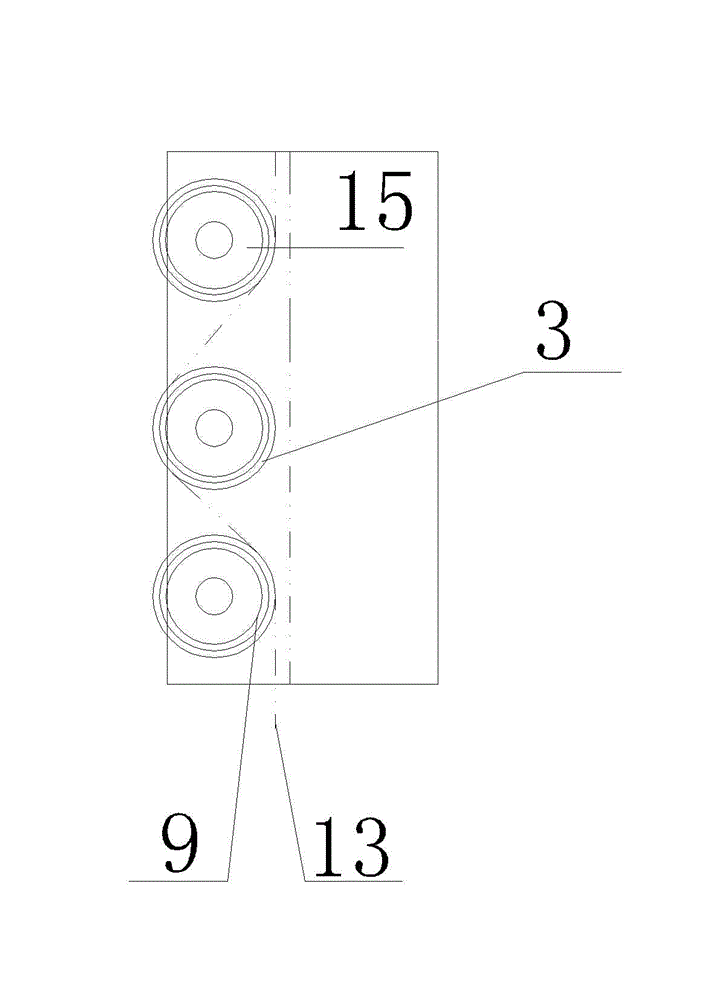

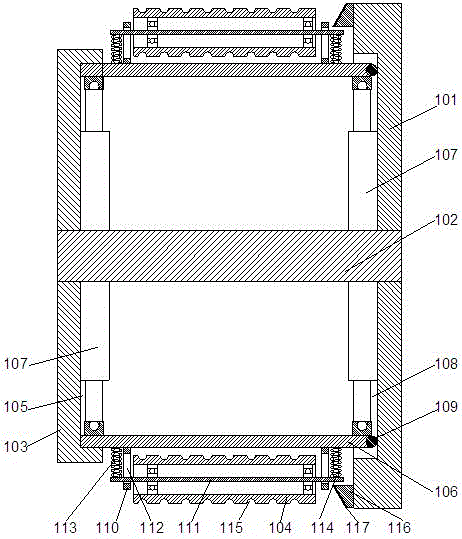

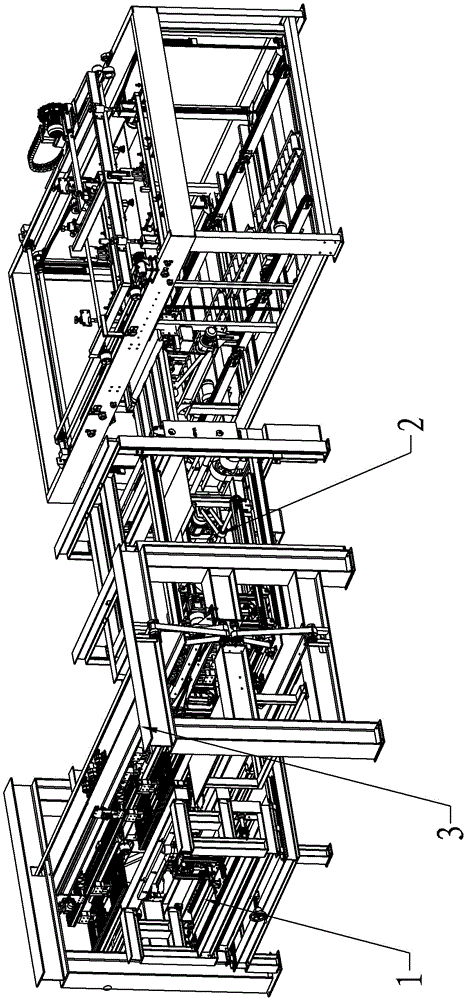

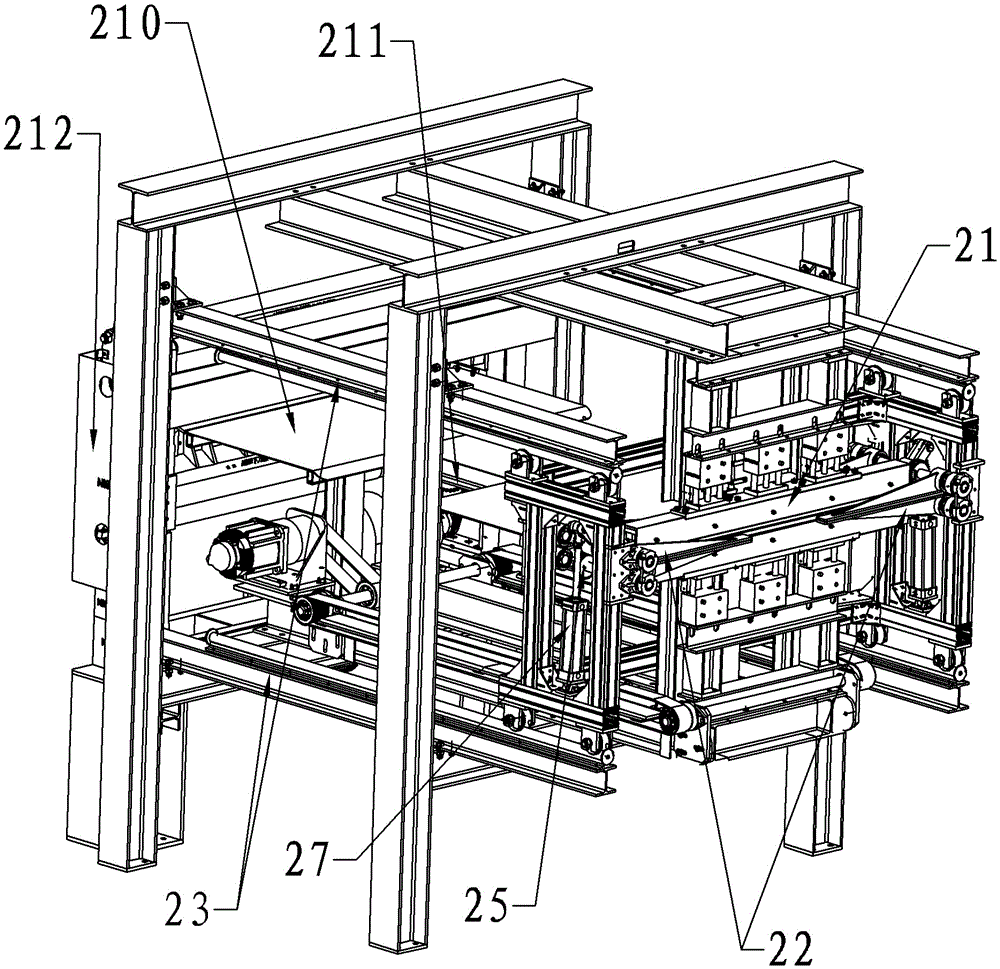

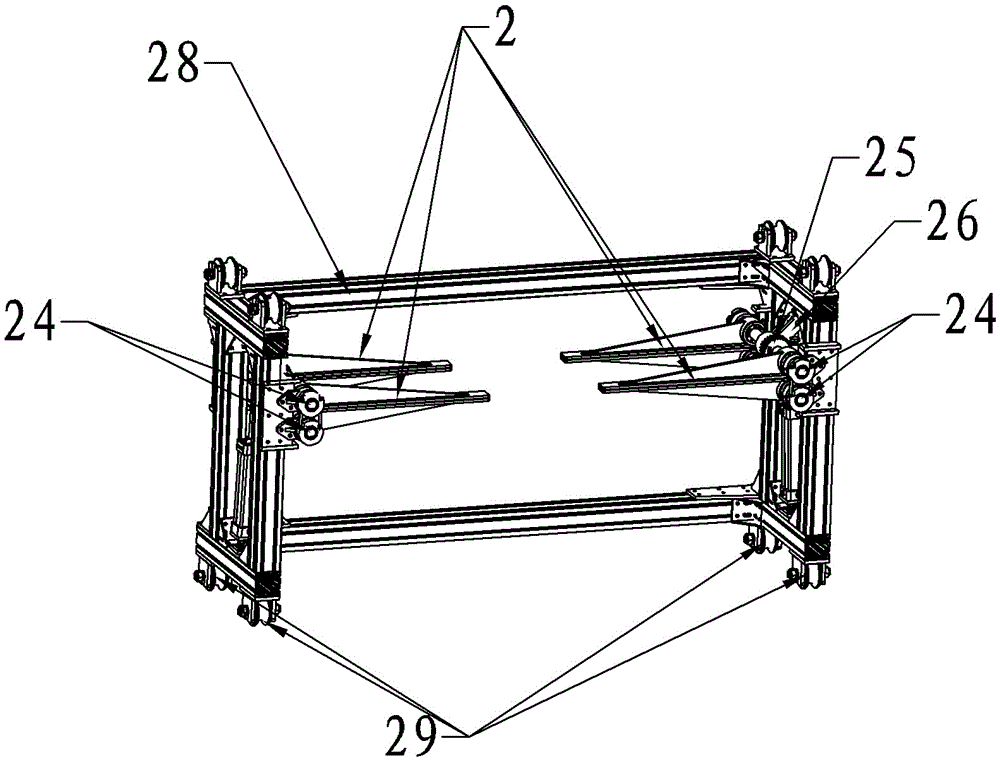

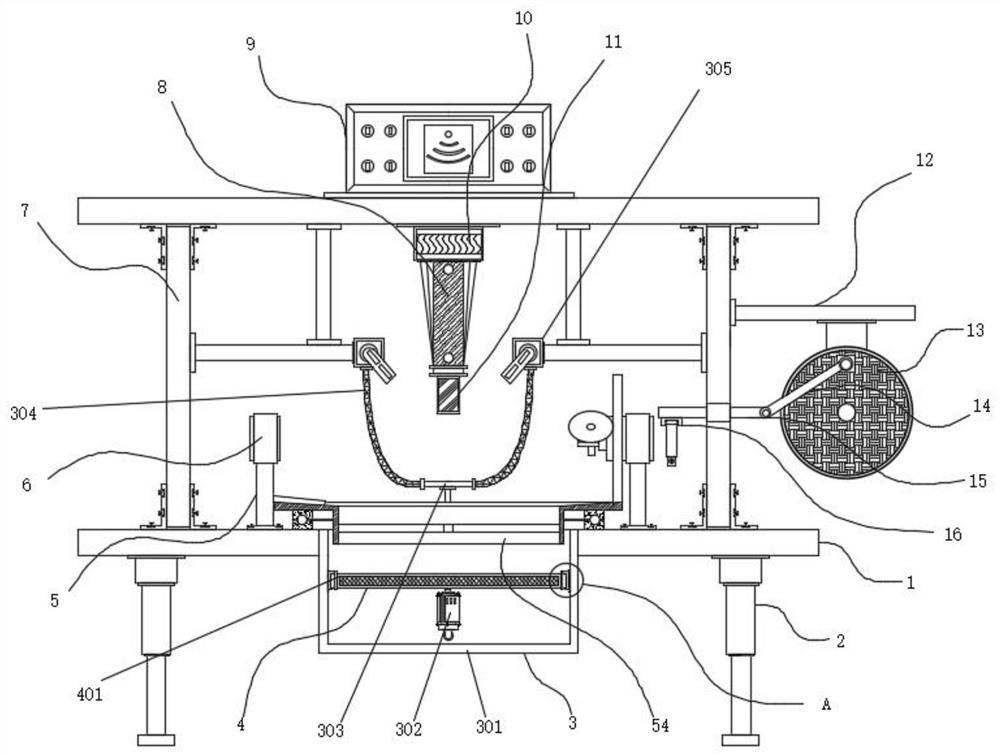

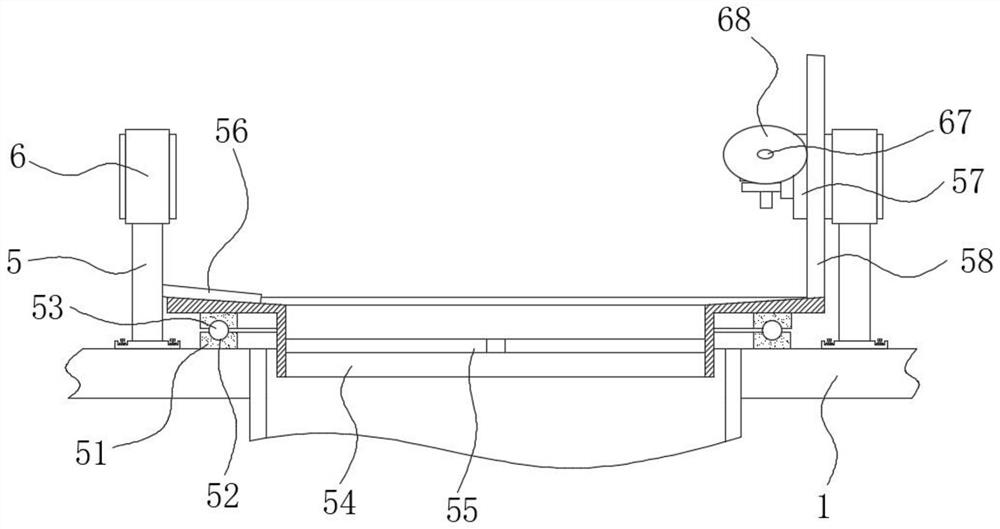

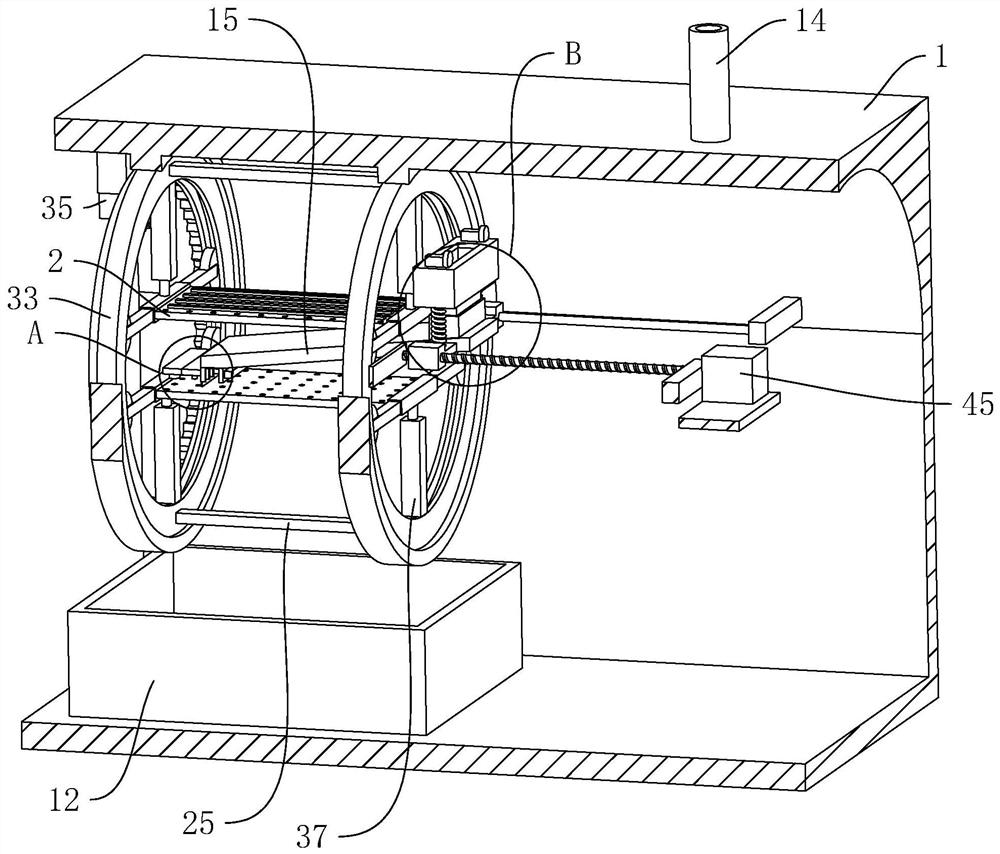

Full-automatic unlimited lengthening machine

ActiveCN105583918AGuaranteed stitching qualityReduce processing costsOther plywood/veneer working apparatusWood veneer joiningEngineeringMachining process

The invention discloses a full-automatic sheet unlimited lengthening machine, which at least comprises a sheet cutting and chamfering mechanism, a sheet unlimited lengthening mechanism and a double-station sheet conveying mechanism; the sheet cutting and chamfering mechanism has the advantages that a notch is flat and smooth, machining precision is high, a large amount of flying dust cannot be generated during a machining process, and the like; the sheet unlimited lengthening mechanism is used for completing splicing between sheets and conveyance after splicing to ensure that spliced parts of the sheets are subjected to a small force during a conveying process, therefore the spliced parts are prevented from being disengaged or staggered; the double-station sheet conveying mechanism is used for completing reclaiming and synchronous conveyance of machining stations to ensure that two machining stations are capable of synchronously obtaining sheets to be machined, so that the requirement of synchronous and continuous machining is met. According to the full-automatic sheet unlimited lengthening machine, all machining procedures from cutting to splicing of the sheets are completed in a full-automatic manner by matching the mechanisms, therefore splicing quality of the sheets is ensured while production efficiency is effectively increased.

Owner:HESHAN JIDING MACHINERY CO LTD

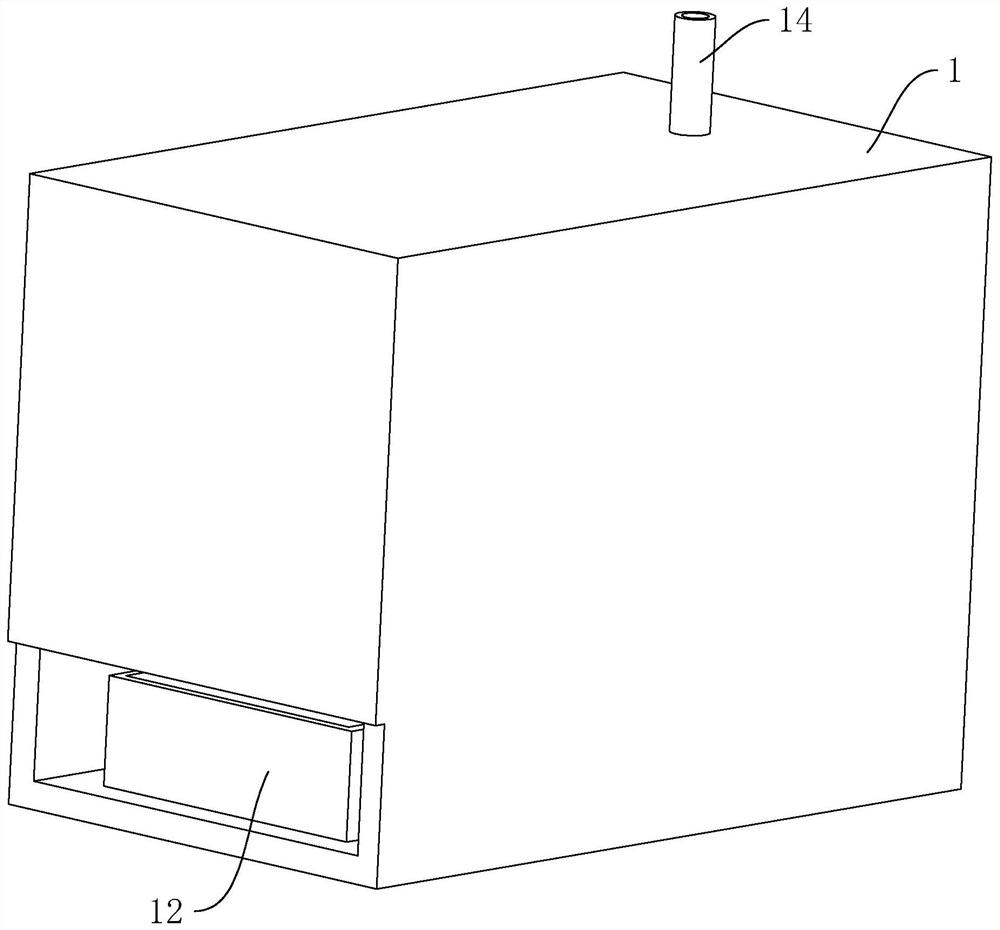

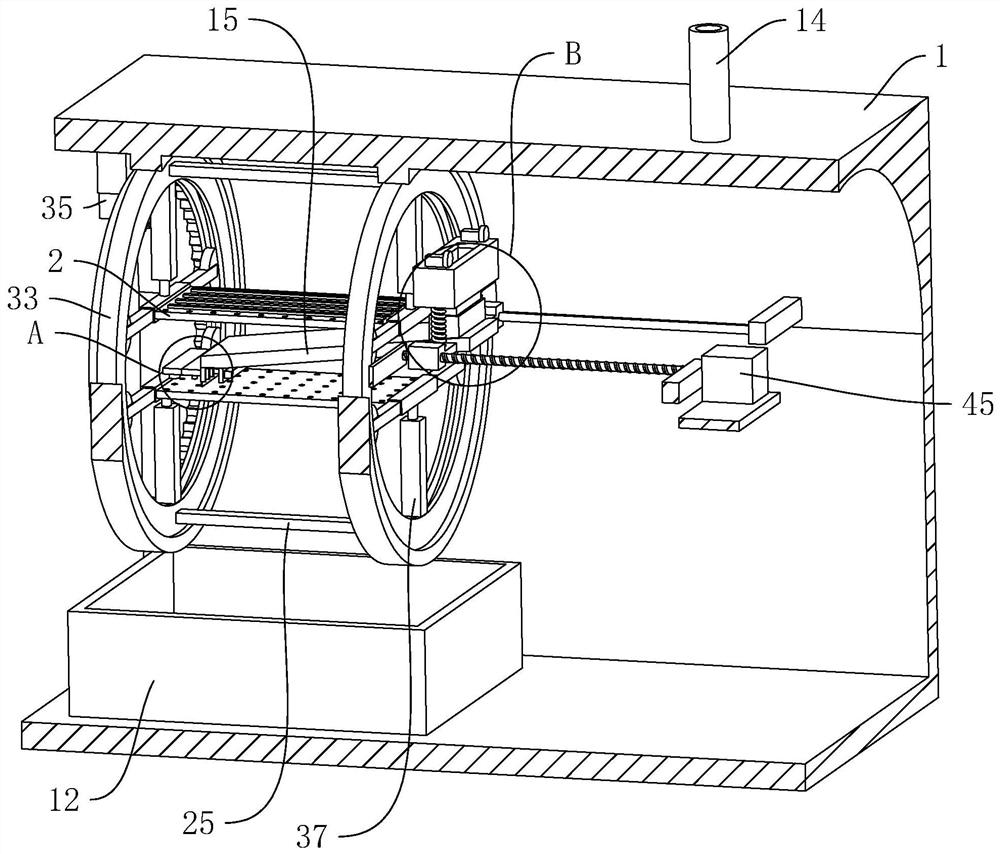

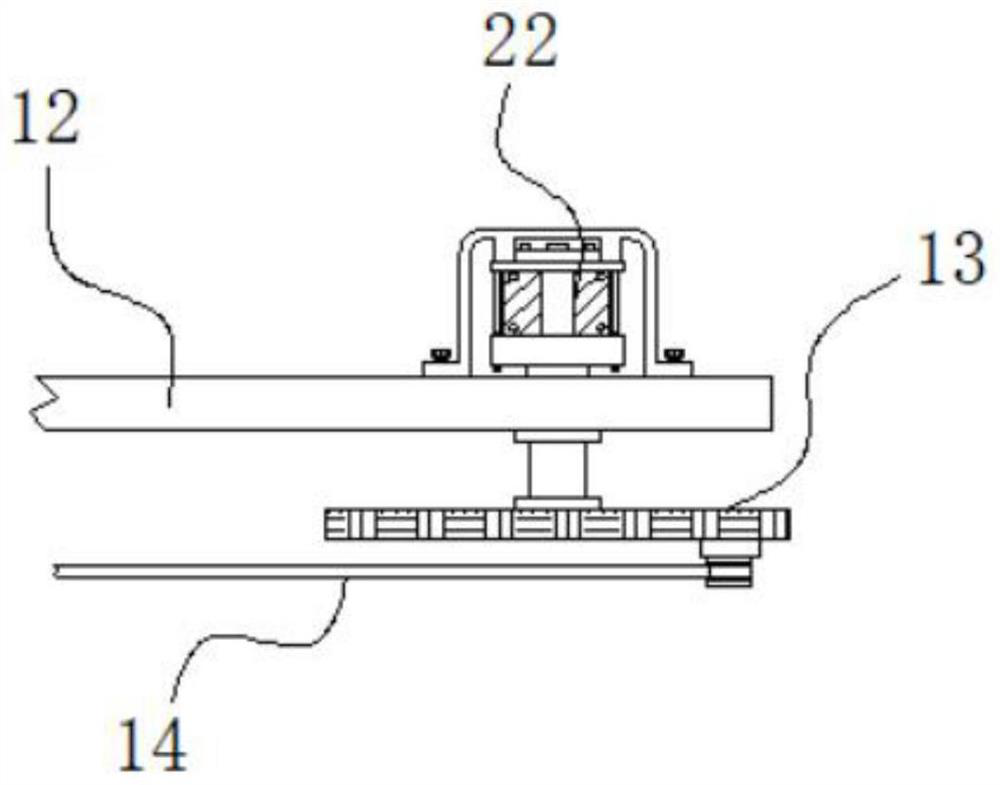

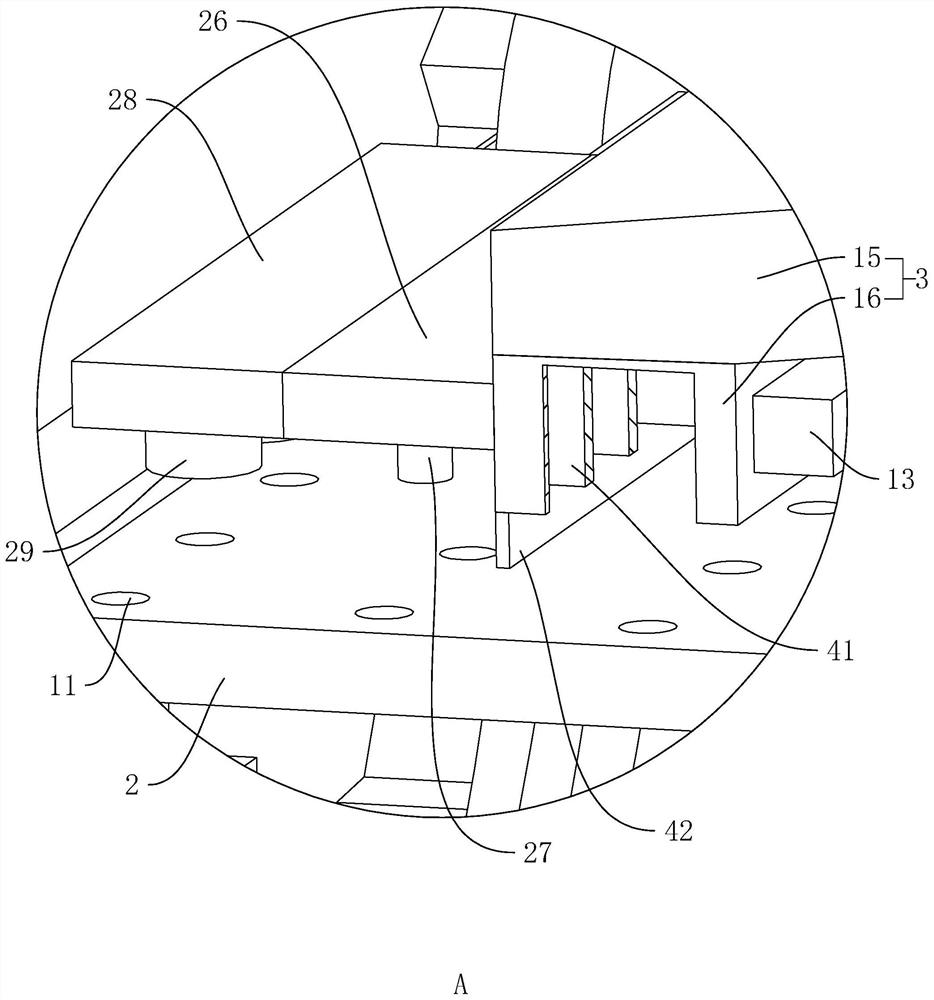

Coating machine and multi-enzyme tablet production process applying coating machine

ActiveCN112168698ANot easy to blockImprove uniformityPretreated surfacesSpray nozzlesSolvent evaporationSpray coating

The invention relates to a coating machine. The coating machine comprises a case, a feeding device arranged in the case and capable of uniformly conveying medicine granules into the case, a material bearing device arranged in the case and used for bearing the medicine granules, a spraying device arranged in the case and used for spraying coating dressing to the medicine granules, and a drying device arranged in the case and used for evaporating a solvent in the coating dressing, wherein the material bearing device comprises two bearing plates arranged in the case and a bearing plate driving mechanism arranged in the case and drives the two bearing plates to move and rotate; and the feeding device comprises a feeding pipe, a storage box, a box vibration mechanism and a feeding pipe moving mechanism, the feeding pipe is connected into the case in a sliding manner and can extend between the two bearing plates, the storage box is arranged at one end, far away from the bearing plates, of the feeding pipe, the box vibration mechanism is arranged in the storage box and enables the storage box to vibrate, and the feeding pipe moving mechanism is arranged in the case and drives the feedingpipe to move along the bearing plates. The medicine granules are uniformly distributed on the bearing plates, so that the medicine granules can be uniformly coated, and the coating uniformity of the product is improved.

Owner:浙江国光生物制药股份有限公司

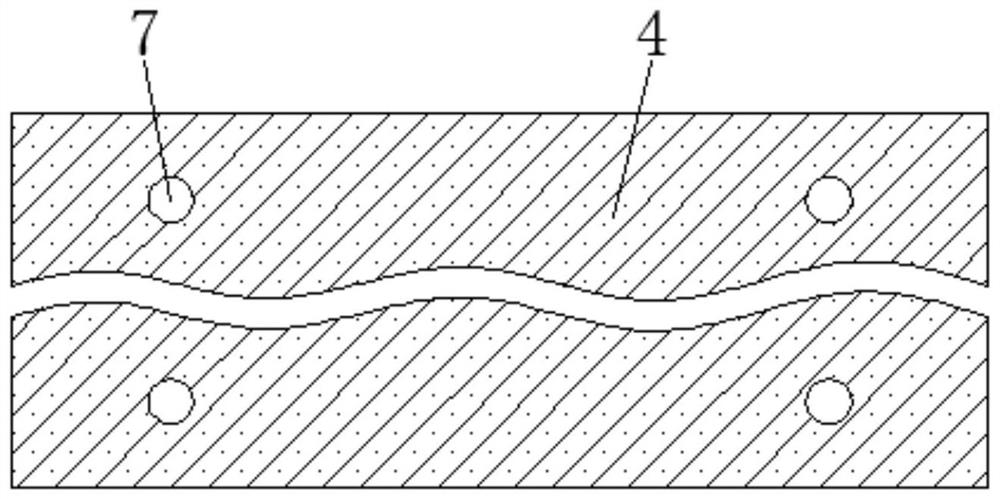

Fire-resistant cloth made of fiber material

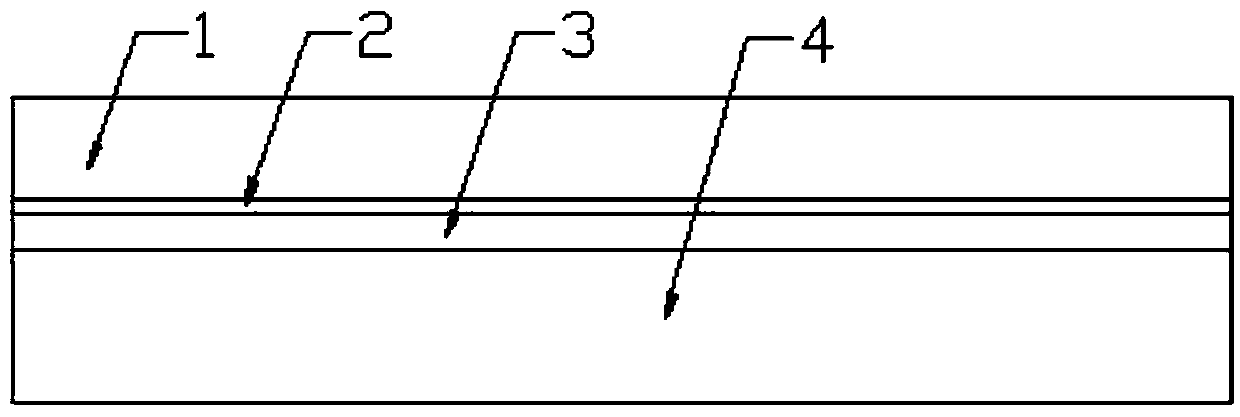

InactiveCN107650477AImprove wear resistanceNo meltingSynthetic resin layered productsCoatingsFiberAdhesive

The invention discloses fire-resistant cloth made of a fiber material. The fire-resistant cloth comprises a wear-resistant layer, an adhesive, a waterproof layer and a bottom coating, wherein the wear-resistant layer is located on the outermost side, the bottom face of the wear-resistant layer is connected with the surface of the waterproof layer, the adhesive is arranged between the wear-resistant layer and the waterproof layer, the wear-resistant layer is fixedly connected with the waterproof layer with the adhesive, the waterproof layer is located on the upper side of the bottom coating, and the bottom face of the waterproof layer is connected with the surface of the bottom coating. According to the fire-resistant cloth, as the wear-resistant layer is made of a wear-resistant nylon oxford material, the wear resistance of the cloth is improved, the cloth is more durable, and the wear phenomenon does not occur easily; as a PTFE membrane is additionally arranged between the wear-resistant layer and the bottom coating, the cloth achieves a waterproof effect, and articles in the cloth are prevented from being wetted; as the bottom coating is made of an organic silicon resin material,the cloth will not be molten in ink jet printing, and meanwhile the thickness of the cloth is increased, which makes the cloth product stiffer and more attractive.

Owner:东台市黄海耐火材料厂

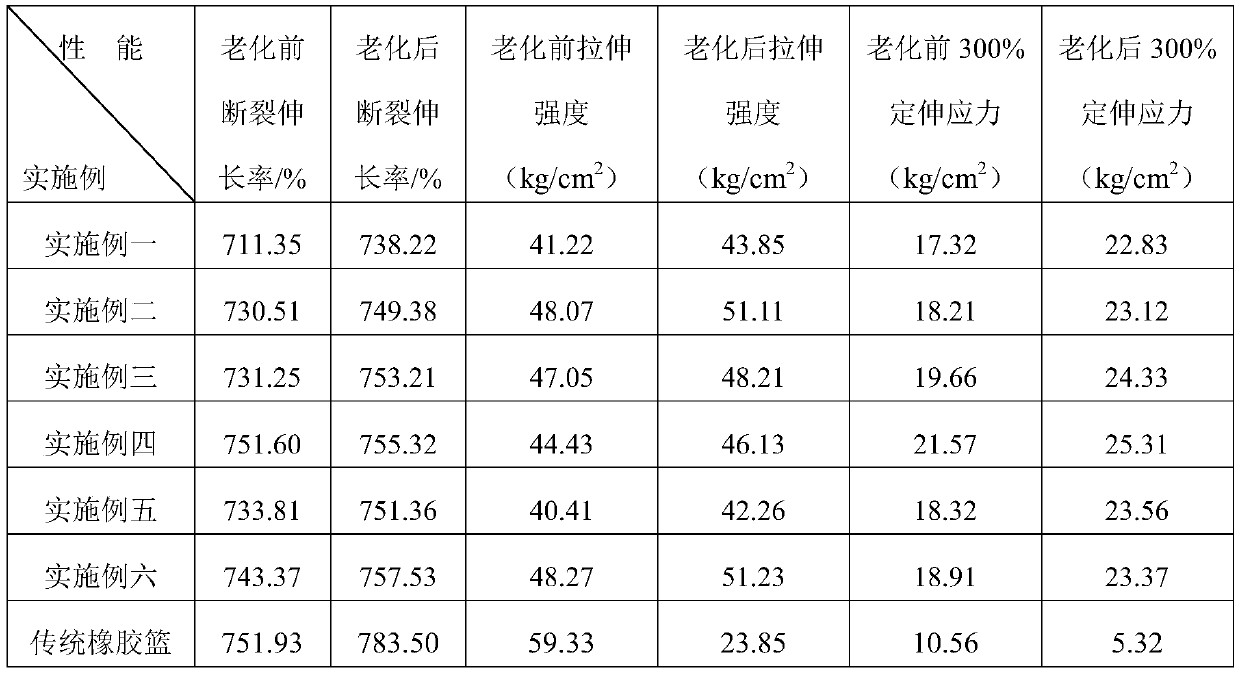

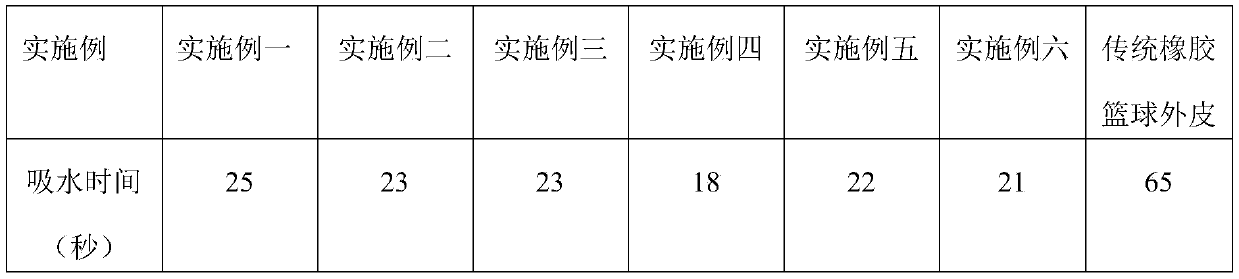

Rubber basketball skin and preparation method thereof

PendingCN111171402AGood weather resistanceImprove wear resistanceHollow inflatable ballsPolymer sciencePolyurethane adhesive

The invention relates to a rubber basketball skin and a preparation method thereof. The rubber basketball skinis prepared from the following raw materials in parts by weight: 10-20 parts of natural rubber, 40-60 parts of butadiene rubber, 2-5 parts of sodium polyacrylate, 3-5 parts of polyurethane adhesive, 2-5 parts of water, 10-15 parts of polyethylene glycol, 15-20 parts of carbon black, 15-20parts of zinc oxide, 10-20 parts of modified attapulgite, 0.5-0.8 part of N, N-di-n-butyl nickel dithiocarbamate, 0.2-0.8 part of sulfur, 1-1.2 parts of an accelerant, and 2-4 parts of a foaming agent. The rubber basketball skin has excellent weather resistance, wear resistance and scratch resistance, in addition, the basketball skin has good water absorption performance, sweat in the palm of a user can be absorbed in time, and excellent touch feeling is brought to the user.

Owner:漳州华飞体育用品有限公司

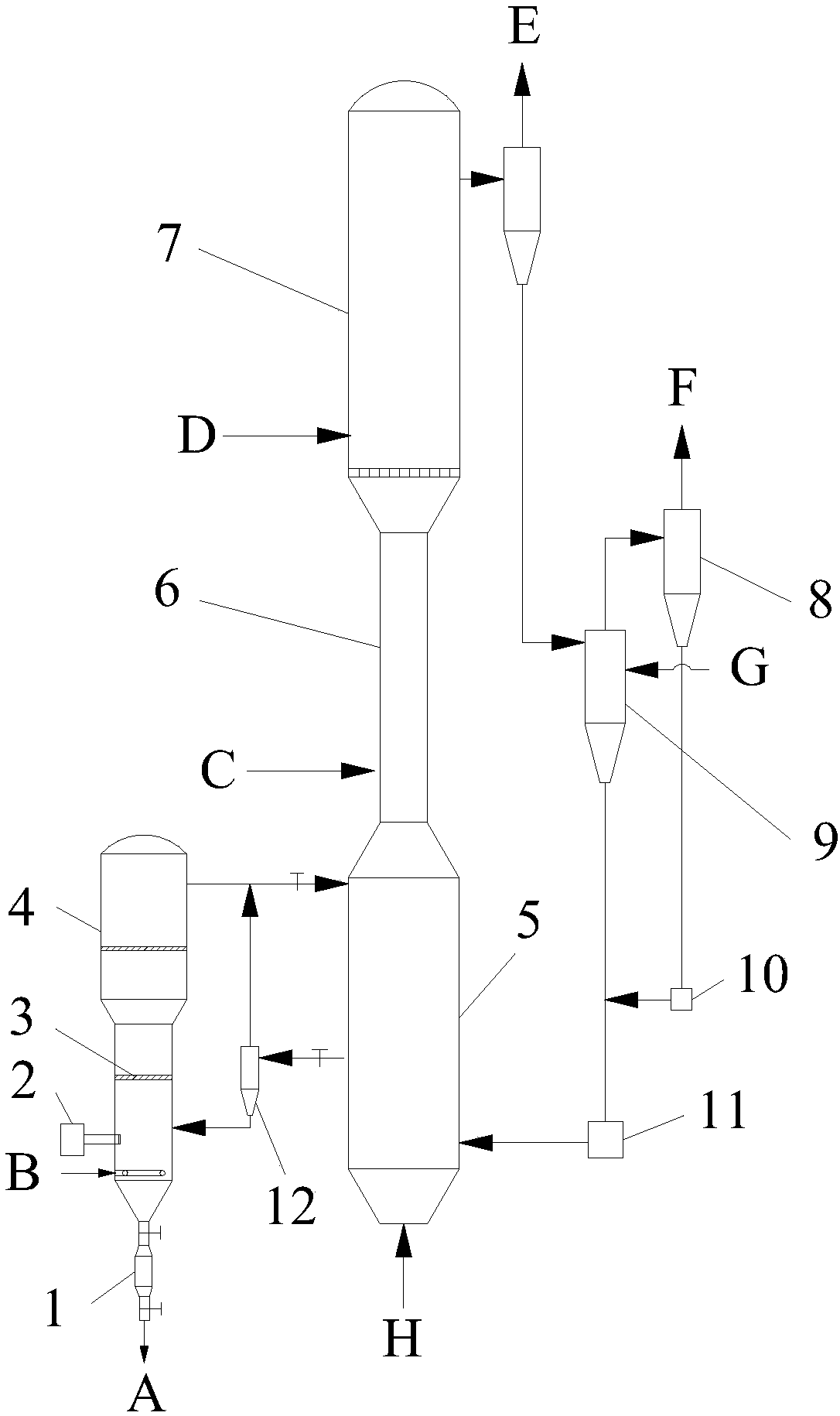

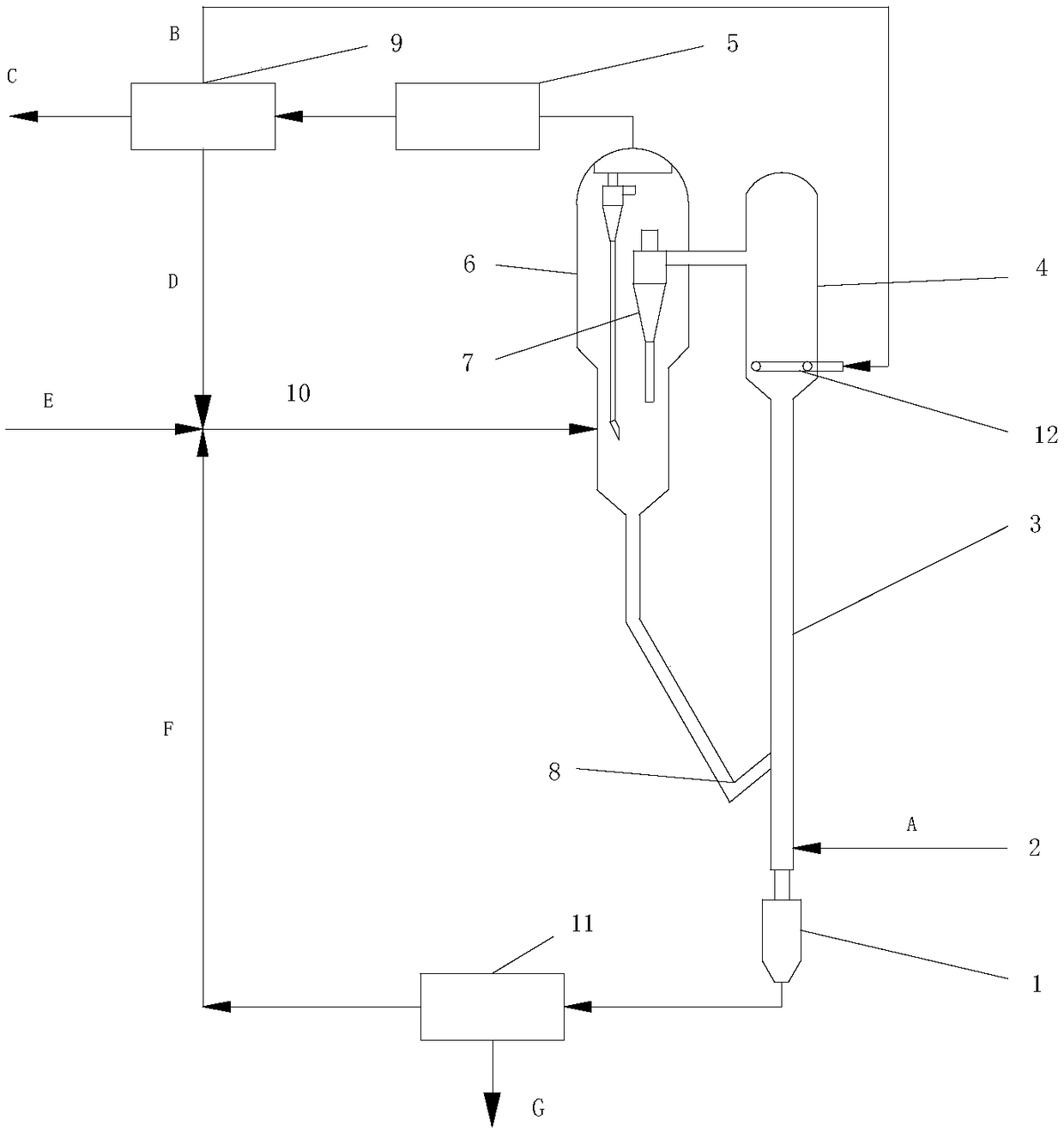

Coupled fluidized bed graded conversion reaction device and reaction method

ActiveCN109401795AEasy to getSave moneyCombustible gas chemical modificationHydrocarbon from carbon oxidesSlagMethane yield

The invention relates to a coupled fluidized bed graded conversion reaction device and a reaction method and mainly aims to solve the problems of low carbon conversion rates, low gasification intensities, low methane yields, hard slag discharge and low coal powder utilization rates in the prior art. By adopting the coupled fluidized bed graded conversion reaction device and the reaction method, acarbon-containing raw material with a catalyst is pyrolyzed in a pyrolyzation furnace, tar gases obtained after pyrolyzation are separated and collected, semicoke granules with the catalyst and a gasifying agent are respectively combusted and gasified in three reaction zones, reacted carbon-containing granules and a part of the catalyst are continuously fed back into the pyrolyzation furnace, ashslag at the bottoms of the reaction zones are firstly subjected to two-stage separation of a granule hydrocyclone separation device and a graded slag discharge device, and are secondly discharged outfrom the device according to acoustic emission monitoring feedback. By adopting the technical scheme, the technical problems are well solved, and the device can be applied to industrial production ofgraded conversion of coal.

Owner:CHINA PETROLEUM & CHEM CORP +1

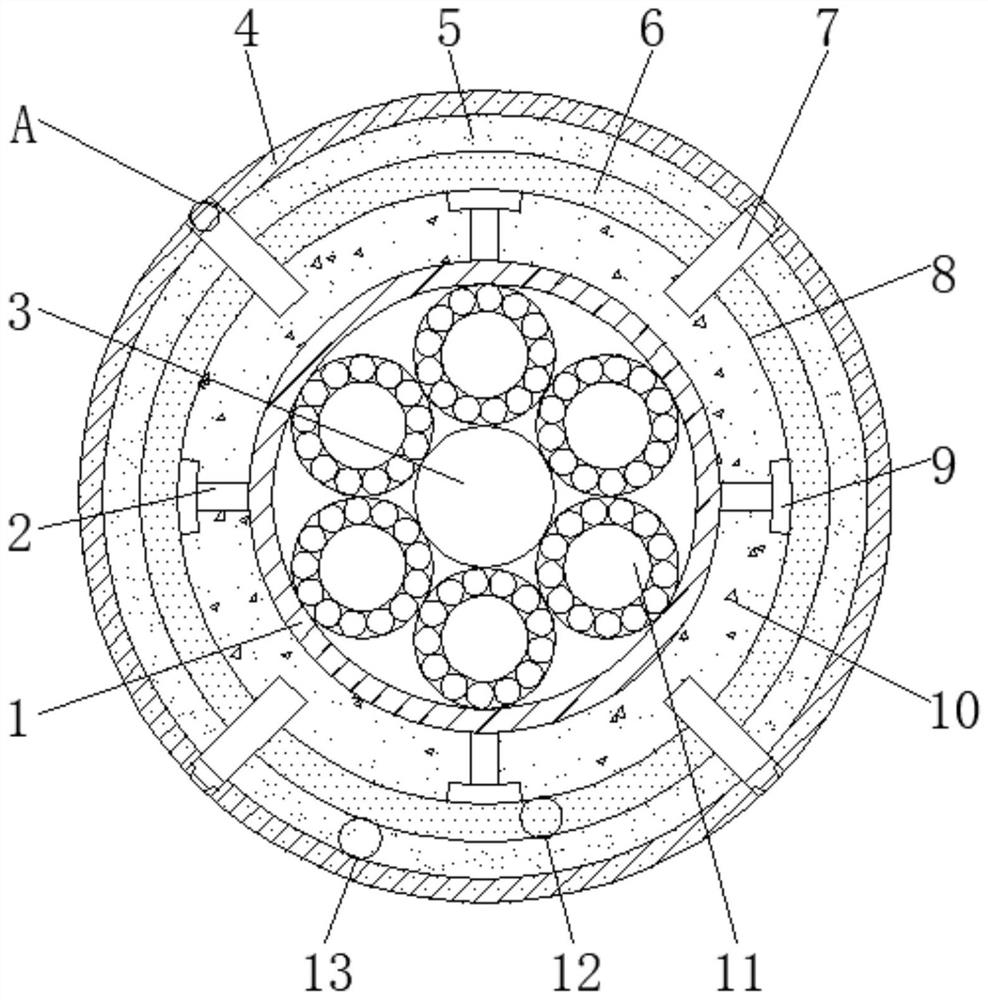

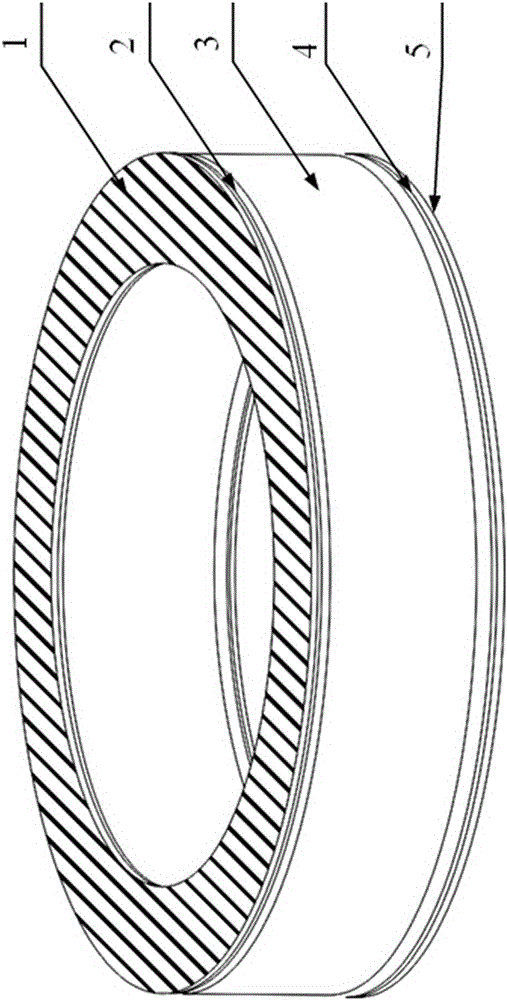

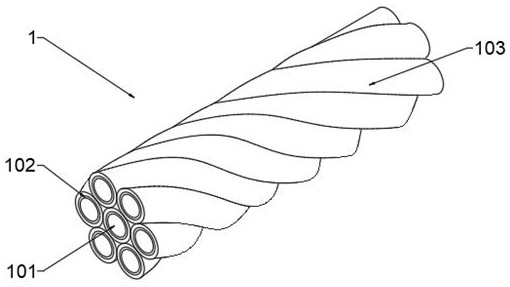

Anti-creeping intelligent cable

PendingCN111653388AImprove securityGuaranteed transfer rateInsulated cablesInsulated conductorsMetal meshEngineering

The invention discloses an anti-creeping intelligent cable. The cable comprises a cable body, a main body wire, a fine metal net sleeve, a flame-retardant clamping cavity and a flame retardant. A mainbody wire is arranged in the center of the interior of the cable body. A flame-retardant clamping cavity is wound on the outer side of the cable body. A flame retardant is filled in the flame-retardant clamping cavity. A fine metal net sleeve is wound on the outer wall of the flame-retardant clamping cavity. An anti-interference structure is arranged in the thin metal net sleeve. A rubber insulating sleeve is wound on the outer wall of the thin metal net sleeve. An insulating structure is arranged in the rubber insulating sleeve, a thermosensitive outer ring sleeve is wound on the outer wallof the rubber insulating sleeve, two sets of linkage grooves are formed in the outer wall of the thermosensitive outer ring sleeve at equal intervals, one end of each linkage groove extends into the flame-retardant clamping cavity, and a plug is installed at one end in each linkage groove. According to the invention, the phenomenon of electric leakage during use of the cable is avoided, the safetyduring use of the cable is improved, and the transmission rate during use of the cable is ensured.

Owner:SHANGHAI PEOPLE ELECTRICAL APPLIANCE GROUP

Metal material surface ultrasonic strengthening treatment device

ActiveCN112059743AEasy to repeat processingImprove processing efficiencyGrinding carriagesGrinding drivesPhysicsEngineering

The invention discloses a metal material surface ultrasonic strengthening treatment device, and particularly relates to the technical field of metal surface processing. The metal material surface ultrasonic strengthening treatment device comprises a supporting plate and supporting legs, the supporting legs are fixedly connected to the four corners of the bottom end of the supporting plate, and a dustproof mechanism is arranged at the bottom end of the supporting plate. A rubber wheel is driven to rotate through friction of metal materials in the reciprocating motion process, the rubber wheel is driven to drive a second friction wheel to rotate under the action of friction force in the rotating process, the second friction wheel generates friction to drive a first friction wheel to rotate,and therefore the first friction wheel generates friction to drive a receiving hopper to rotate; and fan blades arranged in the receiving hopper blow airflow to flow downwards, dust is accelerated tomove downwards into the dustproof mechanism, the dust is prevented from diffusing towards the periphery of the receiving hopper, in the rotating process of the receiving hopper, a material stirring rod scrapes the inner side wall of the receiving hopper, the inner side wall of the receiving hopper can be cleaned, and the dust falling into the receiving hopper can be cleaned away and collected conveniently.

Owner:安徽宏景电镀有限公司

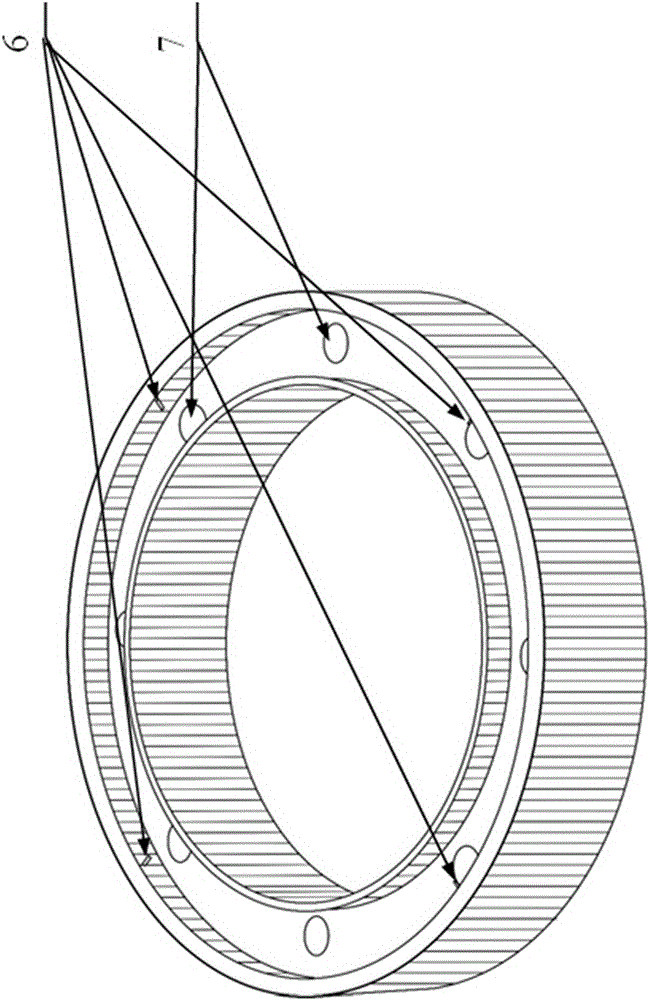

A high-pressure-resistant movable connection device for liquid delivery pipelines

The invention discloses a high-pressure-resisting movable connection device for a liquid conveying pipeline. The device comprises a whole fixing sleeve, two sealing pads, two sealing pad supports and a spring ball assembly, an axial mounting hole for containing the spring ball assembly is formed in the annular portion of the whole fixing sleeve, the two sealing pad supports are arranged at the upper end and the lower end of the whole fixing sleeve respectively, ball grooves which are formed in the two sealing pad supports and used for being matched with balls are towards the whole fixing sleeve, and the two sealing pads are arranged at the outer ends of the two sealing pad supports respectively. The device drives the upper portion and the lower portion to do relative rotation through moving of the sealing pad supports on the balls, friction motion of sealing pads and the pipeline in the prior art is replaced with rolling motion between the balls and the ball grooves, rotation is stable, the sealing performance is good, abrasion is small, service life is long, and the device is particularly suitable for the high-pressure liquid conveying pipeline and the occasions where the space is limited or the pipeline needs to be flexibly rotated under the special condition.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Medicine decocting pot with stirring rod

PendingCN112842901AStir wellImprove the protective effectTransportation and packagingRotary stirring mixersEngineeringStructural engineering

The invention relates to a medicine decocting pot with a stirring rod, which comprises an outer pot, an inner pot and a circular pot cover, wherein the inner pot is arranged in the outer pot in a lifting and penetrating mode, the circular pot cover covers the inner pot, an outer pot part supporting step is arranged on the outer pot, an inner pot part supporting step is arranged on the inner pot, the inner pot is supported on the outer pot part supporting step through the inner pot part supporting step and is placed in the outer pot, a lower cavity located below the inner pot part supporting step is formed between the lower end of the inner pot and the lower end of the outer pot, a plurality of filtering holes communicating the lower cavity with the inner space of the inner pot are formed in the bottom wall of the inner pot, and the inner pot part supporting step and the outer pot part supporting step abut against each other in a sealed mode, so that the outer pot and the inner pot can be connected together in a sealed mode, a stirring shaft is fixedly connected to the pot cover, and the stirring shaft is driven by the pot cover to rotate. The medicine decocting pot has the advantage that stirring can be conducted without opening the pot cover in the decocting process, and the problem that an existing medicine decocting pot with the pot cover cannot be stirred with the cover on in the decocting process is solved.

Owner:ZHEJIANG HOUDAR INTELIGENT TECH CO LTD

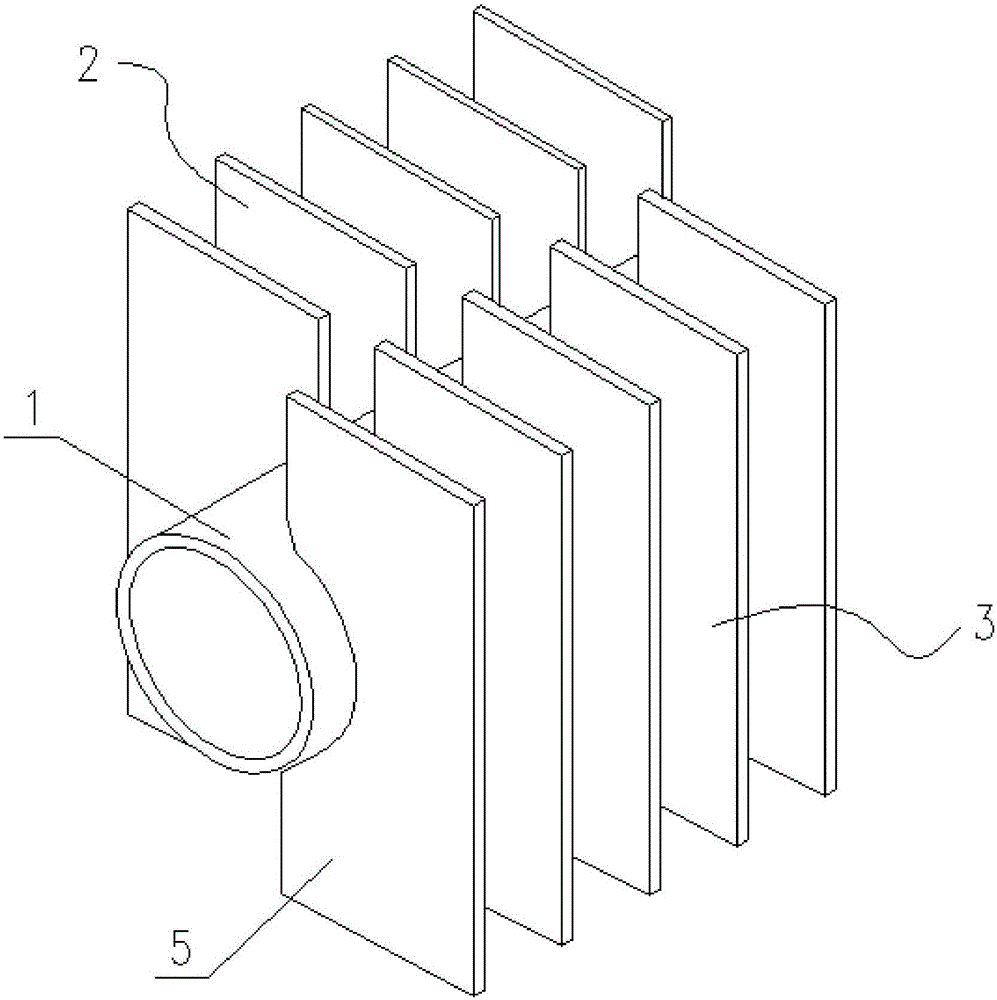

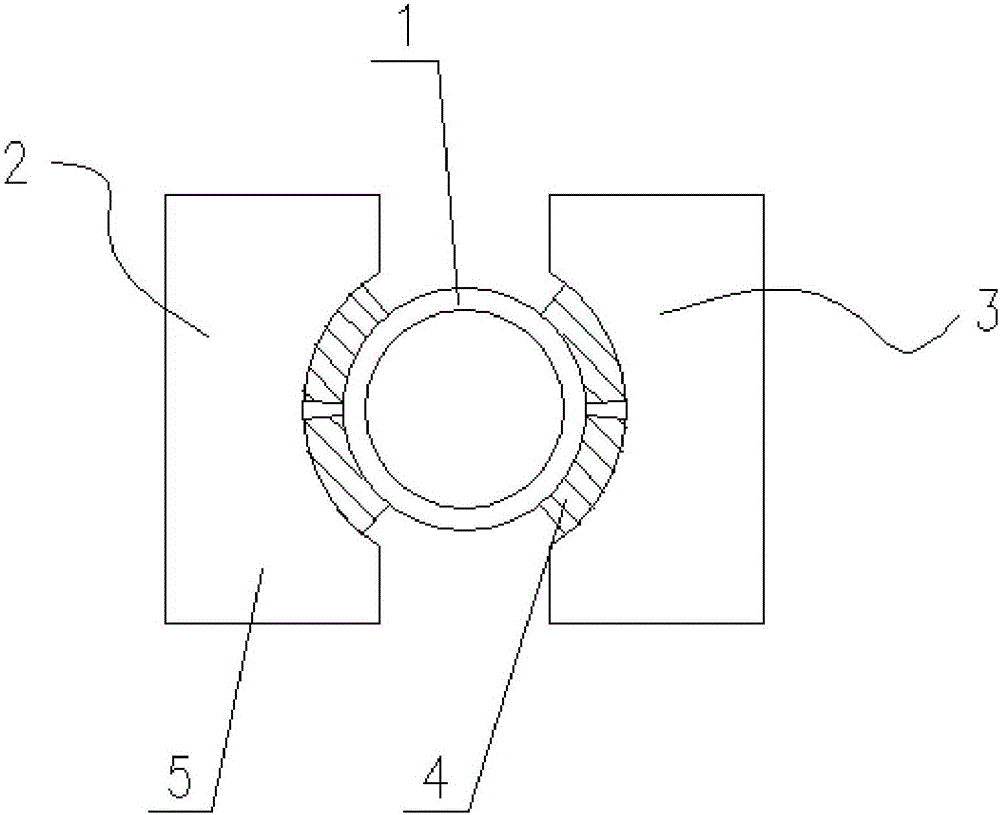

Structure for ultra-supercritical fin low-temperature reheater

InactiveCN106402842AIncrease the heating areaReduce resistanceSteam superheatersEngineeringHeat transfer

The invention relates to a structure for an ultra-supercritical fin low-temperature reheater so as to solve the problems that the heating surface of an existing low-temperature reheater is large in arrangement space and a heating plate of the reheater subjected to abrasion is inconveniently replaced. The structure provided by the invention comprises a low-temperature reheater reheating tube, a first group of low-temperature reheating sheets and a second group of low-temperature reheating sheets, wherein the first and second groups of low-temperature reheating sheets are formed by arranging cuboid fins at equal intervals and are welded on the low-temperature reheater heating tube through a heat transfer base; and the first and second groups of low-temperature reheating sheets are alternately arranged on the left and right sides of the low-temperature reheater reheating tube. According to the structure provided by the invention, the rear smoke channel space of a boiler is effectively utilized, so that the heating surface of the reheater is increased to the maximum extent.

Owner:HARBIN BOILER

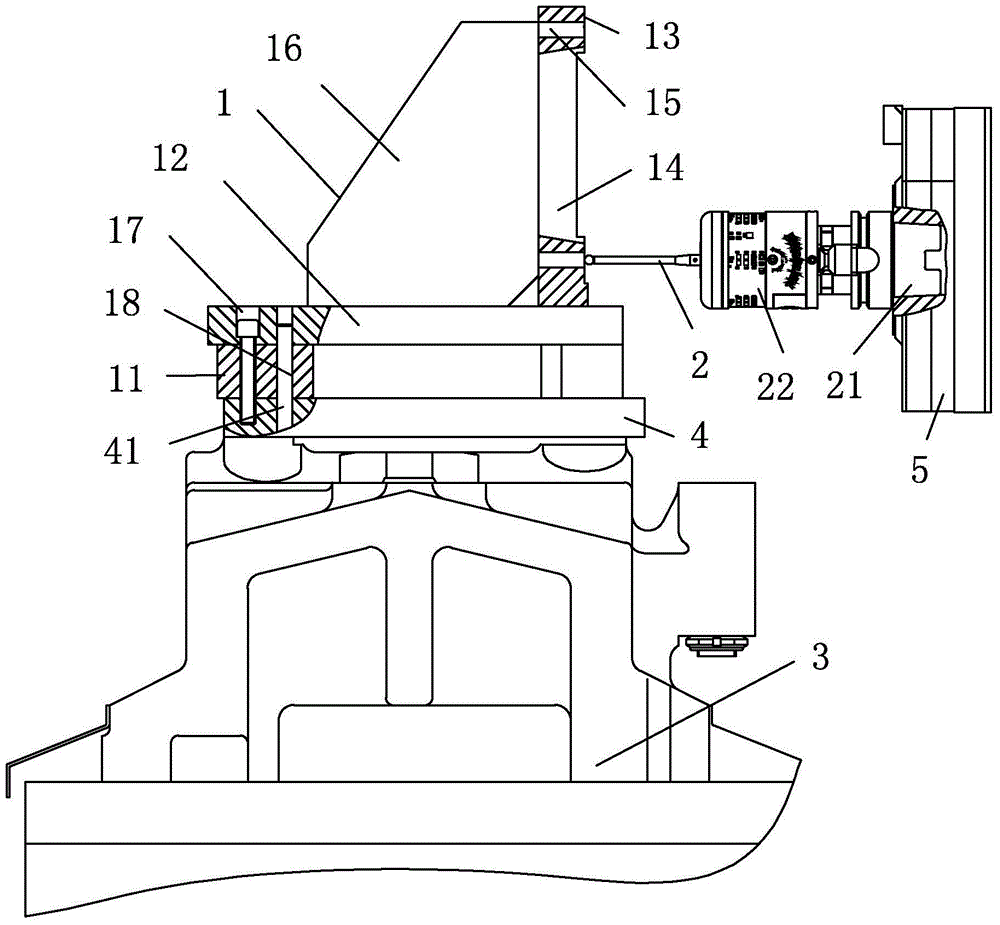

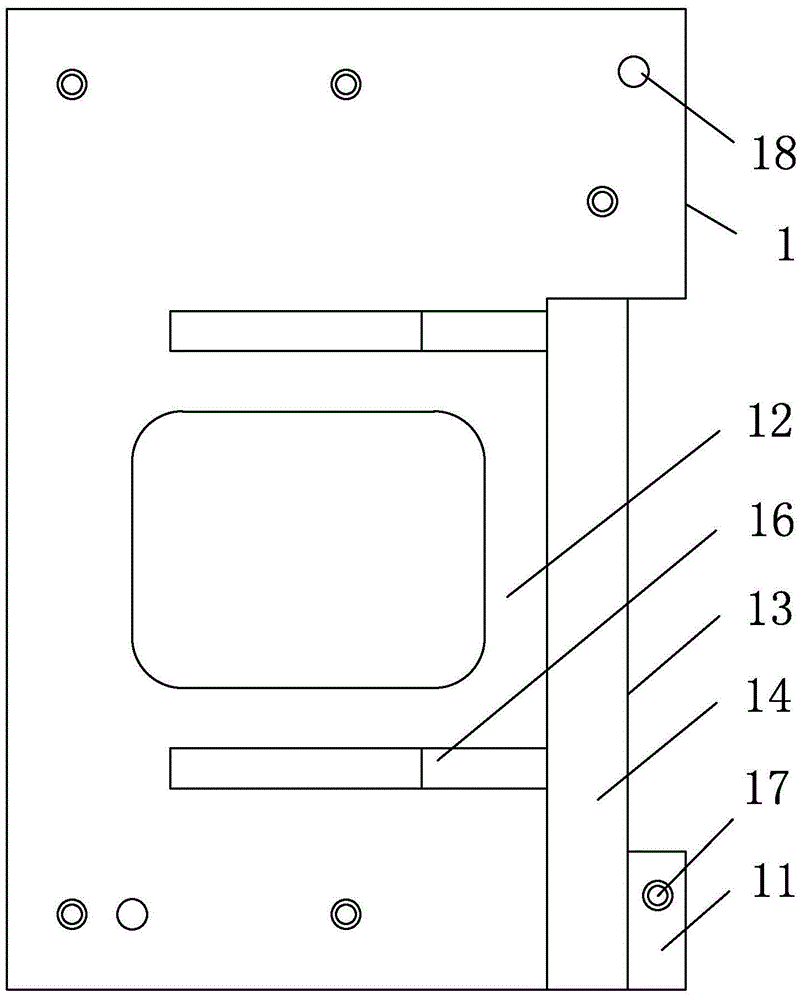

Accuracy calibration device and accuracy calibration method of fixture for box-type parts

InactiveCN104647133BDoes not affect accuracy calibration resultsSmall precision calibration errorAutomatic control devicesMeasurement/indication equipmentsElectricityEngineering

The invention relates to the field of a machining center box type part jig calibration and aims at providing a box type part jig accuracy calibration device and an accuracy calibration method. The box type part jig accuracy calibration device comprises an accuracy calibration base and an infrared probe system. The accuracy calibration base comprises a bottom plate and a vertical calibration plate, wherein the bottom plate is provided with at least two connecting blocks at the lower end surface, and the vertical calibration plate has one end surface provided with a calibration surface perpendicular to the bottom plate and is connected to the bottom plate at the lower end. The calibration surface is provided with at least a calibration hole penetrating through the other end surface of the vertical calibration plate. The lower end surface of each of the two connecting blocks is provided with a connecting through hole penetrating through the upper end surface of the bottom plate and a positioning hole. The infrared probe system comprises an infrared probe with a knife shank and a data transmission unit and a data receiver electrically connected to a controller of a machining center. The box type part jig accuracy calibration device is small in accuracy calibration errors and free of fouling and abrasion affecting calibration results.

Owner:ZHEJIANG GEELY POWERTRAIN CO LTD +3

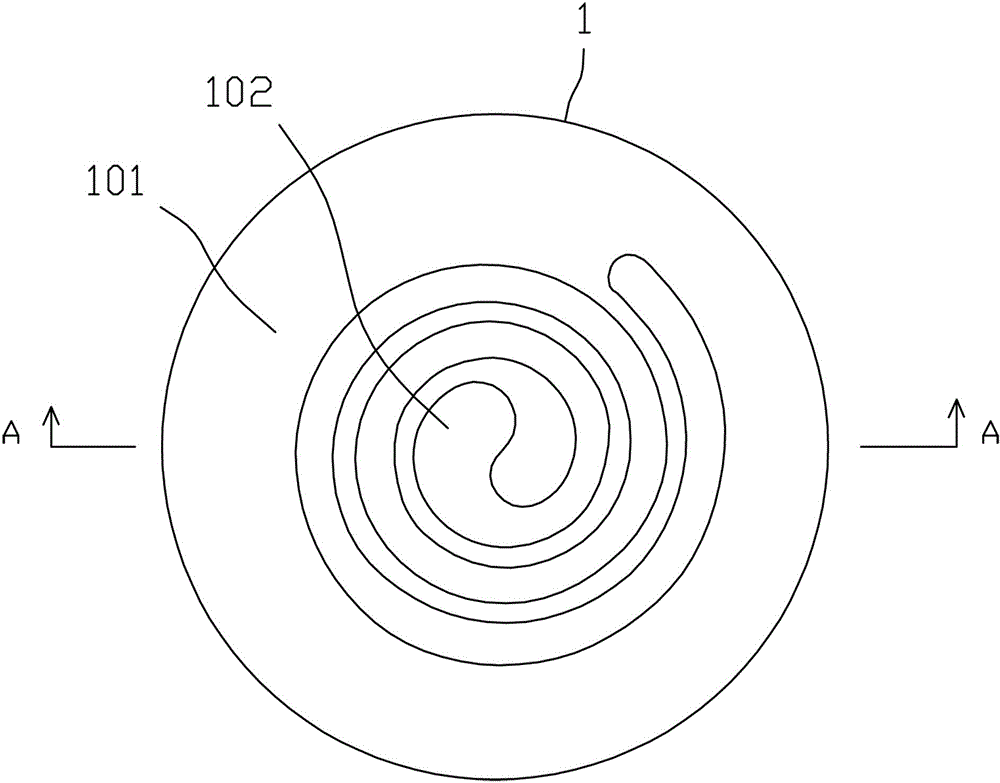

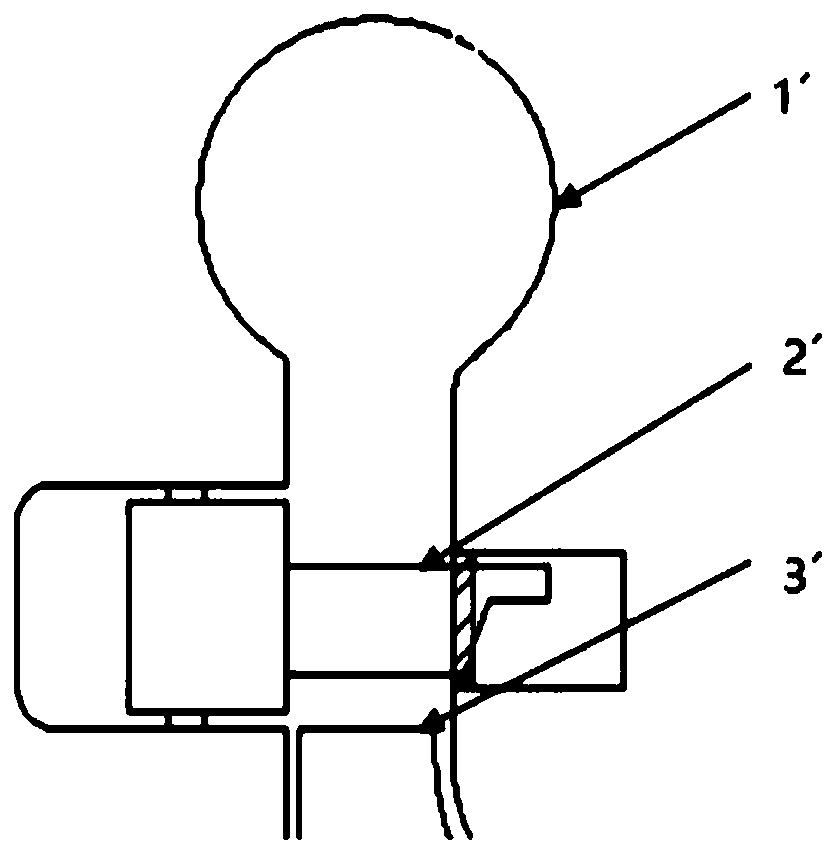

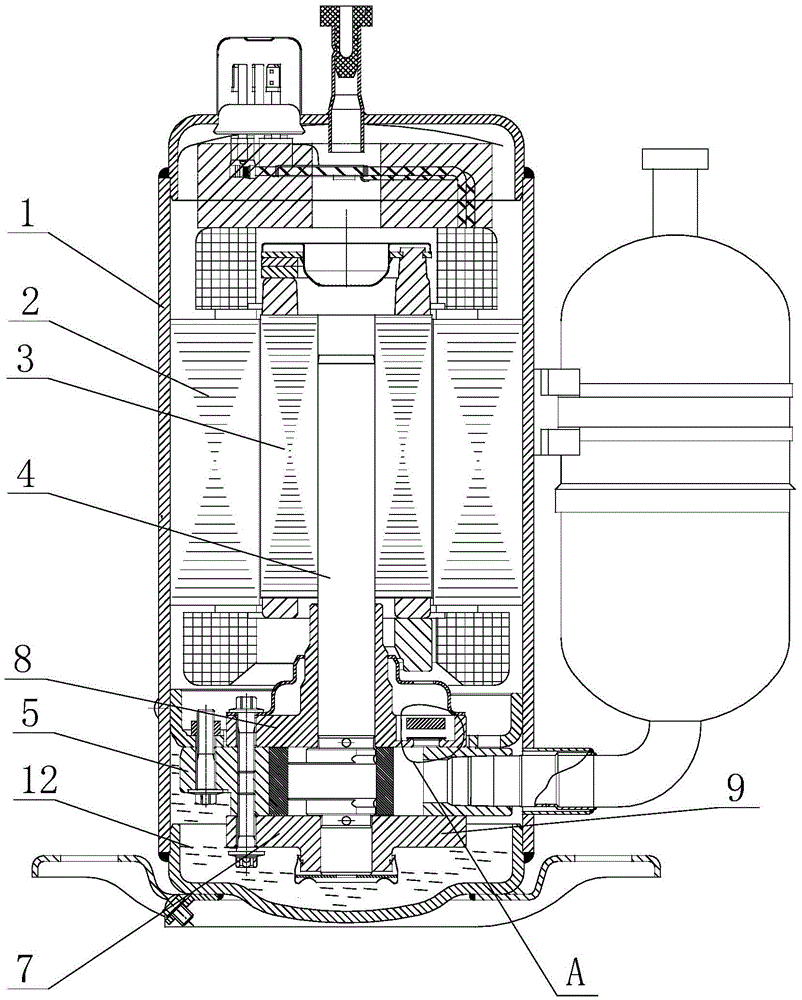

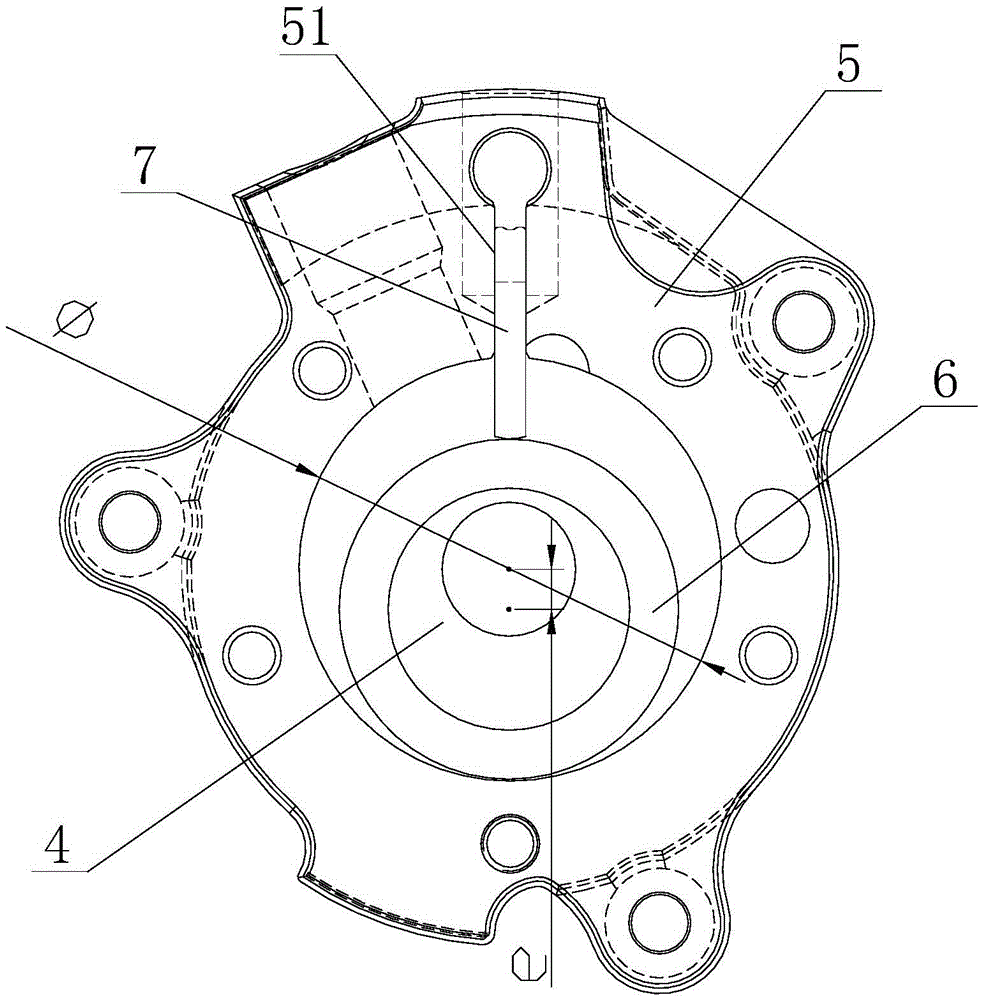

Static scroll plate on scroll compressor, and production method thereof

InactiveCN104481872AAvoid output air pressure dropGuaranteed normal useRotary piston pumpsRotary piston liquid enginesVacuum furnaceLubrication

The invention discloses a production method of a static scroll plate on a scroll compressor. The method comprises the following steps: 1, processing a scroll groove on the work end surface of a substrate; 2, simultaneously sintering spherical copper powder layers on the work end surface of the substrate and the bottom and the two sidewalls of the scroll groove; and 3, putting a liquid self-lubrication material in a vacuum furnace, immersing the substrate in the self-lubrication material, and evacuating the vacuum furnace to make the self-lubrication material permeate into gaps between all spherical copper powders in the spherical copper powder layers. The method allows the work end surface of the produced static scroll plate on the scroll compressor and the bottom and the two sidewalls of the scroll groove to respectively have a self-lubrication effect, so the static scroll plate is basically not worn under conditions with high output air pressure requirements.

Owner:宁波永灵航空配件有限公司

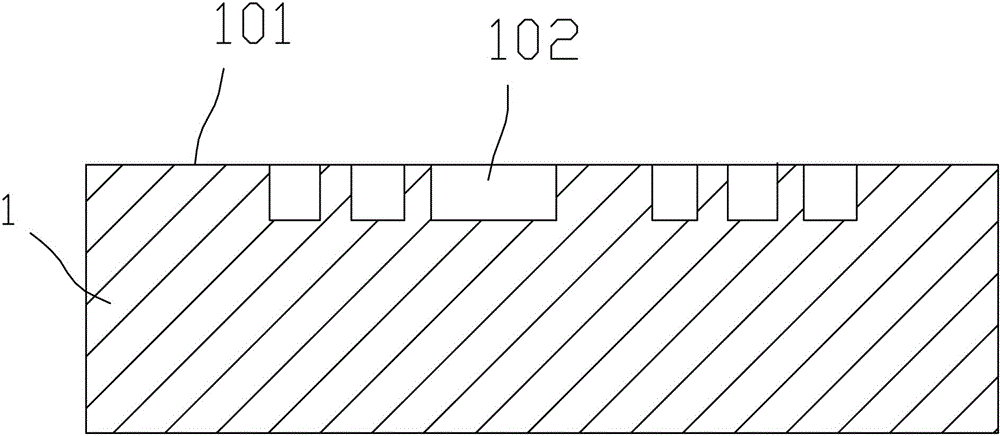

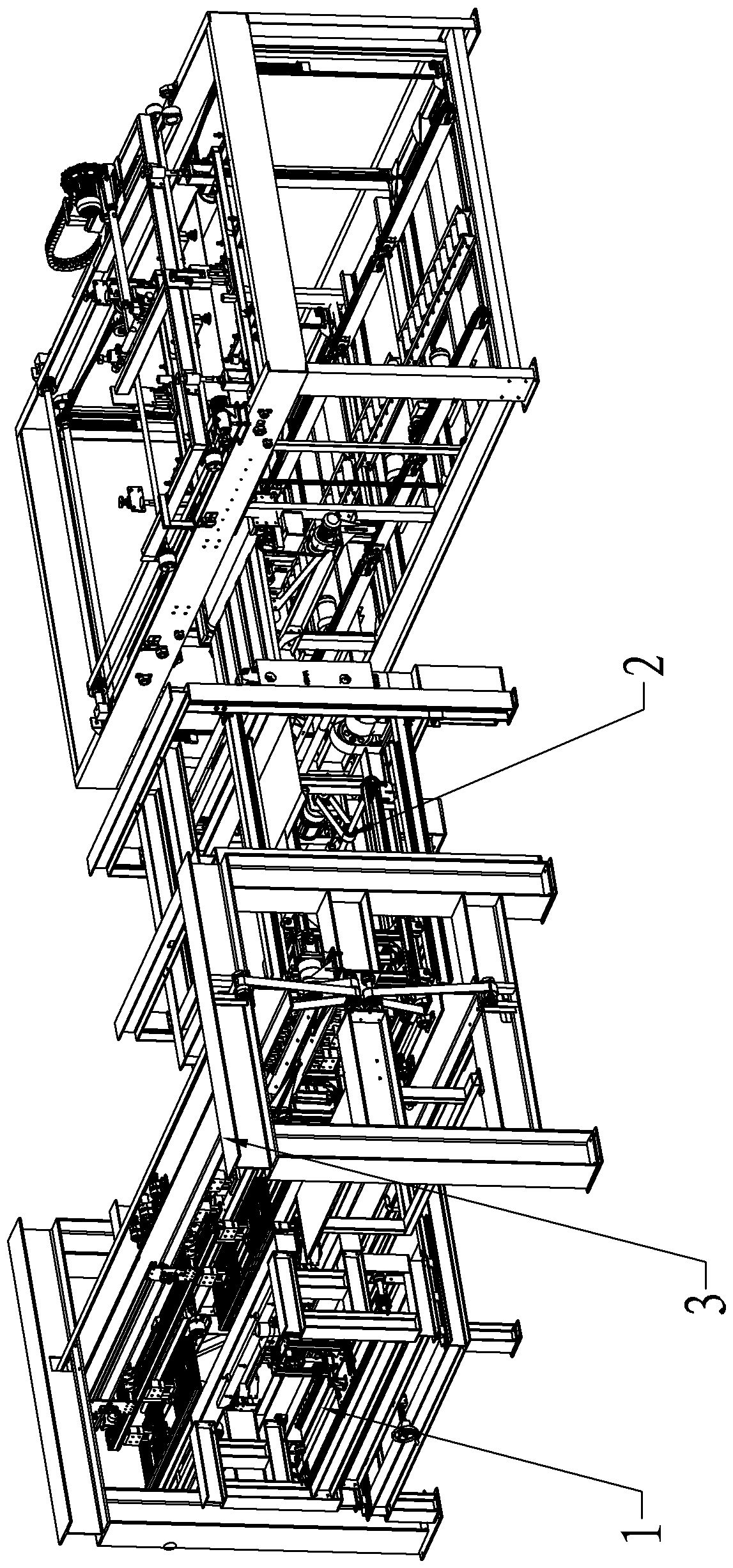

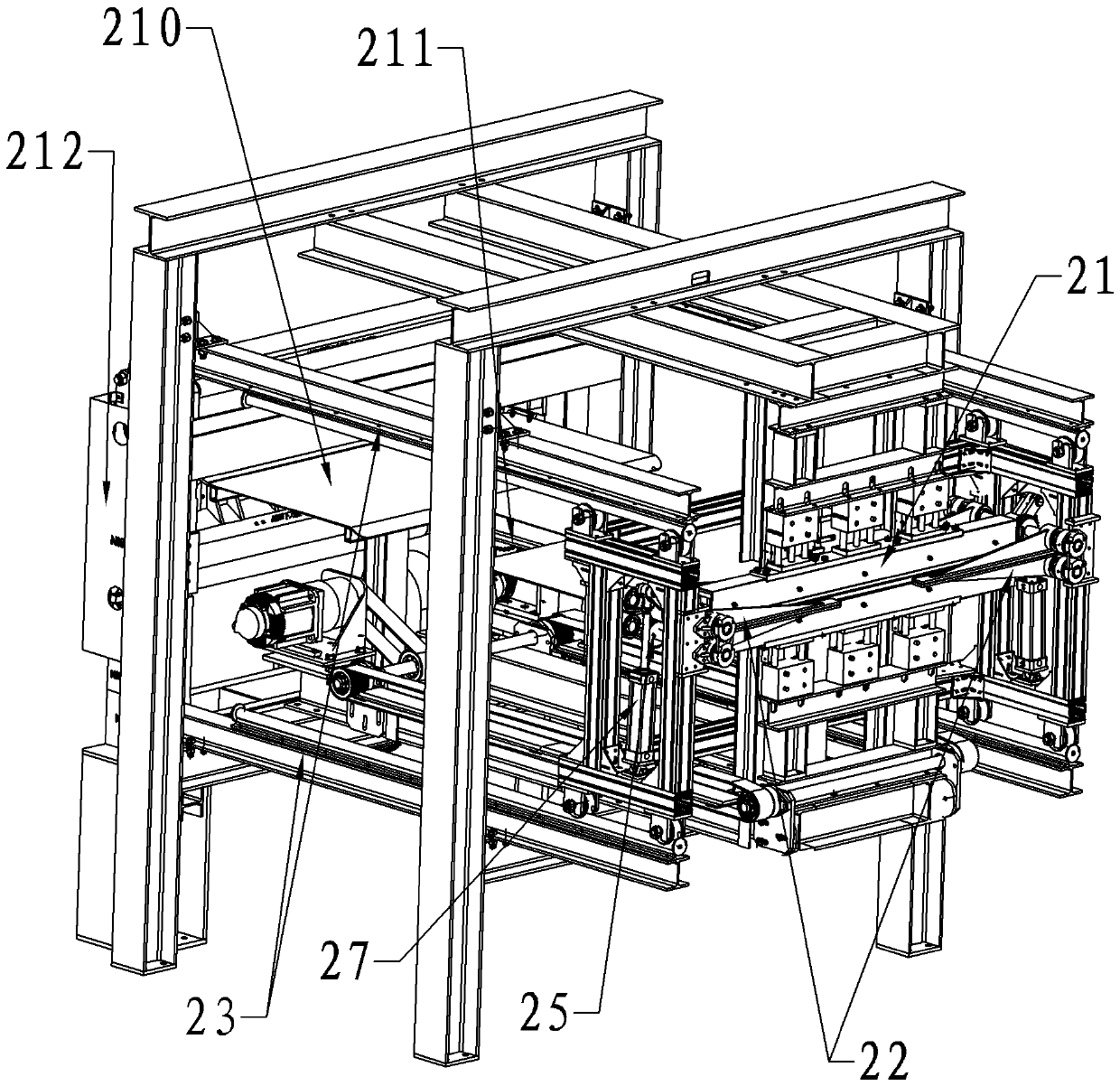

Fully automatic unlimited extension machine

ActiveCN105583918BGuaranteed stitching qualityReduce processing costsOther plywood/veneer working apparatusWood veneer joiningEngineeringFully automatic

The invention discloses a full-automatic sheet unlimited lengthening machine, which at least comprises a sheet cutting and chamfering mechanism, a sheet unlimited lengthening mechanism and a double-station sheet conveying mechanism; the sheet cutting and chamfering mechanism has the advantages that a notch is flat and smooth, machining precision is high, a large amount of flying dust cannot be generated during a machining process, and the like; the sheet unlimited lengthening mechanism is used for completing splicing between sheets and conveyance after splicing to ensure that spliced parts of the sheets are subjected to a small force during a conveying process, therefore the spliced parts are prevented from being disengaged or staggered; the double-station sheet conveying mechanism is used for completing reclaiming and synchronous conveyance of machining stations to ensure that two machining stations are capable of synchronously obtaining sheets to be machined, so that the requirement of synchronous and continuous machining is met. According to the full-automatic sheet unlimited lengthening machine, all machining procedures from cutting to splicing of the sheets are completed in a full-automatic manner by matching the mechanisms, therefore splicing quality of the sheets is ensured while production efficiency is effectively increased.

Owner:HESHAN JIDING MACHINERY CO LTD

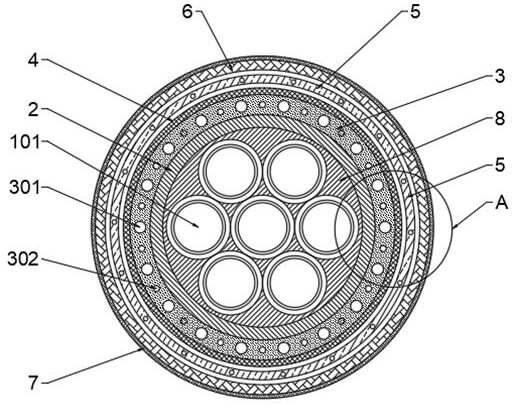

High-flame-retardant multi-layer cable

InactiveCN114068083AAvoid bitesImprove the protective effectInsulated cablesAnimal repellantsFiberEngineering

The invention discloses a high-flame-retardant multilayer cable. The cable comprises a cable core main body and an auxiliary mechanism, a first flame-retardant mechanism is arranged outside the cable core main body, a second flame-retardant mechanism is arranged outside the first flame-retardant mechanism, the auxiliary mechanism is composed of a metal net pipe, an inner sleeve, latex paint and mint fibers, the metal net pipe sleeves the cable core main body, the outer wall of the metal net pipe is sleeved with an inner sleeve, the outer wall of the inner sleeve is coated with the latex paint, and the latex paint is filled with the mint fibers. Through the arrangement of the metal net pipe, the inner sleeve, the latex paint and the mint fibers, a mouse can bite the inner sleeve coated with the latex paint when biting the cable, and the mouse cannot quickly damage the metal net pipe due to the fact that the toughness of the metal net pipe is high; at the moment, mint factors in the mint fibers can emit thick mint smell through the bite part of the cable, so that the mouse which bite the metal net pipe are repelled, and the protection performance of the cable is improved.

Owner:温桂华

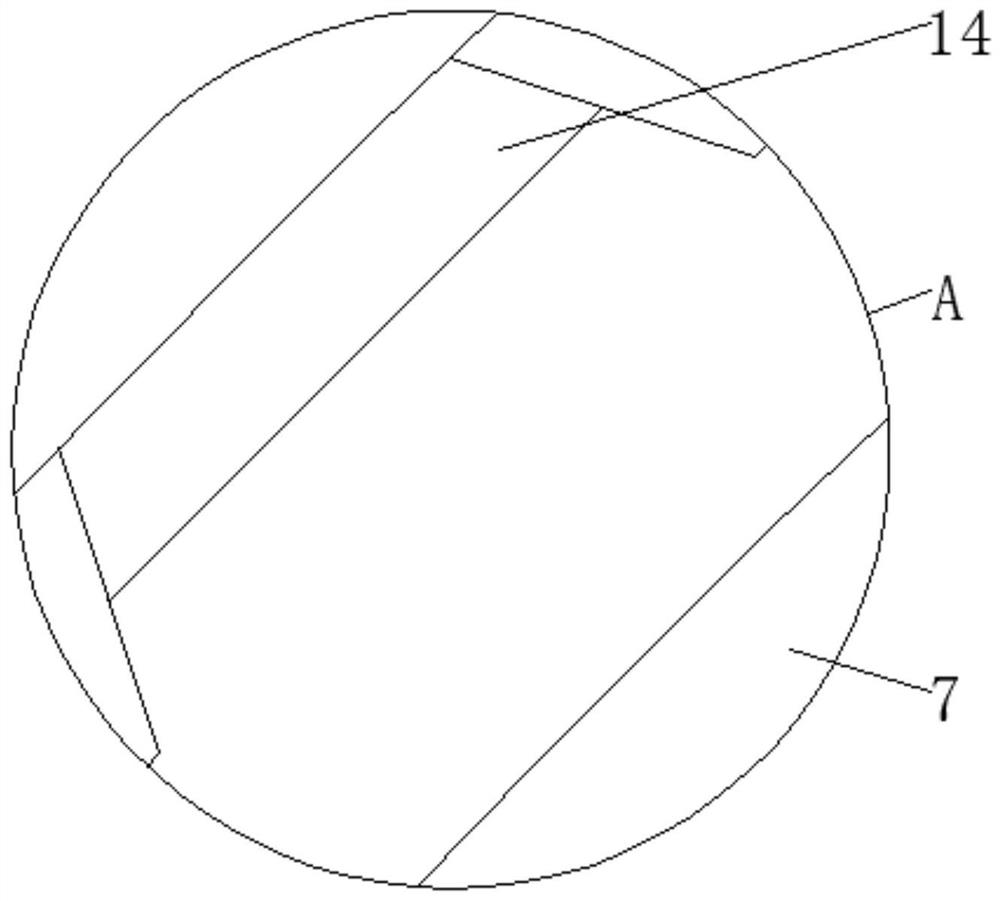

Impermeable membrane construction method

PendingCN112854310ANot prone to wear and tearGood construction performanceProtective foundationGeomembraneStructural engineering

The impermeable membrane construction method comprises the following operation steps that S1, selecting an impermeable membrane meeting construction conditions, the impermeable membrane is a polyethylene geomembrane, storing and transporting the impermeable membrane in a winding mode, the length of each roll of impermeable membrane is 90-105 m, wherein the width of each roll of impermeable membrane is 8-10 m; S2, winding the selected anti-seepage membrane, conveying the wound anti-seepage membrane to an appointed position through a crane, binding the crane and the geomembrane through a special membrane hanging belt, and protecting the anti-seepage membrane, and S3, preparing a peelable protective outer membrane which comprises a peelable outer membrane and a peelable adhesive material. According to the impermeable membrane construction method, the peelable protective outer membrane is arranged on the outer surface, the outer surface of the impermeable membrane is protected during construction laying, the abrasion condition is not prone to occurring, a foundation is subjected to reinforcement operation, the surface is ground flat, the construction effect is improved, the impermeable membrane construction method is more stable, and better use prospects are brought.

Owner:SHANGHAI YINGFAN ENG MATERIAL CO LTD

Curve-shaped forming milling cutter

PendingCN113118533ANot prone to wear and tearThere will be no crashes, etc.Milling cuttersWorkpiecesDeflection angleSheet structure

The invention discloses a curve-shaped forming milling cutter. The cutter is characterized by comprising a cutter body and a cutter handle, the cutter handle is a clamping part, a cutting part is arranged on the cutter body, the cutting part is composed of an even number of cutting edges, the cutting edges are of sheet structures with the same thickness, each cutting edge has the same axial deflection angle, and the angle ranges from 3 degrees to 10 degrees; and an edge part of each cutting edge is composed of an edge part base plane parallel to the axial direction of the cutter body and two radially symmetrical and continuous curved edges protruding out of the base plane, the left end faces of the cutting edges are connected with the edge part base planes through 45-degree inclined planes, and two corner angles formed between the inclined planes and the end faces and between the inclined planes and the edge parts are in smooth transition through arc surfaces. When the curve-shaped forming milling cutter is used for machining an automobile sliding block, one-time machining forming can be achieved, and a sliding cavity with a curve-shaped milling face is obtained; and the inner wall of the curve-shaped sliding cavity is not provided with sharp corner angles, so that the sliding block can be better accommodated to move.

Owner:常州冶戈工具有限公司

Surgical Instruments and Surgical Robots

Owner:SHANGHAI MICROPORT MEDBOT (GRP) CO LTD

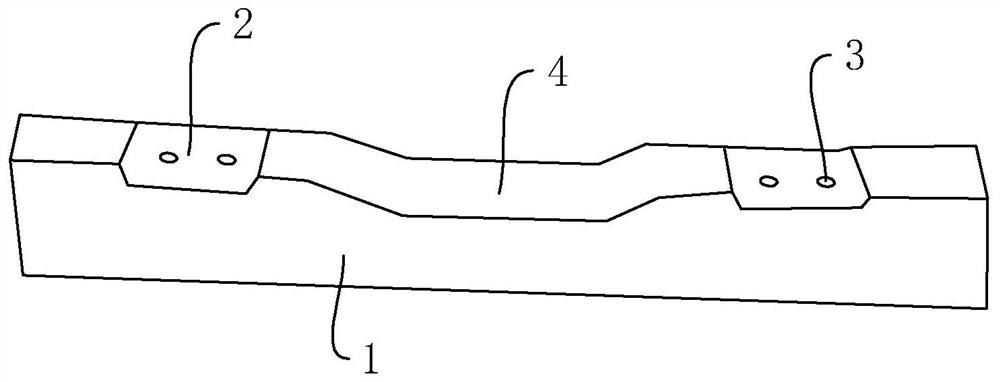

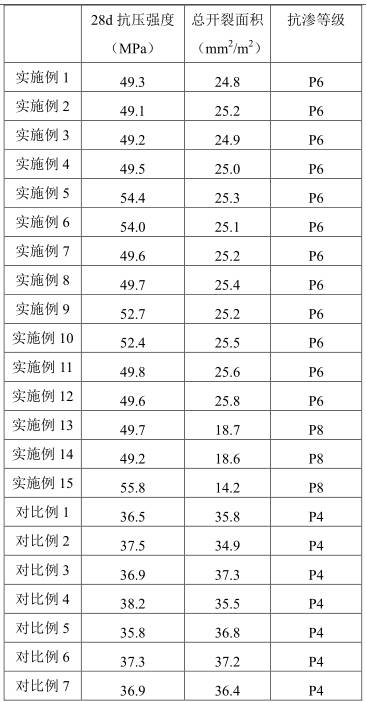

Special concrete for railway sleeper and railway sleeper poured by using concrete

The invention relates to the field of concrete, and particularly discloses special concrete for railway sleepers, which comprises the following components in parts by weight: 256-275 parts of Portland cement; 788 to 974 parts of sand; 896 to 1145 parts of regenerated broken stone; 10 to 22 parts of polypropylene fiber; 14 to 23 parts of polyamide epichlorohydrin resin; 8-14 parts of silica powder; 11 to 21 parts of an admixture; 4-9 parts of a water reducing agent; and 125 to 136 parts of water. The invention further discloses a railway sleeper formed by pouring the concrete. The railway sleeper has the effect that the railway sleeper is not prone to cracks.

Owner:广东华南混凝土有限公司

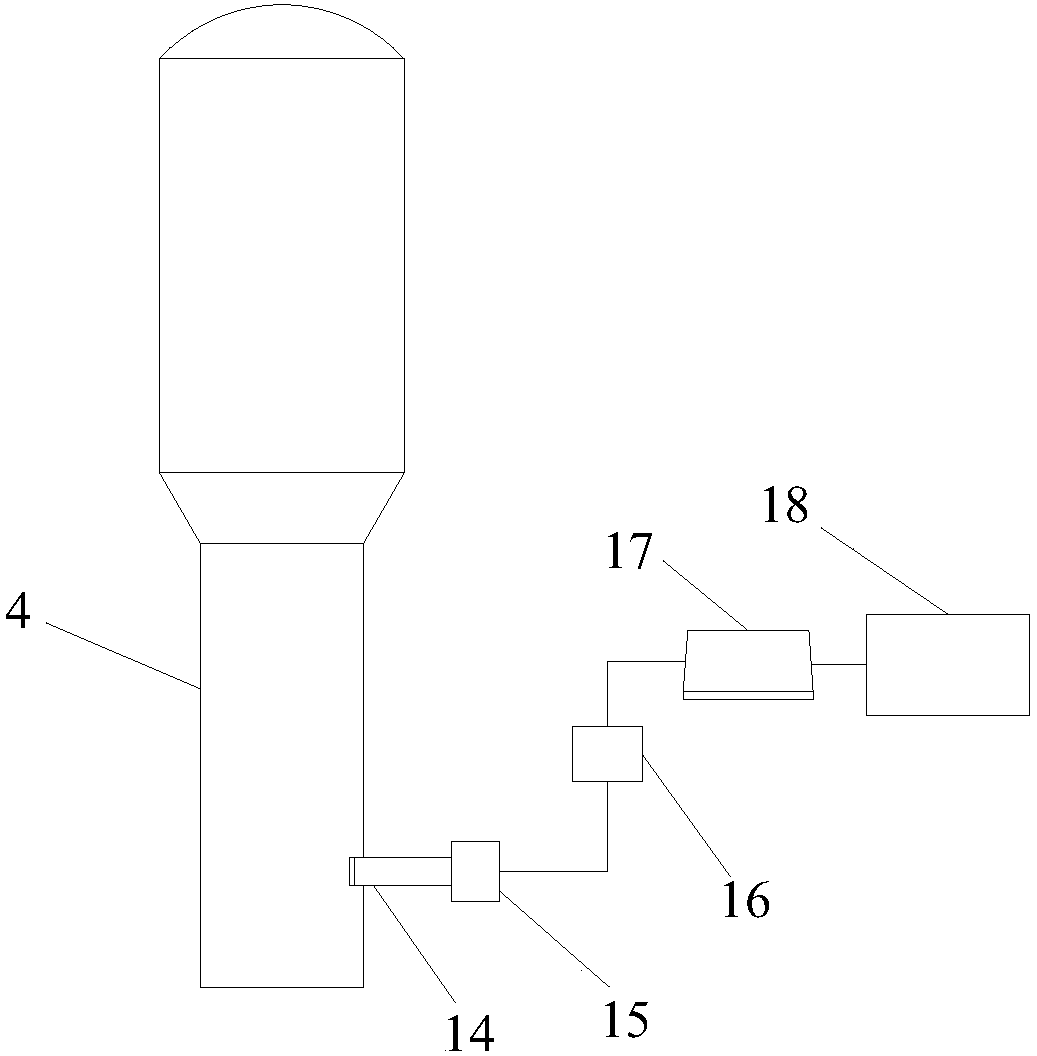

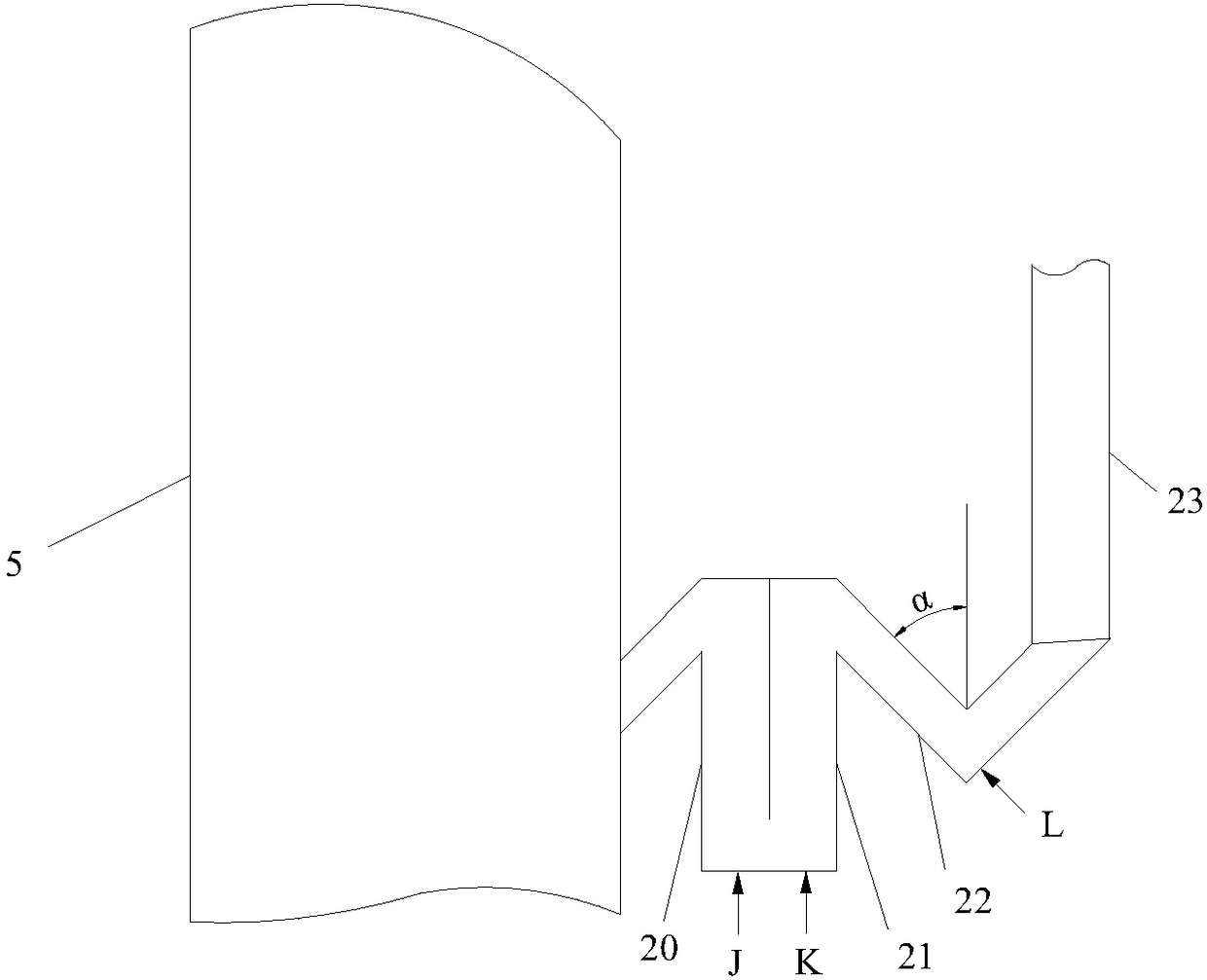

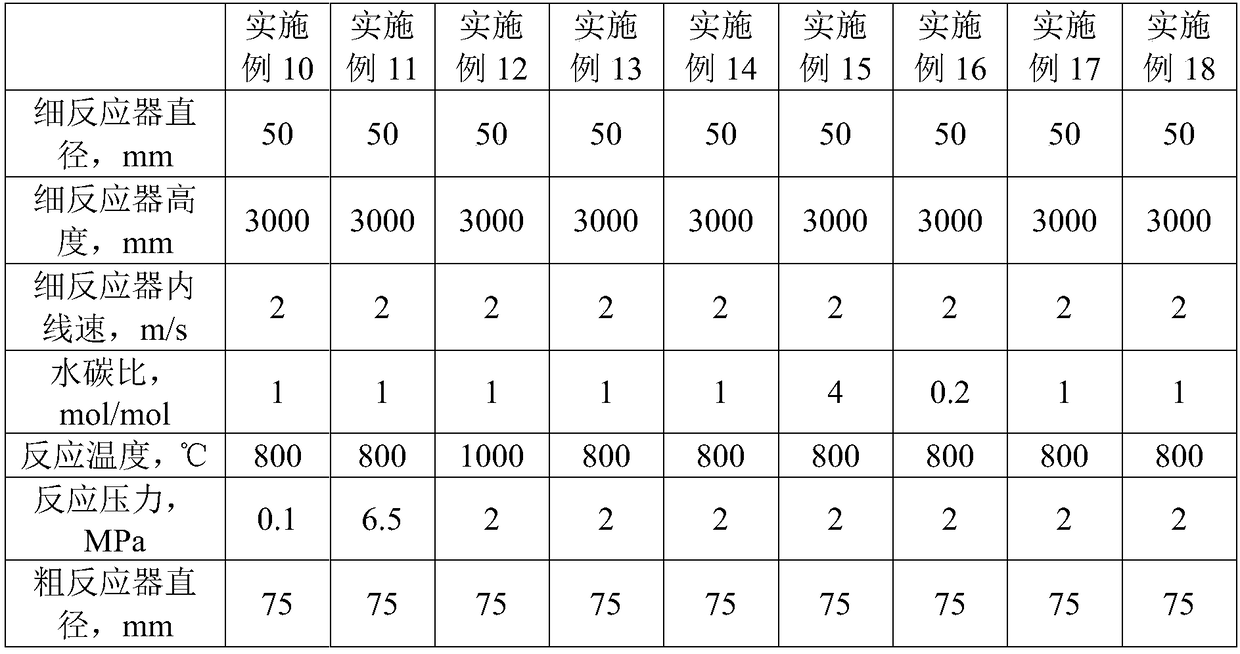

Reaction device and reaction method for catalytic gasification combined fluidized bed

ActiveCN109401792AEasy internal temperature controlImprove gas-solid contact efficiencyGasification processes detailsBulk chemical productionSyngasCombustion

The invention relates to a reaction device and a reaction method for a catalytic gasification combined fluidized bed, and mainly solves the problems of low carbon conversion rate and gasification intensity, low methane yield and relatively low gasification furnace operation stability in the prior art. Through the technical scheme, according to the reaction device and the reaction method for the catalytic gasification combined fluidized bed, a catalyst is supported into a carbon-containing raw material, partial combustion and a gasification reaction are carried out on the supported catalyst, agasifying agent and an oxidizing agent simultaneously at relatively high linear speed and relatively low particle concentration in a fine reactor, and a further gasification reaction is carried out onsubsequently generated synthesis gas and carbon-containing particles without reacting completely in a coarse reactor; and the above technical problems are solved preferably, so that the reaction device and the reaction method can be applied to industrial production of catalytic gasification rich methanogenesis.

Owner:CHINA PETROLEUM & CHEM CORP +1

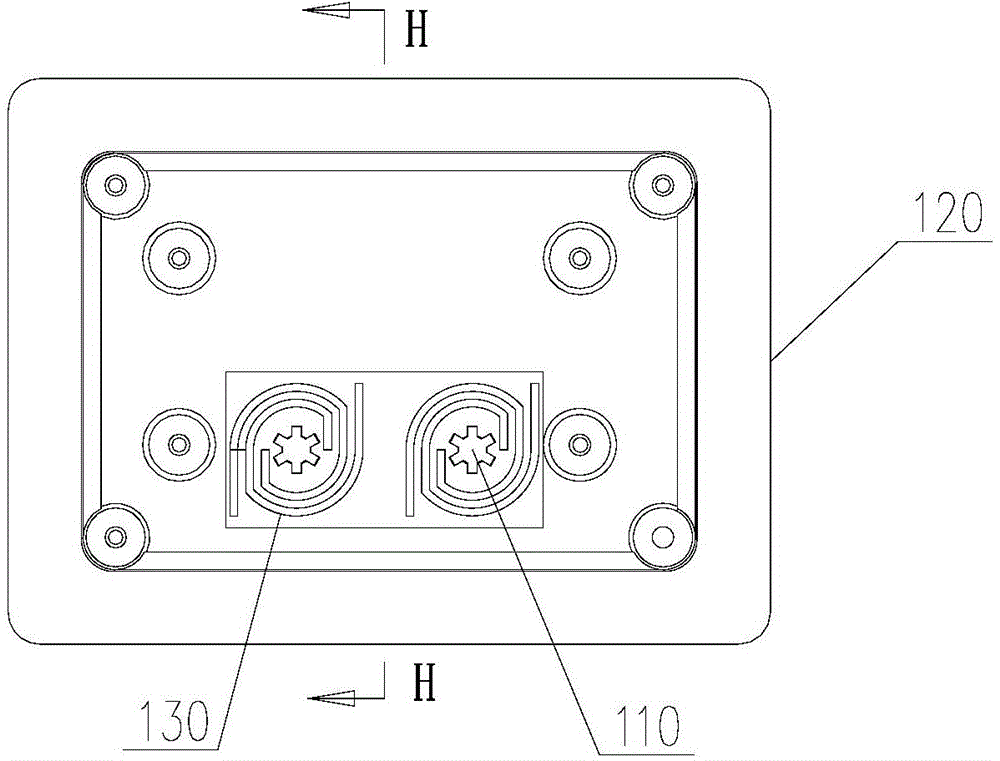

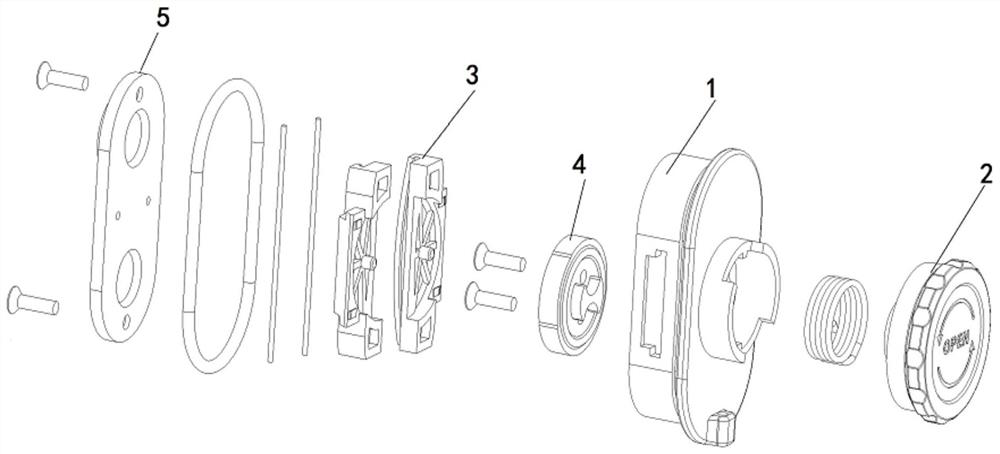

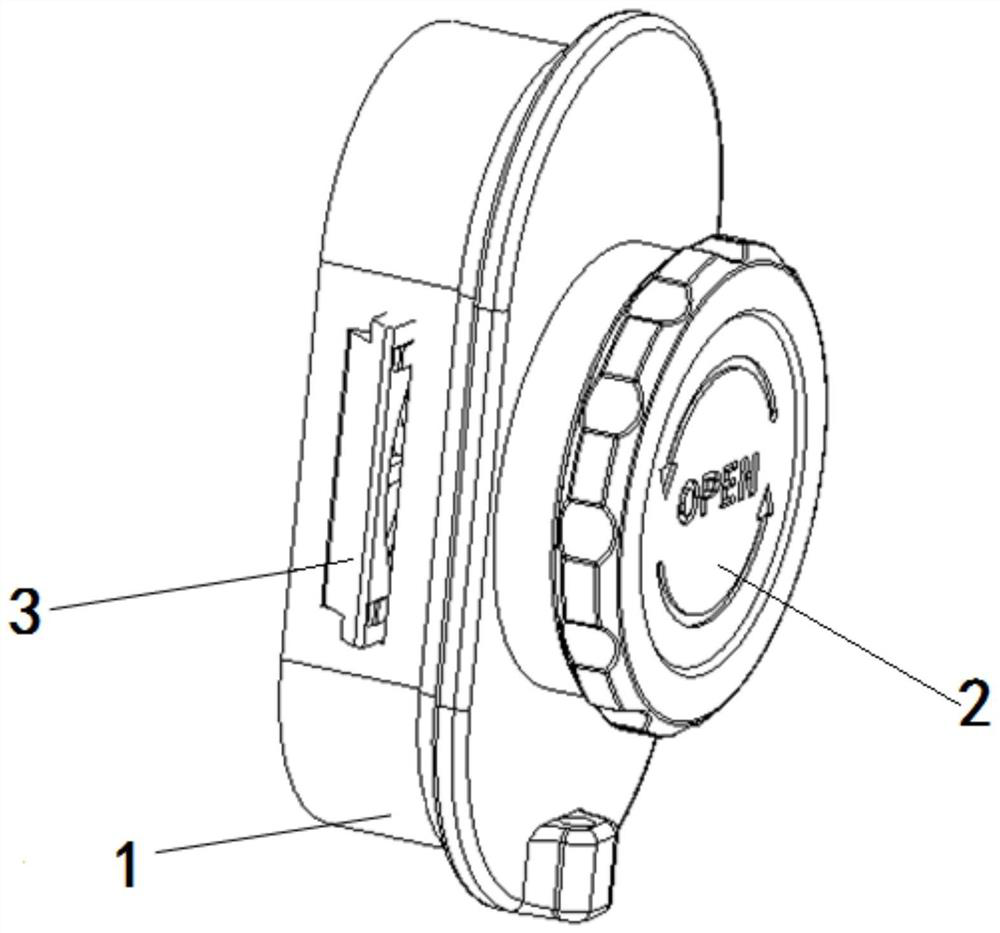

A battery cover device and a battery mounting device having the same

ActiveCN110911605BRealize snap-in installationAchieve disassemblyBattery isolationCell lids/coversStructural engineeringBattery cell

The invention discloses a battery cover device, comprising a battery cover compartment. The battery cover compartment is provided with: a hook for extending to realize the installation between the battery cover device and the battery case, and a hook for passing the circumferential direction of the battery cover device. The knob is rotated to drive the retraction of the hook, the knob is rotatably arranged on the battery cover compartment, the hook is provided with an inclined surface that is easy to be pushed into the battery case, and the hook and the battery cover compartment are compressed and arranged to make the hook pop out of the battery cover. The first elastic part of the battery cover compartment. The battery cover device provided by the present invention is simple and convenient to install and disassemble, and the process of installing and disassembling does not require multiple rotations, which can avoid the phenomenon of easy wear and tear during use, and can improve the speed of installing and disassembling the device. wear and tear. The invention also discloses a battery installation device, comprising the above-mentioned battery cover device and a battery case, and the battery installation device has the advantages of easy use and long service life.

Owner:INFIRAY TECH CO LTD

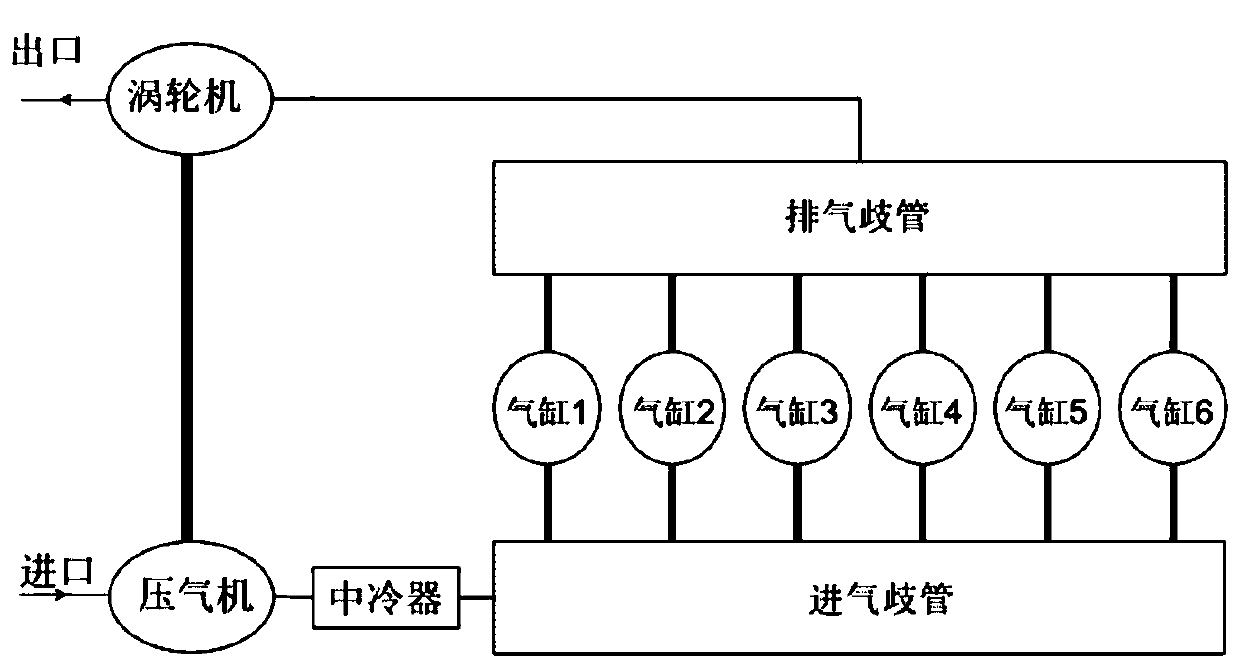

Turbocharger exhaust gas valve base device

PendingCN110332041AImprove sealingIncreased durabilityInternal combustion piston enginesGas turbine plantsTurbochargerBypass valve

The invention relates to a turbocharger exhaust gas valve base device. The turbocharger exhaust gas valve base device comprises a volute and a bypass valve assembly; the bypass valve assembly comprises a valve pin, fins and a valve plate, the valve plate is movably arranged on the valve pin, the volute is provided with a bypass hole matched with the bypass valve assembly and a valve base, the valve base is provided with a conical face, the center of the conical face and the center of the bypass hole coincide, a seal annular face is arranged on the edge of the bypass hole in the conical face, and the outer diameter of the seal annular face is smaller than the outer diameter of the valve plate. The device is simple and reasonable in structure, through design of the bypass hole and the valvebase, the seal durability capacity of the bypass valve in the use can be effectively improved.

Owner:WUXI CUMMINS TURBO TECH

electrical connector

ActiveCN110311242BImprove high frequency performanceAvoid resonanceCoupling contact membersCoupling protective earth/shielding arrangementsElectrical connectionElectrical connector

The invention discloses an electric connector. The electric connector includes a plastic block having a butt joint surface and a mounting surface, and a row of terminals having a pair of signal terminals, wherein each signal terminal has an intermediate portion and an extension arm extending forwards from the intermediate portion, the intermediate portion has a contraction portion, width of the contraction portion is smaller than width of a back end of the extension arm, a first ground terminal is arranged at one side of the signal terminal and has a first fixing portion, the first fixing portion and the adjacent intermediate portion are arranged at a first fixed center spacing interval, a first distance is formed between the first fixing portion and the adjacent contraction portion, a second ground terminal is arranged at the other side of the signal terminal, the second ground terminal has a second fixing portion fixed on the plastic block, the second fixing portion and the adjacentintermediate portion are arranged at a second fixed center spacing interval, a first center spacing is equal to a second center spacing, a second distance is formed between the second fixing portion and the adjacent contraction portion, and the second distance is smaller than the first distance.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

A kind of coating machine and the production process of multi-enzyme tablets using the coating machine

ActiveCN112168698BNot easy to blockImprove uniformityPharmaceutical product form changeSpray nozzlesSolvent evaporationSpray coating

Owner:浙江国光生物制药股份有限公司

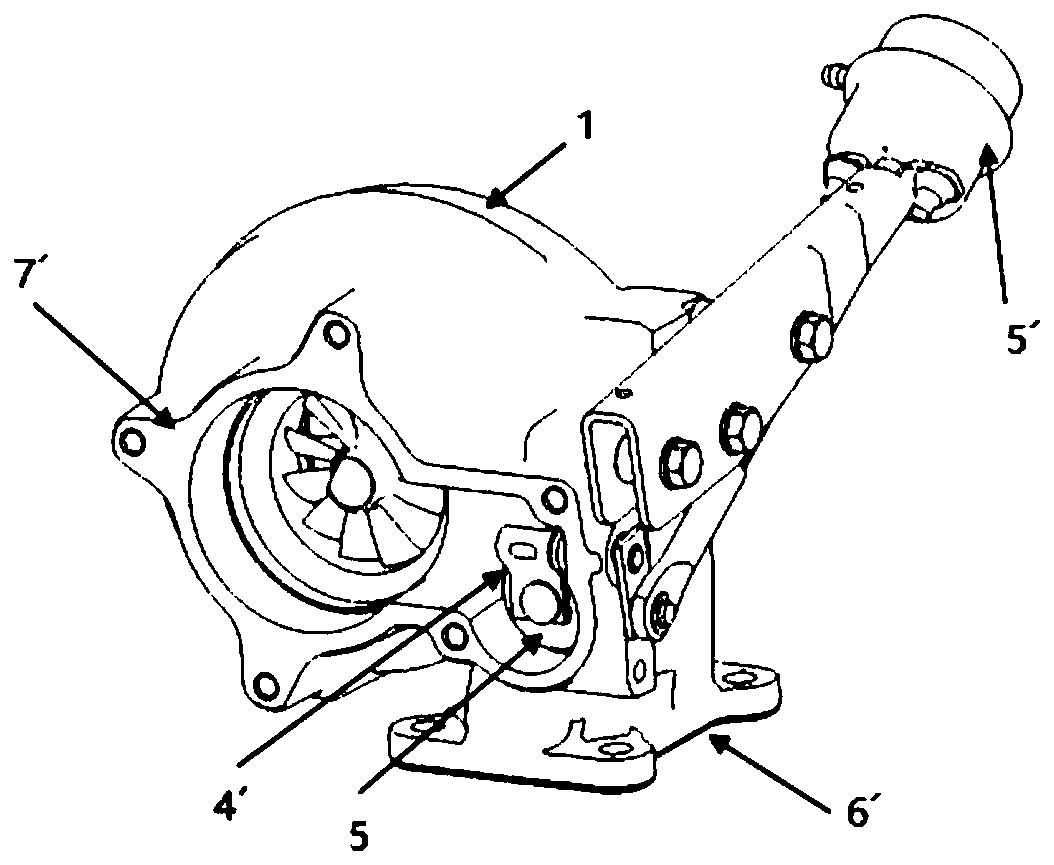

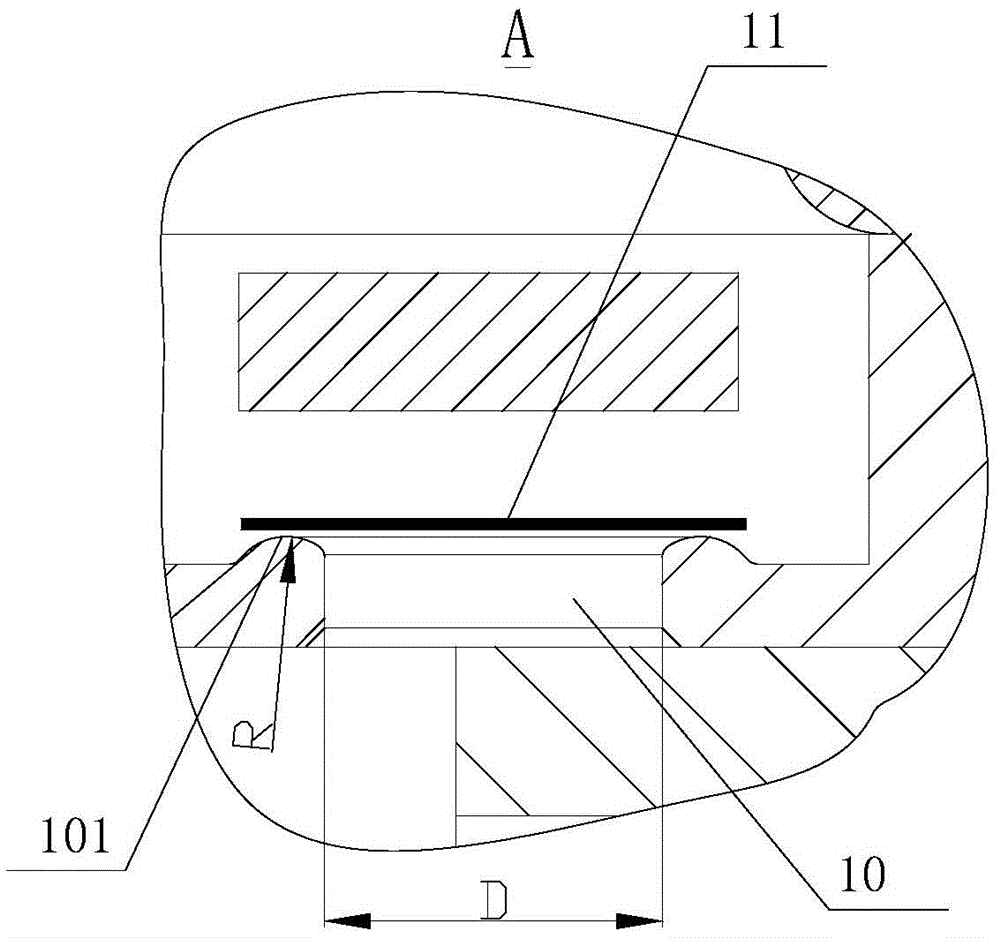

Compressors, air conditioners and water heaters

ActiveCN103742411BNot prone to wear and tearExtended service lifeRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsCompression deviceEngineering

Owner:GUANGDONG MEIZHI COMPRESSOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com