Curve-shaped forming milling cutter

A milling cutter and curve technology, applied in the field of curve forming milling cutter, can solve the problem that the milling cutter cannot be processed and formed at one time, and achieve the effect of not easy to wear and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

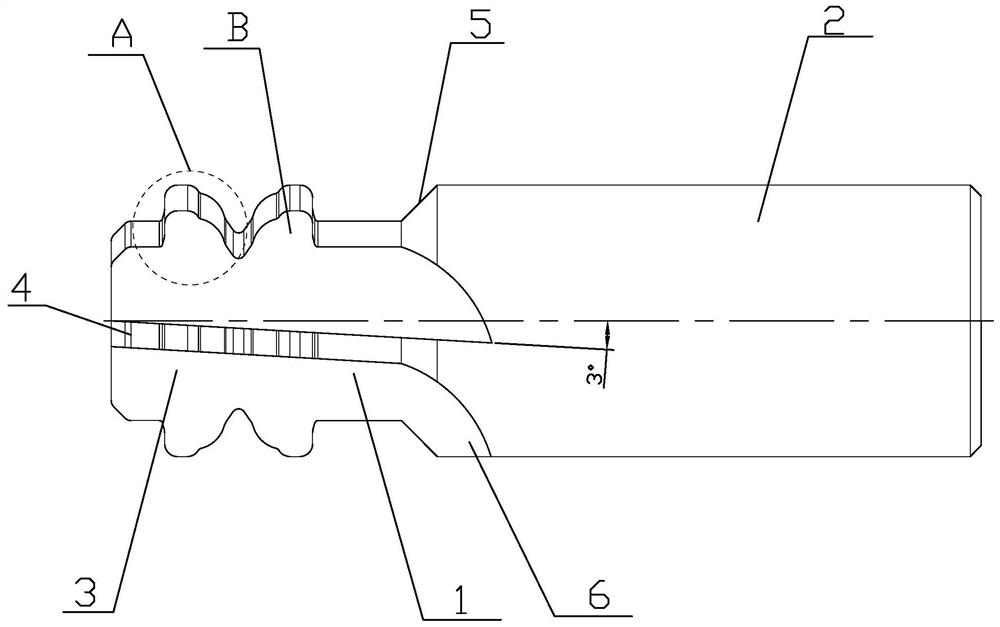

[0013] Such as figure 1 As shown, the curve-forming milling cutter includes a cutter body 1 and a handle 2, the handle 2 is a clamping part, and a cutting part 3 is provided on the cutter body 1, and the cutting part 3 is composed of an even number of cutting edges 4. Edge 4 is a sheet-like structure with uniform thickness, and each of said cutting edges 4 has an equal axial deflection angle, which is 3°-10°; The blade base surface M0 is composed of two radially symmetrical and continuous curved edges A and B protruding from the base surface. The left end surface of the cutting edge 4 is connected to the blade base surface MO by a 45° inclined plane. The two edges and corners formed between the inclined surface and the end surface and the blade all transition smoothly with arc surfaces.

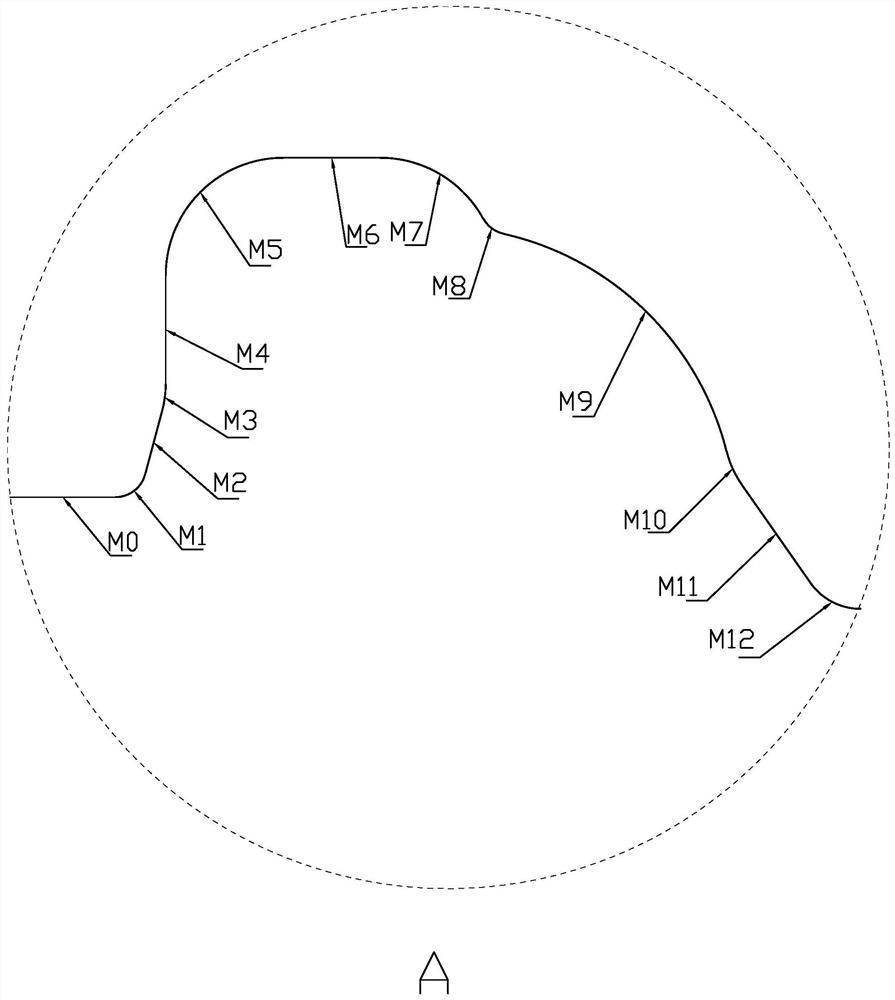

[0014] Such as figure 2 As shown, the line type of the curved edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com