A kind of coating machine and the production process of multi-enzyme tablets using the coating machine

A coating machine and coating technology, which is applied in the direction of making medicines into special physical or taking forms, presses, manufacturing tools, etc., can solve problems such as unevenness, achieve good molding shape, improve uniformity, Consistent effect of coating dressing spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present application will be further described in detail below with reference to the accompanying drawings.

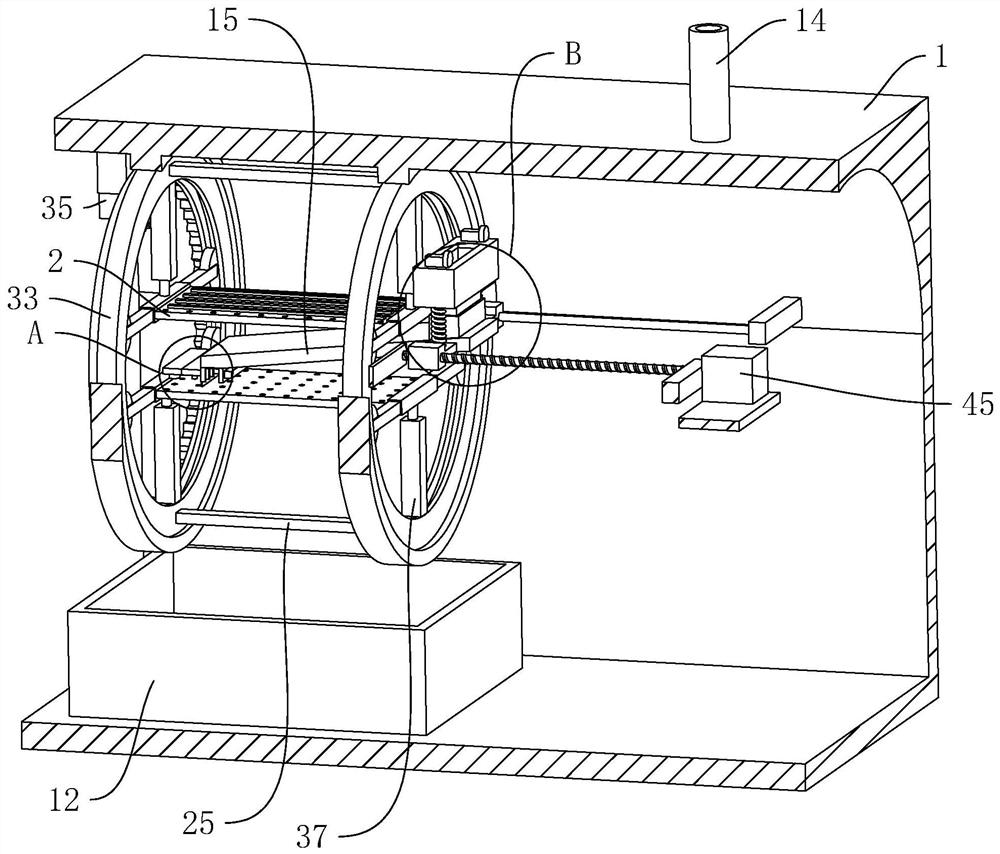

[0039] The embodiment of the present application discloses a coating machine, refer to figure 1 , including the case 1. The upper part of one end of the case 1 in the length direction is fixedly connected with a feeding pipe 14 that communicates with the inside of the case 1. The case 1 is equipped with a feeding device that can evenly transport the medicine particles into the case 1. A material-receiving device for the delivered granules, a spraying device for spraying the coating on the granules, and a drying device for evaporating the solvent in the coating.

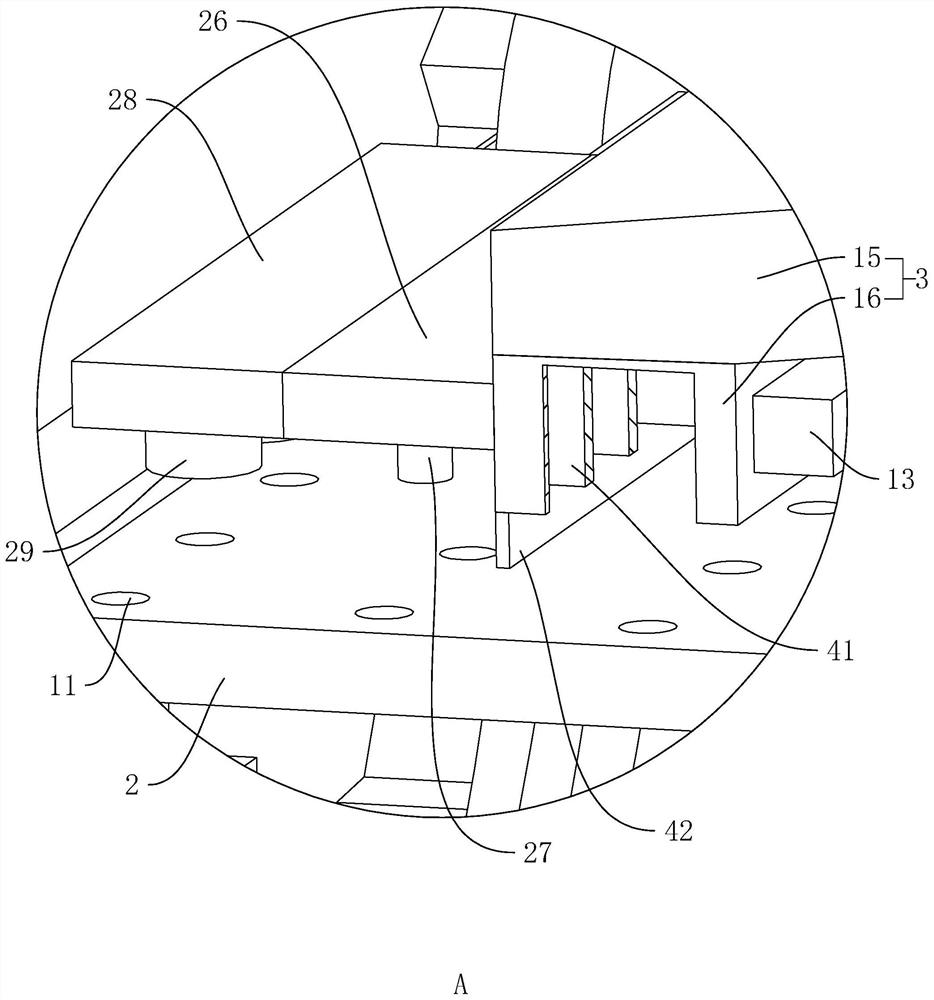

[0040] refer to figure 2 and image 3 , the feeding device includes a feeding pipe 3 located in the case 1 and can move along the length direction of the case 1, the feeding pipe 3 includes a feeding main pipe 15 which is inclined in the length direction, and the low end of the feeding main pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com