Turbocharger exhaust gas valve base device

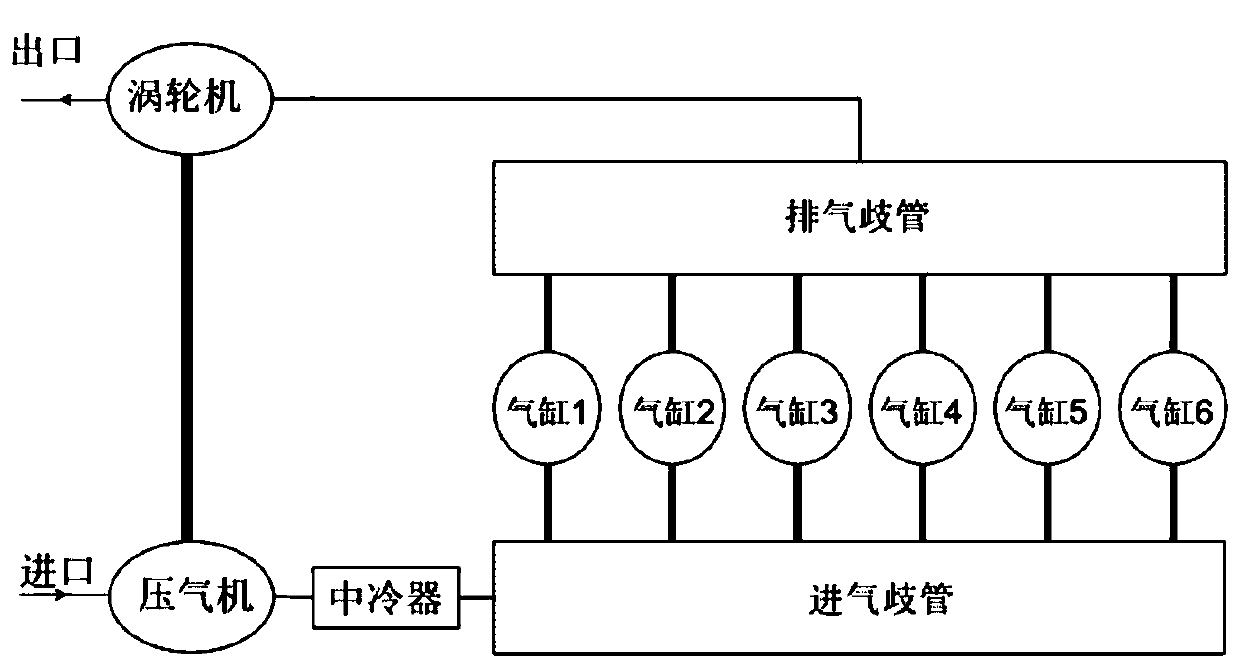

A technology of turbocharger and waste gas valve, which is applied to gas turbine devices, machines/engines, engine components, etc., can solve the problems of poor anti-attenuation ability, unfavorable sealing performance, deteriorated sealing performance, etc., and achieves less wear and better sealing. Performance and durability, low machining concentricity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

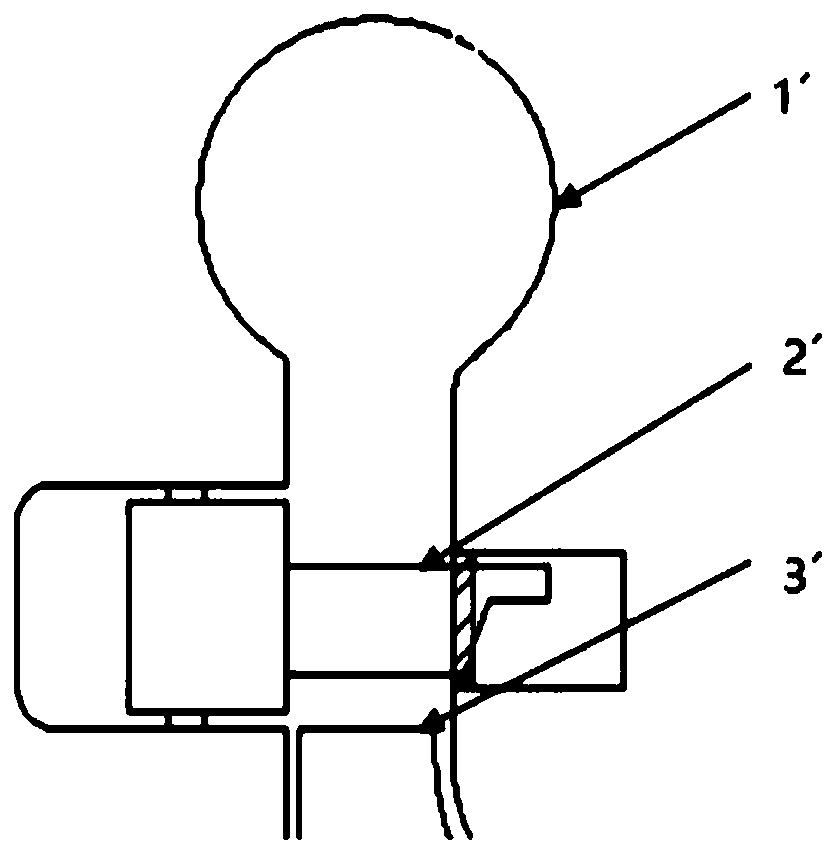

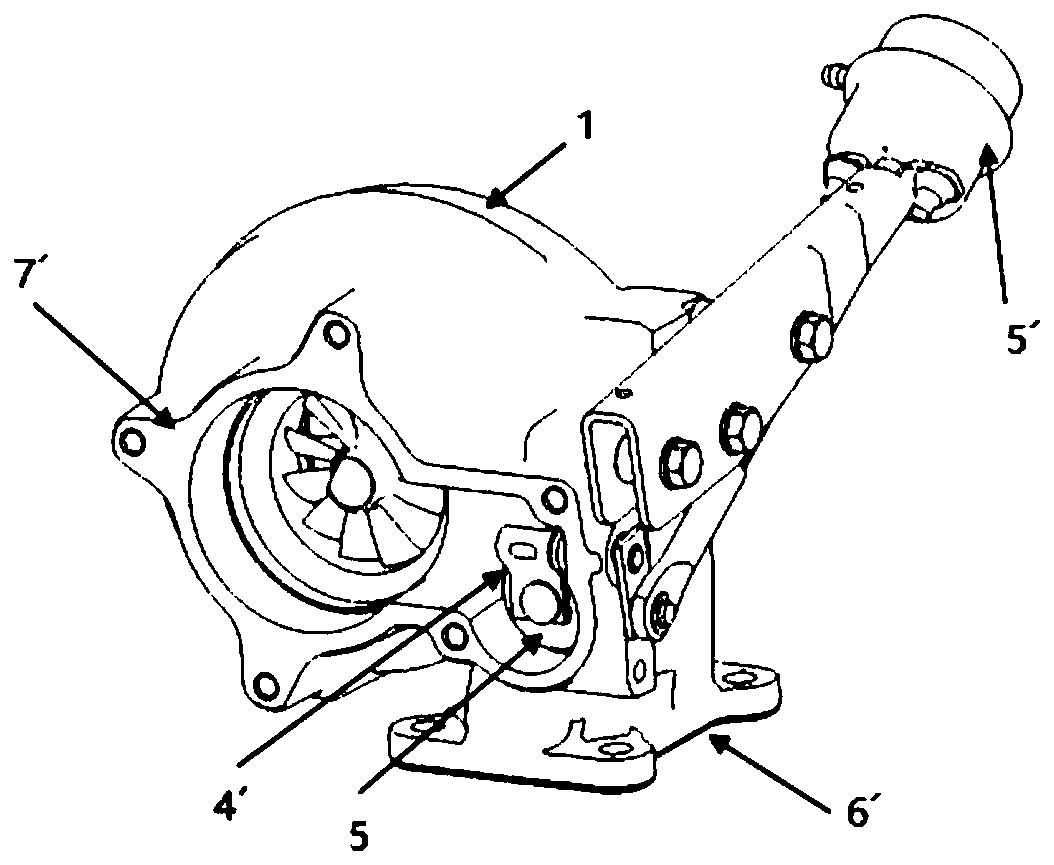

[0025] Such as Figure 4 As shown, a turbocharger exhaust valve seat device related to the present invention includes a volute 1, a bypass valve assembly 2, and the bypass valve assembly 2 includes a valve pin 3, a fin 4 and a valve plate 5, and the fin The sheet 4 is arranged between the valve pin 3 and the valve sheet 5, the valve sheet 5 is movably arranged on the valve pin 3, and the valve sheet 5 can slightly swing up and down on the valve pin 3;

[0026] In order to improve the wastegate sealing ability, such as Figure 4 and Figure 5 As shown, a tapered surface 9 is processed on the valve seat of the volute 1, and coincides with the center of the bypass hole 6, and its intersection line is a circular line on the same plane, so as to realize the connection with the valve plate 5 of the wastegate valve. Line contact is performed to perform line sealing to improve the sealing performance of the wastegate valve. However, the concentricity between the tapered surface 9 of...

Embodiment 2

[0030] Such as Figure 7 As shown, the valve seat 7 in embodiment 2 is the same as that in embodiment 1, and a circle of sealing annular surface 8 is set on the edge of bypass hole 6, the difference is that a ring lower than the sealing annular surface 8 is provided outside the sealing annular surface 8. The plane 10, and the height difference is controlled within 1mm. Similar to the design of the step, the plane below the sealing annular surface 8 can also be used to make the valve plate 5 bounce back to the equilibrium position and fit the sealing annular surface 8 on the valve seat 7 to achieve the same technical effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com