Structure for ultra-supercritical fin low-temperature reheater

A reheater and low-temperature technology, applied in the structural field of supercritical finned low-temperature reheaters, can solve the unfavorable utilization of boiler tail flue area space, the large space for the heating surface of the low-temperature reheater, and the reheater steam The temperature is difficult to reach the design value and other problems, and achieve the effect of high reliability, reduced resistance and simple layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

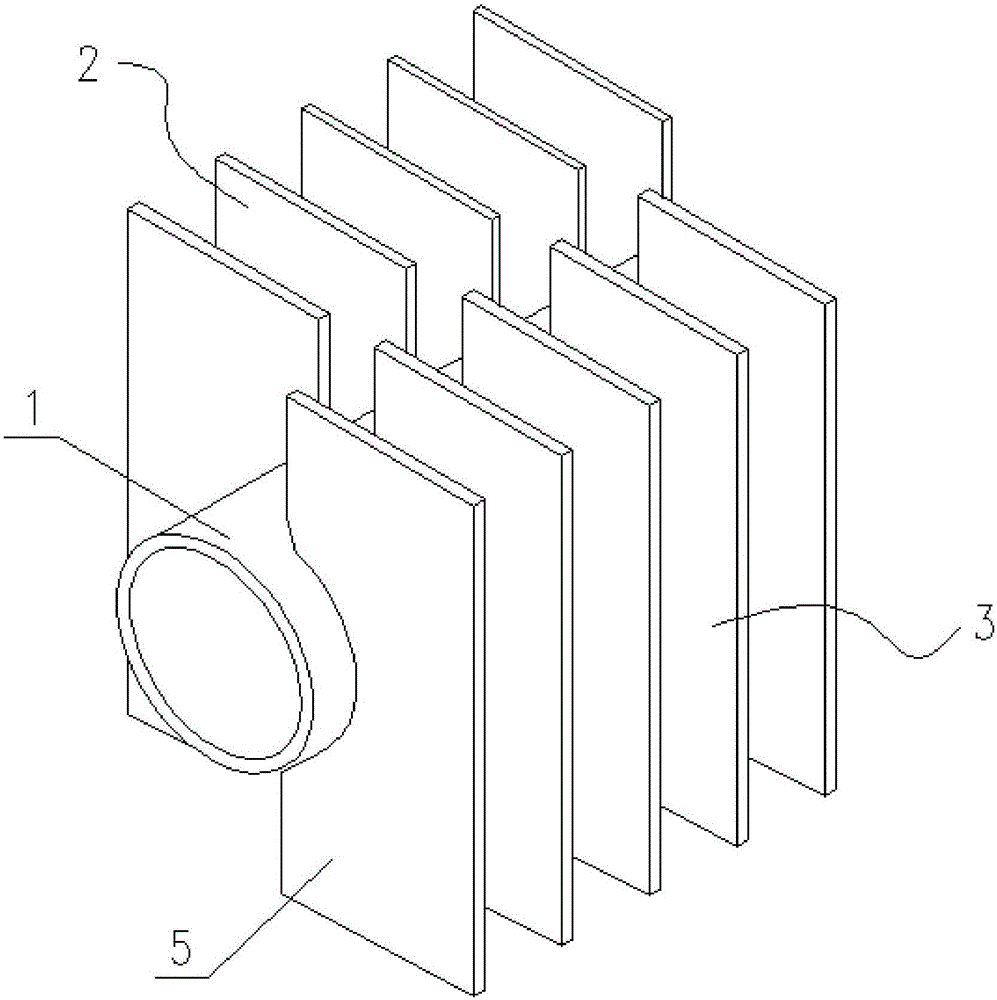

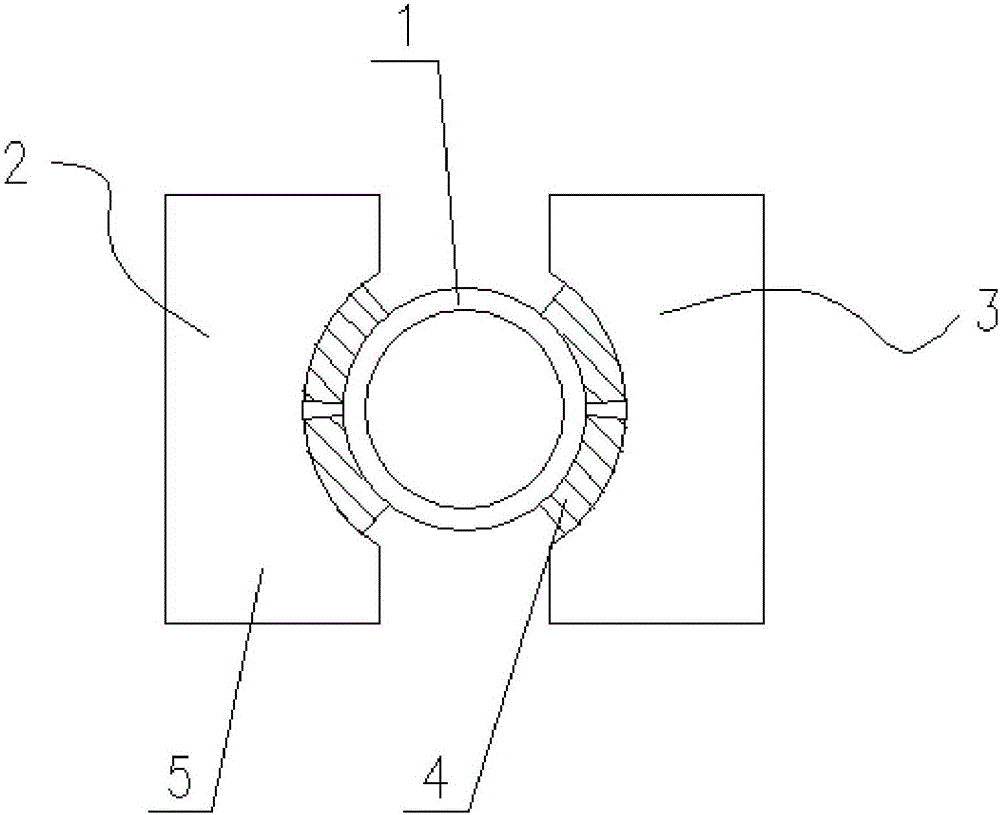

[0021] Specific implementation mode one: combine Figure 1 to Figure 2 To illustrate this embodiment, a structure for a super (super) critical finned low-temperature reheater includes the low-temperature reheater in the heat pipe 1, the first group of low-temperature fins in the heat fin 2 and the second group of low-temperature fins in the heat fin 3, so The first group of low temperature heat fins 2 and the second group of low temperature heat fins 3 are formed by equidistant arrangement of rectangular parallelepiped fins 5, and each rectangular parallelepiped fin 5 has a mounting groove 4. The first group described above The low-temperature heat sheet 2 is set on the left side of the low-temperature reheater on the heat pipe 1, the second group of low-temperature heat sheets 3 is set on the right side of the low-temperature reheater on the heat pipe 1, and the first group of low-temperature heat sheets is set on the heat pipe 2 and the second group of low temperature heat f...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination Figure 1 to Figure 2 Describe this embodiment, a structure for a super (super) critical finned low temperature reheater. The first group of low temperature is on the heat fin 2 and the second group of low temperature is on each cuboid fin 5 of the heat fin 3 The number of installation grooves 4 is two, and the first group of low temperature heat fins 2 and the second group of low temperature heat fins 3 are respectively provided with low temperature reheaters in the heat pipes 1 in the installation ports formed between the heat fins 3 .

specific Embodiment approach 3

[0023] Specific implementation mode three: combination Figure 1 to Figure 2 To illustrate this embodiment, a structure for a super (super) critical finned low-temperature reheater, the thickness of the cuboid fins 5 is 2-6 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com