Rubber basketball skin and preparation method thereof

A basketball and skin technology, applied in the field of rubber basketball skin and its preparation, can solve the problems of easy surface wear, affect the touch feeling, poor weather resistance of the skin, etc., and achieve the effects of excellent weather resistance, not easy to deform, and soft to the touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

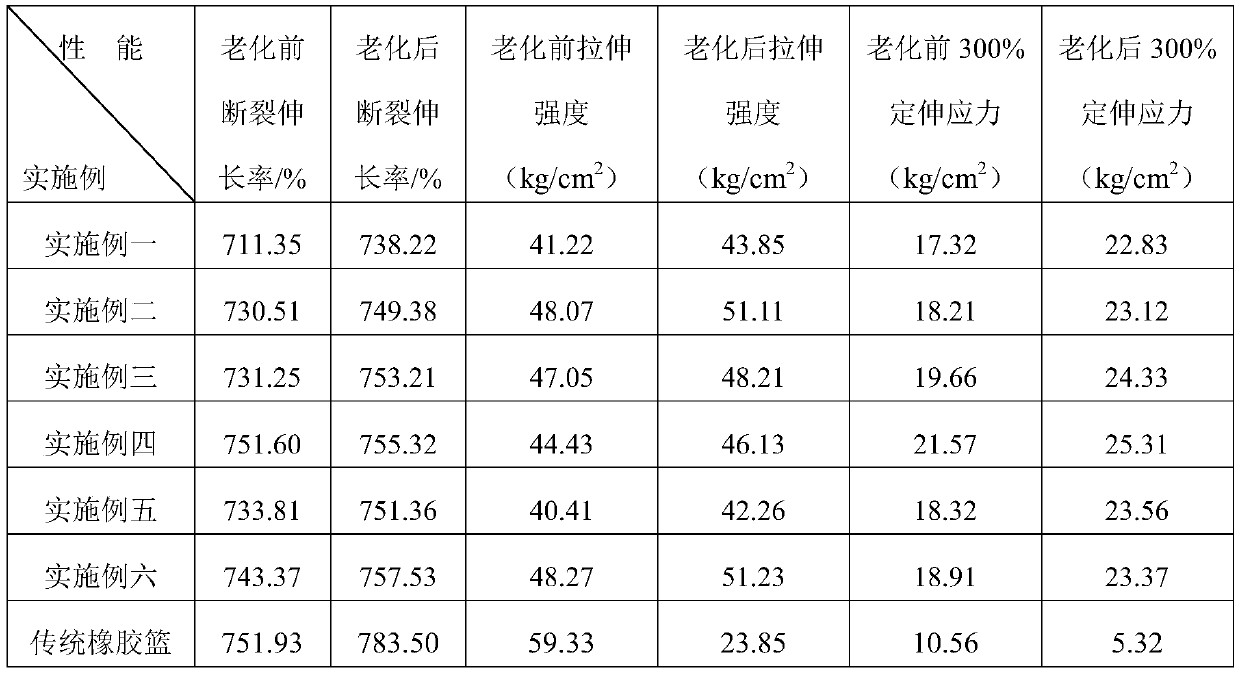

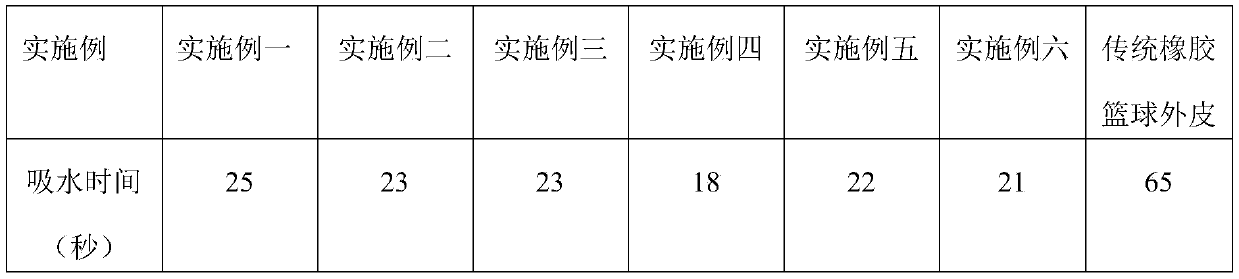

Examples

preparation example Construction

[0020] A kind of preparation method of described rubber basketball skin, it comprises the following processing steps:

[0021] Step (1) preparing a water-absorbing resin solution: mixing sodium polyacrylate, polyurethane adhesive and water and heating to obtain a water-absorbing resin solution;

[0022] Step (2) prepares modified attapulgite;

[0023] Step (3) preparing rubber compound: after mixing the water-absorbing resin solution obtained in step (1) with natural rubber, butadiene rubber and polyethylene glycol, adding it to an internal mixer for mixing to obtain the rubber compound;

[0024] Step (4) preparation of the main glue: add the rubber compound, carbon black, zinc oxide, modified attapulgite, N,N-nickel di-n-butyldithiocarbamate, and accelerators obtained in step (3) to the internal mixer Medium mixing, winner glue;

[0025] Step (5) preparing the rubber basketball skin material: adding the main rubber, foaming agent and sulfur obtained in the step (4) into an ...

Embodiment 1

[0041] A rubber basketball skin, which is prepared from the following raw materials: 10kg of natural rubber, 60kg of butadiene rubber, 2kg of sodium polyacrylate, 5kg of polyurethane adhesive, 5kg of water, 15kg of polyethylene glycol, 15kg of carbon black, 20kg of zinc oxide, modified Attapulgite 10kg, N,N-nickel di-n-butyldithiocarbamate 0.5kg, sulfur 0.2kg, accelerator 1kg, foaming agent 2kg.

[0042] The accelerator is the mixture obtained by mixing zinc ethylphenyl dithiocarbamate, dibenzothiazole disulfide, and accelerator TMTD in a weight ratio of 5:3:2, that is, ethylphenyl dithiocarbamate The weights of zinc carbamate, dibenzothiazole disulfide and accelerator TMTD are 0.5kg, 0.3kg and 0.2kg respectively;

[0043] The foaming agent is azodicarbonamide.

[0044] The preparation method of described rubber basketball skin, it comprises the following processing steps:

[0045] Step (1) Preparation of water-absorbent resin solution: Mix weighed sodium polyacrylate, polyu...

Embodiment 2

[0056] A rubber basketball skin, which is prepared from the following raw materials: 10kg of natural rubber, 60kg of butadiene rubber, 2kg of sodium polyacrylate, 5kg of polyurethane adhesive, 2kg of water, 15kg of polyethylene glycol, 15kg of carbon black, 20kg of zinc oxide, modified Attapulgite 15kg, N,N-nickel di-n-butyldithiocarbamate 0.5kg, sulfur 0.2kg, accelerator 1kg, foaming agent 2kg.

[0057] The accelerator is preferably zinc ethylphenyl dithiocarbamate, dibenzothiazole disulfide, and accelerator TMTD are mixed in a weight ratio of 5:3:2, i.e. ethylphenyl dithiocarbamate The weights of zinc carbamate, dibenzothiazole disulfide and accelerator TMTD are 0.5kg, 0.3kg and 0.2kg respectively;

[0058] The foaming agent is azodicarbonamide.

[0059] The preparation method of described rubber basketball skin, it comprises the following processing steps:

[0060] Step (1) Preparation of water-absorbent resin solution: Mix weighed sodium polyacrylate, polyurethane adhesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com