Patents

Literature

134results about How to "Less likely to break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

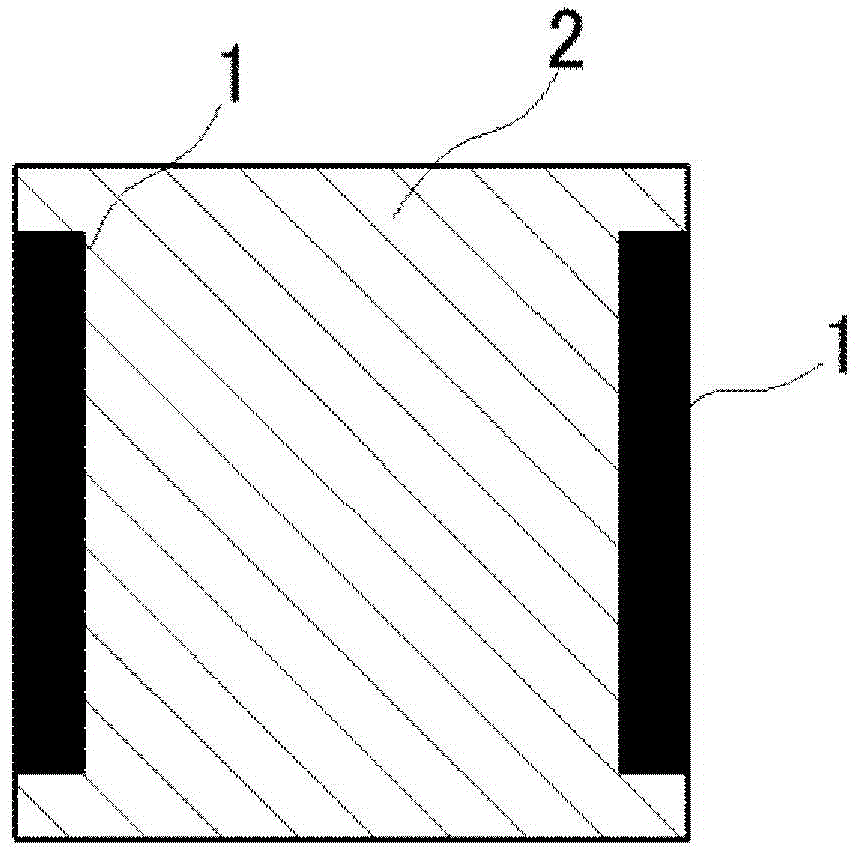

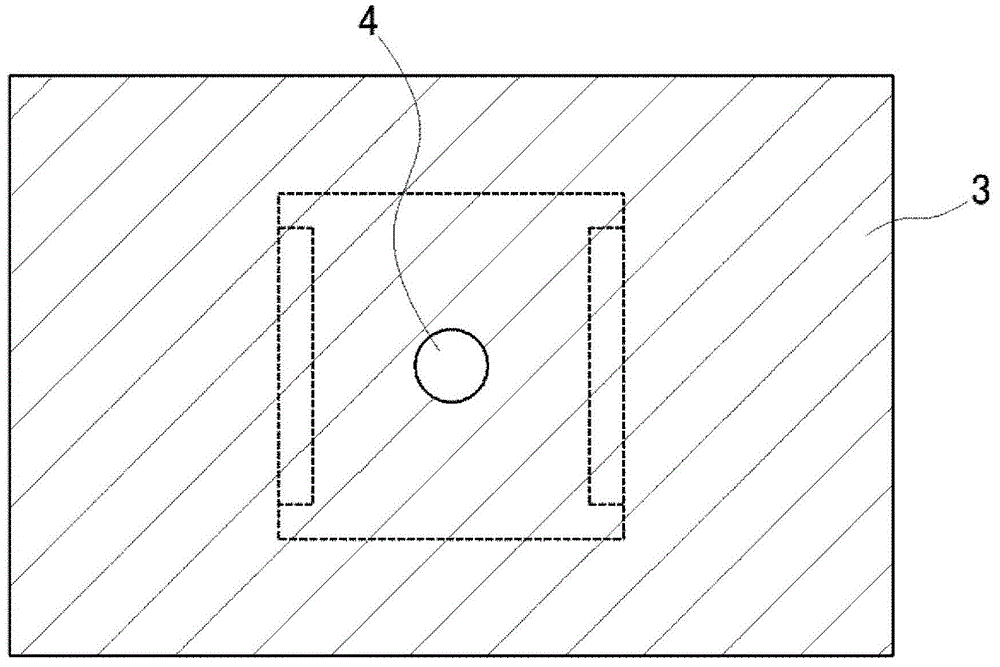

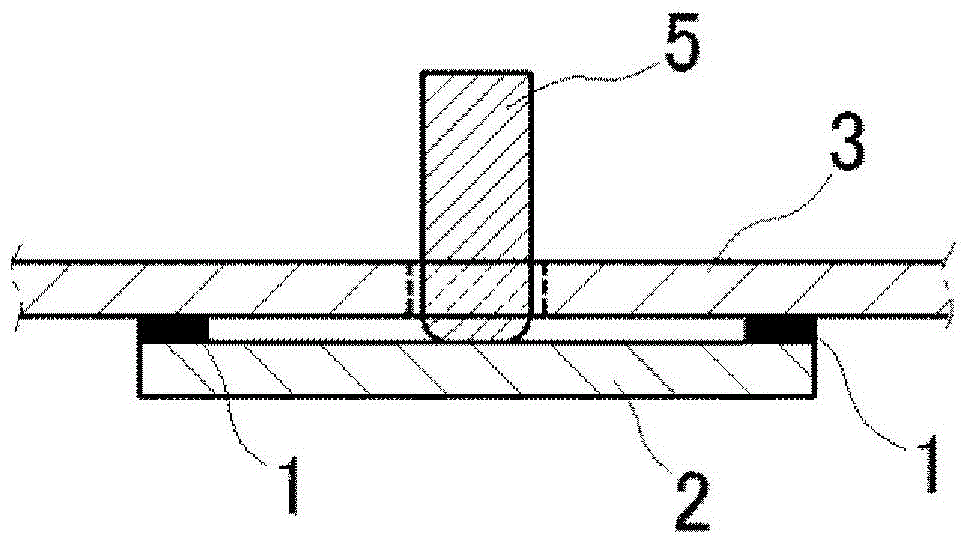

High-efficiency, overvoltage-protected, light-emitting semiconductor device

ActiveUS20070284606A1Improve efficiencyLess likely to breakSolid-state devicesSemiconductor devicesOvervoltageVoltage spike

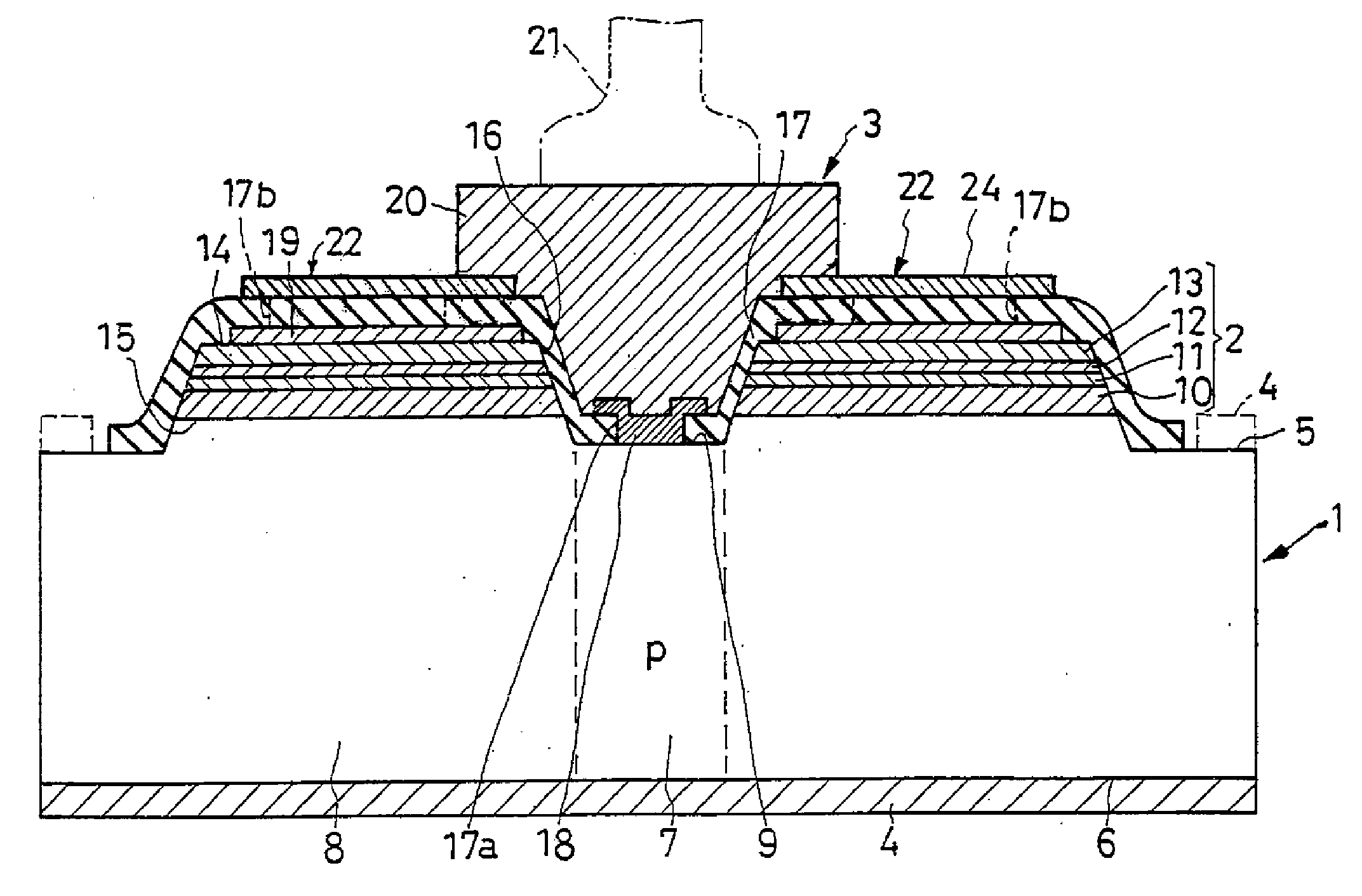

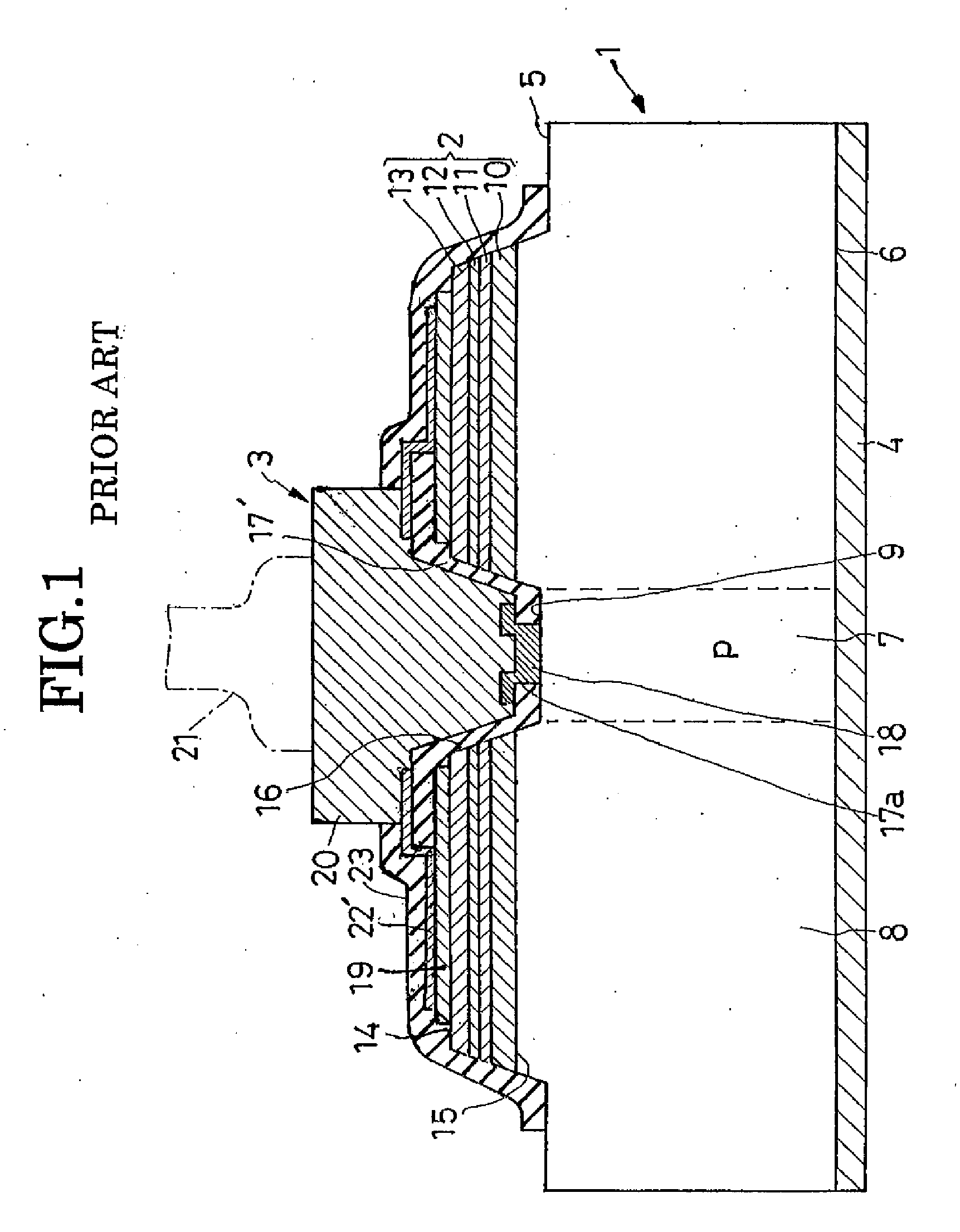

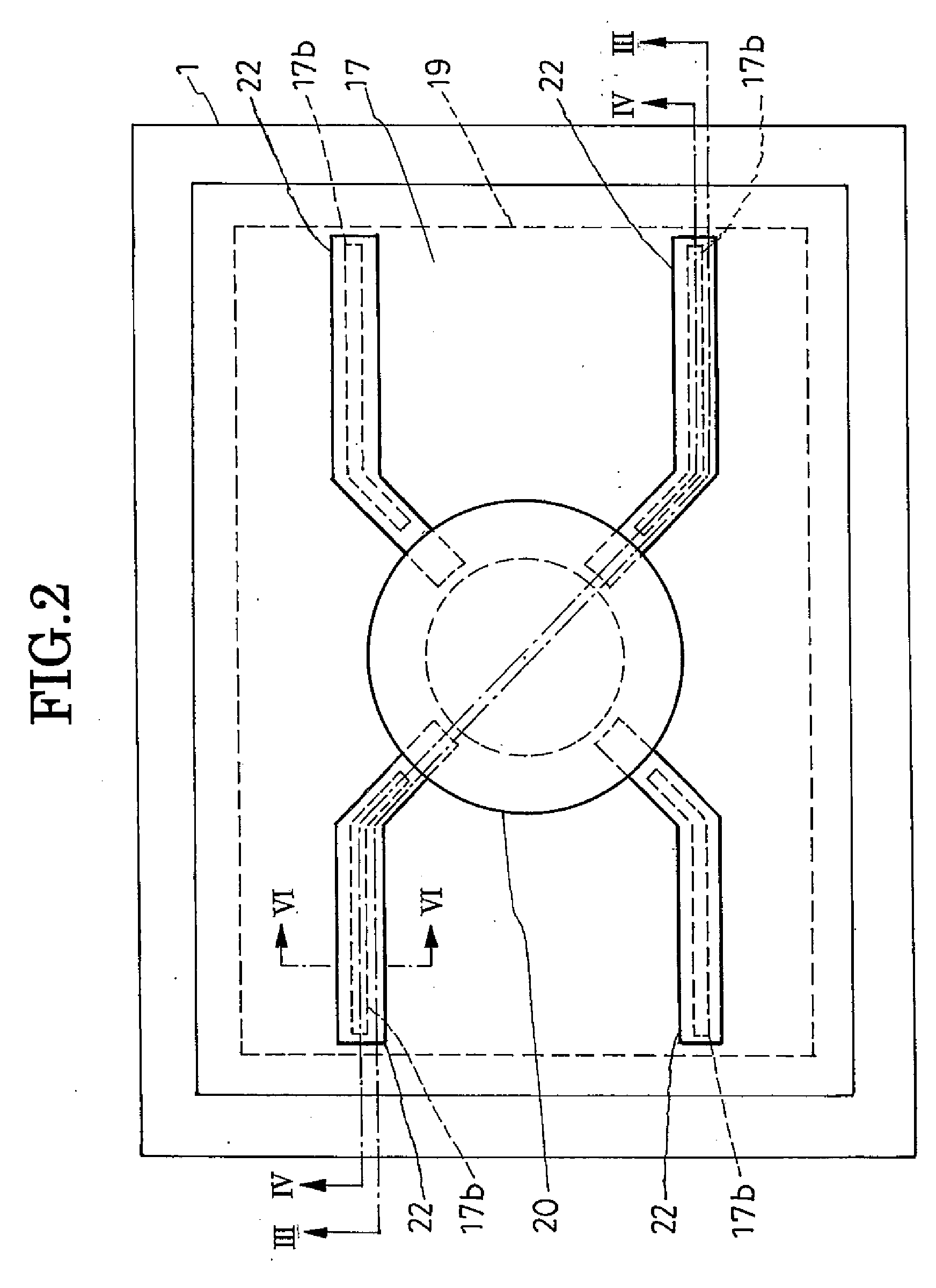

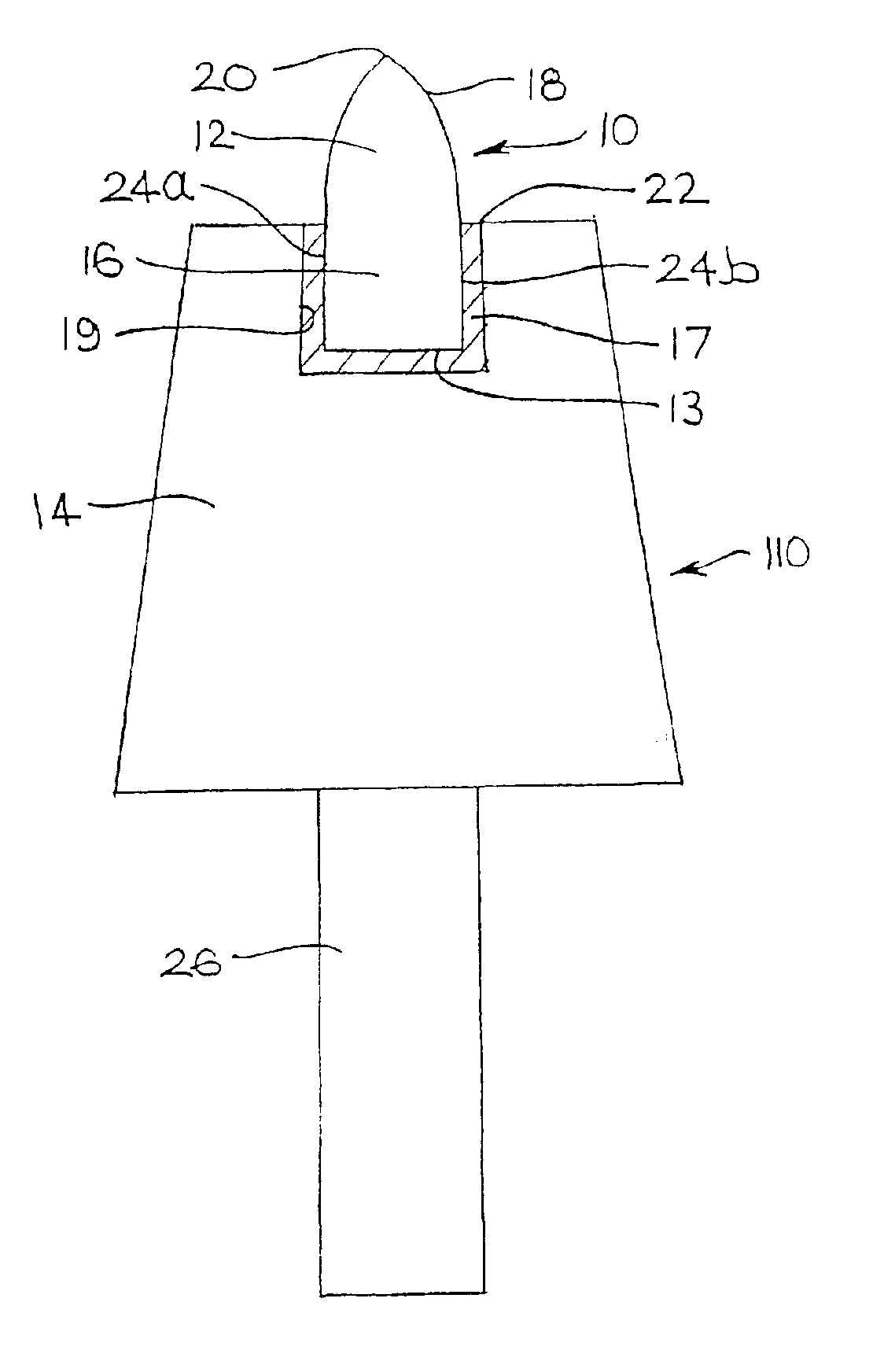

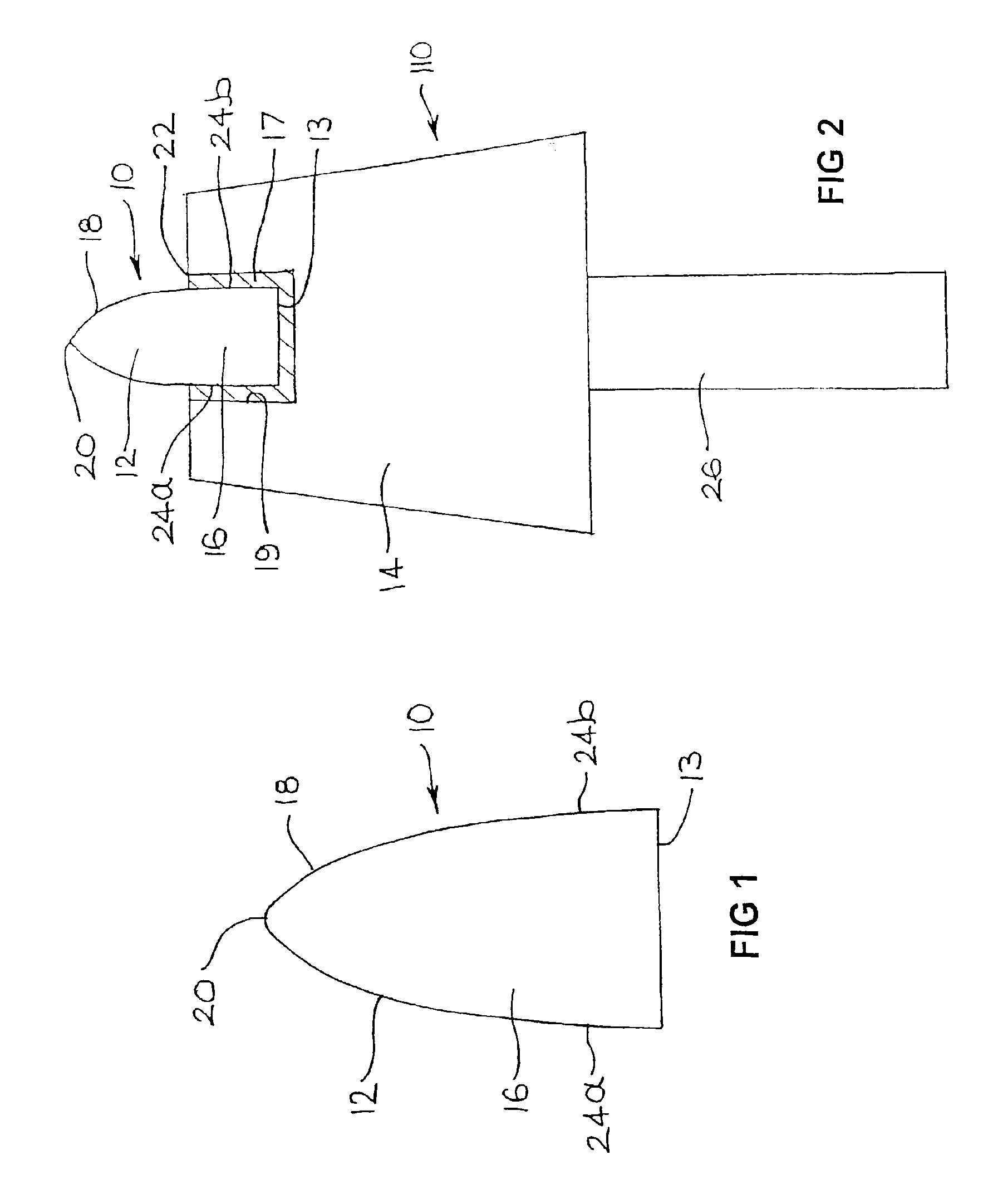

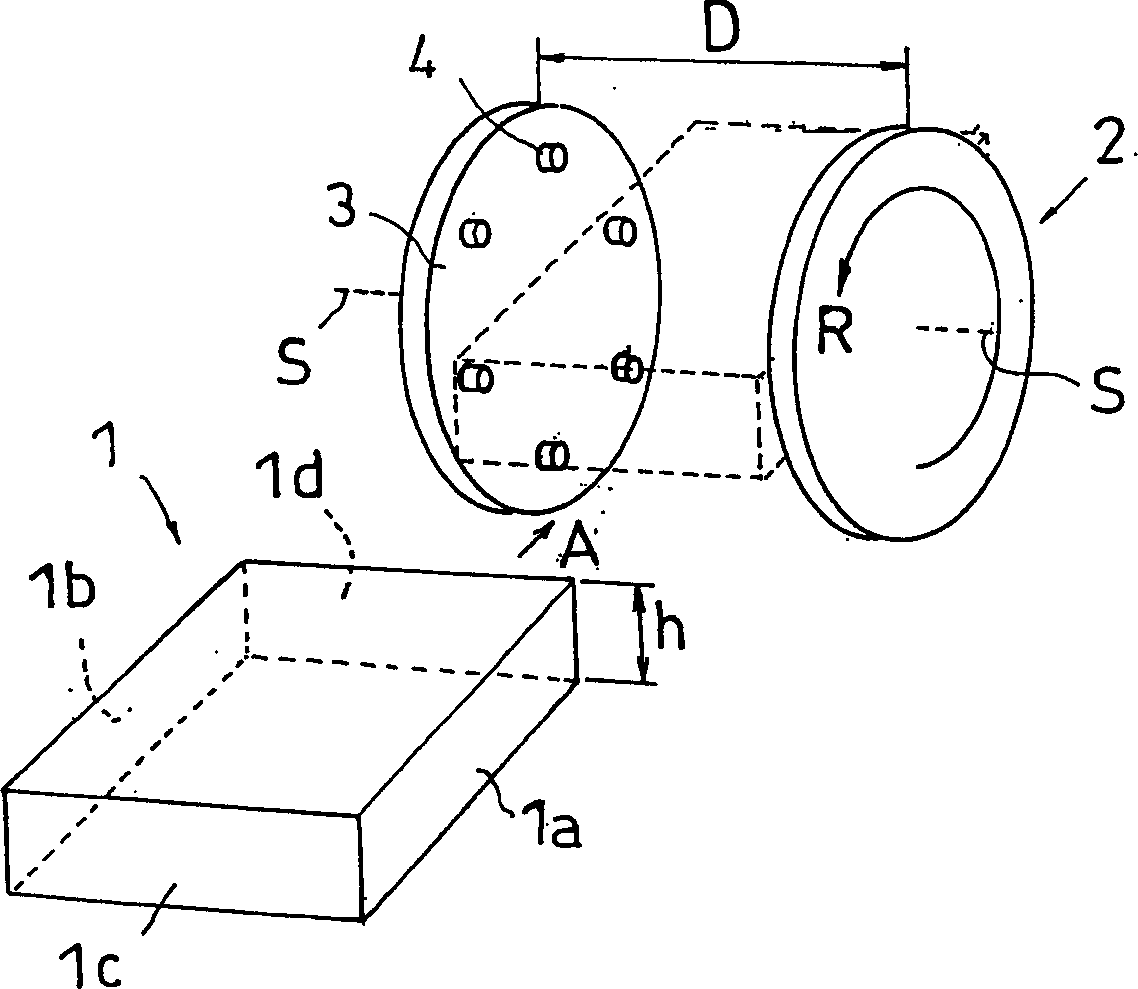

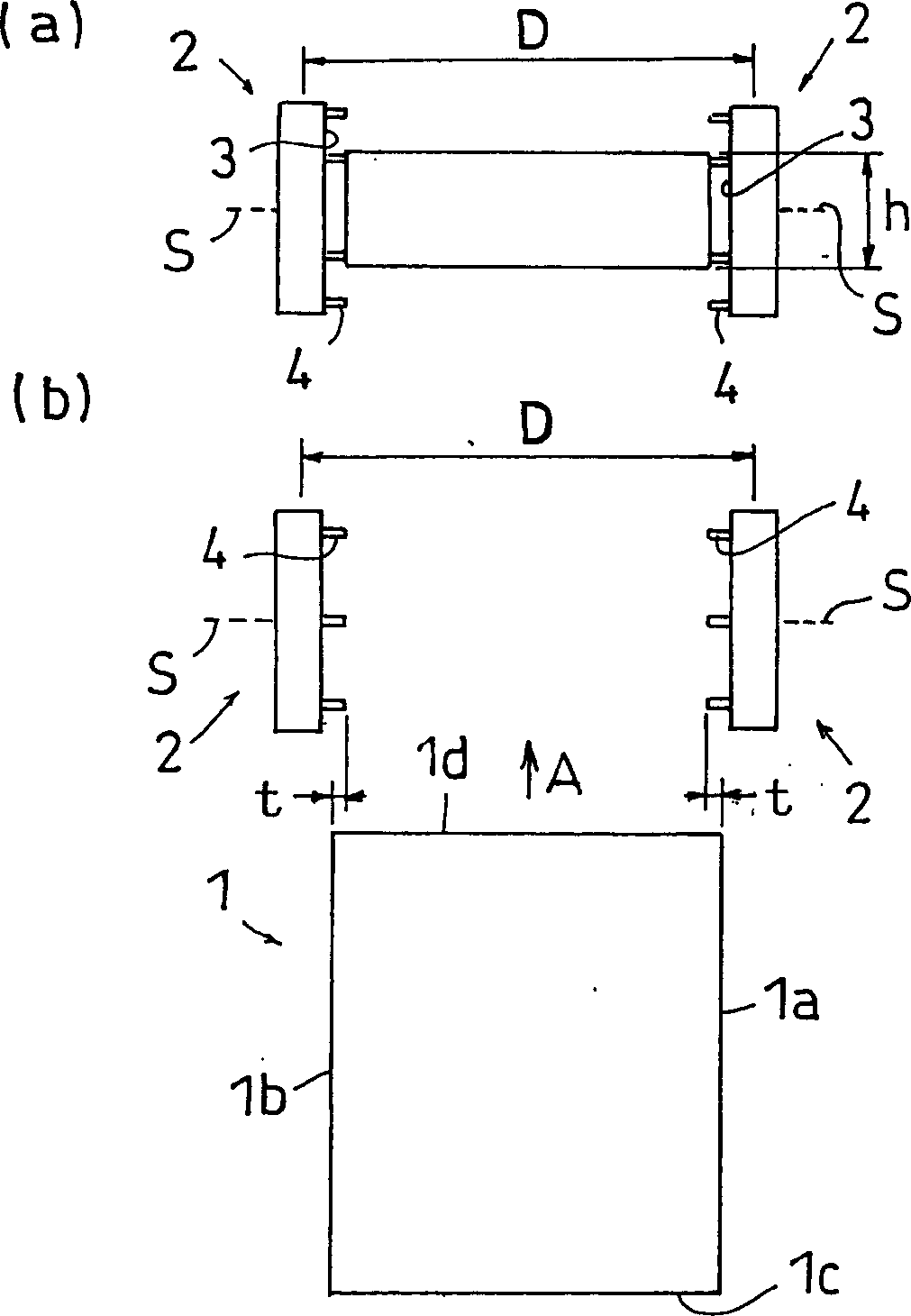

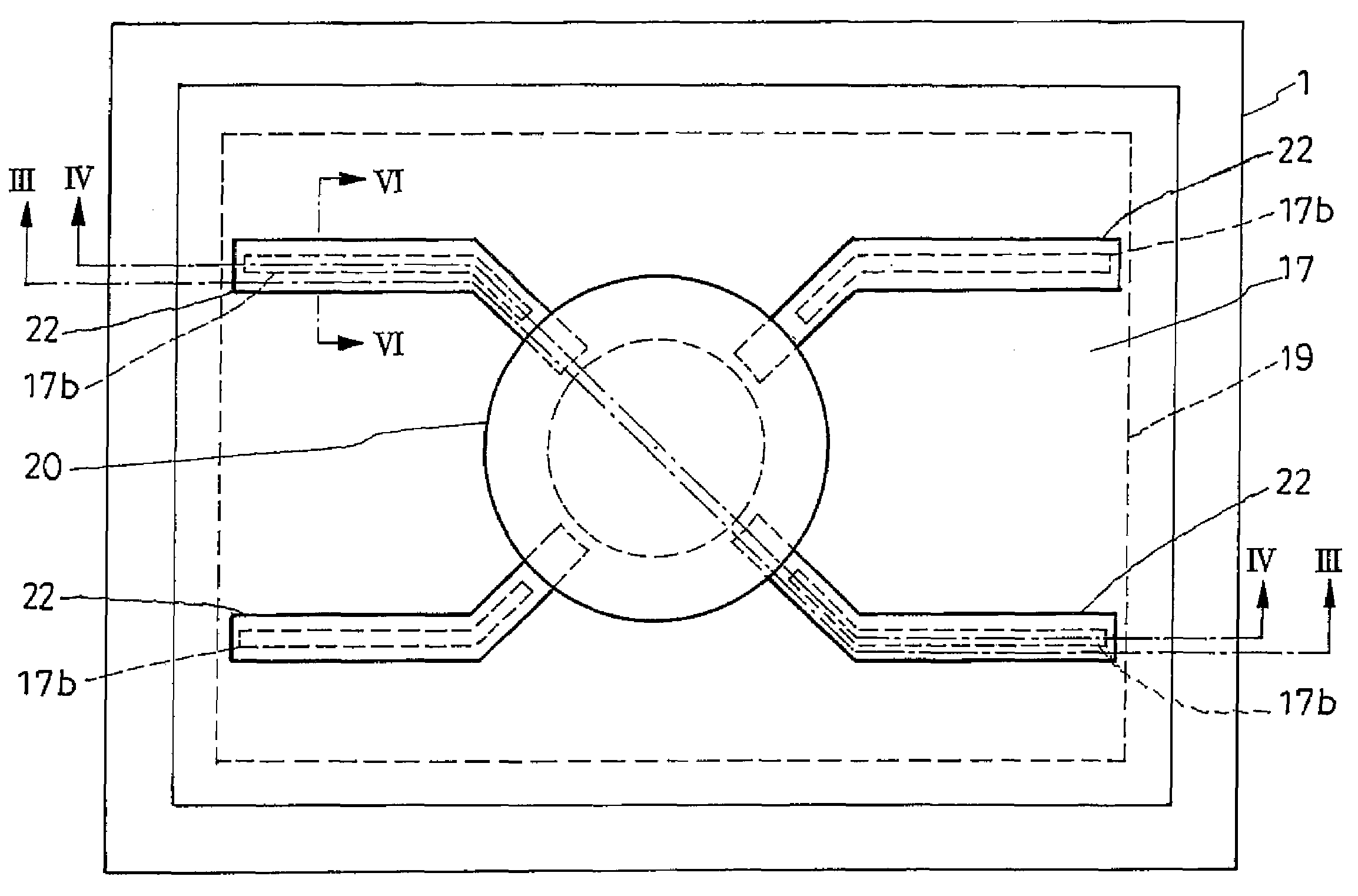

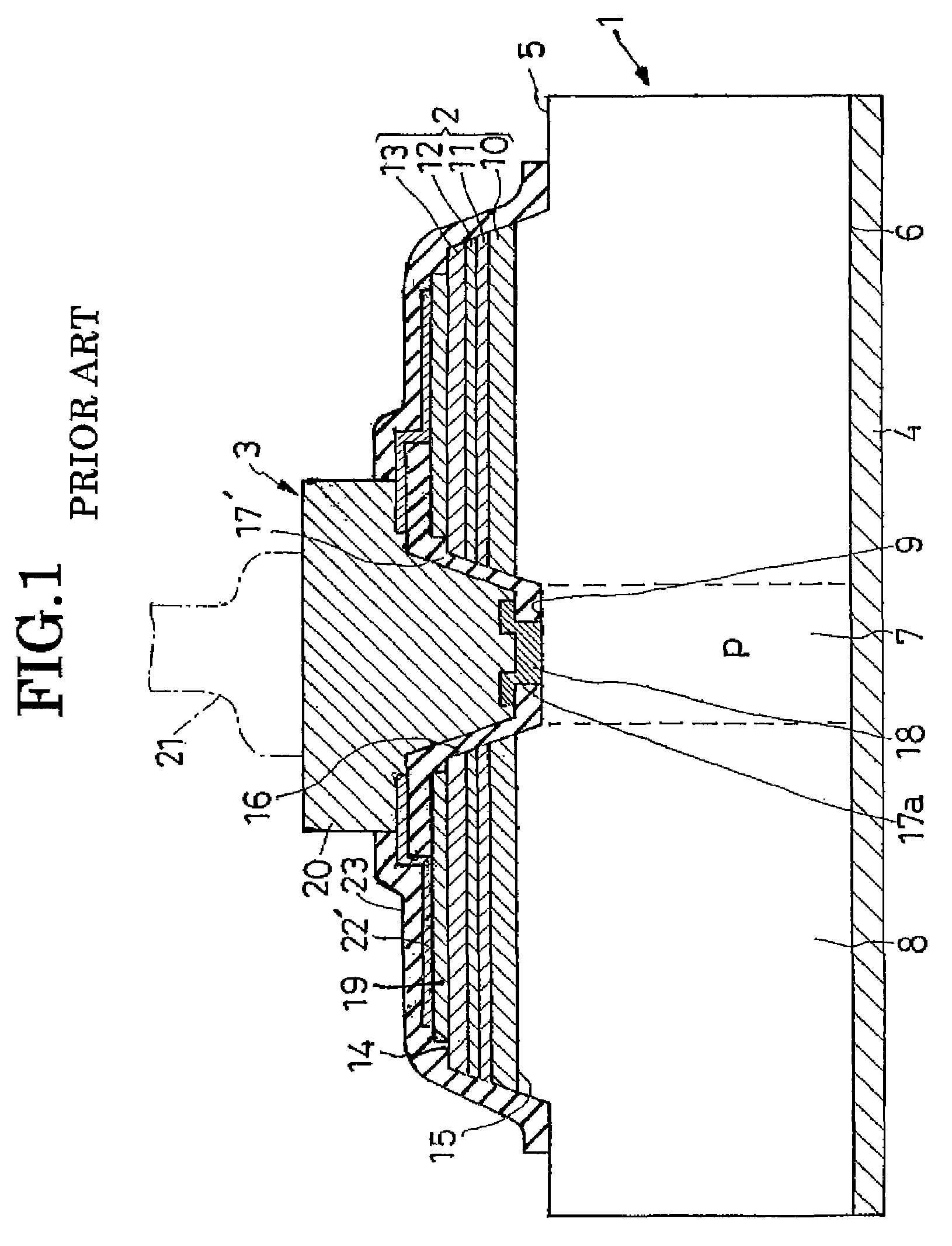

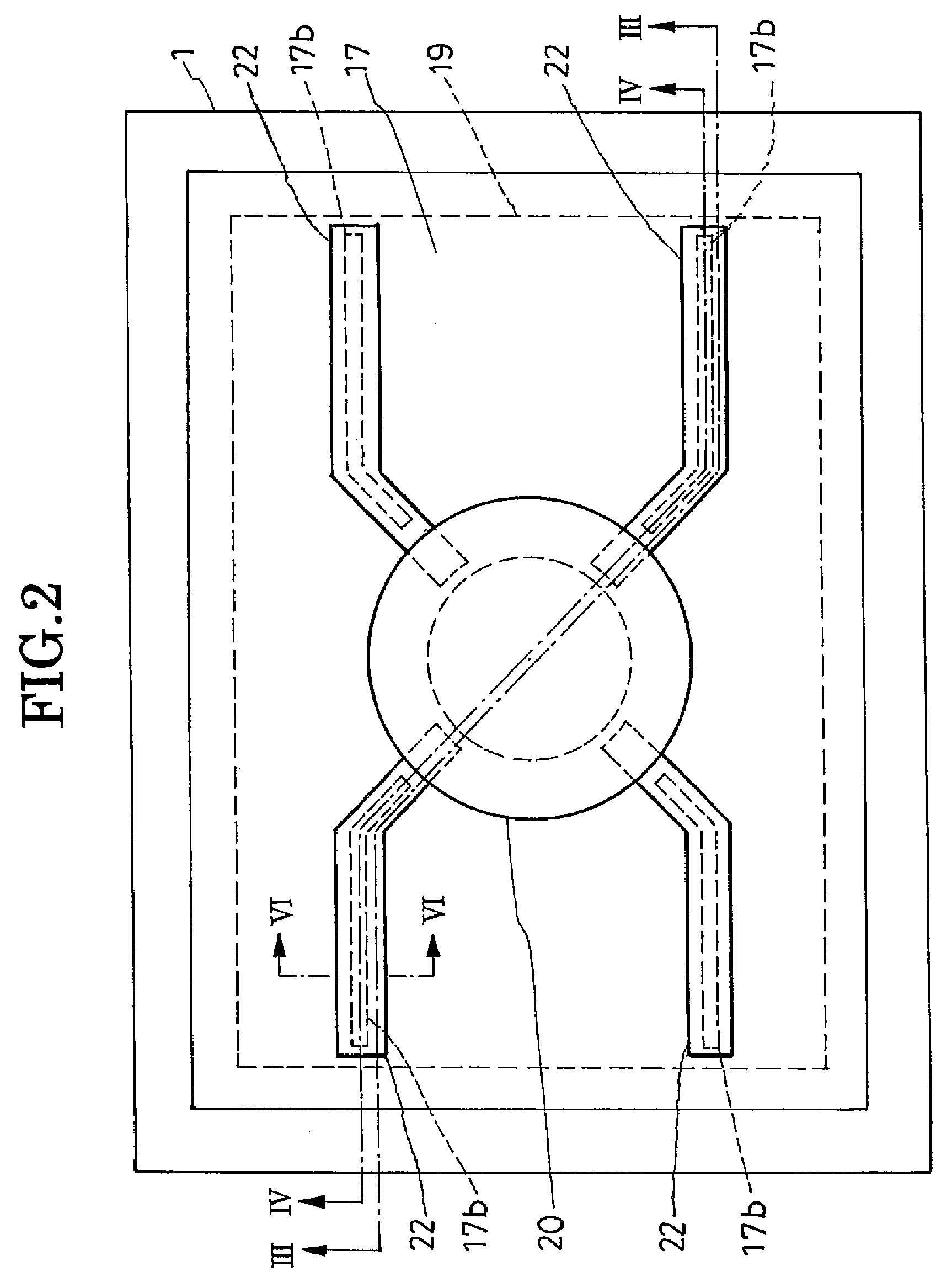

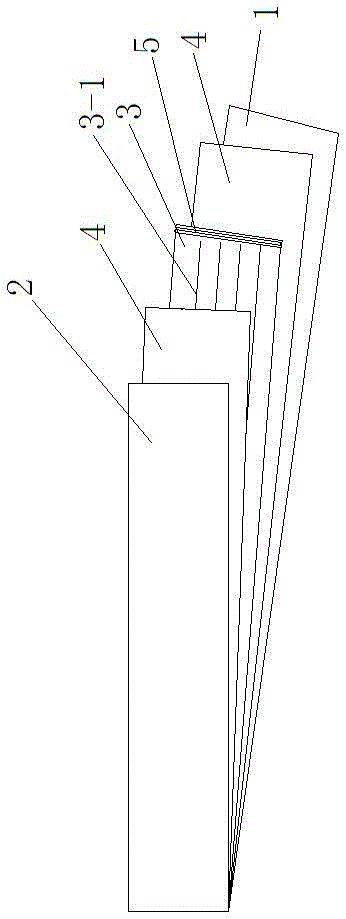

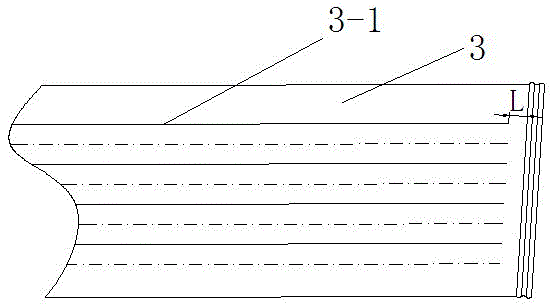

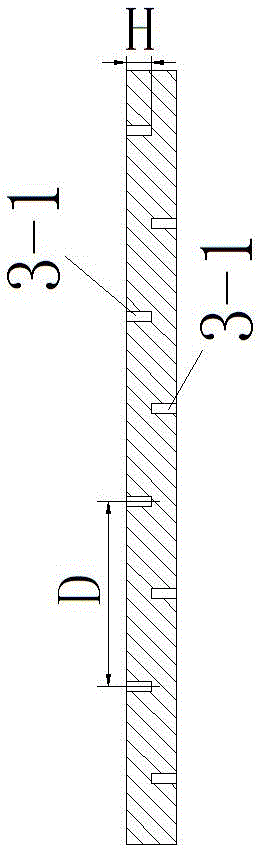

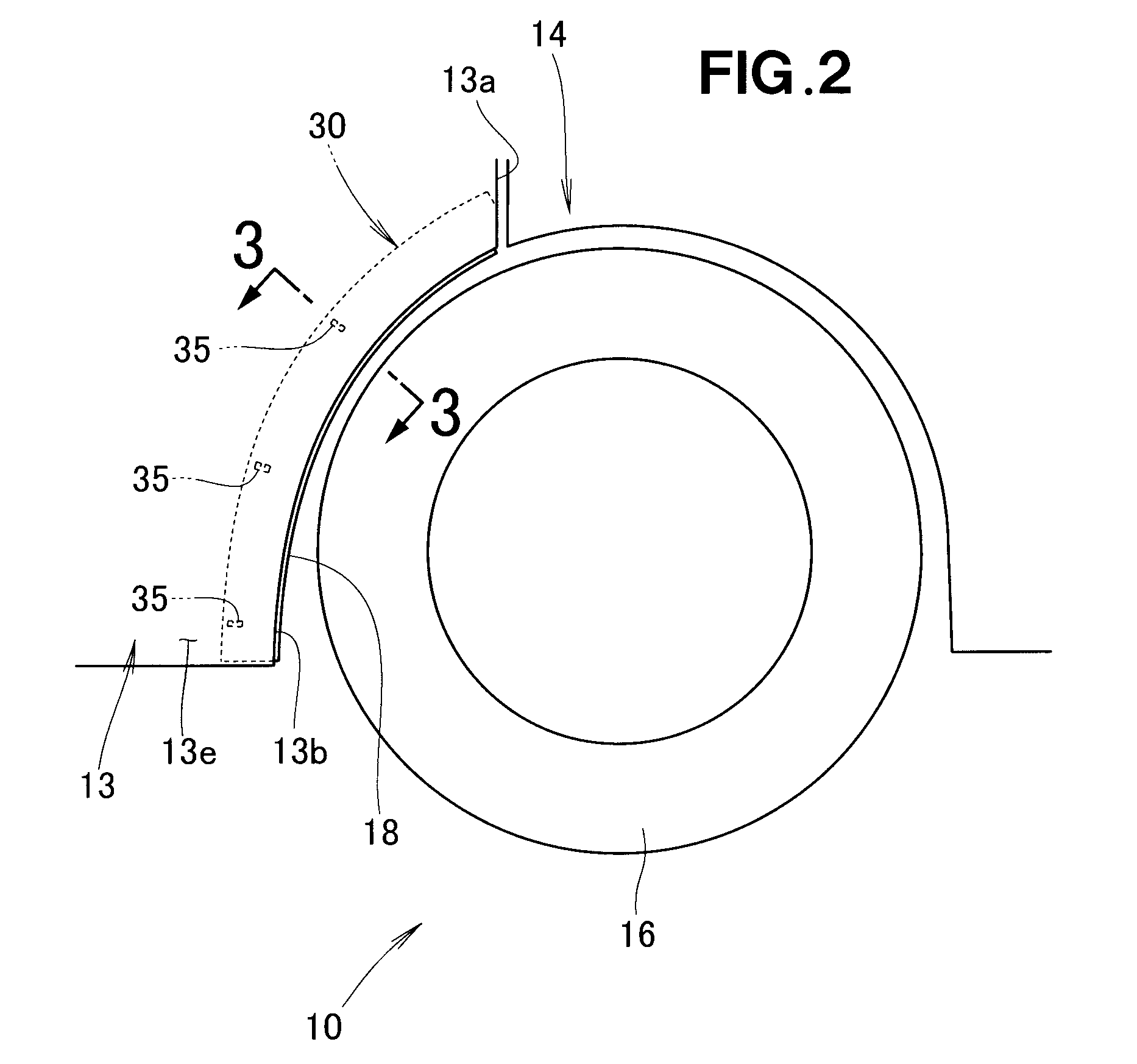

An LED comprises a multilayered light-generating semiconductor region grown on one of a pair of opposite major surfaces of a semiconducting silicon substrate, a bonding pad overlying the light-generating semiconductor region and received in part in a cavity formed centrally therein, and a substrate electrode on the other major surface of the substrate. For protecting the LED from voltage spikes or like transients, an overvoltage protector such as a Schottky barrier diode is interposed between the bonding pad and the substrate. Further, for a uniform current distribution throughout the light-generating semiconductor region, a current-spreading film of electrically conducting, optically transparent material overlies the light-generating semiconductor region and itself covered by a transparent overlay of electrically insulating material. The bonding pad is electrically coupled to the current-spreading film via a plurality of connector strips extending radially from the pad over the transparent overlay. The connector strips have ribs depending therefrom and extending through radial slits in the transparent overlay into electrical contact with the current-spreading film.

Owner:SANKEN ELECTRIC CO LTD

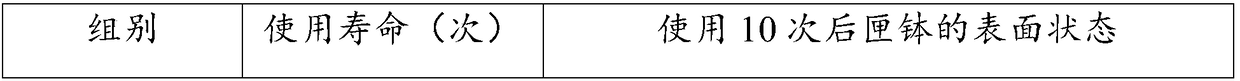

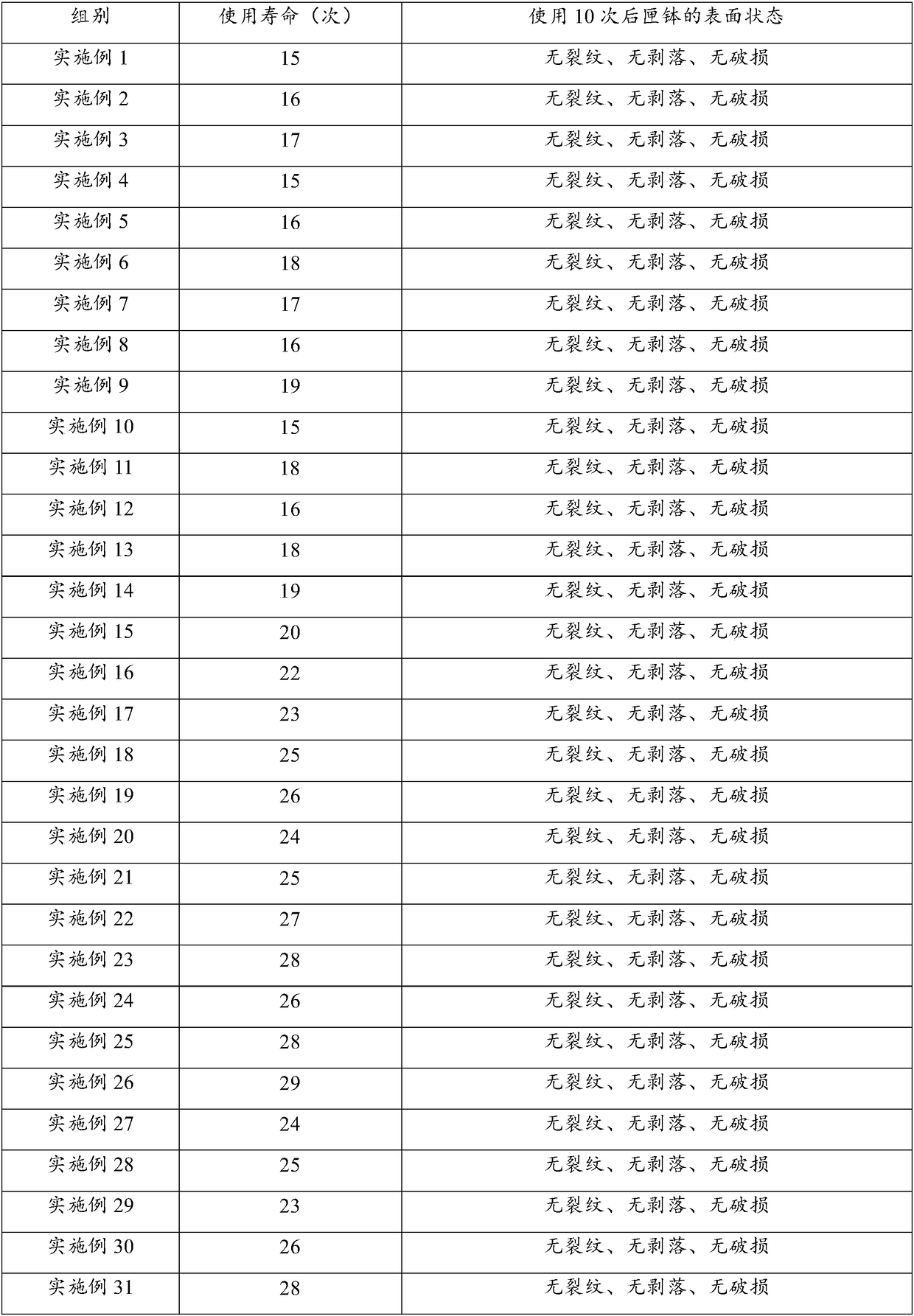

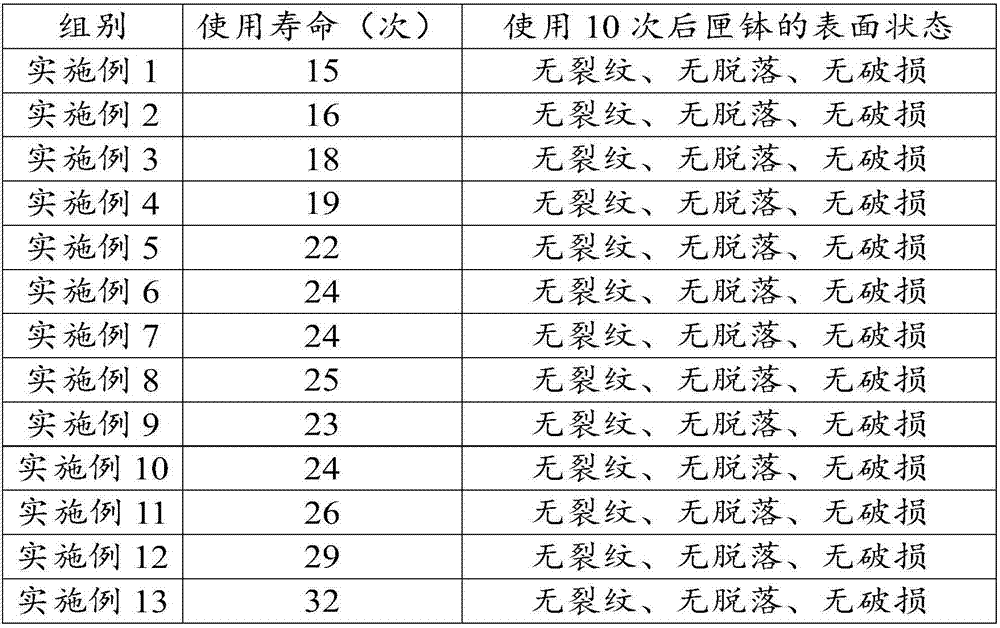

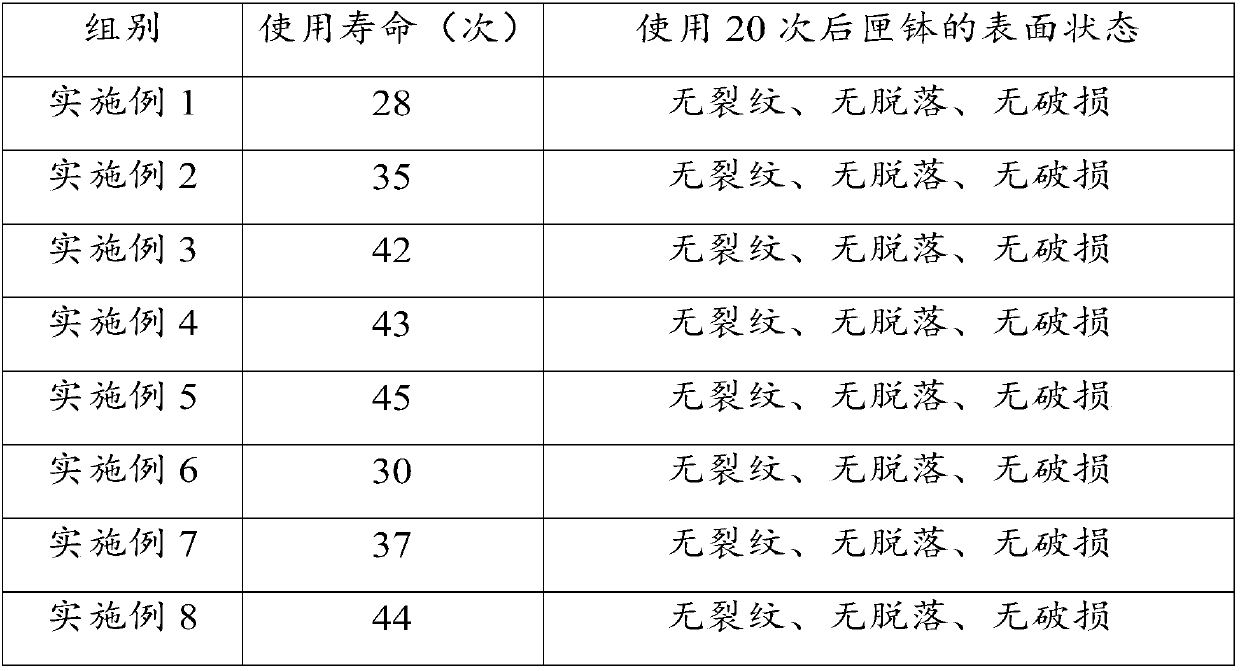

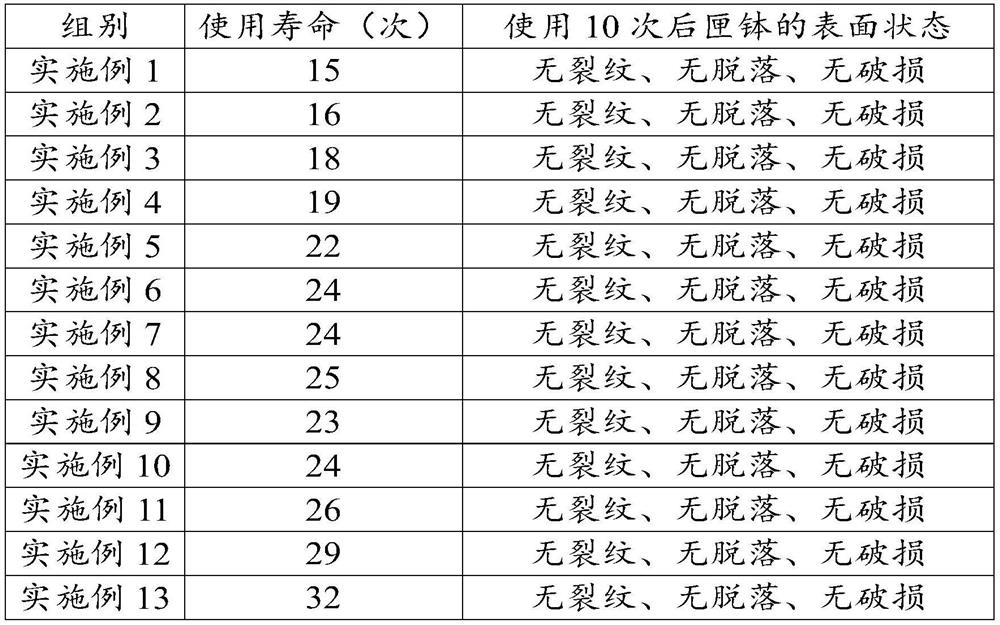

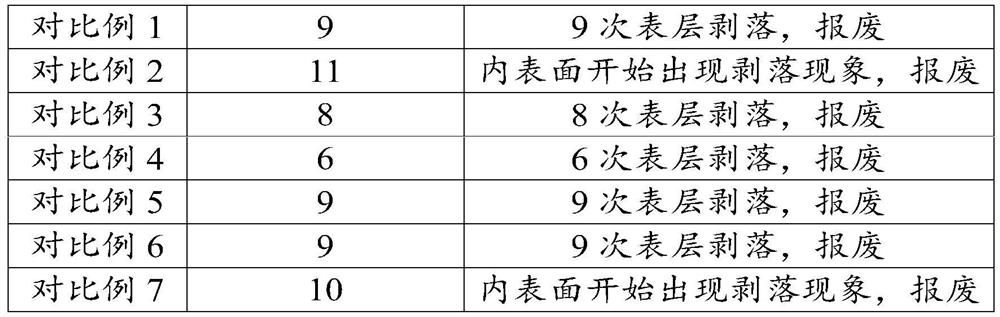

Aluminium titanate-mullite-corundum sagger as well as preparation method and application thereof

The invention provides an aluminium titanate-mullite-corundum sagger as well as a preparation method and an application thereof and relates to the technical field of refractory materials. The aluminium titanate-mullite-corundum sagger mainly adopts aluminium titanate, mullite with specific grain size, corundum powder with specific grain size, titanium dioxide, alumina, magnesia powder and yellow dextrin as raw materials, and has the advantages of long service life and low use cost; besides, the raw materials are widely sourced and low in cost; the preparation method of the aluminium titanate-mullite-corundum sagger adopts simple technological steps, processing is simple and convenient, and the sagger has the advantages of low cost, high performance cost ratio and long service life. When the aluminium titanate-mullite-corundum sagger is applied to production of a lithium-ion battery cathode material, the production cost of ceramics can be effectively reduced due to the fact that the aluminium titanate-mullite-corundum sagger has the advantages of low cost, high performance cost ratio and long service life.

Owner:ZHEJIANG UNIV

Cutting tool and method of using same

InactiveUS6868848B2Less likely to breakCutting is more rapidDrill bitsSlitting machinesSupport matrixChisel

A cutting tool for cutting hard rock, the cutting tool including one or more cutting elements each including a pointed or chisel-shaped body including a diamond composite material including diamond crystals bonded together by a silicon carbide matrix, the each cutting element being mounted into a supporting matrix including a metal matrix composite material, such that the point or chisel edge of the each element protrudes from the matrix.

Owner:COMMONWEALTH SCI & IND RES ORG

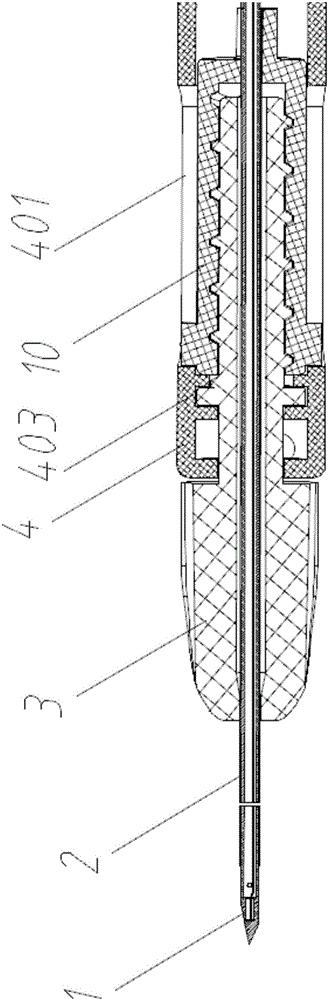

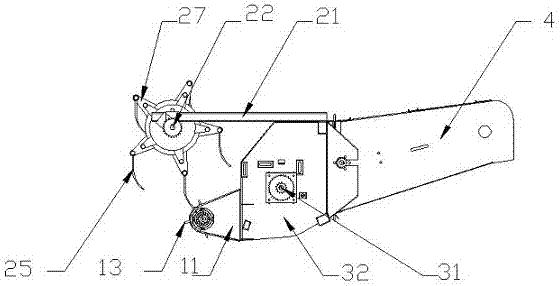

Adjustable water-injection ablation electrode needle

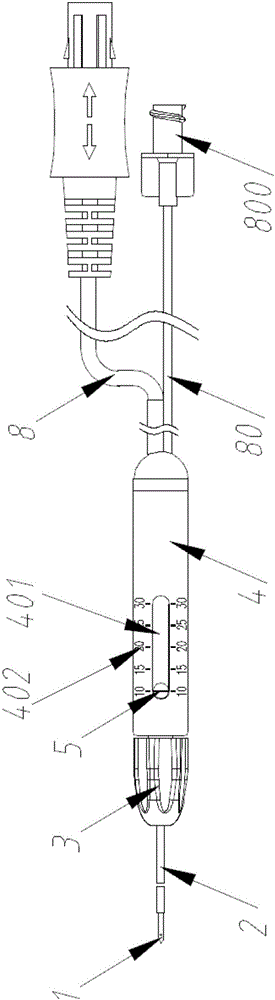

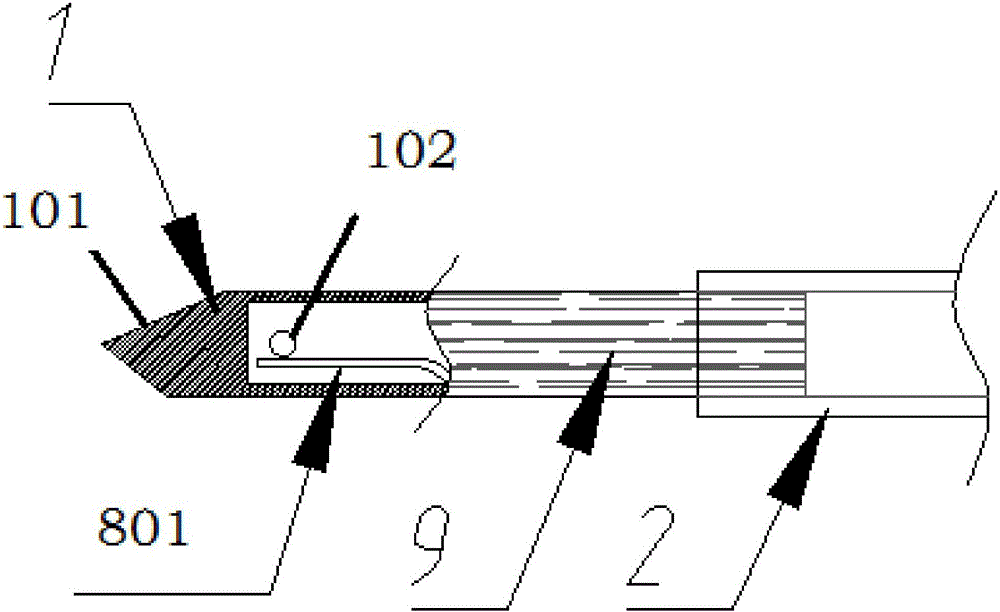

ActiveCN105943159AAdhesion improvement or resolutionAdjust the field of vision to be clearMedical devicesSurgical instruments for heatingElectrosurgeryRadio frequency

The invention discloses an adjustable water-injection ablation electrode needle, and belongs to the field of operating instruments for electrosurgery and the field of operating instruments for minimally invasive ablation. The electrode needle comprises a needle rod, a handle, an adjusting knob, an adjusting sleeve, a scale sliding block, a needle rod fixed seat, a water pipe fixed seat, a water pipe and radio frequency cables, wherein the tip end of the needle rod is composed of a triangular blade which is easy for puncture, and a thin hole is formed in the needle rod; an annular groove is formed in the handle, and a length-adjusting graduation ruler is arranged on the edge of the annular groove; an outer screw thread is formed in the adjusting knob, and the adjusting knob is composed of a plurality of edges provided with rounded corners; the adjusting sleeve and the scale sliding block are bonded by virtue of glue; an inner screw thread, which is matched with the adjusting knob, is formed in the scale sliding block; a scale indicating line is printed on the scale sliding block; the needle rod fixed seat and the needle rod are connected by virtue of glue; the water pipe fixed seat and the water pipe are connected by virtue of glue; and the radio frequency cables are welded on the needle rod. The adjustable water-injection type ablation needle disclosed by the invention is convenient to operate and clear in scale, and the ablation needle is convenient for doctors to observe in an operation.

Owner:ANGEL MEDICAL TECH NANJING

Adhesive tape

ActiveCN104039911AImprove impact resistanceNot easy to disengageFilm/foil adhesivesThin material handlingShock resistanceCompressive strength

Owner:DIC CORP

Cutting method and cutting apparatus for layered sheet, layered sheet, optical element and image display

ActiveCN1640597AHigh dimensional accuracyReliable and efficient machiningPolarising elementsPlaning/slotting machinesMachiningImage display

Owner:NITTO DENKO CORP

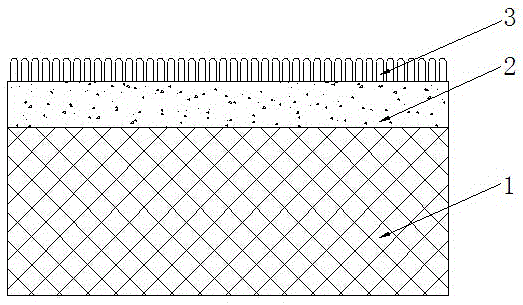

Polyurethane logistics conveyer belt and manufacturing method thereof

ActiveCN105668121AHigh bonding strengthHigh strengthConveyorsLamination ancillary operationsPolyesterFiber

The invention discloses a polyurethane logistics conveyer belt and a manufacturing method of the polyurethane logistics conveyer belt. The polyurethane logistics conveyer belt comprises a middle framework fabric layer, polyurethane adhesive dipped in the middle framework fabric layer and a wear-proof thermoplastic polyurethane elastomer film surface layer. Polyester fiber base fabric is dipped into a polyurethane adhesive solution, dried and shaped, the surface of the polyester fiber base fabric is attached to an extruded thermoplastic polyurethane elastomer film, polishing treatment and other processes are conducted on the back face of the polyester fiber base fabric, and then the polyurethane logistics conveyer belt is manufactured. The conveyer belt is an open conveyer belt, and steel buckle flocking connectors are adopted. Compared with the prior art, the polyurethane logistics conveyer belt has the excellent properties of being low in mass, low in energy consumption, resistant to wear, free of burrs, resistant to low temperature and the like. Especially, flocking is conducted at the positions of the steel buckle connectors, steel buckles and a rolling wheel can be prevented from generating friction damage, and the service life of the conveyer belt is prolonged.

Owner:AA IND BELTING (SHANGHAI) CO LTD

High-efficiency, overvoltage-protected, light-emitting semiconductor device

ActiveUS7576367B2Improve efficiencyLess likely to breakSolid-state devicesSemiconductor devicesOvervoltageVoltage spike

An LED comprises a multilayered light-generating semiconductor region grown on one of a pair of opposite major surfaces of a semiconducting silicon substrate, a bonding pad overlying the light-generating semiconductor region and received in part in a cavity formed centrally therein, and a substrate electrode on the other major surface of the substrate. For protecting the LED from voltage spikes or like transients, an overvoltage protector such as a Schottky barrier diode is interposed between the bonding pad and the substrate. Further, for a uniform current distribution throughout the light-generating semiconductor region, a current-spreading film of electrically conducting, optically transparent material overlies the light-generating semiconductor region and itself covered by a transparent overlay of electrically insulating material. The bonding pad is electrically coupled to the current-spreading film via a plurality of connector strips extending radially from the pad over the transparent overlay. The connector strips have ribs depending therefrom and extending through radial slits in the transparent overlay into electrical contact with the current-spreading film.

Owner:SANKEN ELECTRIC CO LTD

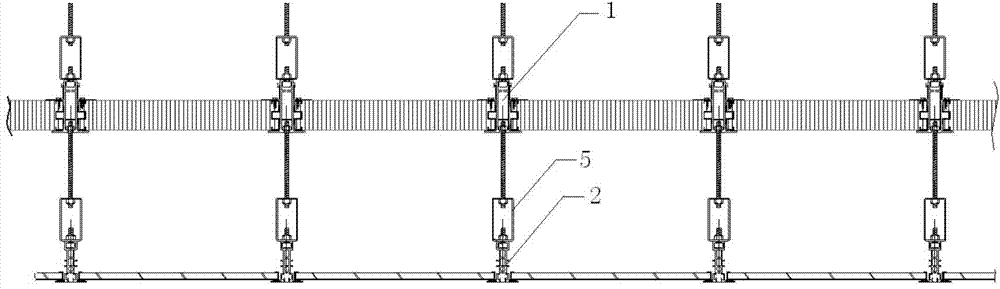

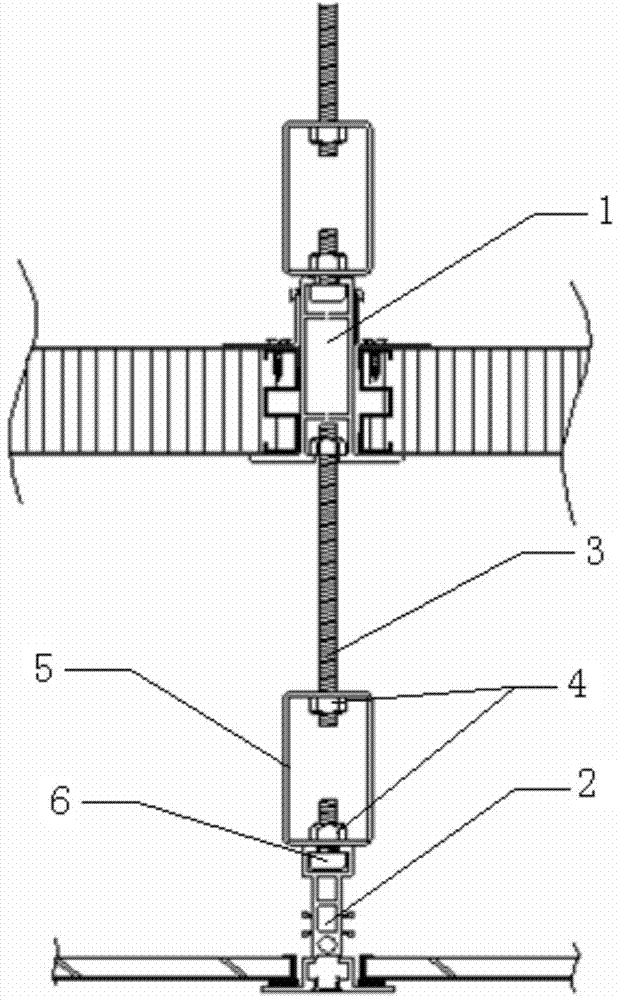

Double-layer assembling keel for suspended ceiling

The invention discloses a double-layer assembling keel for a suspended ceiling. The double-layer assembling keel for the suspended ceiling comprises an upper layer keel, a lower layer keel and a connecting piece, wherein the connecting piece comprises a threaded rod and nuts. The double-layer assembling keel for the suspended ceiling is characterized in that the connecting piece further comprises a level adjustor, the level adjustor is located between the threaded rod and the lower layer keel, one end of the threaded rod is inserted into a bottom slot of the upper layer keel and is fixed through one nut, the other end of the threaded rod is connected with the top of the level adjustor through the other nut, and the bottom of the level adjustor is connected with a top slot of the lower layer keel through a bolt. The double-layer assembling keel for the suspended ceiling has the advantages that sound insulation and dustproof effects are good, and meanwhile the distance between the upper layer keel and the lower layer keel can be adjusted freely by adding the level adjustor.

Owner:KUNSHAN MAX METAL

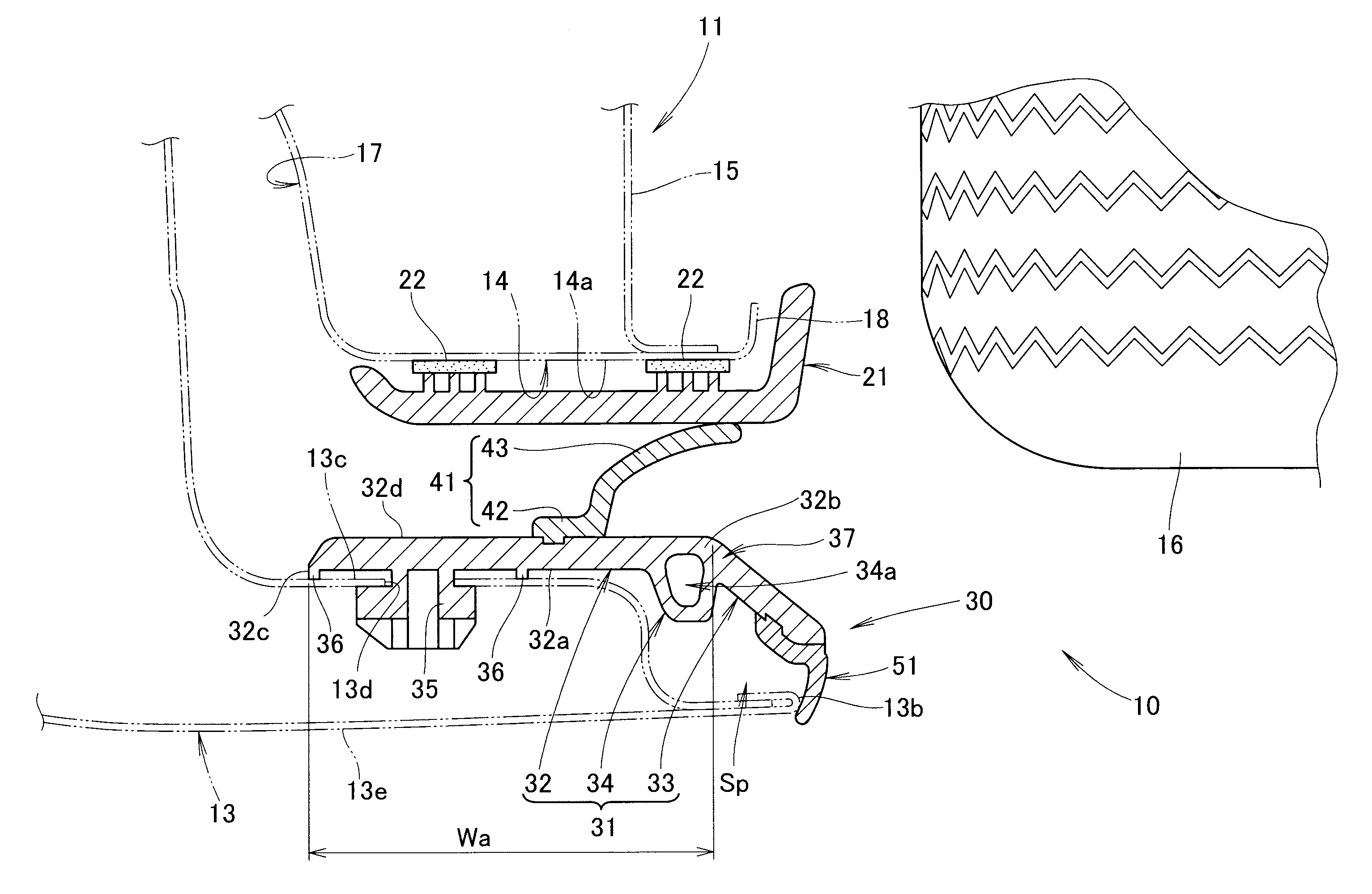

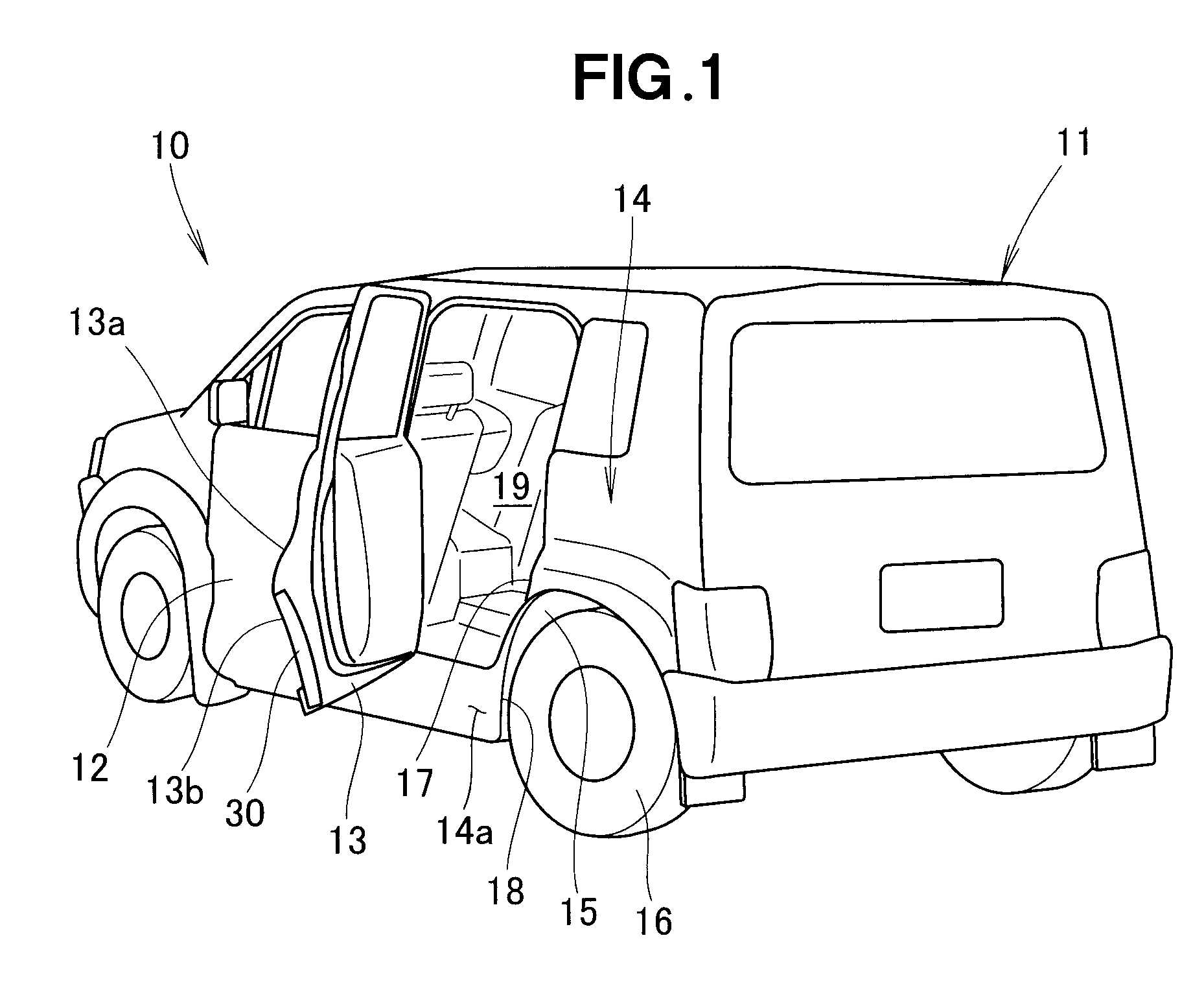

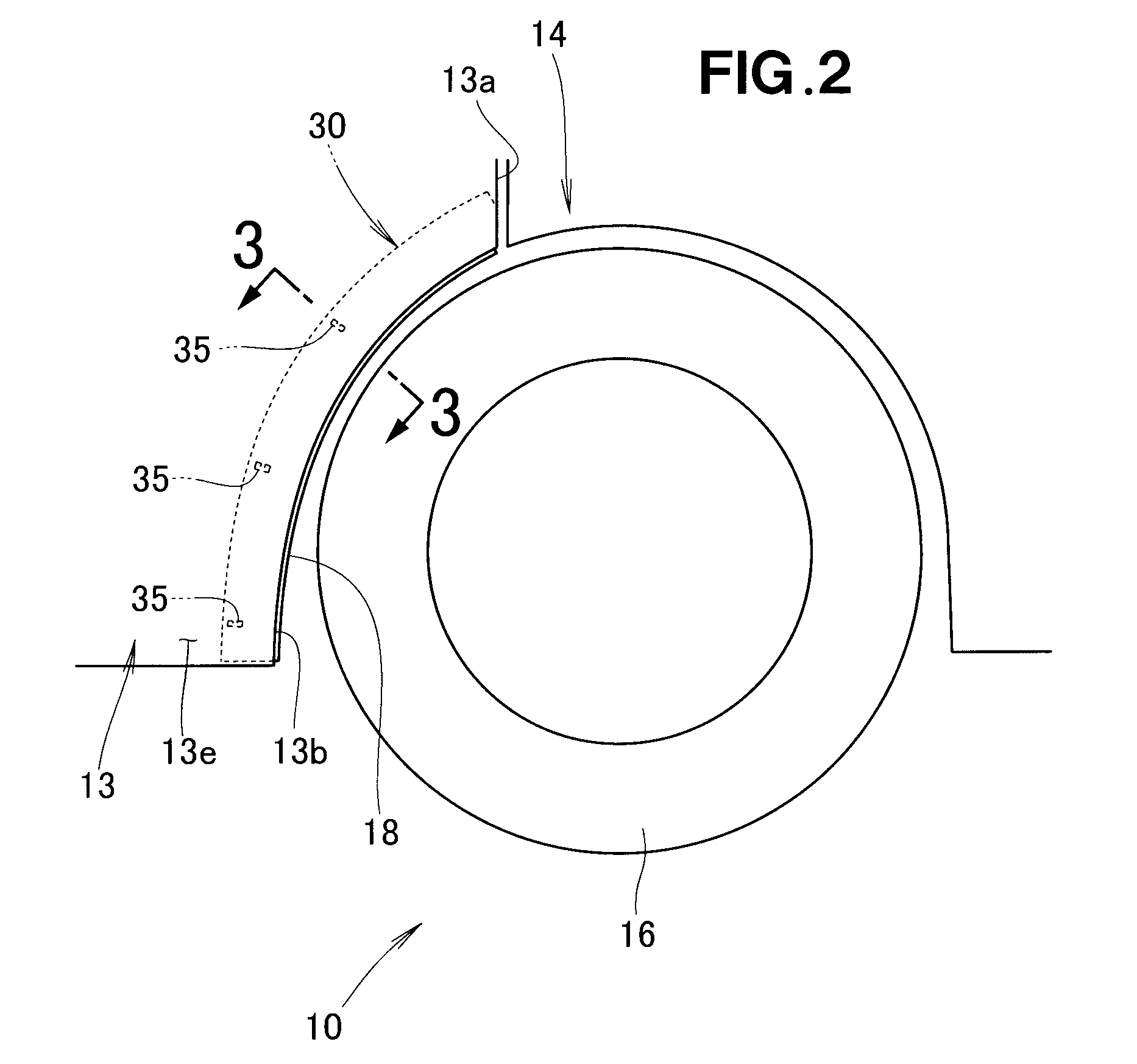

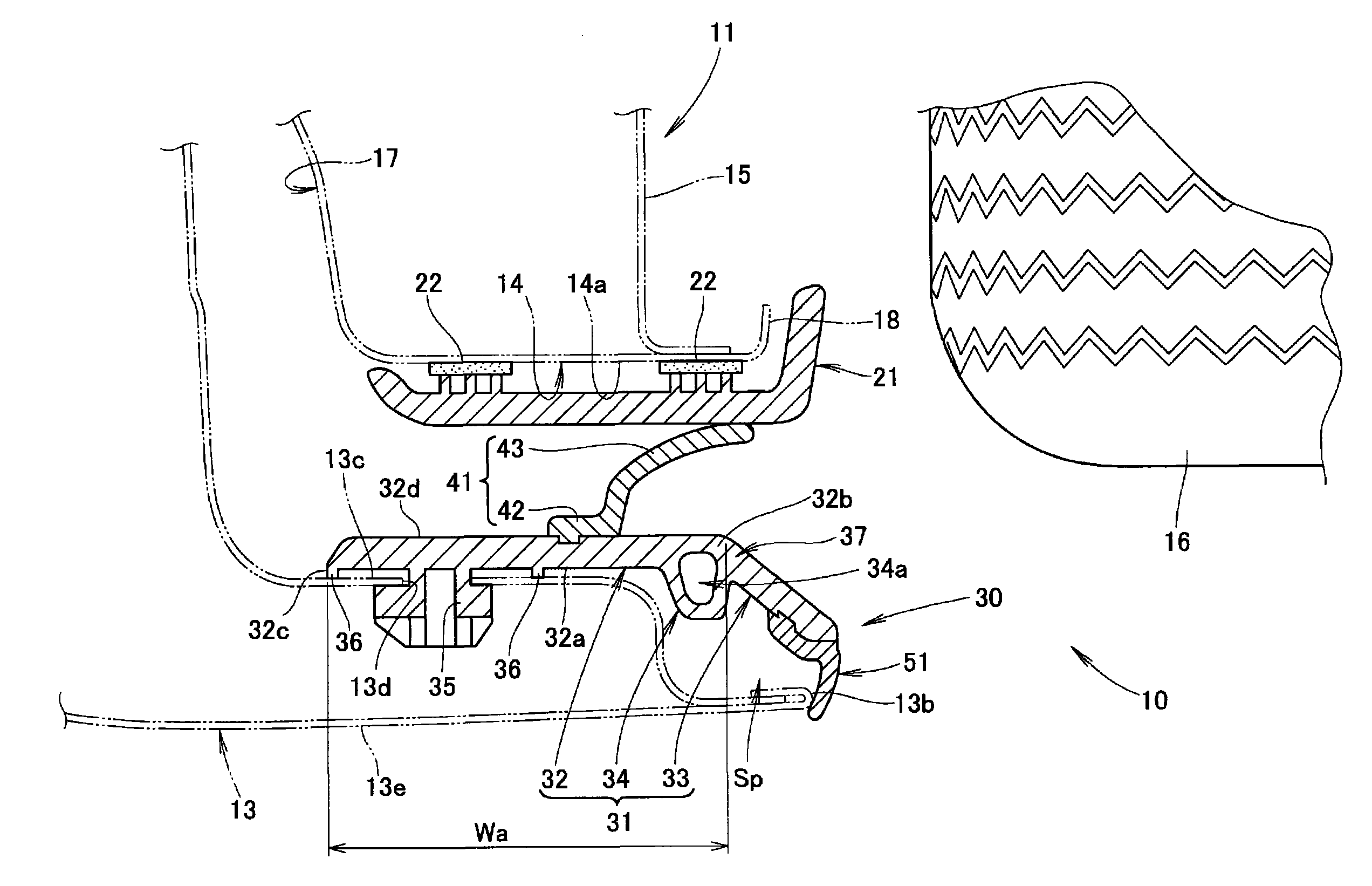

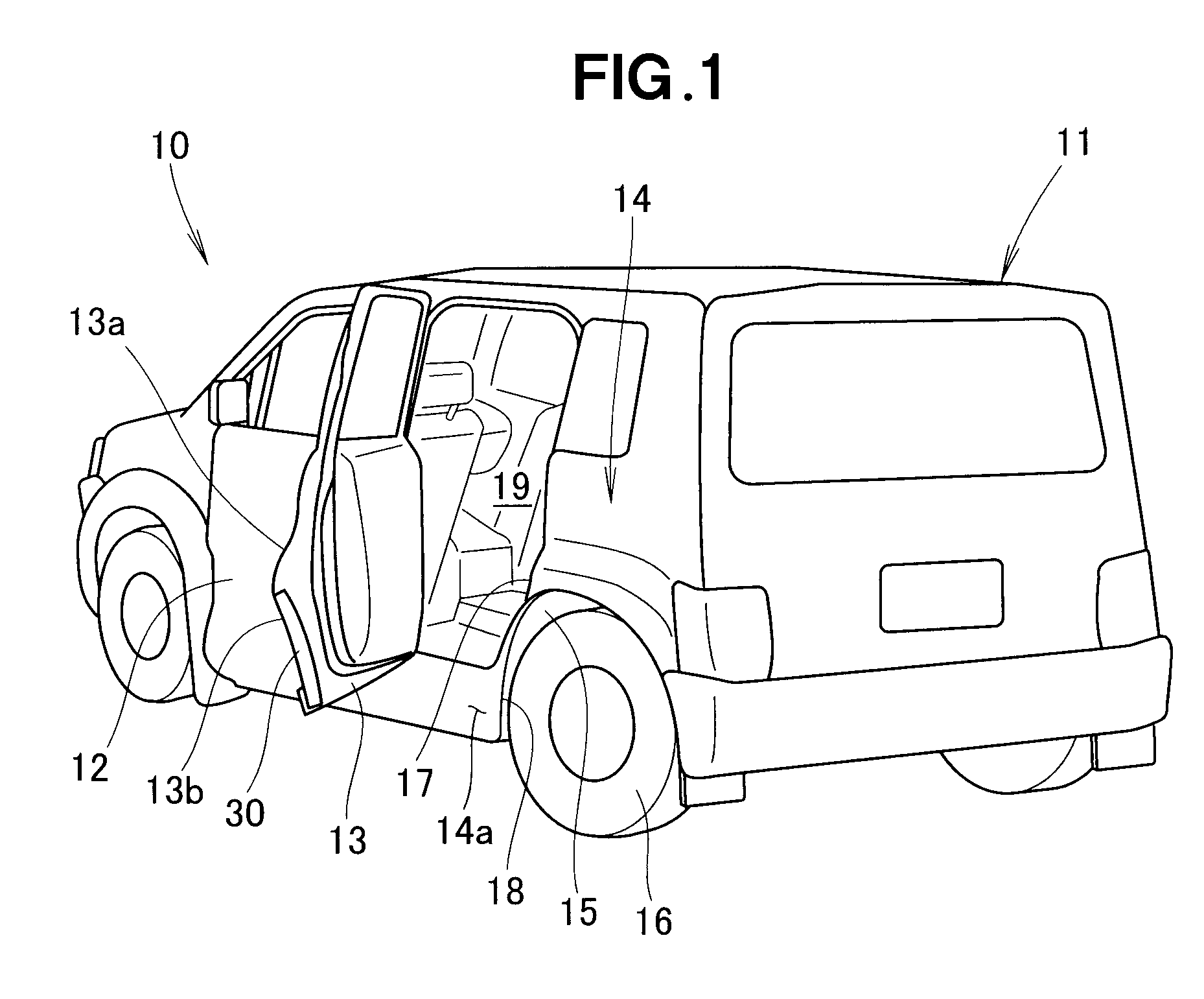

Wheel-arch protector for vehicle

ActiveUS20110115253A1Improve sound insulationLess likely to breakWindowsEngine sealsEngineeringMechanical engineering

A wheel-arch protector mounted on the rear edge of a side door for covering a wheel arch for a rear wheel, the wheel-arch protector including a protector body formed from a polymer material and a seal part formed from a polymer material that elastically deforms more readily than the polymer material for forming the protector body. The body includes a mounting baseplate, a extending plate, and a distended part. The extending plate extends from an end of the mounting baseplate to outside in a widthwise direction of the vehicle. The distended part is distended to an inner angle part of a corner between the mounting baseplate and the extending plate and has a hollow part. The seal part is comprised of a basal part formed on a vehicle-interior-facing surface of the mounting baseplate and a seal-lip part formed on the basal part. The basal part is set apart toward another end of the mounting baseplate relative to the hollow part.

Owner:HONDA MOTOR CO LTD +1

Composite sagger and preparation method and application thereof

ActiveCN108101558AStrong corrosion resistanceLow costCell electrodesCharge supportsAluminiumMagnesium

The invention relates to the field of refractory materials and specifically provides a composite sagger and a preparation method and application thereof. The composite sagger is prepared from a bottommaterial and a surface material, wherein the bottom material is mainly prepared from kaolin of specific content, talc, alpha-aluminum oxide, high bauxite, high bauxite with particle size of 0.5mm orless, flint clay with particle size of 1mm or less and flint clay with particle size of 1-2mm; the surface material is mainly prepared from aluminum titanate with particle size of 1.5mm or less and ofspecific content, corundum with particle size of 1mm or less, corundum with particle size of 46.9mu m or less, titanium dioxide, alpha-aluminum oxide, magnesium oxide and yellow dextrin. The composite sagger has the advantages of low cost, high cost performance, high corrosion resistance and long service life.

Owner:ZHEJIANG UNIV

Diamond drill and method for making same

InactiveCN101032842ADrilling smoothlyNot easy to collapseStone-like material working toolsSlugDrilling force

The diamond drilling bit includes one steel bit body and one thin wall diamond cone integrated with the steel bit body. The thin wall diamond cone has linear or spiral slug slot and one un-slotted smooth surface. The slot makes the bit operating in intermittent, rather than continuous, grinding in enhanced drilling force, high drilling speed, fluent slug removing and reduced drilling resistance and heat. Timely cooling of the drilling bit and the machined material can avoid deformation and burns.

Owner:GUILIN CHAMPION UNION DIAMOND CO LTD

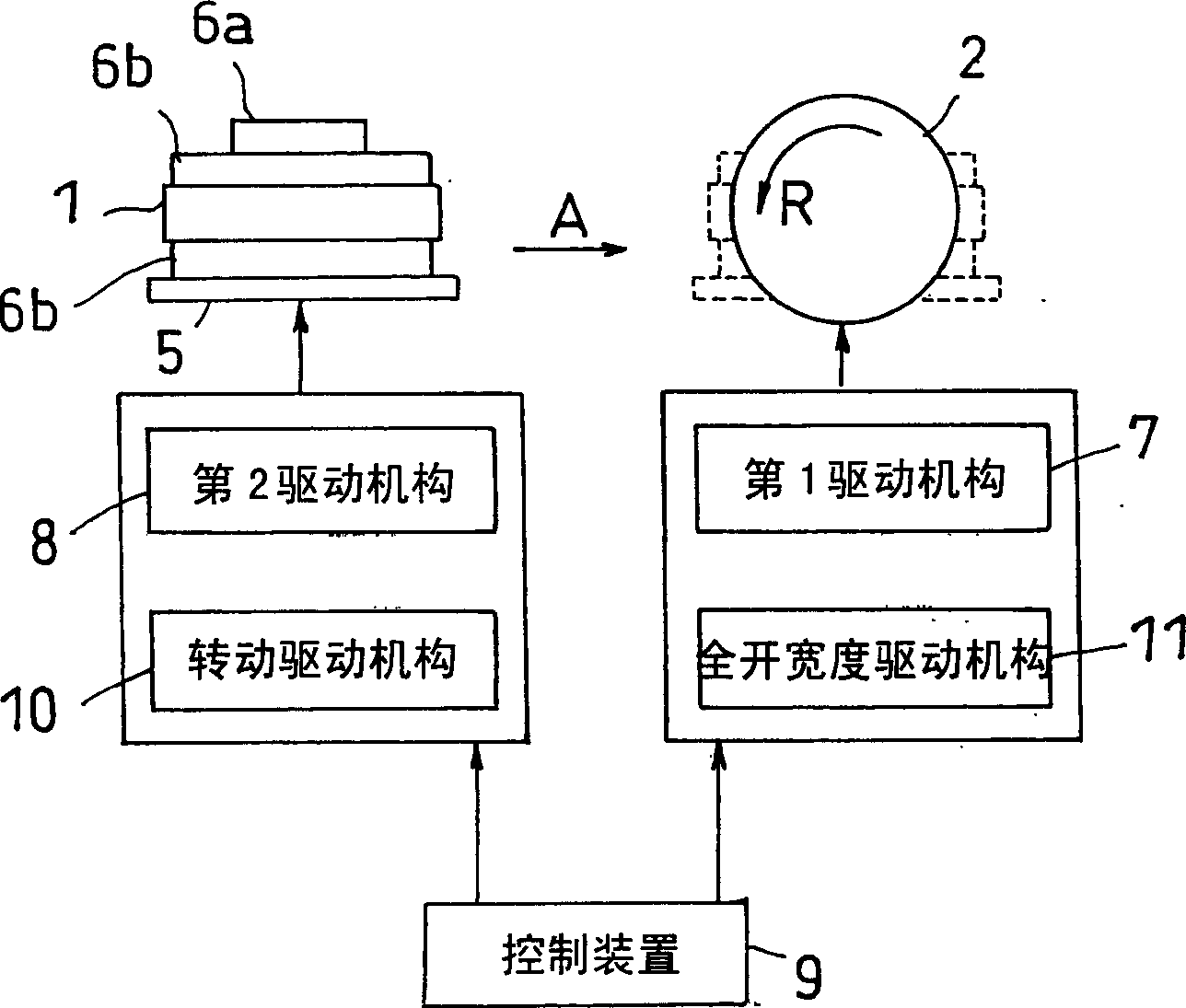

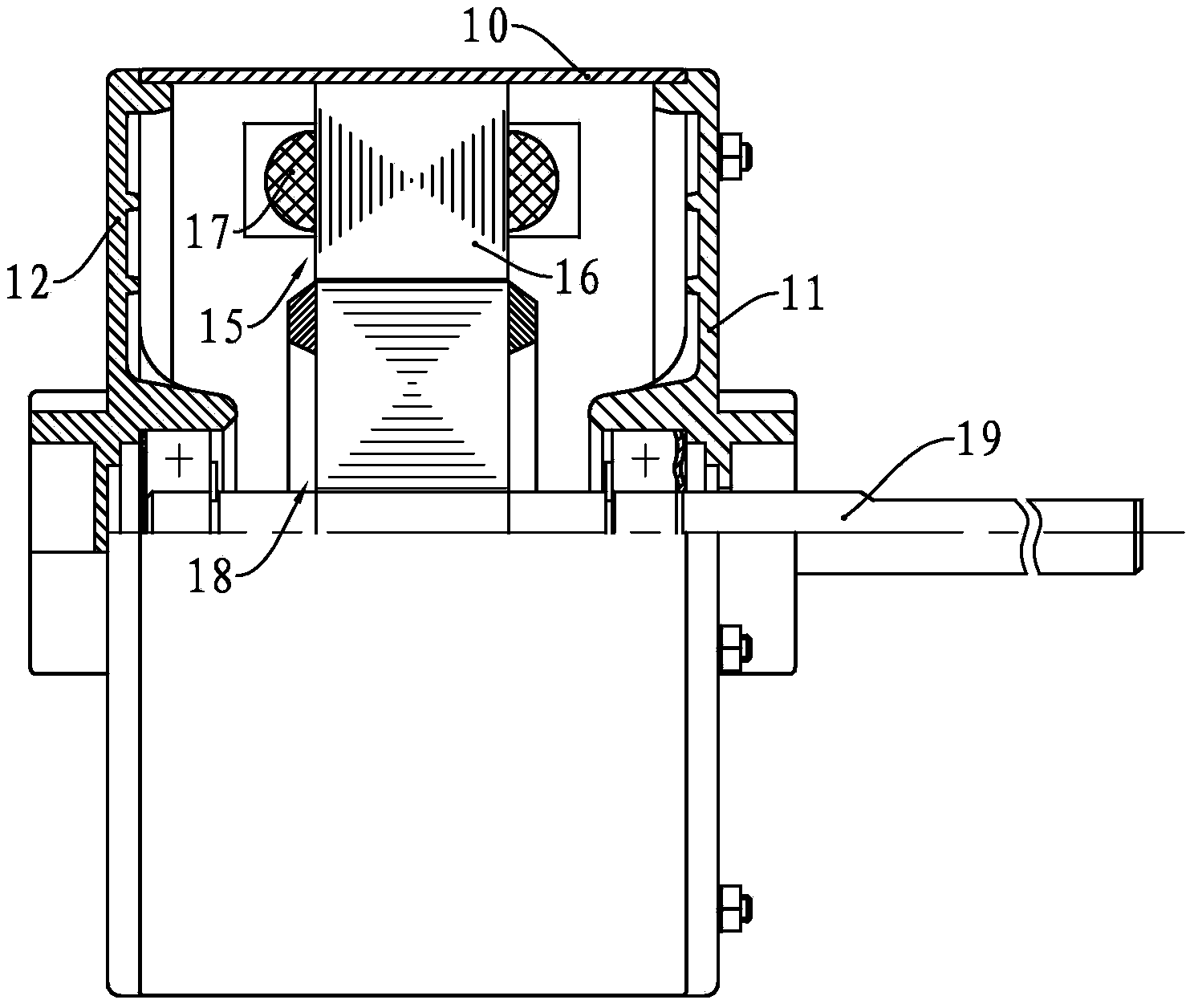

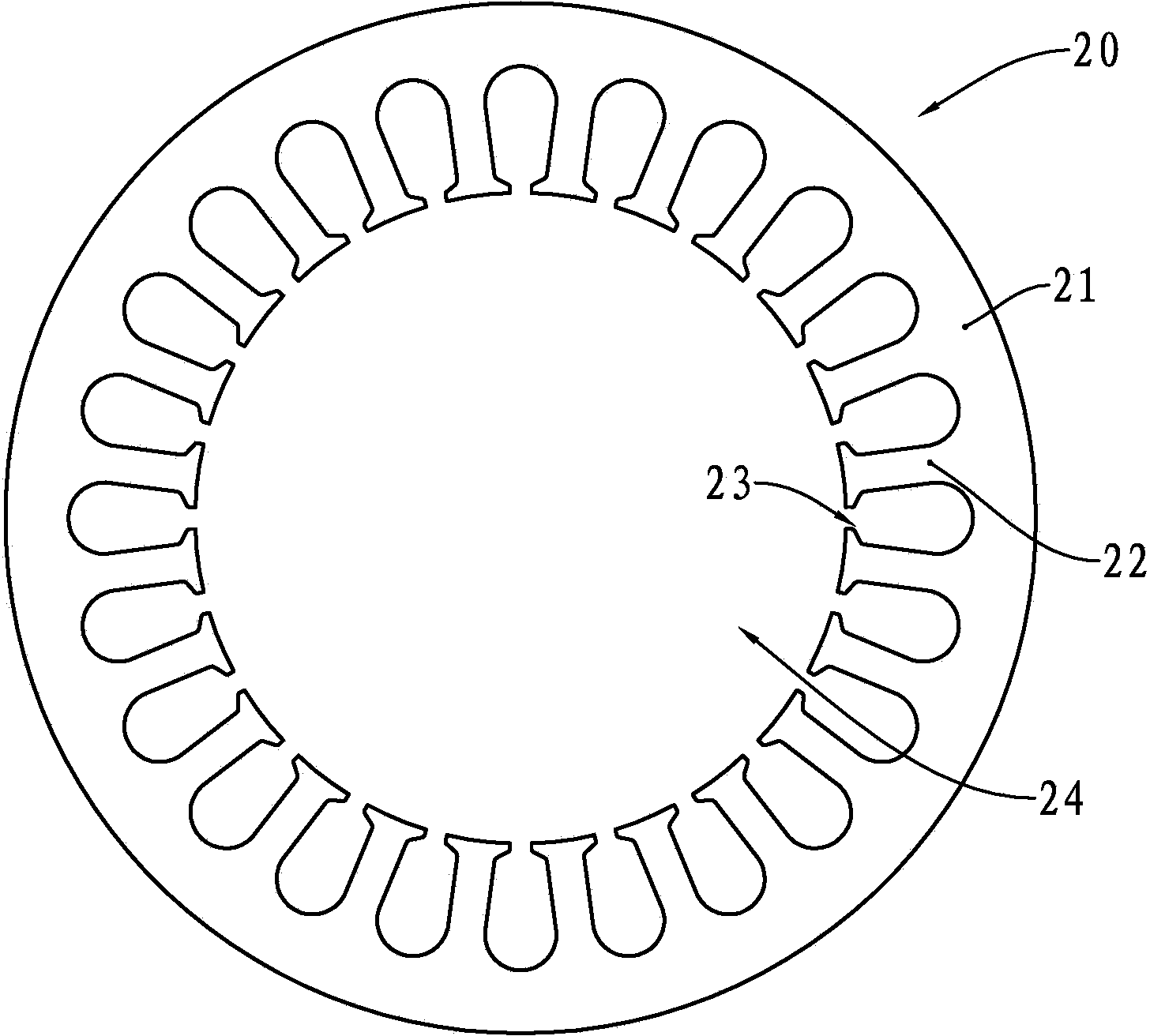

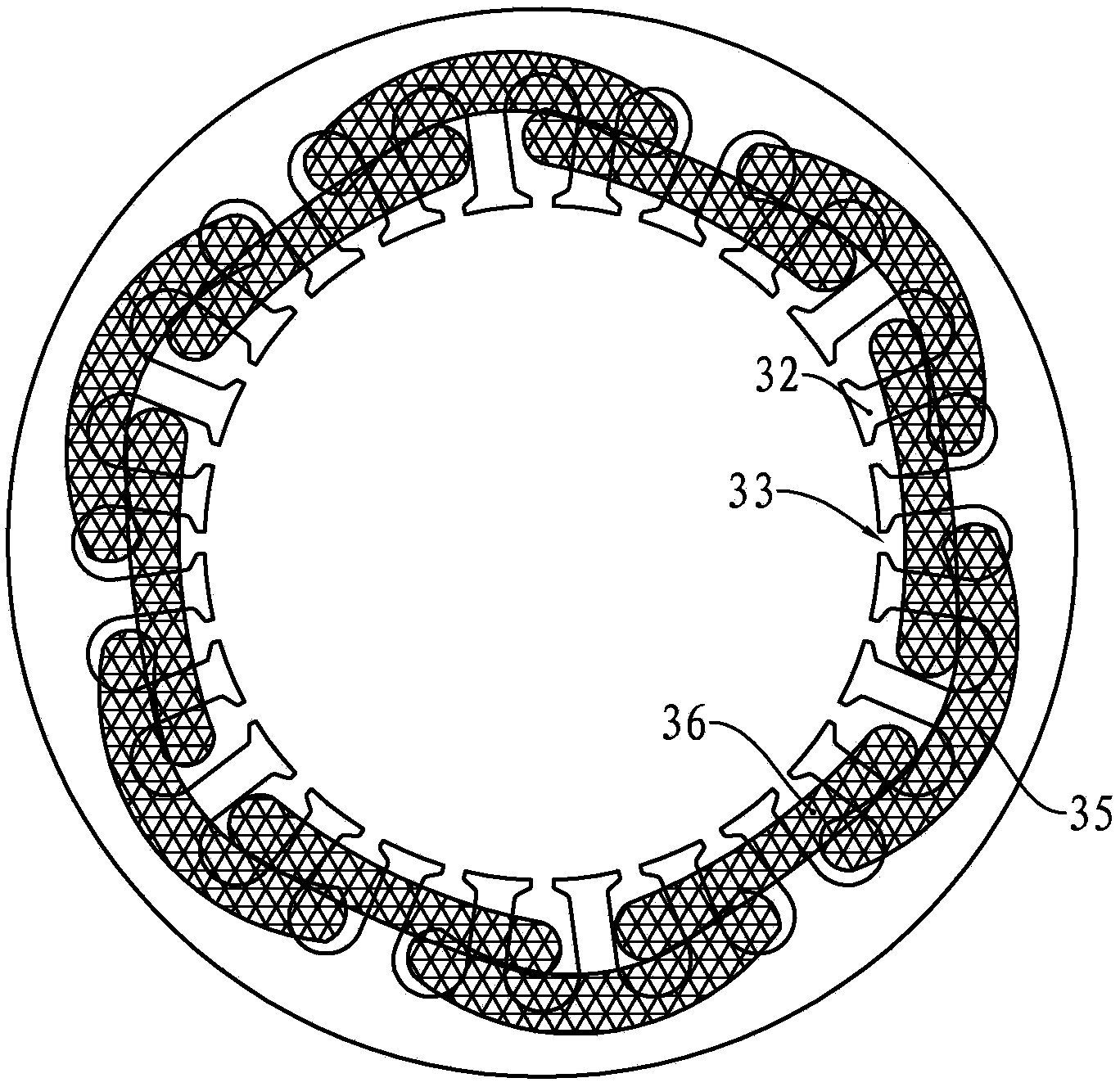

Stator punching piece, stator core and motor

InactiveCN103457365AAvoid breakingSimple structureMagnetic circuit stationary partsPunchingEngineering

The invention provides a stator punching piece, a stator core and a motor. The stator punching piece is provided with an annular yoke part and a tooth part detachably connected with the yoke part. The tooth part is located in the yoke part, a plurality of teeth are circumferentially arranged on the tooth part, tooth roots of every two adjacent teeth are connected through a bridge part, every bridge part is provided with an inner arc close to the circle center of the tooth part and an outer arc far away from the circle center of the tooth part, inner arcs of a plurality of bridge parts are located on a first circumference, outer arcs of the plurality of bridge parts are located on a second circumference, and the first circumference and the second circumference are concentric circles with the circle center of the tooth part serving as the circle center. The stator core is provided with a first tooth part formed by stacking the stator punching pieces. The motor is provided with a stator and a rotor, and the stator comprises the stator core. Flux leakage of the stator core can be reduced, breakage of the stator punching piece from the bridge parts is avoided, and quality of the stator punching piece is improved.

Owner:GREE ELECTRIC APPLIANCES INC +4

Composite saggar as well as preparation method and application thereof

ActiveCN108083823AStrong corrosion resistanceLow costElectrode manufacturing processesSecondary cellsSillimaniteSaggar

The invention relates to the field of refractory materials and particularly provides a composite saggar as well as a preparation method and an application thereof. The composite saggar comprises a bottom material and a surface material. The bottom material is mainly prepared from kaolin, sillimanite with specific particle size, aluminum oxide with specific particle size, corundum with specific particle size, andalusite with specific particle size and mullite with specific particle size. The raw materials of the base material have rich source and low cost, so that the cost of the bottom material is lower. The surface material is mainly prepared from a corundum surface material, a spinel surface material, a zirconium oxide surface material, a zirconium silicate-zirconium oxide surface material or a corundum-spinel surface material. All the raw materials of the surface material cooperate with one another, so that the surface material has good corrosion resistance. The composite saggar haslower cost, good corrosion resistance and the advantage of long service life.

Owner:ZHEJIANG UNIV

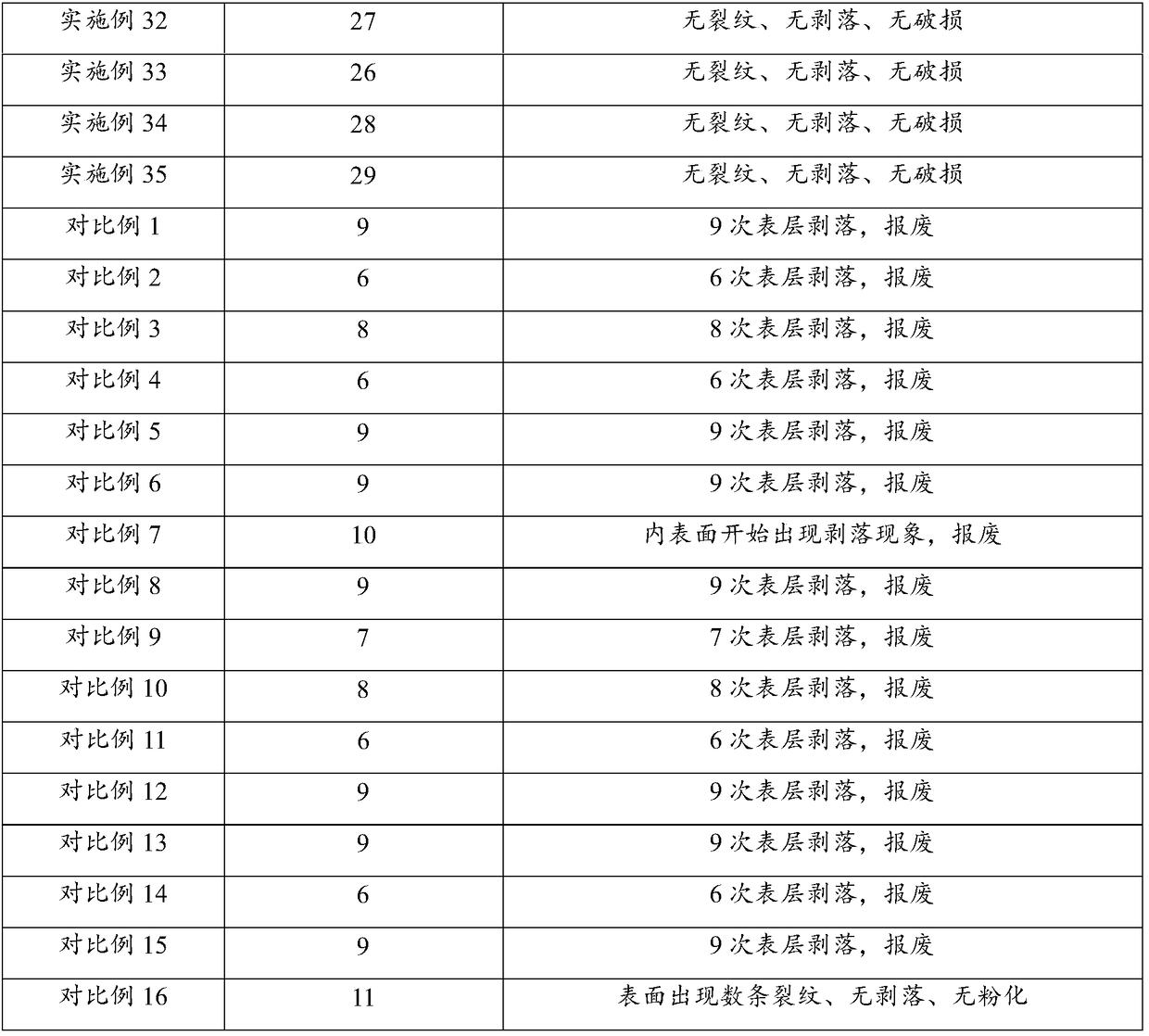

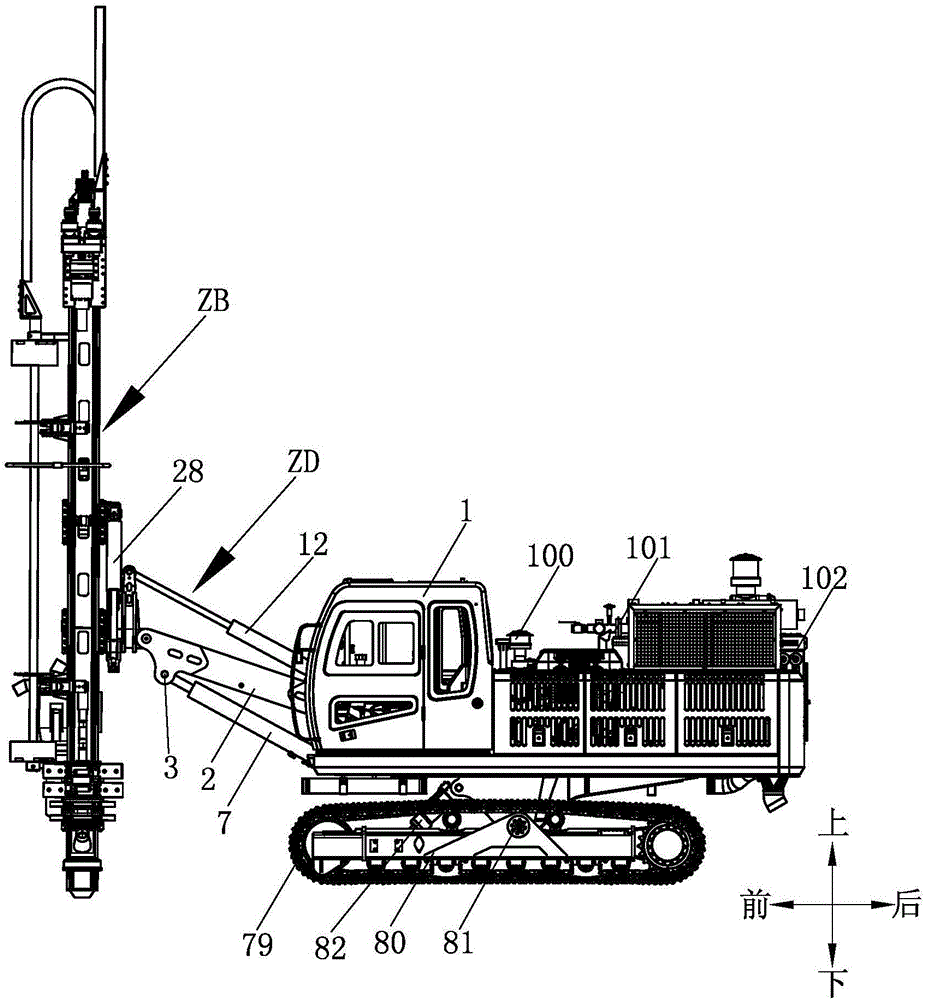

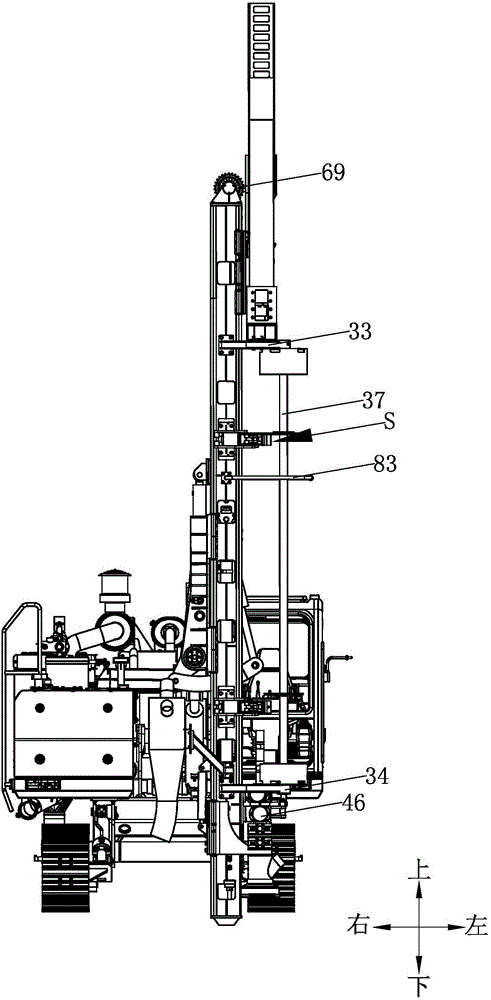

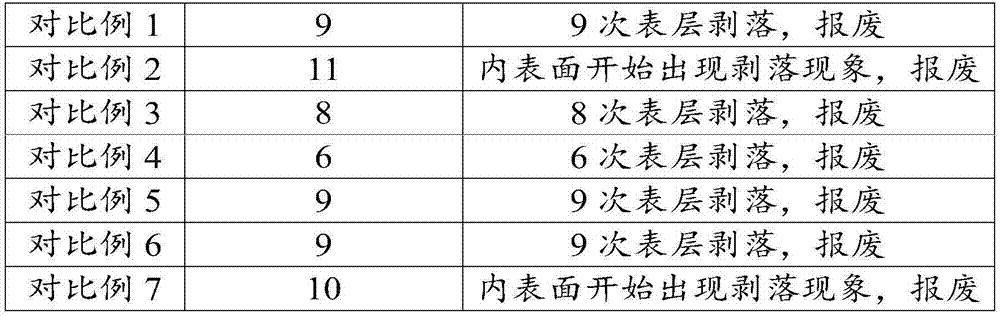

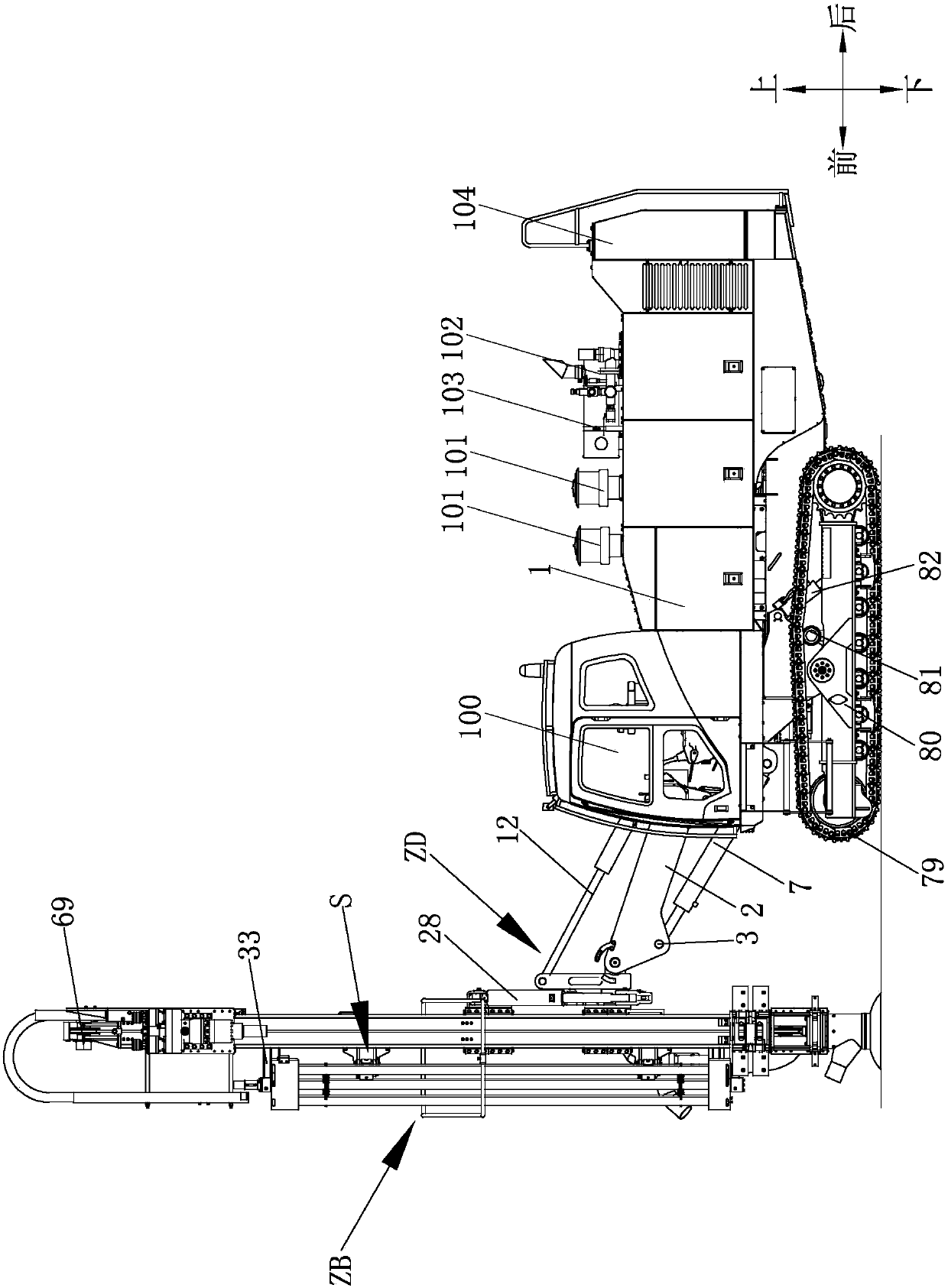

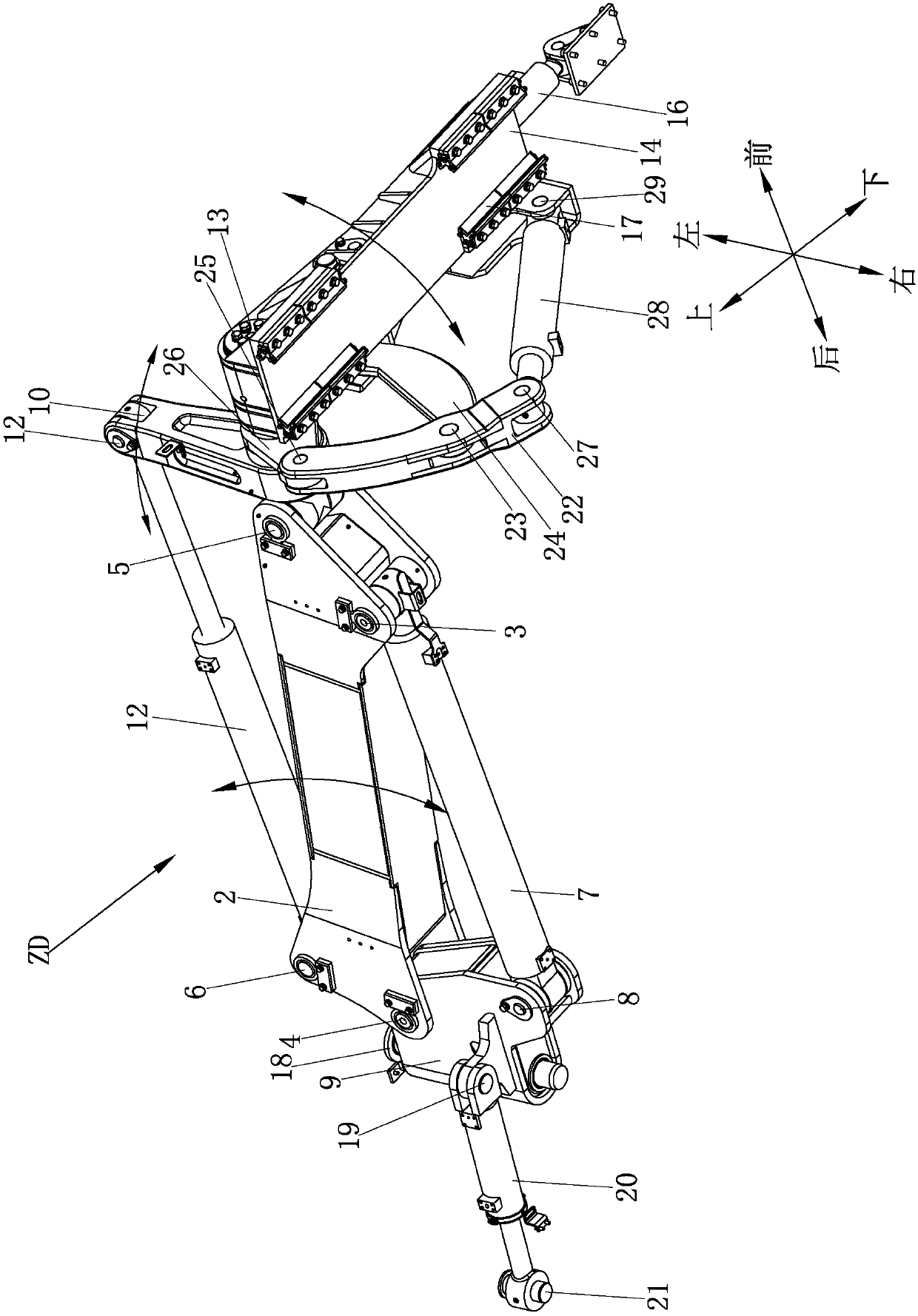

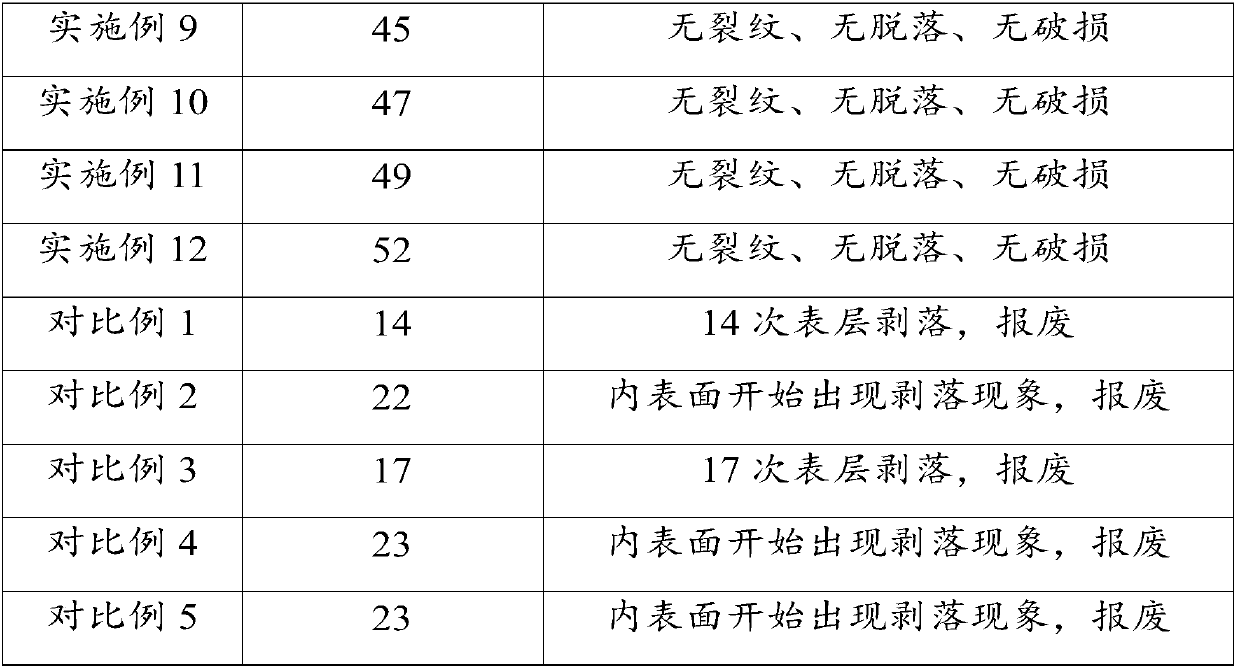

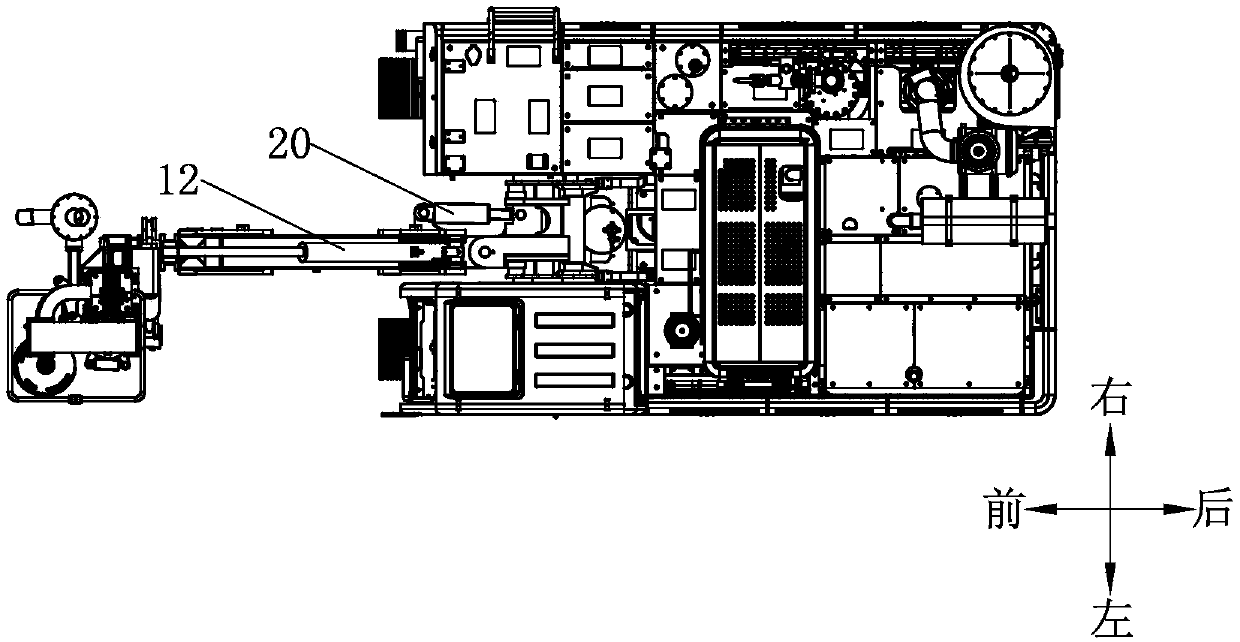

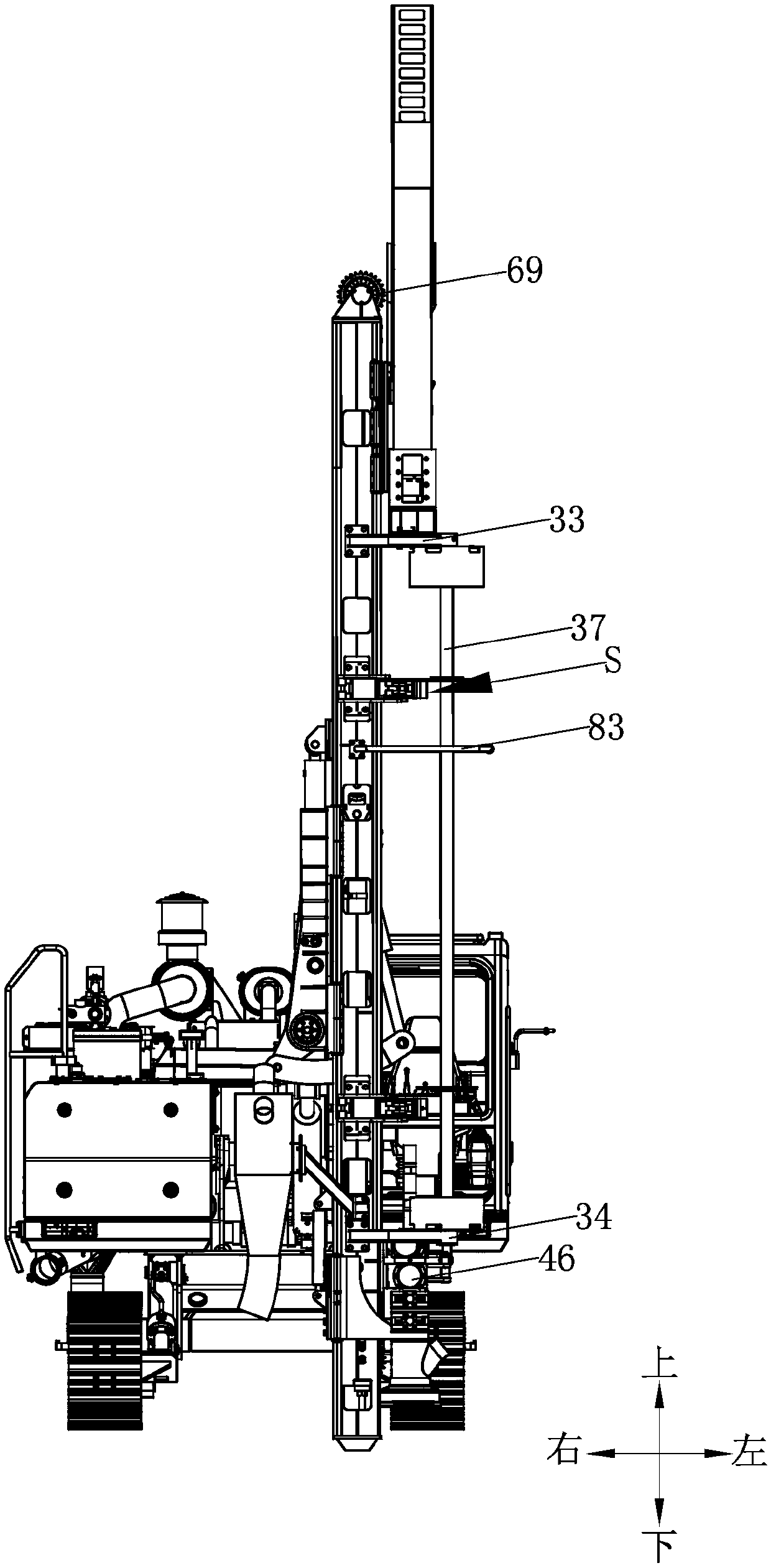

High-speed hydraulic drill with two engines

ActiveCN106014203AIncreased drilling depthReduce weightDrilling rodsConstructionsManipulatorEnergy consumption

The invention discloses a high-speed hydraulic drill with two engines. The high-speed hydraulic drill comprises a vehicle body and a drill arm assembly, wherein two engines are installed on the vehicle body, the vehicle body is installed on a chassis, and a left crawler unit and a right crawler unit are arranged on the chassis side by side; and a direct-acting arm assembly is arranged at the front part of the vehicle body, is connected with the drill arm assembly, and can drive the drill arm assembly to swing left and right, swing back and forth or move up and down. According to the drill arm assembly, a plurality of drill rods can be effectively connected through coordination of a drill pipe storage mechanism, a drill rod gripping manipulator and a disconnection rod device, thereby prolonging the total length of the drill rod; and a drill arm assembly feeding mechanism adopts a wire rope structure, and the wire rope is strong in impact resistance, convenient to replace and maintain and low in cost. A drill stand adopts an integral structure and is made of aluminum alloy, so that the weight of the high-speed hydraulic drill can be greatly reduced, the energy consumption of the entire vehicle can be effectively reduced, and the center of gravity of the entire vehicle can be prevented from facing forwards.

Owner:重庆勤牛工程机械有限责任公司

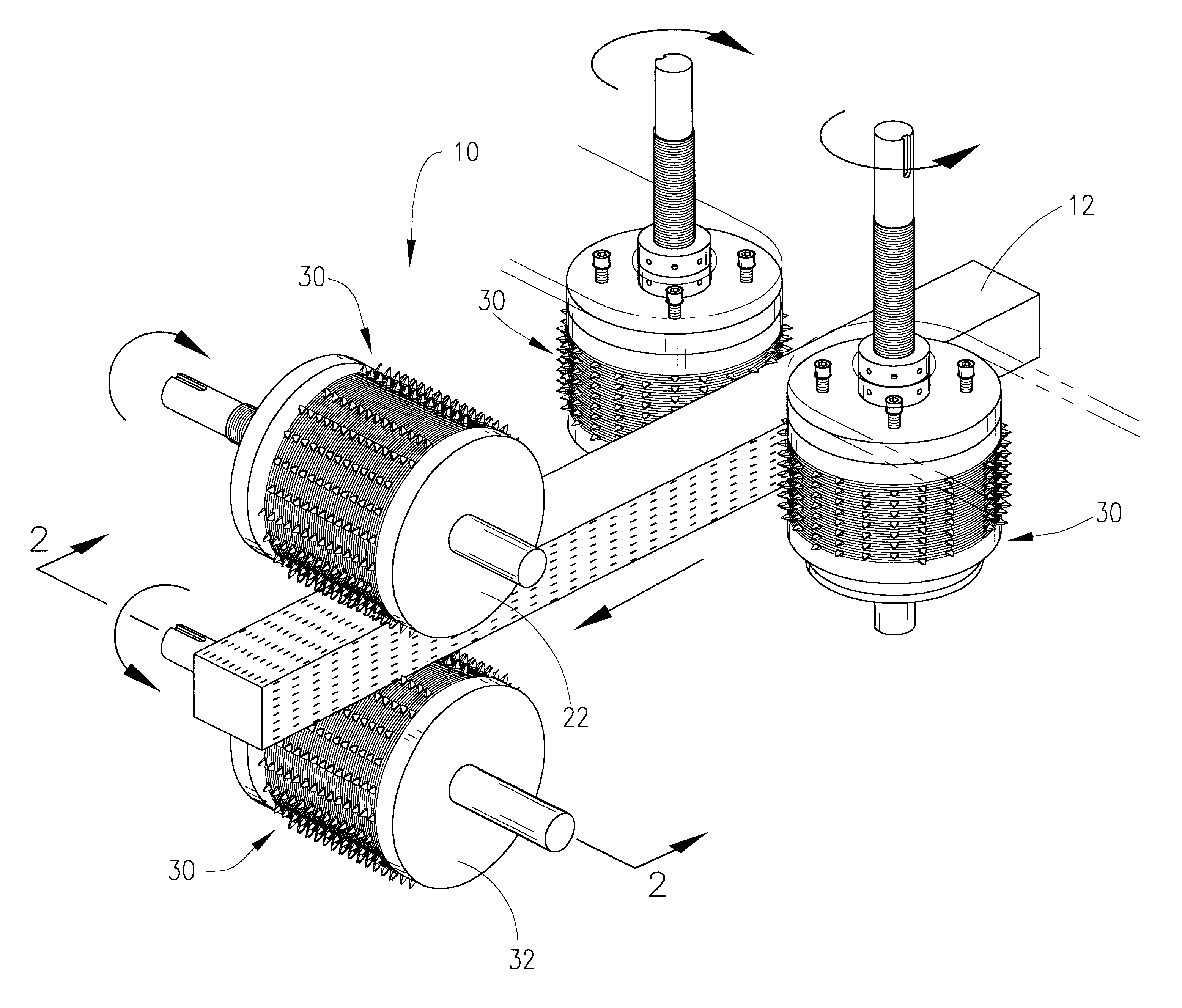

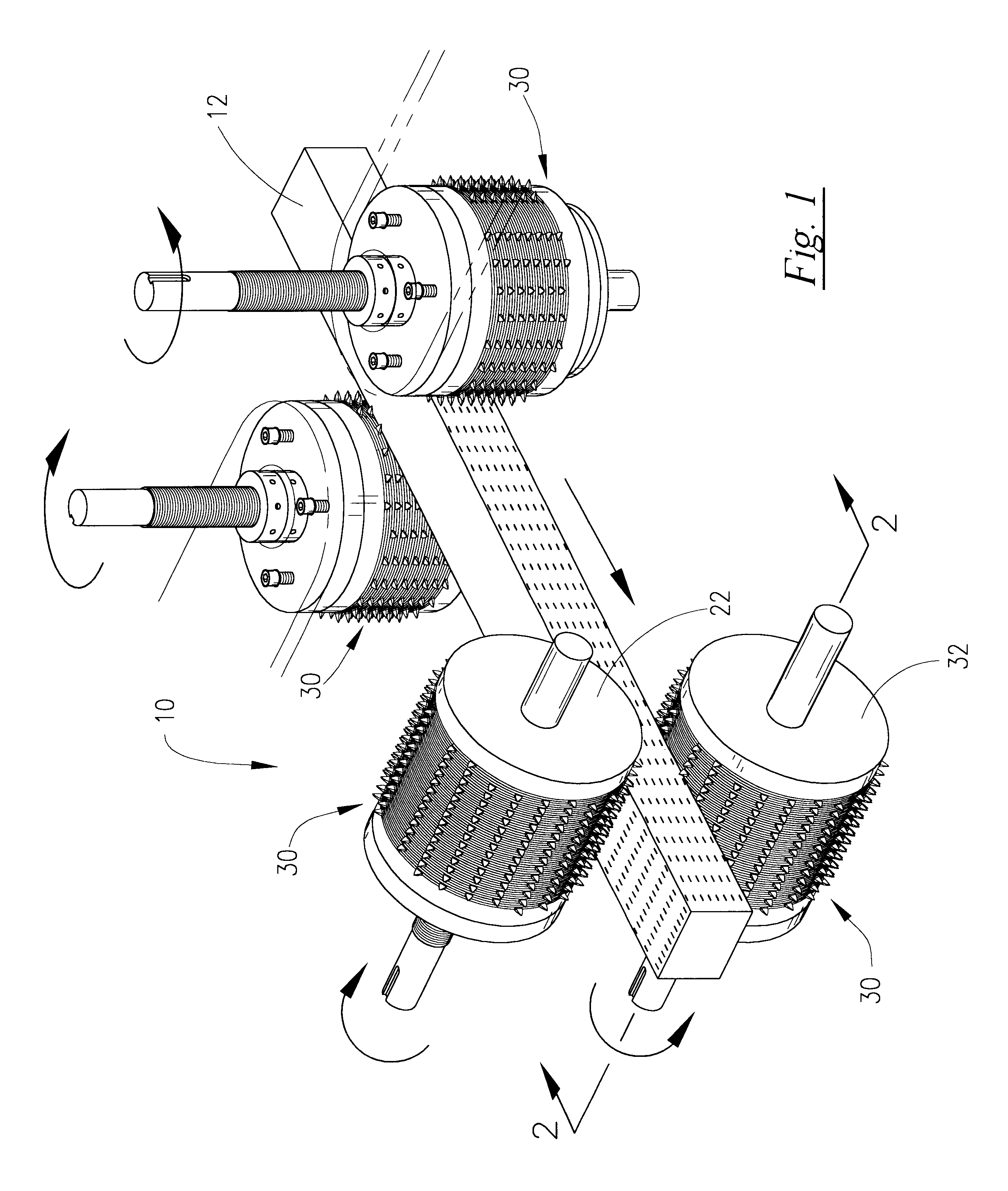

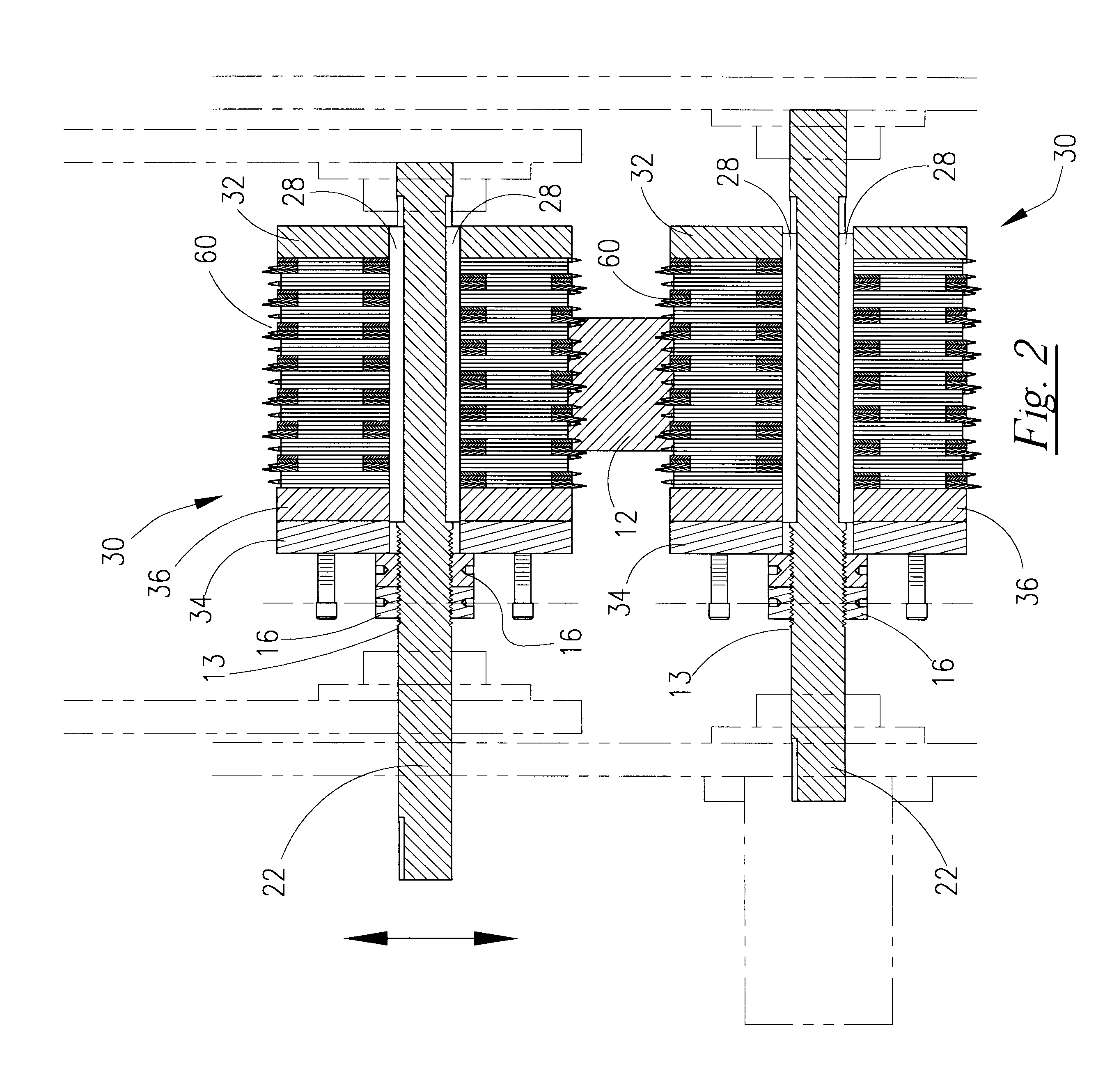

Timber incisor

InactiveUS6276412B1Less likely to bendLess likely to breakWooden sticks manufactureWood compressionEngineeringWood cutting

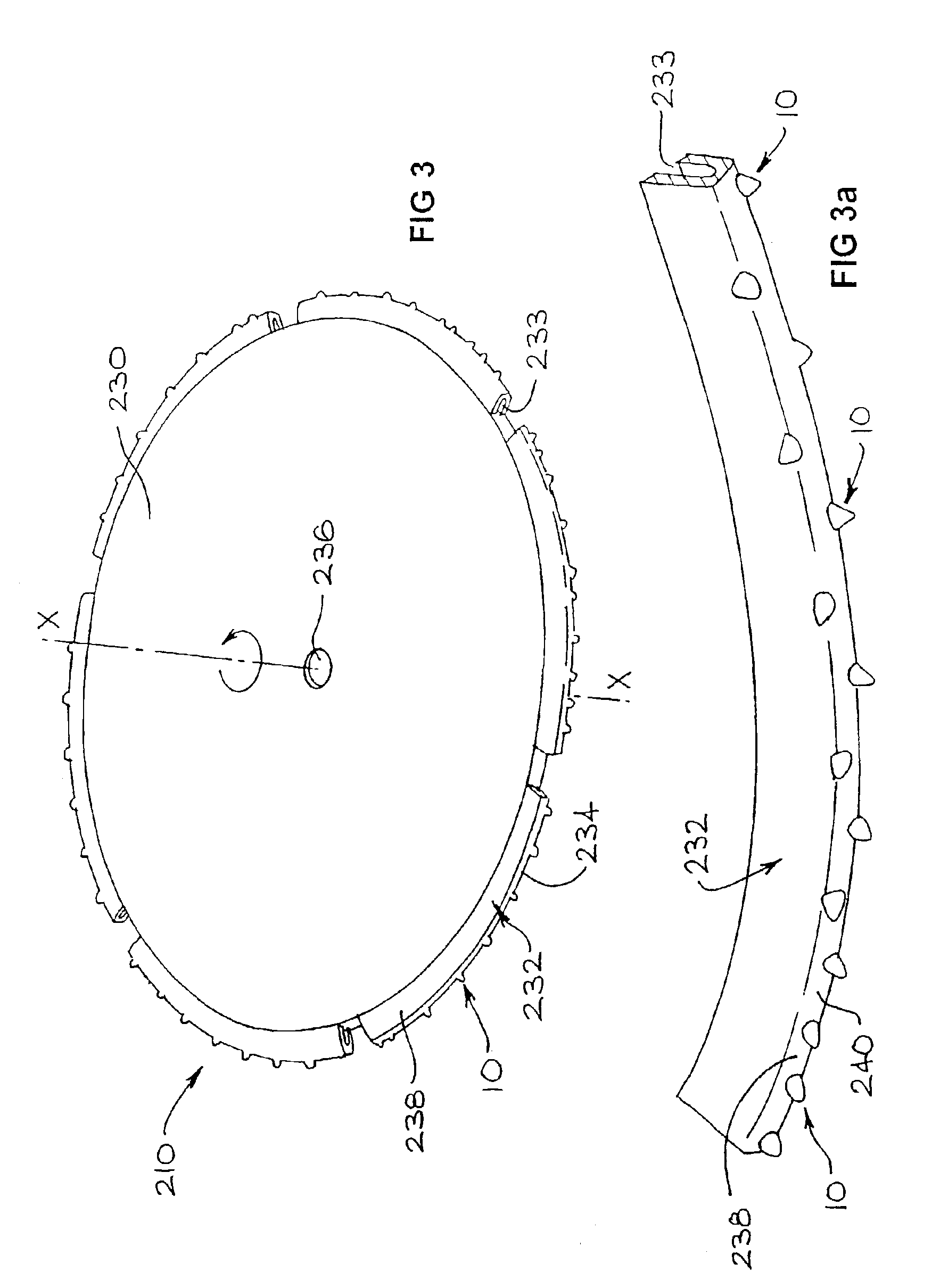

In a timber incising machine incorporating a shaft mounted rotating incisor drum, an improved incising drum comprising a shaft configured for rotation by the incising machine; a plurality of circular incisor plates, each of the incisor plates having a plurality of equally spaced incisor teeth extending radially from the radial edge of the circular incisor plates at a desired location. A plurality of incisor plates are stacked in a desired quantity and positioned to place the incisor teeth in a desired pattern and fixed together to form a plate array as a single unit. A plurality of the plate arrays are mounted on the shaft so as to form a rotatable drum having a plurality of radially extending incisor teeth positioned in a desired pattern.

Owner:RITA JOHNSTON & THE ESTATE OF JAMES JOHNSTON

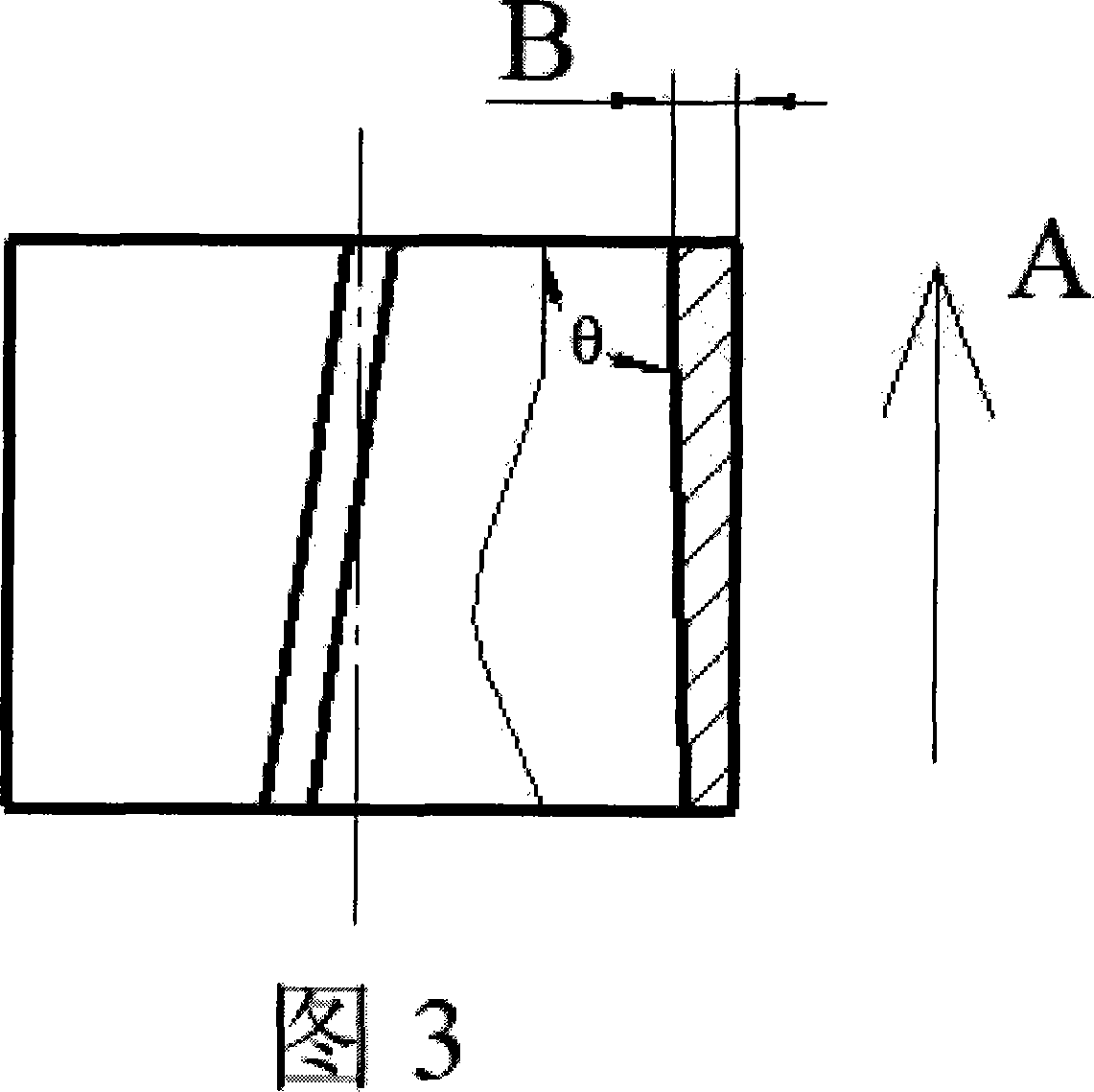

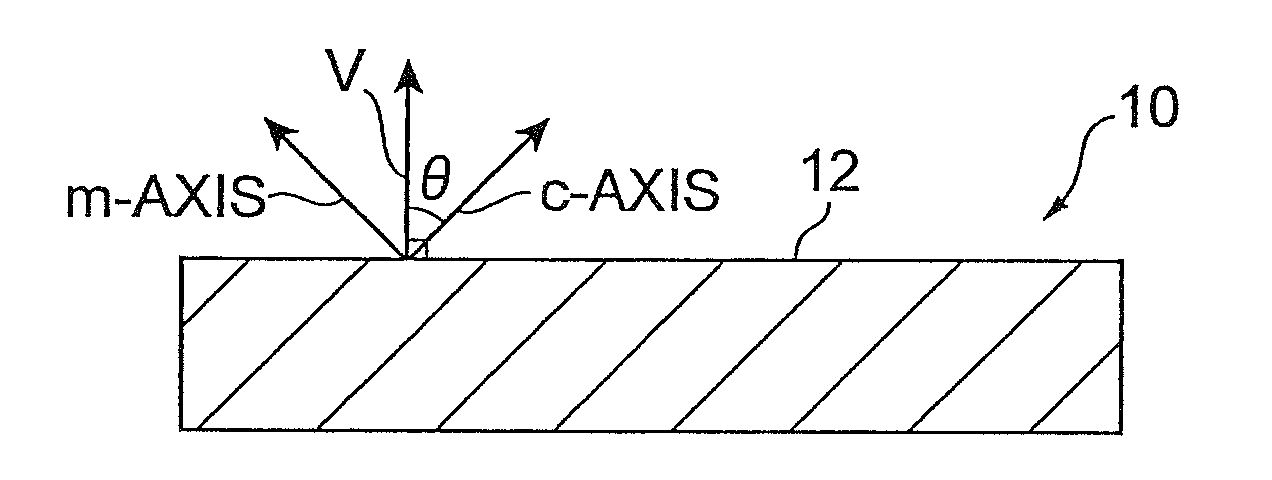

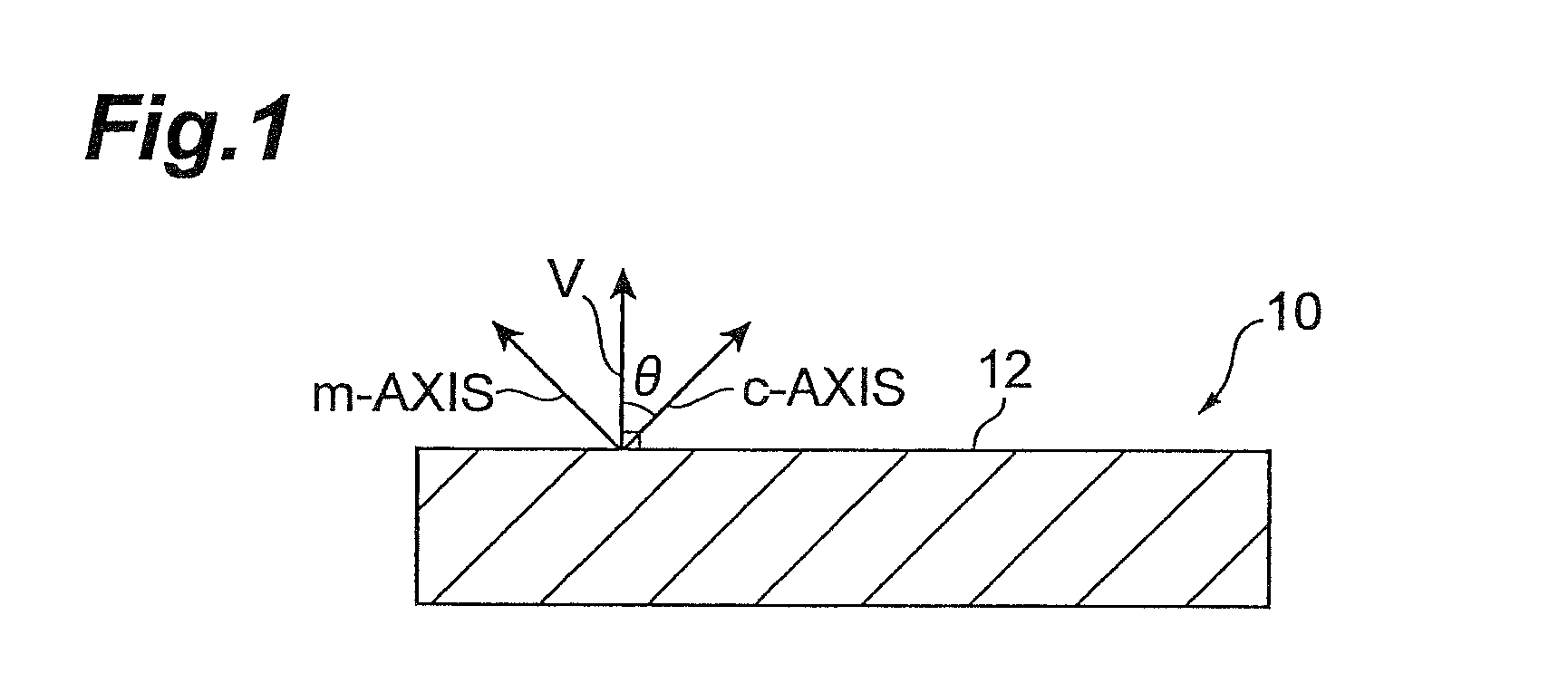

Gallium nitride substrate

ActiveUS20110073871A1Avoid crackingLess likely to breakPolycrystalline material growthAfter-treatment detailsGallium nitrideFracture toughness

A gallium nitride substrate comprising a primary surface, the primary surface being tilted at an angle in a range of 20 to 160 degrees with respect to a C-plane of the substrate, and the substrate having a fracture toughness of more than or equal to 1.36 MN / m3 / 2.

Owner:SUMITOMO ELECTRIC IND LTD

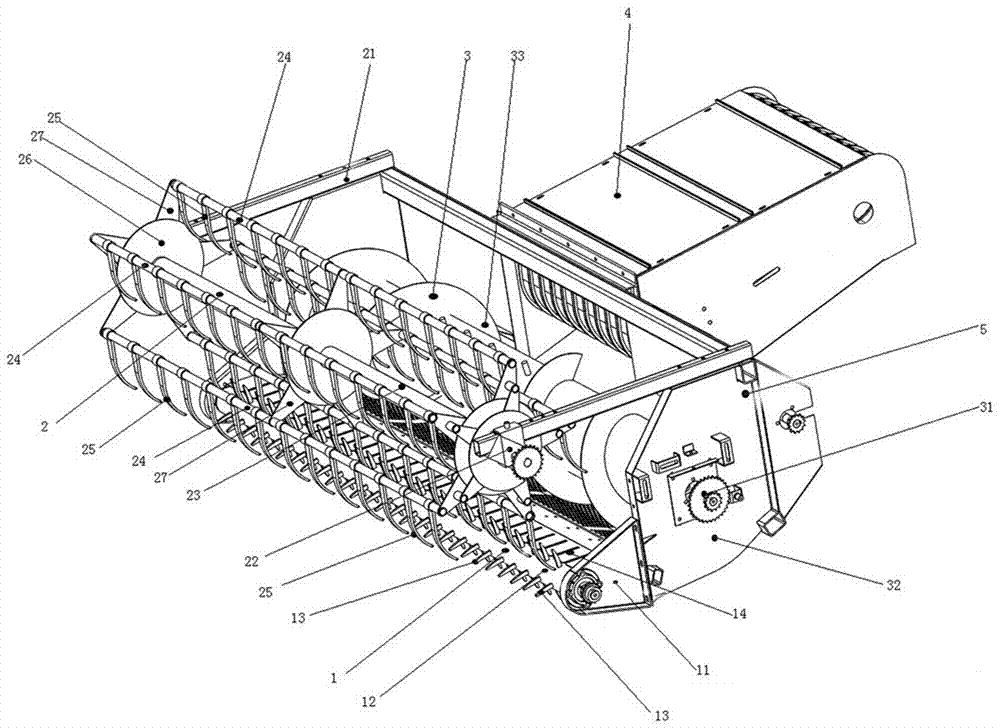

Pickup platform applicable to peanut harvesters

PendingCN107371557AEasy to installEasy maintenanceLoadersDigger harvestersPolyesterAgricultural engineering

The invention relates to a pickup platform applicable to peanut harvesters. The pickup platform comprises a pickup system, a conveying system and a frame; the pickup system and the conveying system are fixedly mounted through the frame; the pickup system is mounted in the front of the conveying system; the pickup system comprises a pickup device and a seedling shifting device; the conveying system comprises an auger device and a bridge cross device; the pickup device is arranged at the front bottom of the frame, and the seedling shifting device is arranged ahead of the pickup device and is located above the pickup device; the auger device is fittingly arranged under the seedling shifting device and is located in the rear of the pickup device; the bridge cross device is located in the rear of the auger device. The pickup platform is easy in mounting and simple in maintenance; meanwhile, the seedling-shifting elastic teeth are made from polyester elastic tooth materials, thereby being less prone to breakage in long-time operation.

Owner:PUYANG NONGFA MACHINERY MFG

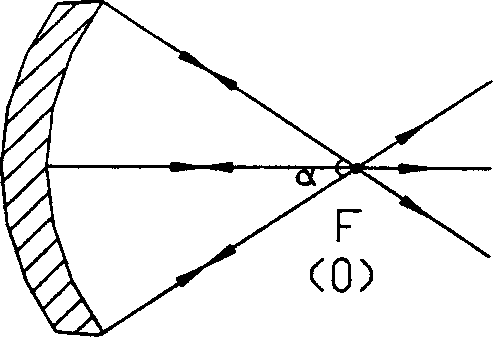

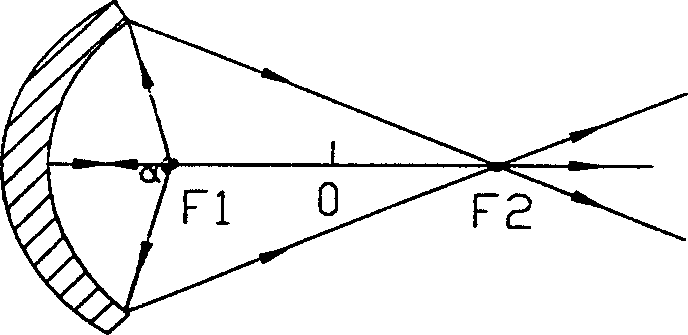

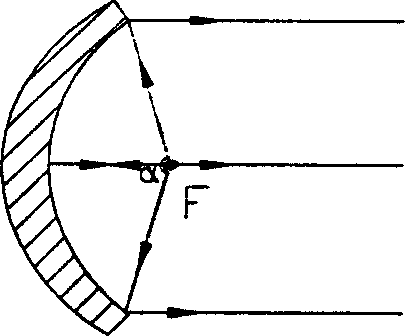

Curved reflector

This invention discloses a curved reflecting mirror, which is used to reflect the light from light source in the projection system. The inner surface of the said curved reflecting mirror serves as reflecting surface. The said curved surface comprises non-sphere mirror and sphere mirror, which are in same axis and their inner surfaces, are designed relatively and their focal point overlaps. And the said sphere mirror bottom is opened with a hole as light-out channel. The light source is located on the overlapping focal point. The said invention can increase light effect and prolong service life, and reduce cost and increase reflecting light uniformity.

Owner:罗筱泠

Anti-deformation solid wood core floor

InactiveCN104652776AWith anti-deformation functionSatisfied with the effectWood working apparatusWood layered productsSolid woodSurface layer

The invention relates to an anti-deformation solid wood core floor. The anti-deformation solid wood core floor comprises a veneer layer at the bottom, a surface layer of an upper surface layer, and a solid wood core material layer between the surface layer and the veneer layer, wherein balance layers are arranged between the surface layer and the solid wood core material layer, and between the veneer layer and the solid wood core material layer; a plurality of vertical anti-deformation saw cutting grooves are uniformly formed in the upper and lower surfaces of the solid wood core material layer along the transverse direction; the plurality of vertical anti-deformation saw cutting grooves in the upper surface of the solid wood core material layer and the plurality of vertical anti-deformation saw cutting grooves in the lower surface of the solid wood core material layer are mutually staggered; end part distances are reserved on the vertical anti-deformation saw cutting grooves in the upper and lower surfaces of the solid wood core material layer along the vertical two end parts of the solid wood core material layer. The anti-deformation solid wood core floor has the characteristics of high strength and strong anti-deformation capability; a phenomenon that a wood edge of a locking part is broken is unlikely to occur; the structure is stable and the locking is firm. A wood strip edge frame does not need to be additionally spliced and the industrial automatic production can be realized; the effect of solid wood floors is met and the anti-deformation solid wood core floor is suitable for mounting a heating floor and woods are saved; the yield is improved and the cost is reduced.

Owner:江苏德威木业有限公司

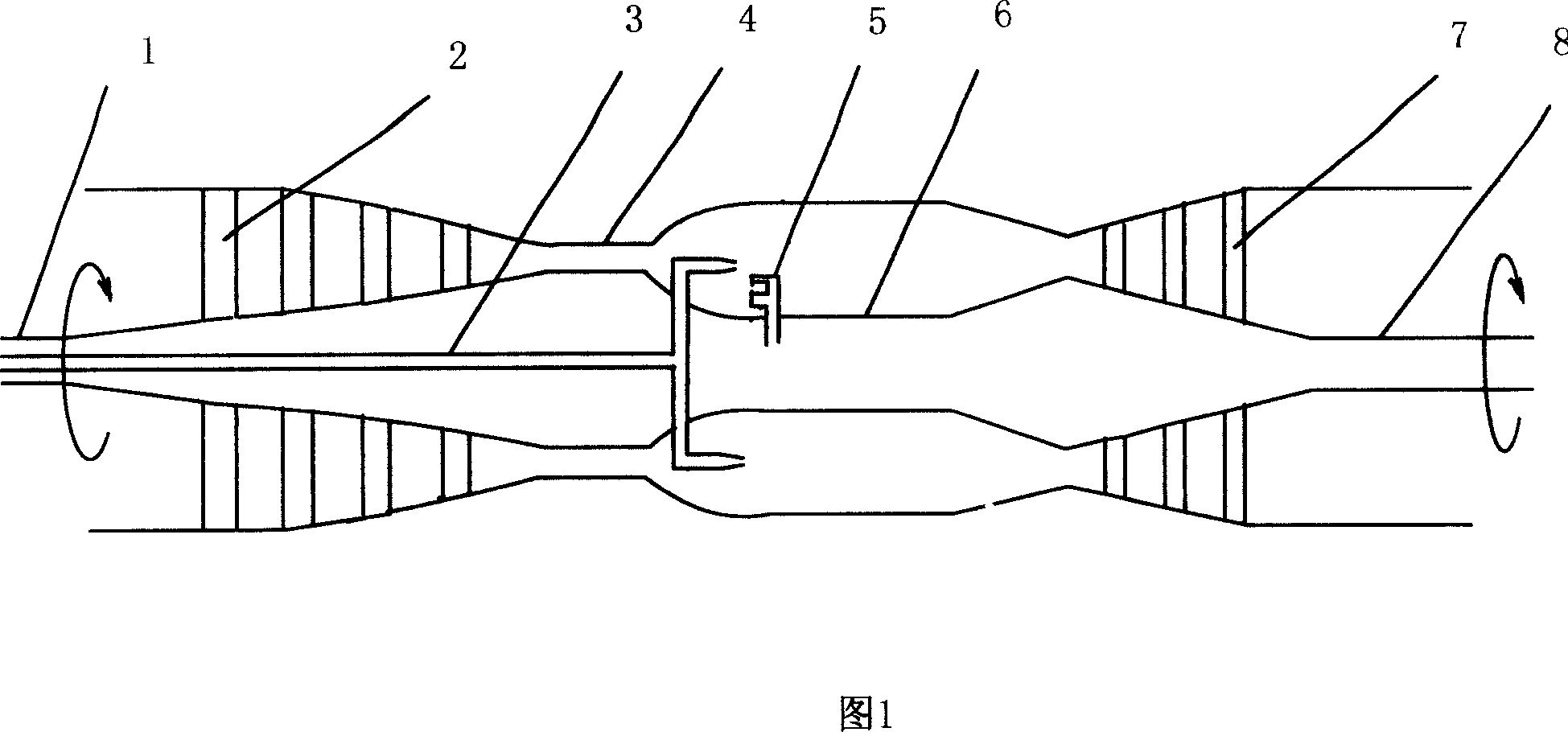

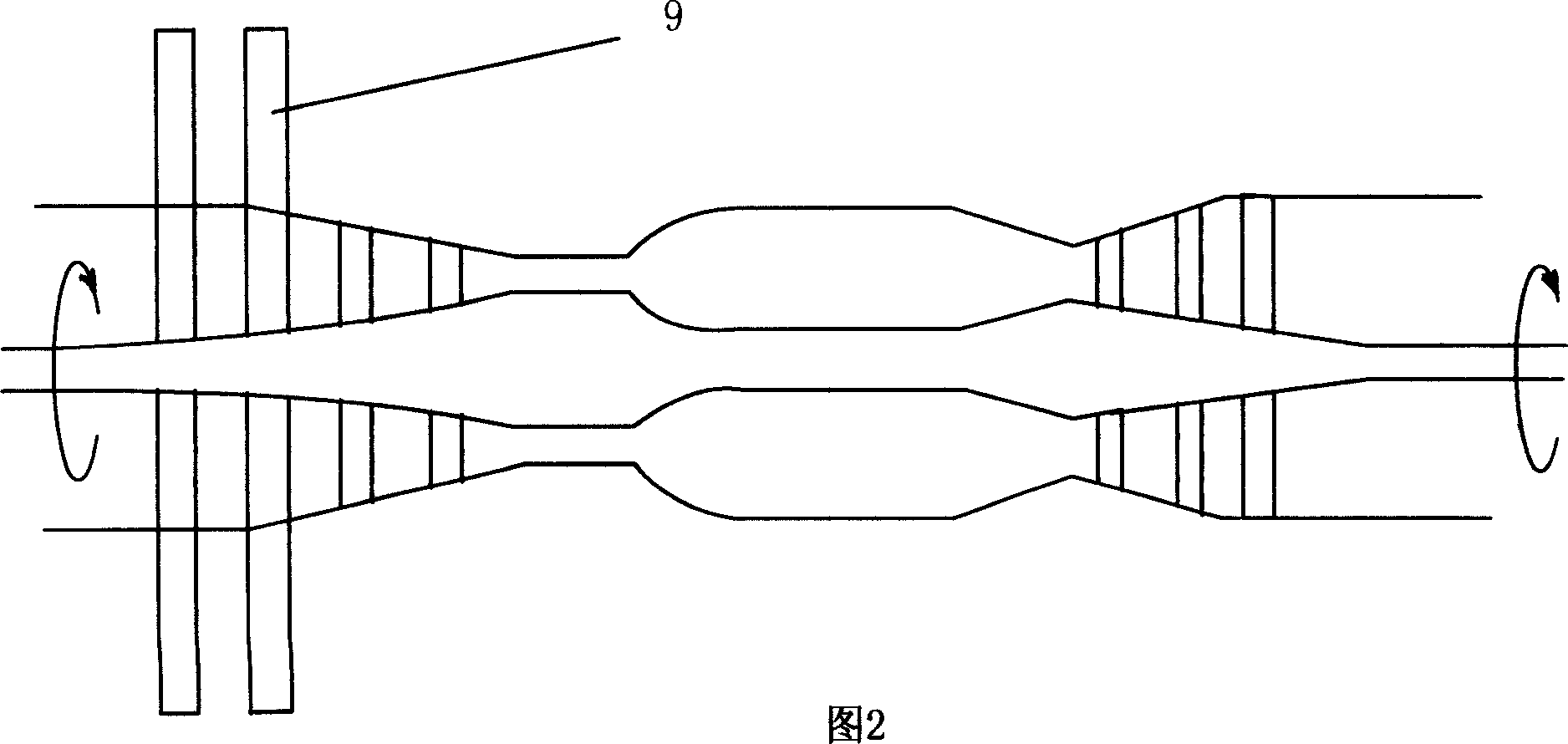

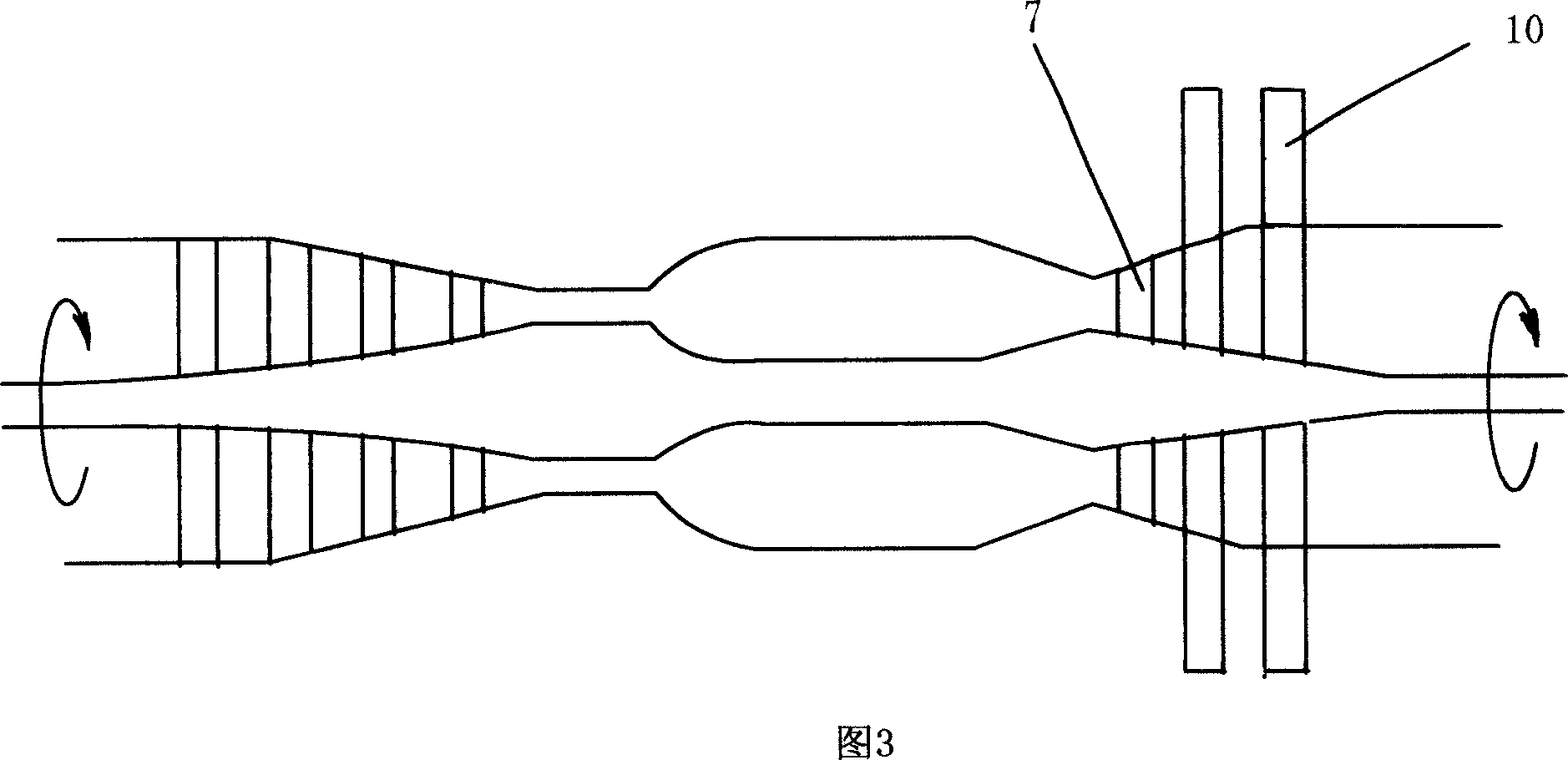

Rotary jet engine

InactiveCN1924319AEasy to dissipate heatRaise the initial gas temperatureGas turbine plantsNozzleRotary engine

Owner:李志文

Wear resistant cast steel for agricultural machinery subsoiler and heat treatment process thereof

The invention discloses wear resistant cast steel for agricultural machinery subsoiler. The wear resistant cast steel comprises the following chemical components in percentage by weight: 0.29-0.34 of C, 0.40-0.50 of Si, 1.45-1.60 of Mn, 0.65-0.80 of Cr, S not more than 0.020, P not more than 0.020, and the balance of Fe and inevitable impurities. The subsoiler prepared by the wear resistant cast steel is heated by an electric furnace after casting, cleaning, polishing and machining; and the heat treatment process comprises the following steps: (1) total annealing: the temperature of the furnace is heated to reach 900-920 DEG C, and is insulated by 3 h; and the subsoiler is discharged from the furnace for air cooling after being cooled below 300 DEG C along with the furnace; (2) normalizing: the temperature of the furnace is heated to reach 880-900 DEG C, and is insulated by 2 h; and the subsoiler is discharged from the furnace for air cooling; (3) quenching: the temperature of the furnace is heated to reach 860-880 DEG C, and is insulated by 2 h; and the subsoiler is discharged from the furnace for liquid cooling; and (4) tempering: the temperature of the furnace is heated to reach 240-250 DEG C, and is insulated by 3 h; and the subsoiler is discharged from the furnace for air cooling. Through reasonable matching of the chemical components and the heat treatment process, the subsoiler is higher in hardness and tensile strength, is excellent in impact toughness, and is low in manufacturing cost.

Owner:LANZHOU LS GRP +1

Wheel-arch protector for vehicle

ActiveUS8172306B2Less likely to breakImprove sound insulationWindowsEngine sealsMechanical engineeringEngineering

Owner:HONDA MOTOR CO LTD +1

Corrosion-resistant saggar as well as preparation method and application thereof

ActiveCN108083824AImprove corrosion resistanceImprove thermal shock resistanceElectrode thermal treatmentCoesiteRefractory

The invention relates to the field of refractory materials and particularly provides a corrosion-resistant saggar as well as a preparation method and an application thereof. The corrosion-resistant saggar comprises a bottom material and a surface material, wherein the bottom material is mainly prepared from specific content of kaolin, talc, alpha-alumina, high bauxite, high bauxite with the particle size not larger than 0.5 mm, flint clay with the particle size not larger than 1 mm and flint clay with the particle size being 1-2 mm; the surface material is mainly prepared from specific contentof alumina with the particle size not larger than 0.7 mu m, alpha-alumina with the particle size not larger than 46.9 mu m, zirconium silicate with the particle size not larger than 46.9 mu m, zirconium silicate with the particle size not larger than 1 mm and cordierite with the particle size being 0.5-1.25 mm. The corrosion-resistant saggar has the advantages of low cost, high cost performance,good corrosion resistance and long service life.

Owner:ZHEJIANG UNIV

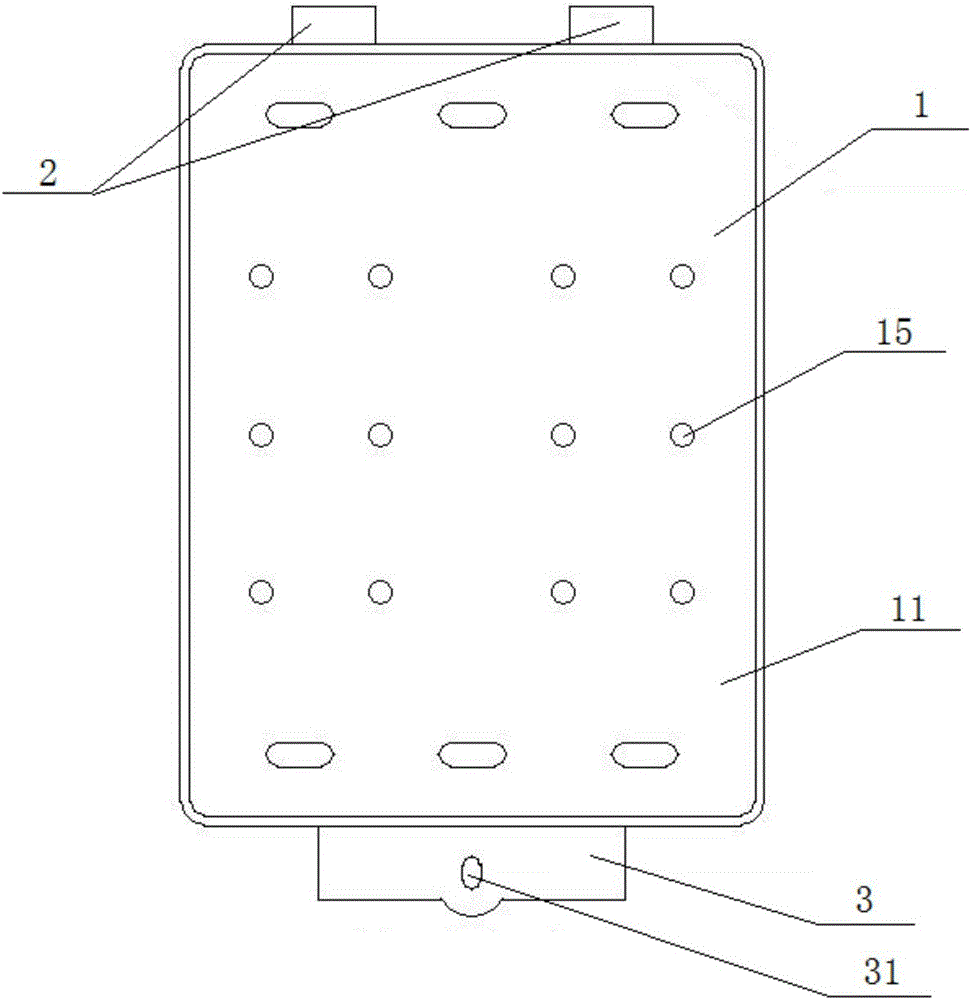

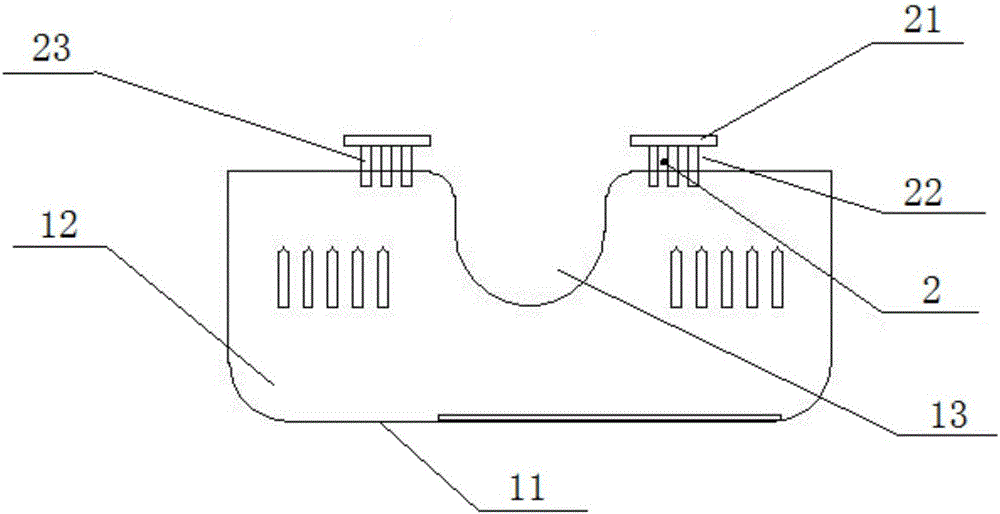

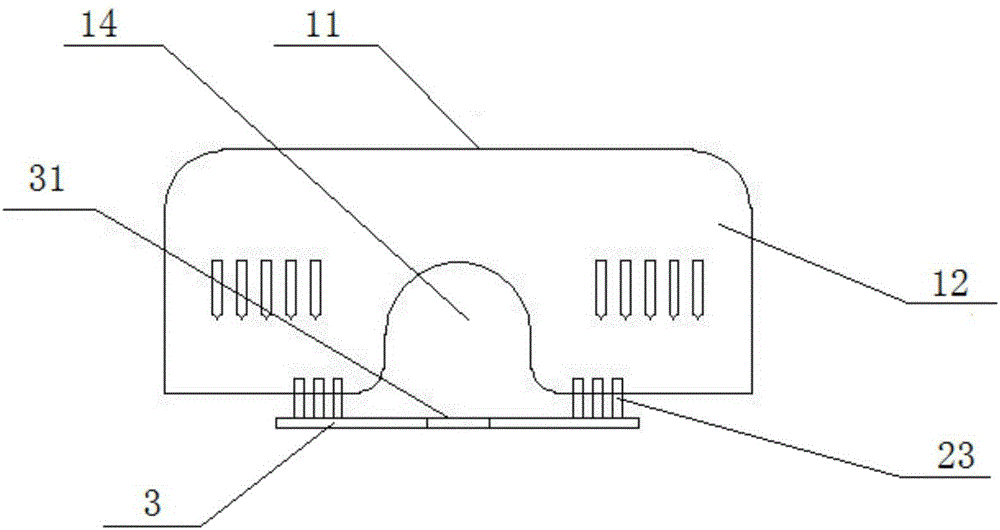

Buckle-type control box used for being connected with frame of electric vehicle

InactiveCN106218773AEasy to operateSave manpower and material resourcesAcoustic signalElectric/fluid circuitVehicle frameEngineering

The invention provides a buckle-type control box used for being connected with the frame of an electric vehicle. The buckle-type control box comprises a box body, buckles and a buckle tongue, the box body comprises a cover plate and a side enclosure wall which are enclosed to form a rectangular box structure, an upper cable entry hole is formed in the middle of the side enclosure wall on the upper side, a lower cable entry hole is formed in the middle of the side enclosure wall on the lower side, each of the left and right sides of the upper cable entry hole is provided with one buckle connected with the frame, a buckle gap is reserved between a buckle plate of the buckles and the side enclosure wall, the buckle tongue protruding downwards and outwards connected to the position of the lower cable entry hole is arranged on the side enclosure wall, and a fixing screw hole used for being connected with the frame is arranged in the middle of the buckle tongue. The buckle-type control box has the advantages that the buckle-type control box is fixed with the frame only by screwing a screw in a fixed screw hole of the buckle tongue, convenience in operation is achieved, environmental monitoring alarm can be performed, and a controller is enabled to run in safe external environment.

Owner:小刀科技股份有限公司

Combination saggar and production method and application thereof

The invention relates to the field of refractory materials, in particular to a combination saggar and a production method and application thereof. The combination saggar comprises a base material anda face material; the base material is mainly prepared from, by specific contents, kaolin, talcum, alpha-alumina, bauxite, bauxite not greater than 0.5 mm in particle size, flint clay not greater than1 mm in particle size, and flint clay 1-2 mm in particle size; the face material is mainly prepared from, by specific contents, spinel not greater than 13 mu m in particle size, alpha-alumina, spinelnot greater than 46.9 mu m in particle size, spinel not greater than 1 mm in particle size, and cordierite 0.5-1.25 mm in particle size. The combination saggar has the advantages of low cost, high cost performance, good corrosion resistance and long service life.

Owner:ZHEJIANG UNIV

High-speed hydraulic drilling rig with monomotor

ActiveCN105909170ALow operating environment requirementsExpand the scope of workDrilling rodsConstructionsAlloyManipulator

The invention discloses a high-speed hydraulic drilling rig with a monomotor. The high-speed hydraulic drilling rig comprises a vehicle body and a drilling boom assembly, wherein an engine is mounted on the vehicle body, the vehicle body is mounted on a chassis, and a left crawler travel device and a right crawler travel device are arranged on the chassis side by side; a straight movable boom assembly is arranged at the front part of the vehicle body, is connected with the drilling boom assembly, and can drive the drilling boom assembly to swing left and right, swing front and back, and rise and fall down. According to the drilling boom assembly of the high-speed hydraulic drilling rig disclosed by the invention, a drilling warehouse mechanism, drilling rod grabbing manipulators and disassembling and connecting rod devices are matched, so that a plurality of drilling rods can be effectively connected, and the total length of the drilling rods can be extended; a drilling boom assembly feeding mechanism adopts a steel rope structure, steel ropes are high in impact resistance, convenient to exchange and repair, and low in cost. A drilling frame adopts an integral structure and is made of aluminum alloys, so that the weight of the high-speed hydraulic drilling rig disclosed by the invention can be substantially reduced, the energy consumption of the complete vehicle can be effectively reduced, and the situation that the center of gravity of the complete vehicle faces forward can be avoided.

Owner:重庆勤牛工程机械有限责任公司

Aluminium titanate-spinel saggar, preparation method and application thereof

ActiveCN108033787AGood heat resistanceGood thermal shock resistanceCharge supportsTitanium dioxideSaggar

The invention relates to the field of refractory kilns and particularly provides an aluminium titanate-spinel saggar, a preparation method and application thereof. The aluminium titanate-spinel saggaris mainly prepared from the following raw materials in parts by mass: 25-35 parts of aluminium titanate, 15-25 parts of spinel with the particle diameter being not more than 1mm, 20-30 parts of spinel with the particle diameter being not more than 46.9mu m, 8-12 parts of titanium dioxide, 12-16 parts of aluminium oxide, 0.5-1.5 parts of magnesium oxide powder and 2-4 parts of yellow dextrin. Thealuminium titanate-spinel saggar provided by the invention has the advantages of strong corrosion resistance, good heat stability, long service life and low use cost, and has the beneficial effects that the source of all the raw materials is wide, and the price is low, so that the production cost of the saggar is also lower.

Owner:ZHEJIANG UNIV

A high-speed hydraulic drilling rig with twin engines

ActiveCN106014203BLow operating environment requirementsExpand the scope of workDrilling rodsConstructionsTape speedGravity center

The invention discloses a high-speed hydraulic drill with two engines. The high-speed hydraulic drill comprises a vehicle body and a drill arm assembly, wherein two engines are installed on the vehicle body, the vehicle body is installed on a chassis, and a left crawler unit and a right crawler unit are arranged on the chassis side by side; and a direct-acting arm assembly is arranged at the front part of the vehicle body, is connected with the drill arm assembly, and can drive the drill arm assembly to swing left and right, swing back and forth or move up and down. According to the drill arm assembly, a plurality of drill rods can be effectively connected through coordination of a drill pipe storage mechanism, a drill rod gripping manipulator and a disconnection rod device, thereby prolonging the total length of the drill rod; and a drill arm assembly feeding mechanism adopts a wire rope structure, and the wire rope is strong in impact resistance, convenient to replace and maintain and low in cost. A drill stand adopts an integral structure and is made of aluminum alloy, so that the weight of the high-speed hydraulic drill can be greatly reduced, the energy consumption of the entire vehicle can be effectively reduced, and the center of gravity of the entire vehicle can be prevented from facing forwards.

Owner:重庆勤牛工程机械有限责任公司

Composite box bowl, preparation method and application

The invention relates to the field of refractory materials, in particular to a combination saggar and a production method and application thereof. The combination saggar comprises a base material anda face material; the base material is mainly prepared from, by specific contents, kaolin, talcum, alpha-alumina, bauxite, bauxite not greater than 0.5 mm in particle size, flint clay not greater than1 mm in particle size, and flint clay 1-2 mm in particle size; the face material is mainly prepared from, by specific contents, spinel not greater than 13 mu m in particle size, alpha-alumina, spinelnot greater than 46.9 mu m in particle size, spinel not greater than 1 mm in particle size, and cordierite 0.5-1.25 mm in particle size. The combination saggar has the advantages of low cost, high cost performance, good corrosion resistance and long service life.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com