Cutting method and cutting apparatus for layered sheet, layered sheet, optical element and image display

A technology of optical components and laminations, applied in optics, polarizing components, metal processing, etc., can solve problems such as large cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

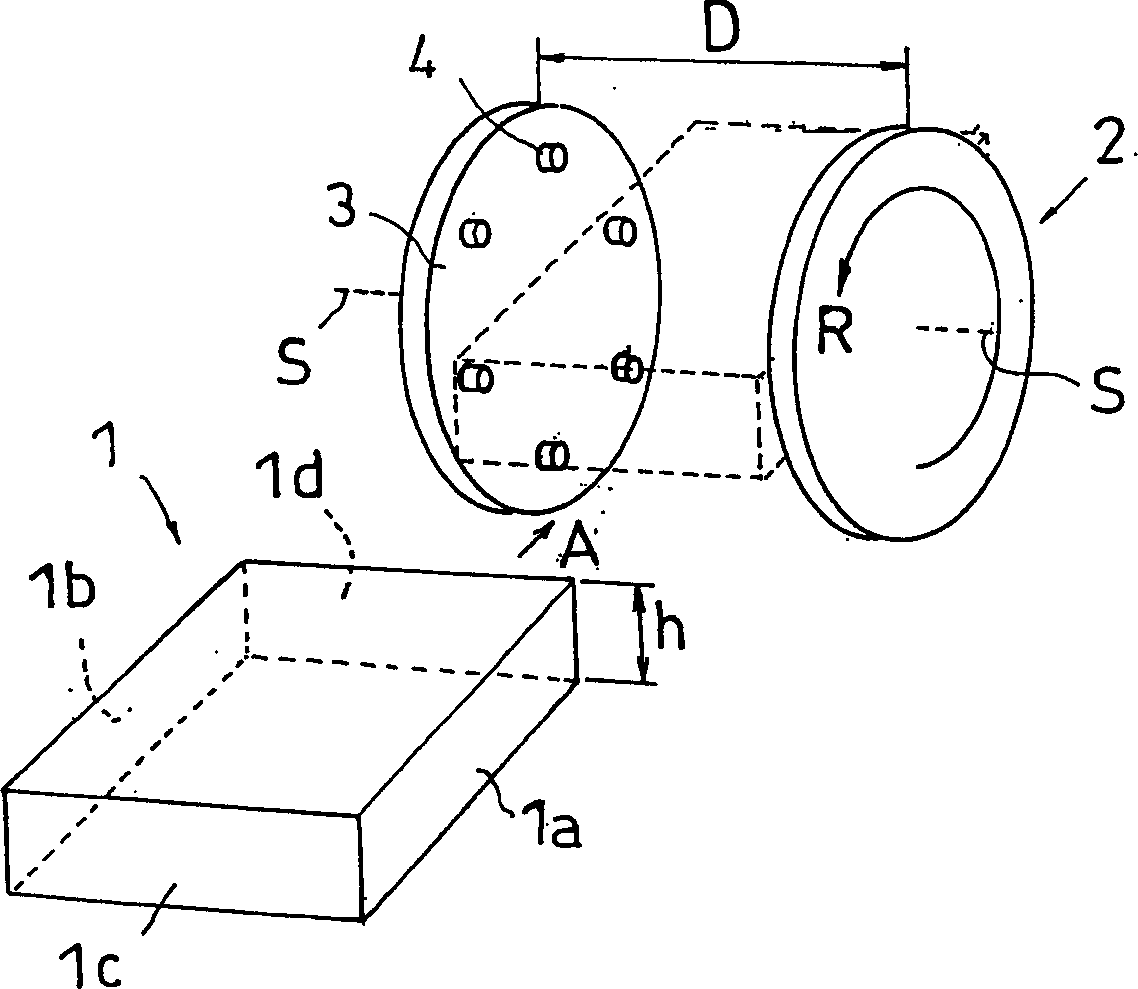

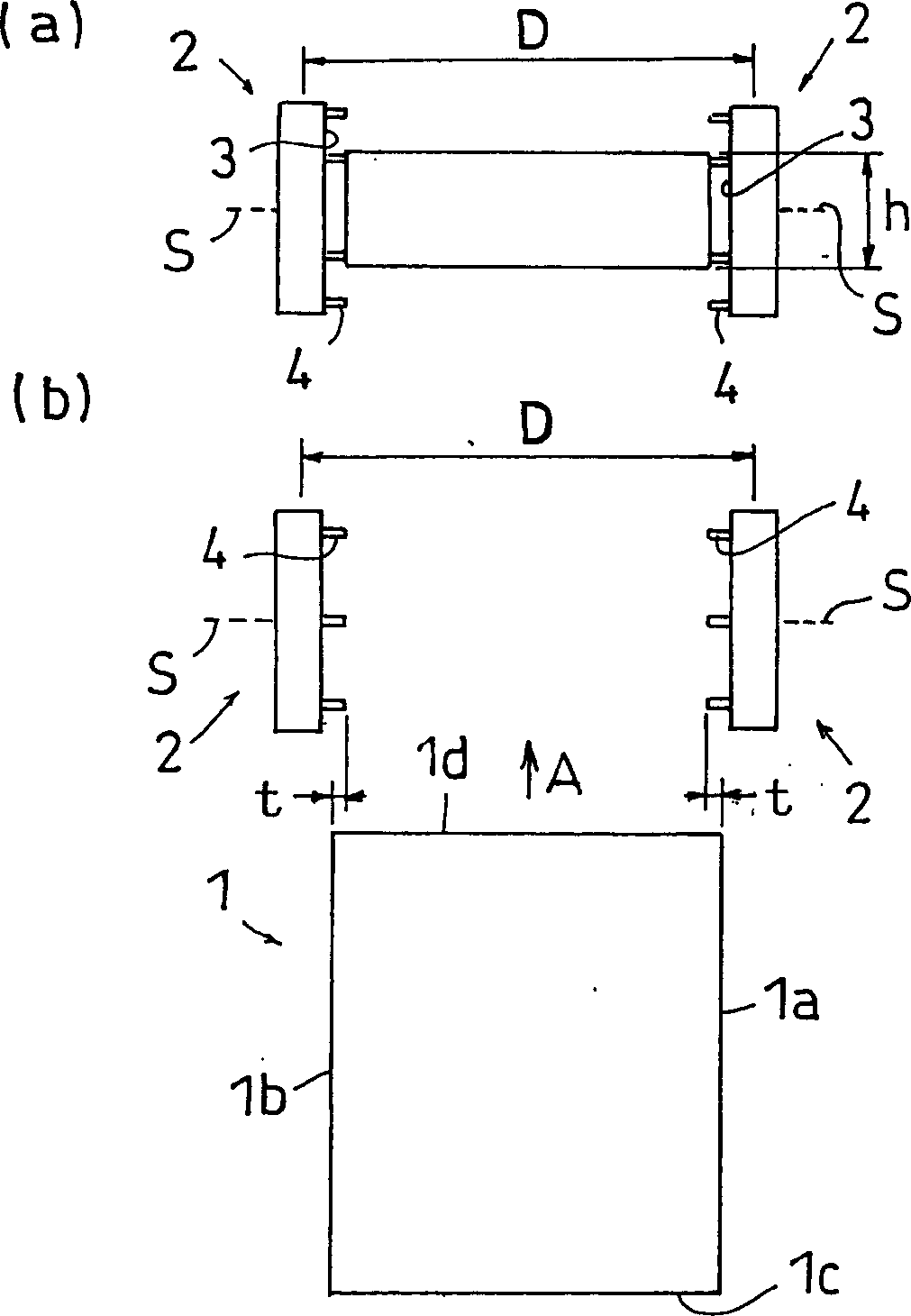

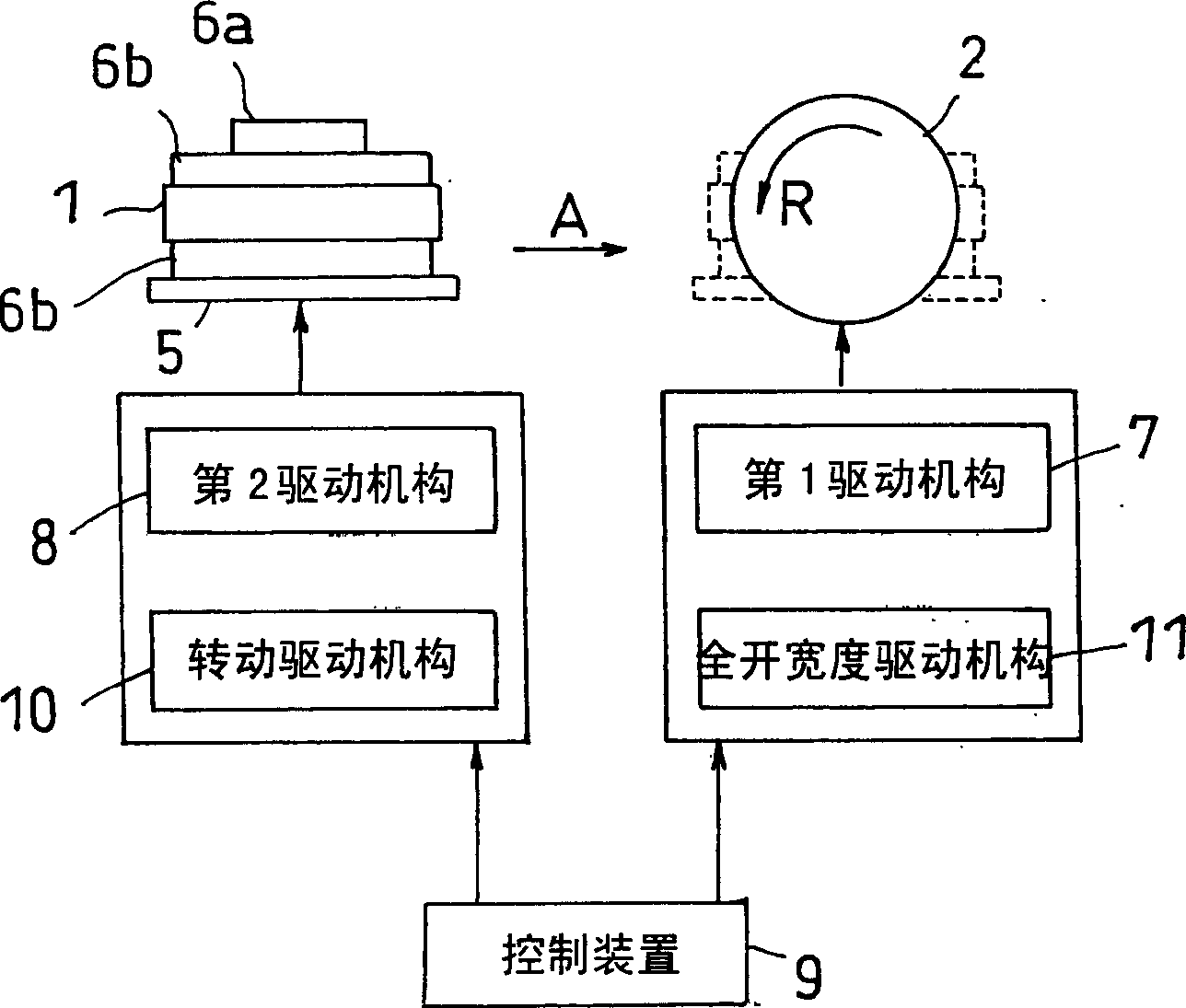

Method used

Image

Examples

Embodiment approach

[0092] (1) In the above-mentioned embodiment, the example in which cutting is performed by moving the workpiece 1 toward the cutting member side is described, but the present invention is not limited thereto, and the cutting member 2 may be moved toward the workpiece 1. Direction movement for cutting. In addition, it is not limited to the example of carrying the workpiece 1 between a pair of cutting members 2 as shown in the above-mentioned embodiment, and it is also possible to use one cutting member 2 for processing, or use a plurality of cutting members 2 for one cutting surface. And for processing. Furthermore, the cutting member 2 can be relatively moved in a direction substantially perpendicular to the cutting surface.

[0093] (2) In the cutting machine of the present invention, the second drive mechanism 8 may also function as the rotation drive mechanism 10, or may be provided independently. The same applies to the first drive mechanism 7 and the full-open width dri...

Embodiment 1~5

[0098] Thirty sheets of the above-mentioned polarizing plates cut to 310 mm x 235 mm were stacked in the thickness direction, and cut to 305 mm x 230 mm according to the above-mentioned embodiment. When performing the cutting process, the rotational speed of the cutting member and the moving speed of the base were set to the conditions shown in Table 1, and were used as Examples 1 to 5, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com