Rotary jet engine

A technology of rotary jet and engine, which is applied in the direction of machines/engines, gas turbine devices, mechanical equipment, etc. It can solve the problems of complex structure of turbine and compressor, limitation of engine power and efficiency, easy to be burned by high-temperature gas, etc., and achieve weight reduction , Improve the initial temperature of gas, low cost and technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

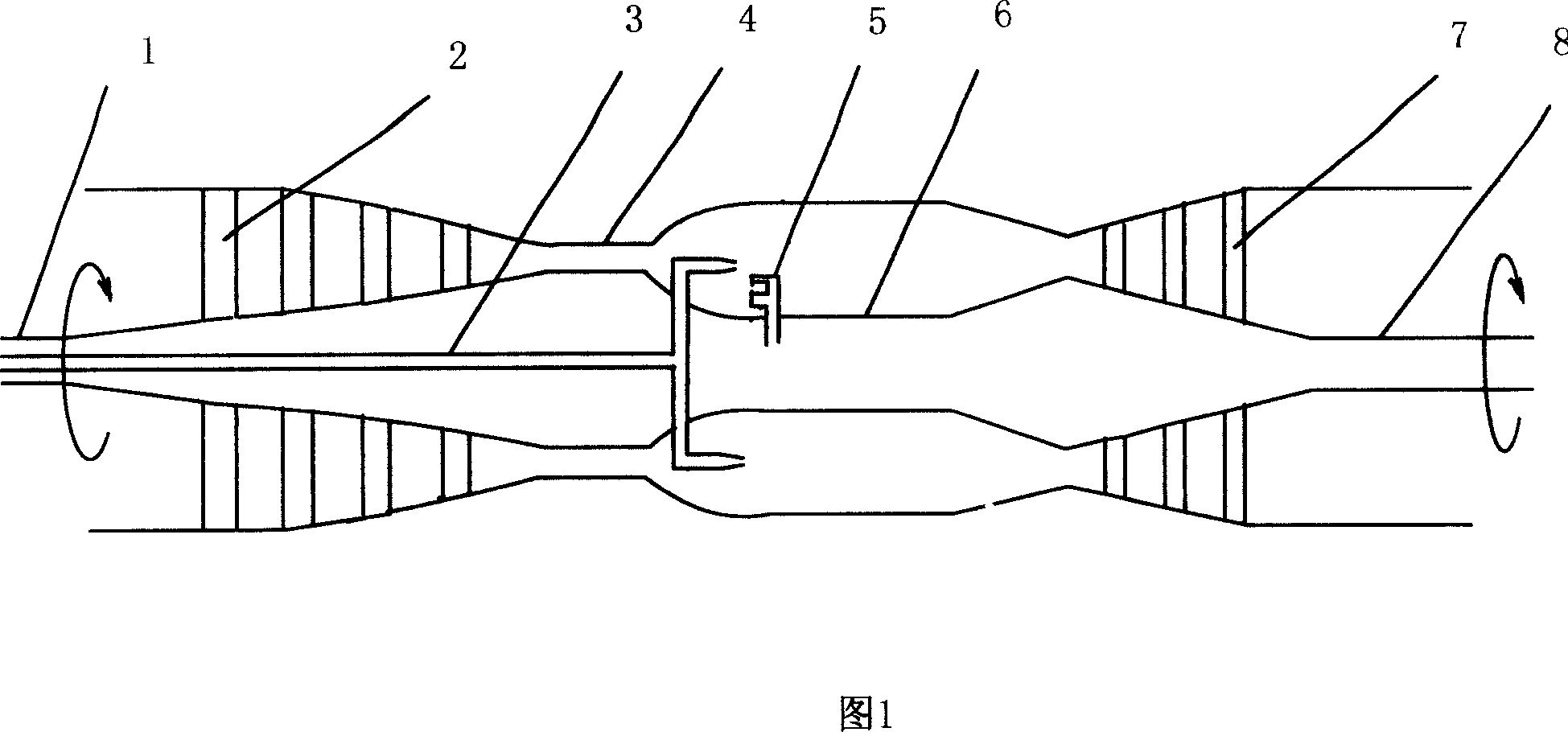

[0011] The present invention is different from the traditional turbojet engine, the traditional turbojet engine realizes the working cycle by driving the compressor to rotate through the rotating shaft through the turbine, while other parts of the engine are stationary, while the present invention is made by the blades (7) at the rear of the combustion chamber The inner wall (6) and the outer wall (4) drive the blade (2) to rotate around the axis, that is, the whole engine is rotated to realize the work cycle. The whole engine is a rotor, that is to say, the blade (2) and the blade ( 7) The two ends are respectively connected with the inner wall (6) and the outer wall (4), and the inner wall (6) is formed by connecting the inner wall of the compressor, the inner wall of the combustion chamber and the inner wall of the nozzle, and the outer wall (4) is formed by the inner wall of the compressor The outer wall, the outer wall of the combustion chamber and the outer wall of the no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com