Method and milling cutter for repairing surface defect of cement concrete construction member

A cement concrete and concrete technology, which is used in building maintenance, building structure, construction, etc., can solve the problems of segmental misalignment, honeycomb hemp surface, affecting the appearance quality, etc., and achieve the effect of good heat dissipation conditions and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The method for repairing the surface defect of the cement concrete component in the present embodiment is to carry out as follows:

[0046] 1. At the position of the surface defect of the cement concrete member 1, draw the repair range of the regular geometric shape;

[0047] 2. According to the position, scope and depth of surface defect repair of component 1, choose cement concrete milling machine 3 or portable electric drill. When the area of the repair groove is large or the depth is deep, the workload of repair is large, and the milling machine is selected. On the contrary, jackhammer can be used directly, and the construction is carried out as follows:

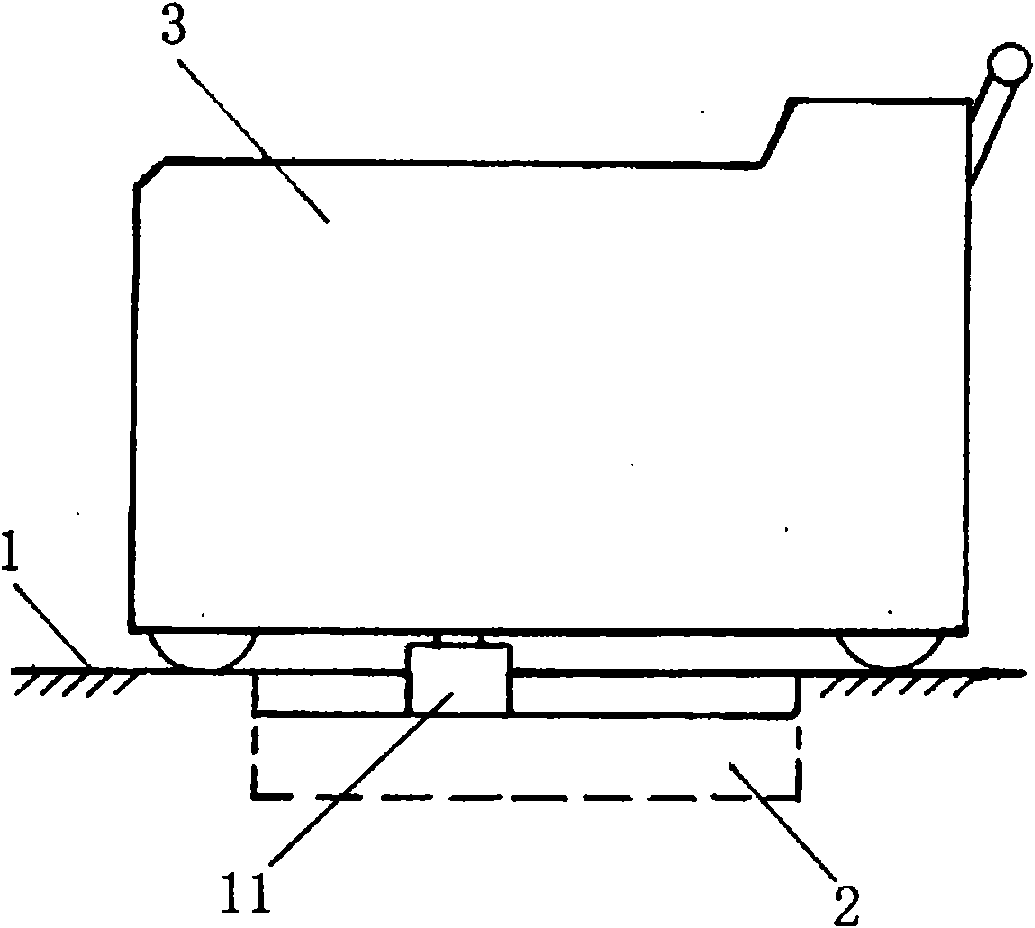

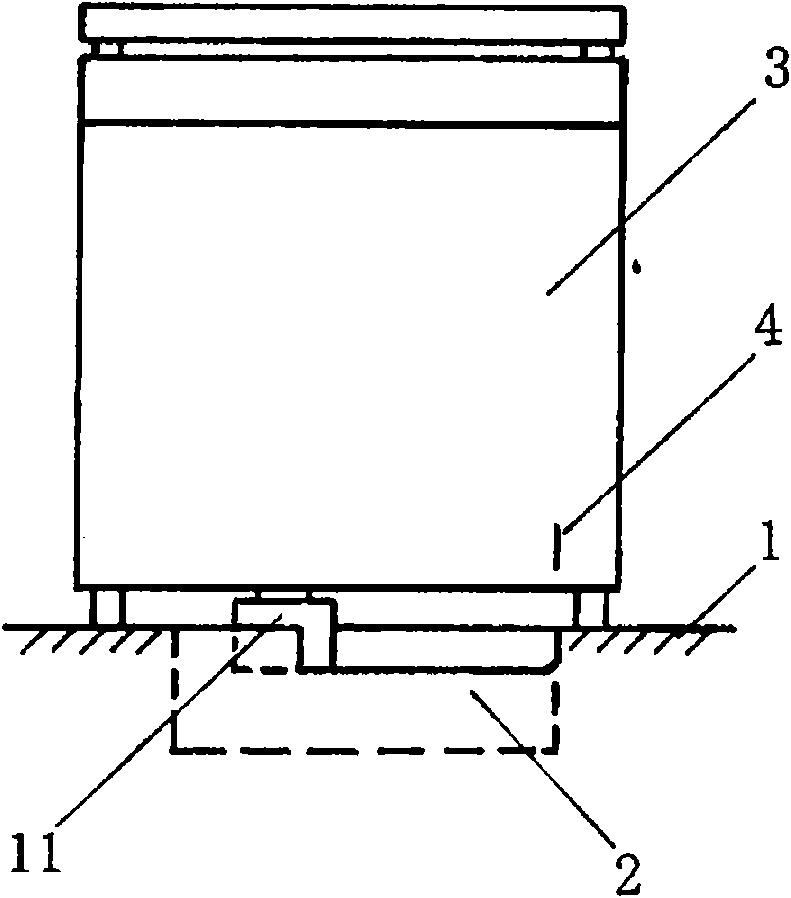

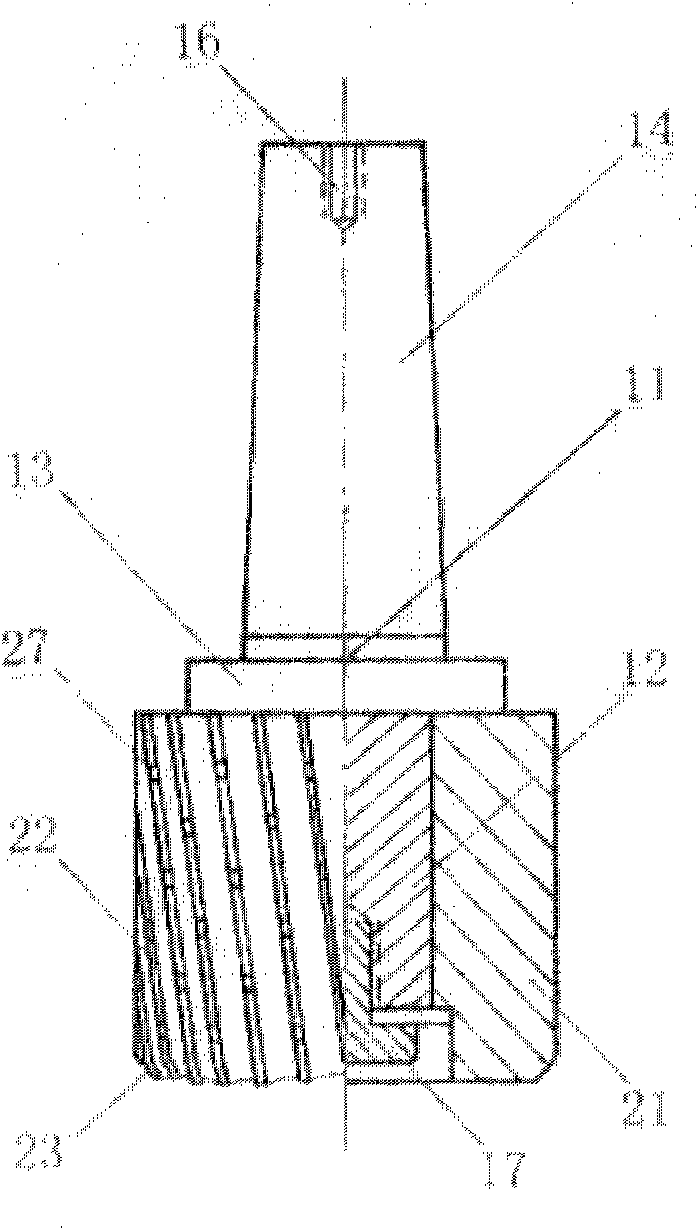

[0048] a. The construction method using cement concrete milling machine 3, see Figure 1A and Figure 1B :

[0049] i. For the top surface defect of component 1, place the cement concrete milling machine 3 directly on the defective position of component 1; Align the direction scale 4 with the boundary line o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com