Patents

Literature

69results about How to "Small cutting force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

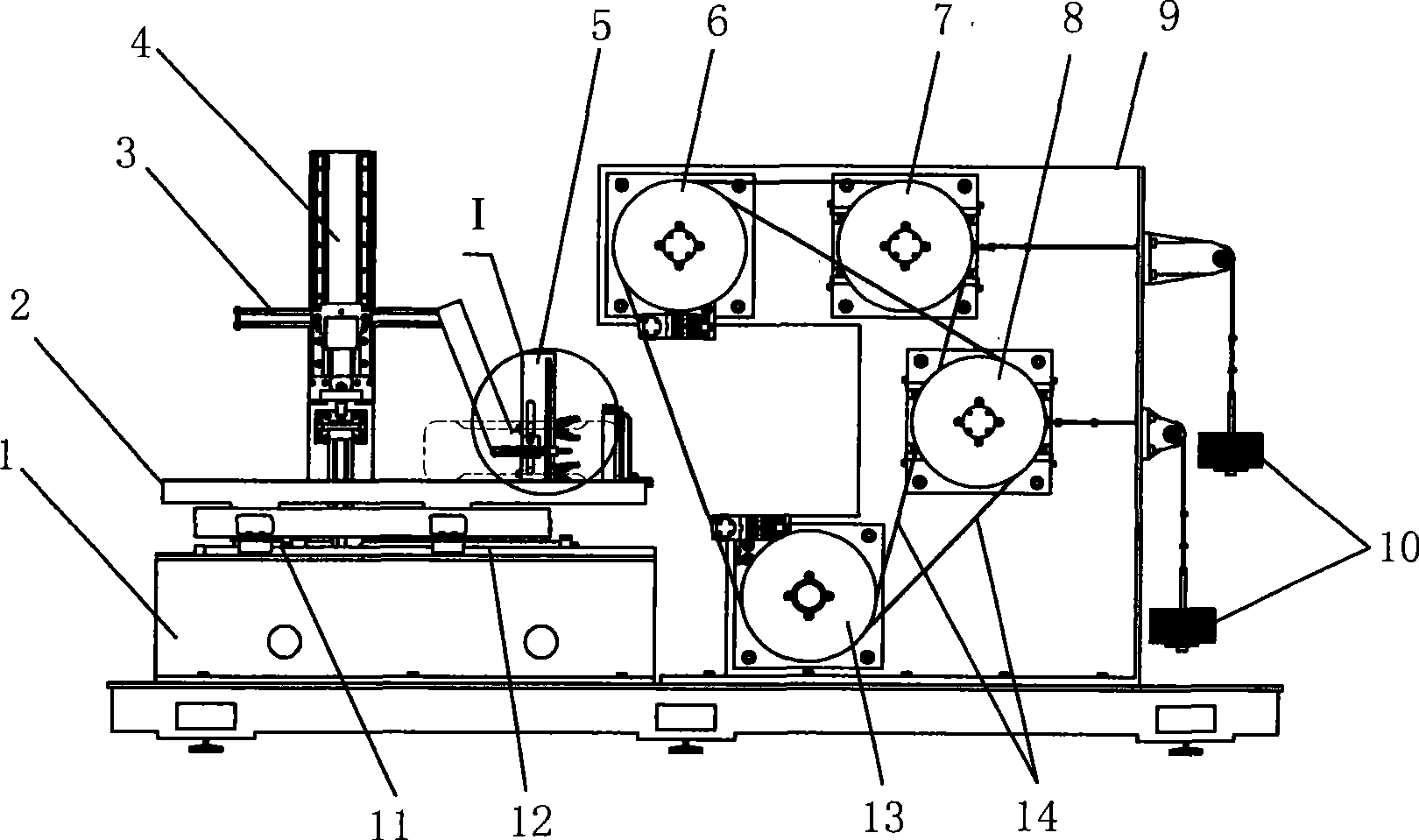

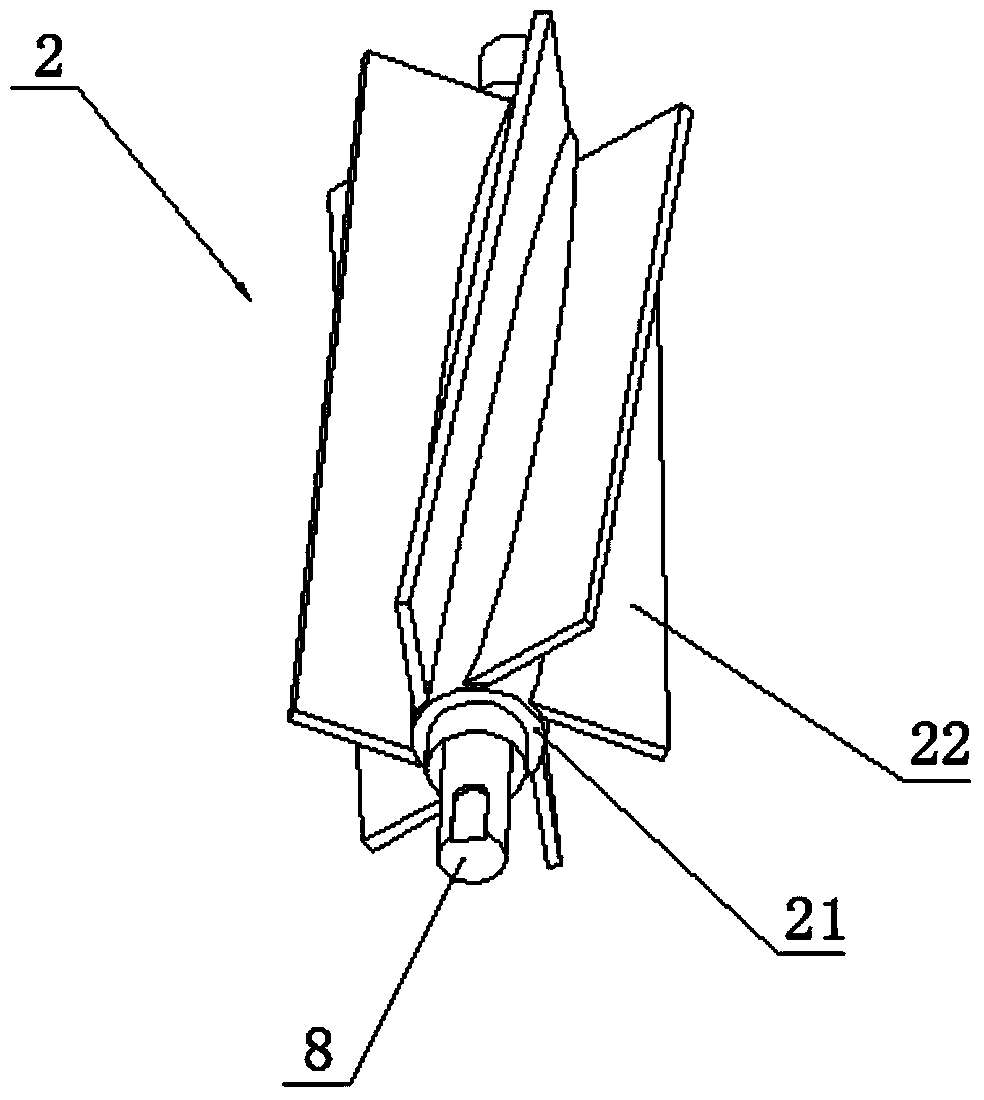

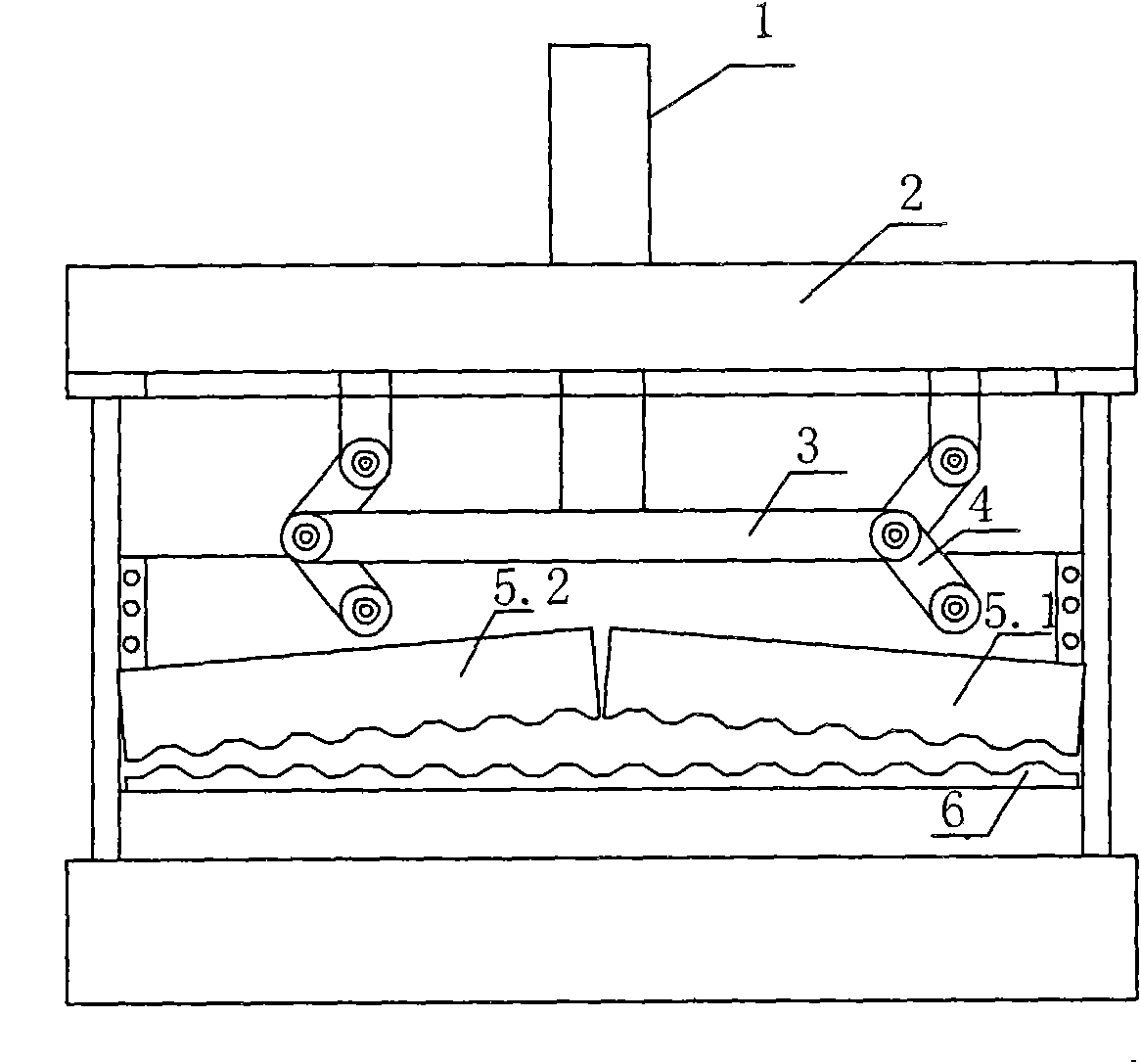

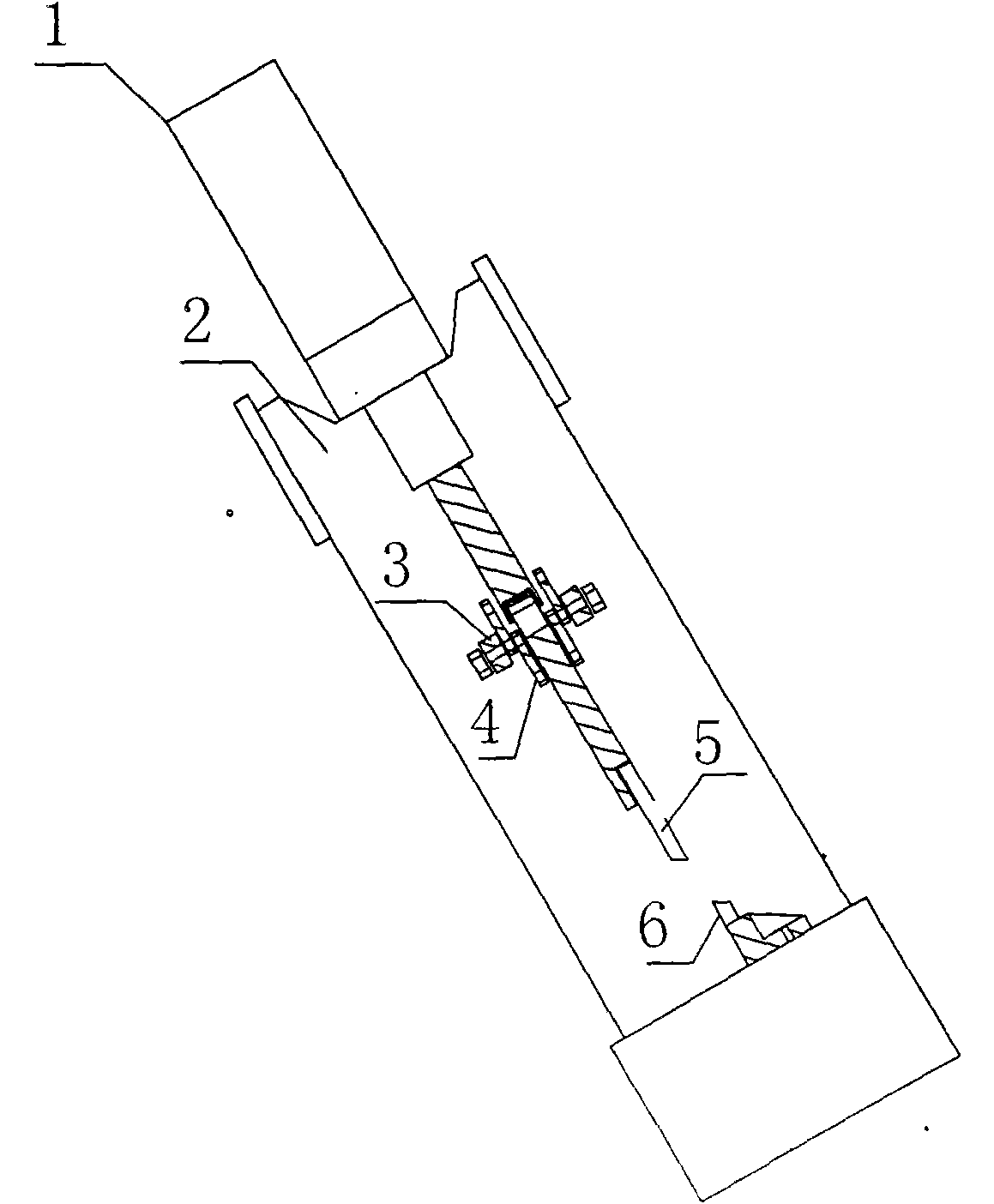

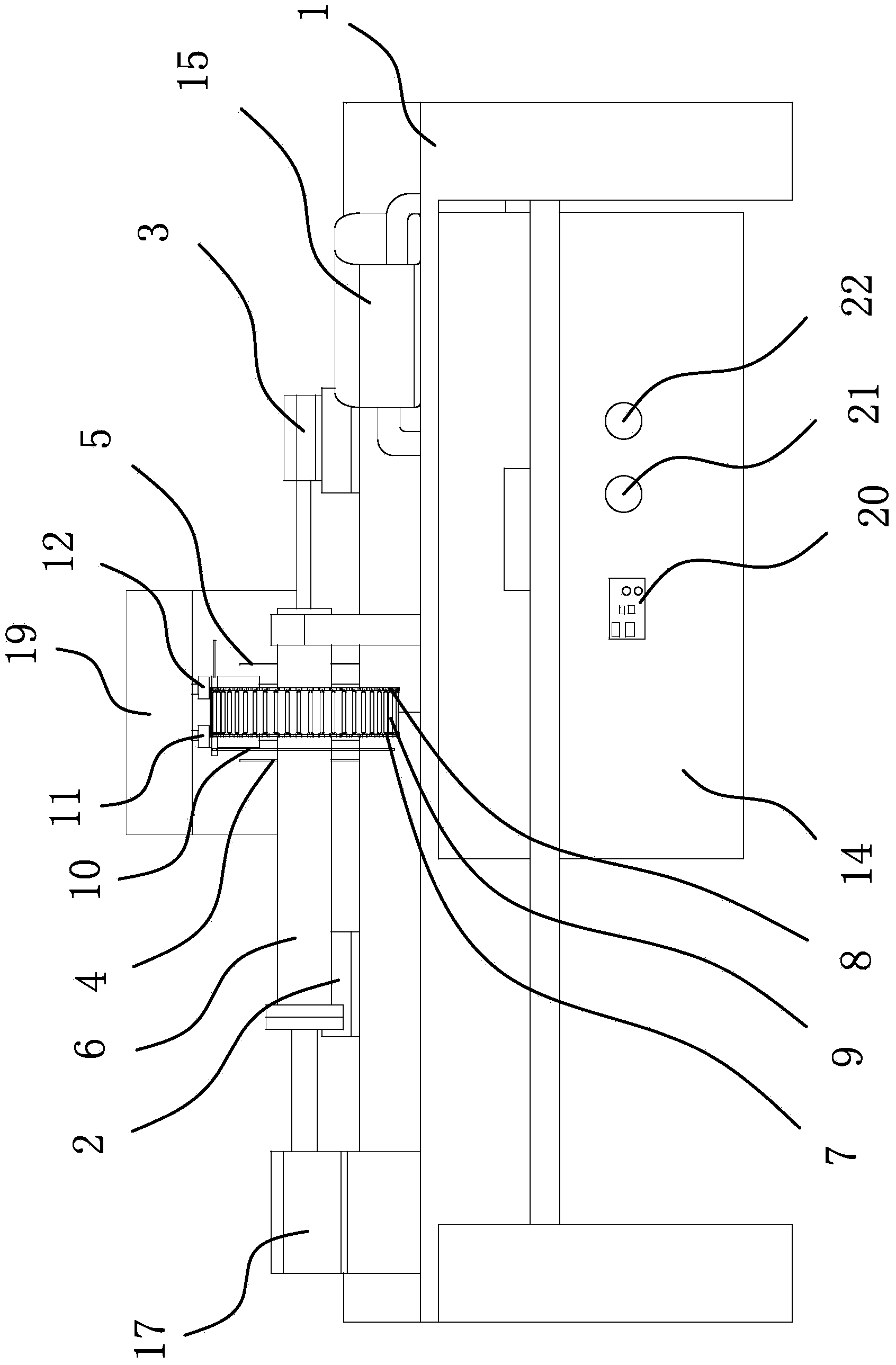

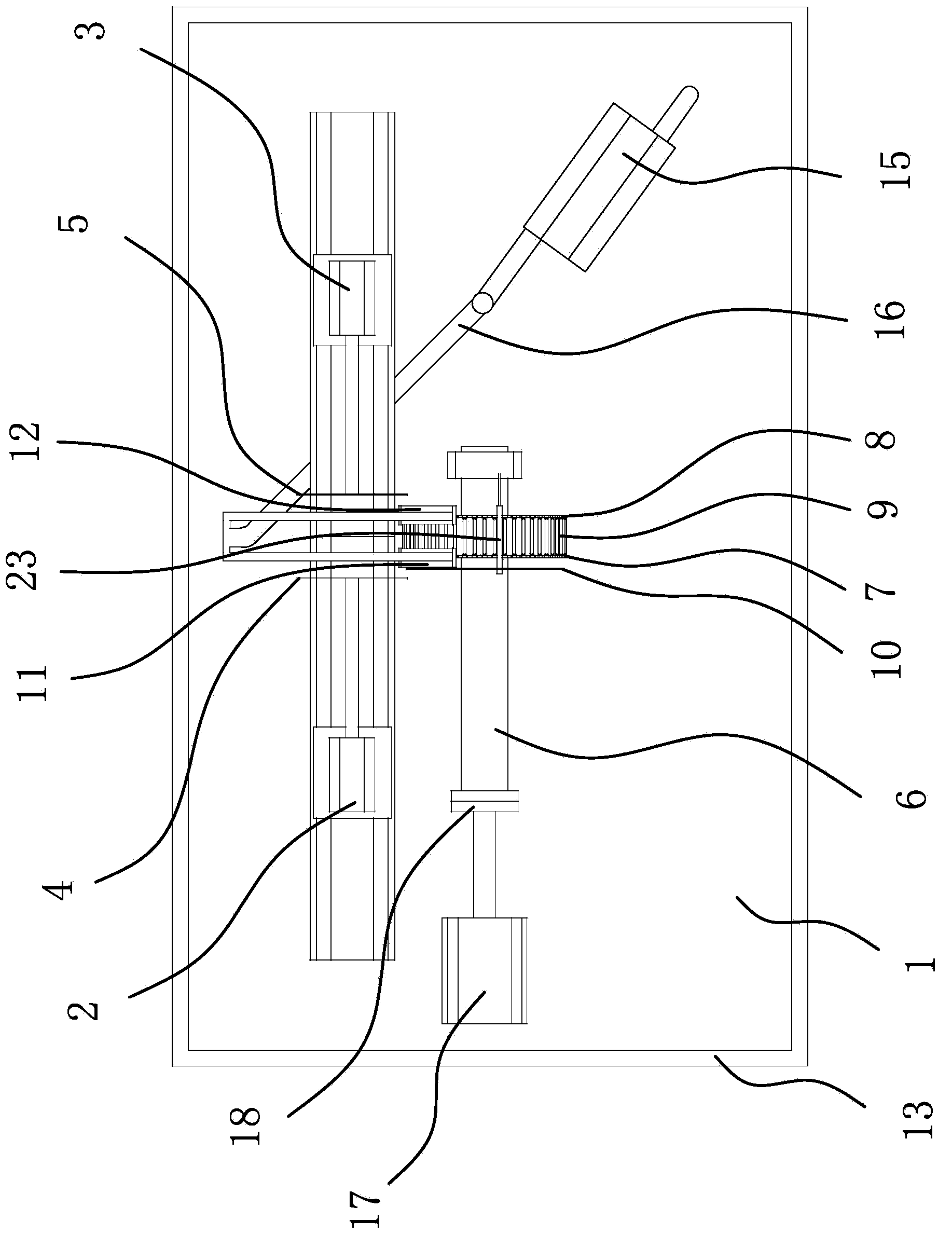

Cutting wire production method and cutting wire and tyre cutting device

ActiveCN101417478AExtended service lifeNot easy to peel offMetal working apparatusStone-like material working toolsDrive wheelEngineering

The invention provides a method for manufacturing a cutting wire and the cutting wire, and the method is characterized by taking a steel wire rope as the substrate and consolidating the abrasive material on the steel wire rope substrate by using metal binder or resinoid bond in electroplating manner. The abrasive material is normal or super hard abrasive material of different grain sizes. The processing technology of the cutting wire is reasonable, and the manufactured cutting wire has wide cutting range, good cutting quality and little pollution. The invention also provides a tire cutting device, comprising a lathe bed, a sliding working table which is provided with a fixture, an annular cutting device, driving wheels, driven wheels, a strainer for the annular cutting device and a cutting motor. The device is characterized in that the annular cutting device is an annular cutting wire which takes the steel wire rope as the substrate and consolidates the abrasive material on the surface. The driving wheels and the driven wheels have two sets and drive the two cutting wires to rotate synchronously, thus forming the double-cut cutting. The device has the advantages of high cutting efficiency, good cutting quality and little pollution.

Owner:青岛厚泽锦业技术有限公司

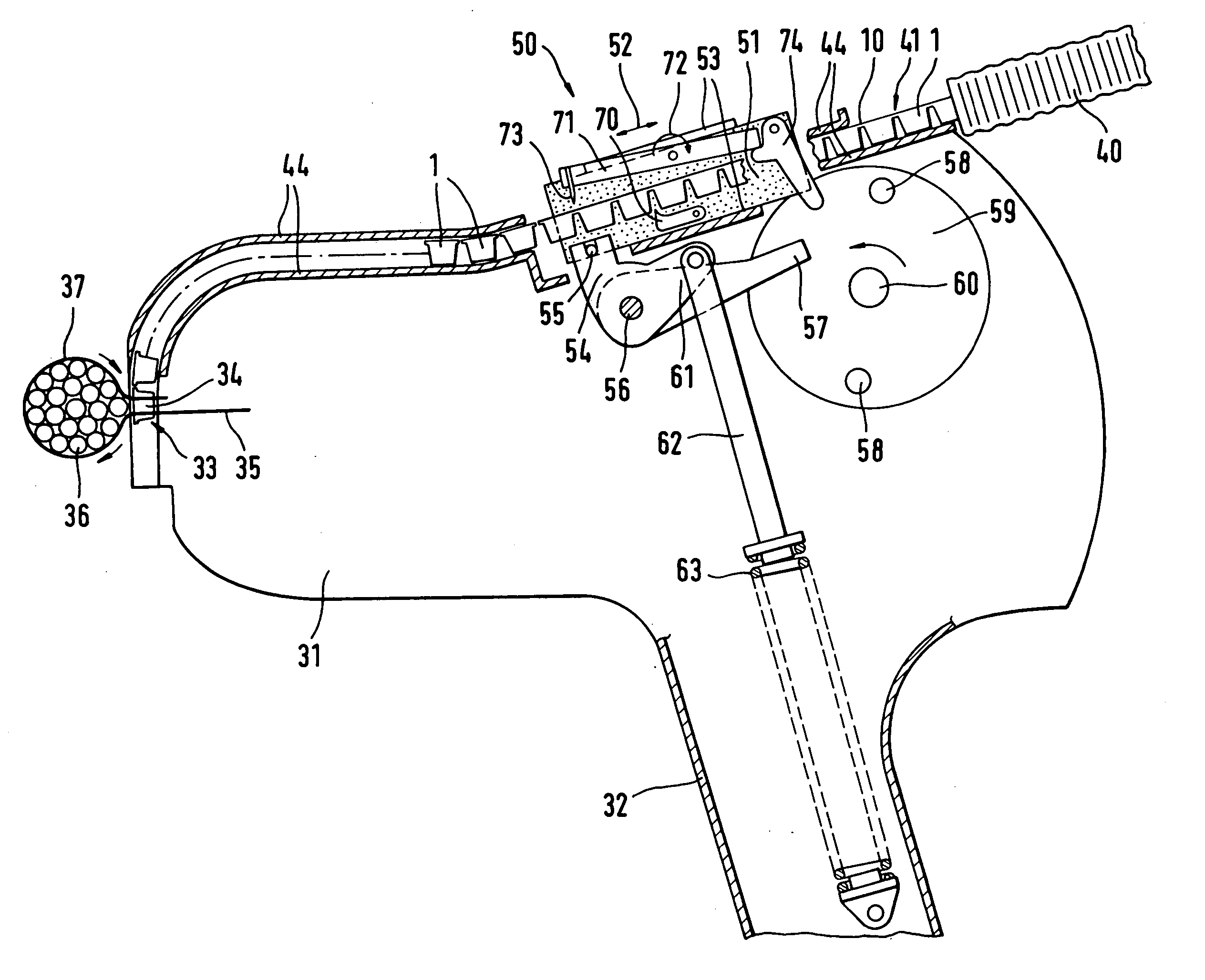

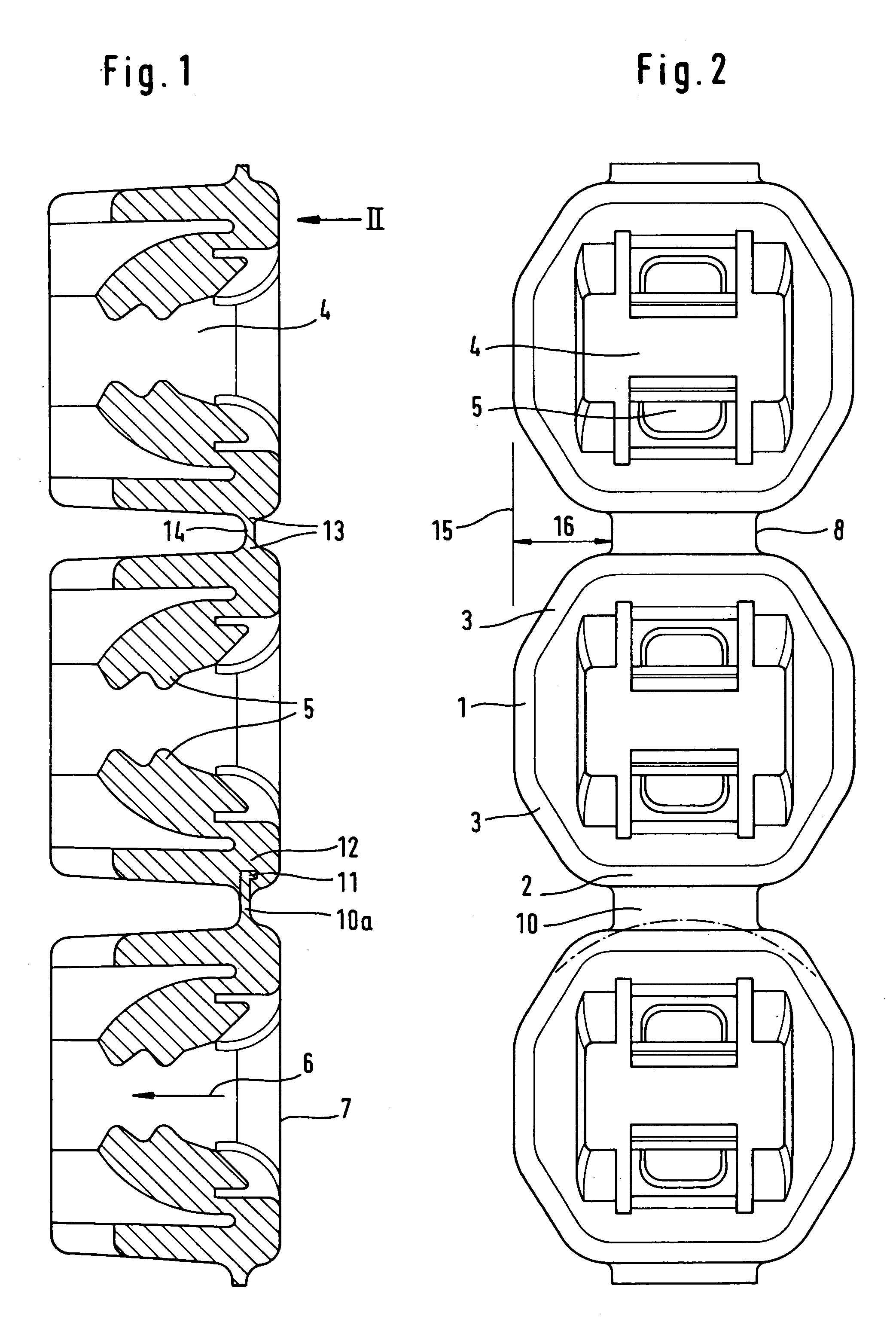

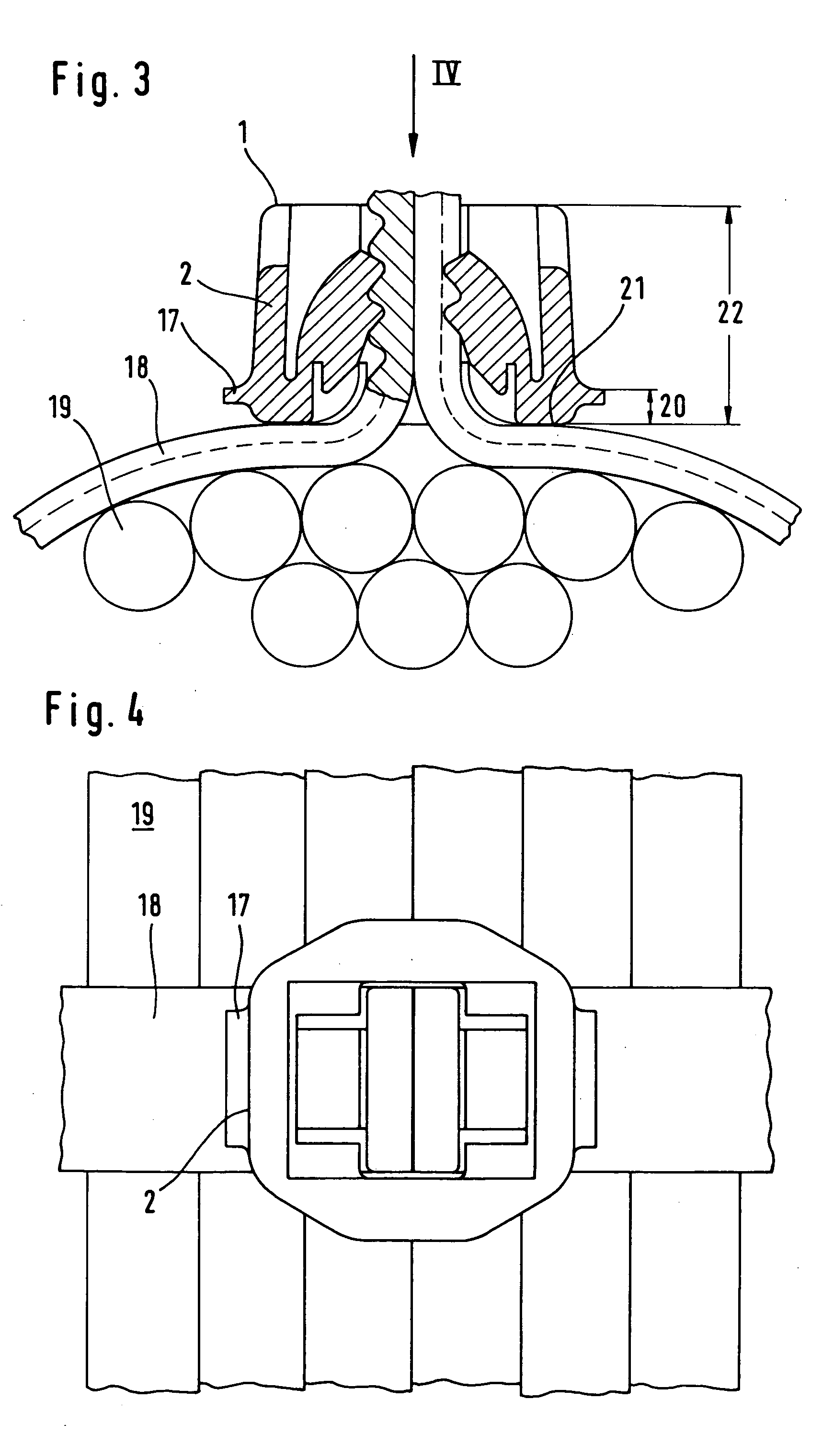

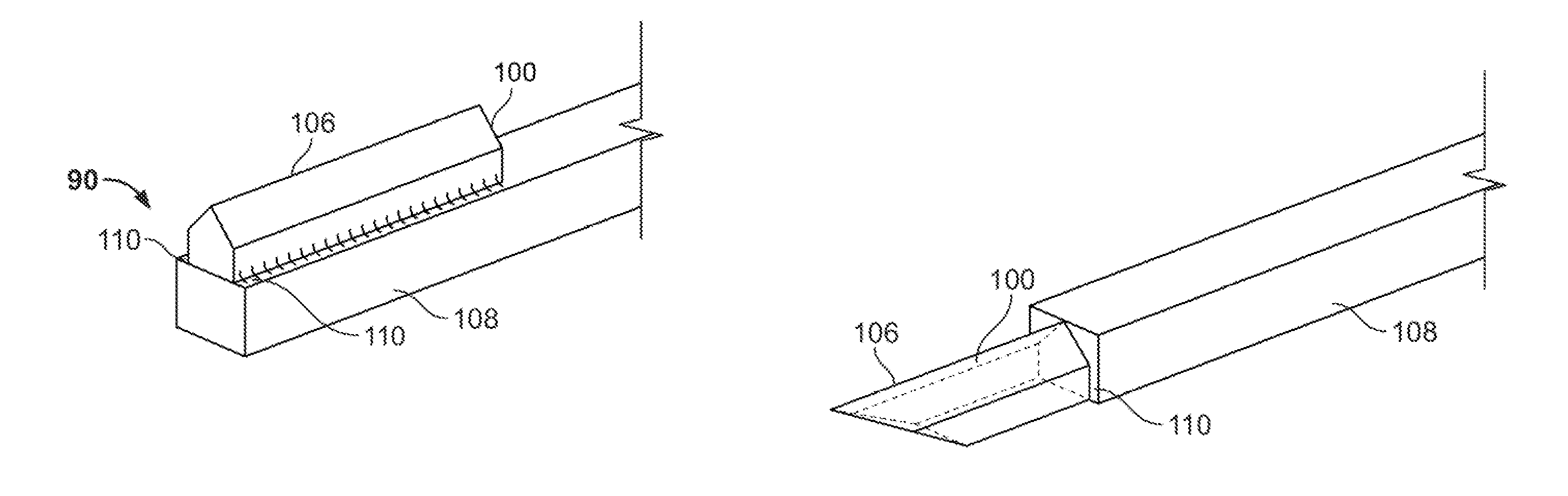

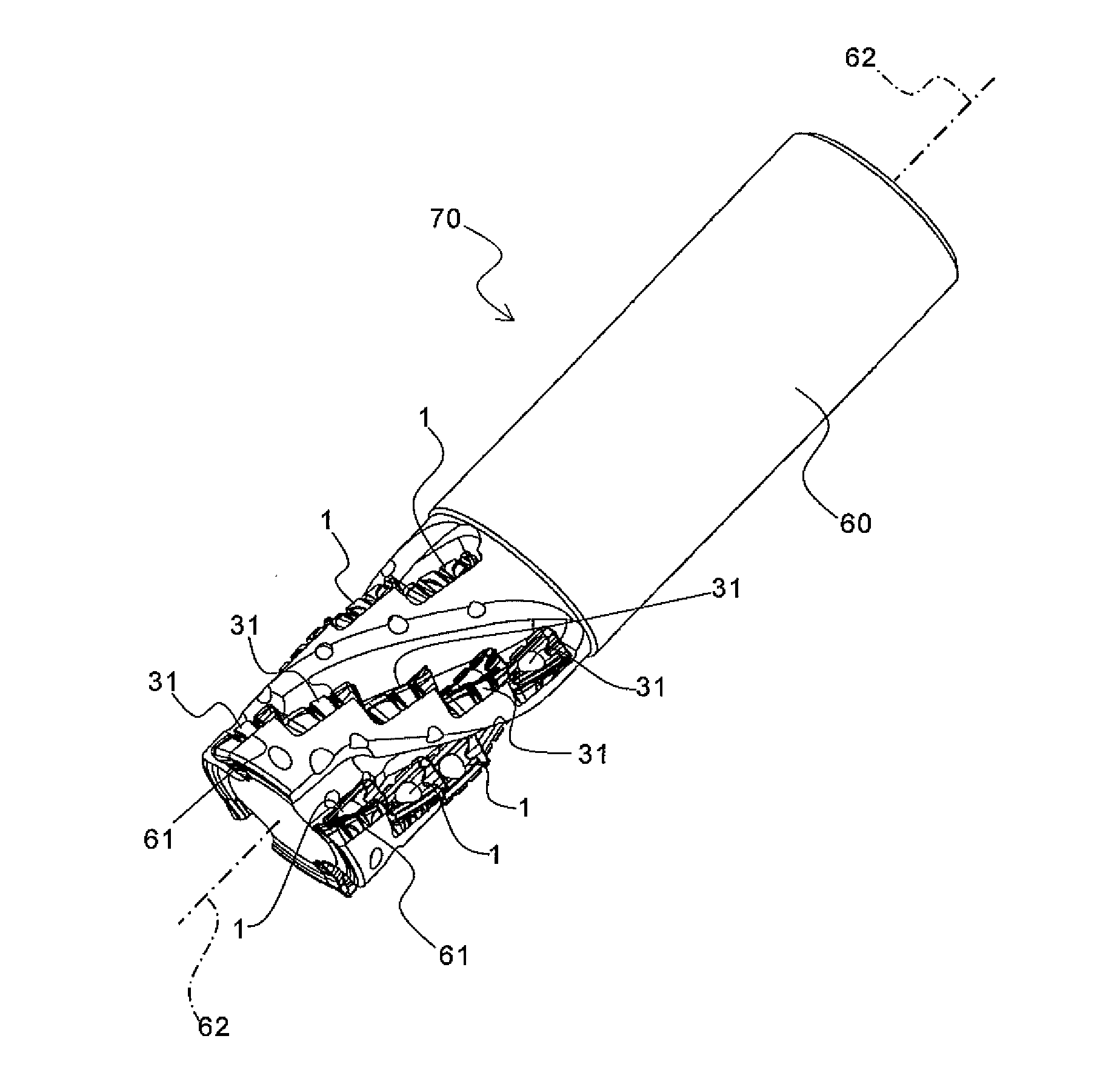

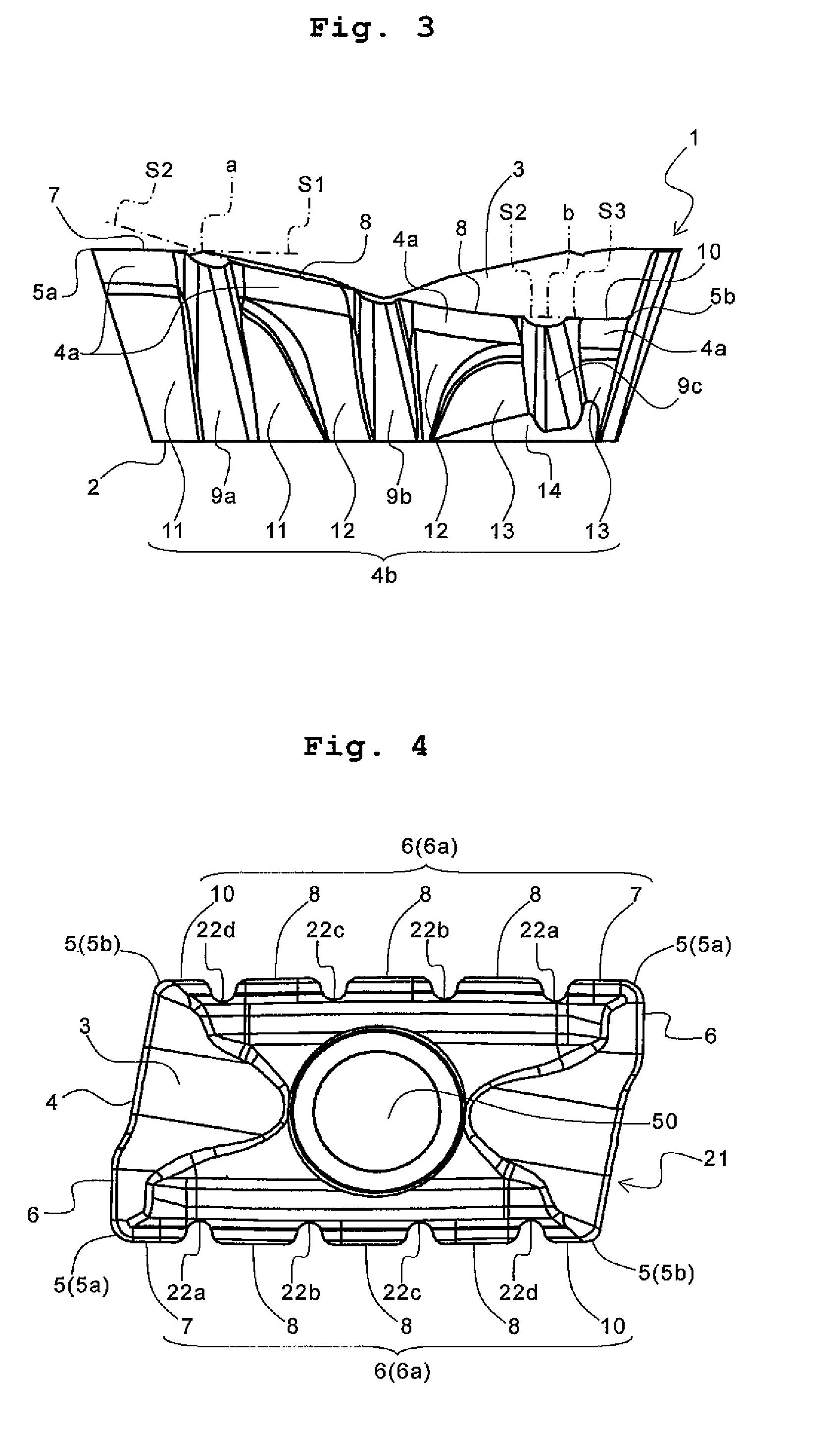

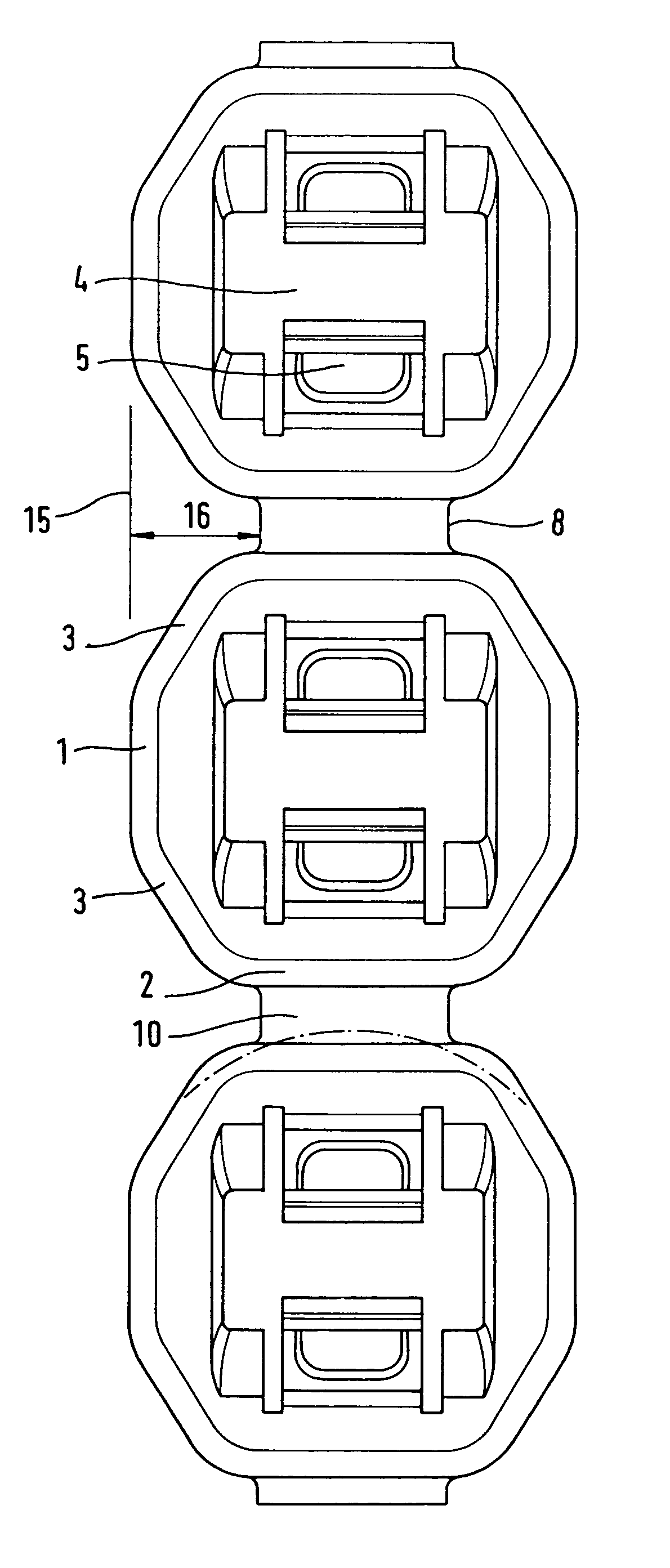

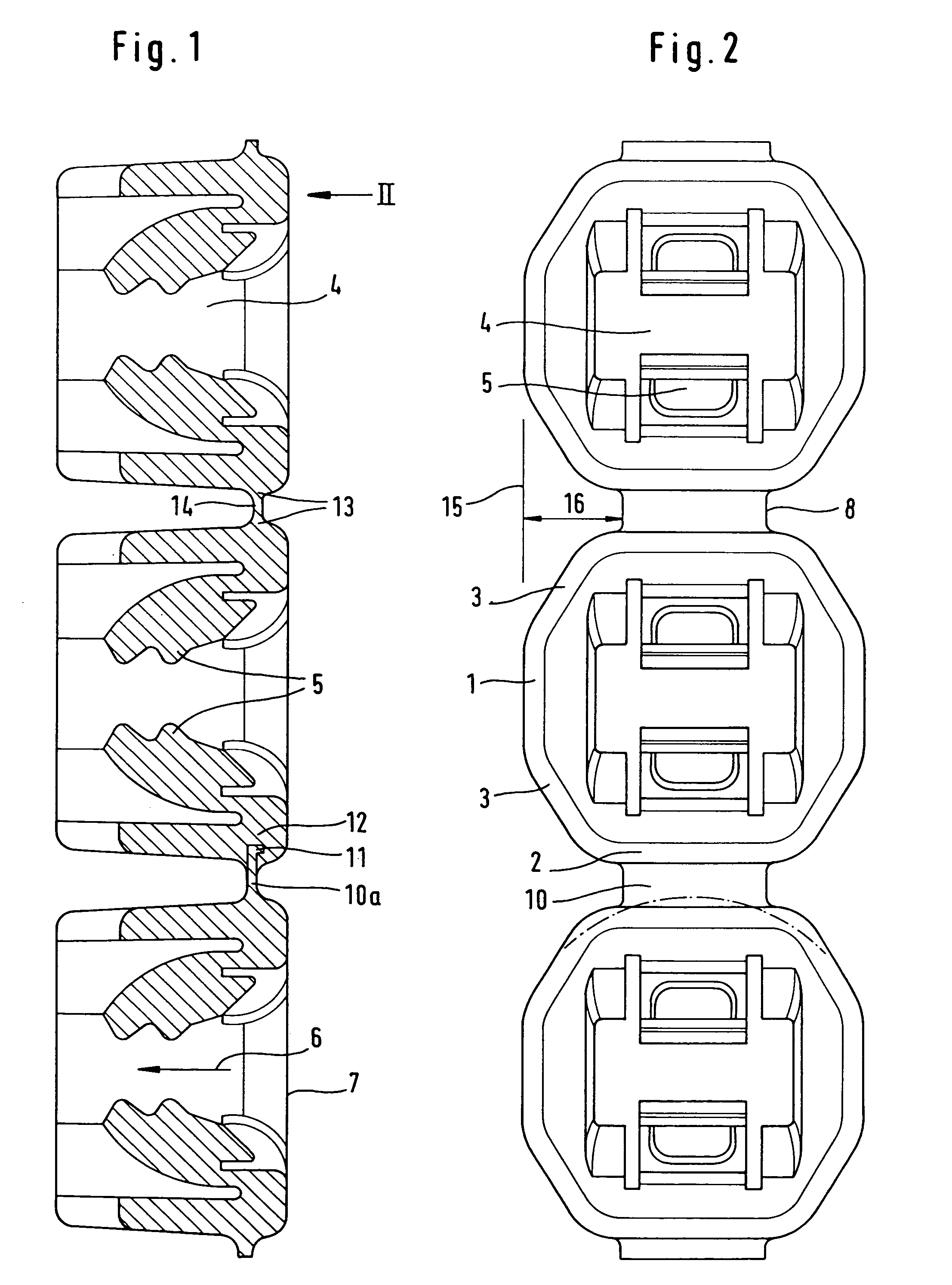

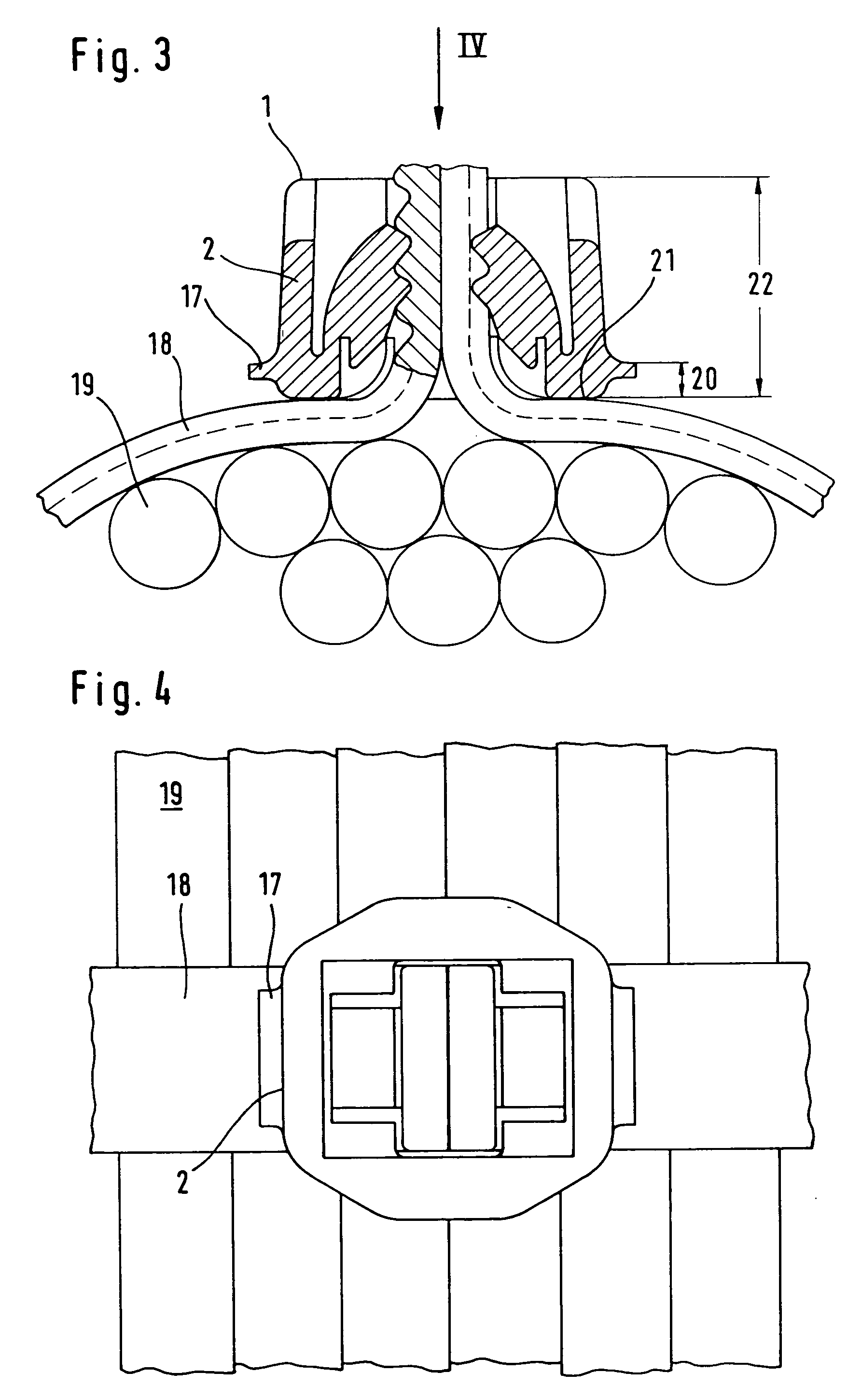

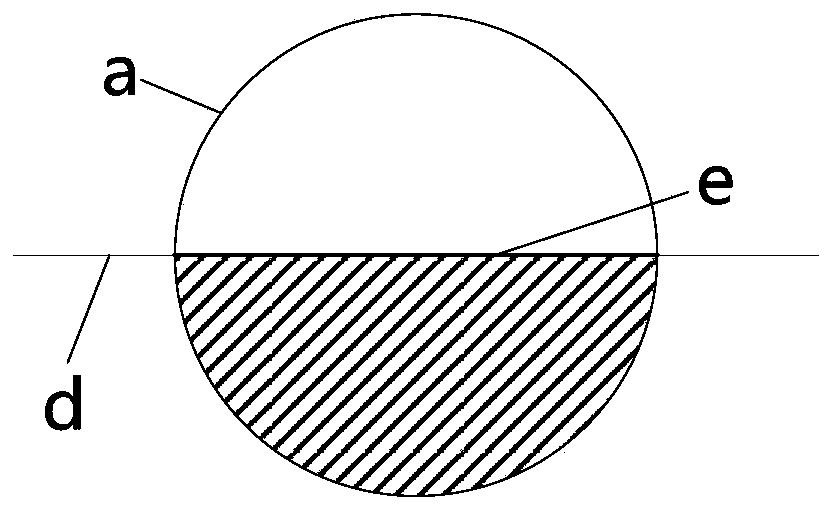

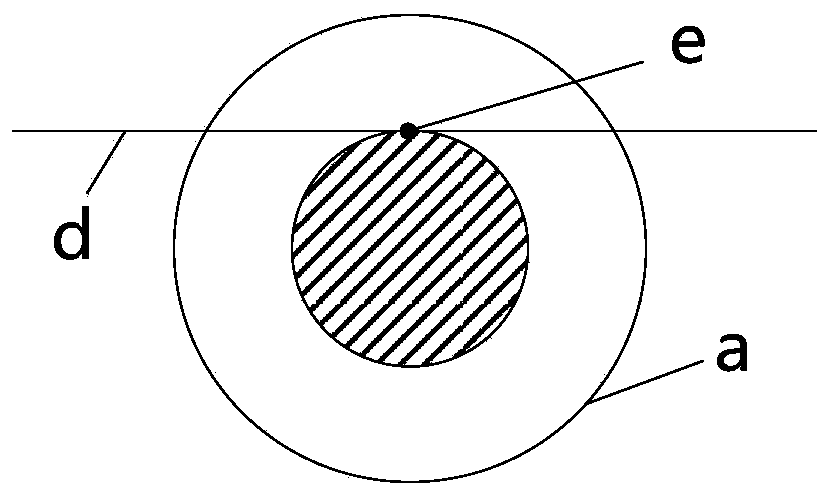

Magazine strip for ratchets and tool for handling the same

InactiveUS20060027278A1Reduce riskReduce the risk of injuryPipe supportsFlexible elementsEngineeringMechanical engineering

A magazine strip of tie ratchets (1) which are provided for holding the ends of ties for binding elongated articles such as cable harnesses and are connected to one another by webs (10), the width of which is not greater than half the ratchet width and which are arranged adjacent to the tie entry side (7) of the ratchets (1) The webs have a length of not more than 1.3 mm and / or one sixth of the ratchet dimension in the direction of the magazine strip. The width of the essentially parallel wall sections which carry the webs is expediently not greater than three quarters of the entire width of the ratchets. The thickness / width ratio of the webs should be not greater than ⅕. The invention also relates to a tool for binding cable harnesses which ensures that the webs are cut exactly in the center.

Owner:HELLERMANN TYTON GMBH

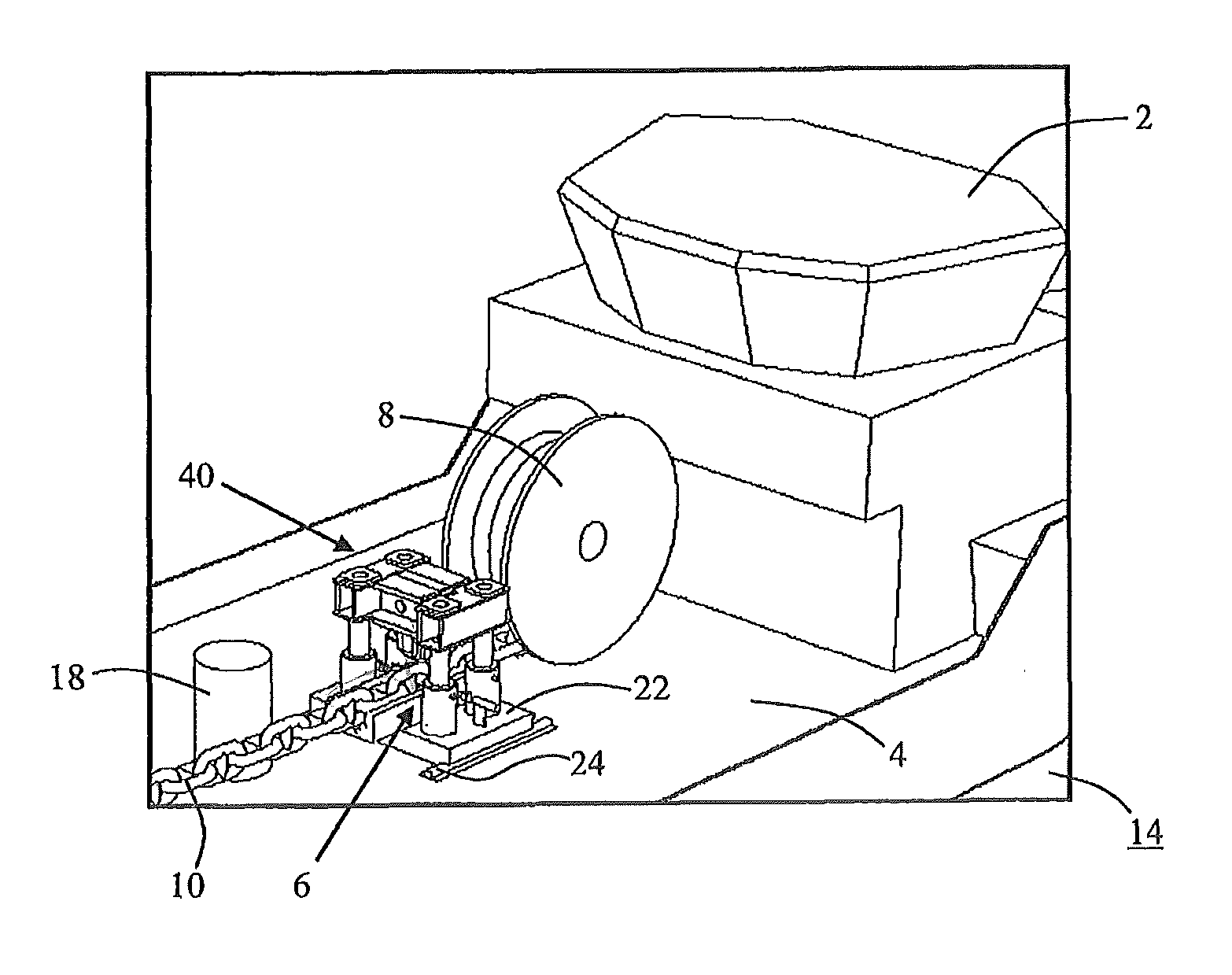

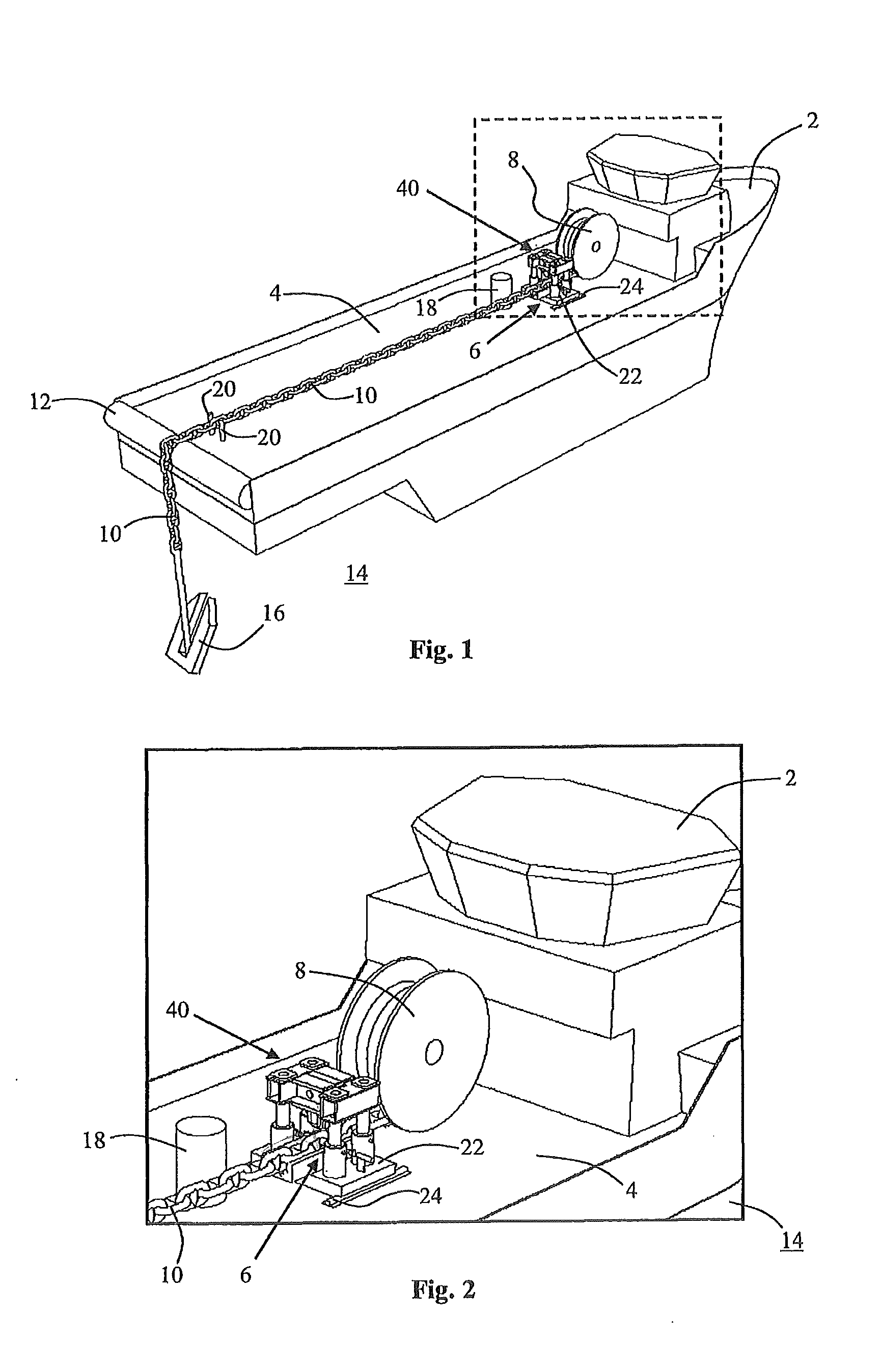

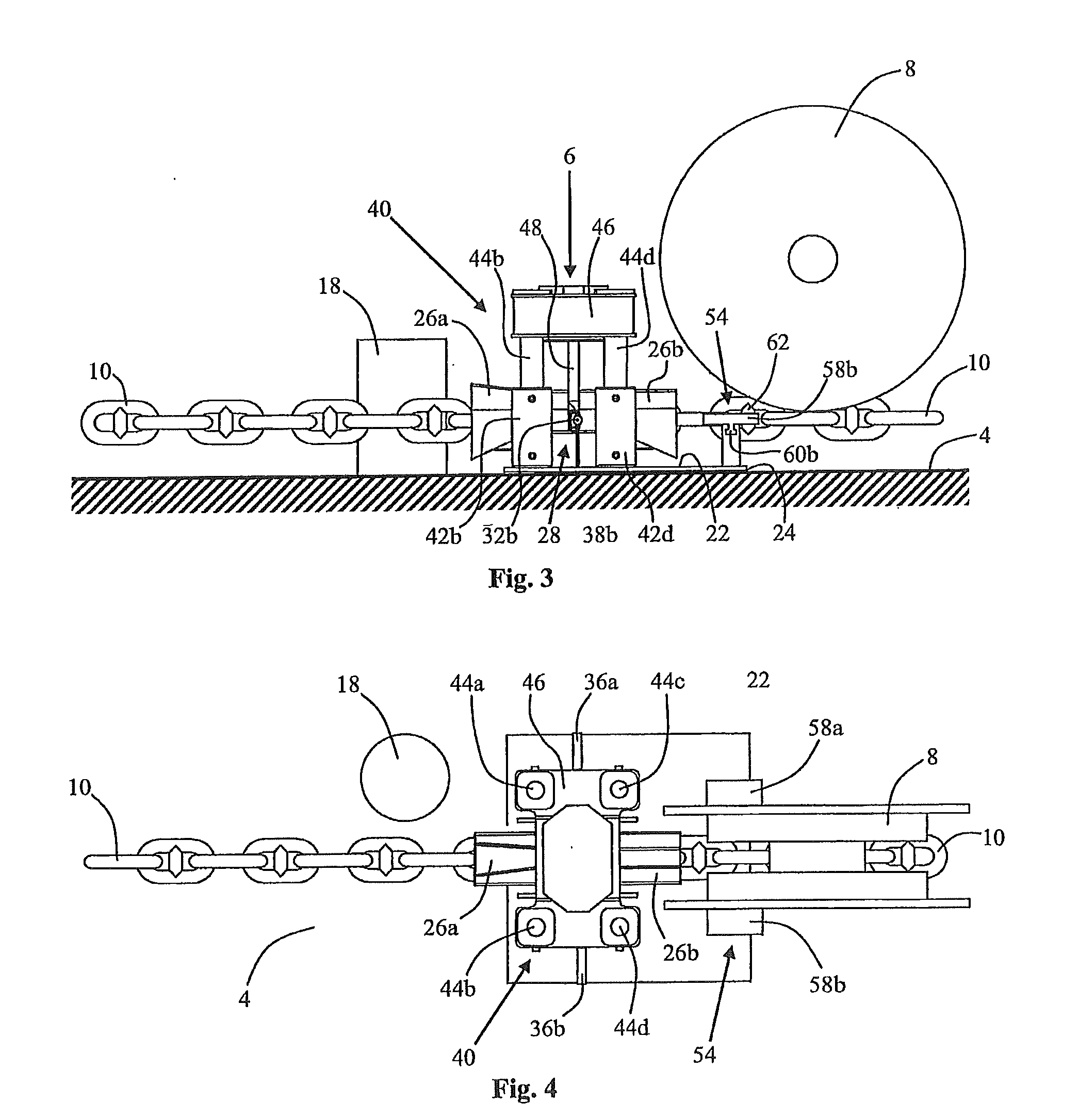

Cutting Device, Method and Use for Cutting of a Line Extending from a Floating Vessel

ActiveUS20130098214A1Improve personnel safetyAvoid damageAnchor handling/lashingVessel safetyMechanical engineeringInduction coil

Cutting device, method and use are for cutting of a line extending from a floating vessel. The cutting device is structured for placement on the vessel. The cutting device comprises: at least one guide structured for directional steering of the line past a cutting area for the line; and at least one of the following cutting-promoting devices: at least one induction coil device directed inwards toward the cutting area and structured for heating, hence weakening, of the line within the cutting area; and at least one moveable cutting knife with an opposite contact surface directed inwards toward the cutting area and also structured for cutting of the line within the cutting area.

Owner:SMART INSTALLATIONS

Micro surgical cutting instruments

InactiveUS7963042B2Precise cuttingMinimize damageIncision instrumentsCoatingsSurgical bladeEngineering

Owner:MYNOSYS CELLULAR DEVICES INC

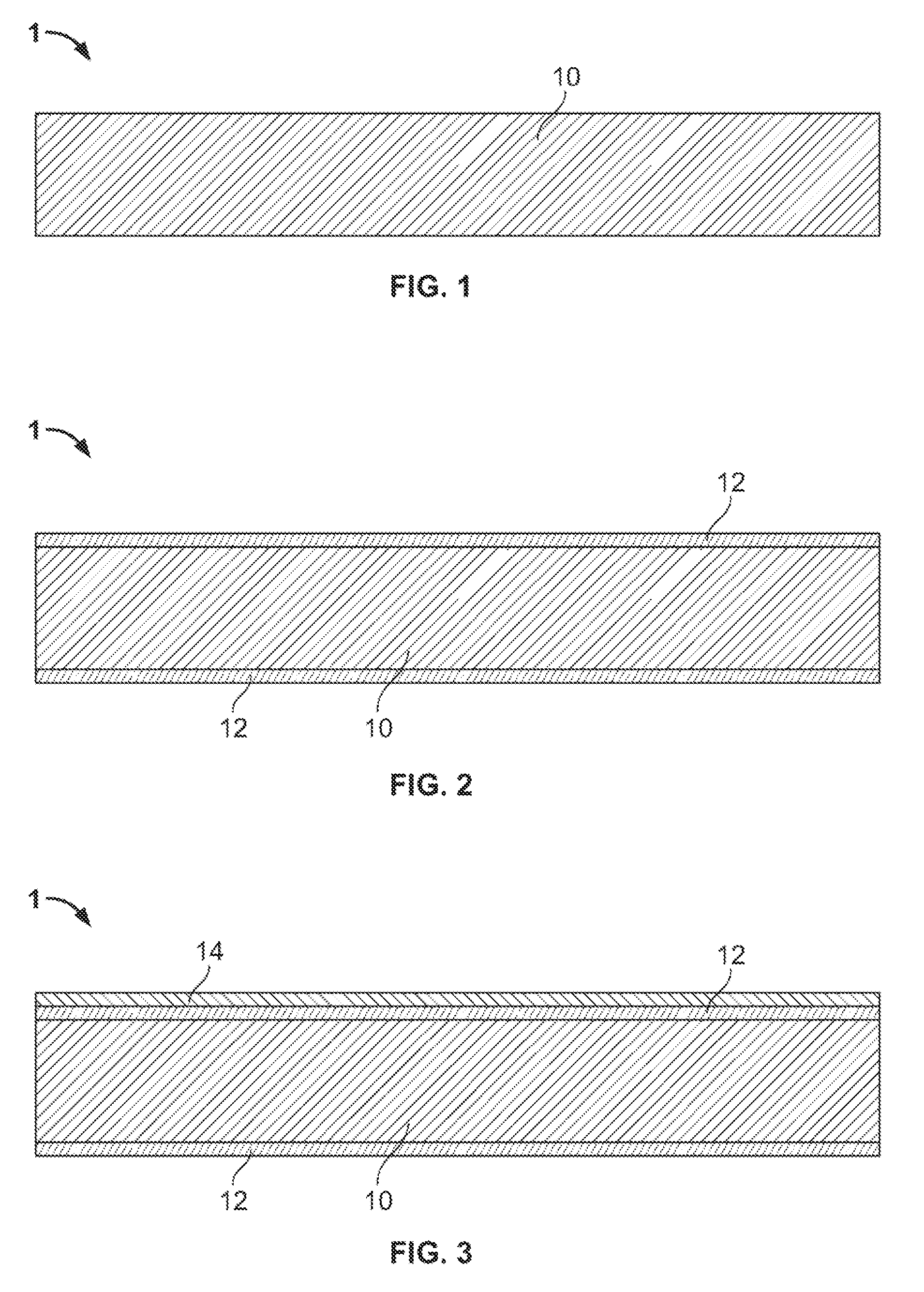

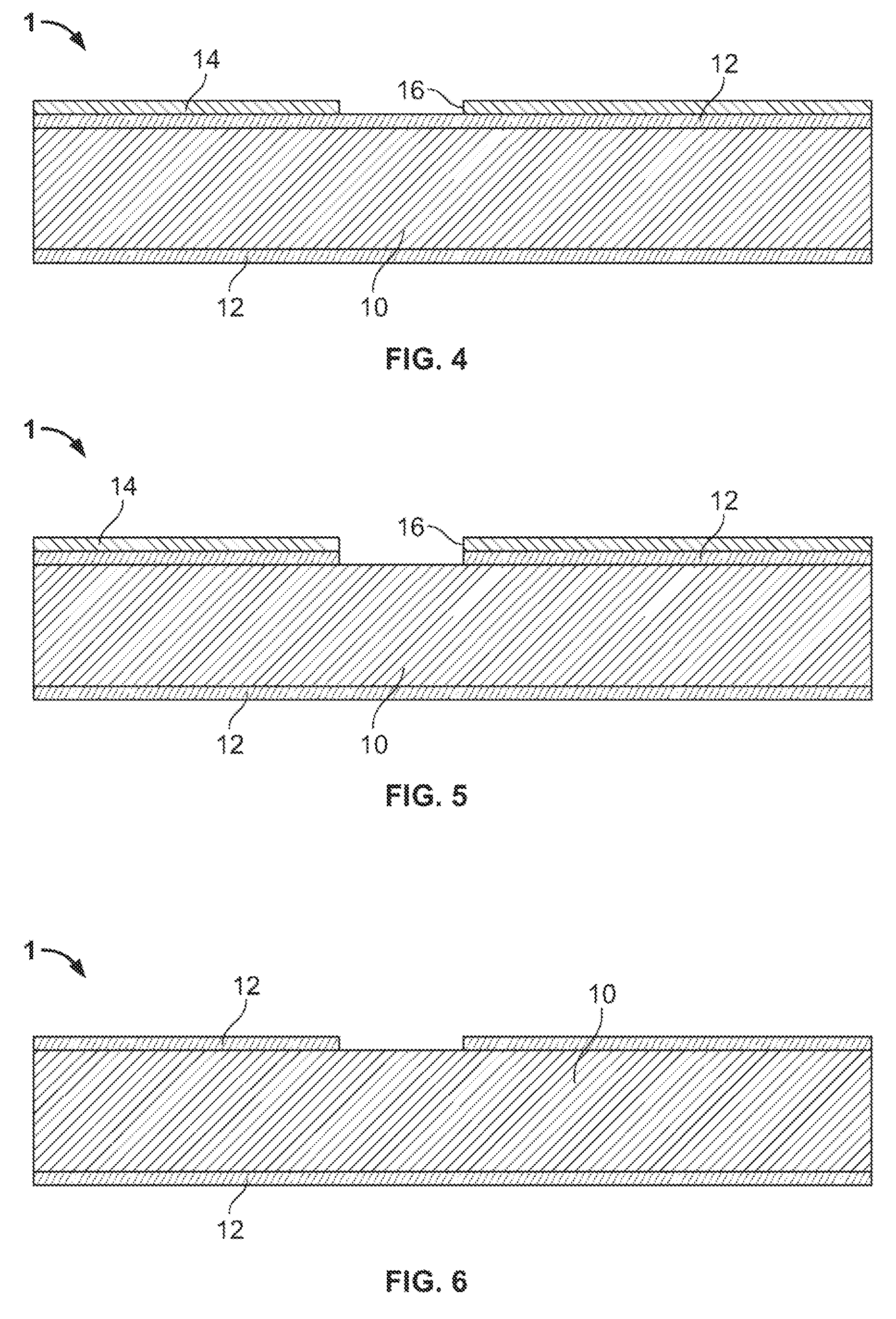

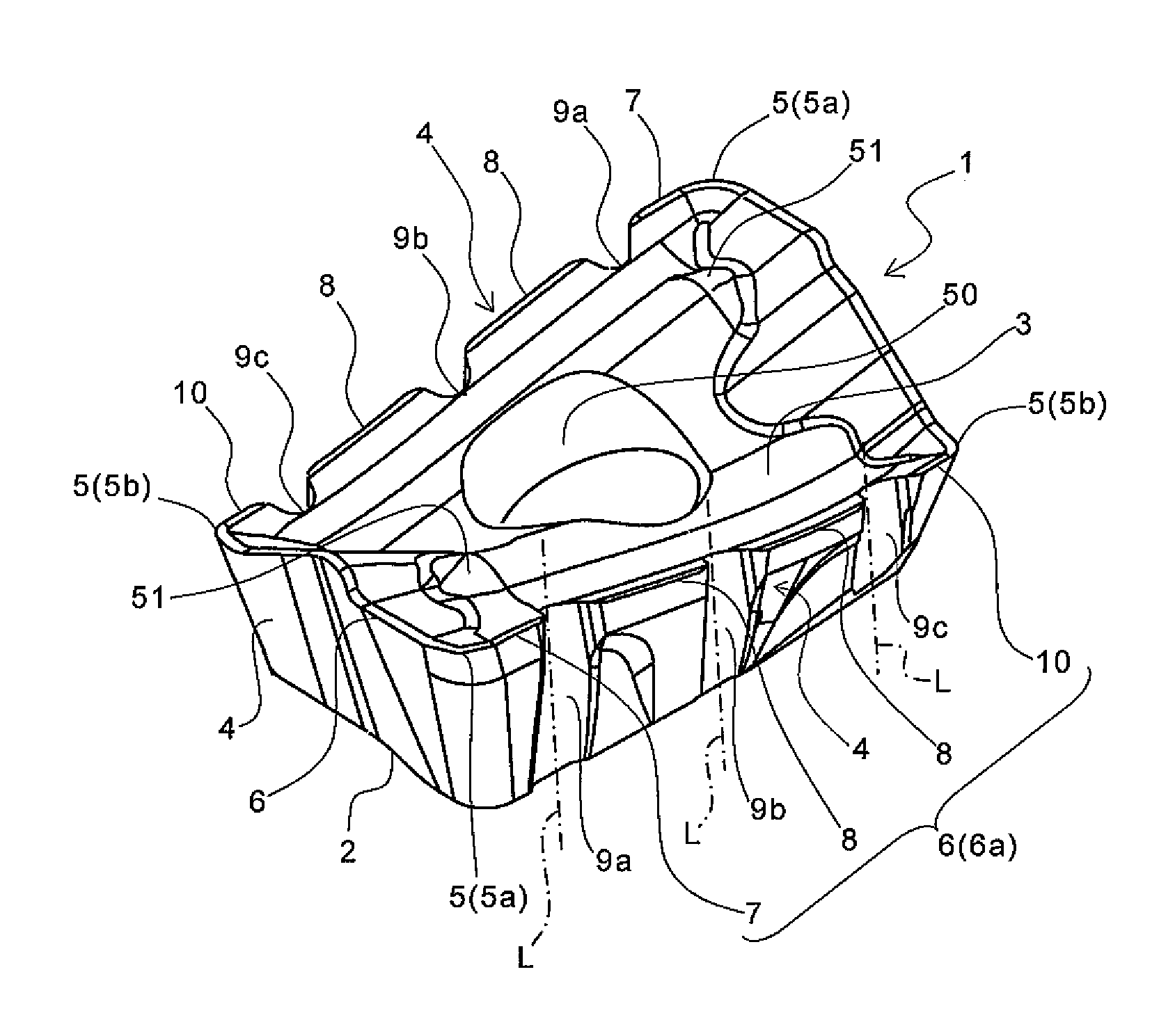

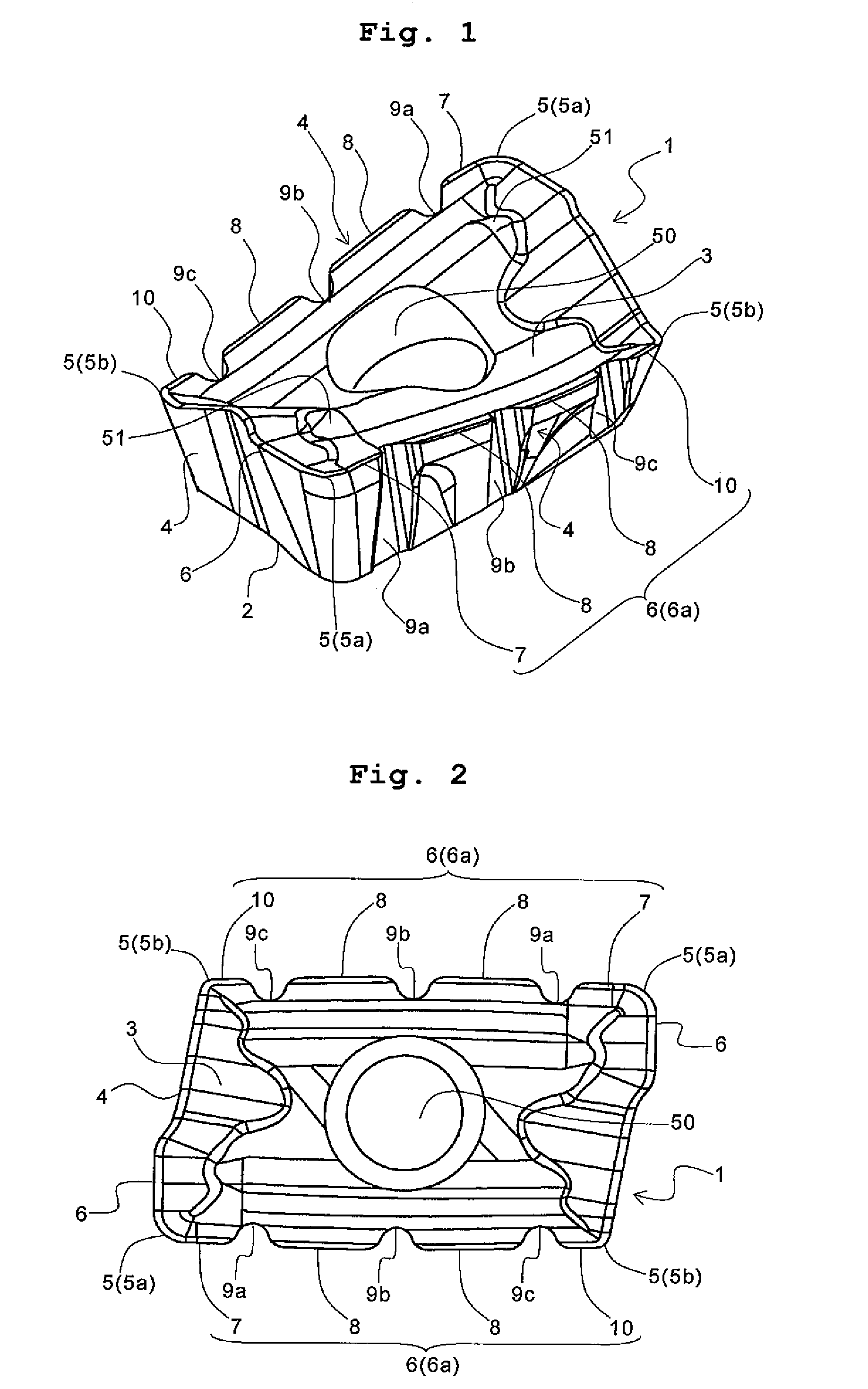

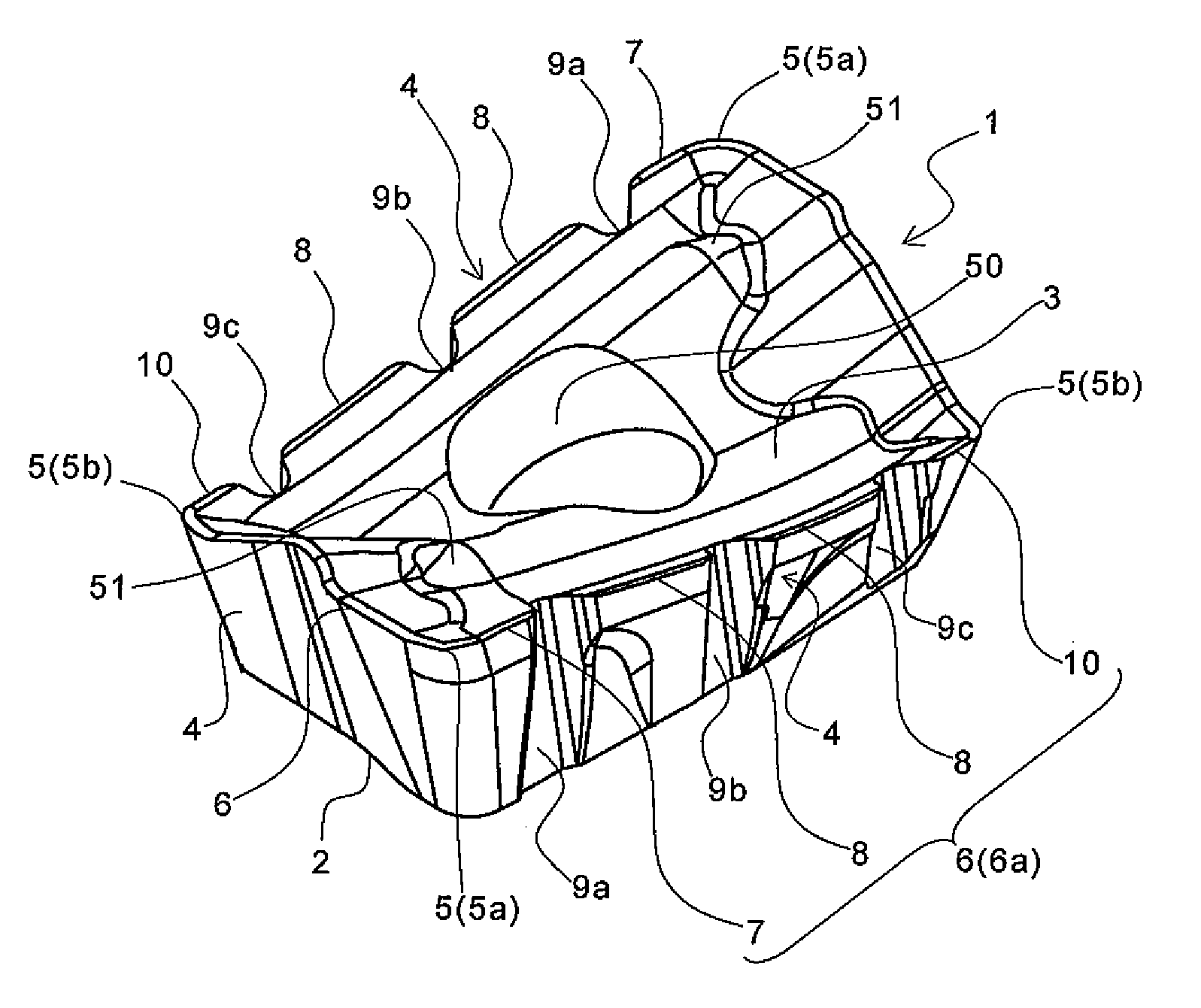

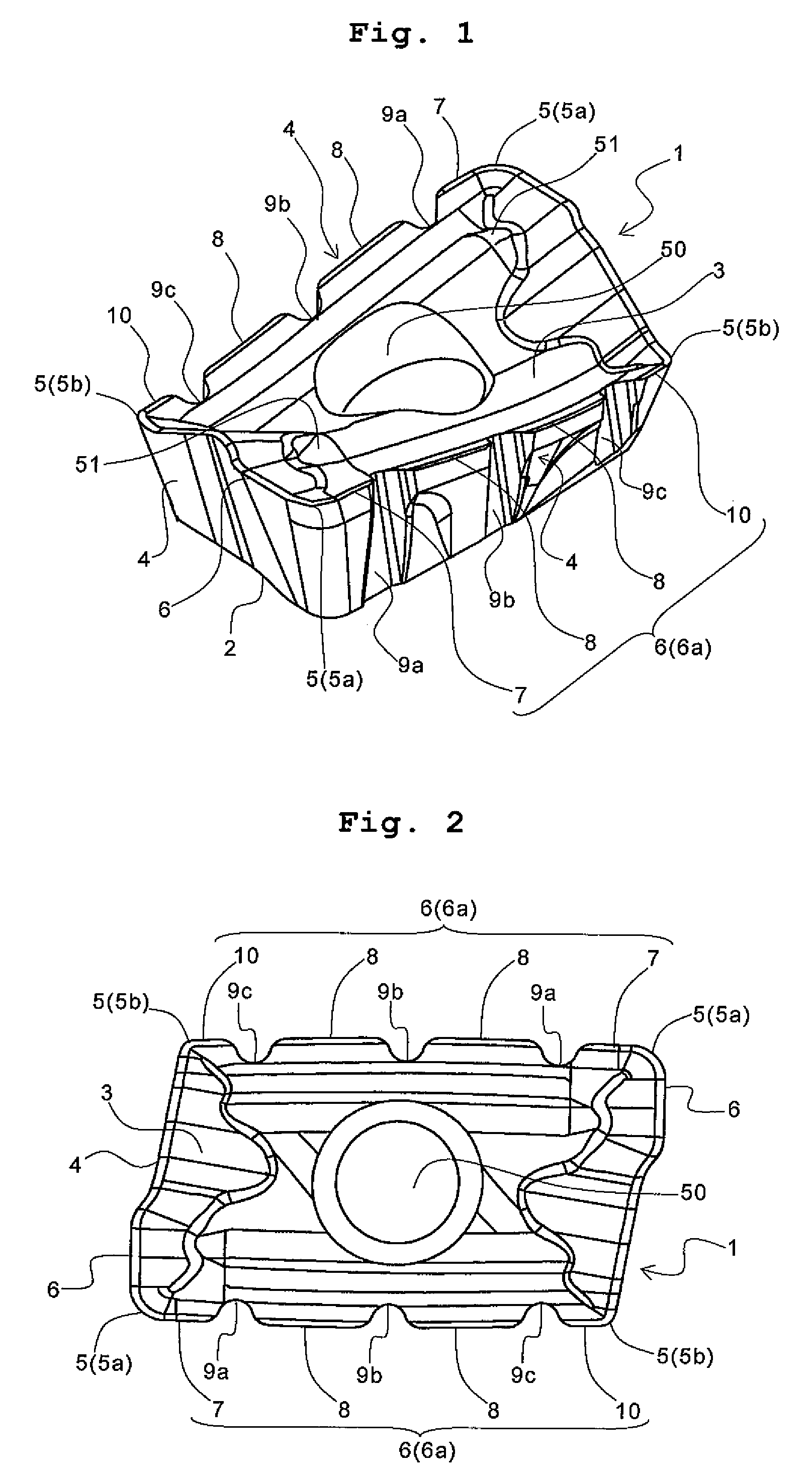

Cutting insert, cutting tool using the same, and cutting method

ActiveUS8419319B2Small cutting forceImprove cutting performanceMilling cuttersShaping cuttersEngineeringCutting force

A cutting edge is formed at a ridge between an upper surface and a side surface. In the side surface, a plurality of grooves are formed so as to extend from the side surface to the upper surface to divide the cutting edge, and the clearance angles within these grooves are formed so as to increase from one end of the cutting edge toward the other end of the cutting edge. This achieves a cutting insert having small cutting force and excellent cutting performance. Among the plurality of grooves, the groove nearest to the one end of the cutting edge has preferably a width increasing from the upper surface of the cutting insert toward the lower surface.

Owner:KYOCERA CORP

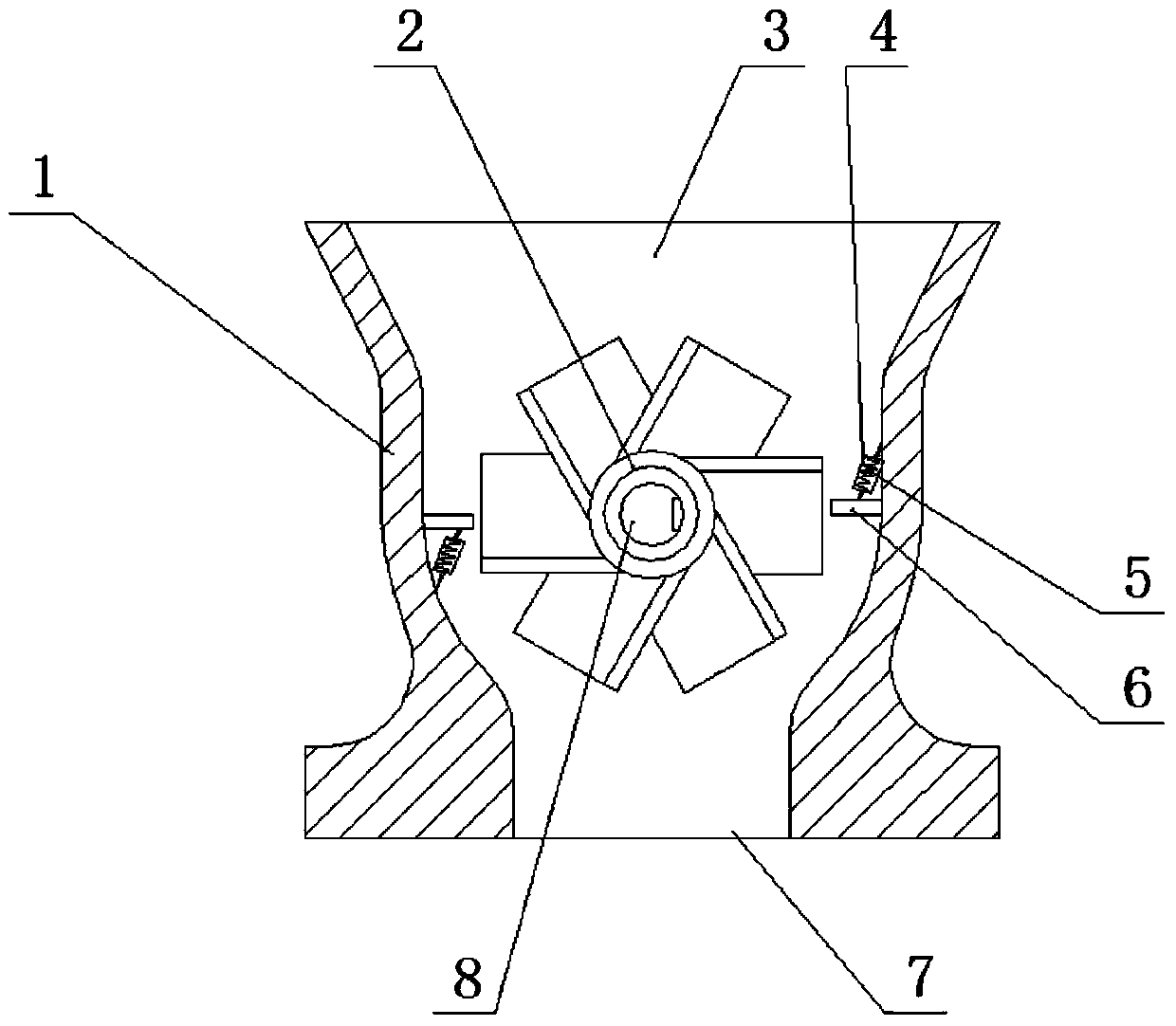

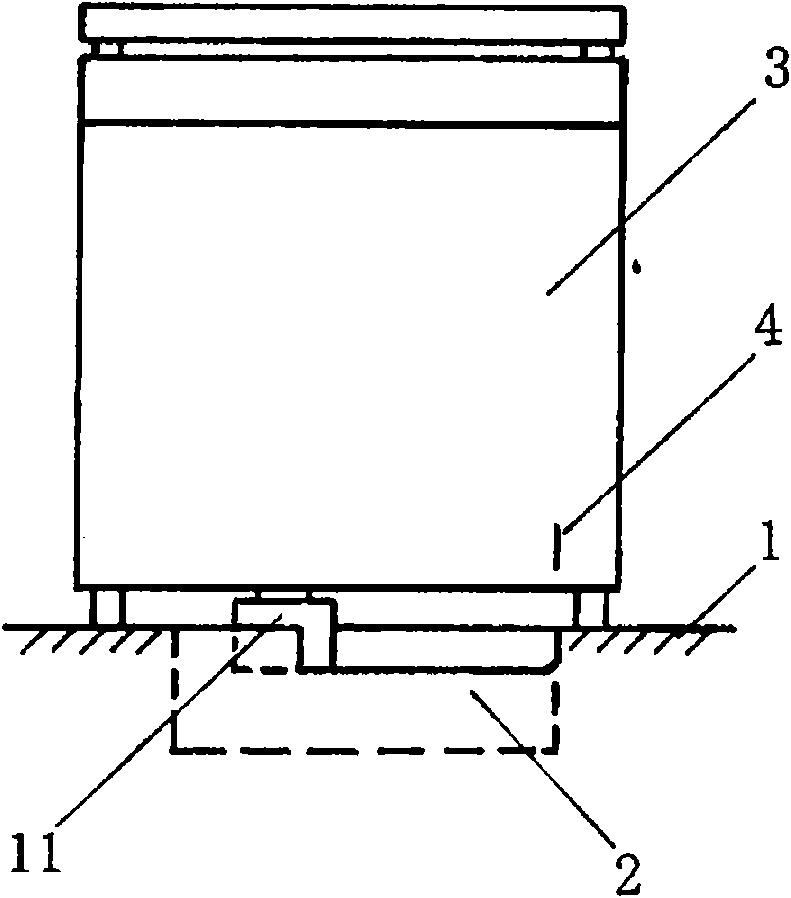

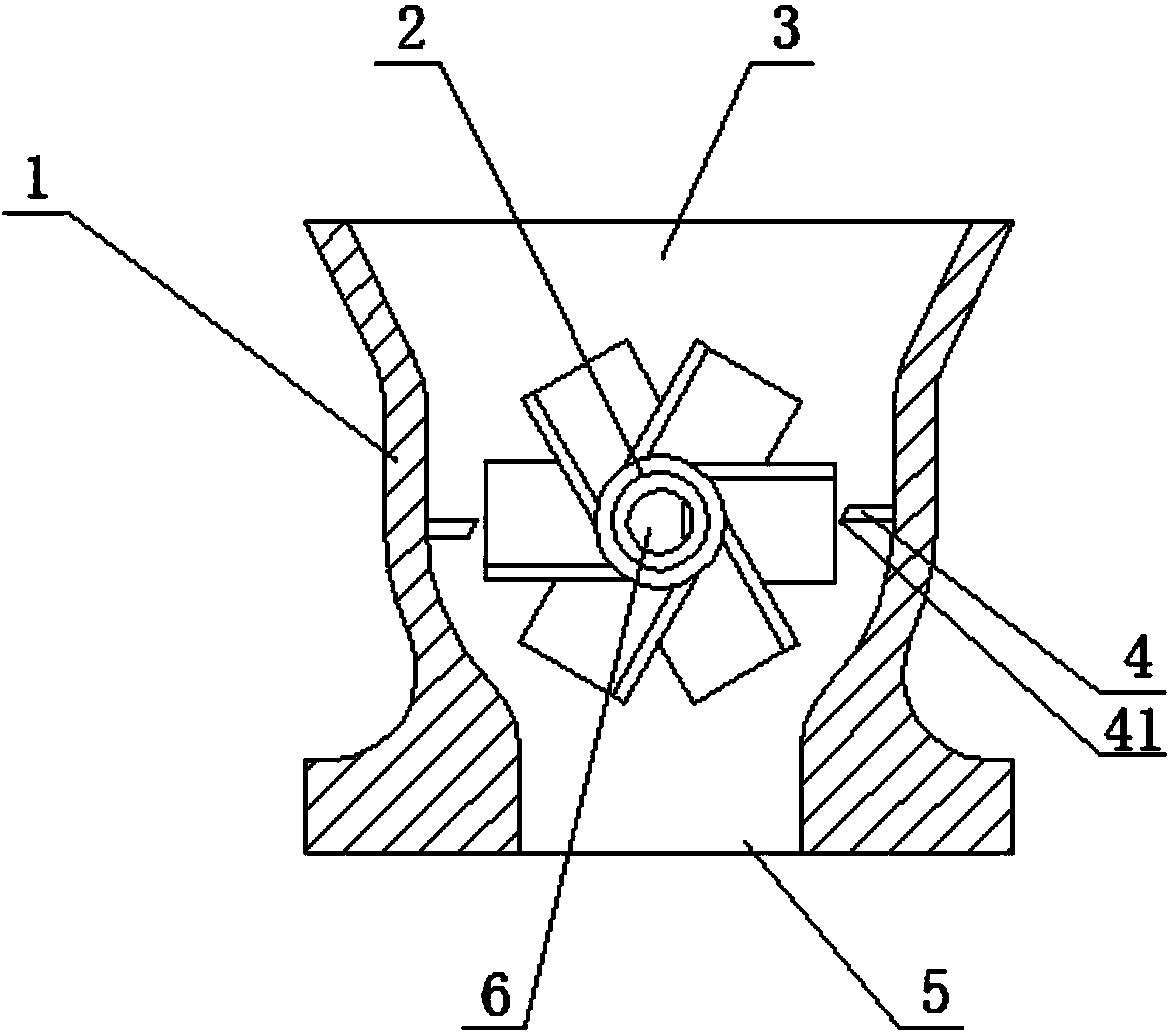

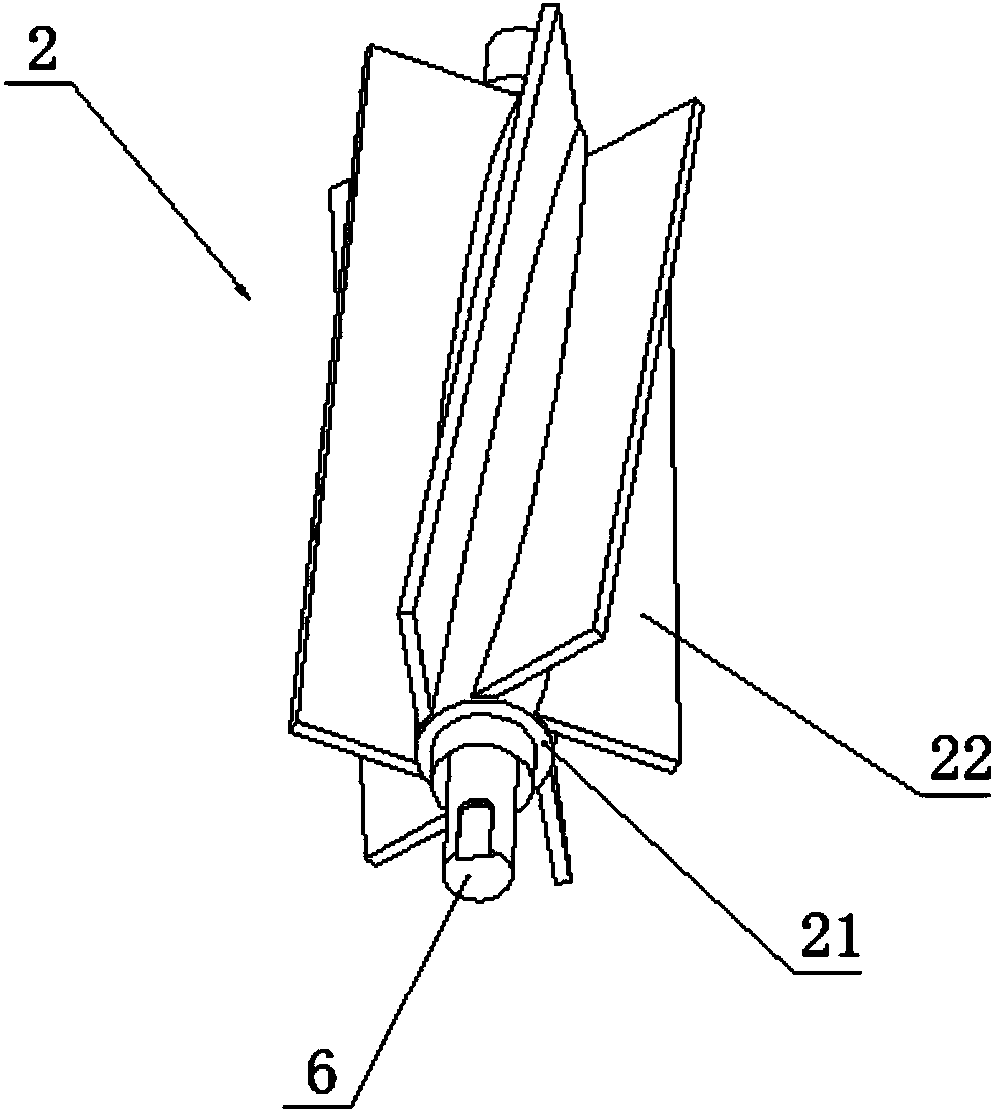

Anti-blocking star type cinder valve

The invention discloses an anti-blocking star type cinder valve. The anti-blocking star type cinder valve comprises a shell and an impeller shaft, wherein the upper end and the lower end of the shell are provided with a feed port and a discharge port respectively, and the impeller shaft is arranged inside the shell and driven by a drive device to rotate. An impeller is fixedly arranged on the impeller shaft in a sleeved mode, and blades of the impeller deviate from the axis of a hub by an angle. The two radial sides, corresponding to the axis of the impeller hub, of the inner wall of the shell are provided with two baffles respectively, one side of each baffle is hinged to the inner wall of the shell, the two baffles are connected with one ends of two pre-tightening springs respectively, the other ends of the two pre-tightening springs are connected with the inner wall of the shell, and when the blades of the impeller rotate to the position corresponding to the baffles, gaps are reserved between the other sides of the baffles and the front edges of the blades of the impeller. According to the anti-blocking star type cinder valve, the shearing force can be reduced, and the blocking accident can be effectively prevented.

Owner:广西奥士达环境工程有限公司

Micro surgical cutting instruments

InactiveUS20090131961A1Small cutting forceLittle strengthIncision instrumentsCoatingsSurgical bladeEngineering

Owner:MYNOSYS CELLULAR DEVICES INC

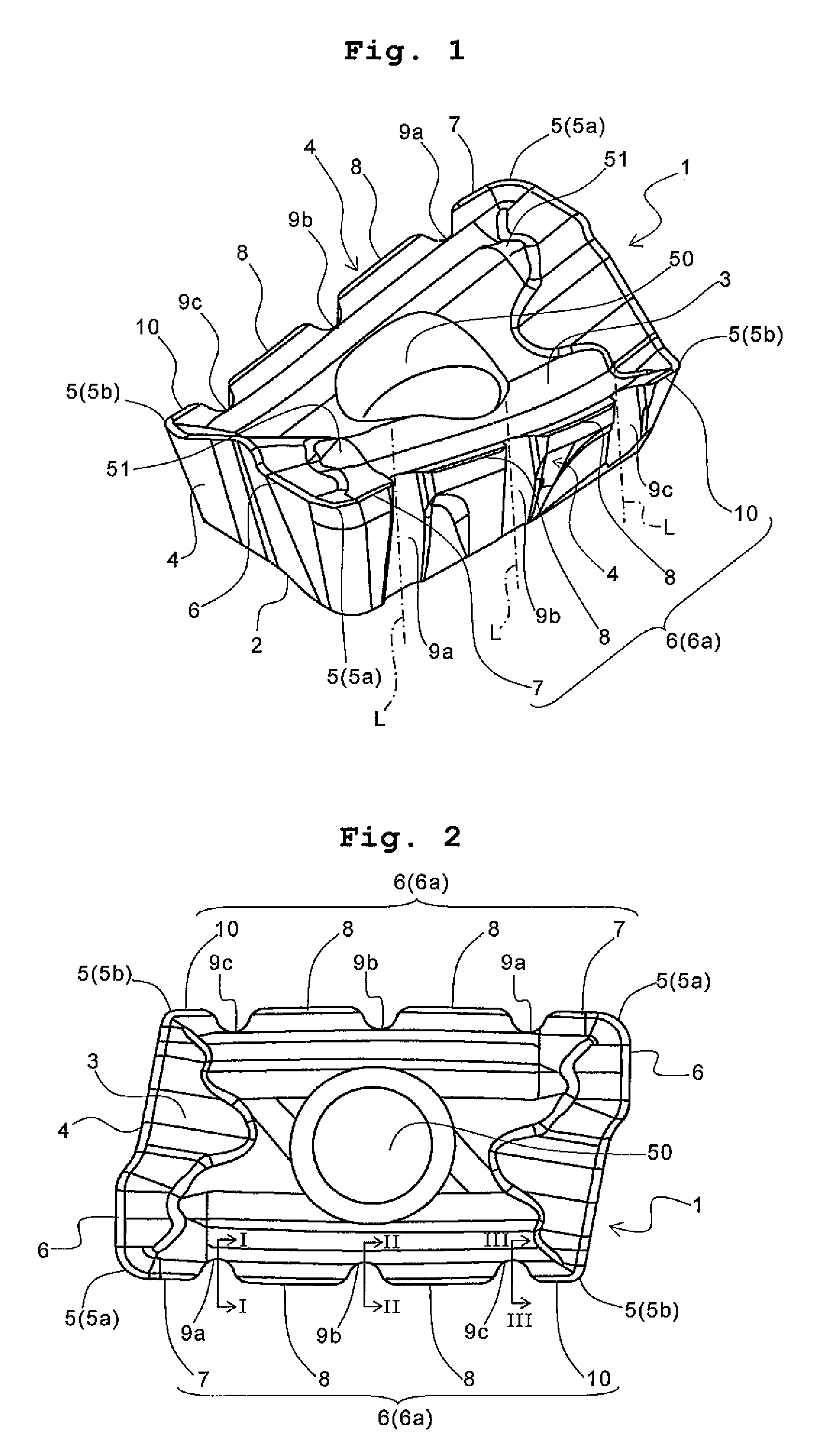

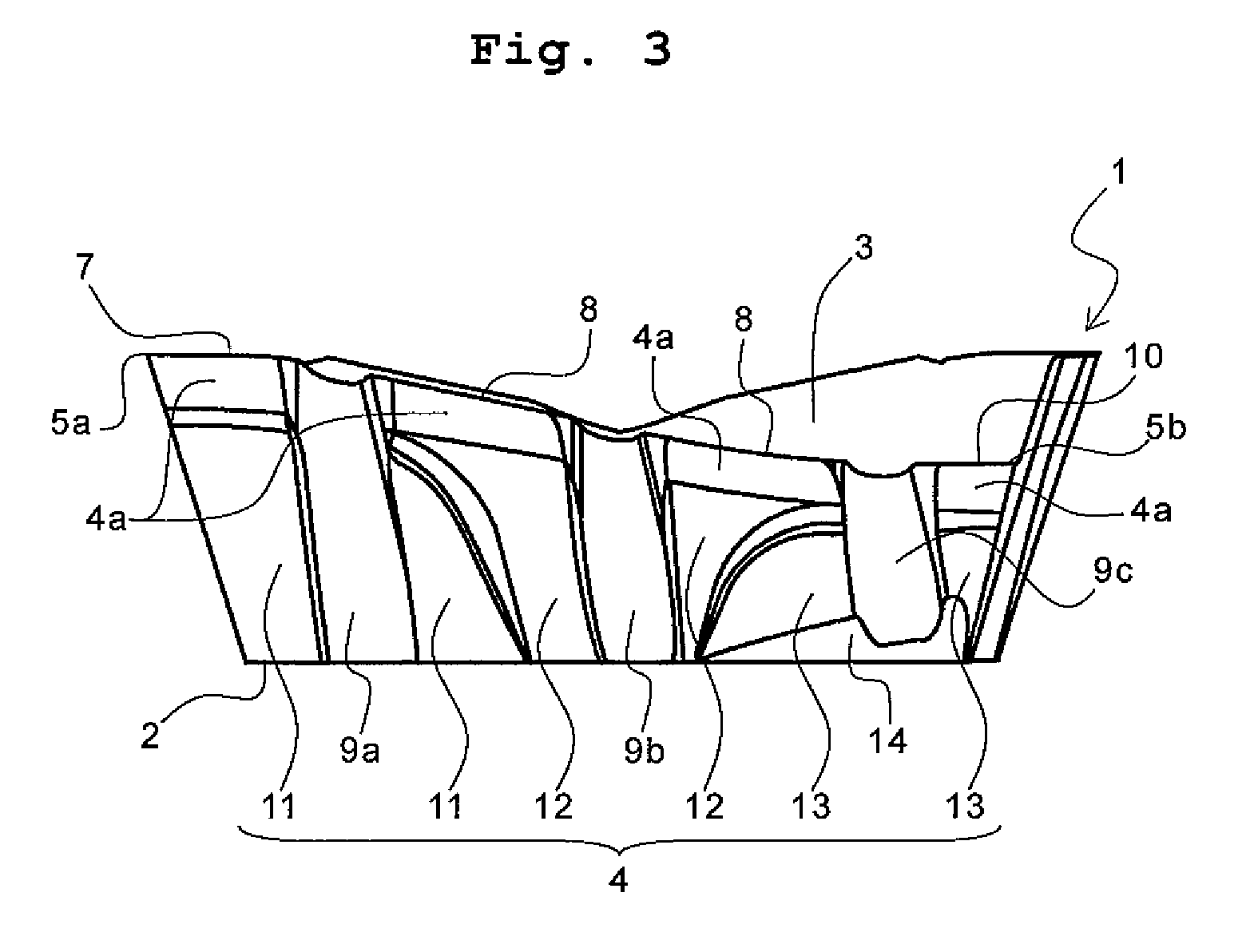

Cutting insert, cutting tool using the same, and cutting method

ActiveUS20110027027A1Reduce generationSmall cutting forceWood turning toolsTransportation and packagingHeight decreaseEngineering

An insert comprises an insert main body having an upper surface and a plurality of side surfaces, a cutting edge located between both ends of a ridge which is between at least one side surface among the side surfaces and the upper surface, a high-positioned portion located at one end of the ridge, and a low-positioned portion located lower in the thickness direction of the insert main body than the high-positioned portion and located at the other end of the ridge. The cutting edge comprises a first flat cutting edge having substantially the same height as the high-positioned portion, and a tilted cutting edge having a height decreasing from the high-positioned portion toward the low-positioned portion. On at least the one side surface, at least one groove extends from the side surface to the upper surface to divide the cutting edge by the groove, and at least the one groove is formed at a region including an intersection of a first extension line formed by imaginarily extending the first flat cutting edge with a second extension line formed by imaginarily extending the tilted cutting edge. This enables reduction in the occurrence of vibration during cutting, and the chipping.

Owner:KYOCERA CORP

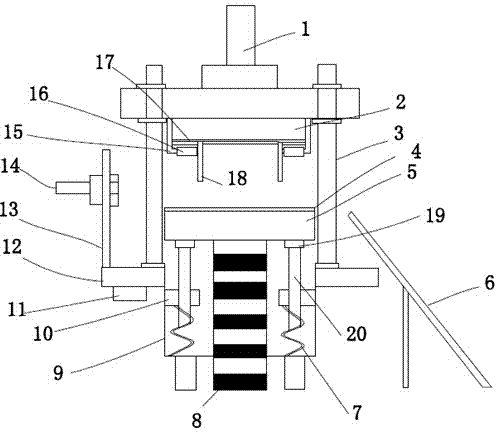

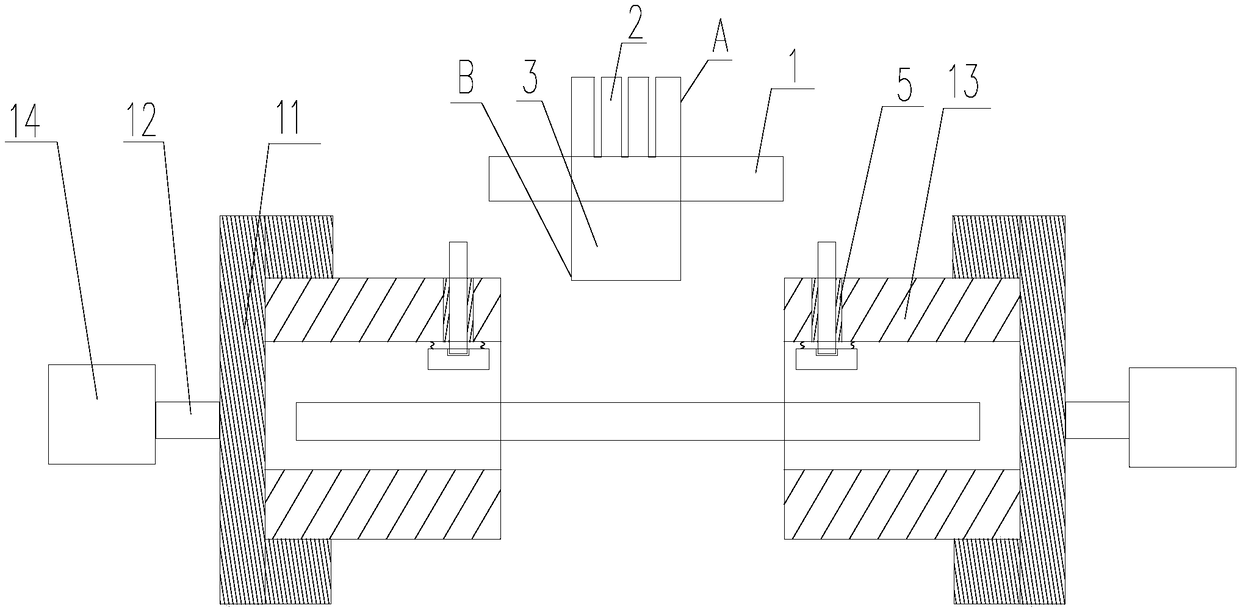

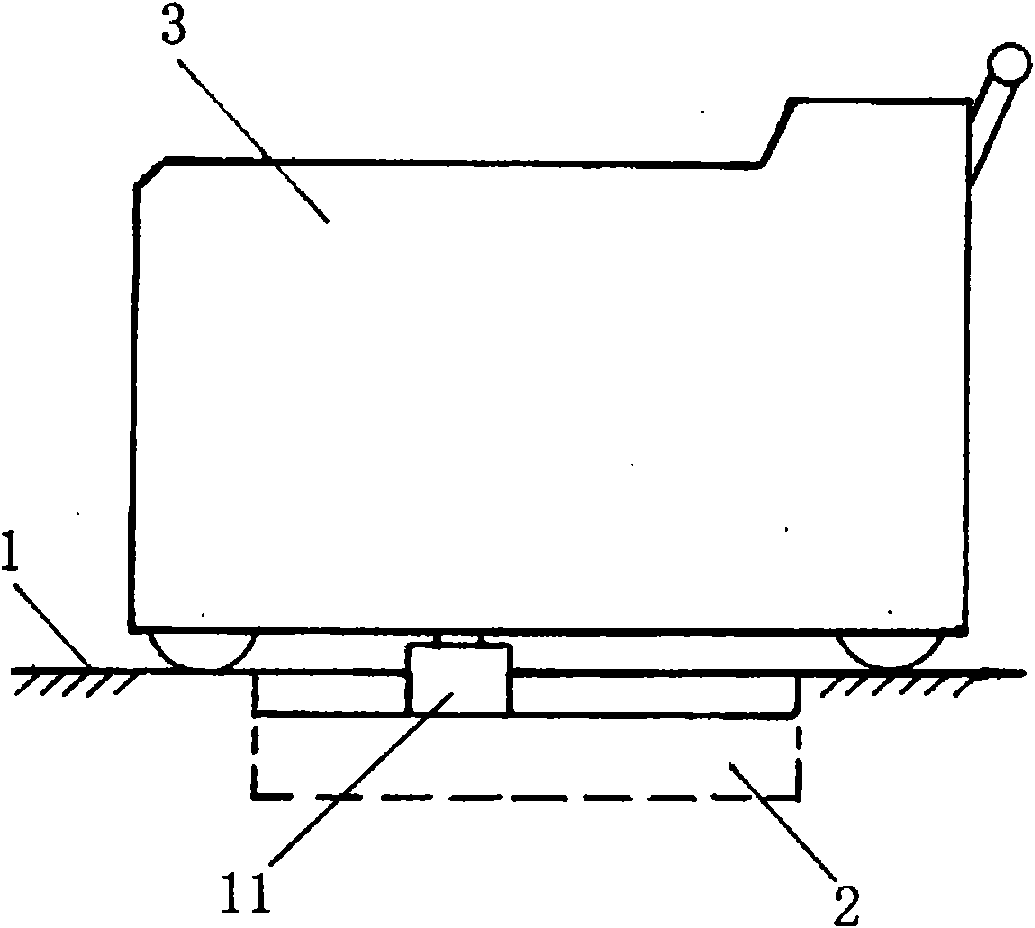

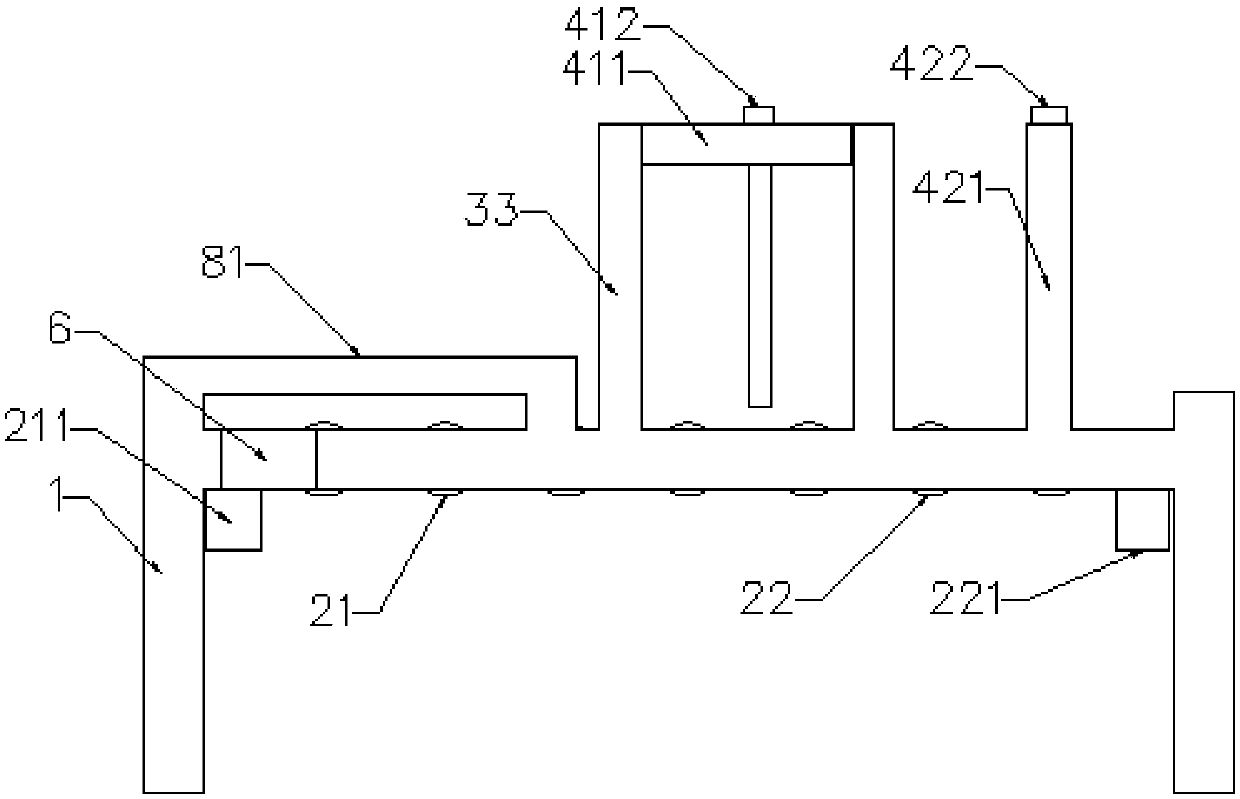

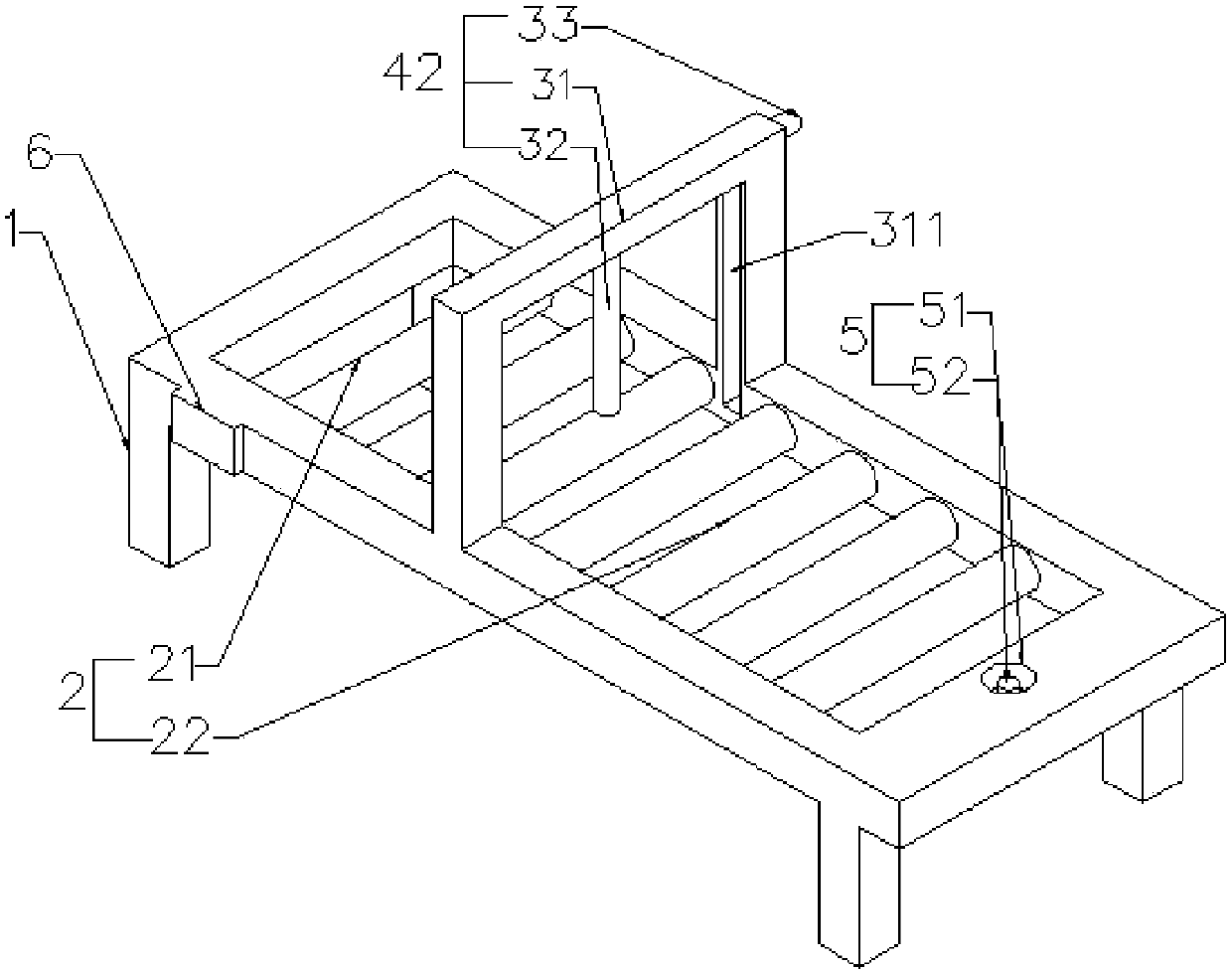

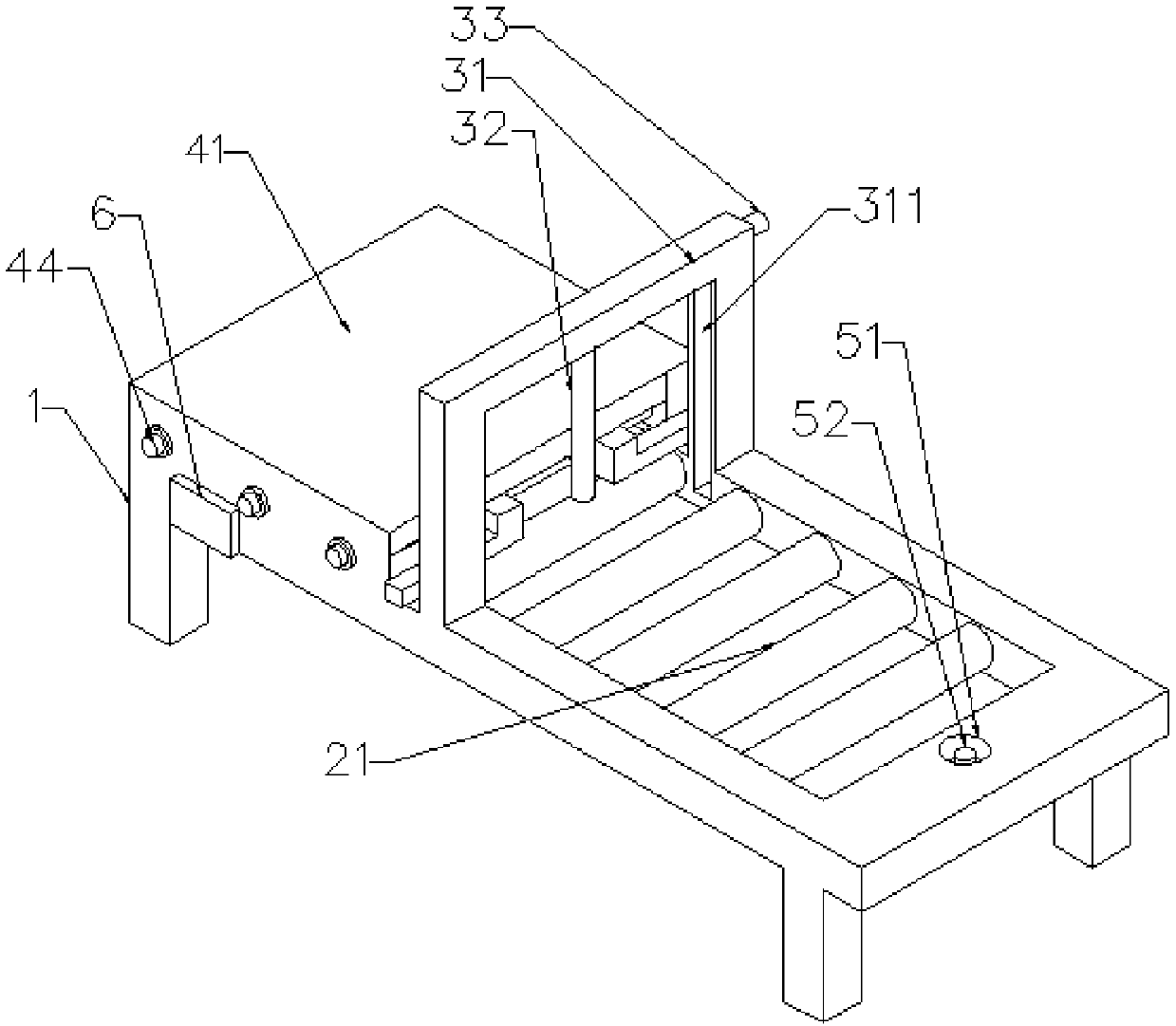

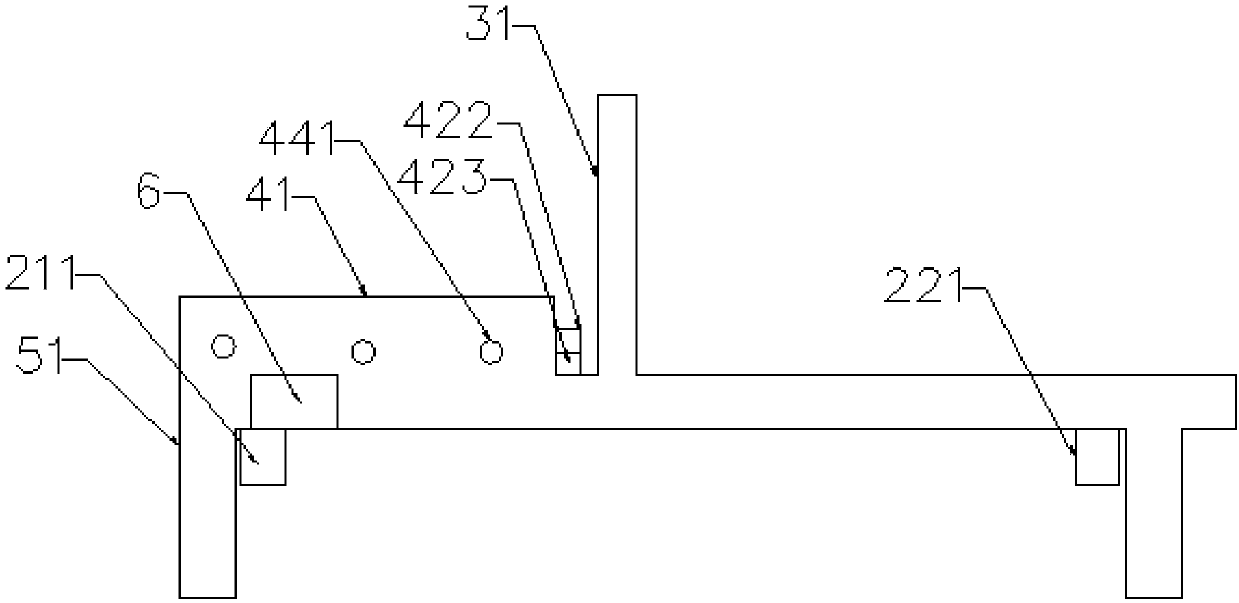

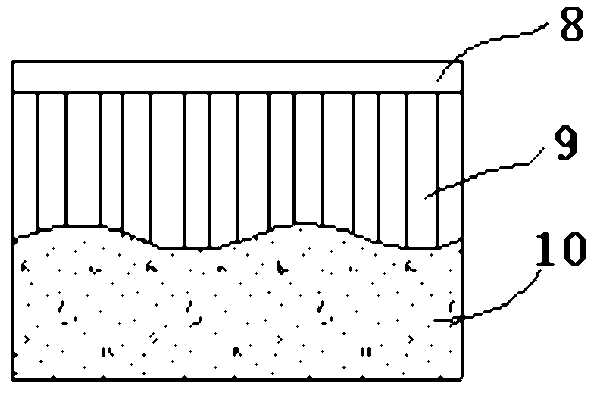

Cutting equipment of autoclaved aerated concrete blocks

InactiveCN104842466ASmall cutting forceAvoid damageWorking accessoriesStone-like material working toolsMaster cylinderSlide plate

The invention discloses cutting equipment of autoclaved aerated concrete blocks. The cutting equipment comprises a master cylinder, two cylinder pillars, a workbench and an electric telescopic bar. The upper surface of a transverse plate is provided with the cylinder pillars; a tool holder is mounted at the bottom of the master cylinder; an inner cavity of the tool holder is provided with filler and a slide plate sequentially from inside to outside; the lower end of the slide plate is provided with a cutting tool; the left and right ends of the cutting tool are provided with fixing blocks; the lower end of the workbench is provided with a guide pillar; the guide pillar penetrates limiting blocks fixed on the sidewall of a base and is connected with the top end of a spring. The inner cavity of the tool holder is provided with the filler, the guide pillar is disposed in an inner cavity of the base, the spring is mounted at the lower end of the guide pillar, and thus cutting force of tools applied to the workbench can be effectively relived and damage of the tools and a tool table can be effectively avoided; the limiting blocks mounted on the left and right of the base allow the spacing of the tools to be adjusted, meeting the needs for different sizes.

Owner:HANCHUAN XINXIN TECH

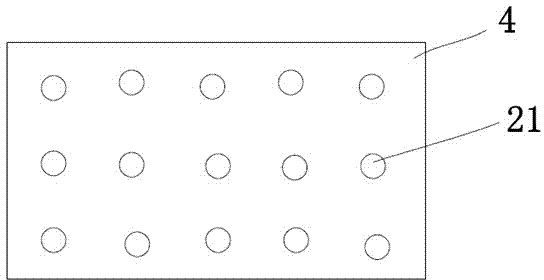

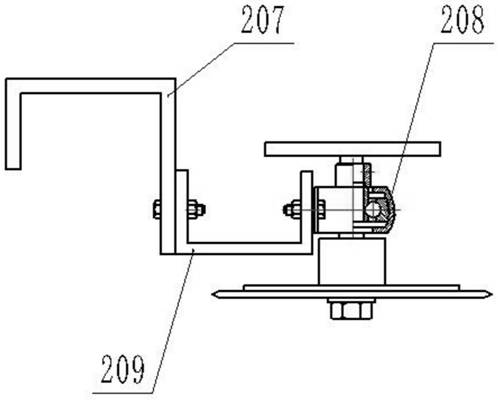

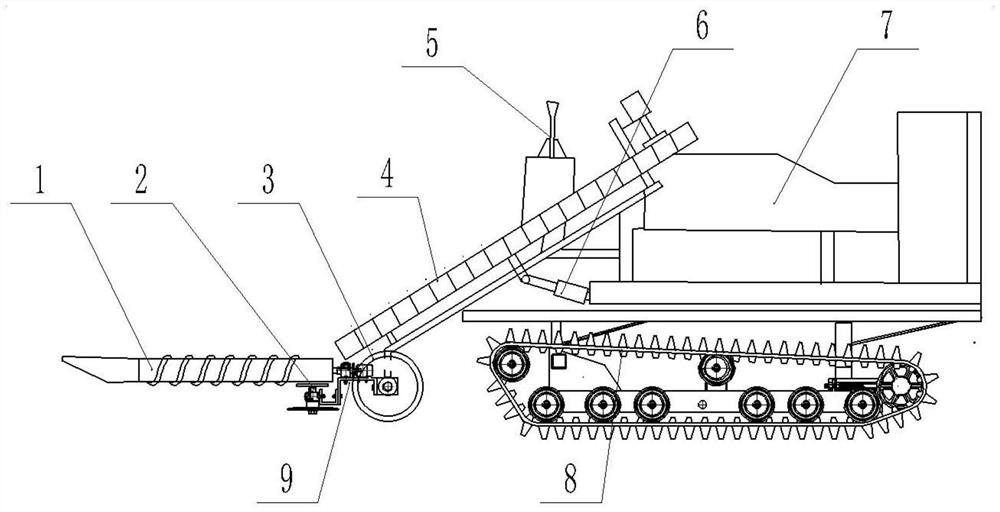

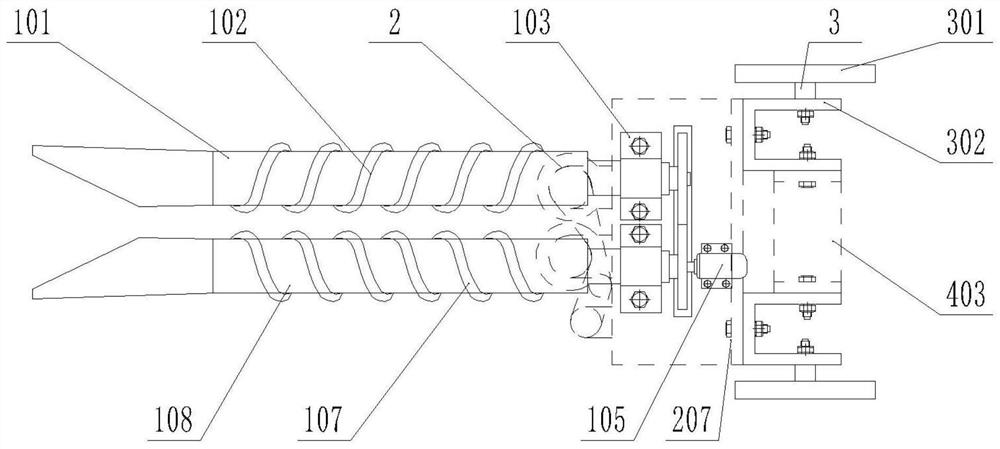

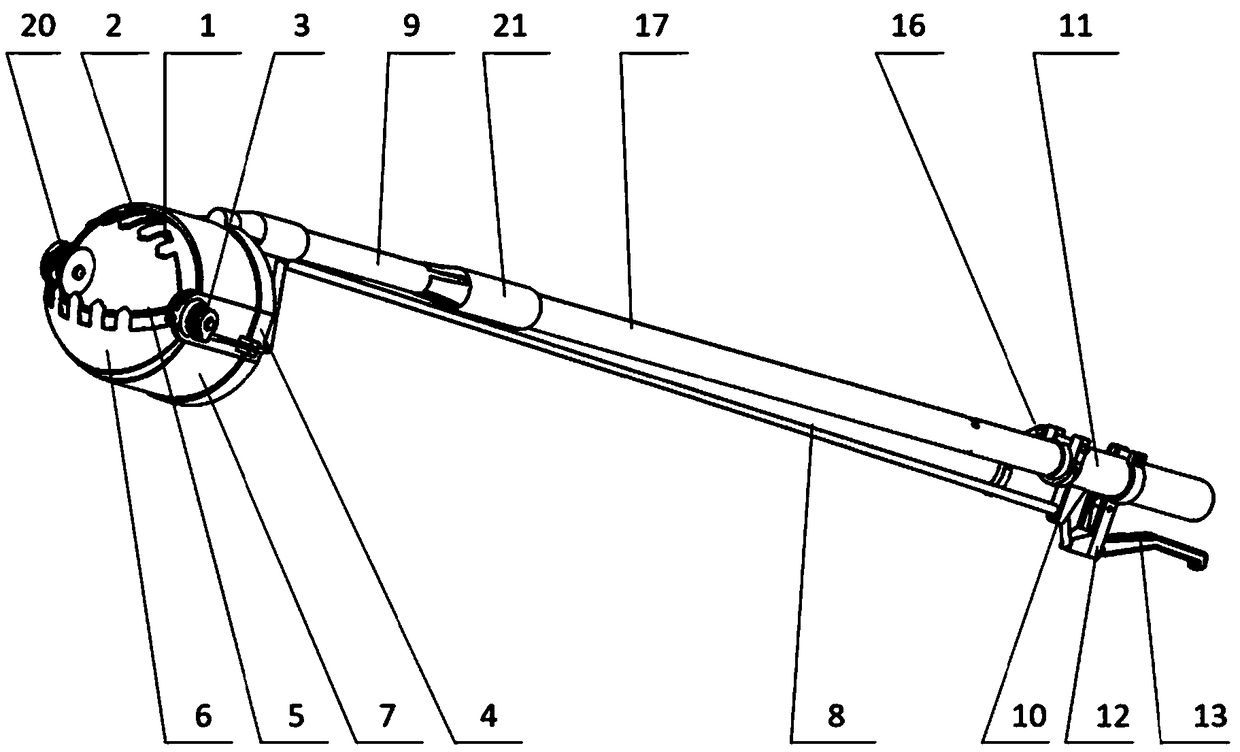

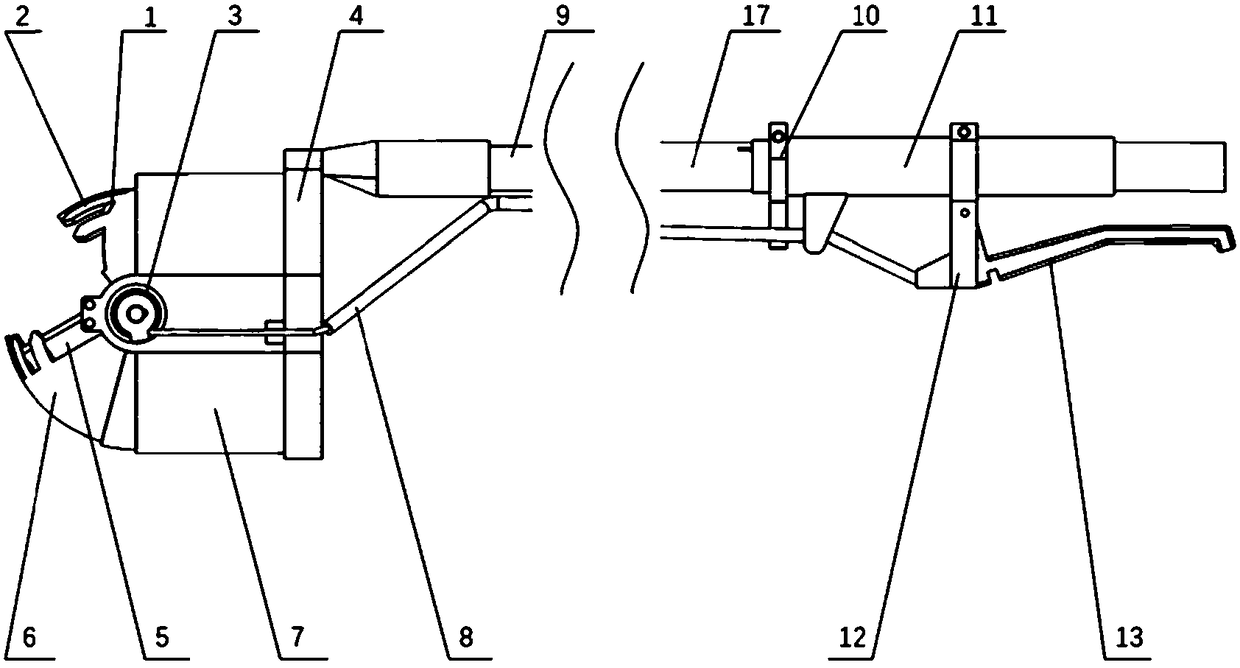

Disordered close planting broccoli harvester with intelligent cutting function

PendingCN113207422ACutting stabilityRealize orderly lifting and conveyingHarvestersAgricultural undercarriagesAgricultural engineeringDisc cutter

The invention provides a disordered close planting broccoli harvester with an intelligent cutting function. The disordered close planting broccoli harvester comprises a double-helix leaf removing device, a constant-speed reverse double-disc cutting device, walking auxiliary wheels, a transverse conveying device, a lifting supporting rod, a collecting device and a crawler chassis; the collecting device is installed on the crawler chassis, and the transverse conveying device is installed on the crawler chassis through a lifting supporting rod; the constant-speed reverse double-disc cutting device comprises a motor A, a right disc cutter, a left disc cutter and a cutter support; a cutter connecting plate is fixed to the cutter support, one end of the transverse conveying device is installed on the cutter support, the walking auxiliary wheels are installed on the two sides of the cutter support, and the double-helix leaf removing device is installed on the cutter support; and the constant-speed reverse double-disc cutting device is located below the double-spiral leaf removing device. The disordered close planting broccoli harvester realizes stable cutting of broccoli rootstocks, and ensures that the cut rootstocks avoid cut abnormity problems such as damage, splitting and the like.

Owner:JIANGSU UNIV

Anti-deformation cutting device of metal hose

InactiveCN108856860AActive fixed connectionReduce distortionTube shearing machinesShearing machine accessoriesScrew threadMetal hose

The invention discloses an anti-deformation cutting device of a metal hose. The rotation speed of a cutter body is 0.5N times of the rotation speed of the metal hose, wherein N is a positive integer,and the cutter body only rotates one round; the two ends of the metal hose are placed into a cylindrical placing box with the middle part being hollow, the placing box is provided with four through holes, the through holes are in threaded connection with connection rods, the two ends of the connection rods are at outside of the through holes, the ends, in the placing box, of the connection rods are connected with connection plates, the connection plates on the four connection rods form a hollow cylinder, the connection rods rotate in the through holes to adjust the distance between the connection plates and the inner wall of the placing box, and the metal hose is fixed into the hollow cylinder composed of the four connection plates. The device can effectively relieve the stress when cutting the metal hose to prevent the metal hose from deforming in the cutting process, and thus the metal hose is more convenient to use for a long time.

Owner:CHENGDU ZHIRONG ZHICHUANG INTPROP MANAGEMENT CO LTD

Cutting insert, cutting tool using the same, and cutting method

ActiveUS8579558B2Reduce generationSmall cutting forceWood turning toolsTransportation and packagingHeight decreaseEngineering

Owner:KYOCERA CORP

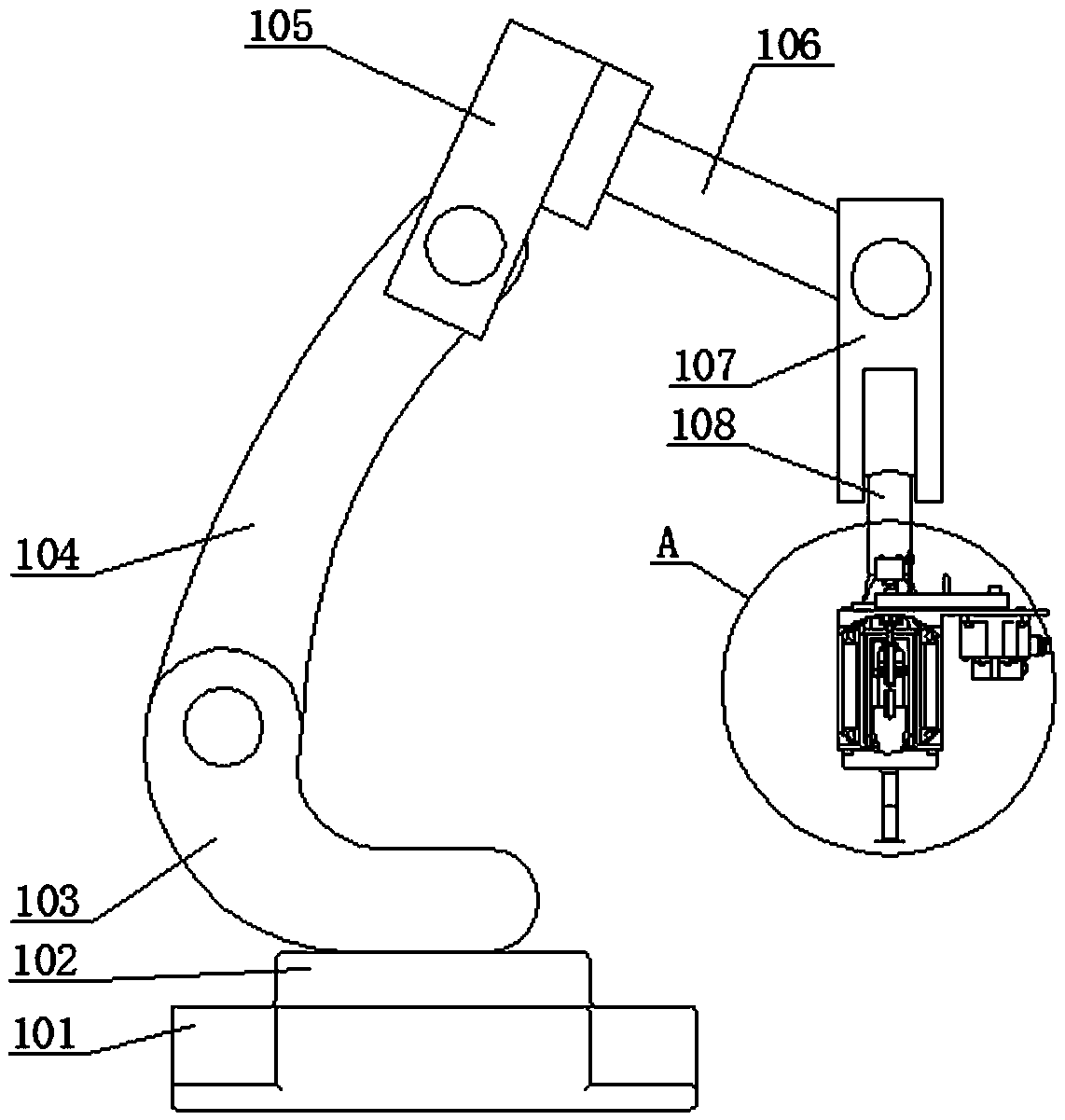

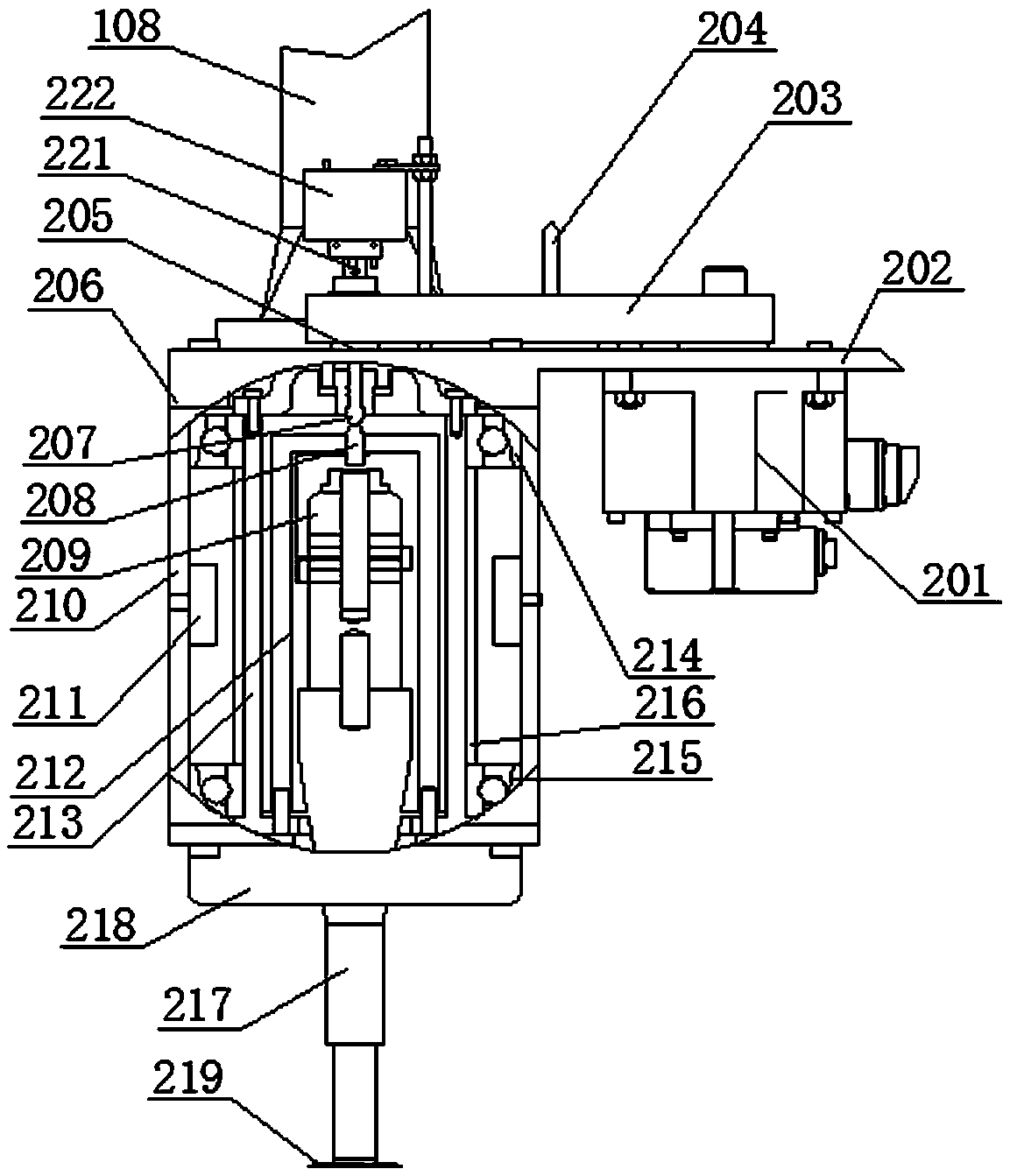

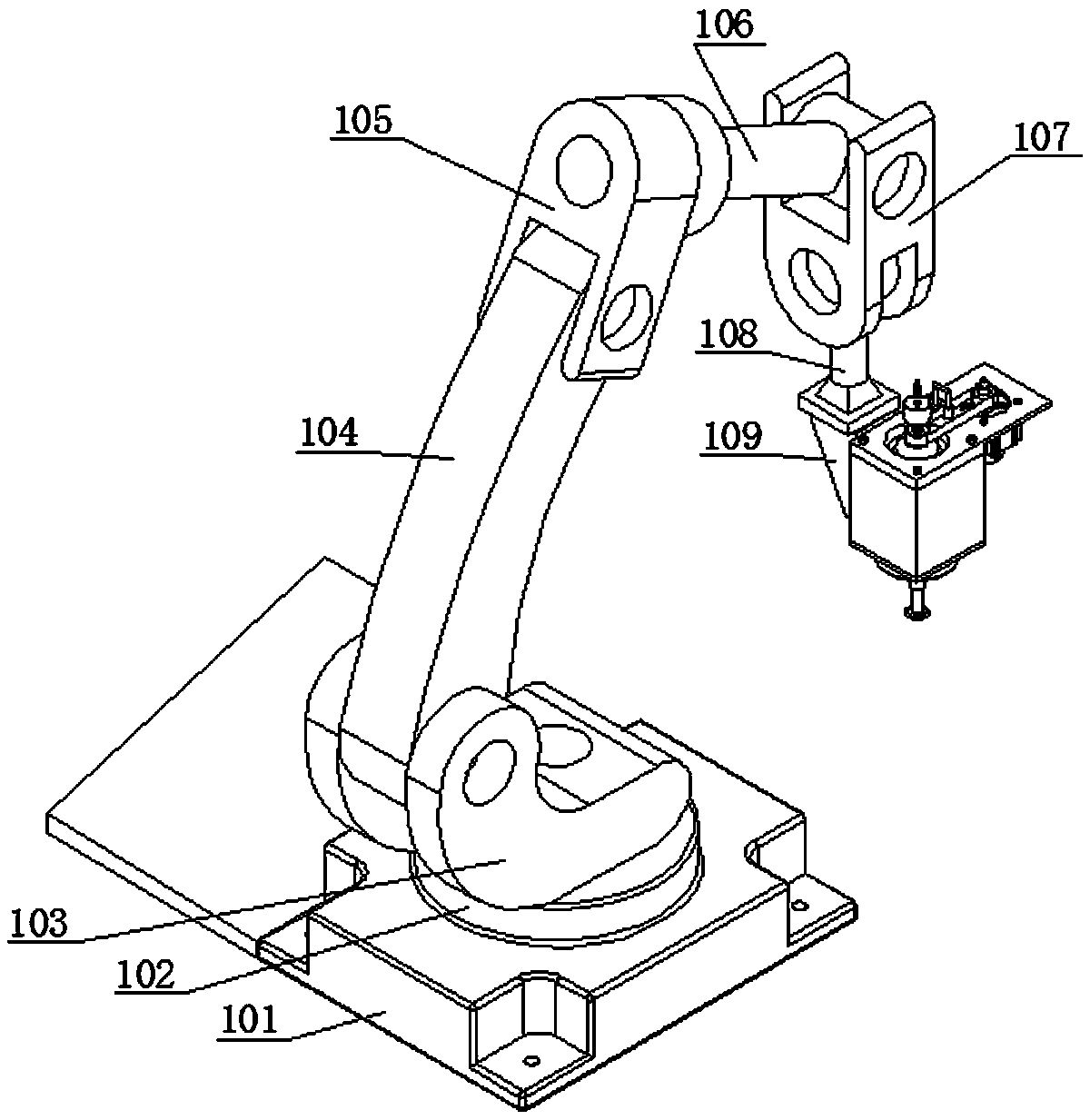

Ultrasonic cutting robot

PendingCN108161458ANo pollution in the processReduce volumeProgramme-controlled manipulatorOther manufacturing equipments/toolsNumerical controlPunching

The invention discloses a ultrasonic cutting robot, and belongs to the technical field of cutting devices. The ultrasonic cutting robot comprises a robot mechanism and a ultrasonic cutting main shaftmechanism; the ultrasonic cutting main shaft mechanism is mounted at the tail end of the robot mechanism; the robot mechanism adjusts the position and the direction of the ultrasonic cutting main shaft mechanism; and the ultrasonic cutting main shaft mechanism comprises a servo motor, a synchronous belt, a ultrasonic main shaft, an upper contact, a lower contact, a transducer and an amplitude change rod. A robot technology, a numerical control technology, a ultrasonic vibration machining technology and a composite material machining process are applied to the composite material cutting industry to replace five-axis and six-axis linkage numerical control machine tools for composite material machining so as to meet composite material complex shape cutting, milling and punching.

Owner:杭州辉昂科技有限公司

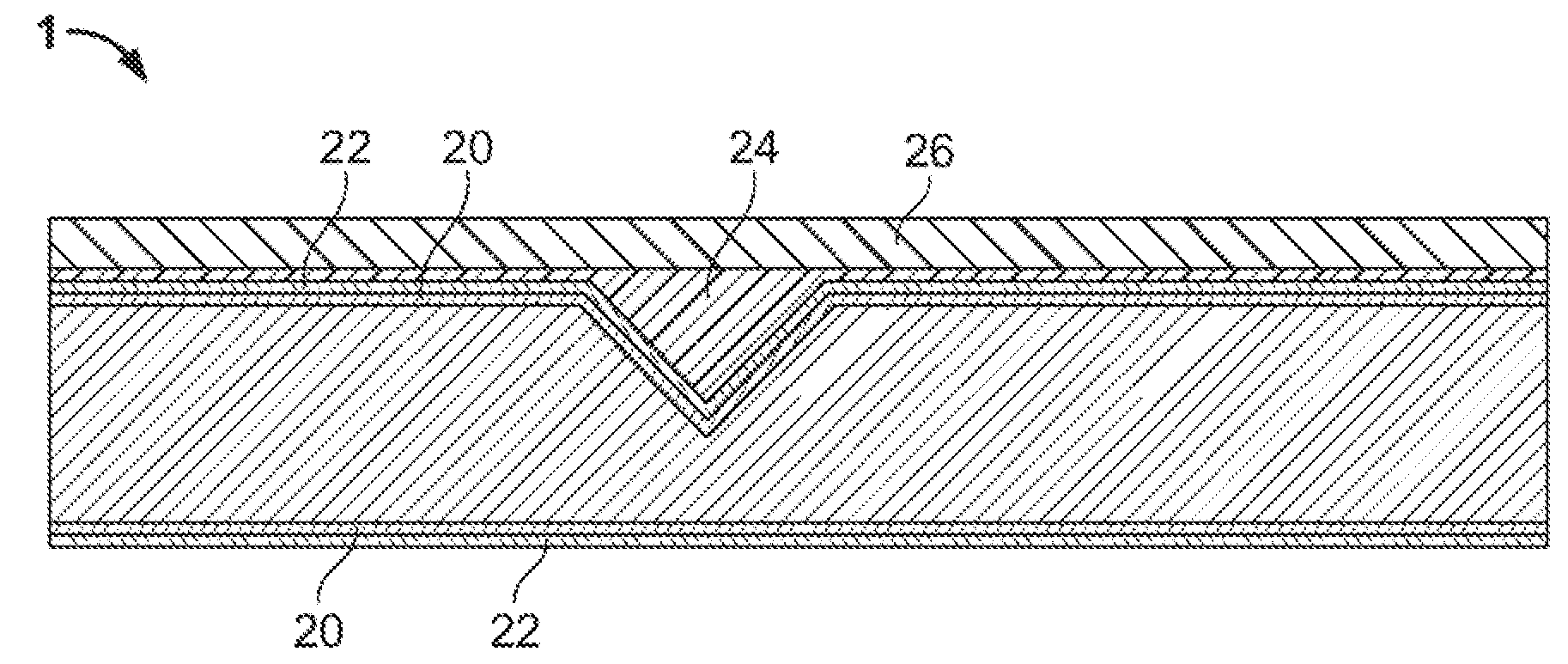

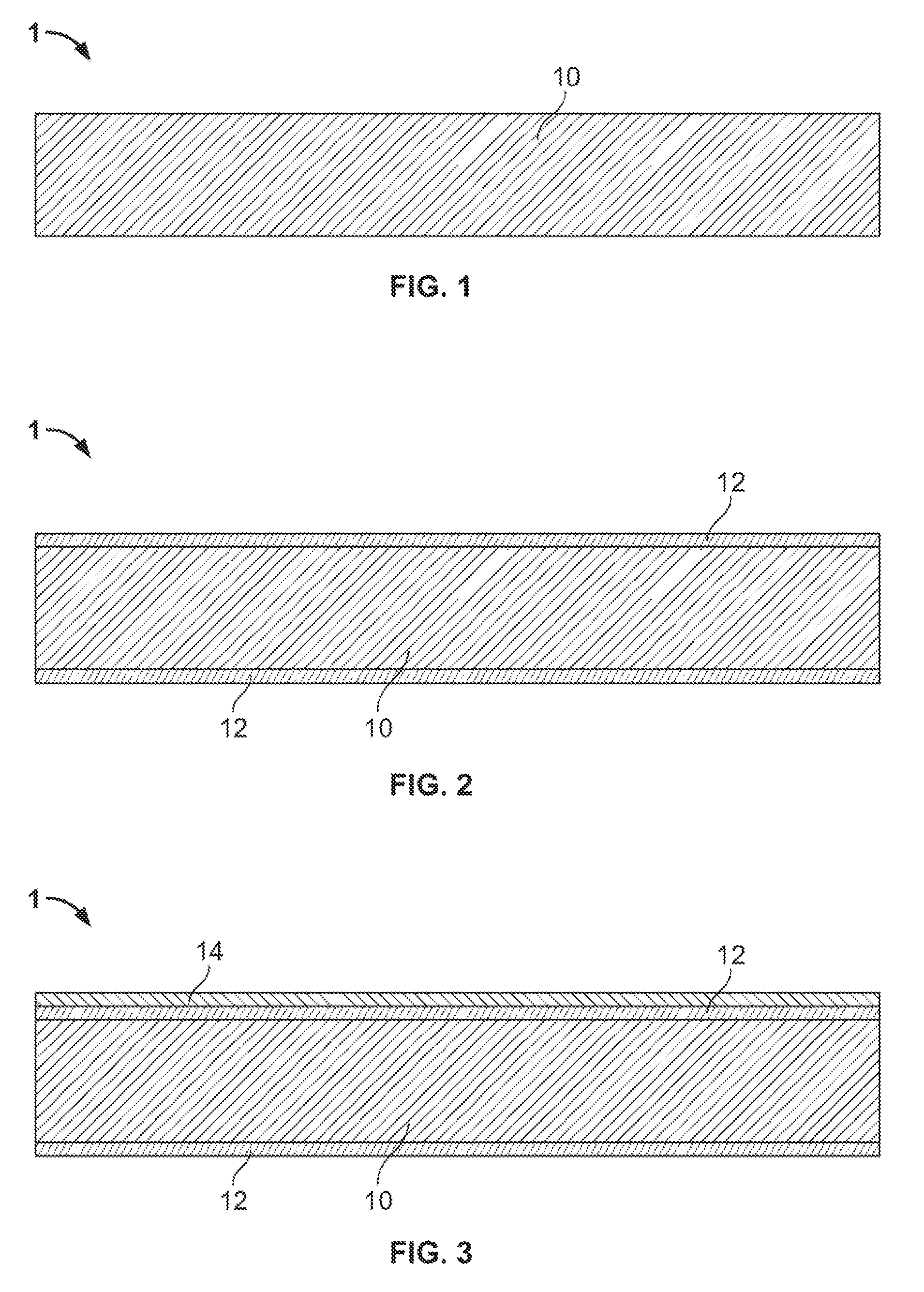

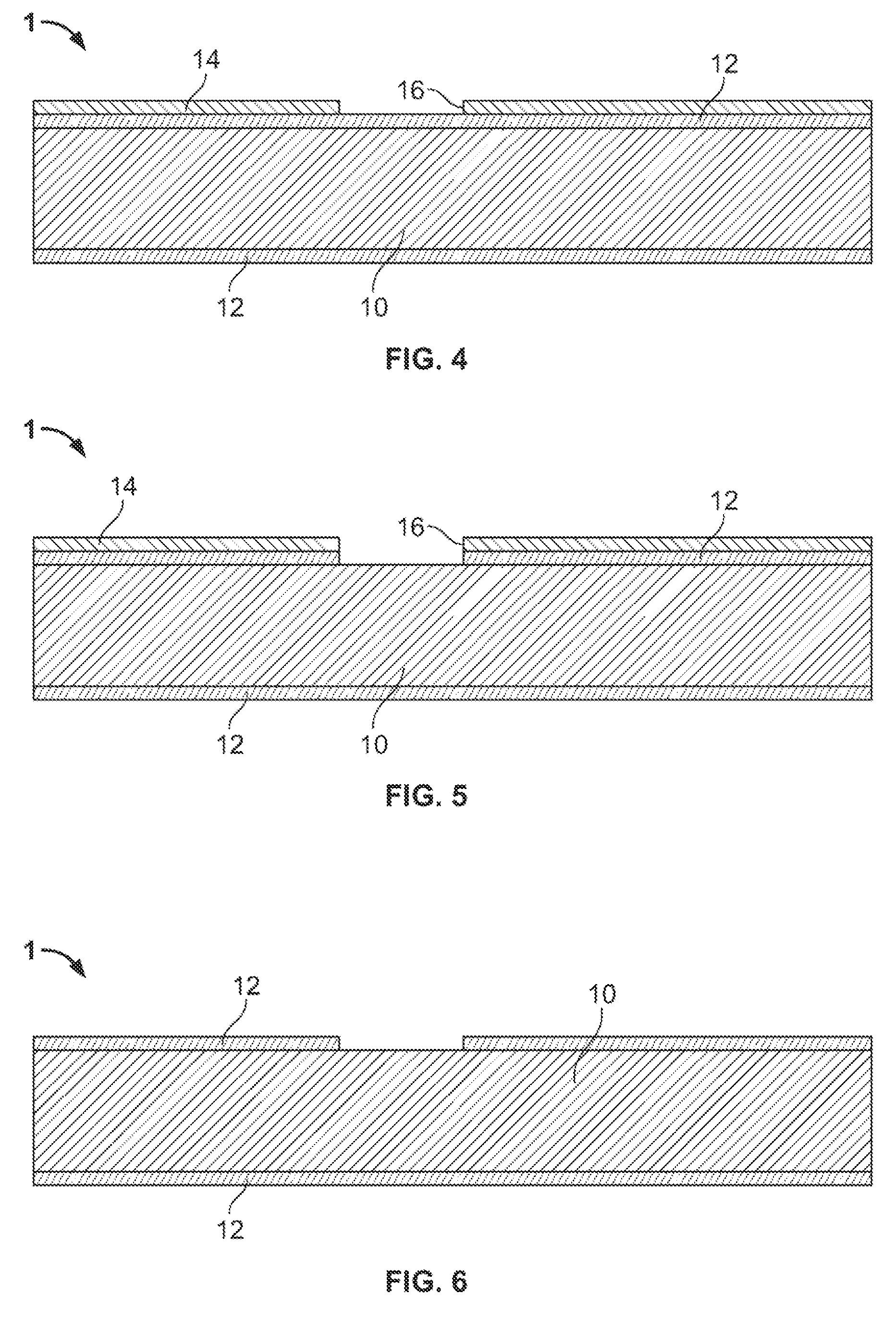

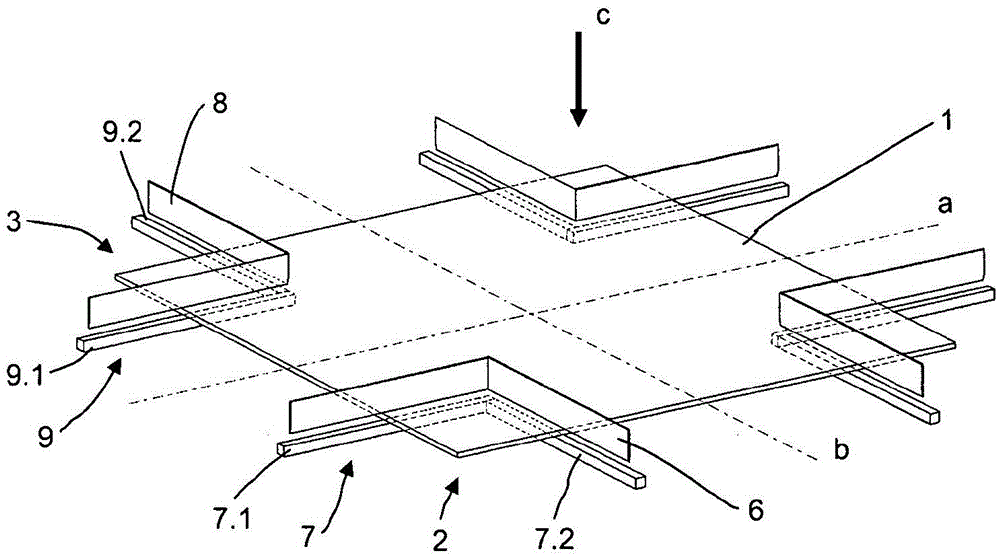

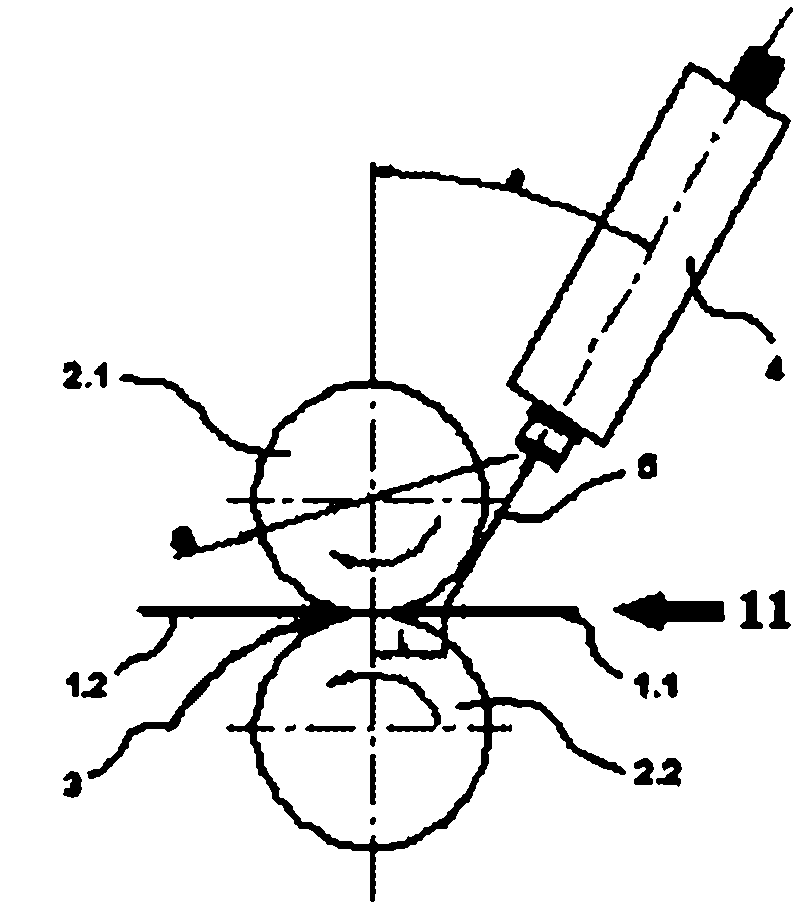

Device for cutting material sheets

InactiveCN105690861AReduce replacementSimplified Bias CorrectionBox making operationsPaper-makingEngineeringMechanical engineering

A device for cutting plane material sheets (1) to a sectionally concave contour by separating several discontiguous sections (2, 3), with at least two cutting units (4) that respectively feature a knife (6, 8) and a cutting bar (7, 9) and can be positioned relative to one another by adjusting devices (11, 12, 13, 14) such that format adjustments and corrections can be realized without tool change.

Owner:KOLBUS

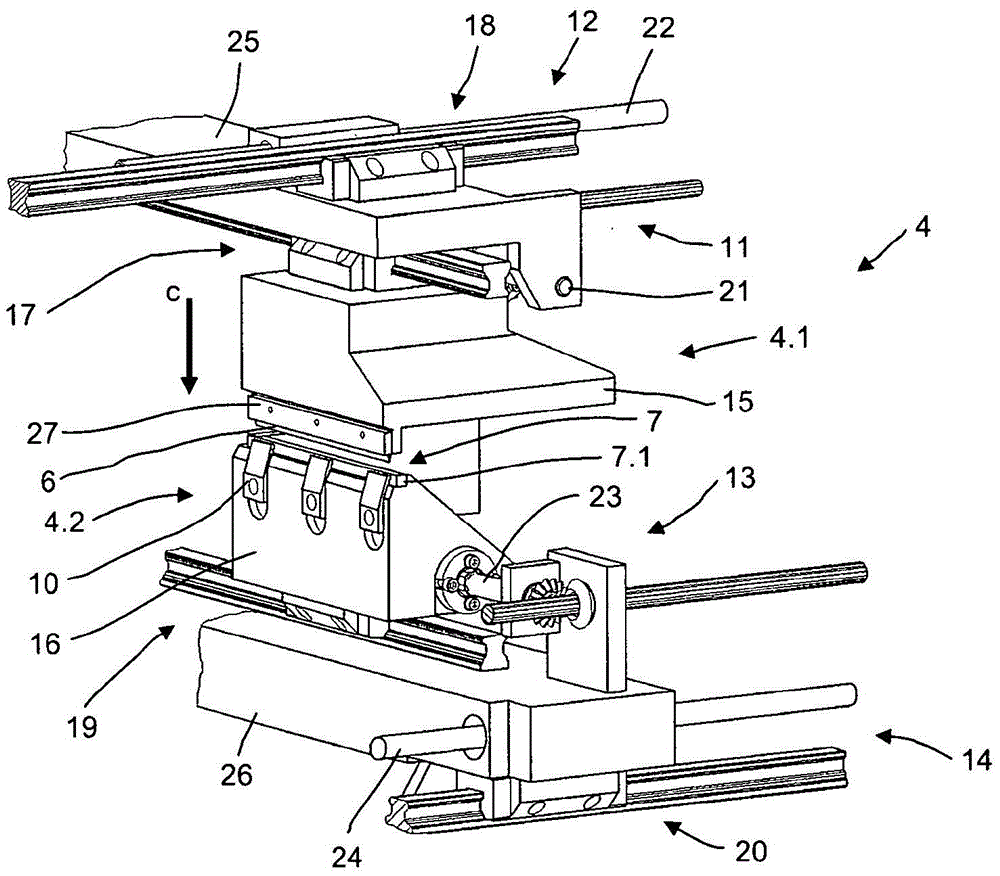

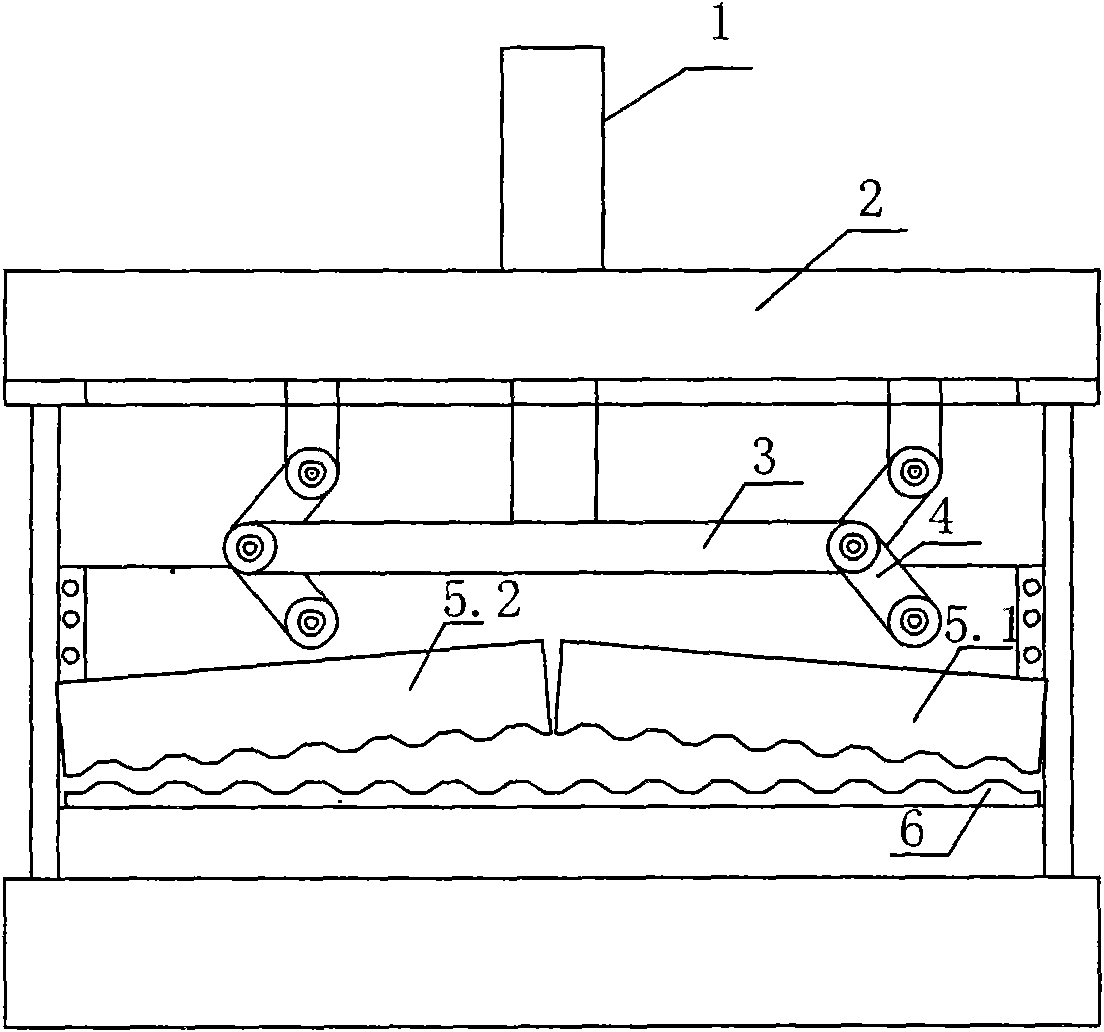

Method and device for cutting metal-moulded honeycomb thin wave plate

The invention relates to a method and a device for cutting a metal-moulded honeycomb thin wave plate, which are characterized in that: the cutting is performed from two sides to the middle part of the wave plate in a shearing way to make a shearing face at an oblique angle of 60+ / -10 degrees. The method and the device simply and obliquely cut the moulded honeycomb thin wave plate accurately at one time without additionally processing the oblique angle; at the same time, a cutting opening is flat and straight, has no burr edge and does not need to be deburred; and the cutting force in opposite direction is uniform and does not cause wave deformation, so secondary reshaping and processing are not needed. An upper cutter cuts at a high speed and with a high cutting efficiency while moving downwards and is used together with a wave plate continuously moulding machine; and equipment is simple and can obliquely cut at any oblique angle. A balance device arranged on the upper cutter can ensure that shearing on two sides is synchronous and that the shearing does not deform substantially. The cutting method of cutting from two sides to the middle part in the shearing way is weak in cutting force, simple in used equipment, low in requirement on the equipment and low in cost.

Owner:JIANGSU RUISHENG WATER TREATMENT

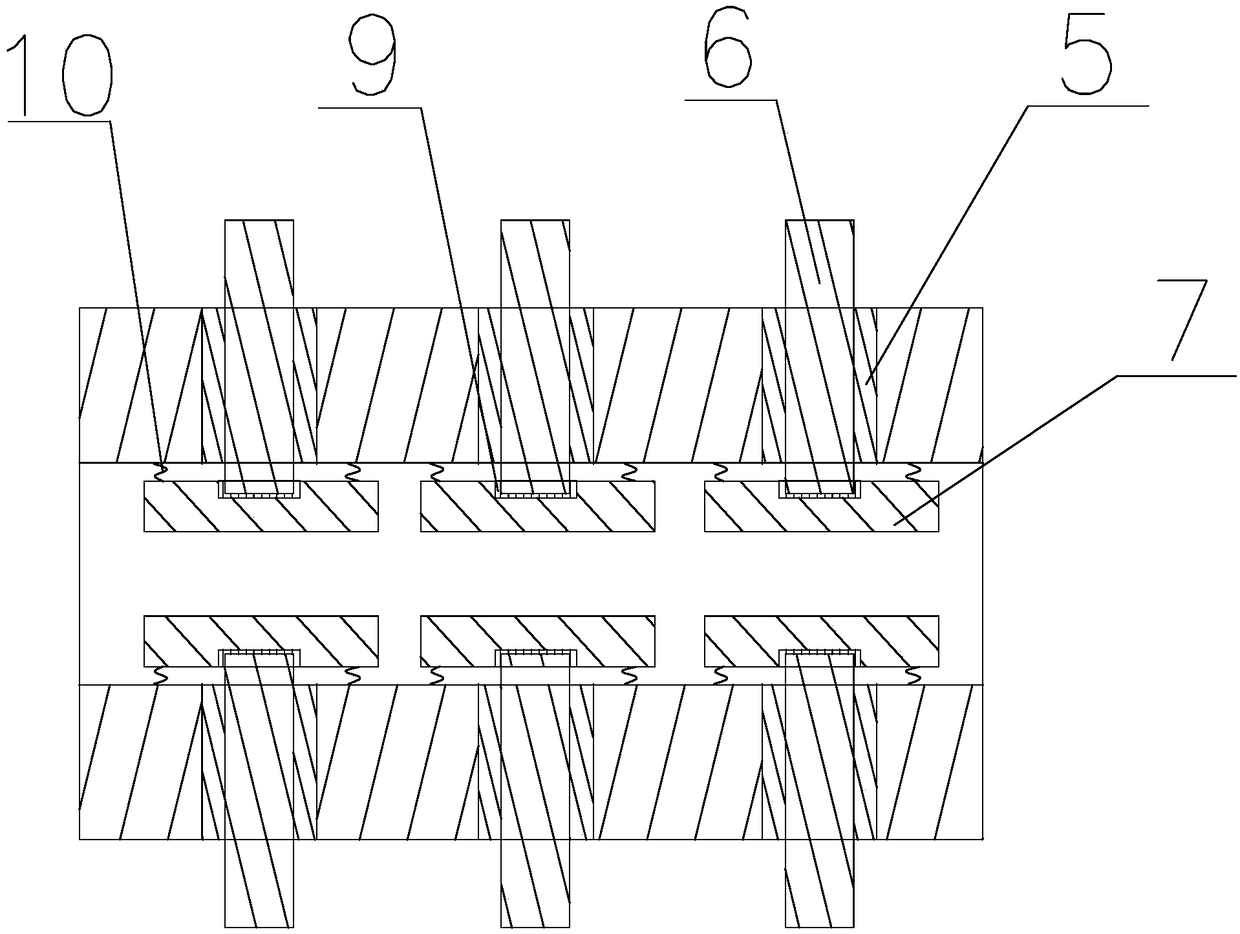

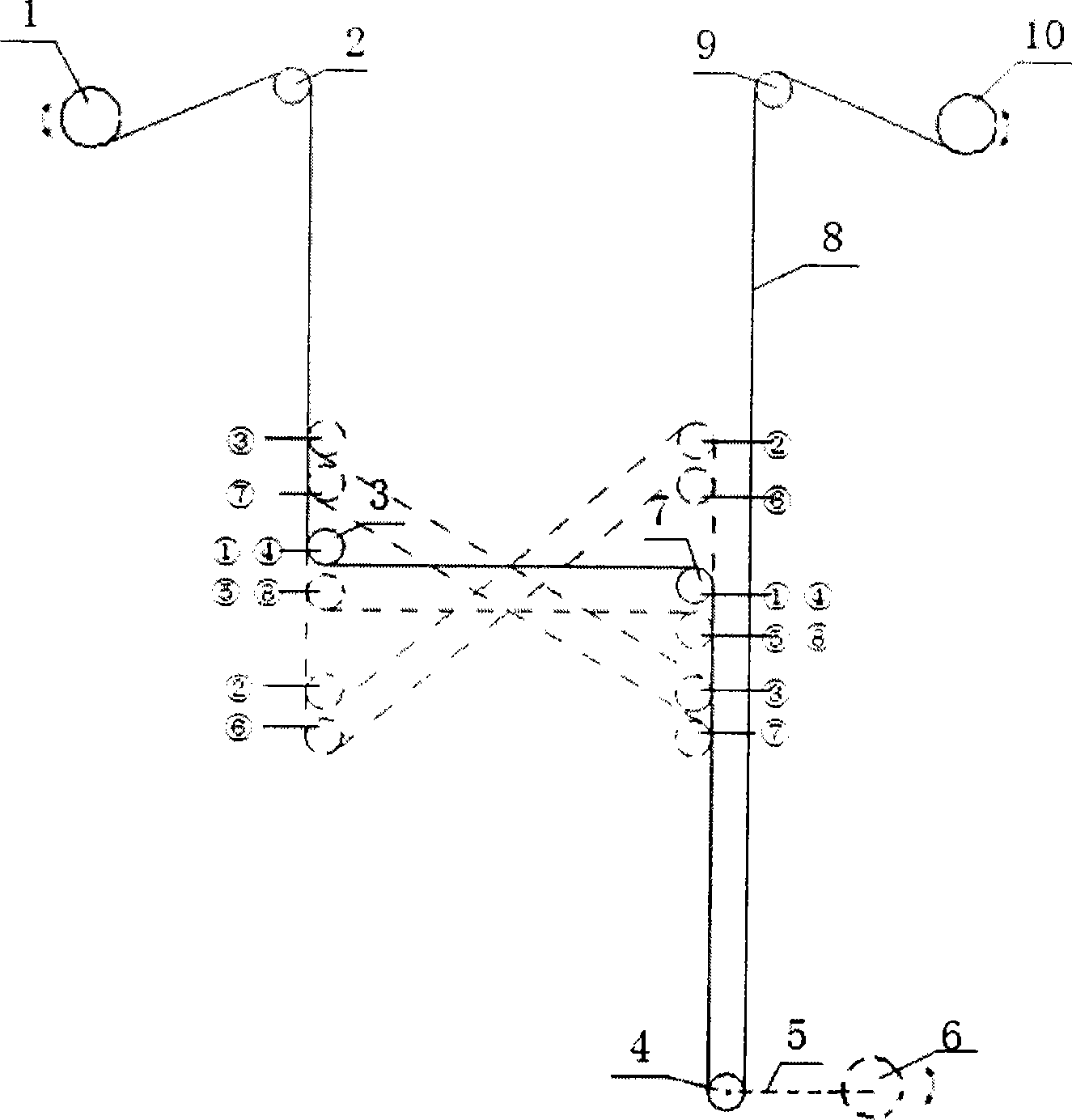

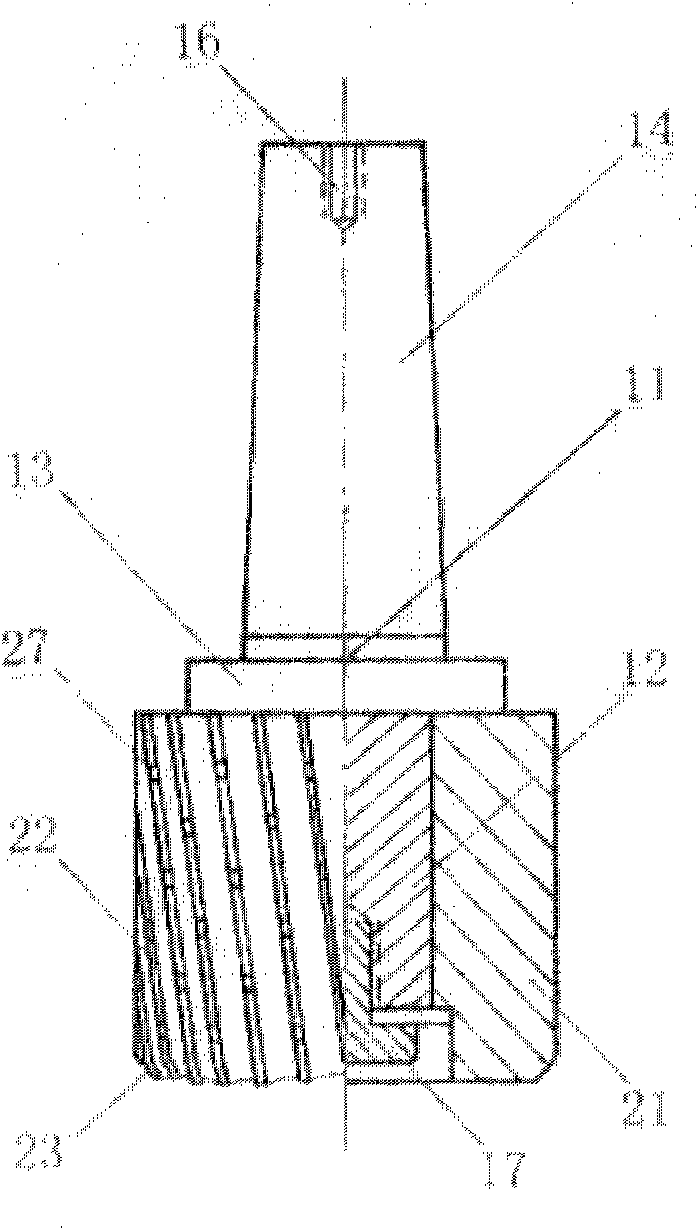

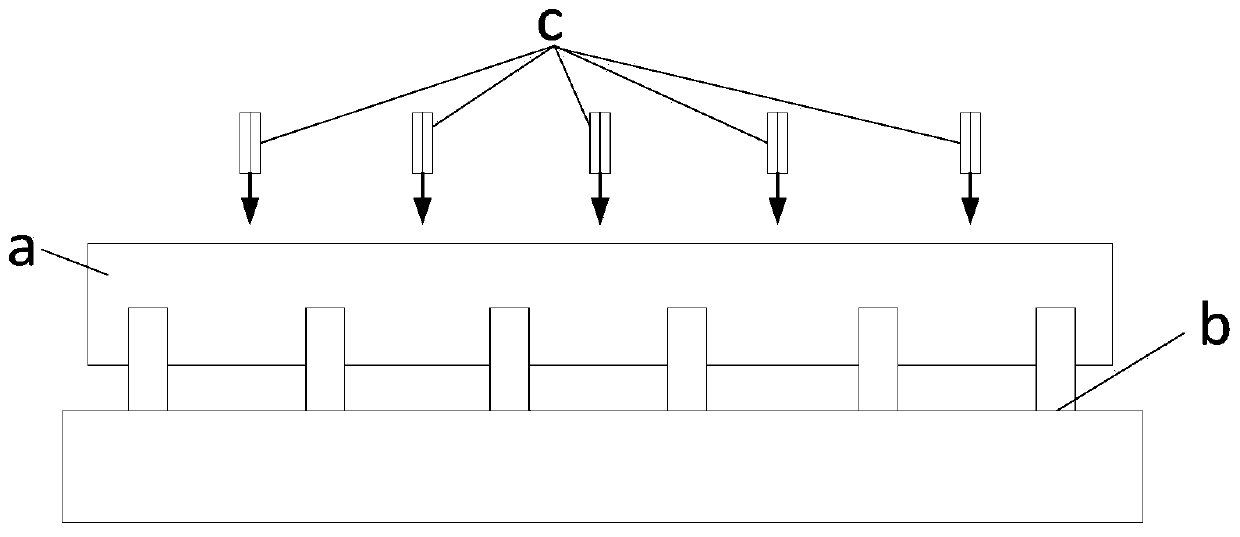

Differential wire conveyor for diamond wire saw cutter

InactiveCN104290208AMeet surface quality requirementsSmall cutting forceFine working devicesStone-like material working toolsDiamond wire sawElectric machinery

The invention discloses a differential wire conveyor for a diamond wire saw cutter. The differential wire conveyor comprises two pay-off (take-up) drums, two wire guide wheels, two differential wheels and a tension wheel. By reasonably setting the turning direction and speed of two variable frequency adjustable-speed motors, the differential wheels are driven to move up and down in different directions, a diamond saw wire between the differential wheels moves in a cutting path with reciprocating cross diagonal motion and slow downward feed, and traditional parallel linear feed cutting is replaced with the cross diagonal cutting of the diamond saw wire. The differential wire conveyor has the advantages that crisp and hard material can be cut stably, cut surfaces are smooth, and processed surface quality is significantly improved.

Owner:TAIZHOU POLYTECHNIC COLLEGE +1

Method and milling cutter for repairing surface defect of cement concrete construction member

InactiveCN101876208AGuaranteed cutting forceGuaranteed StrengthBuilding repairsCeramic shaping apparatusMilling cutterArchitectural engineering

The invention discloses a method and a milling cutter for repairing surface defect of a cement concrete construction member, which is used for repairing the surface defects of the building construction members, such as cement concrete wall, piers, girders, plates and the like. For defects of cracks, local damage, voids and pits and the like on the surface of the building construction member, the method and the special milling cutter of the invention firstly remove defects, form a repairing groove and pour concrete again to repair. The method and the milling cutter of the invention can process the surface of the construction member into geometry, such as a plane, a cambered surface, a groove and the like, and especially processes the boundary surface of the repairing groove into regular, smooth, rough and circular-arc corner, which is favourable for construction stress and combination of new and old concrete, improves appearance quality and solves the difficulty problem that the surface of the cement concrete construction member is difficult to repair.

Owner:HEFEI UNIV OF TECH

Efficient insulating plate cutting device with drying function

PendingCN107775677AWith drying functionSmall cutting forceMetal working apparatusEngineeringCutting force

The invention provides an efficient insulating plate cutting device with a drying function. The efficient insulating plate cutting device with the drying function comprises a base, a conveying mechanism, cutting mechanisms, fixing mechanisms, a dehumidifying mechanism and a controller, wherein the conveying mechanism is arranged in the middle of the base; insulating plates successively pass through the dehumidifying mechanism, the cutting mechanism A, the fixing mechanism A, the cutting mechanism B and the fixing mechanism B along the conveying mechanism; the conveying mechanism comprises a conveying roller group A and a conveying roller group B; the conveying roller group A and the conveying roller group B are separately driven by a motor A and a motor B; the conveying roller group A andthe conveying roller group B are separately arranged in the front and at the rear of the cutting mechanism A; a photoelectric sensor is arranged at the tail end of the base; and the controller is connected with the motor A, the motor B, the cutting mechanism A, the cutting mechanism B, the fixing mechanism A, the fixing mechanism B and the photoelectric sensor. By the controller, the motor A and the motor B are controlled to be started at different times, meanwhile, with the aid of the photoelectric sensor, the insulating plates are cut automatically, the insulating plates are heated and dehumidified during conveying of the conveying roller group A, the cutting force of the insulating plates is reduced, and the cutting efficiency is improved.

Owner:TIANJIN JINCHENGTAI ENERGY SAVING BUILDING MATERIAL TECH

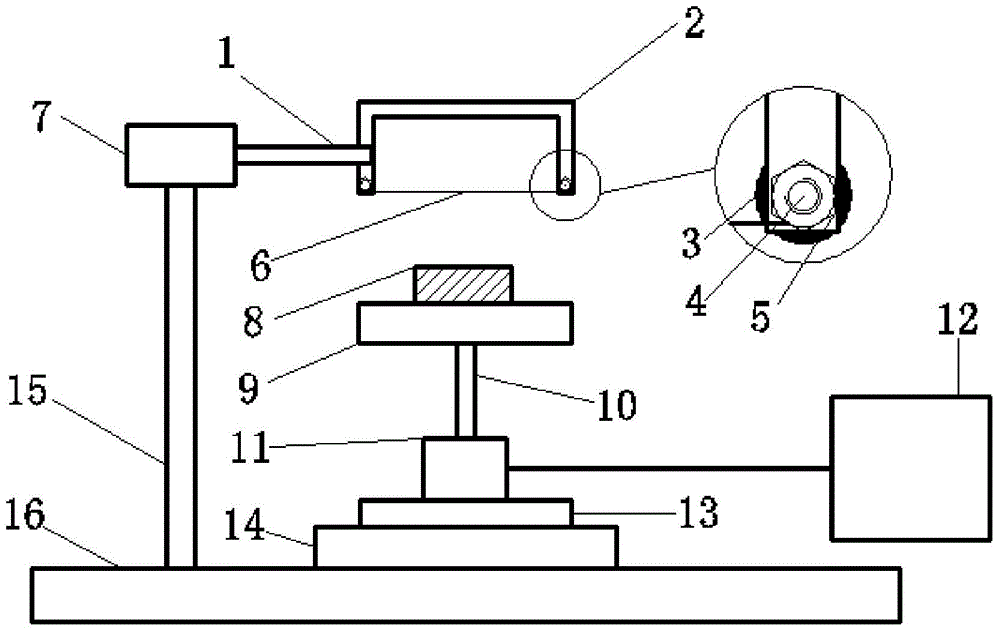

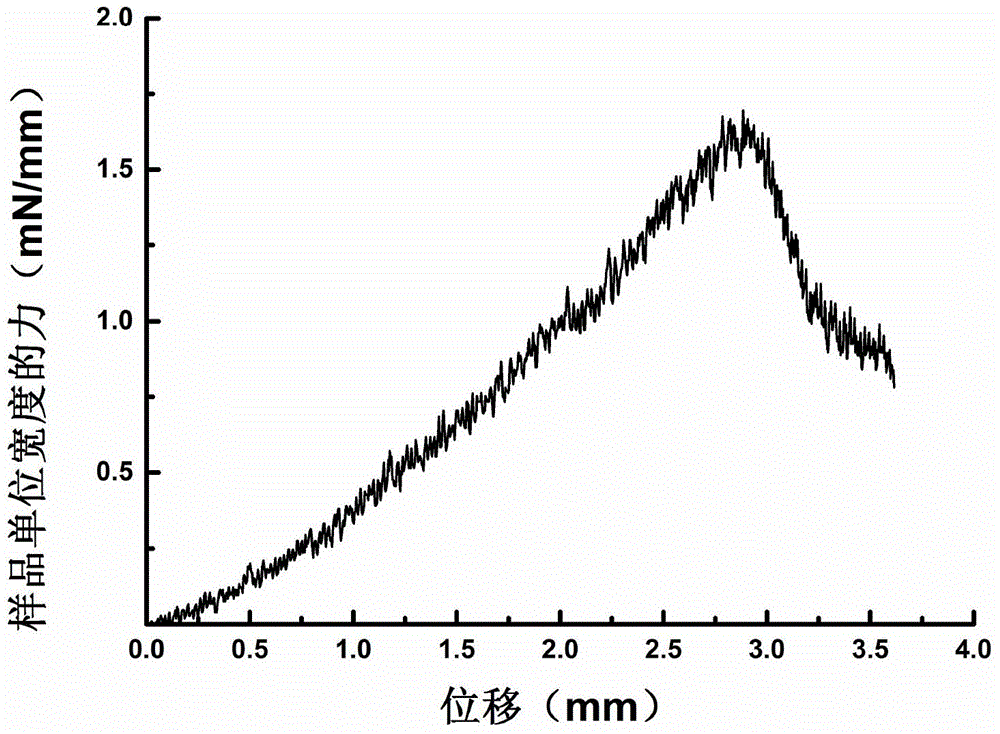

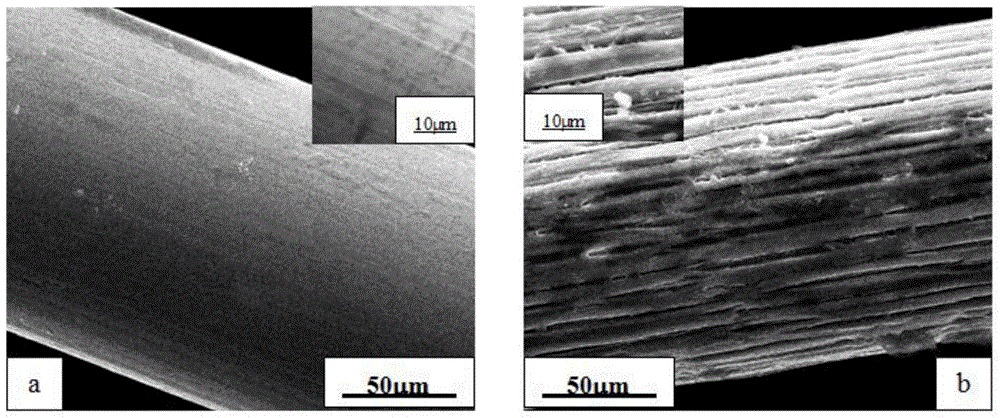

Metal wire tool for minimally invasive cutting of biological soft tissues

InactiveCN104634609AAvoid damageTruly reflect the mechanical propertiesWithdrawing sample devicesMicro nanoLinear motion

The invention belongs to the technical fields of soft materials and experimental mechanics, and discloses a metal wire tool for minimally invasive cutting of biological soft tissues. The tool comprises a metal wire cutter and a vibration device, wherein a metal wire is subjected to surface etching through a chemical method and has a proper micro-nano texture; by combination with a reciprocating linear motion cutting mode provided by the vibration device, the adhesive power between the biological soft tissues and the tool can be effectively reduced when the biological soft tissues are cut; the to-be-exerted cutting force is reduced; the destructive effects on soft tissues in the cutting process are reduced; minimally invasive cutting is achieved; a sample with a precise physical dimension can be obtained by cutting; and the cut sample can relatively really reflect the mechanical property of the biological soft tissues. The tool is simple in manufacturing method, convenient and fast to operate, low in cost and convenient to produce and popularize.

Owner:DALIAN UNIV OF TECH

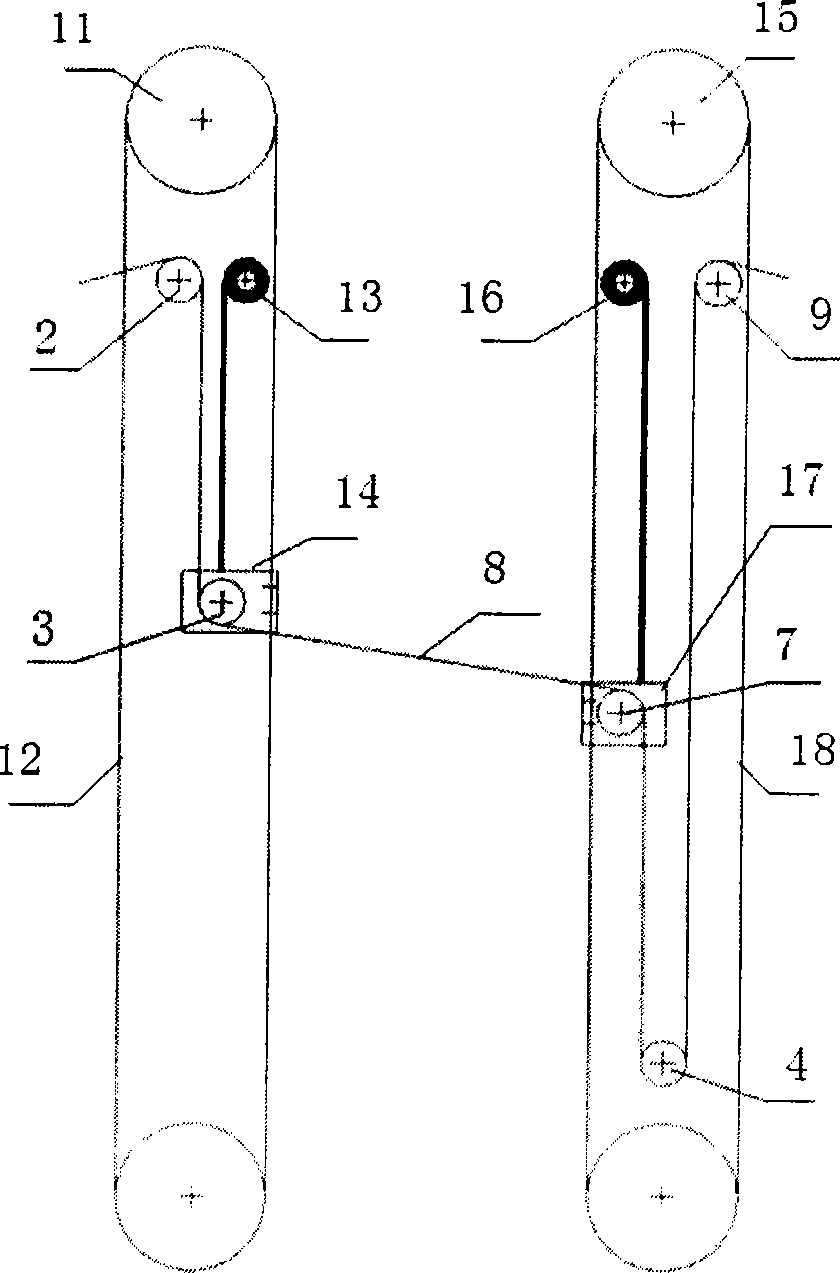

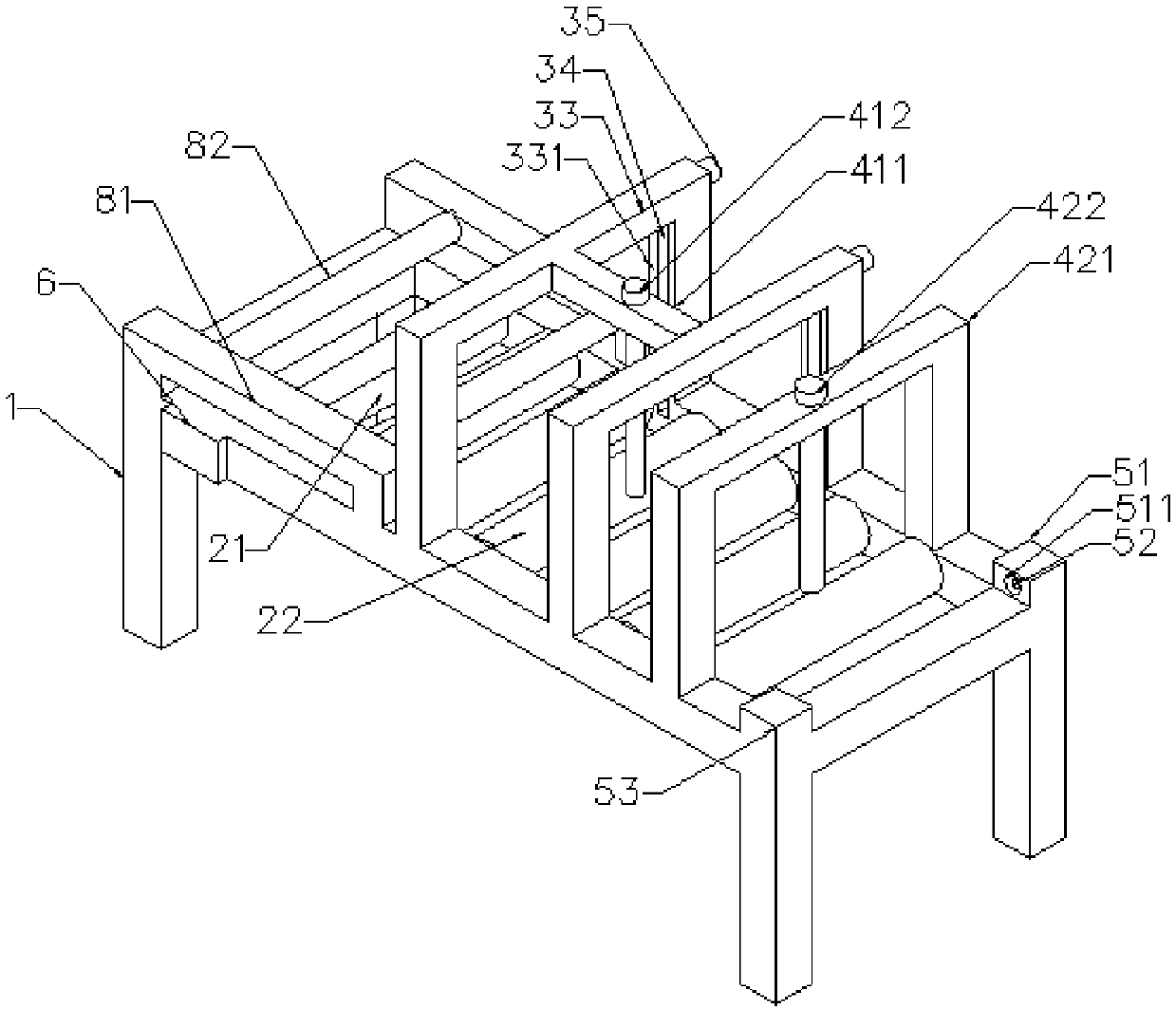

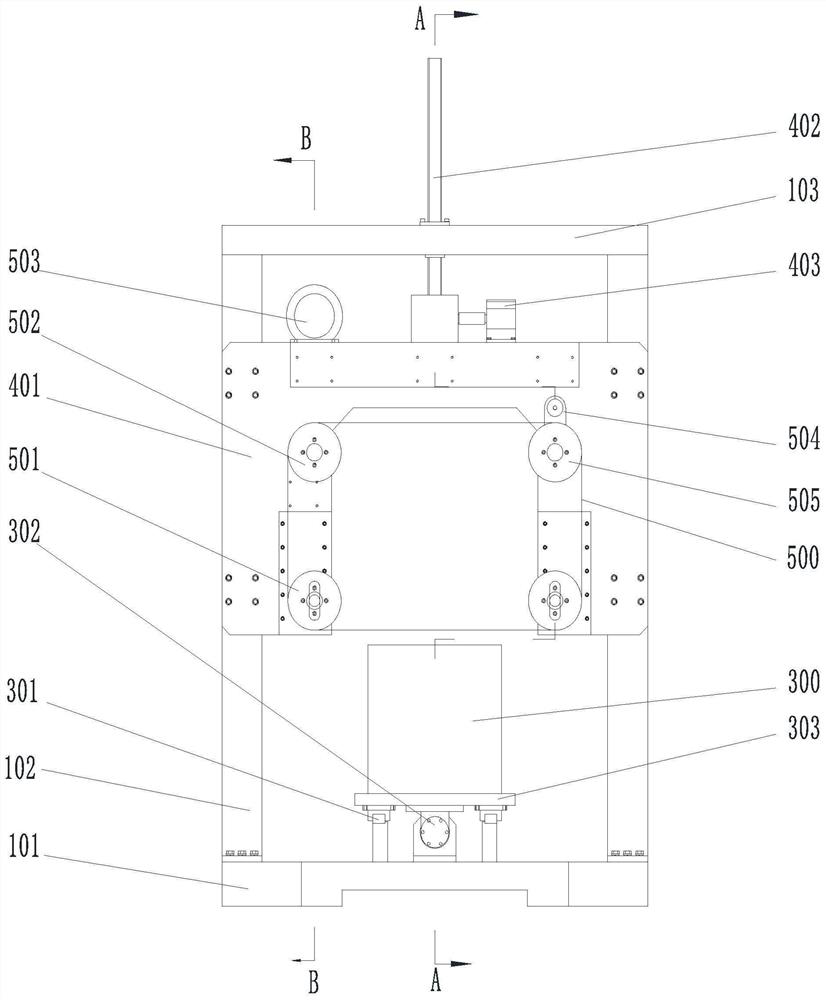

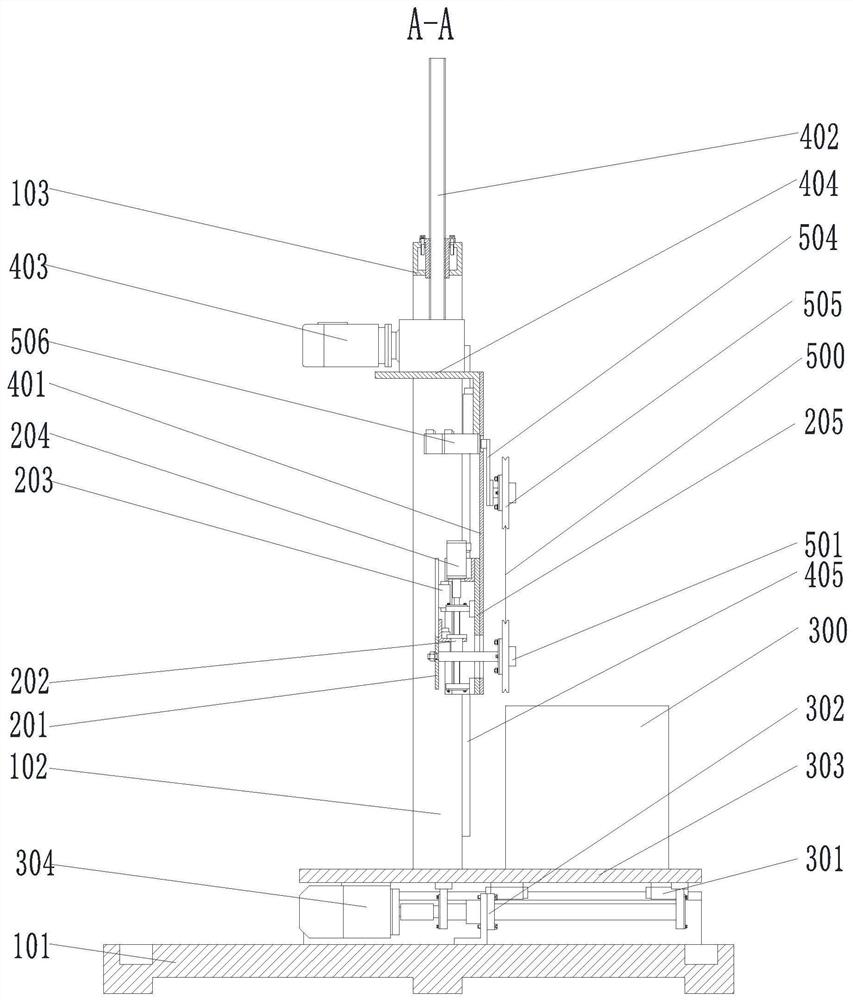

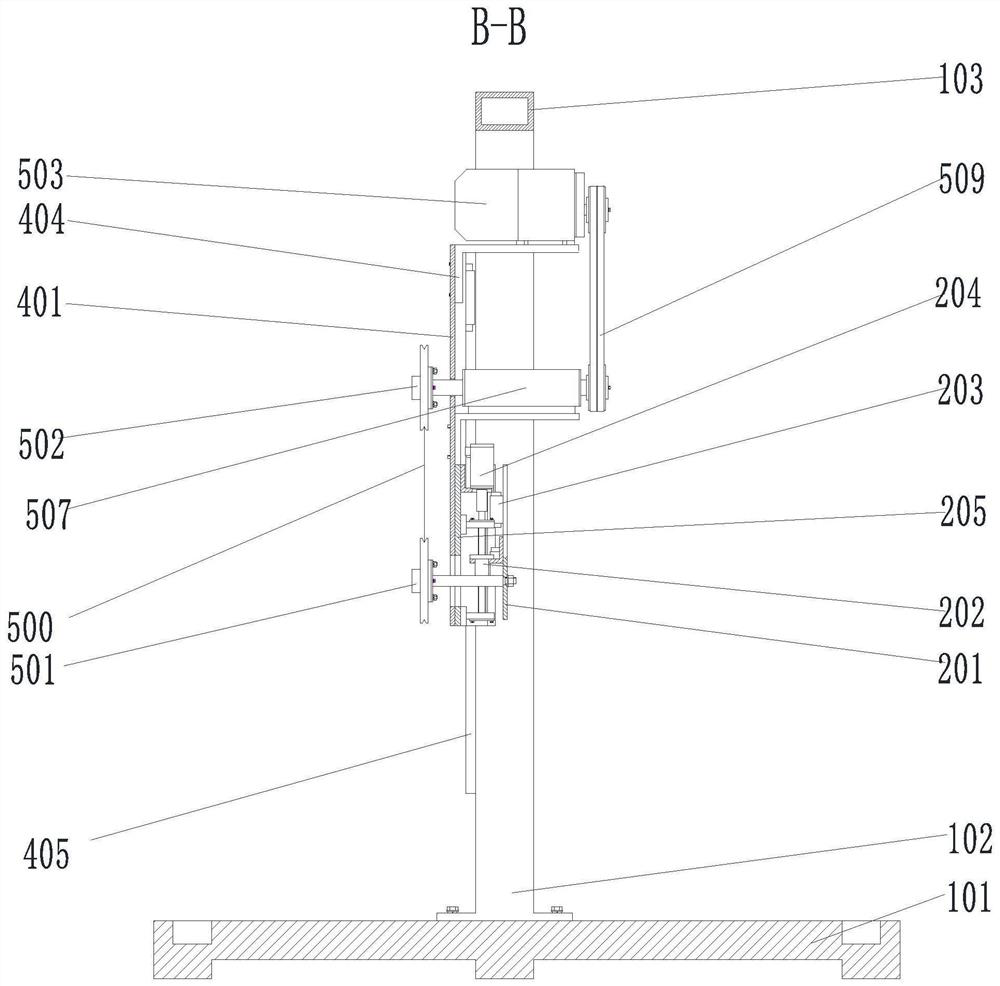

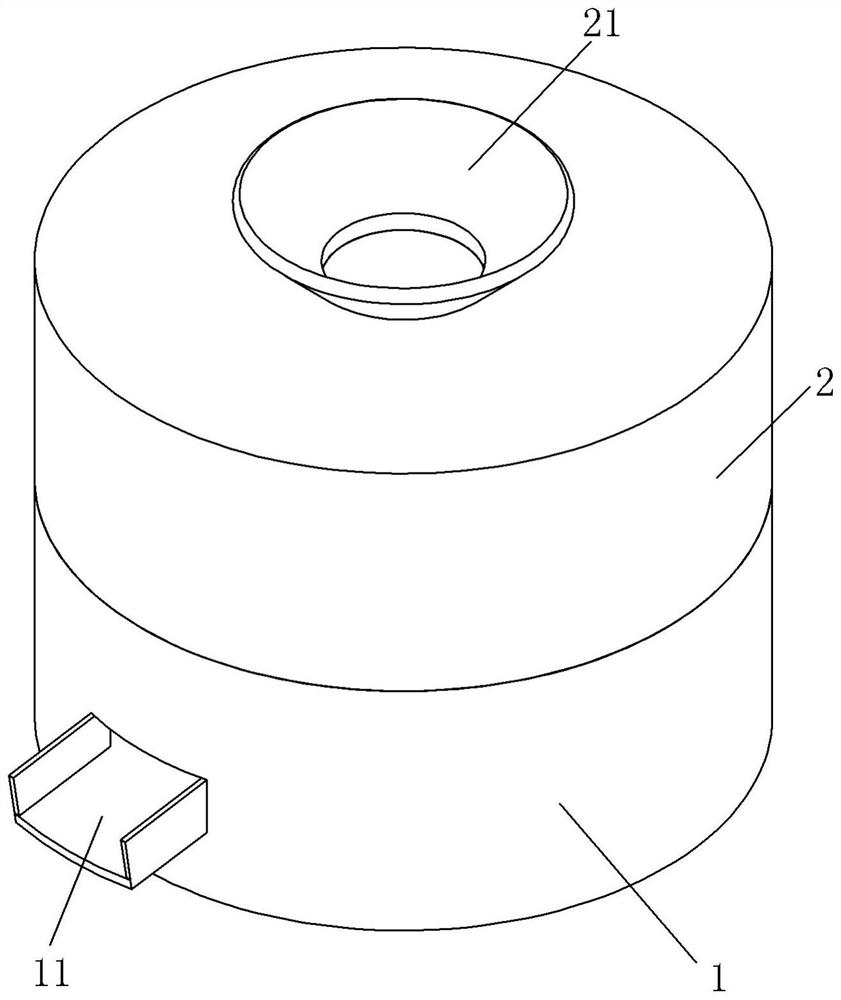

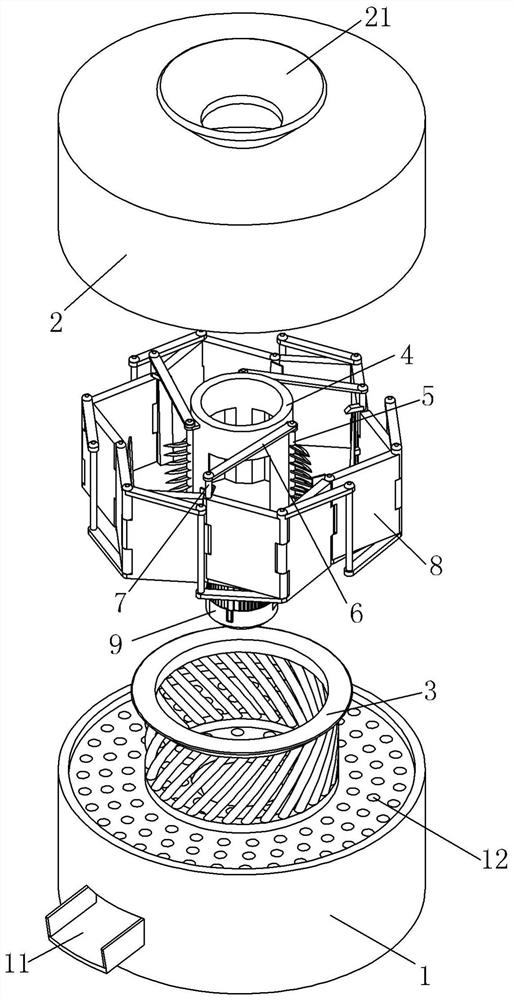

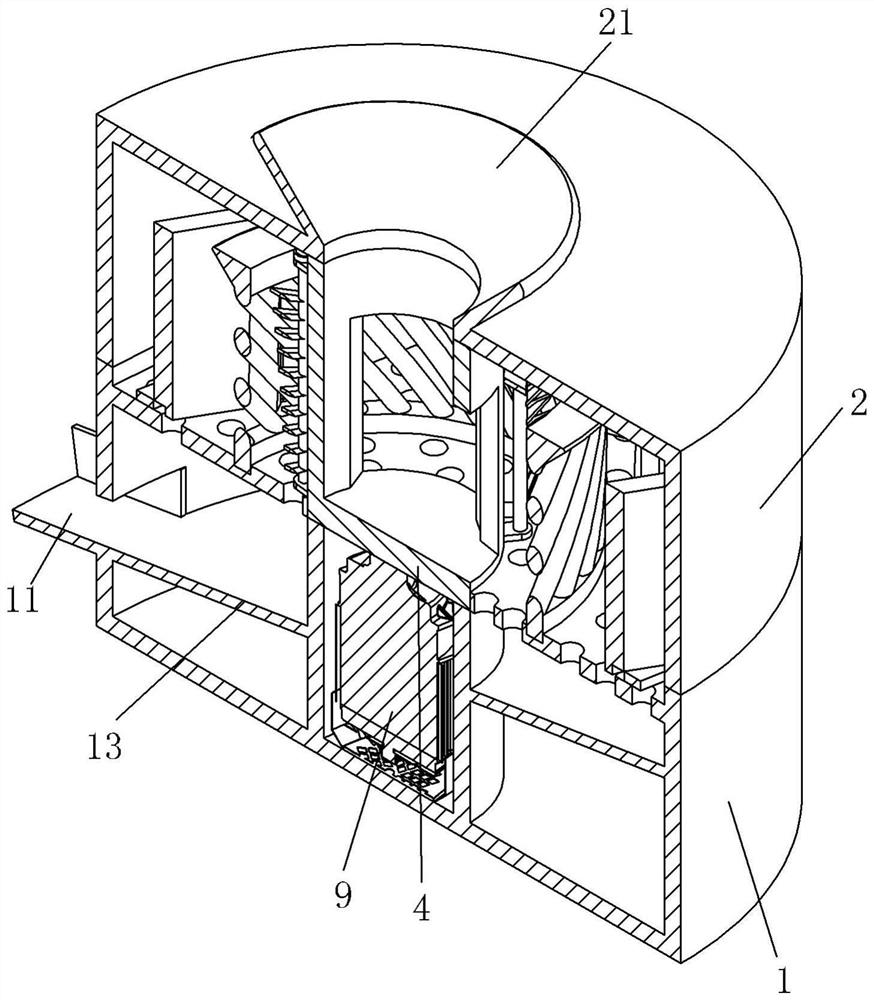

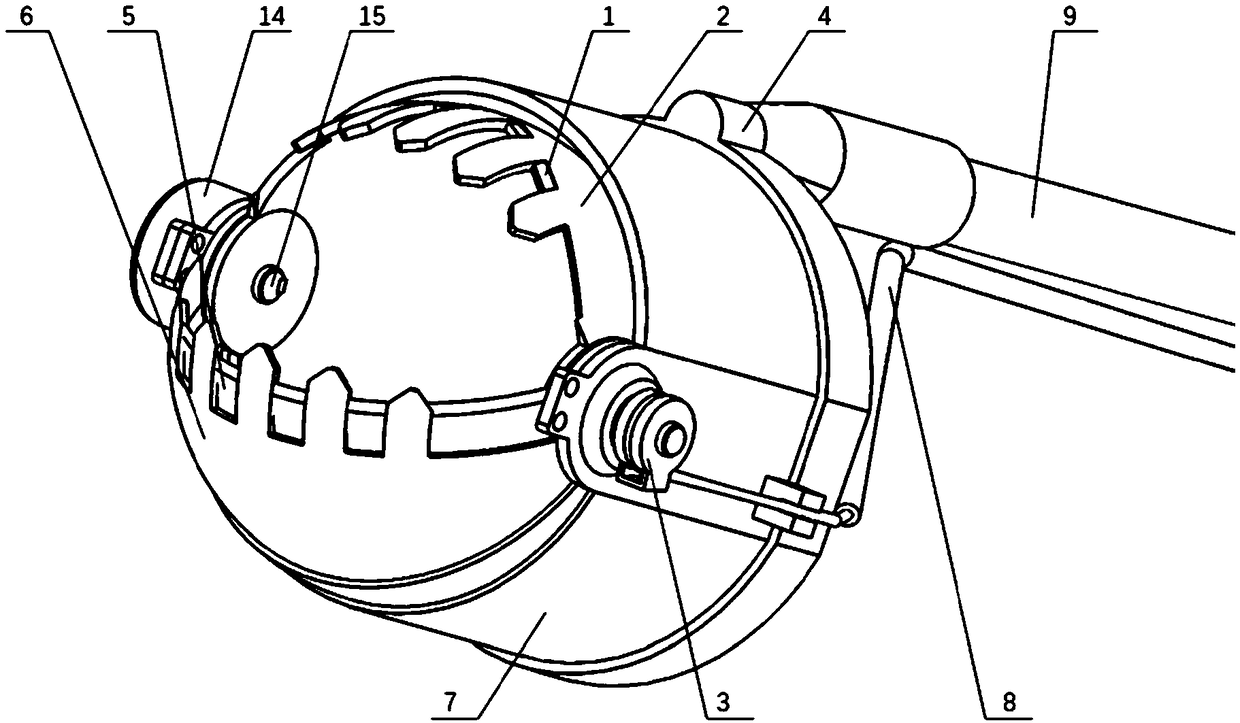

Annular diamond wire saw cutting machine

PendingCN111843043ASmall cutting forceAvoid breakingMetal sawing devicesWorking accessoriesDiamond wire sawStructural engineering

The invention discloses an annular diamond wire saw cutting machine. The annular diamond wire saw cutting machine comprises a cutting machine frame, a worktable system arranged on the cutting machineframe and used for placing a to-be-cut workpiece, and a cutting system arranged above the worktable system and used for cutting the workpiece. The cutting machine moves up and down alternately throughtwo guiding wheels, the swinging of the part, participating in cutting, of a diamond wire between the two guiding wheels is achieved, the cutting force of the diamond wire is reduced, the diamond wire is prevented from breaking, meanwhile the contact area between a cutting line and the workpiece is constantly changed due to the alternating movement of the guiding wheels, the fatigue fracture of the diamond wire can be prevented, meanwhile the continuous contact with the workpiece can also be ensured, the situation that due to the irregular workpiece, the diamond wire and the workpiece sometimes are in contact and sometimes are separated, resulting in the impact of each contact, and leading to the fracture of the diamond wire is avoided, and thus the cutting machine is suitable for regularworkpiece cutting, also suitable for irregular workpiece cutting, and suitable for promotion.

Owner:壶关高测新材料科技有限公司

Star-like unloader

The invention discloses a star-like unloader comprising a housing, an impeller shaft and an impeller. The upper and lower ends of the housing are provided with a feed hole and a discharge hole respectively. The impeller shaft driven to rotate by a drive device is disposed within the housing. The impeller fixedly sleeves the impeller shaft; blades of the impeller skew off the axis of a hub at a certain angle. Two scrapers are arranged on the inner wall of the housing on two radial sides of the axis of the hub of the impeller. When the blades of the impeller rotate to the corresponding parts of the scrapers, gaps are reserved between the front edges of the scrapers and the front edges of the blades of the impeller. Linear shearing of materials is converted into point shearing, so that shearing force is decreased and the impeller is effectively prevented from jamming.

Owner:广西奥士达环境工程有限公司

Magazine strip for ratchets

A magazine strip of tie ratchets which are provided for holding the ends of ties for binding elongated articles such as cable harnesses and are connected to one another by webs, the width of which is not greater than half the ratchet width and which are arranged adjacent to the tie entry side of the ratchets. The webs have a length of not more than 1.3 mm and / or one sixth of the ratchet dimension in the direction of the magazine strip. The width of the essentially parallel wall sections which carry the webs is expediently not greater than three quarters of the entire width of the ratchets. The thickness / width ratio of the webs should be not greater than 1 / 5. The invention also relates to a tool for binding cable harnesses which ensures that the webs are cut exactly in the center.

Owner:HELLERMANN TYTON GMBH

Novel thermal insulation plate cutting device

InactiveCN107775678AWith fixed functionAvoid displacementMetal working apparatusThermal insulationEngineering

The invention provides a novel thermal insulation plate cutting device. The novel thermal insulation plate cutting device comprises a base, a conveying mechanism, a cutting mechanism, a dehumidifyingmechanism and a controller. The conveying mechanism is arranged in the middle of the base, and the dehumidifying mechanism and the cutting mechanism are arranged on the base sequentially along a conveying direction of the conveying mechanism. The conveying mechanism comprises a conveying portion A and a conveying portion B, and the conveying portion A and the conveying portion B are arranged in front and rear of the cutting mechanism respectively and driven by motors A and B respectively. The cross section of an outer cover of the dehumidifying mechanism is in a U shape with the open side down, the outer cover is internally provided with a heating plate and two limiting walls, and the limiting walls are connected with the side wall of the outer cover through adjusting mechanisms. A photoelectric sensor is arranged at the tail end of the base, and the controller is connected with the motors A and B, the cutting mechanism, the dehumidifying mechanism and the photoelectric sensor. The controller controls the motors A and B not to start simultaneously, automatic thermal insulation plate cutting is realized by the aid of the photoelectric sensor, heating and fixing of heat insulation plates are realized through the dehumidifying mechanism to reduce thermal insulation plate cutting force, and cutting efficiency is improved.

Owner:TIANJIN JINCHENGTAI ENERGY SAVING BUILDING MATERIAL TECH

Cutting method with auxiliary laser heating for metal strip

ActiveCN102837124AImprove cut qualityShear Yield Strength ControlLaser beam welding apparatusShearing machine accessoriesMetal stripsVolumetric Mass Density

The invention relates to a cutting method with auxiliary laser heating for a metal strip. Laser is adopted to heat and then cut the metal strip. The cutting method is characterized in that heating temperature Th is equal to xi multiplied by A, then multiplied by F, then multiplied by A<x>s, and then multiplied by U<-1.5>, wherein U is the running speed of the metal strip, and the unit of U is m / min; F is the power of a laser device, and the unit of F is W; AS is the laser spot area, and the unit of AS is mm<2>; the xi is a constant correlated to the density and the specific heat capacity of the metal strip, and is equal to (0.3-0.8)e3; x is a constant correlated to the thickness of the metal strip, and is equal to a value between -0.75 and 0.0; the cutting temperature T is equal to Th minus delta T; and the delta T in the formula is the temperature drop of the metal strip. The cutting method has the advantages that the cutting method is high in heating efficiency, and is adapted to high-speed cutting, particularly high-speed cutting of an ultrathin strip with a high-quality requirement.

Owner:BAOSHAN IRON & STEEL CO LTD

Glass tube cutting machine

The invention provides a glass tube cutting machine, belonging to the technical field of machinery. The glass tube cutting machine solves the problems of difficulty in cutting glass tubes, low efficiency and the like in the prior art. The glass tube cutting machine comprises a worktable, wherein a left motor and a right motor are arranged on the worktable; an output shaft of the left motor is fixed with a left saw blade, and an output shaft of the right motor is fixed with a right saw blade; a rotating shaft is arranged on the worktable; a left delivery gear and a right delivery gear are sheathed and fixed to one end of the rotating shaft; a rotatable roller is arranged between each tooth of the left delivery gear and the corresponding tooth of the right delivery gear; a left water outlet pipe and a right water outlet pipe are respectively arranged above the left delivery gear and the right delivery gear; a water inlet end of the left water outlet pipe and an water inlet end of the right water outlet pipe are respectively connected with a water supply device; the pipe body of the left water outlet pipe is provided with a left water outlet; and the pipe body of the right water outlet pipe is provided with a right water outlet. The glass tube cutting machine has the advantages of high cutting stability and high efficiency.

Owner:浙江罗丹照明电器有限公司

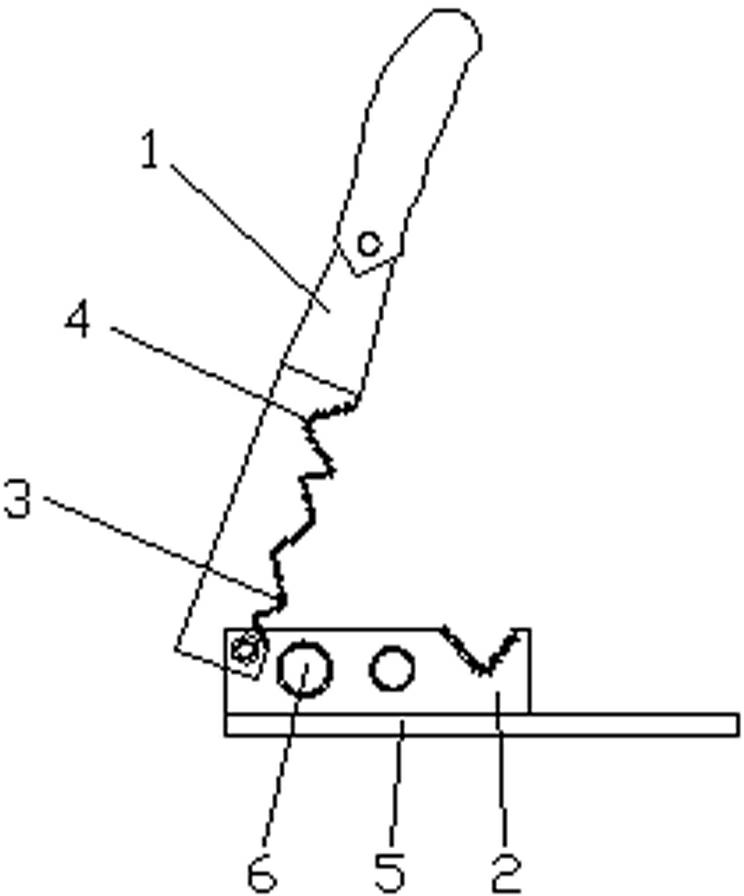

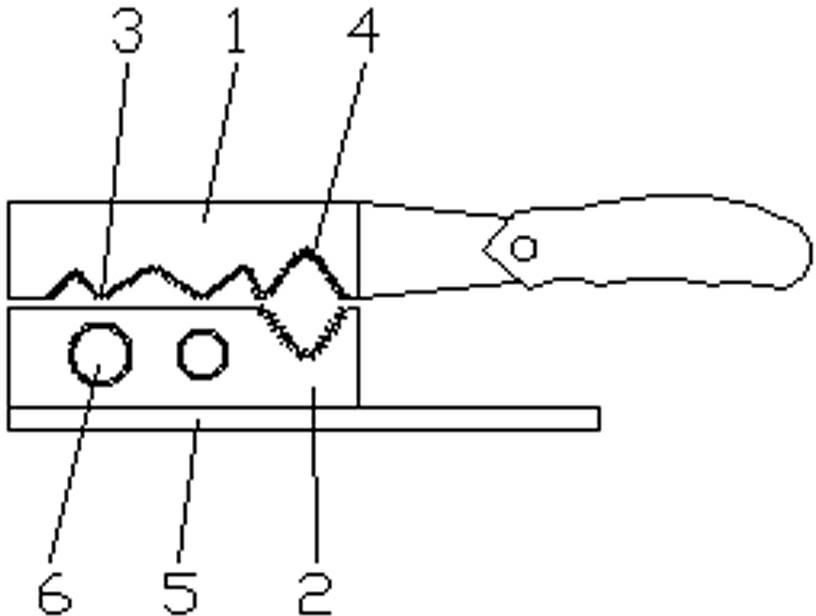

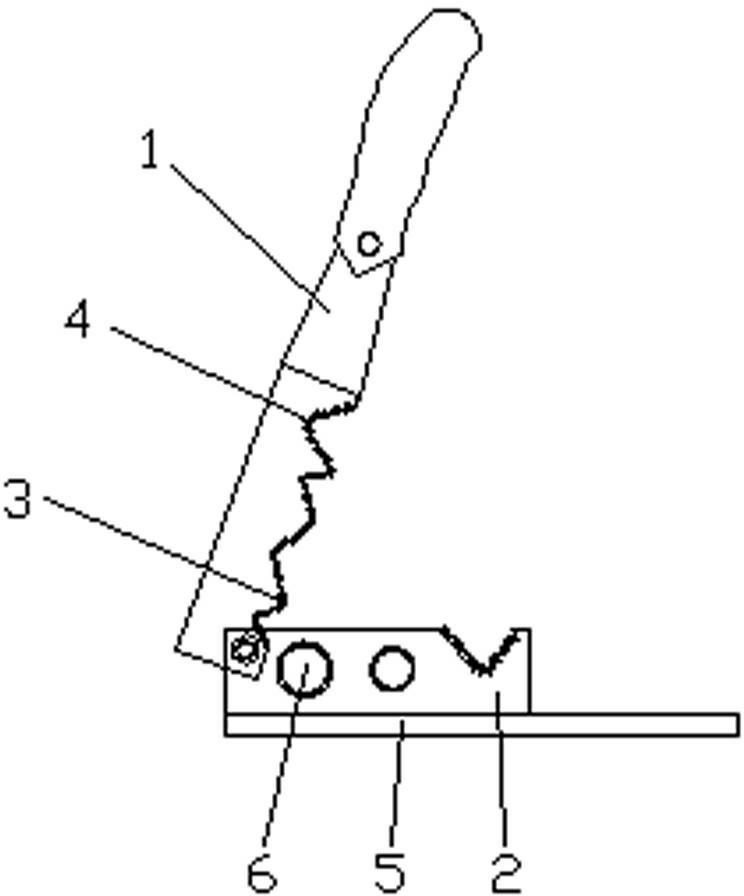

Field snail tail chopper with acute teeth and sharp mouth

InactiveCN102350708AIncrease in sizeHigh cutting forceMetal working apparatusShellfish processingCutting forceKnife blades

The invention relates to a field snail tail chopper with acute teeth and a sharp mouth. The field snail tail chopper comprises a movable cutter positioned on the upside and a fixed cutter positioned on the downside, wherein one end of the movable cutter is connected with one end of the fixed cutter through a bolt; the front end of the cutting edge part of the movable cutter is provided with a plurality of tooth tips, and the back end of the cutting edge part is provided with a groove with gear stamps; the fixed cutter is fixed by a fixed seat; tooth ring holes corresponding to the tooth tips of the movable cutter are formed on the fixed cutter; and the back end of the fixed cutter is provided with a groove provided with gear stamps corresponding to the groove of the movable cutter. Hard field snails can be put into the tooth ring holes to remove tails, and the tails of the field snails can be removed in the groove according to the size of the field snails. The field snail tail chopper has the characteristics of low manufacturing cost, small volume, strong cutting force, simple and convenient operation, fast processing and high working efficiency, and upper and lower blades can be taken down for sharpening, so the field snail tail chopper is applicable to families and various food and beverage service industries.

Owner:陈景洪

Energy-saving and environment-friendly plastic pipe fitting crushing and recycling device

ActiveCN113665031AIncrease effective lengthGood cutting effectPlastic recyclingMechanical material recoveryGrindingStructural engineering

The invention relates to the field of plastic product recycling, in particular to an energy-saving and environment-friendly plastic pipe fitting crushing and recycling device which comprises a base, an elastic screen, an inner cylinder, a grinding ring, a cutting assembly and a rocker, a filter screen is arranged on the base, the elastic screen comprises an upper ring, a lower ring and a plurality of elastic strips, and the lower ring is fixedly installed on the filter screen. The outer circumference of the upper ring is provided with an inclined surface which extends downwards and inwards; the upper end of each elastic strip is respectively connected with the upper ring and the lower ring; the inner cylinder is rotatably mounted in the elastic screen around the vertical axis, a cutting cavity is defined by the inner cylinder and the elastic screen, and the upper end of the elastic strip is located on the front side of the lower end of the elastic strip in the rotating direction of the inner cylinder; the grinding ring is located outside the elastic screen and is coaxial with the lower ring, and a grinding cavity is defined by the grinding ring and the elastic screen; and the gap between the elastic strips is adjusted according to the resistance when materials are accumulated in the cutting cavity and the grinding cavity, so that the speed of the materials entering the grinding cavity from the cutting cavity is controlled, and the crushing efficiency is prevented from being influenced by material accumulation and blockage in the cutting cavity or the grinding cavity.

Owner:沭阳九鼎钢铁有限公司

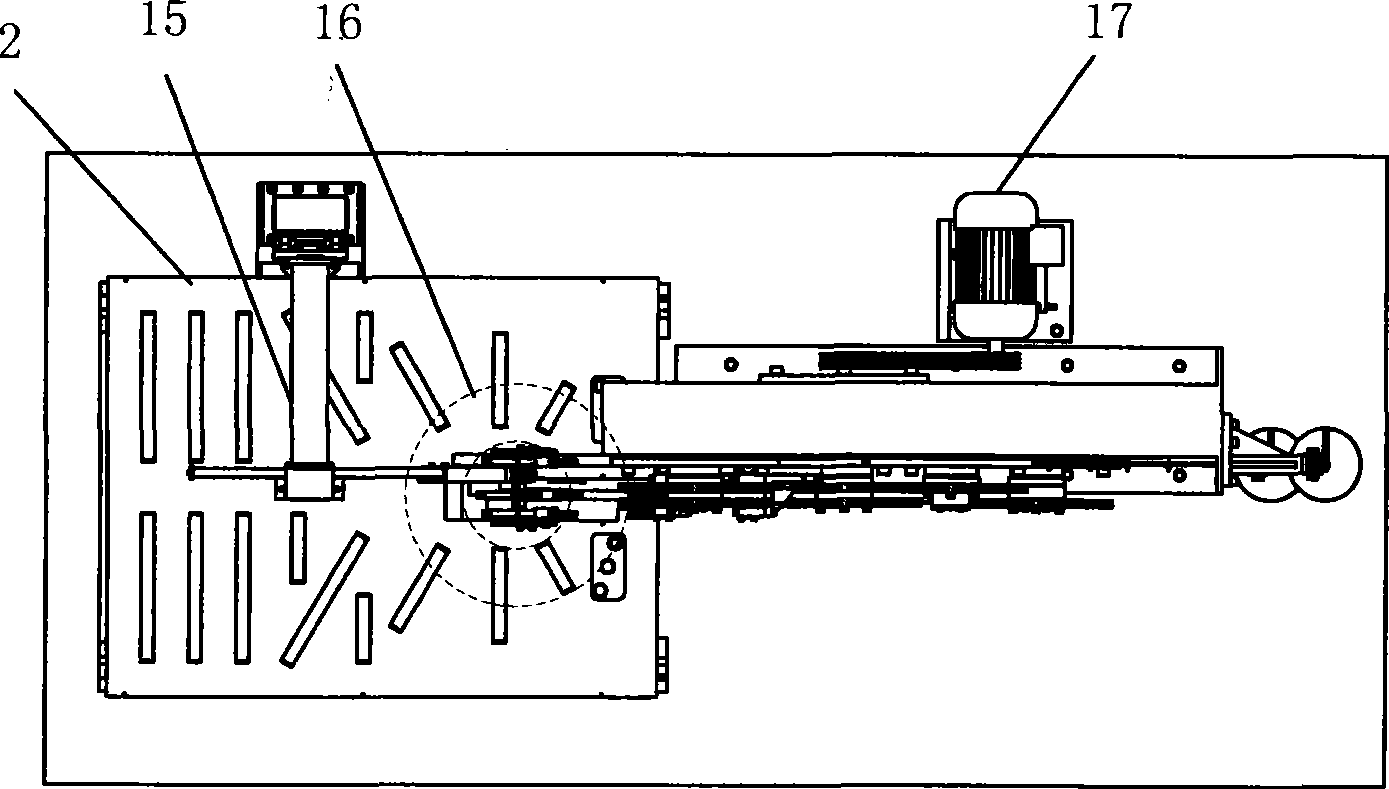

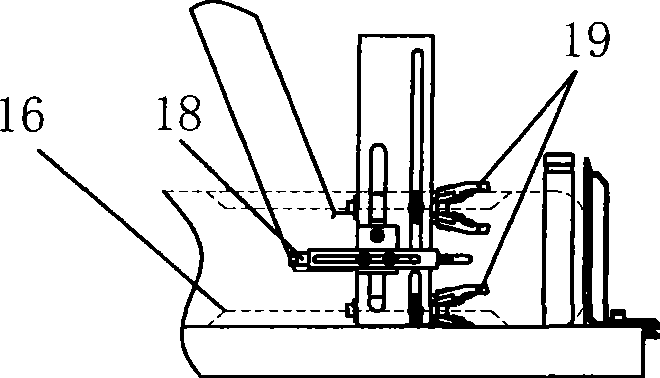

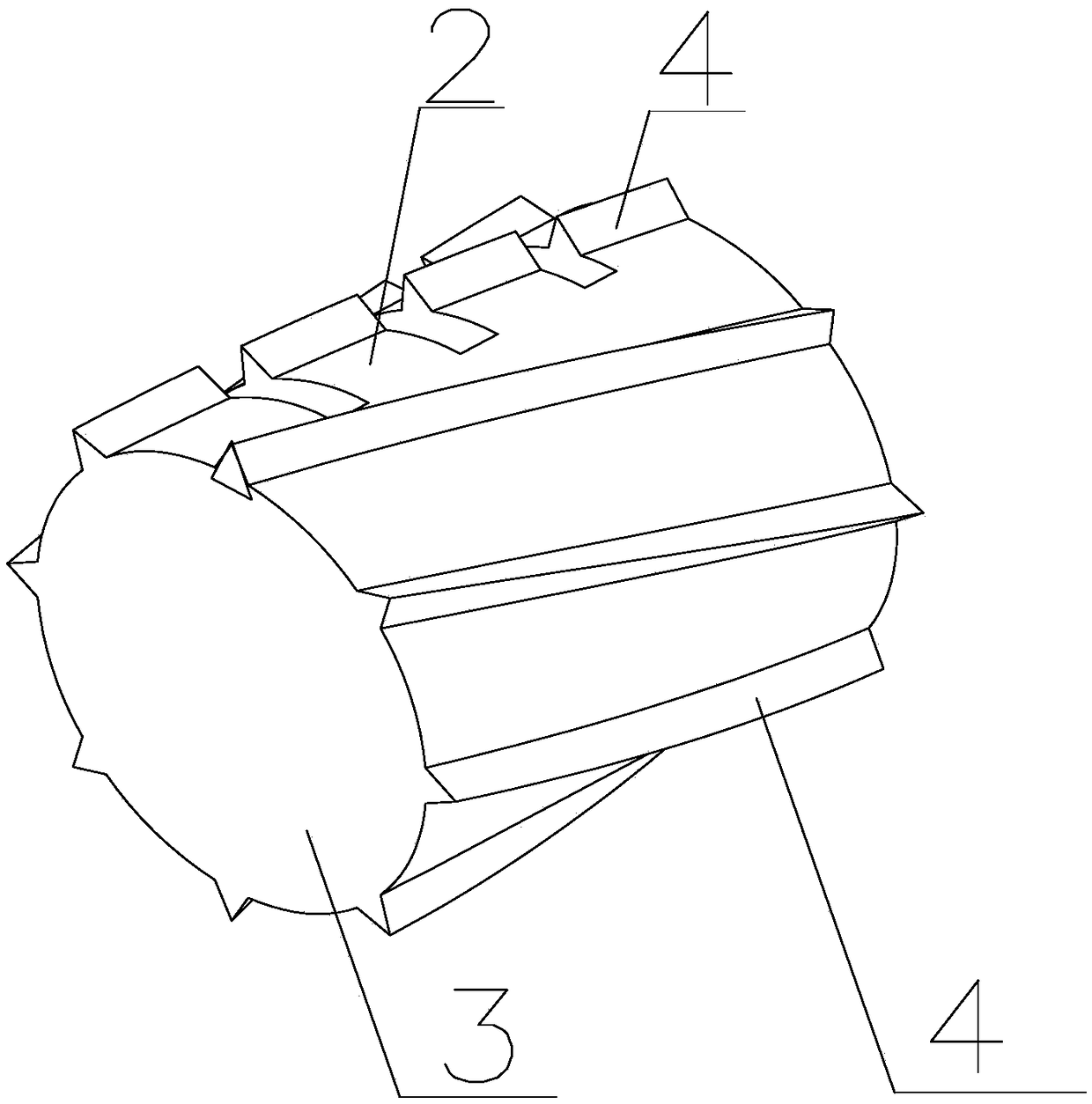

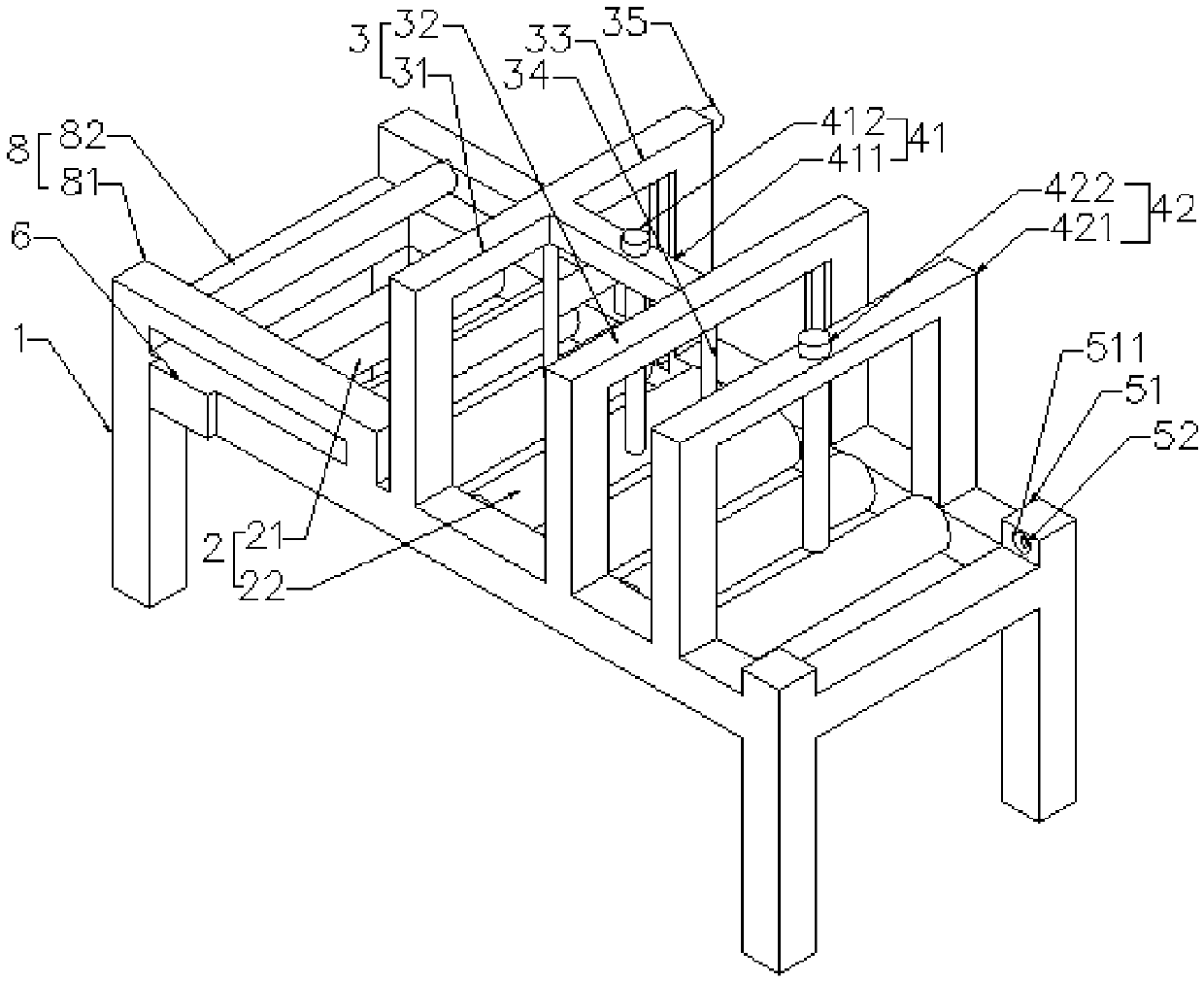

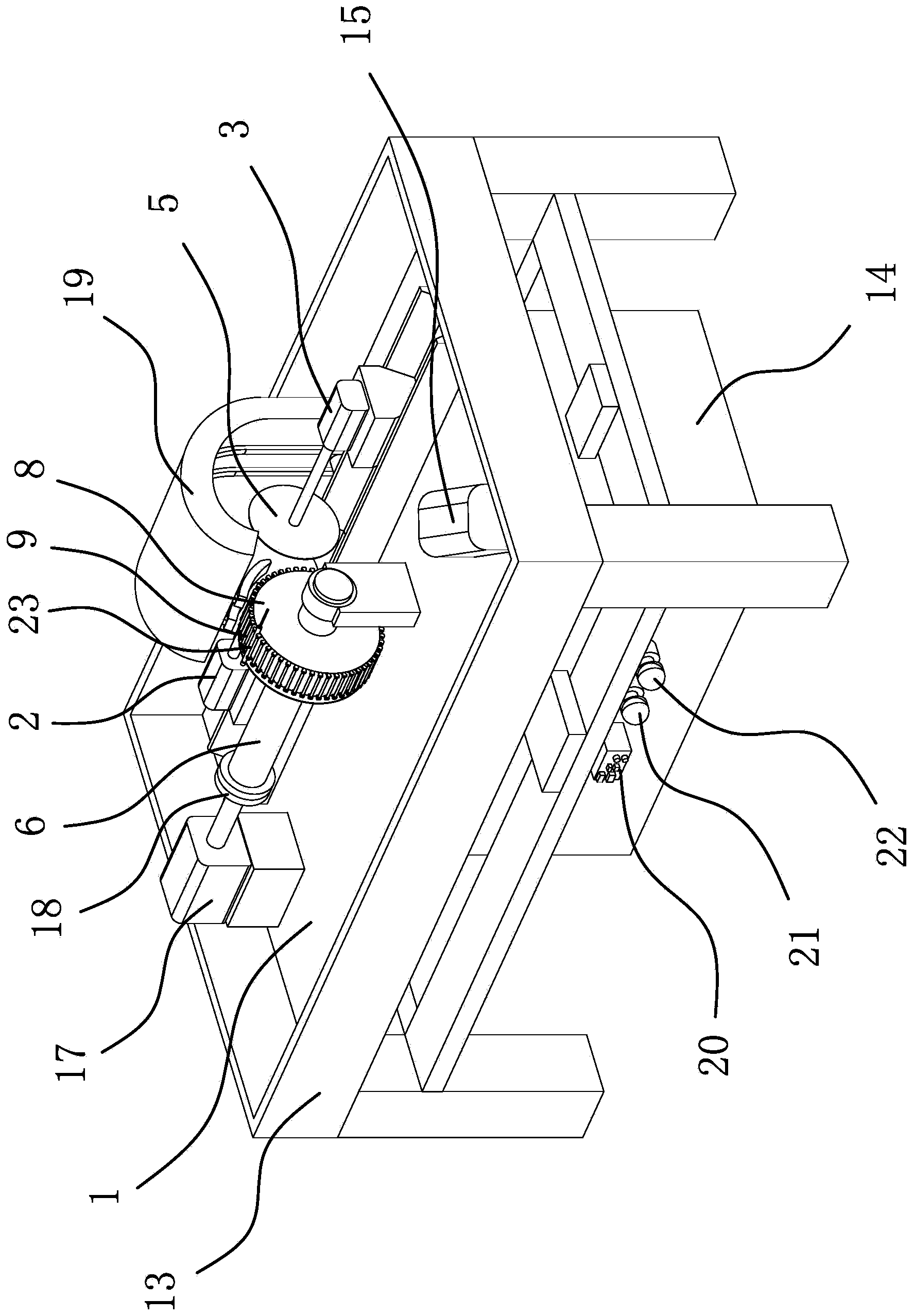

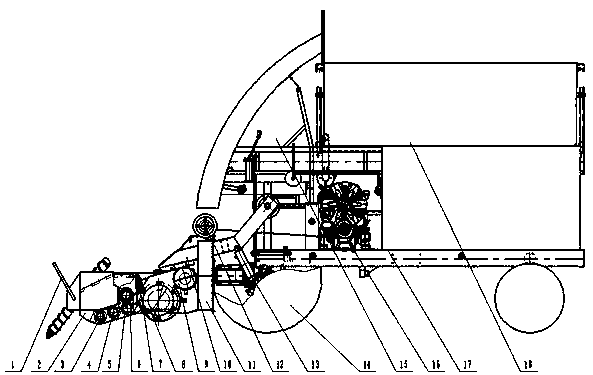

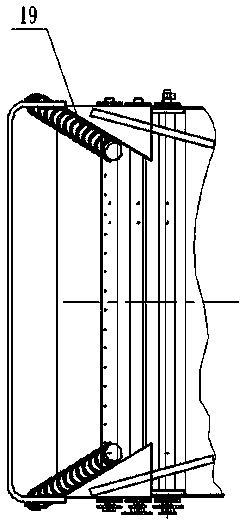

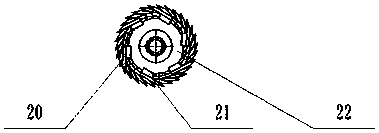

Hob shredding type multifunctional green feed harvester

PendingCN110301218AGuaranteed not to fall offMeet secondary growth needsMowersEngineeringMechanical engineering

The invention relates to a hob shredding type multifunctional green feed harvester and belongs to the technical field of agricultural machinery. The hob shredding type multifunctional green feed harvester. The hob shredding type multifunctional green feed harvester comprises a plant presser 1, a header lateral plate 2, a rhizome cutting hob 3, a primary plant guide roller 4, a secondary plant guide roller 5, a shredding feeding roller 6, a fixed cutter mechanism 7, a hob shredding device 8, a conveying auger 9, a frame 10, a conveying fan part 11, a transmission system 12, a header lifting part 13, a traveling part 14, a cab 15, an engine 16, a main frame 17, a feed bin 18, a longitudinal plant collecting part 19 and the like. The creatively designed hob shredding type multifunctional green feed harvester has the advantages that root cuts cut by the hob are neat, forced conveying and feeding are performed, the hob type cutting and shredding manner only cut and does not rub, and wind-power conveying, belt conveying and chain harrow conveying are provided to satisfy the harvesting needs of different green feed.

Owner:SHANDONG UNIV OF TECH

Efficient multi-cutter cutting machine for workpiece rotation

PendingCN111559023AReduce lossShort contact lengthWorking accessoriesFine working devicesIndustrial engineeringCutting tool

The invention discloses an efficient multi-cutter cutting machine for workpiece rotation. The efficient multi-cutter cutting machine comprises a base and a rack arranged above the base, wherein the base is provided with a crystal support assembly used for supporting workpieces; a cutting assembly used for cutting the workpieces is arranged above the rack and comprises cutting tool bits, a diamondwire drive mechanism and a walking drive assembly, wherein the cutting tool bits are used for achieving workpiece cutting through diamond wires, the diamond wire drive mechanism is used for driving the diamond wires in the cutting tool bits to move to achieve cutting action, and the walking drive assembly is used for moving the cutting tool bits; and a plurality of cutting tool bits are arranged and sequentially arranged in the length direction of the workpieces, and the distances between the cutting tool bits and the workpieces are different. According to the multi-cutter cutting machine produced through the scheme, the cutting process is smooth, the phenomena of edge breakage and the like are avoided, the whole operation process can be rapidly finished by one person, multi-person cooperative operation is not needed, the cut workpieces can be separated, the efficient multi-cutter cutting machine can be used for single-cutter cutting and can also achieve multi-cutter cutting, and applicability and expansibility are very high.

Owner:QINGDAO GAOCE TECH CO LTD

Hemispherical picking device and operating method thereof

The invention discloses a hemispherical picking device and an operating method thereof. The hemispherical picking device comprises a shearing device, a supporting device and a transmission control device. The shearing device and the transmission control device are mounted on the supporting device, and the execution end of the transmission control device is connected with the shearing device. The shearing device is a hemispherical shearing device, and the hemispherical shearing device comprises a fixed sleeve, a fixed hemisphere and a cutting hemisphere. The fixed sleeve is fixedly disposed onthe supporting device, the fixed hemisphere is fixedly arranged at the upper opening end of the fixed sleeve, and the cutting hemisphere is arranged at the upper opening end of the fixed sleeve in a rotating mode. The fixed hemisphere and the cutting hemisphere can be meshed, and the length of the supporting device is adjustable. The hemispherical picking device is simple in structure, convenientto operate, good in practicability, capable of achieving continuous picking and collecting, high in picking efficiency, capable of reducing manual picking cost and the workload of picking workers andsuitable for picking fruit at higher positions.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com