Ultrasonic cutting robot

A cutting robot and ultrasonic technology, applied in the direction of manipulators, program-controlled manipulators, metal processing machinery parts, etc., can solve the problems of large machine tool area, complex machine tool structure, and large machine tool quality, so as to achieve fast cutting speed and reduce equipment occupation. The effect of floor area and high automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

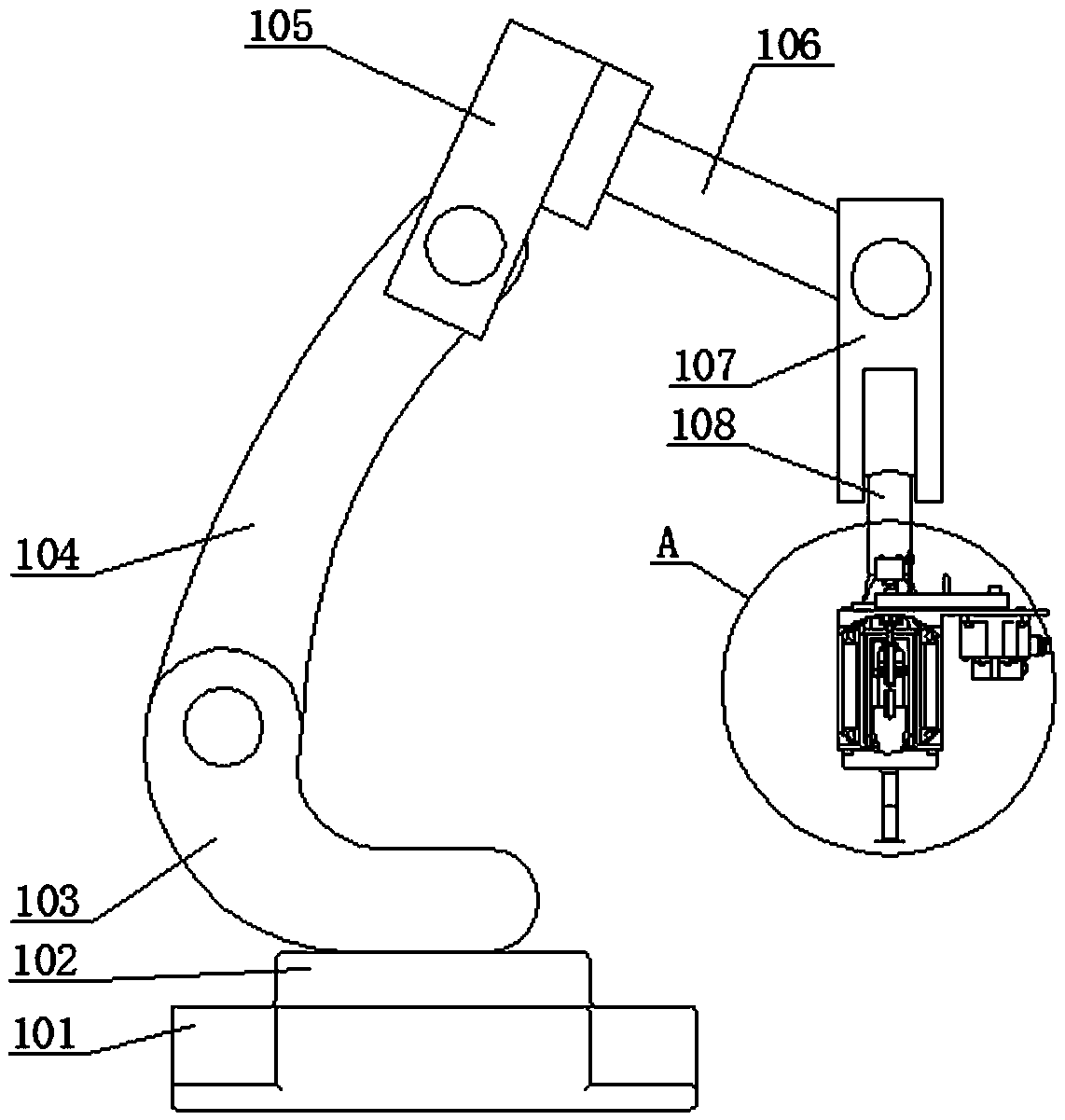

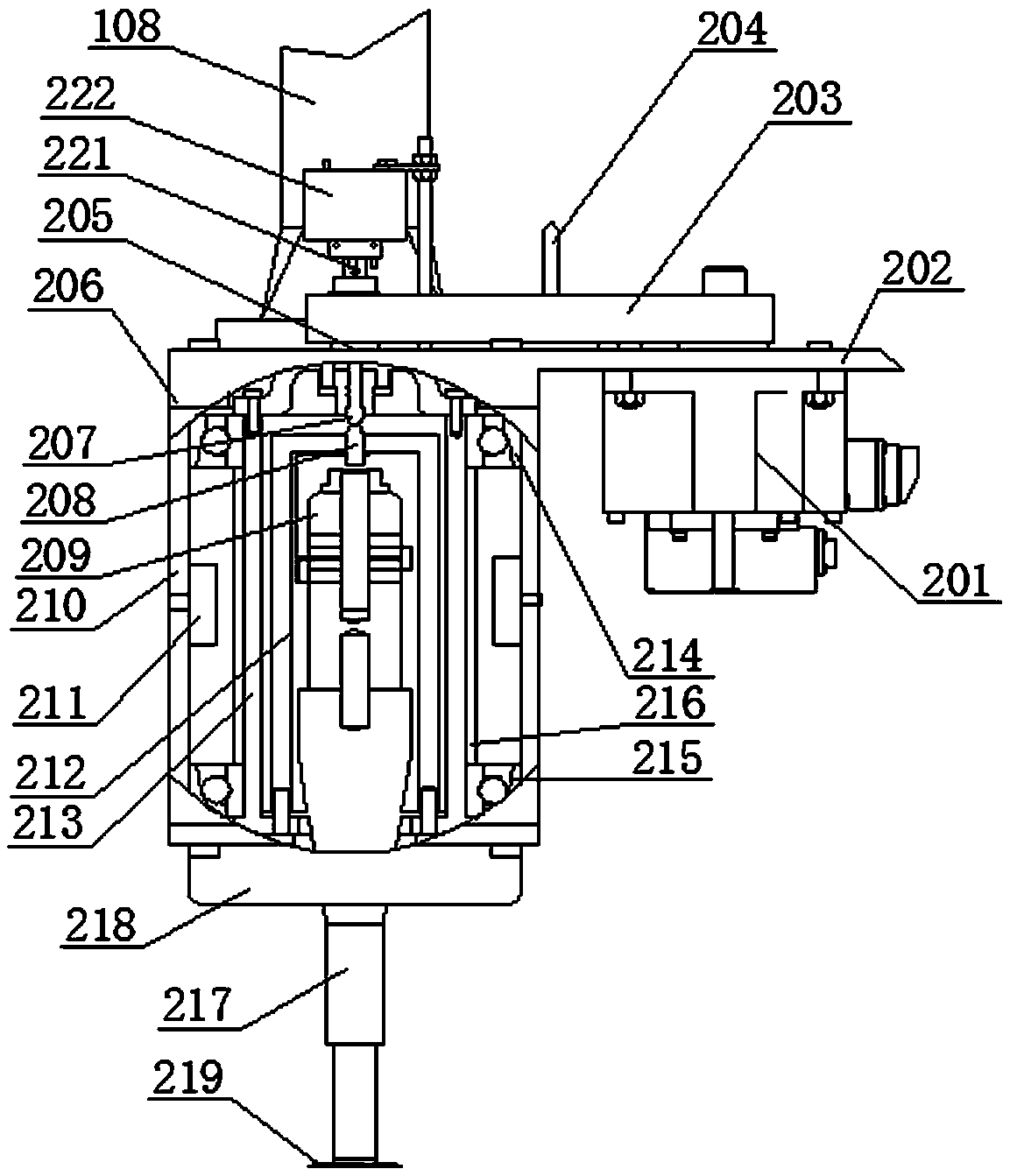

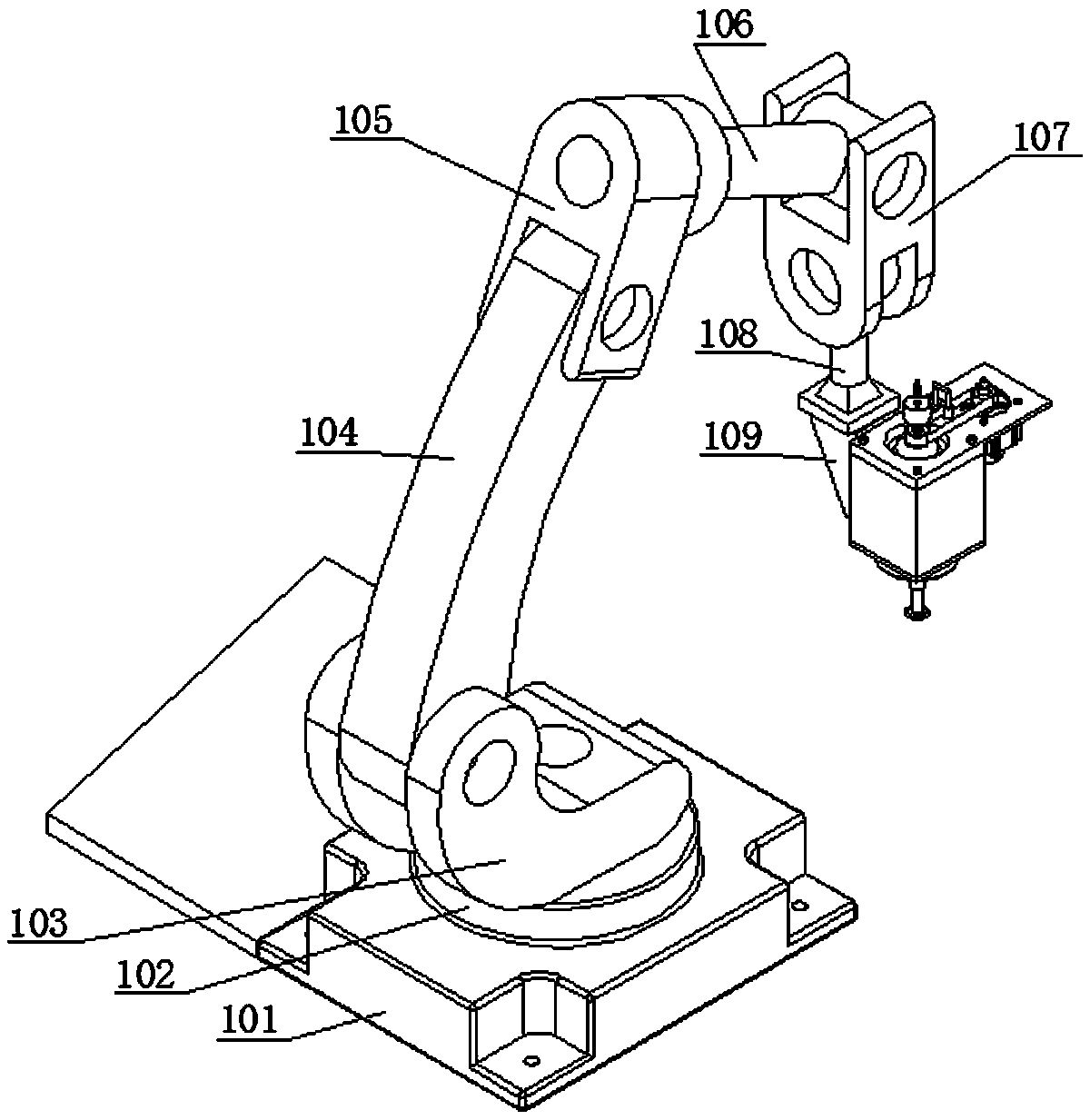

[0037] An ultrasonic cutting robot includes a robot mechanism and an ultrasonic spindle mechanism; the ultrasonic spindle mechanism is installed at the wrist end of the robot mechanism, and the robot mechanism is used to adjust the position and direction of the ultrasonic mechanism.

[0038] The robot mechanism includes a rotating base 102 , a pitching arm 103 , a pitching rear arm 104 , a pitching forearm 105 , a rotating forearm 106 , a pitching wrist 107 , a first support 108 and a second support 109 .

[0039] The bottom of the pitch boom 103 is rotatably mounted on the slewing base 102 . A control device 101 is arranged on the rotating base 102 . A steering gear is arranged between the pitching arm 103 and the rotating base 102 , and the rotation shaft of the steering gear is vertically arranged and passed through the pitching arm 103 and the rotating bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com