Patents

Literature

72 results about "Height decrease" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Negative obstacle detection method based on local structure feature of laser radar point cloud

ActiveCN106650640ADetection results are not affected by light conditionsMeasure distance directlyScene recognitionPattern recognitionPoint cloud

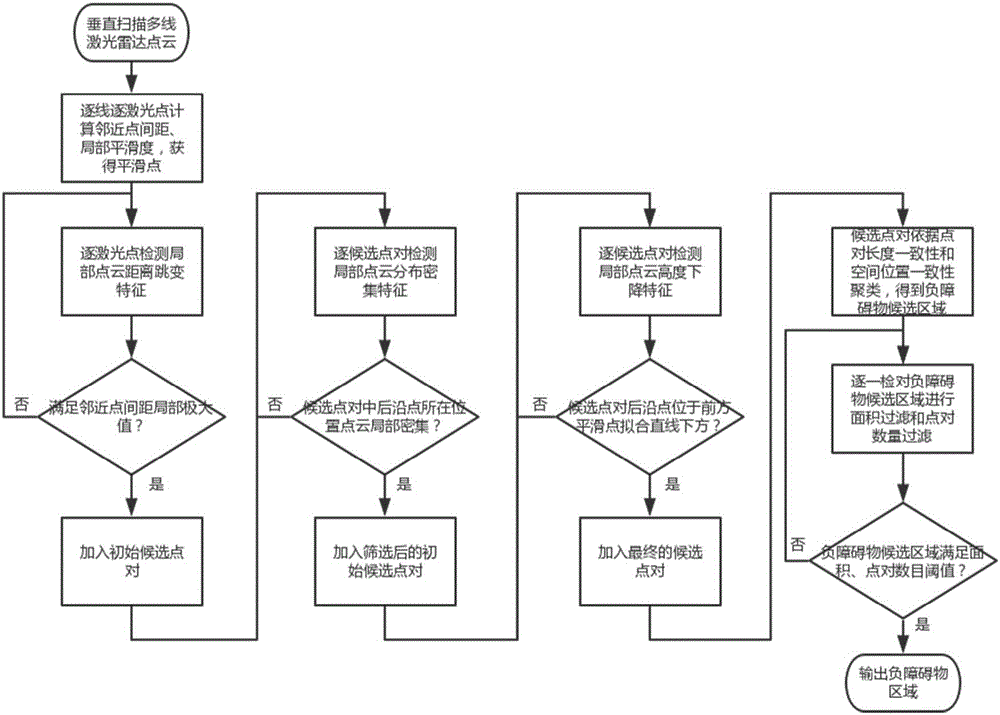

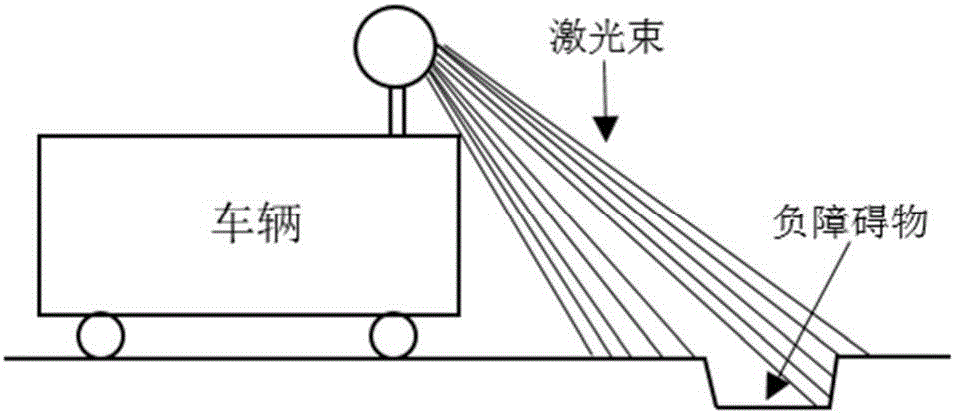

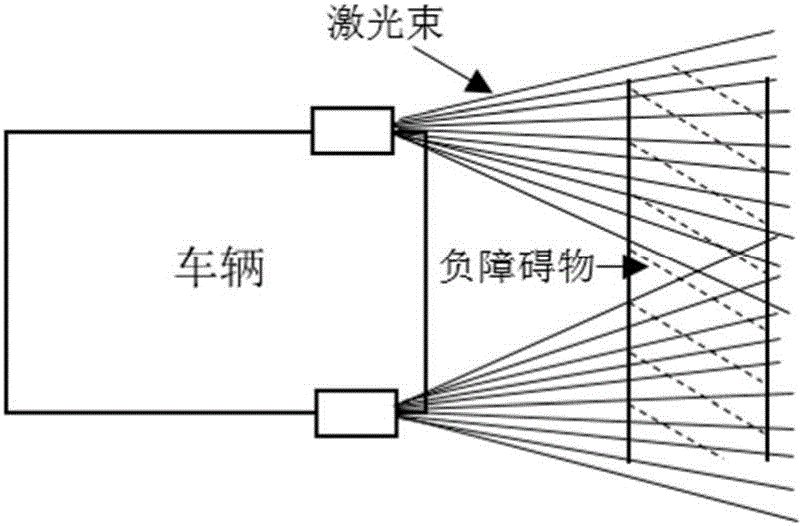

The invention discloses a negative obstacle detection method based on the local structure feature of a laser radar point cloud. In collected laser radar point cloud data, three structure features including local point cloud distance hopping, local point cloud dense distribution and local point cloud height decreasing are detected line by line; on the basis of the three structure features, candidate point pairs which may belong to a negative obstacle are obtained through extraction and screening in single line laser point cloud; all candidate point pairs obtained by the laser point cloud of each line laser are clustered on the basis of point pair length consistency and spatial position consistency to obtain a negative obstacle candidate area; and through area filtering and point pair amount filtering, obtaining a negative obstacle area. By use of the method, the negative obstacle in environment can be effectively detected, and the method has the advantages of good detection success rate, small calculation cost and high instantaneity.

Owner:ZHEJIANG UNIV

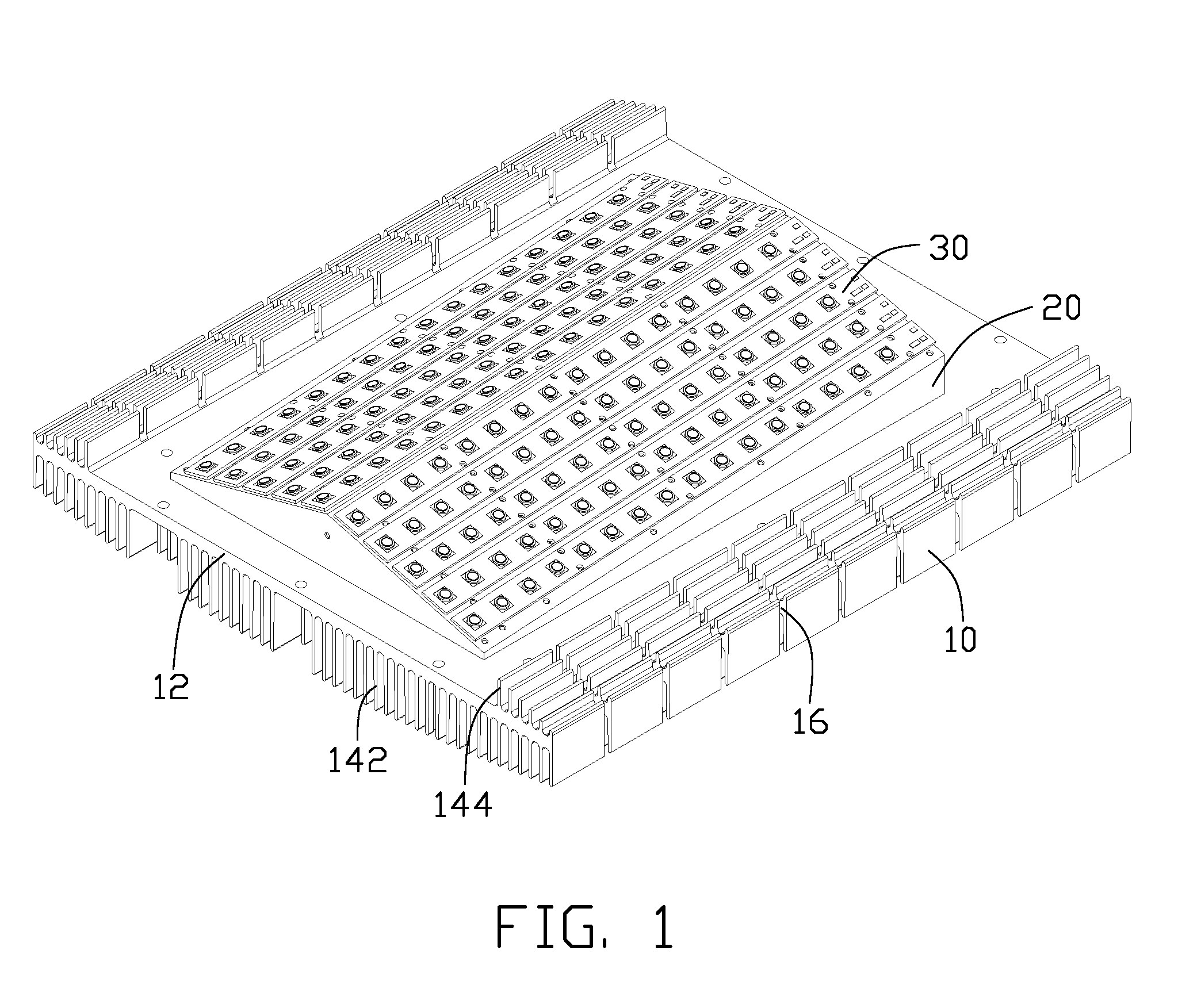

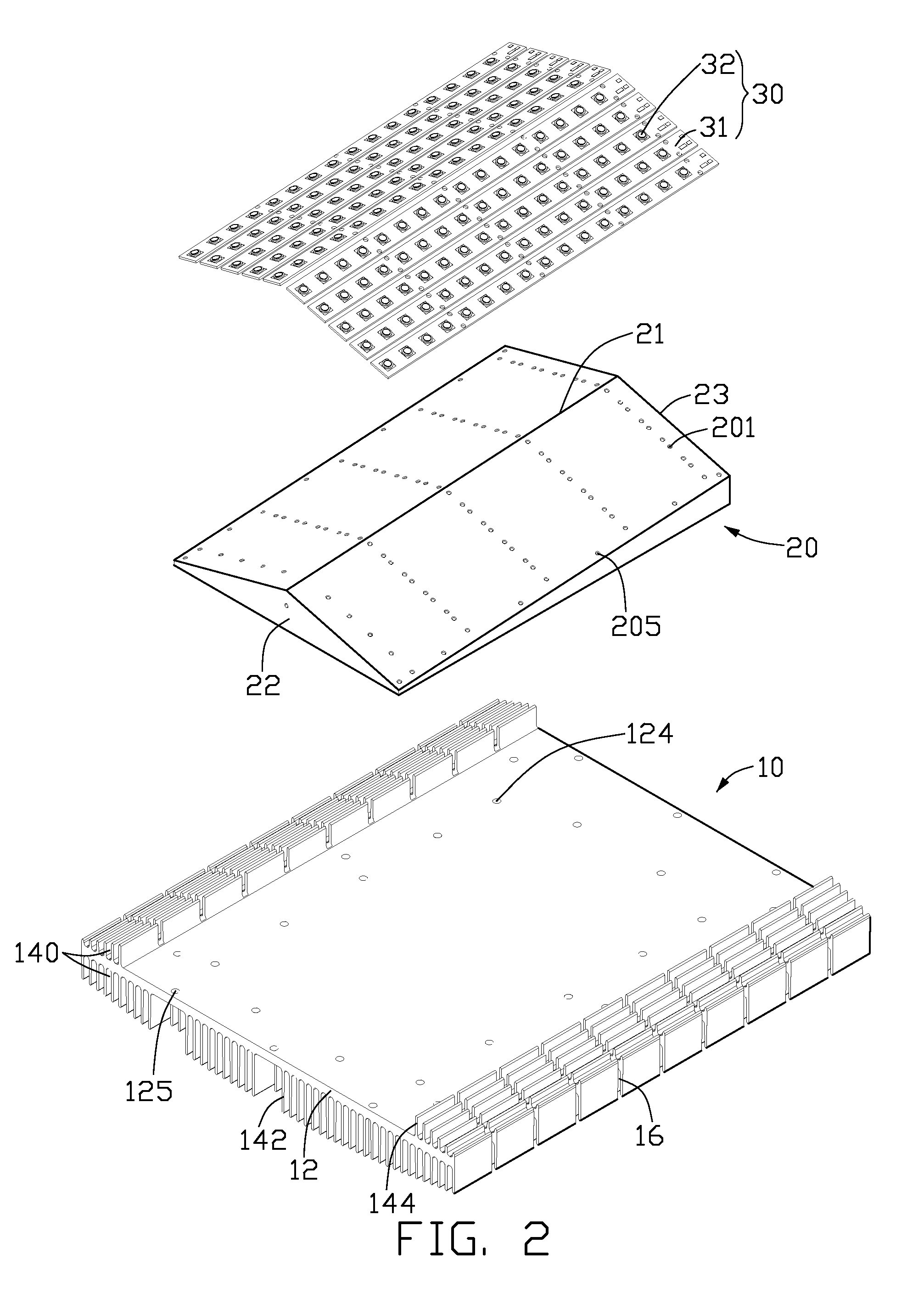

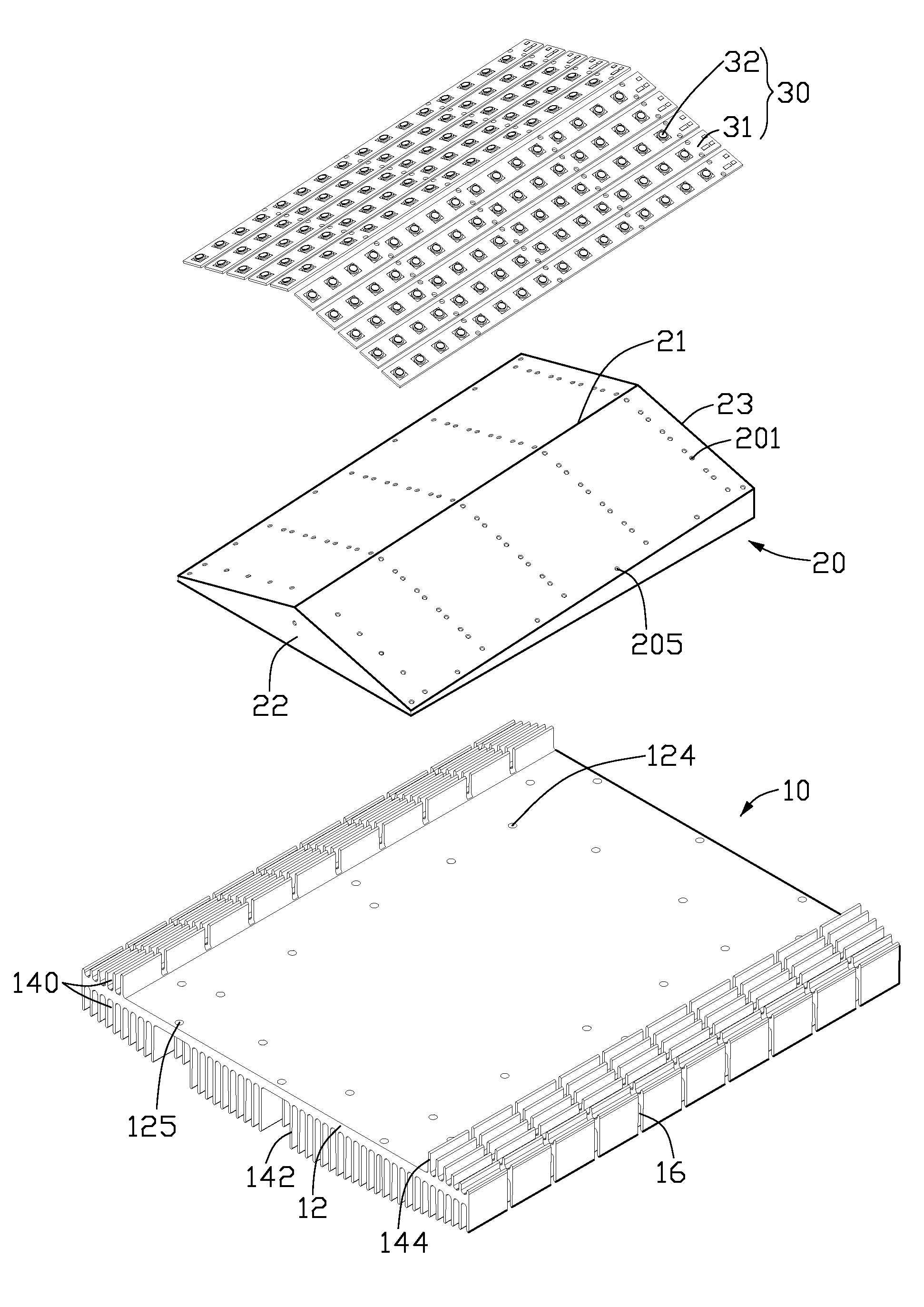

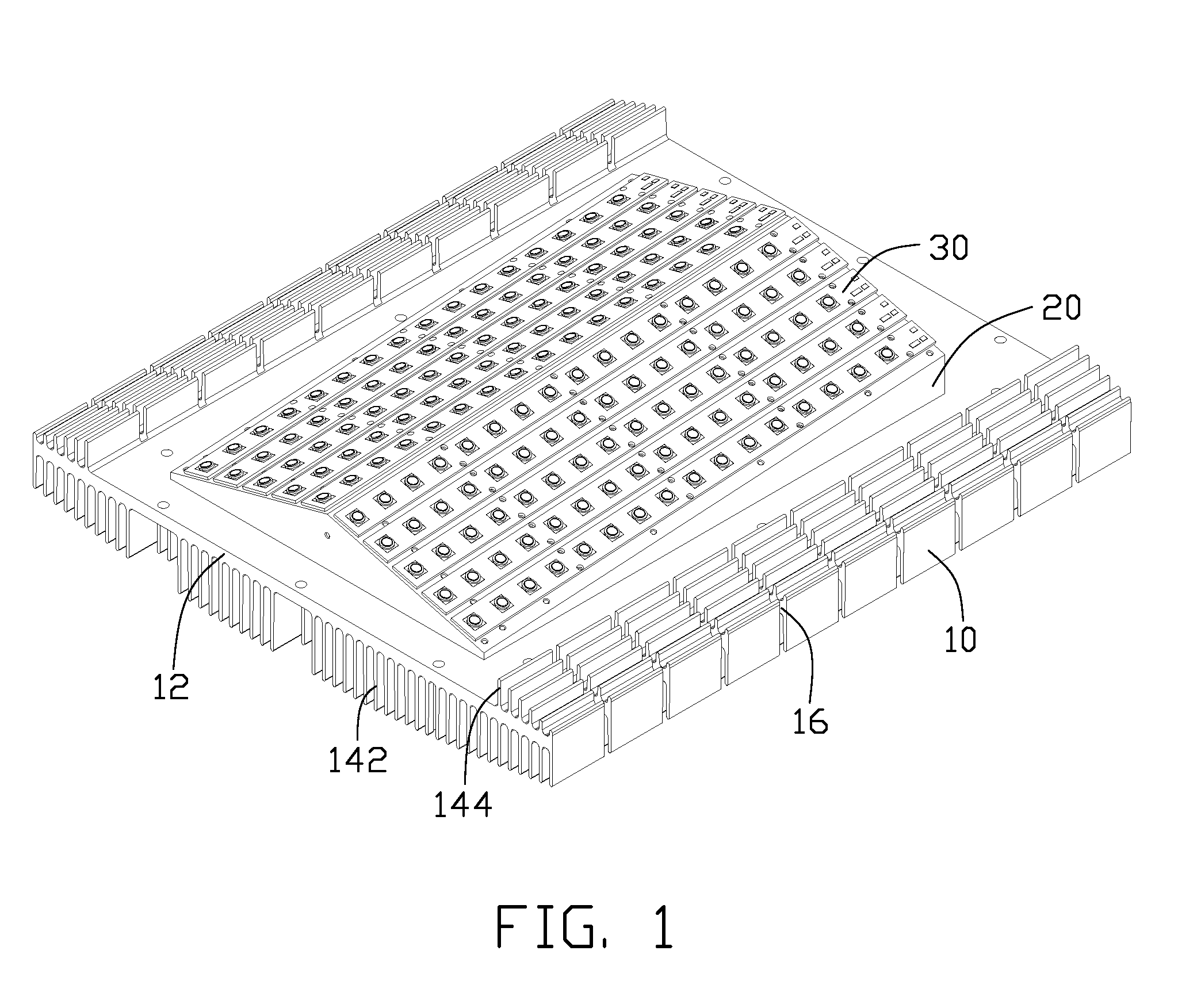

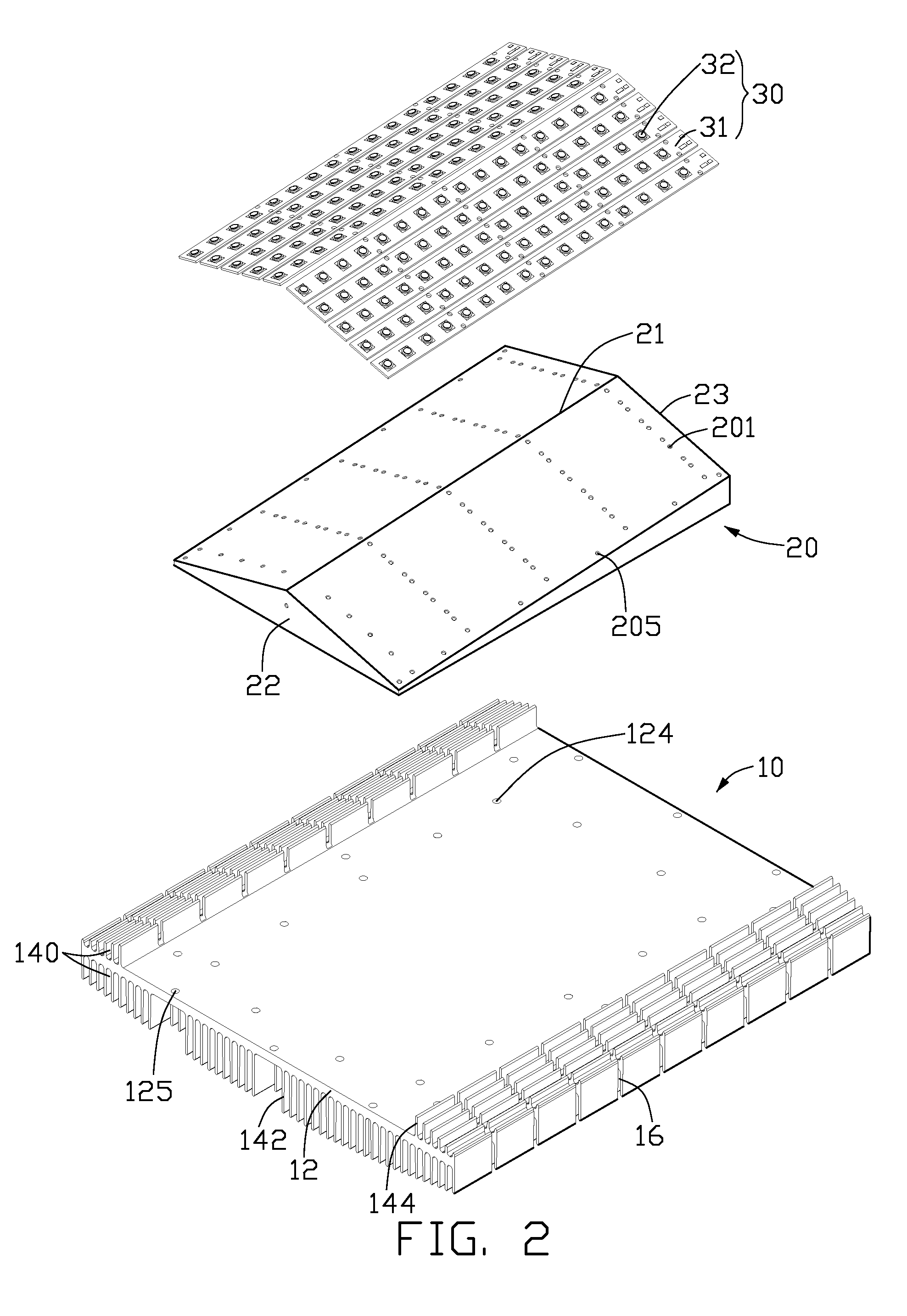

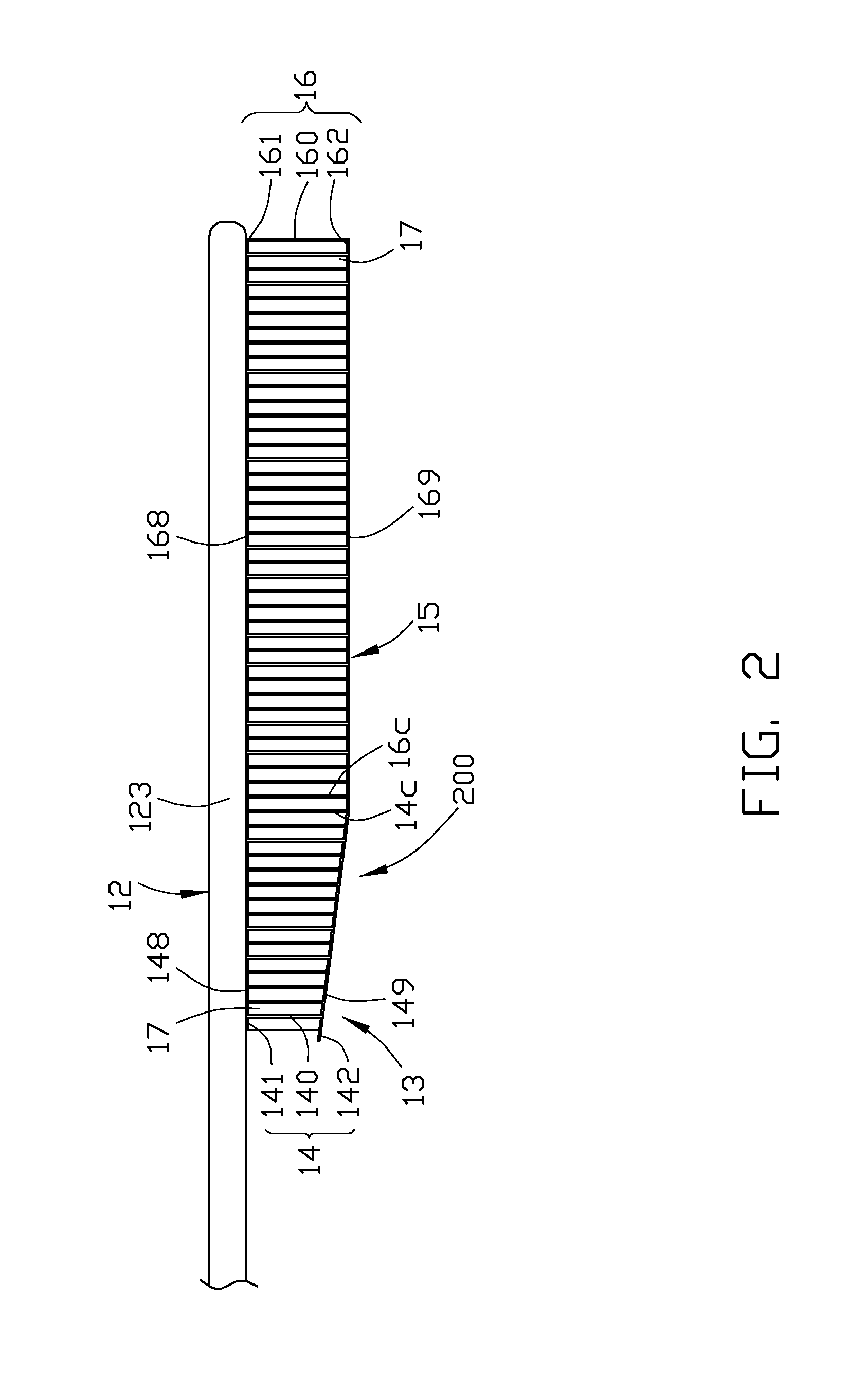

LED lamp with a heat dissipation device

InactiveUS7766513B2Increase temperatureDissipate heat generatedLighting support devicesPoint-like light sourceHeight decreaseLED lamp

An LED lamp includes a heat sink, a triangular-shaped ridge positioned on the heat sink and an LED module mounted on the ridge. The heat sink includes a base and a plurality of first and second fins respectively extending from a first and a second surface of the base, with a plurality of channels defined between the first and second fins. The ridge is positioned on the second surface of the base. The ridge has a lateral surface which has a height decreasing from a middle to a lateral side of the ridge and decreasing from a rear end to a front end of the ridge. The LED module is mounted on the lateral surface of the ridge.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

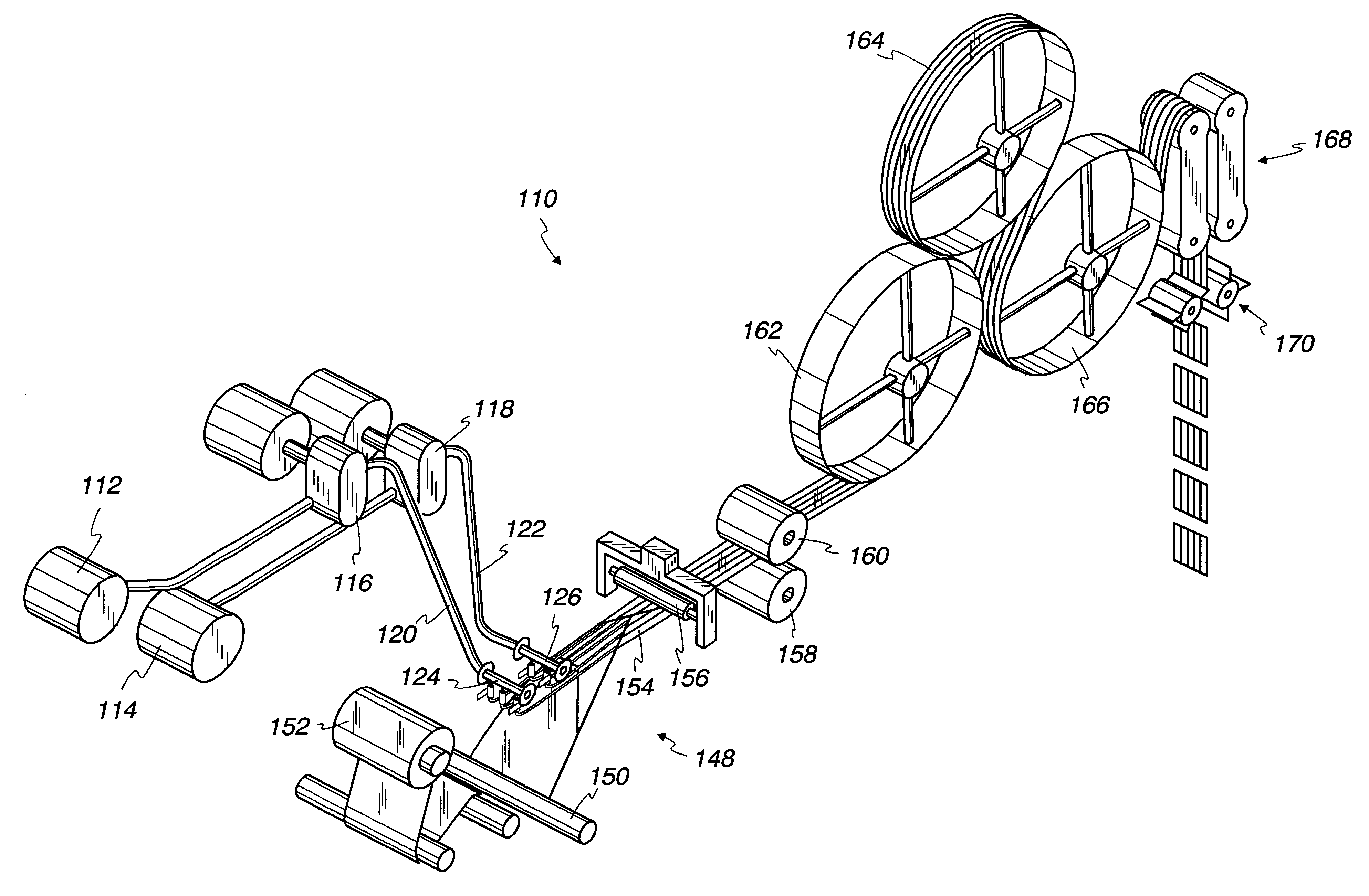

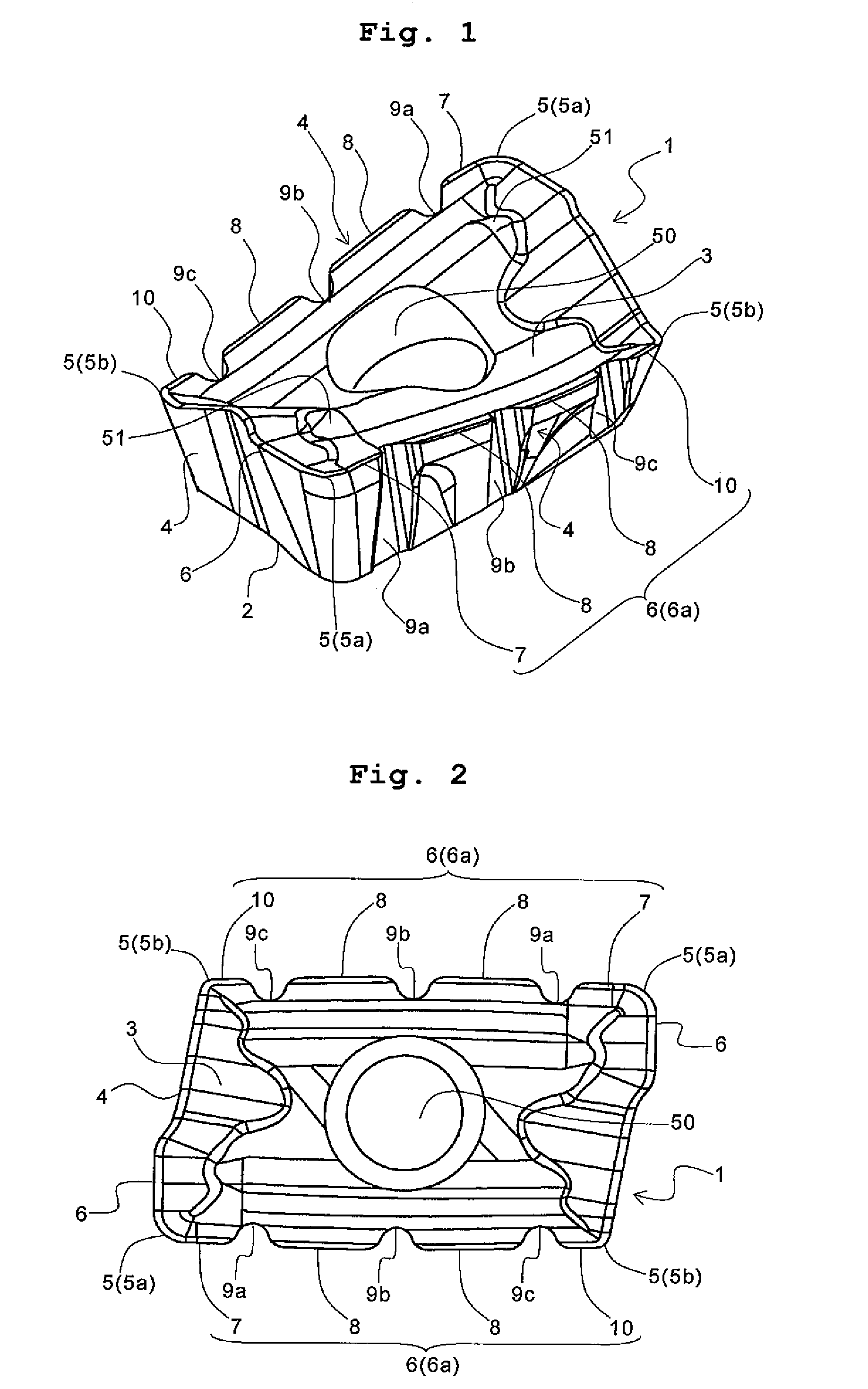

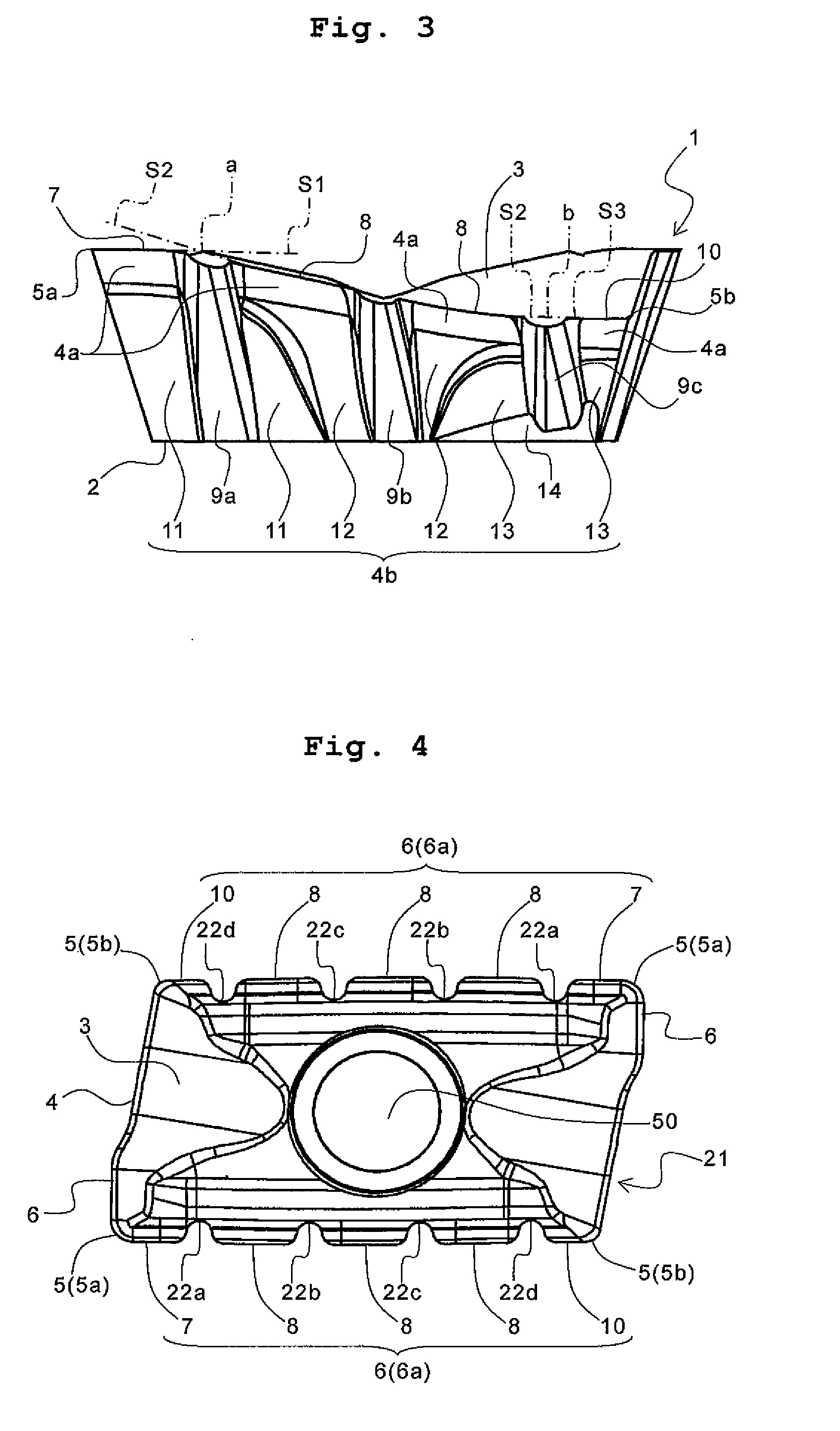

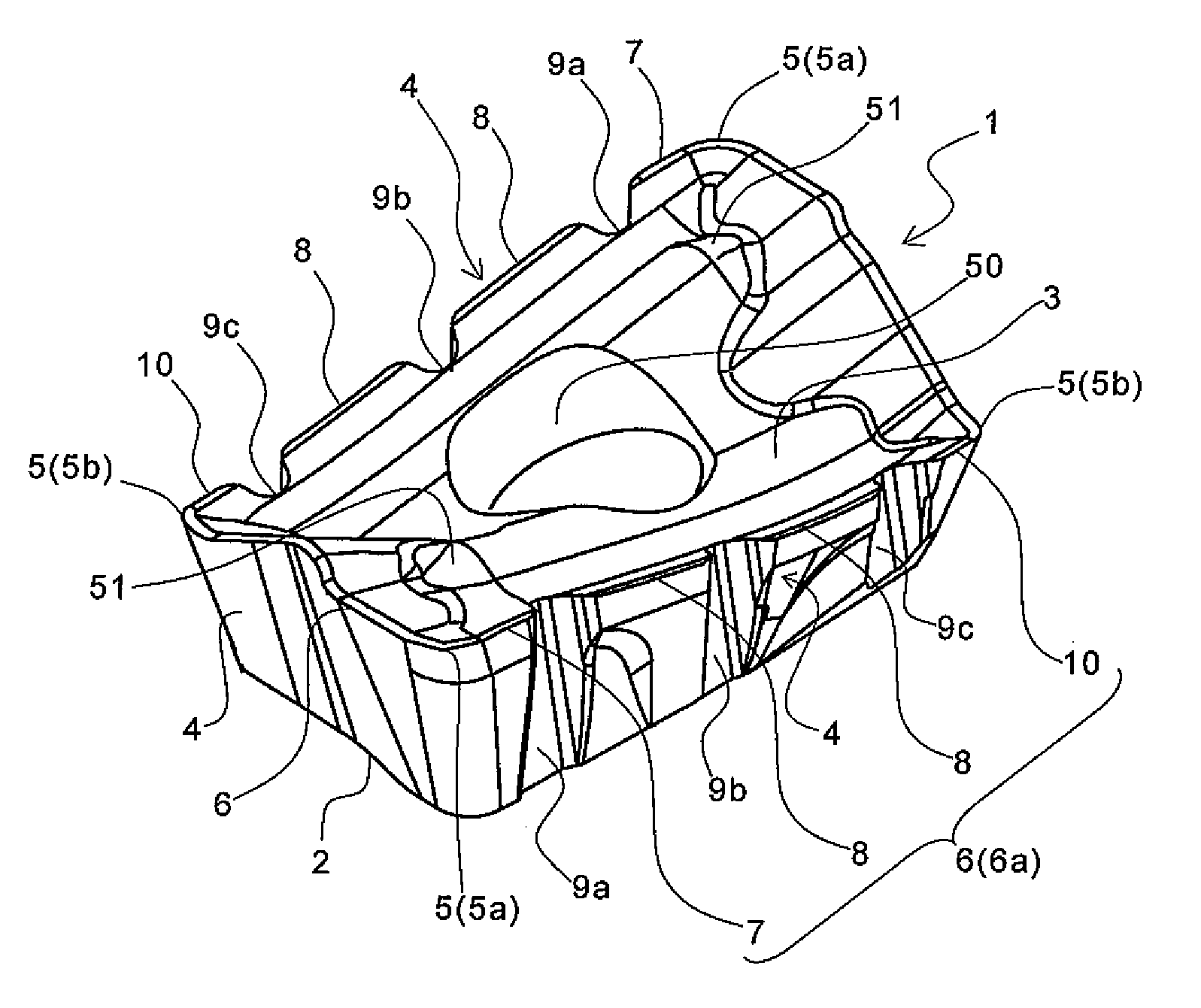

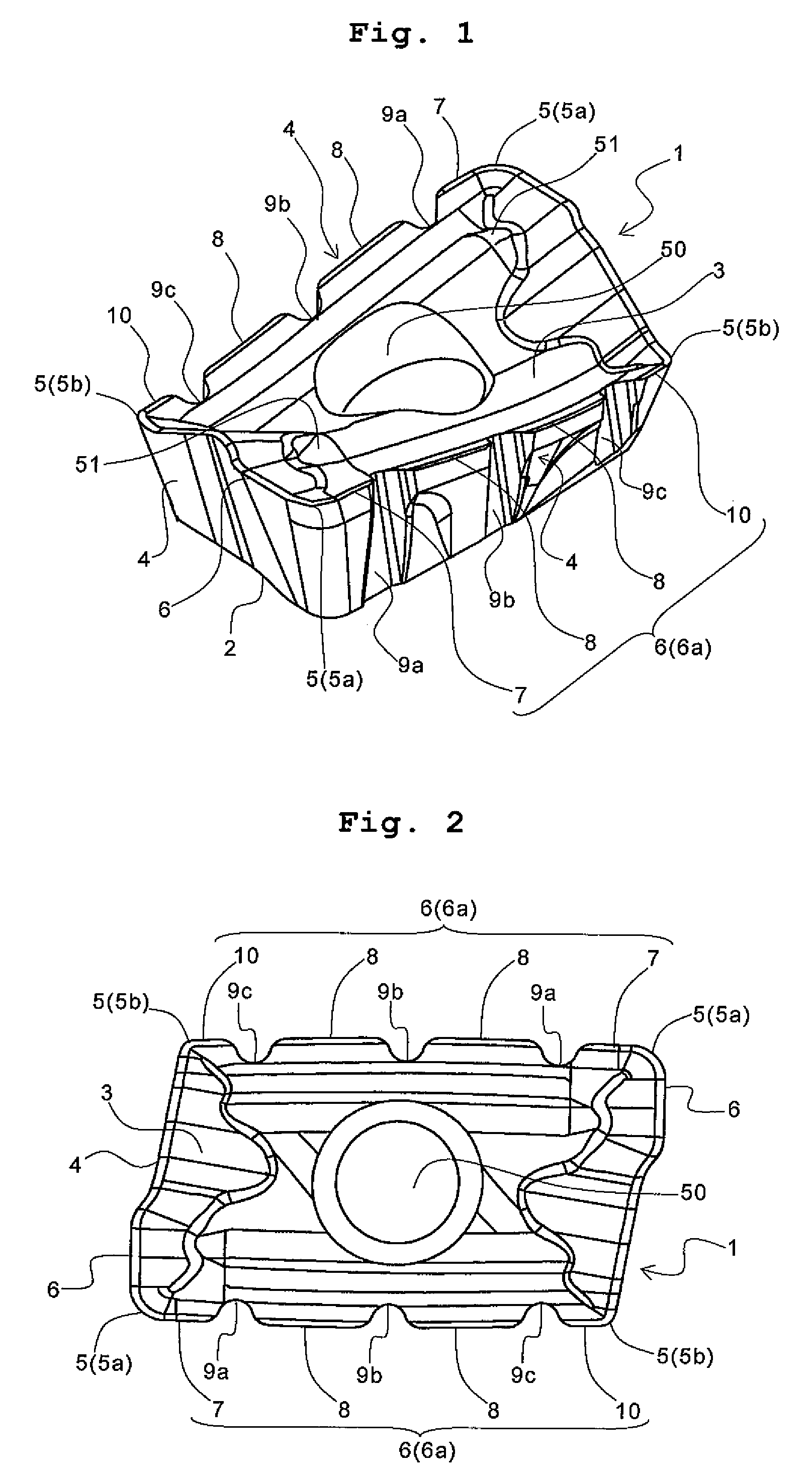

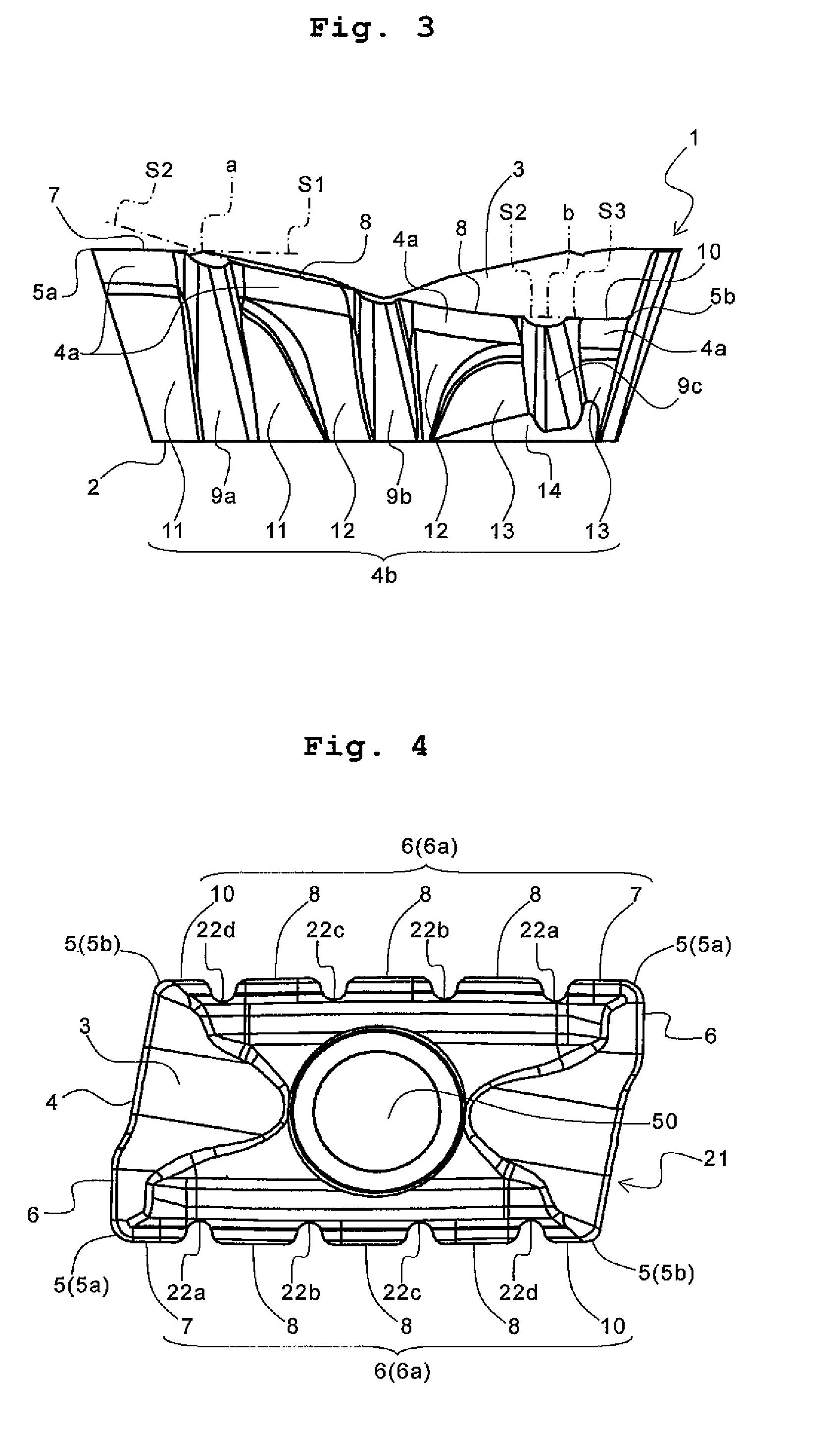

Track for all terrain vehicle

A track for a vehicle travelling on all terrain, especially those displaying ruts, is formed of an endless longitudinal body displaying a series of longitudinally spaced drive lugs on its inner surface and a series of longitudinally spaced profiles on its outer surface. Each profile displays a height decreasing in value from the center of the body to the outer edge thereof. The body is formed of flexible rubber material and is free of conventional transversally extending reinforcing embedded rods thus providing reduced transverse rigidity to the body and allowing the body to curvingly flex when engage in ruts.

Owner:CAMOPLASY INC

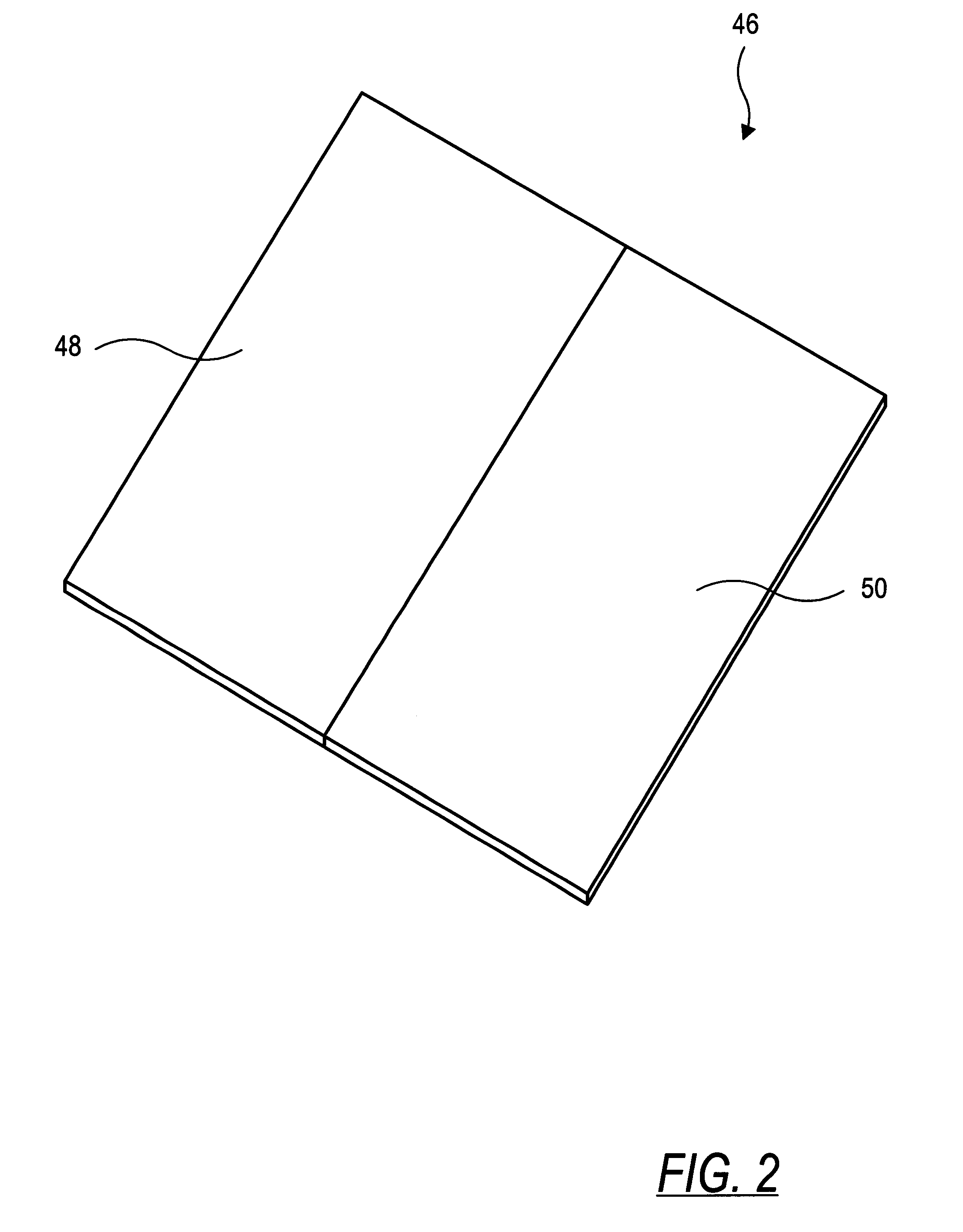

Inner panel for a vehicle door

Owner:SSAB HARDTECH AB

Apparatus for continuous manufacture of multi-colored and/or multi-flavored food product

Owner:KRAFT FOODS GRP BRANDS LLC

LED lamp with a heat dissipation device

InactiveUS20090129103A1Reduce the overall heightIncrease temperatureLighting heating/cooling arrangementsOptical signallingHeight decreaseEngineering

An LED lamp includes a heat sink, a triangular-shaped ridge positioned on the heat sink and an LED module mounted on the ridge. The heat sink includes a base and a plurality of first and second fins respectively extending from a first and a second surface of the base, with a plurality of channels defined between the first and second fins. The ridge is positioned on the second surface of the base. The ridge has a lateral surface which has a height decreasing from a middle to a lateral side of the ridge and decreasing from a rear end to a front end of the ridge. The LED module is mounted on the lateral surface of the ridge.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

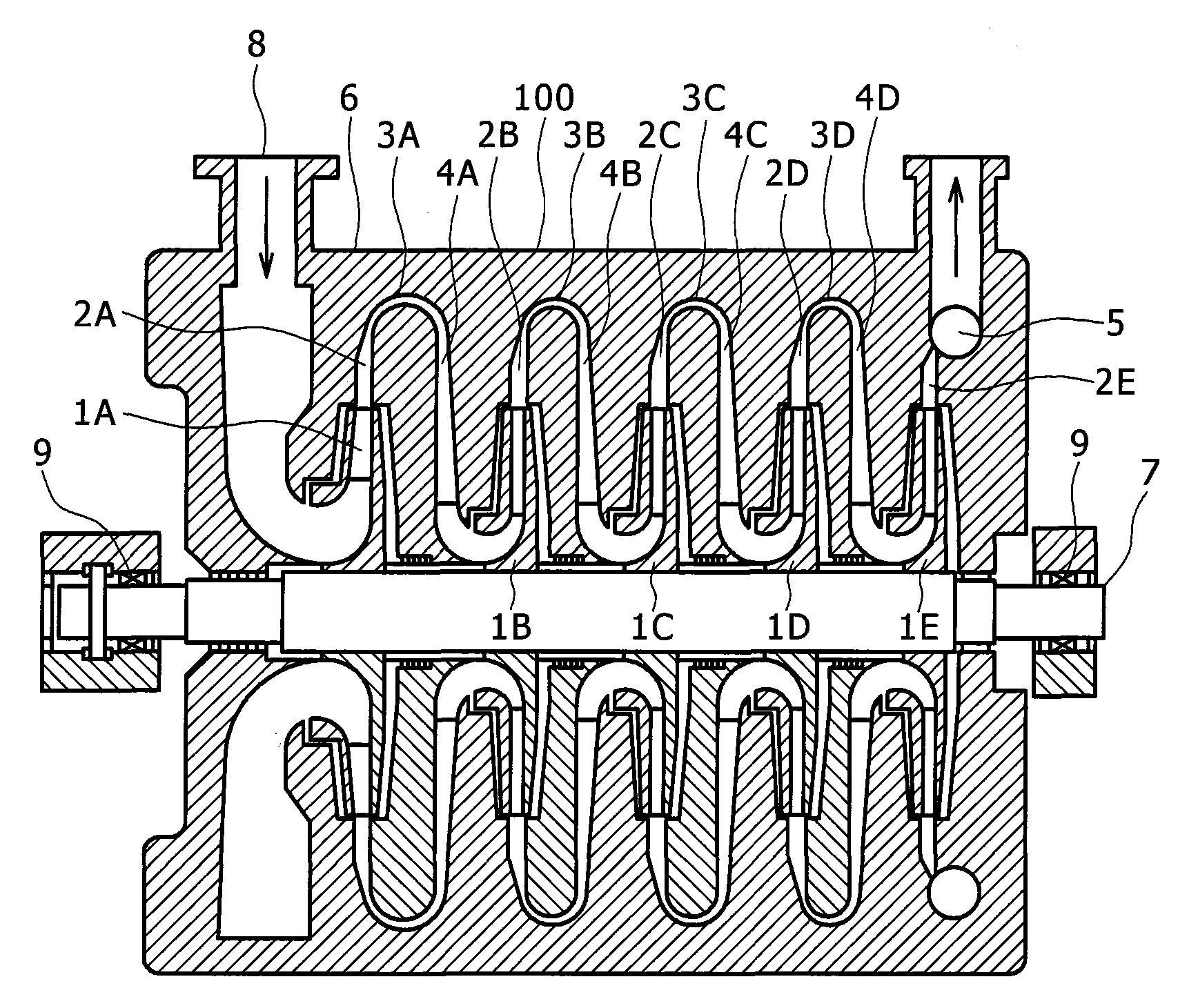

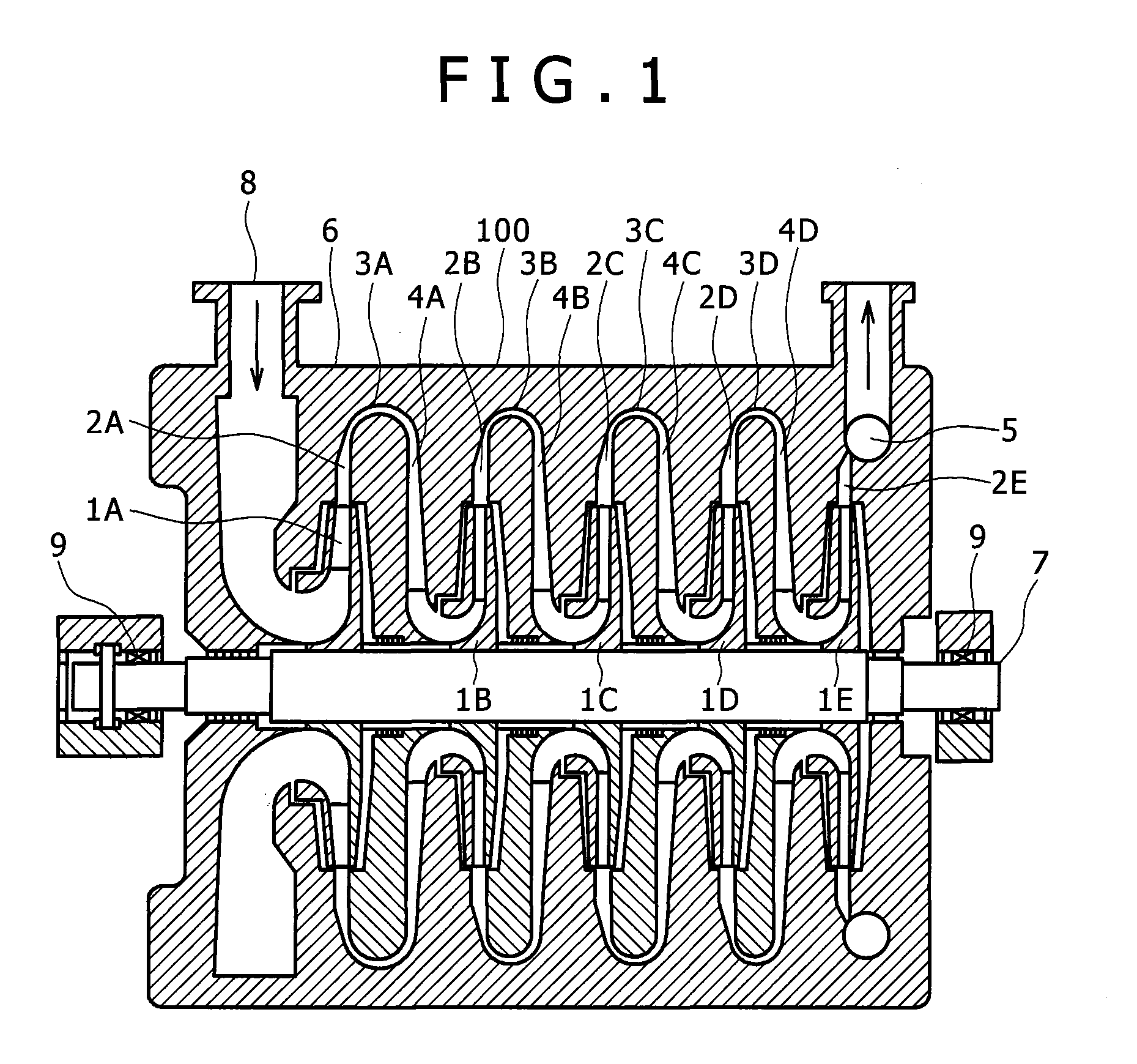

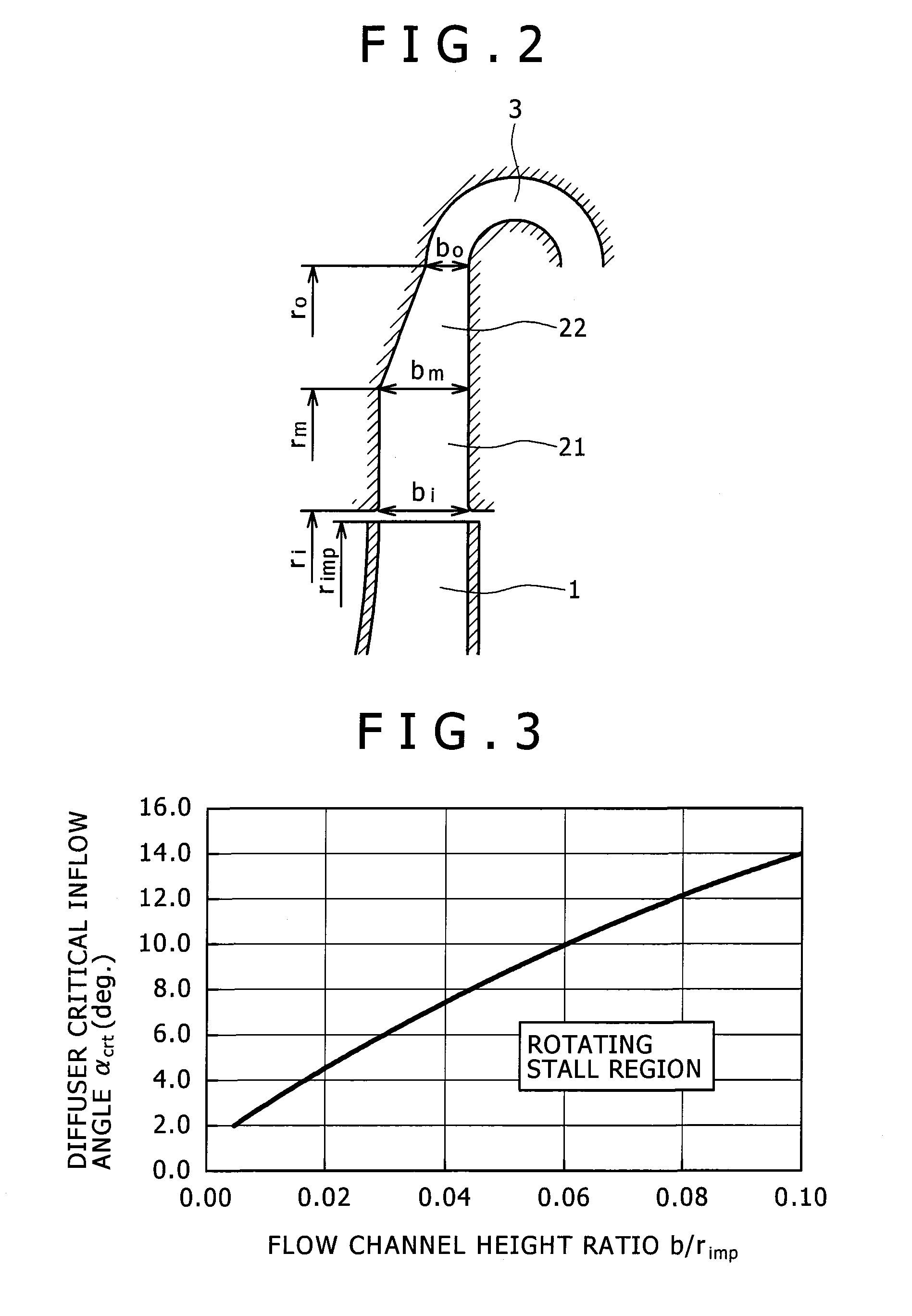

Centrifugal compressor having vaneless diffuser and vaneless diffuser thereof

ActiveUS20090317248A1Improve efficiencyAvoid it happening againPump componentsStatorsHeight decreaseHigh pressure

In a high pressure centrifugal compressor, the occurrence of rotating stall noticeable in a comparatively-low specific speed wheel stage is prevented, thereby high efficient fluid performance is obtained and reliability is improved. The centrifugal compressor has a first vaneless diffuser with a constant flow channel height on the downstream side of an impeller, and a second vaneless diffuser in which the flow channel height decreases in a flow direction from an inlet to an outlet on the downstream side of the first vaneless diffuser. These diffusers are combined with an impeller using thick blades.

Owner:HITACHI IND PROD LTD

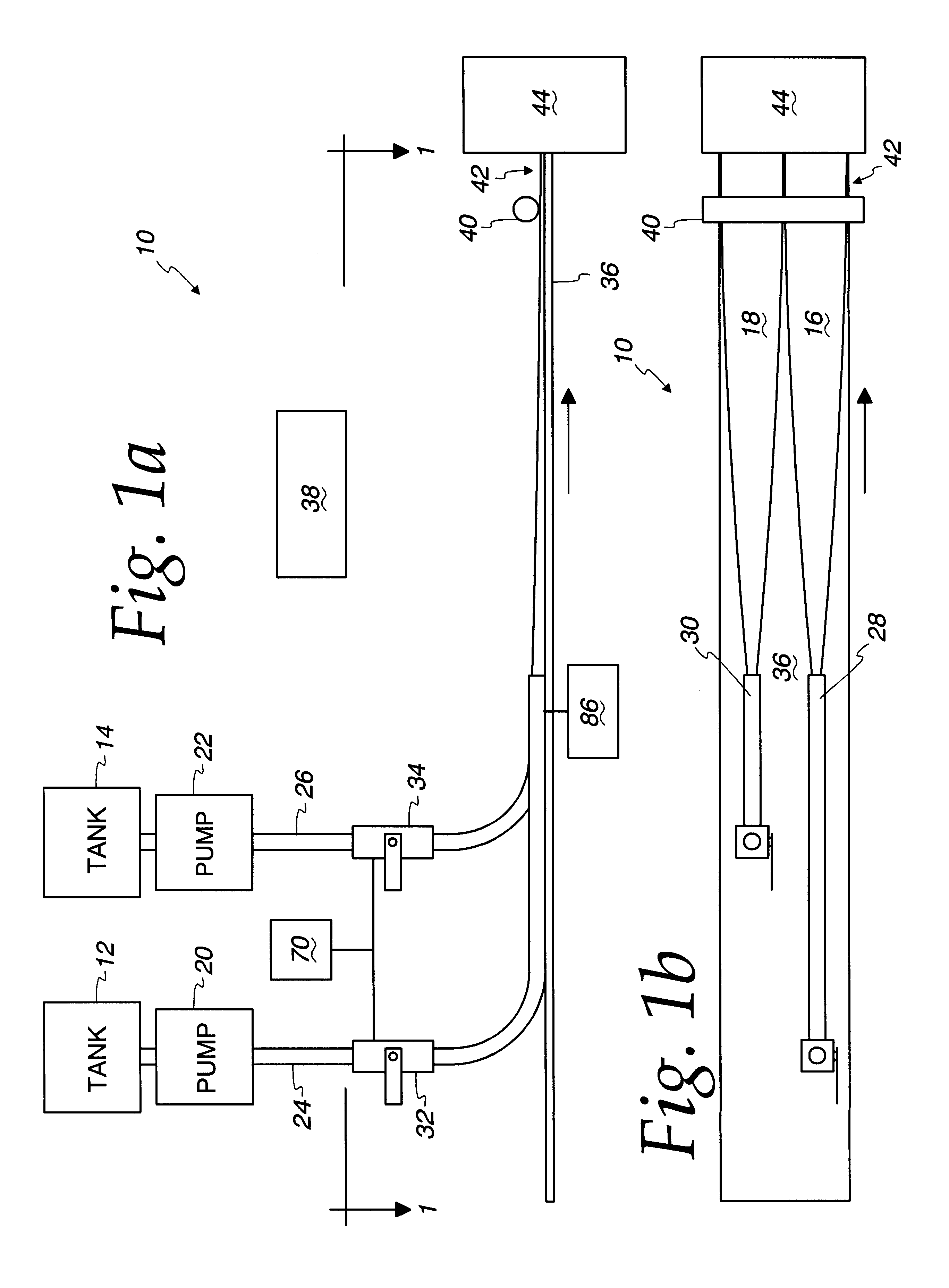

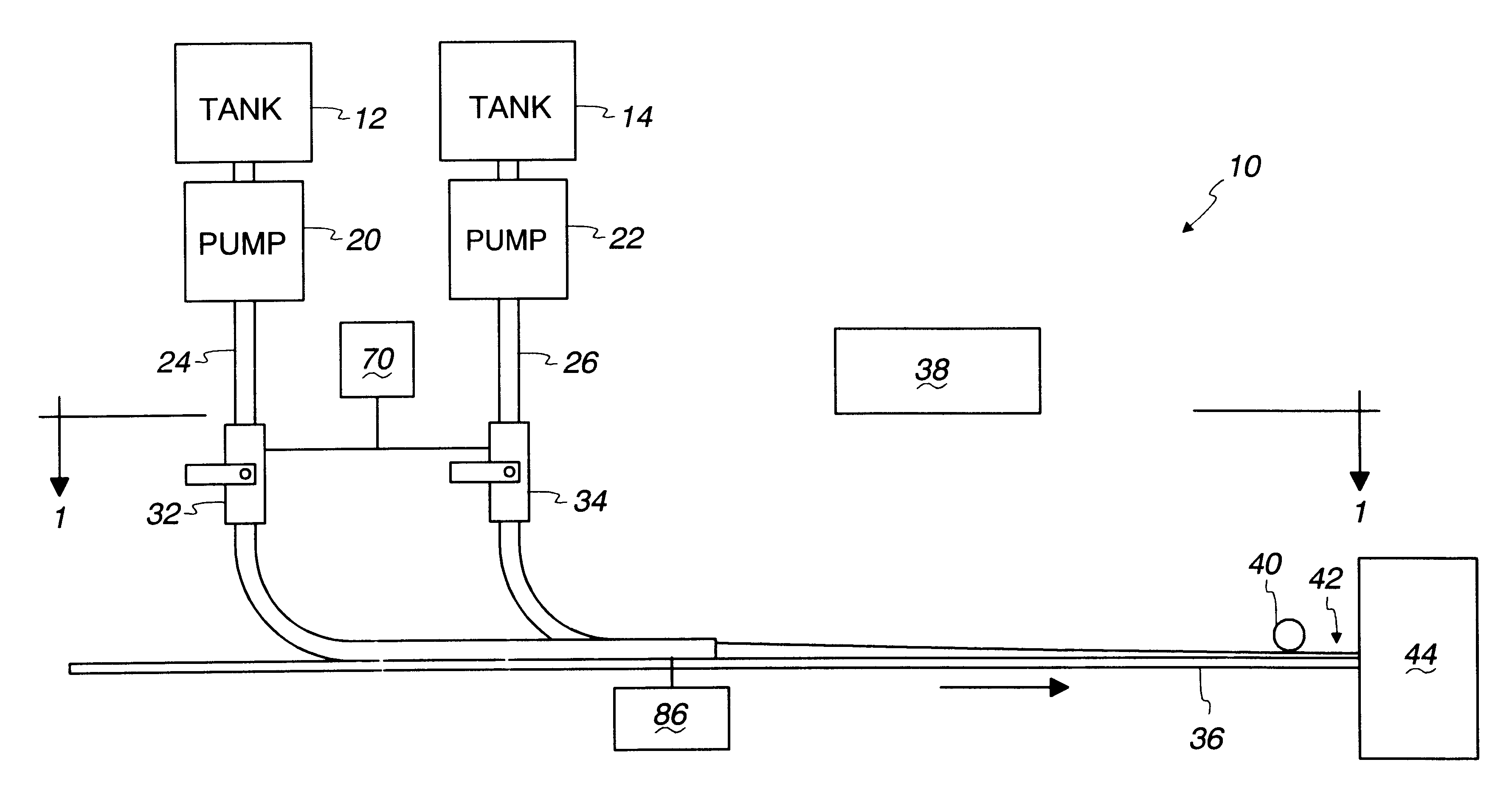

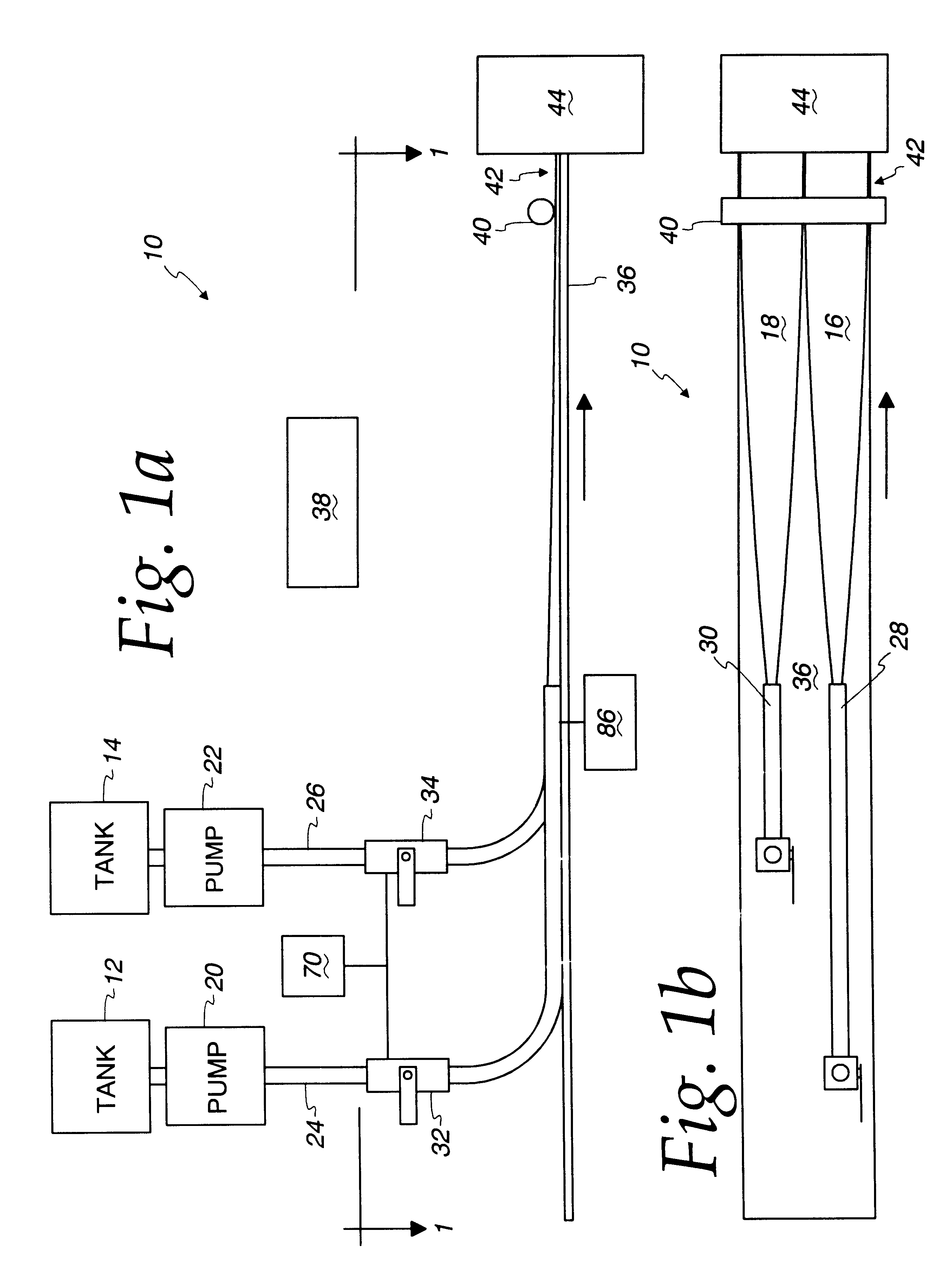

Method for continuous manufacture of multi-colored and/or multi-flavored food product

A method and an apparatus for manufacturing a food product having a plurality of sections having different characteristics, such as different colors and / or flavors. The method and apparatus has a first nozzle extruding a first stream of a liquid food product having a first characteristic onto a moving platform. The first stream has a height and a width with respect to the platform. A second nozzle extrudes a second stream of a liquid food product having a second characteristic onto the platform. The second stream has a height and a width with respect to the platform. The second nozzle is adjacent to the first nozzle providing adjacent first and second streams on the moving platform. The first stream and second stream spread out such that their heights decrease and their widths increase. When the increasing width of the first stream abuts the increasing width of the second stream, the first stream has a first viscosity and the second stream has a second viscosity which inhibit substantial mixing of the first and second streams when the two streams abut.

Owner:KRAFT FOODS GRP BRANDS LLC

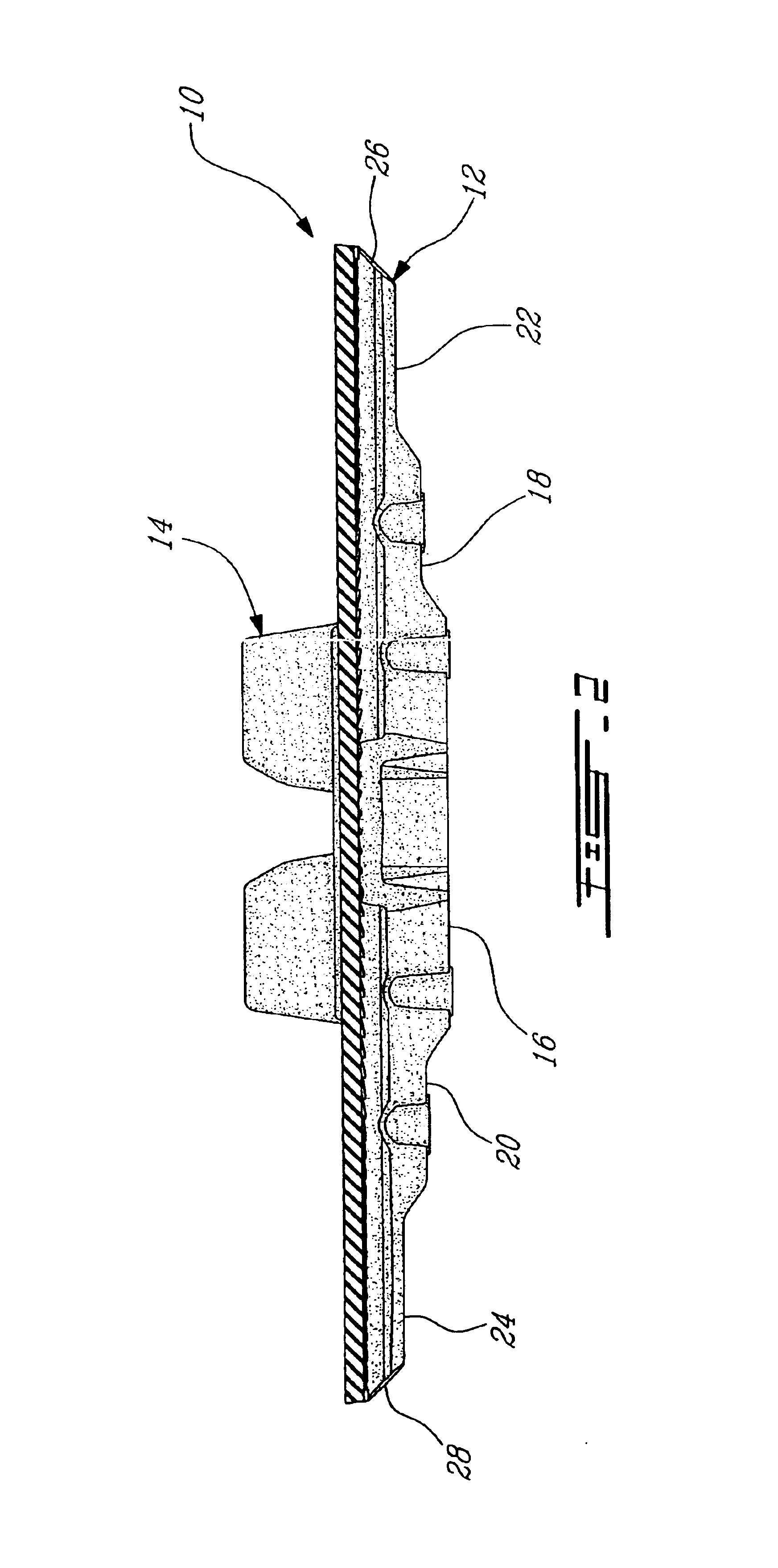

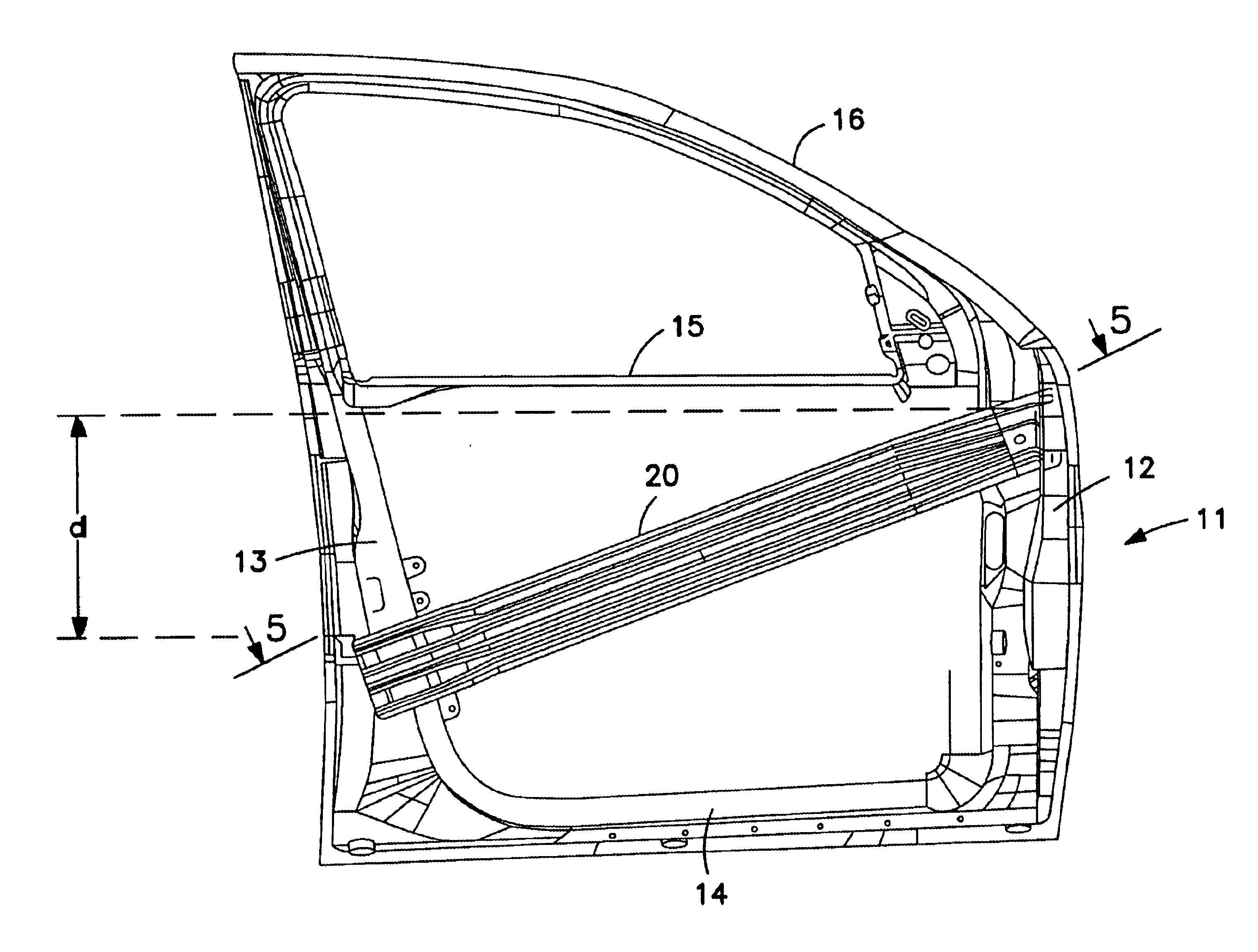

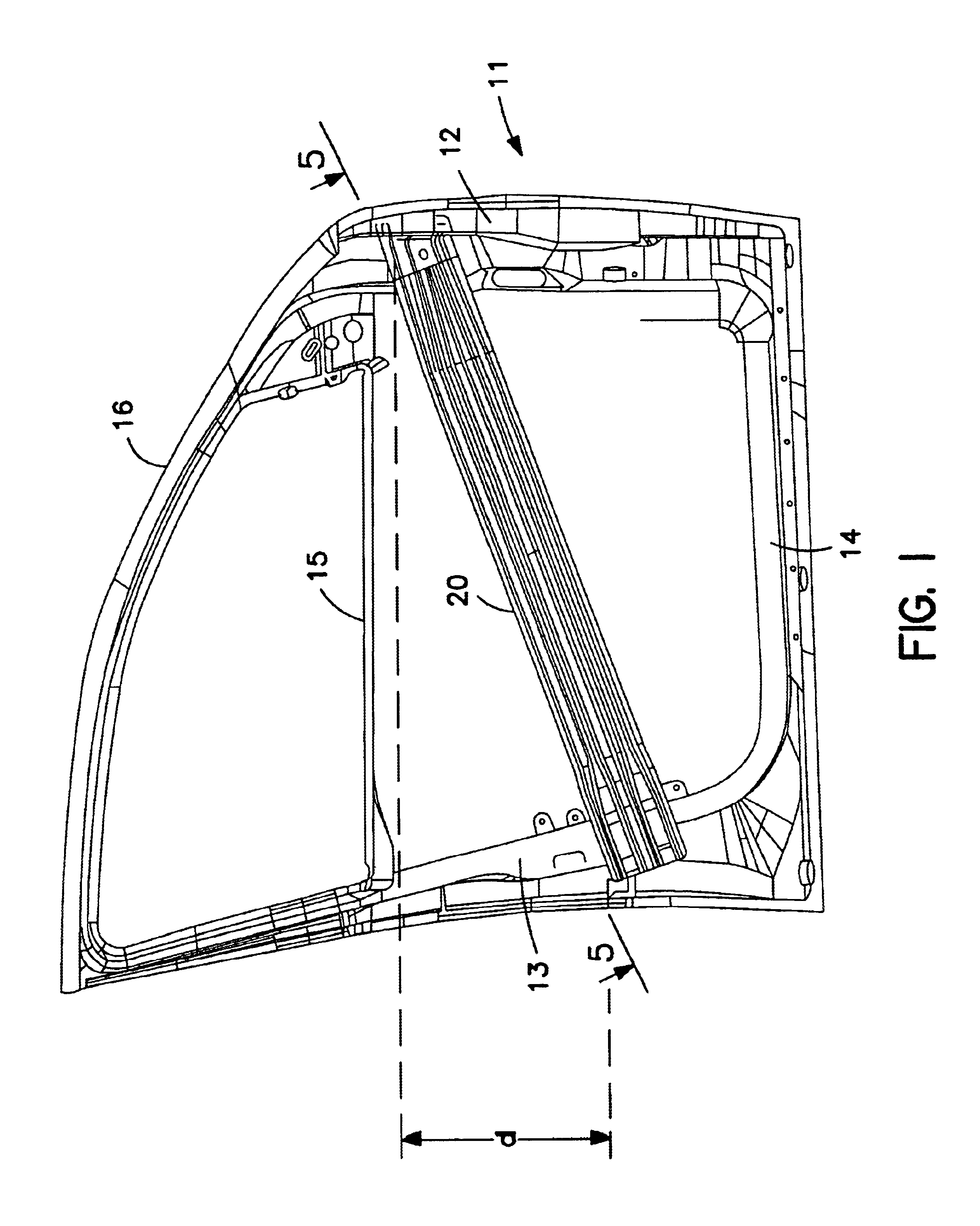

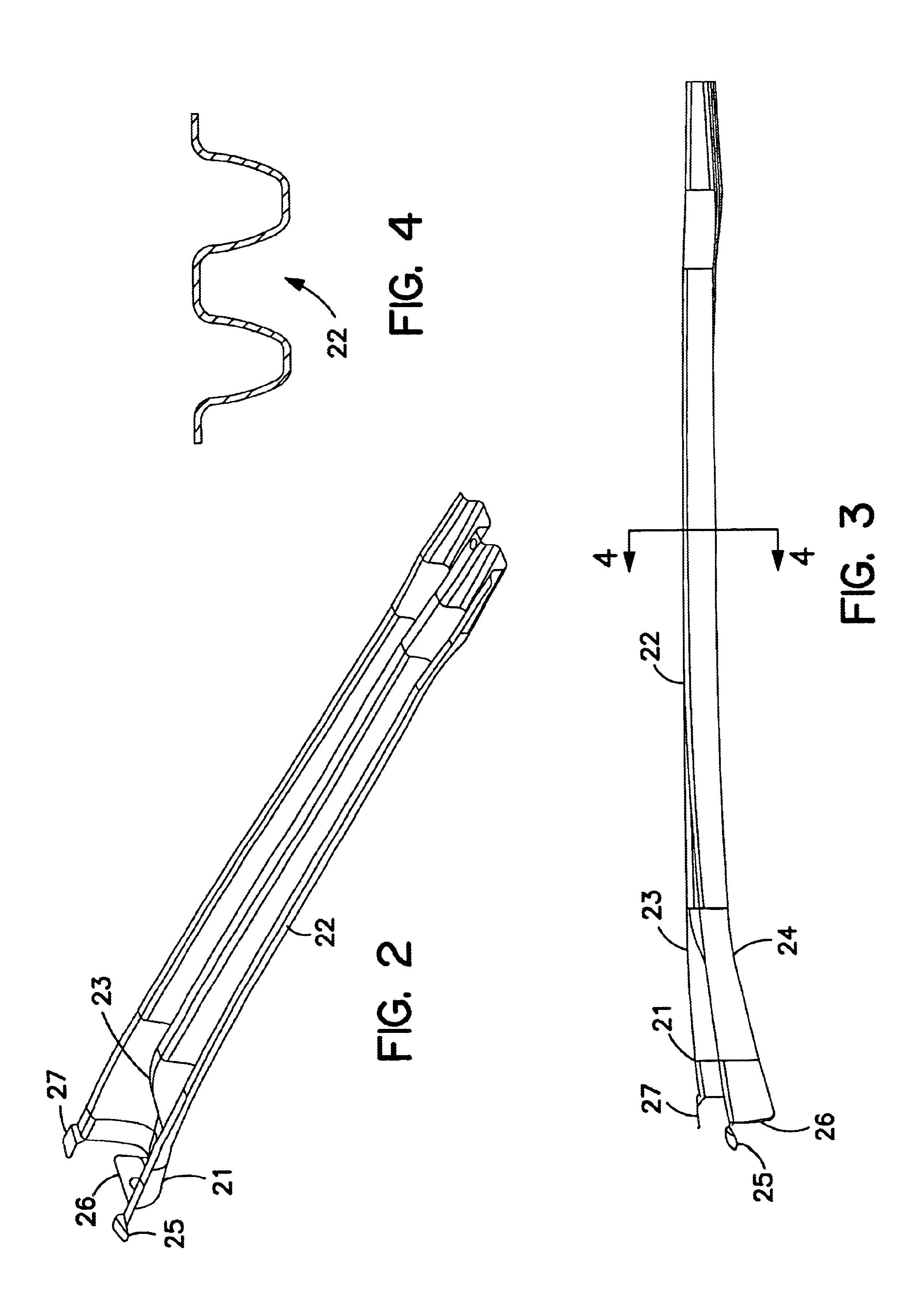

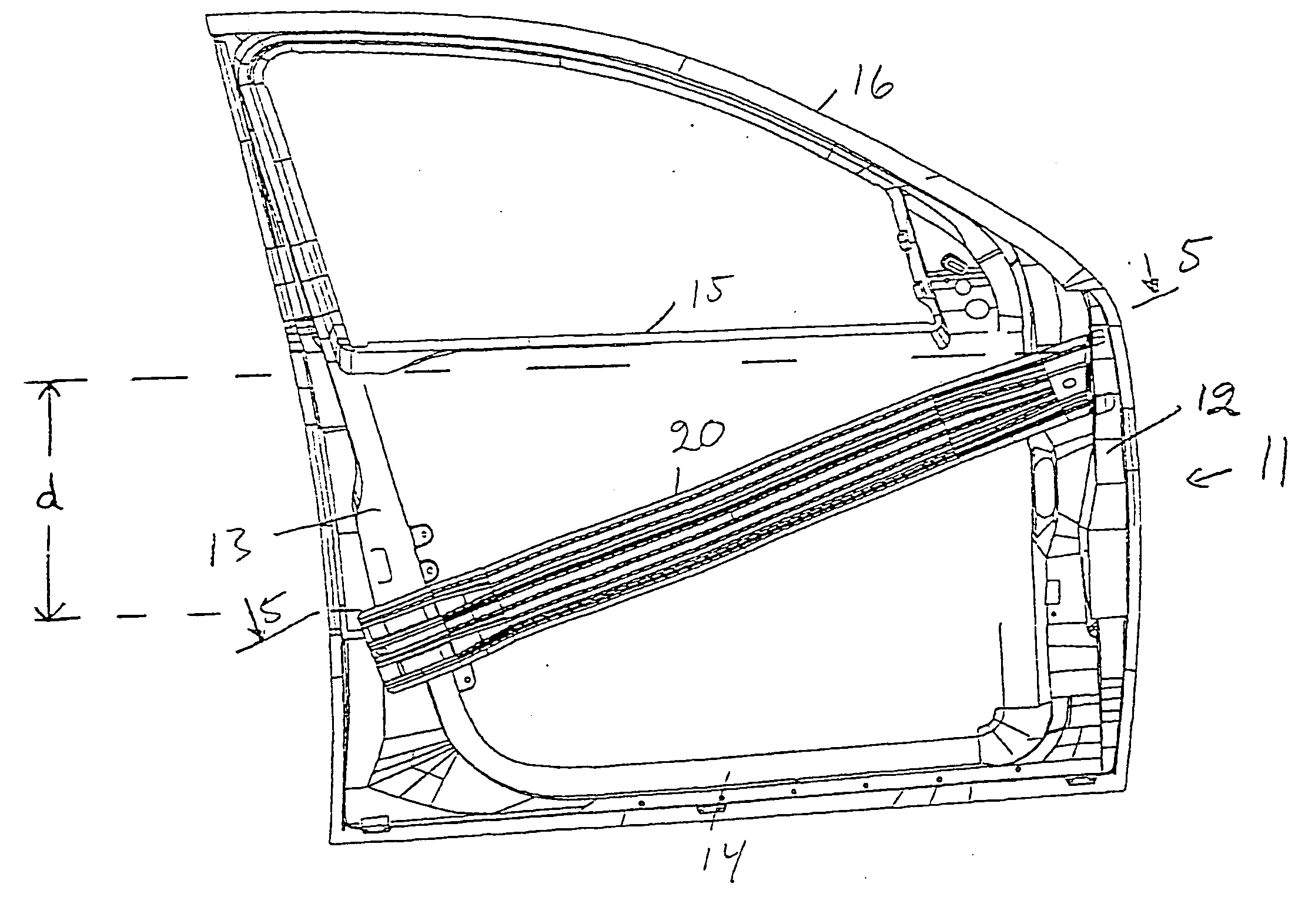

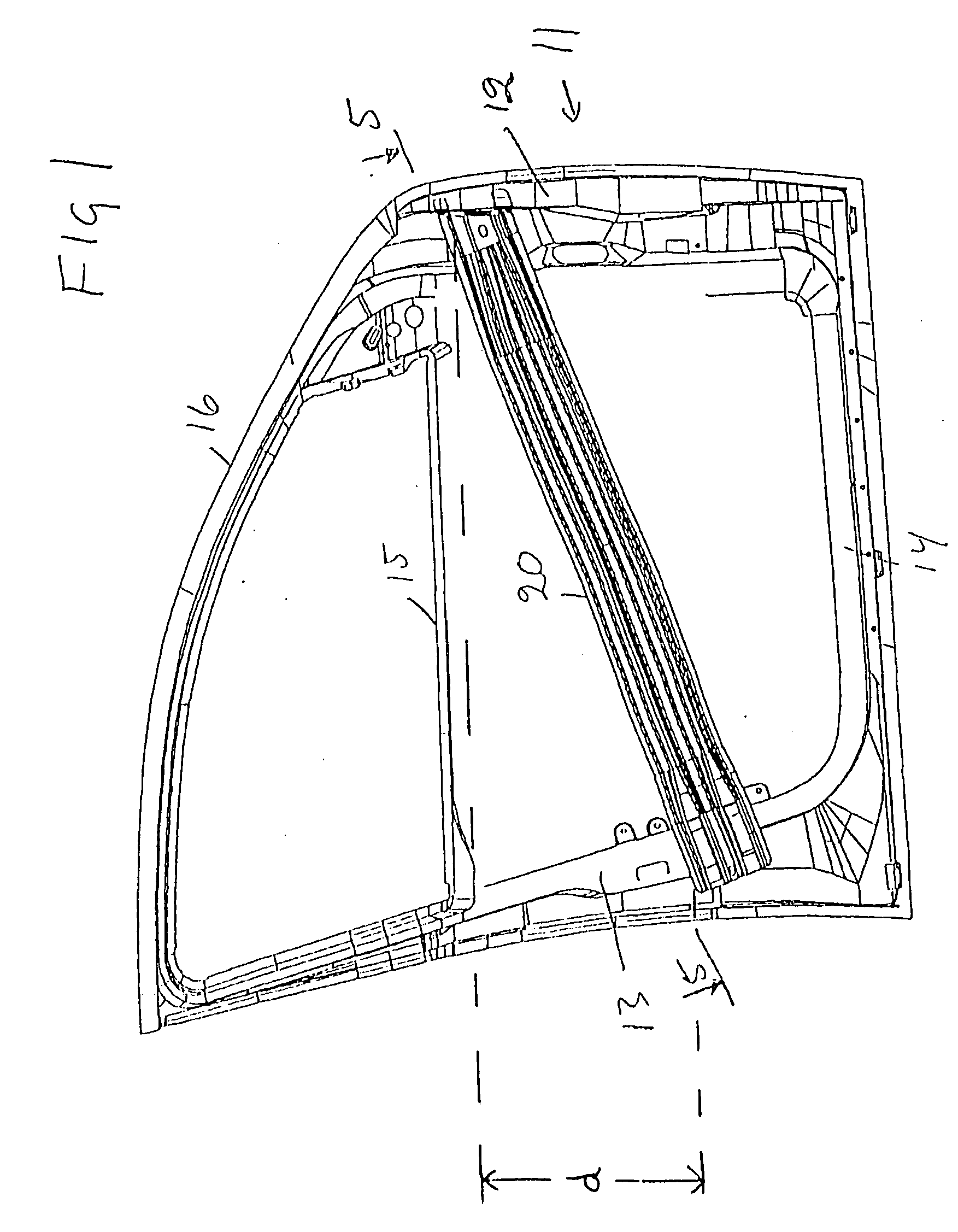

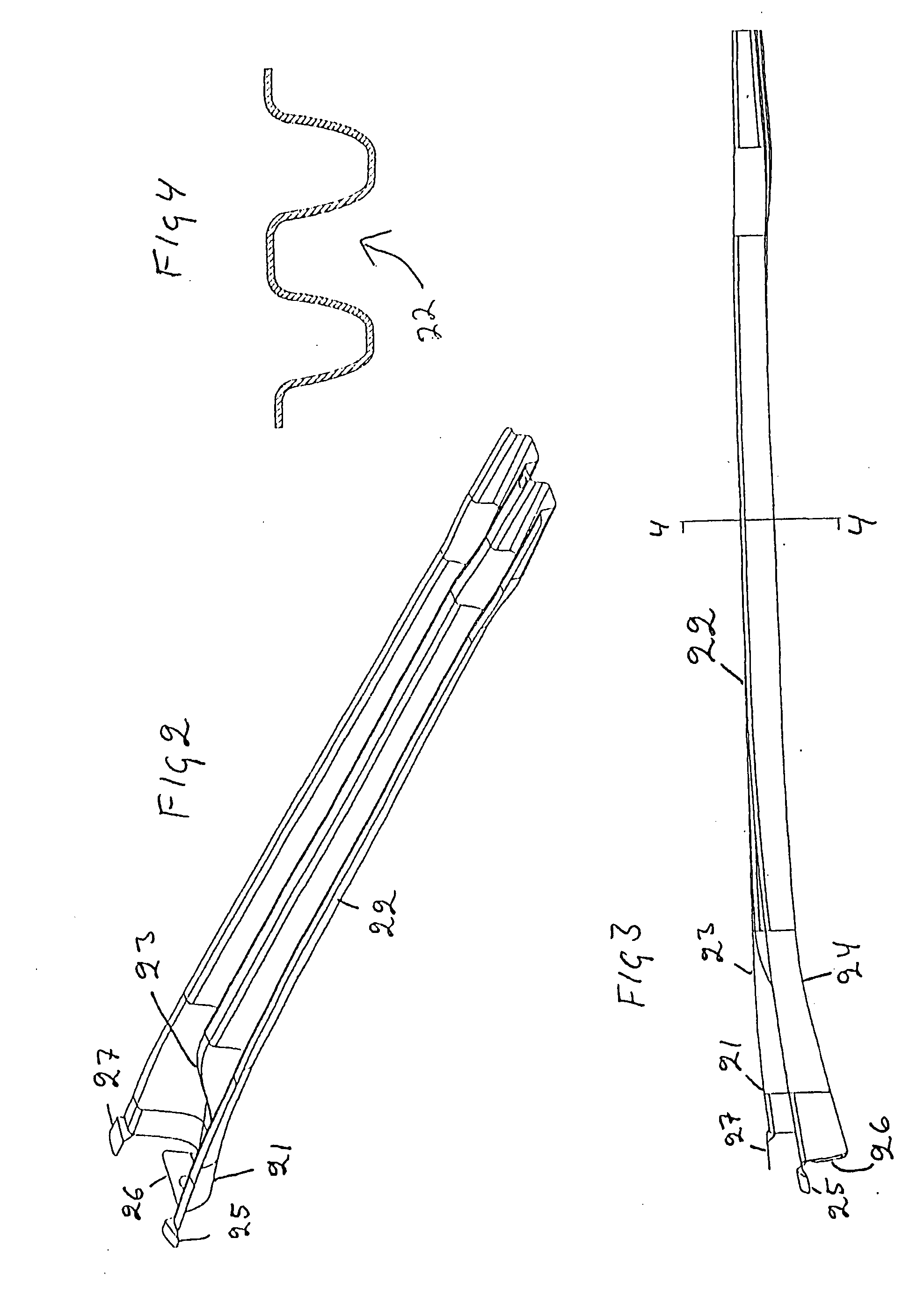

Inner panel for a vehicle door

InactiveUS20040036316A1Easy constructionVehicle seatsPedestrian/occupant safety arrangementHeight decreaseEngineering

A vehicle door has an inner panel (11) on which an outer panel is fitted. The inner panel is covered by a loose panel, the trim. The inner panel has a front end wall (12) and a rear end wall (13). A reinforcement beam (20) is fastened between the end walls for transmitting force from a door pillar (33) to which the door is attached to a door pillar (34) behind the door, in the event of a collision. The reinforcement beam has a high single hat profile (21) which is fastened to the upper part of the front end wall, and extends in a curve out towards the external part of the inner panel, where the profile height is lower. The profile height decreases continuously from the high profile height to the low profile height, and the single hat profile (21) extends into a double hat profile (22). The reinforcement beam also functions as a side impact guard.

Owner:SSAB HARDTECH AB

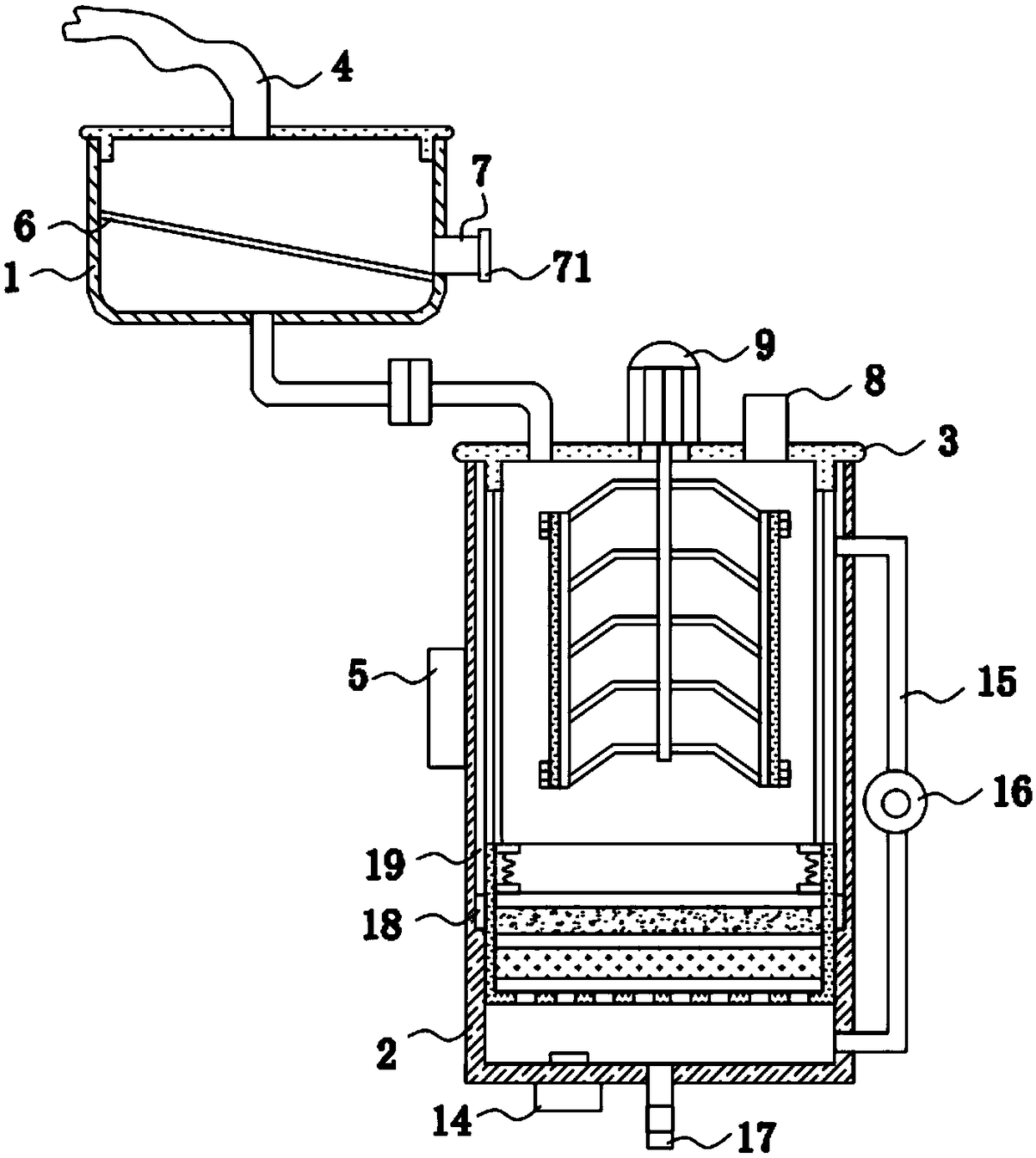

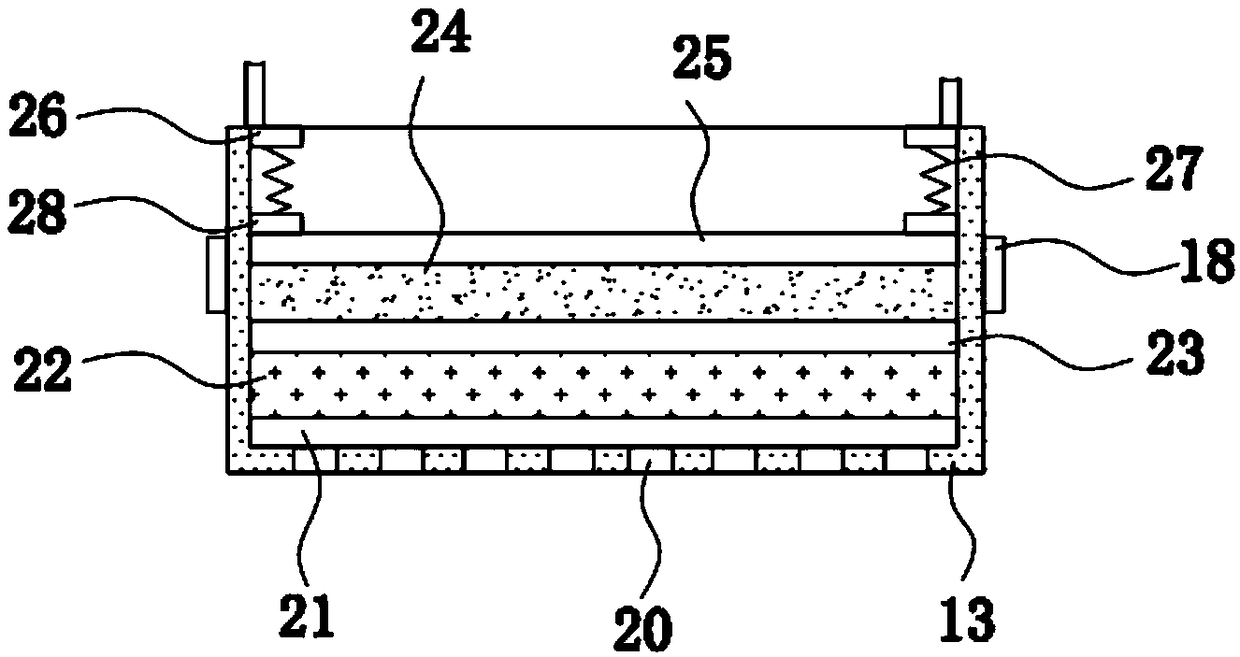

Sewage treating device and treating method by using same

InactiveCN108996830AClean up and discharge in timeEasy to addSpecific water treatment objectivesTreatment involving filtrationHeight decreaseSewage

The invention discloses a sewage treating device. The sewage treating device comprises a purifying box body and a filtering box body, wherein the upper ends of the purifying box body and the filteringbox body are respectively snapped with a top cover; the middle position of the top cover arranged at the upper part of the purifying box body communicates with a water inlet pipeline; the bottom partof the purifying box body communicates with the top cover arranged at the upper part of the filtering box body through a hose and a flange; a steel-wire filter screen with height decreasing from leftto right is arranged on the inner walls of the purifying box body; the right side wall of the purifying box body also communicates with a square residue-cleaning pipe; and the right side of the top cover of the filtering box body communicates with a chemical feeding pipeline. According to the invention, through the water inlet pipeline communicating with the top cover of the purifying box body, sewage can be poured into the purifying box body; poured sewage can be primarily filtered through the steel-wire filter screen arranged on the inner walls of the purifying box body and decreasing in height from left to right; and after completion of filtering, the end cover located at the tail end of the square residue-cleaning pipe is opened to timely clear and discharge large impurities.

Owner:温仕鑫 +4

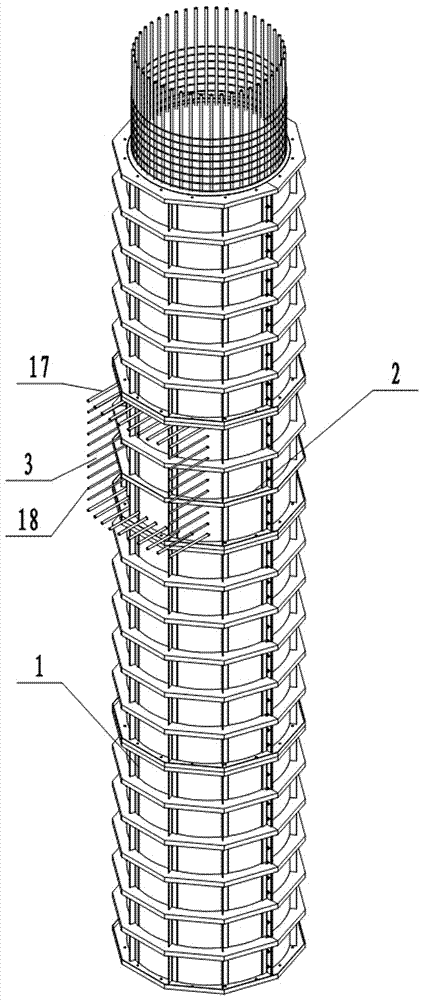

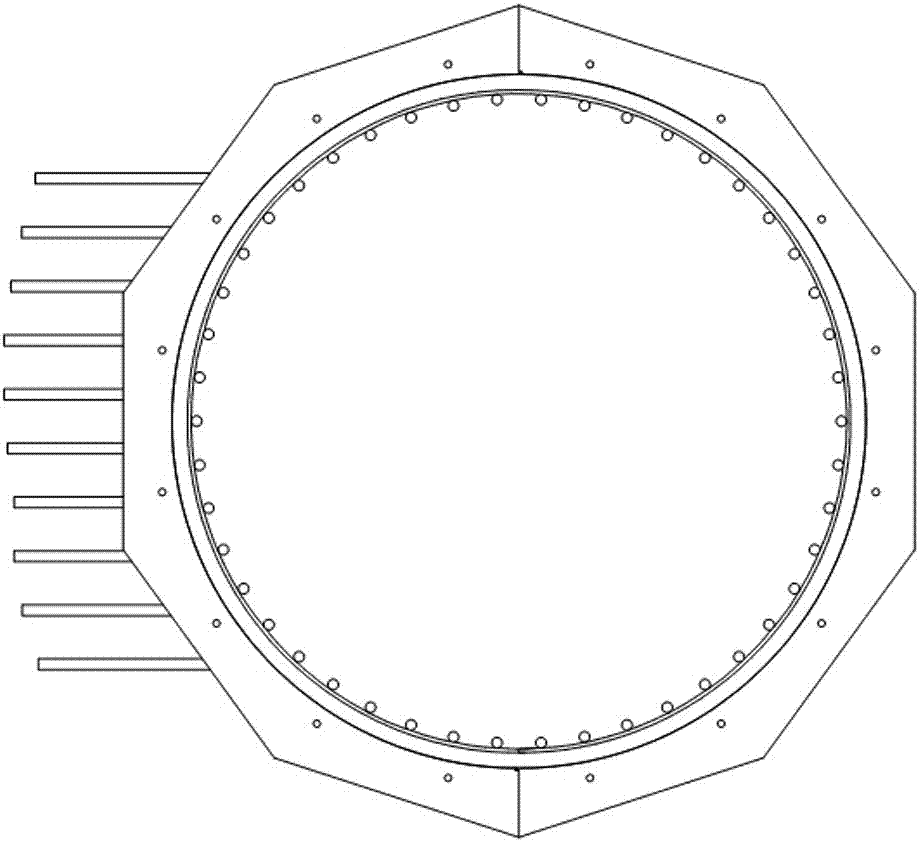

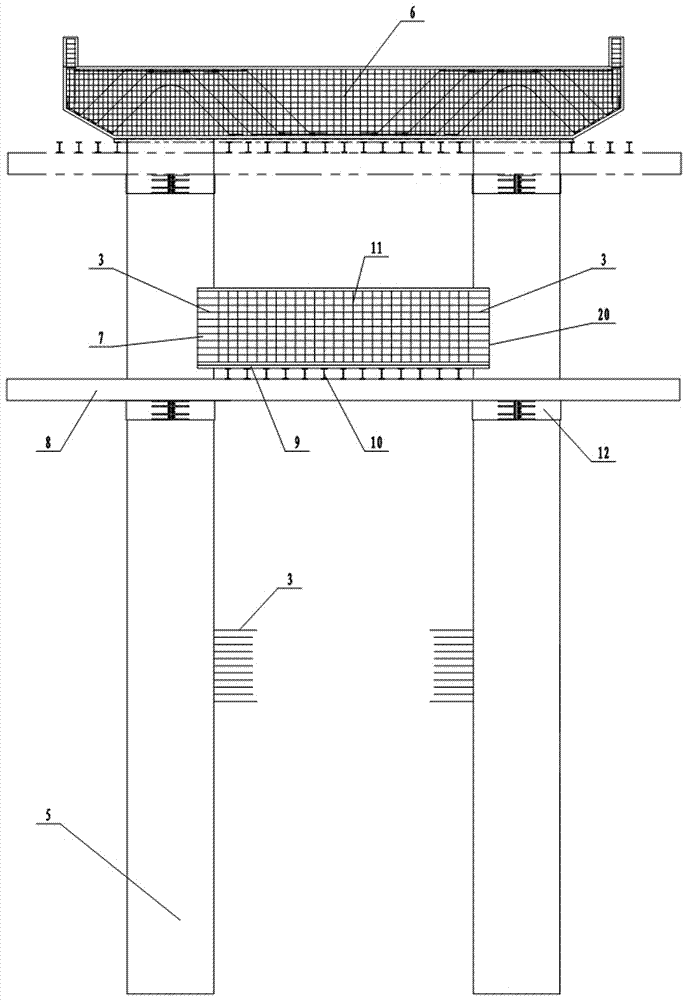

Capping beam and straining beam reverse construction method of concrete cylinder piers

PendingCN107100069AOutstanding FeaturesHighlight significant progressBridge structural detailsForms/shuttering/falseworksHeight decreaseEngineering

The invention relates to the field of bridge construction, in particular to a capping beam and straining beam reverse construction method of concrete cylinder piers. According to the method, on the basis of a traditional column formwork, embedded steel bar matrix holes are formed according to a straining beam steel bar arrangement diagram, it is achieved that steel bars are embedded at the embedded steel bar matrix positions according to requirements during the construction of bridge cylinder piers, straining beams are not constructed at first, pier columns are firstly constructed to the pier tops, then capping beams are constructed, finally, bottom supporting structures of the capping beams are integrally lowered to serve as bottom supporting structures of the nearest straining beam on the lower side, the straining beams are constructed, and construction is conducted on the straining beams in sequence in a height decreasing mode so as to achieve the aim of straining beam reverse construction. By means of the method, the problem that a construction road is changed or broadened can be avoided, and the method has the advantages that the pier column construction sections are reduced, the construction progress is accelerated, full and effective utilization of the construction formwork is ensured, the process that the bottom supporting structures of the straining beams and the capping beams need to be built and removed repeatedly is omitted, and the construction cost is reduced.

Owner:GUANGXI ROAD CONSTR ENG GRP CO LTD

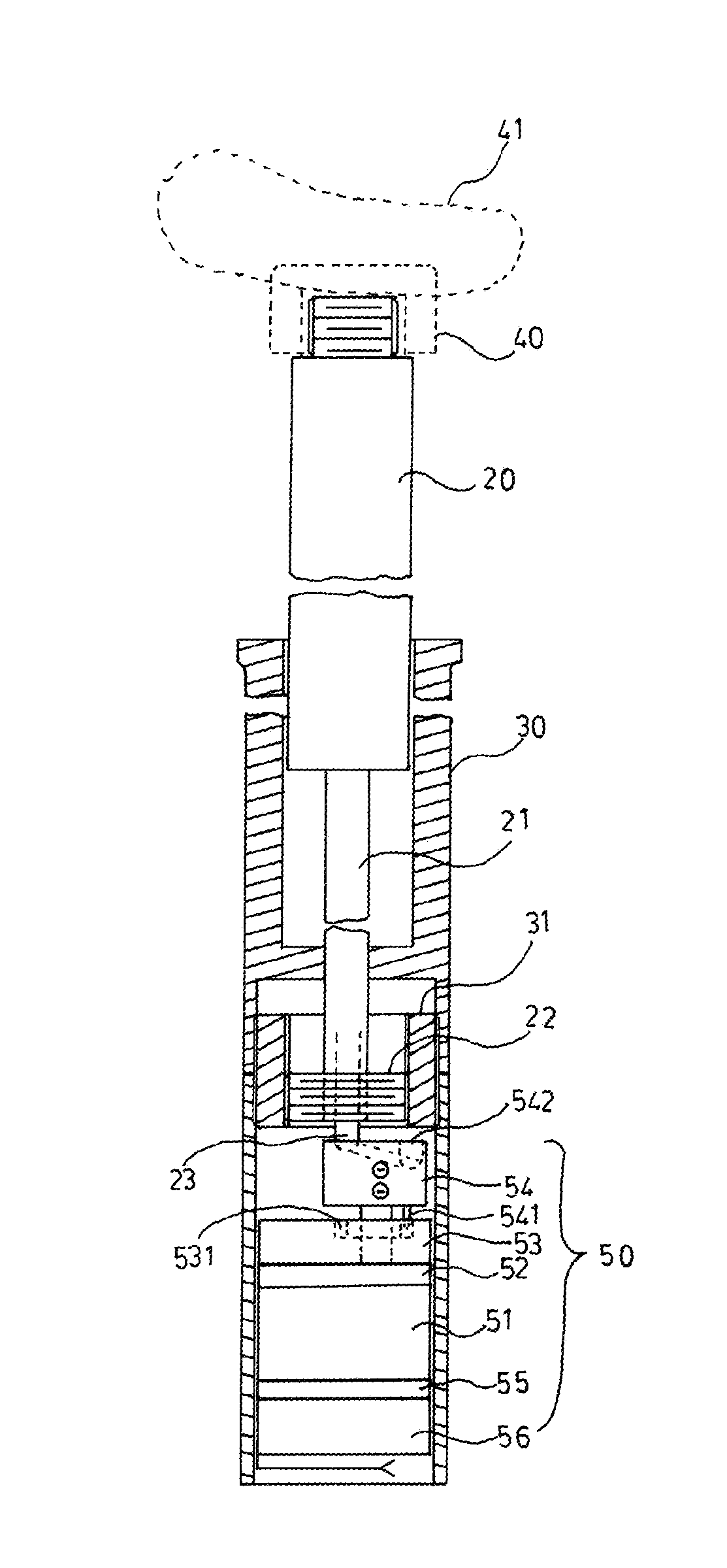

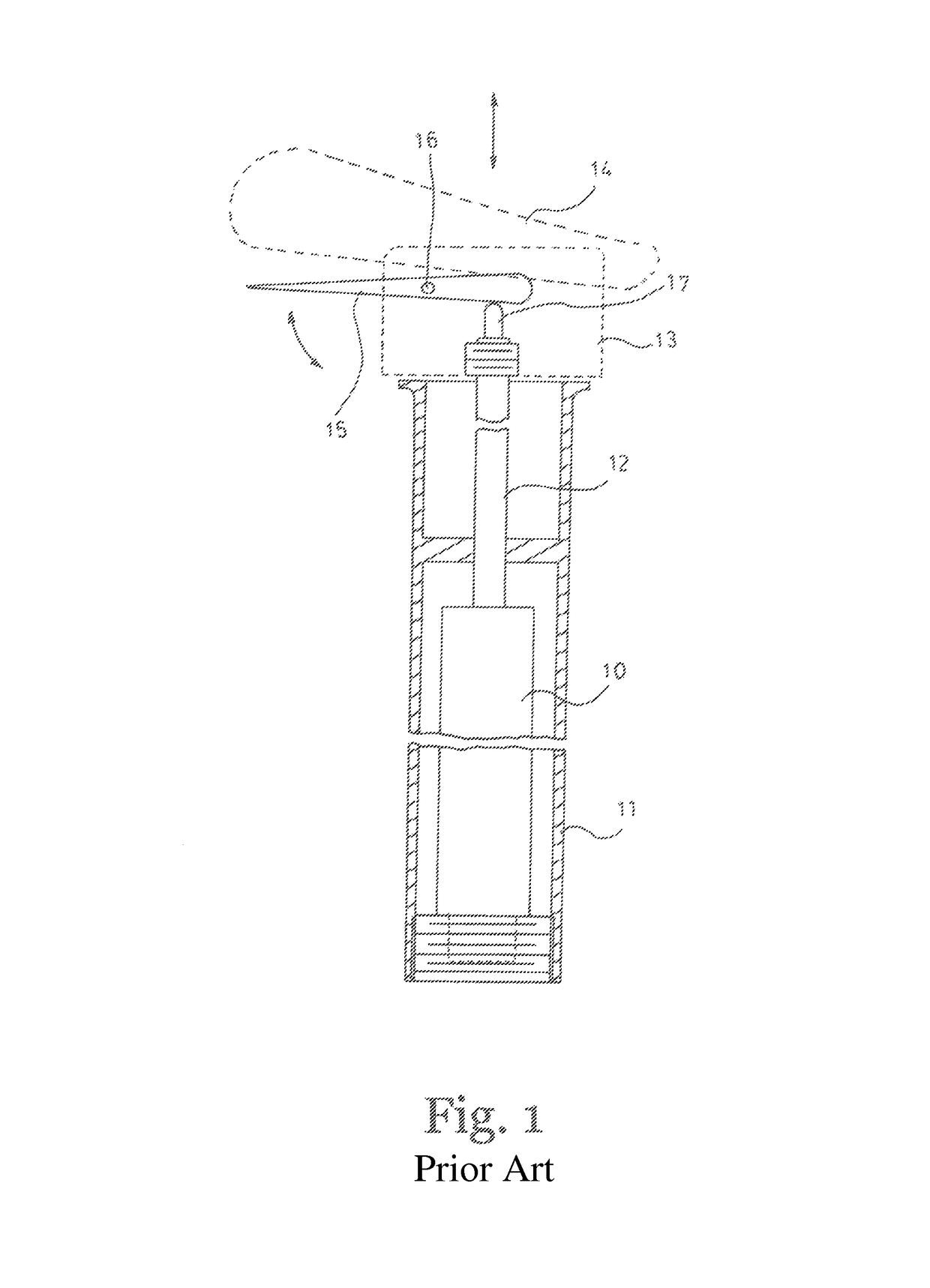

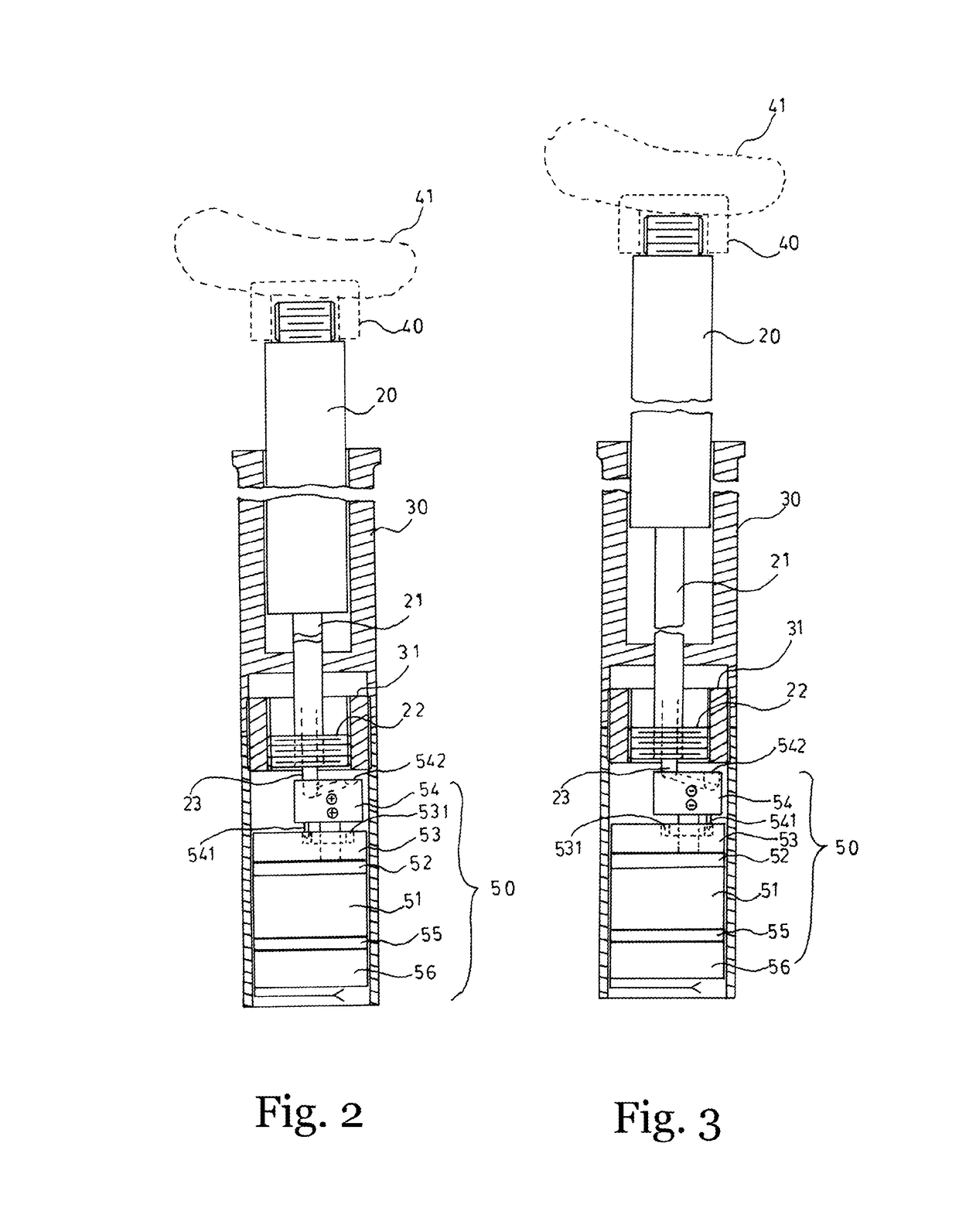

Height adjustment device for bicycle saddle

A height adjustment device for a bicycle saddle is provided and essentially includes a hydraulic cylinder, an adjustment disk, and a driving mechanism. An annular guiding groove is disposed on the adjustment disk and has a bottom whose height decreases from one end of the annular guiding groove to the other end of the annular guiding groove. When the adjustment disk is being driven by a motor, the annular guiding groove enables a relief valve of the hydraulic cylinder to turn on and turn off according to the level of the accumulated pressure, so as to fine-tune saddle height.

Owner:LAI SHANG HUA

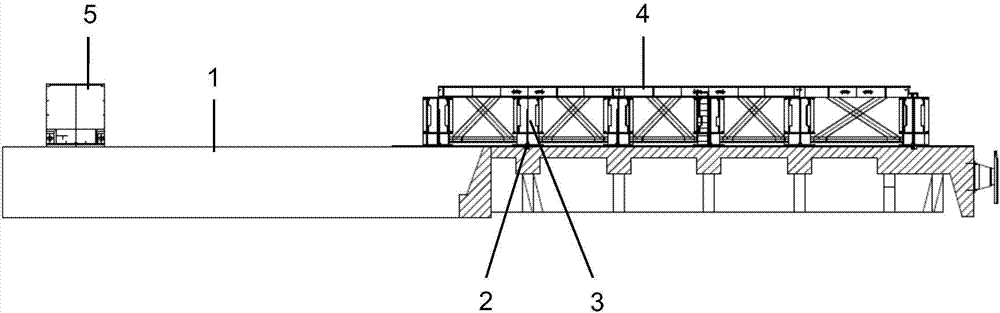

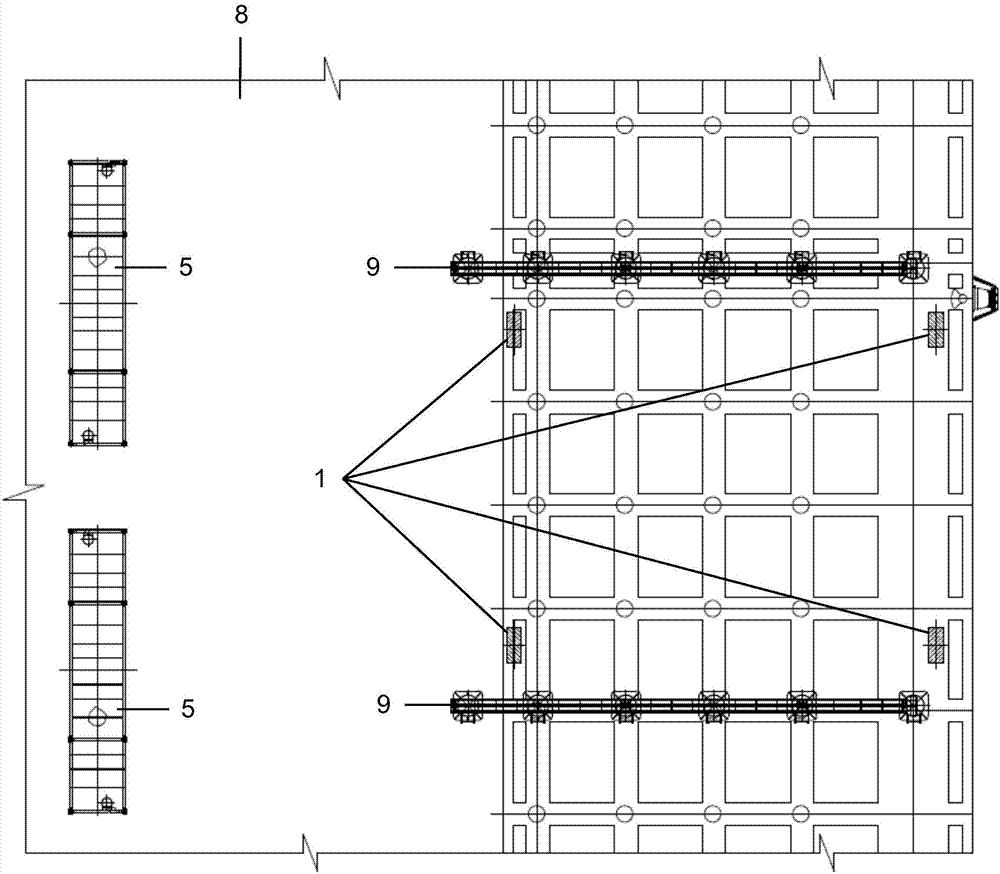

Foundation pile static load test system

InactiveCN107012899AAvoid destructionAvoid Pile Breaking AccidentsFoundation testingHeight decreaseRebar

The invention discloses a foundation pile static load test system and particularly relates to a test system applied to the field of large-tonnage foundation pile static bearing capacity detecting engineering. The foundation pile static load test system comprises secondary beams, a loading main beam, counterforce piles, force transferring anchor discs, a test pile and jacks. The secondary beams are located on the loading main beam. The loading main beam is located on the force transferring anchor discs. The force transferring anchor discs are located on the counterforce piles. The jacks are arranged on the test pipe and located below the loading main beam. The foundation pile static load test system further comprises main steel bars. The force transferring anchor discs and the counterforce piles are connected through the main steel bars. The loading main beam is connected with the force transferring anchor discs through high-strength thread steel bars. According to the foundation pile static load test system, in a large-tonnage foundation pile static load test, not only is the pile-loading height decreased, but also the anti-pull bearing capacity of an engineering pile is reasonably utilized.

Owner:中冶检测(四川)技术服务有限公司

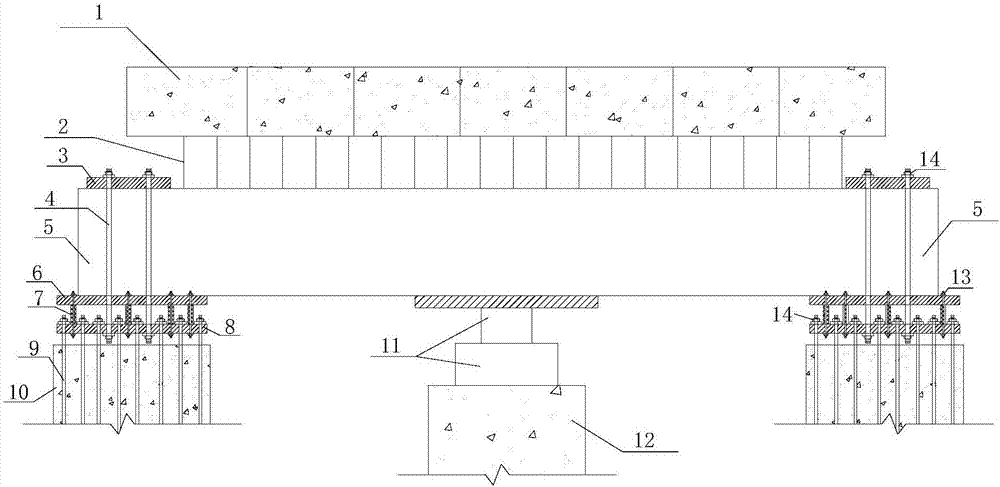

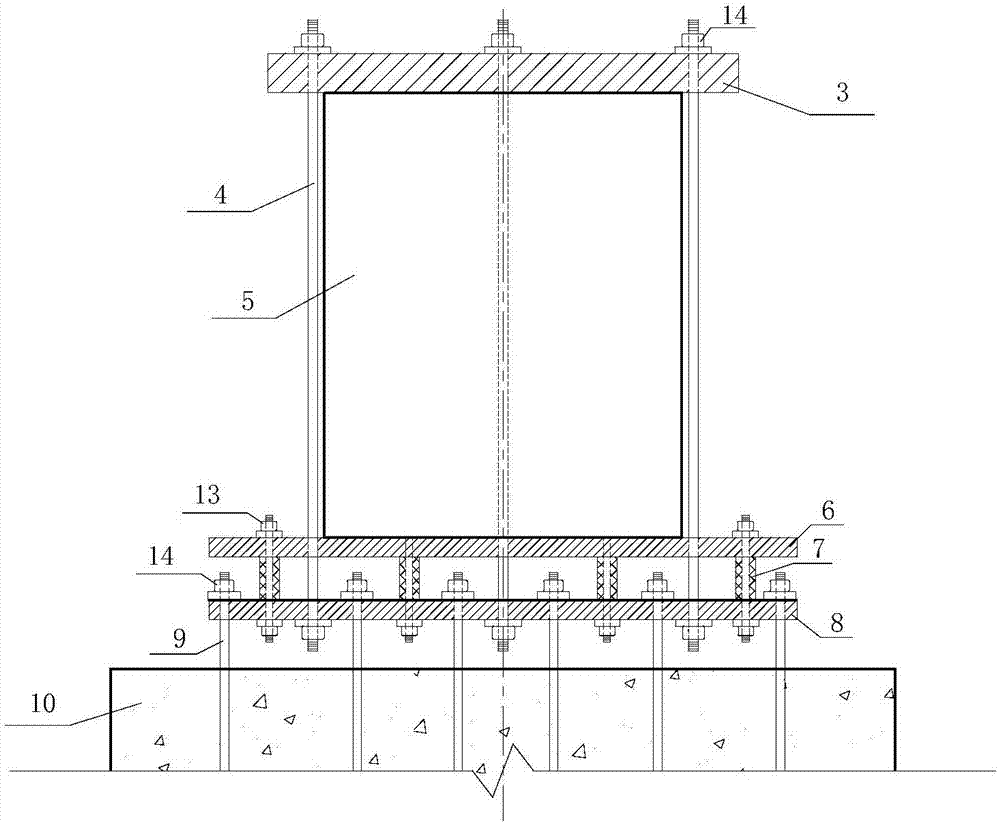

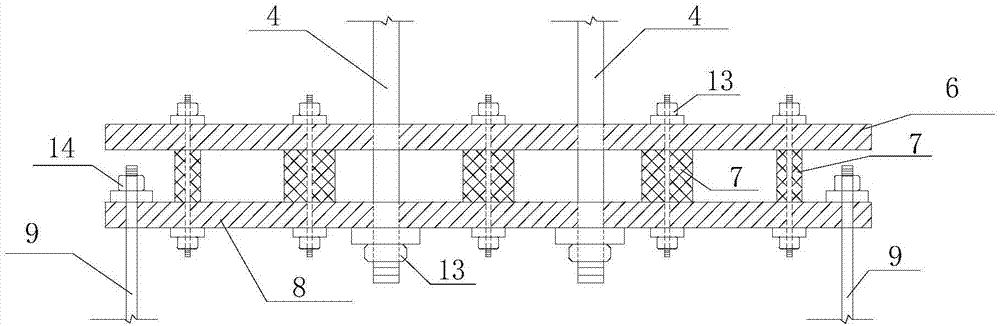

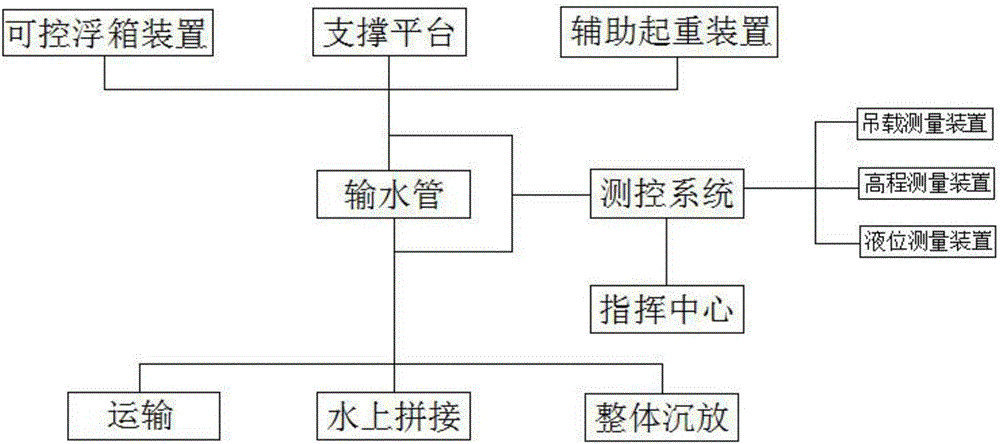

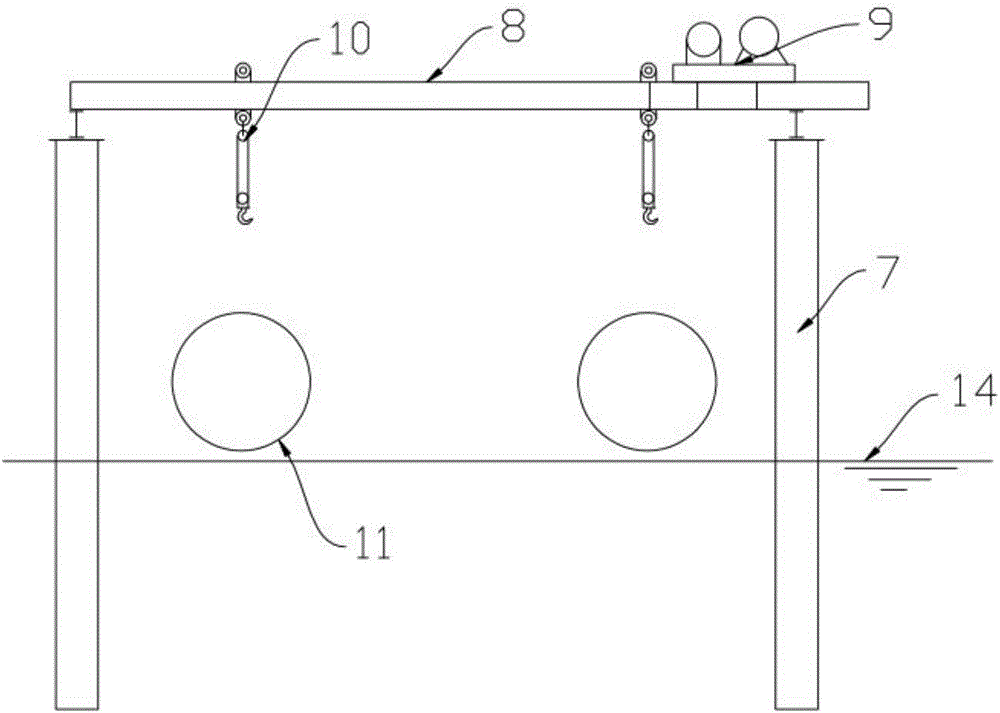

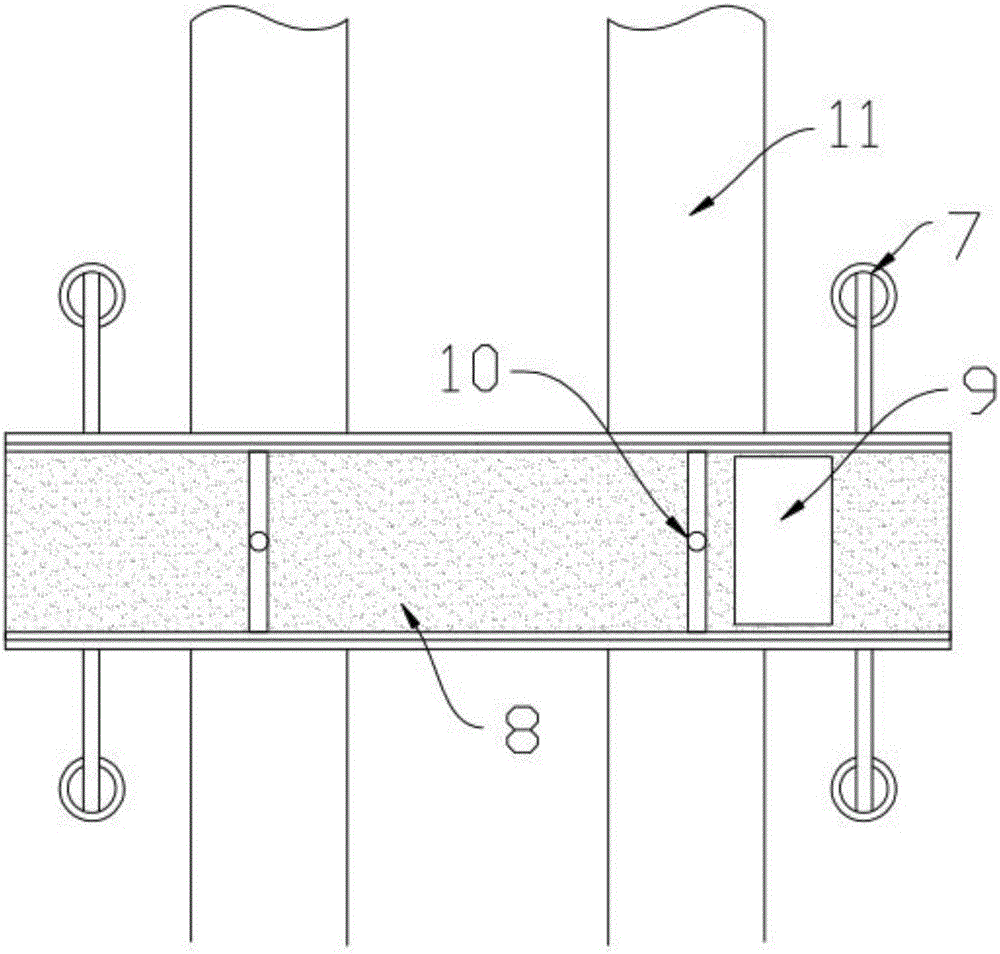

Large-diameter long-distance water transmission pipeline splicing, sinking and placing system and method thereof

ActiveCN106247011APrecise positioningHigh precisionPipe laying and repairMeasurement deviceLiquid level measurement

The invention discloses a large-diameter long-distance water transmission pipeline splicing, sinking and placing system and a method thereof. The system is characterize by comprising controllable floating box devices which are installed on a water transmission pipe and capable of changing the sizes of buoyancy; a support platform which is installed on pipe piles; auxiliary lifting device which is installed on the support platform and is used for assisting to lift, sink and place the water transmission pipe; a command center and a measurement and control mechanism which is used for monitoring the construction process. the measurement and control mechanism sends data to the command center, wherein the measurement and control mechanism comprises a lifting carrying measurement device, a height measurement device and a liquid level measurement device; the lifting carrying measurement device is used for measuring the gravity changes of the water transmission pipe; the height measurement device is used for measuring the height decreased displacement of the water transportation pipe; the liquid level measurement device is used for measuring the height of the water transportation pipe relative to the water surface. The sinking placing system and method of water transmission pipelines have simple construction process, high safety, require less ships, have high adjustability and are convenient for control.

Owner:中铁城乡环保工程有限公司 +3

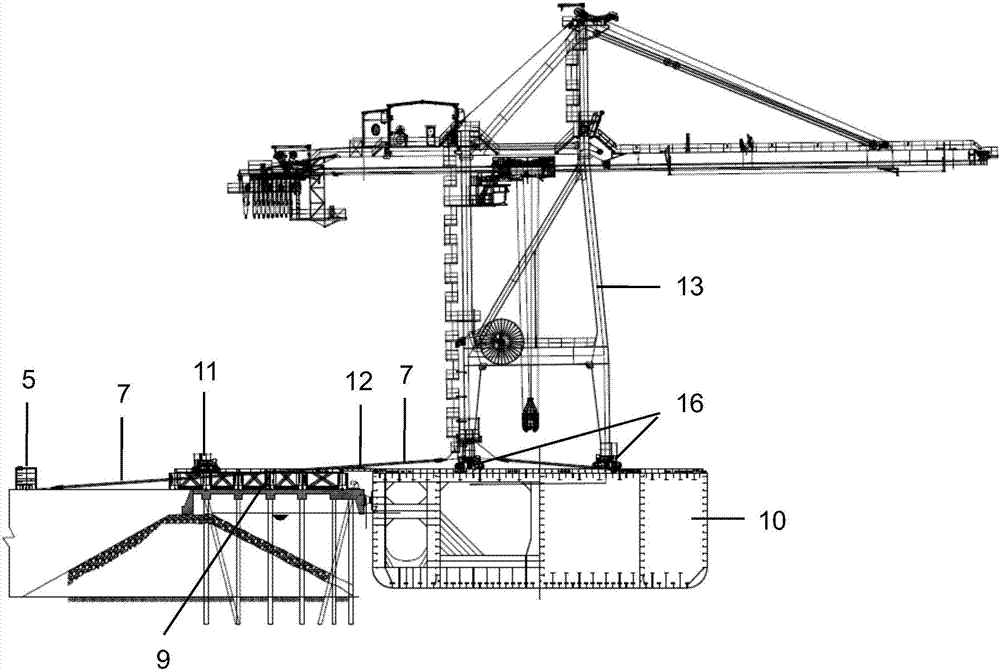

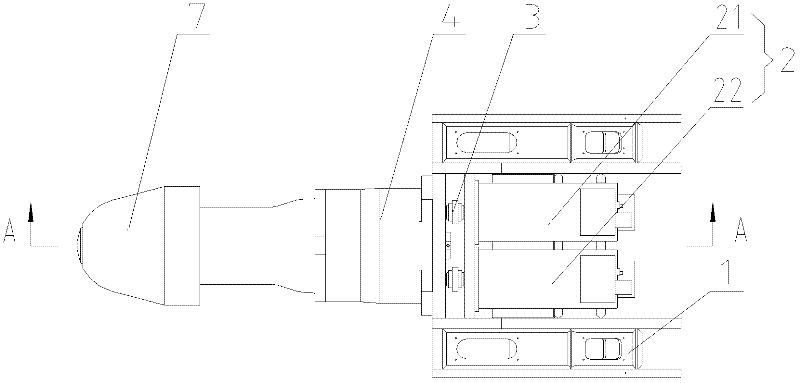

Ship unloading method of bridge crane at shallow water wharf

The invention discloses a ship unloading method of a bridge crane at a shallow water wharf. Ship unloading track beams are used for compensating for the height difference between the shallow water wharf and a transport chip; bridge crossing track beams are mounted between the ship unloading track beams and the transport ship; ro-ro trolleys are mounted at the position where a cart walking mechanism is demounted; a winch and a pulley set are used for controlling movement of the bridge crane on the ship unloading track beams, and the bridge crane shifts in place; vertical movement of anchoring brackets on the side face of a lower cross beam is controlled by jacking devices; the jacking devices achieve jacking up, the ro-ro trolleys and wharf tracks are demounted, and the cart walking mechanism is mounted and restored; the jacking devices descend till walking wheels of a cart fall into the wharf tracks; and after the jacking devices are moved away, the whole ship unloading work is completed. According to the ship unloading method, the stability of the bridge crane in the horizontal and vertical movement process during ship unloading can be kept, the structure stability and reliability during height decrease can be guaranteed, the bearing requirement of the shallow water wharf can be met, and gravity loads of the bridge crane are transmitted to wharf pile foundations and other stress structures through ship unloading tracks.

Owner:SHANGHAI ZHENHUA HEAVY IND

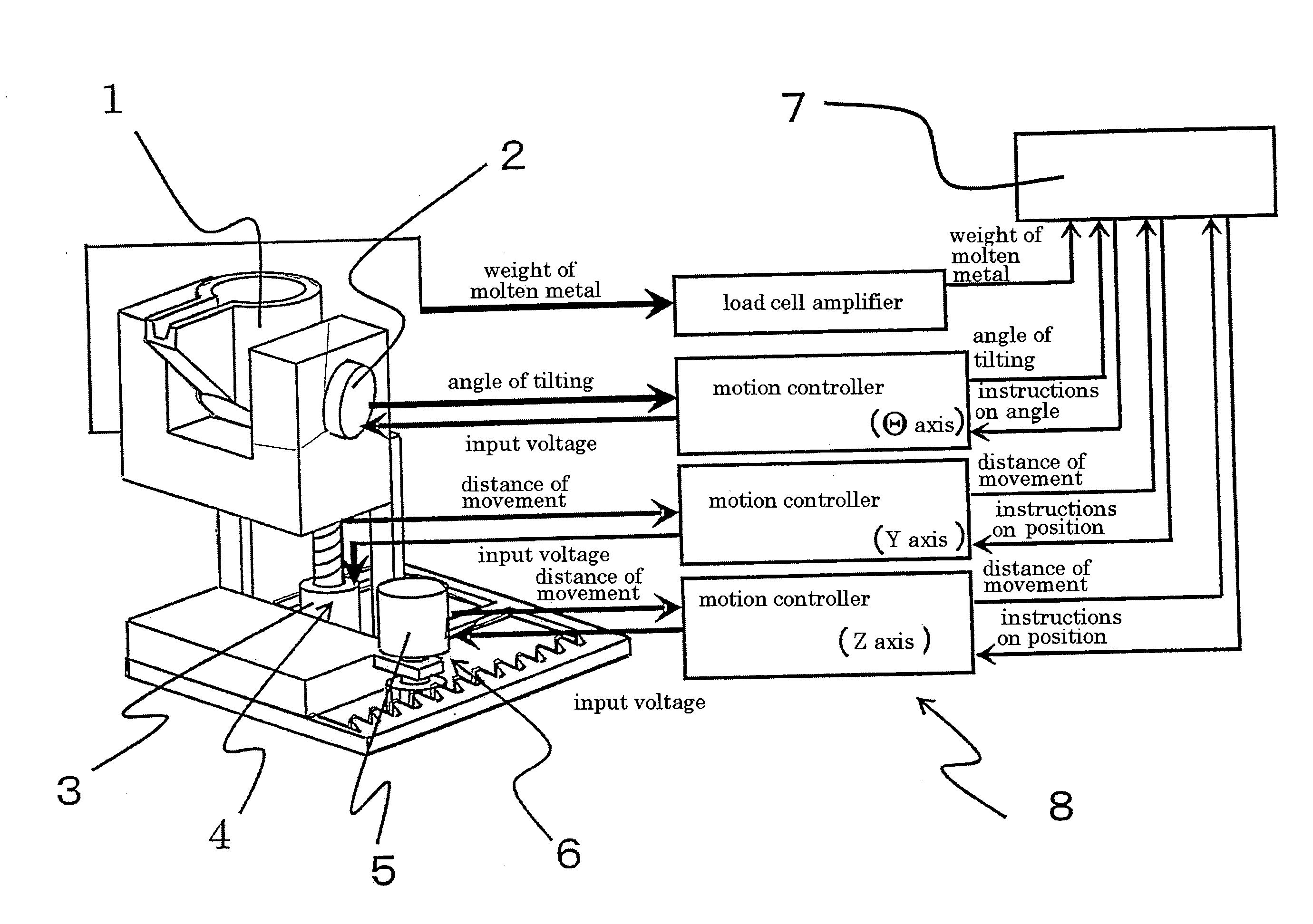

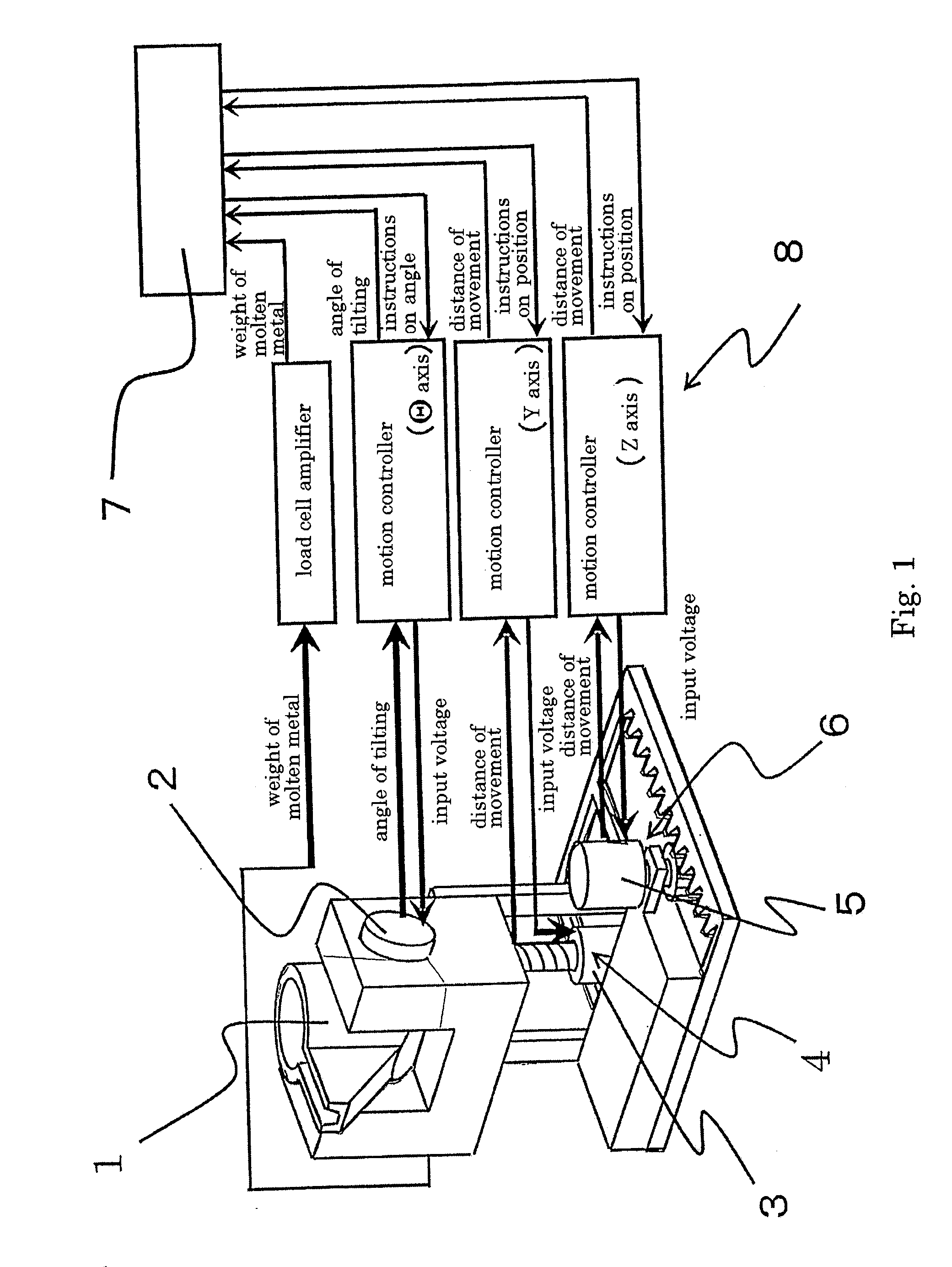

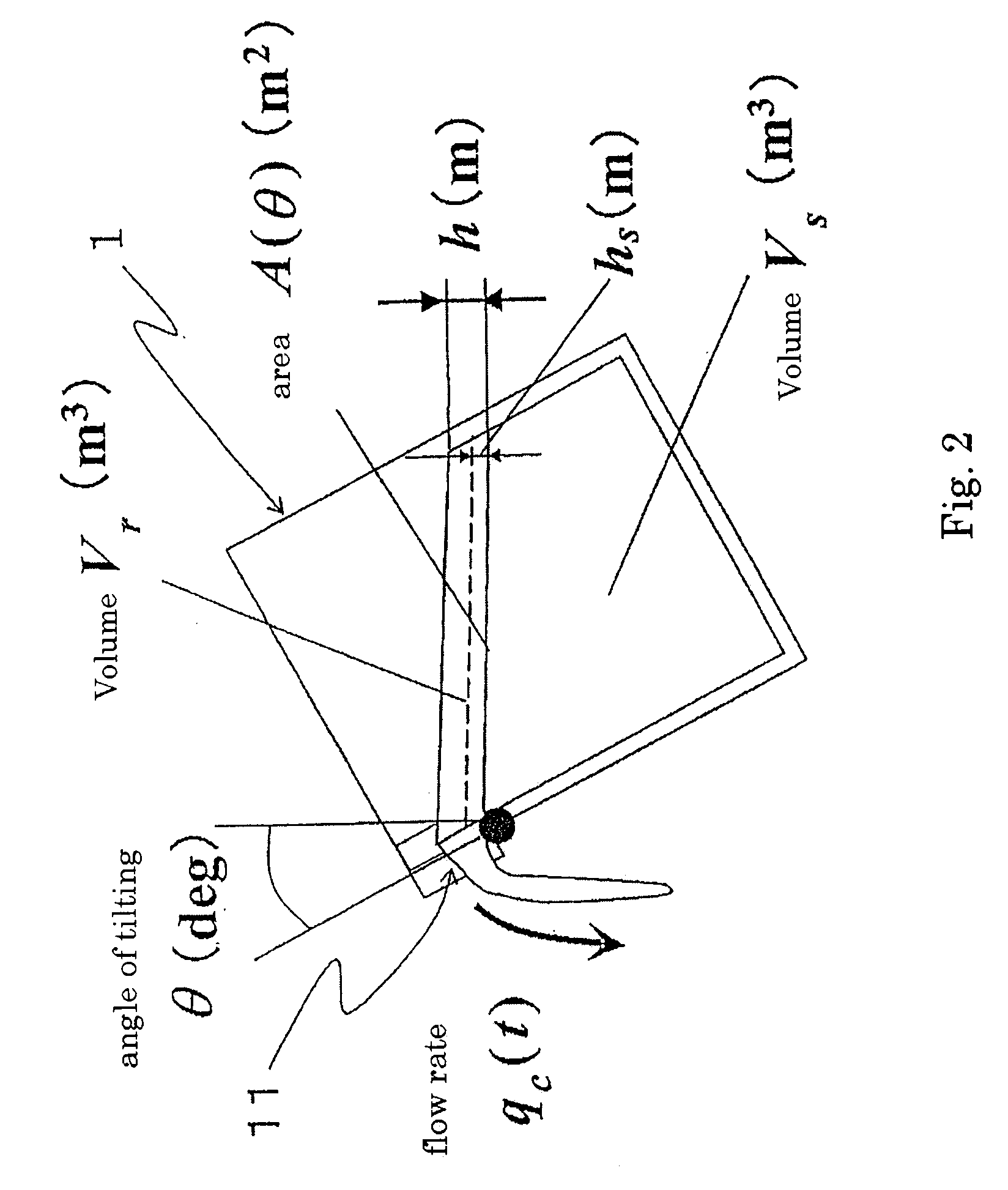

Tilting-type automatic pouring method and storage medium

ActiveUS20100133302A1Keep for a long timeAccurate weighingMelt-holding vesselsMolten metal pouring equipmentsMetallurgyHeight decrease

The present invention provides a tilting-type automatic pouring method wherein a very speedy and highly accurate pouring can be realized, which method pours molten metal into a mold by tilting a ladle that holds the molten metal, and the present invention also provides the storage medium for programs used for the method.The tilting-type automatic pouring method of the present invention uses a) the relationship of (1) the height of the molten metal during backward tilting of the ladle, which height is calculated from the height of the molten metal above the outflow position, which height decreases, when the forward tilting of the ladle stops and from the height of the molten metal that is above the outflow position and that decreases after the backward tilting of the ladle starts, and (2) the weight of the molten metal poured from the ladle into the mold, and b) the model expression for the flow of the molten metal, which expression defines the weight of the molten metal that flows from the ladle into the mold.In the tilting-type automatic pouring method of the present invention, the final weight of the molten metal that is poured is estimated by assuming that the final weight of the molten metal that is poured from the forward tilting of the ladle to its backward tilting is equal to the sum of the weight of the molten metal that is poured at the start of the backward tilting and the weight of the molten metal that is poured after the start of the backward tilting.

Owner:SINTOKOGIO LTD +1

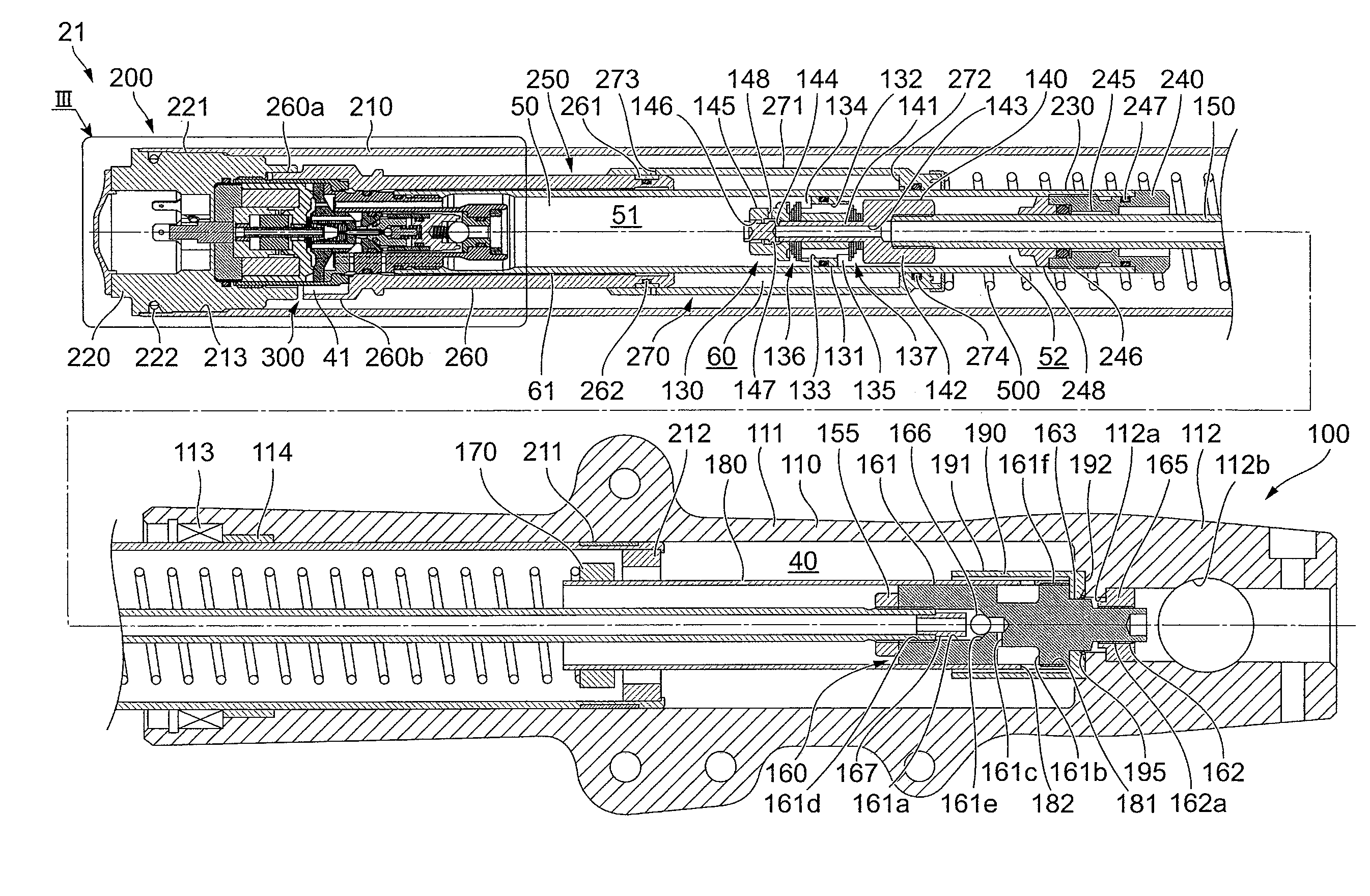

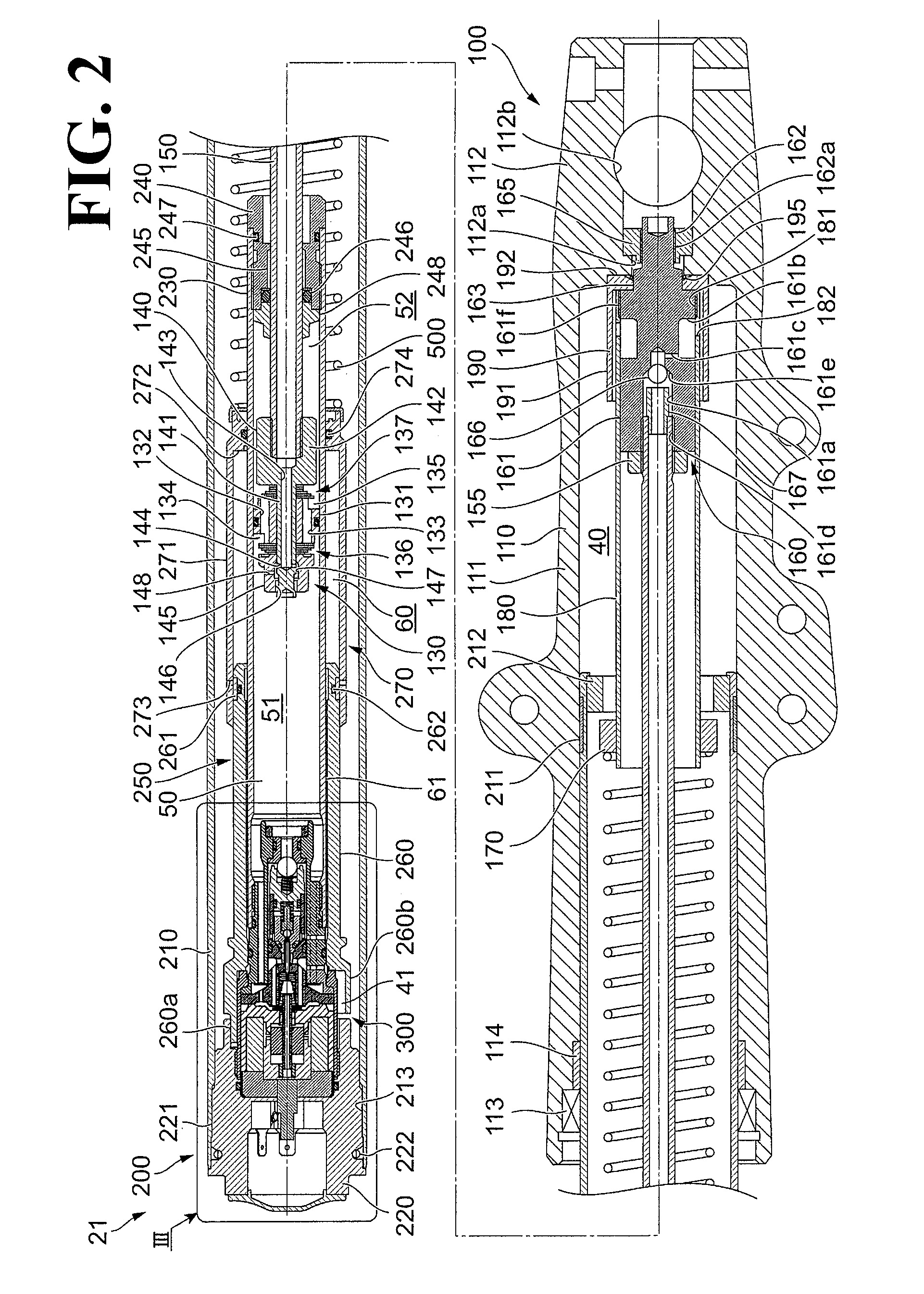

Vehicle height adjustment device

In a vehicle height adjustment device, an operation amount of an actuator increases in accordance with supplied current, a detector detects a vehicle height, and a changer changes the vehicle height in accordance with the operation amount of the actuator. The changer shifts to a vehicle height increasing state or to a vehicle height decreasing state based on whether the operation amount is not higher than a predetermined amount. A controller controls the current supplied to the actuator to make the relative position have a target value. The controller determines a target current supplied to the actuator based on a control map that correlates a deviation between the target value of the relative position and a detection value to the target current.

Owner:HITACHI ASTEMO LTD

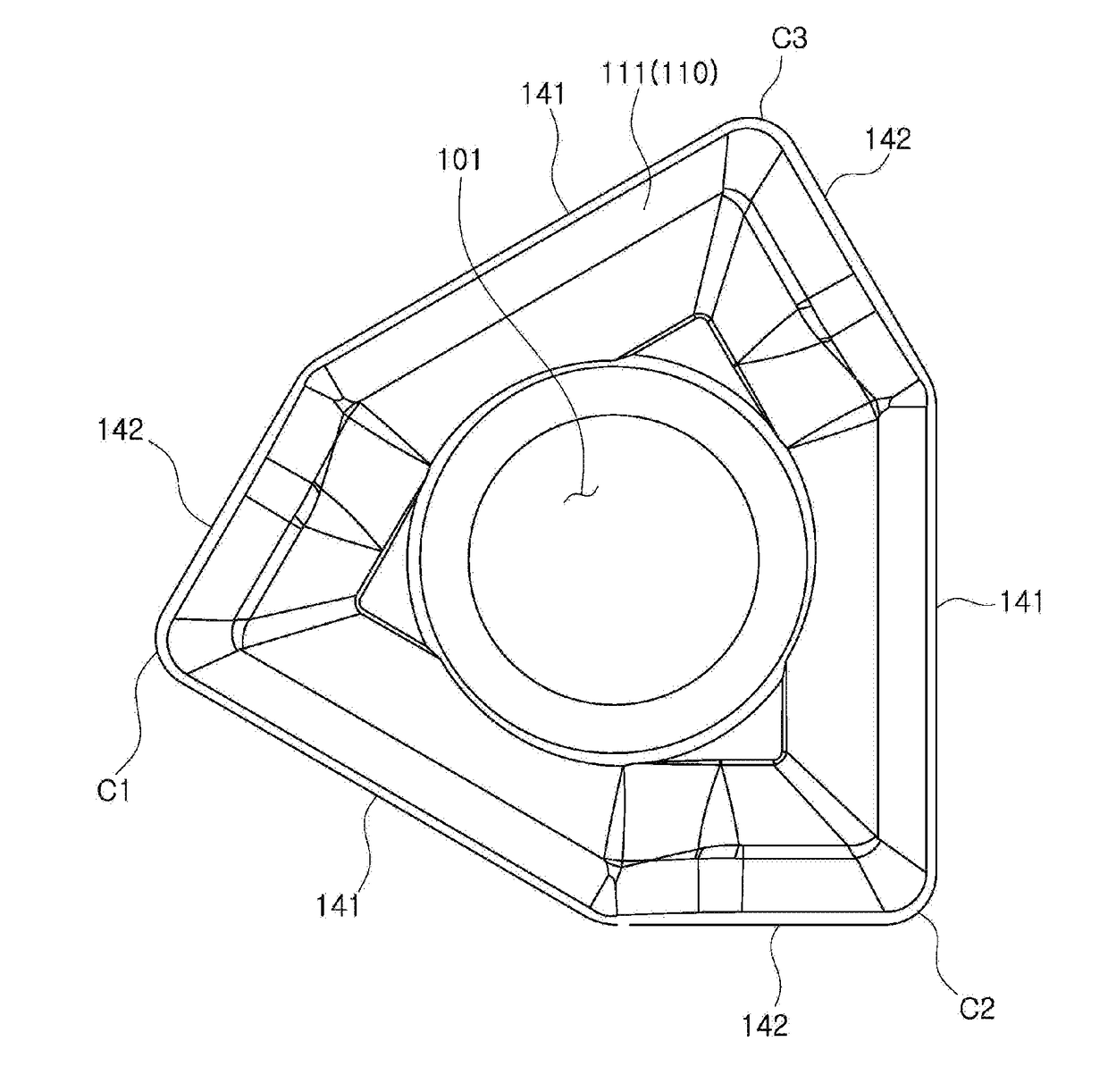

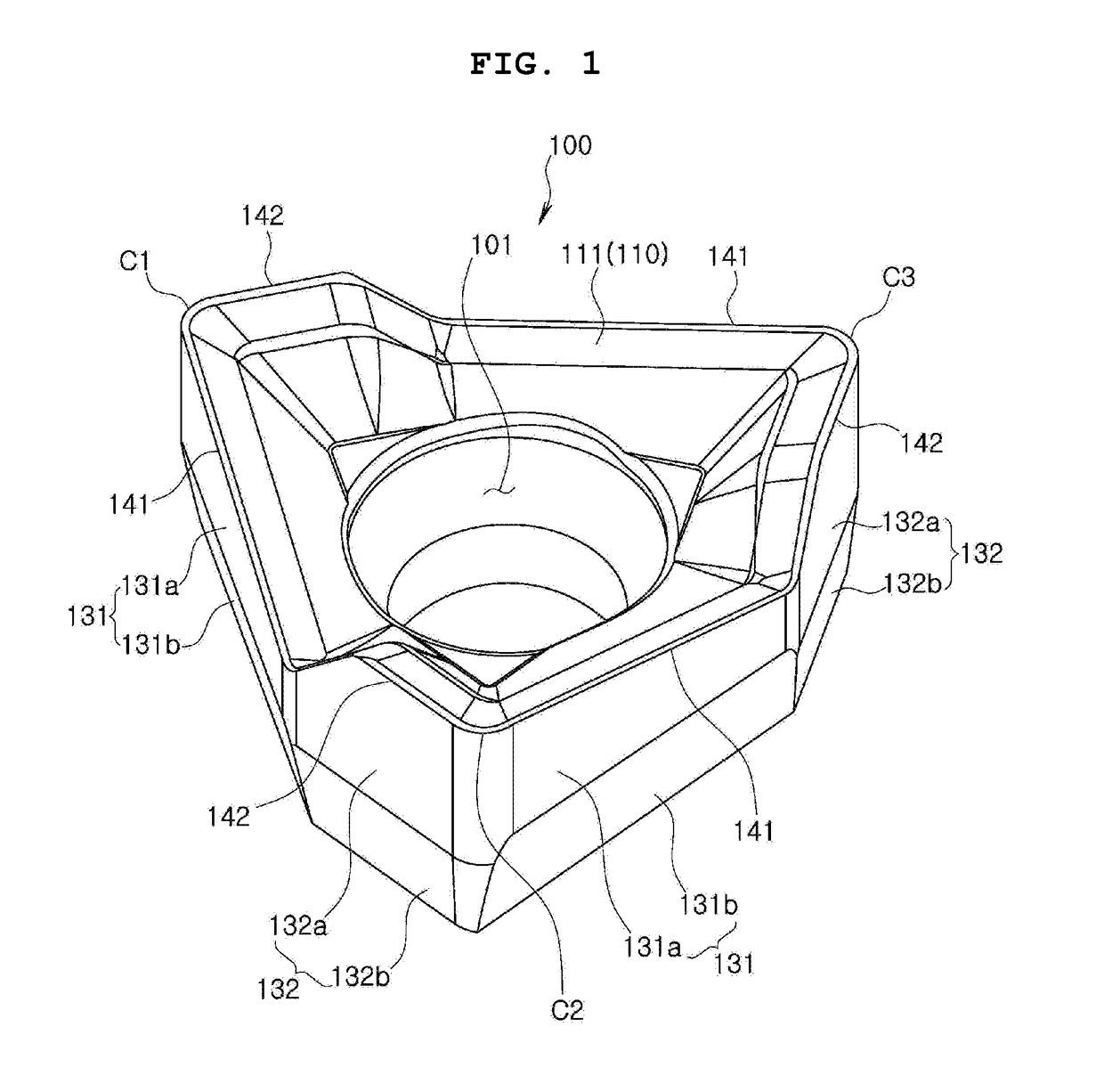

Cutting insert, cutting tool using the same, and cutting method

ActiveUS20110027027A1Reduce generationSmall cutting forceWood turning toolsTransportation and packagingHeight decreaseEngineering

An insert comprises an insert main body having an upper surface and a plurality of side surfaces, a cutting edge located between both ends of a ridge which is between at least one side surface among the side surfaces and the upper surface, a high-positioned portion located at one end of the ridge, and a low-positioned portion located lower in the thickness direction of the insert main body than the high-positioned portion and located at the other end of the ridge. The cutting edge comprises a first flat cutting edge having substantially the same height as the high-positioned portion, and a tilted cutting edge having a height decreasing from the high-positioned portion toward the low-positioned portion. On at least the one side surface, at least one groove extends from the side surface to the upper surface to divide the cutting edge by the groove, and at least the one groove is formed at a region including an intersection of a first extension line formed by imaginarily extending the first flat cutting edge with a second extension line formed by imaginarily extending the tilted cutting edge. This enables reduction in the occurrence of vibration during cutting, and the chipping.

Owner:KYOCERA CORP

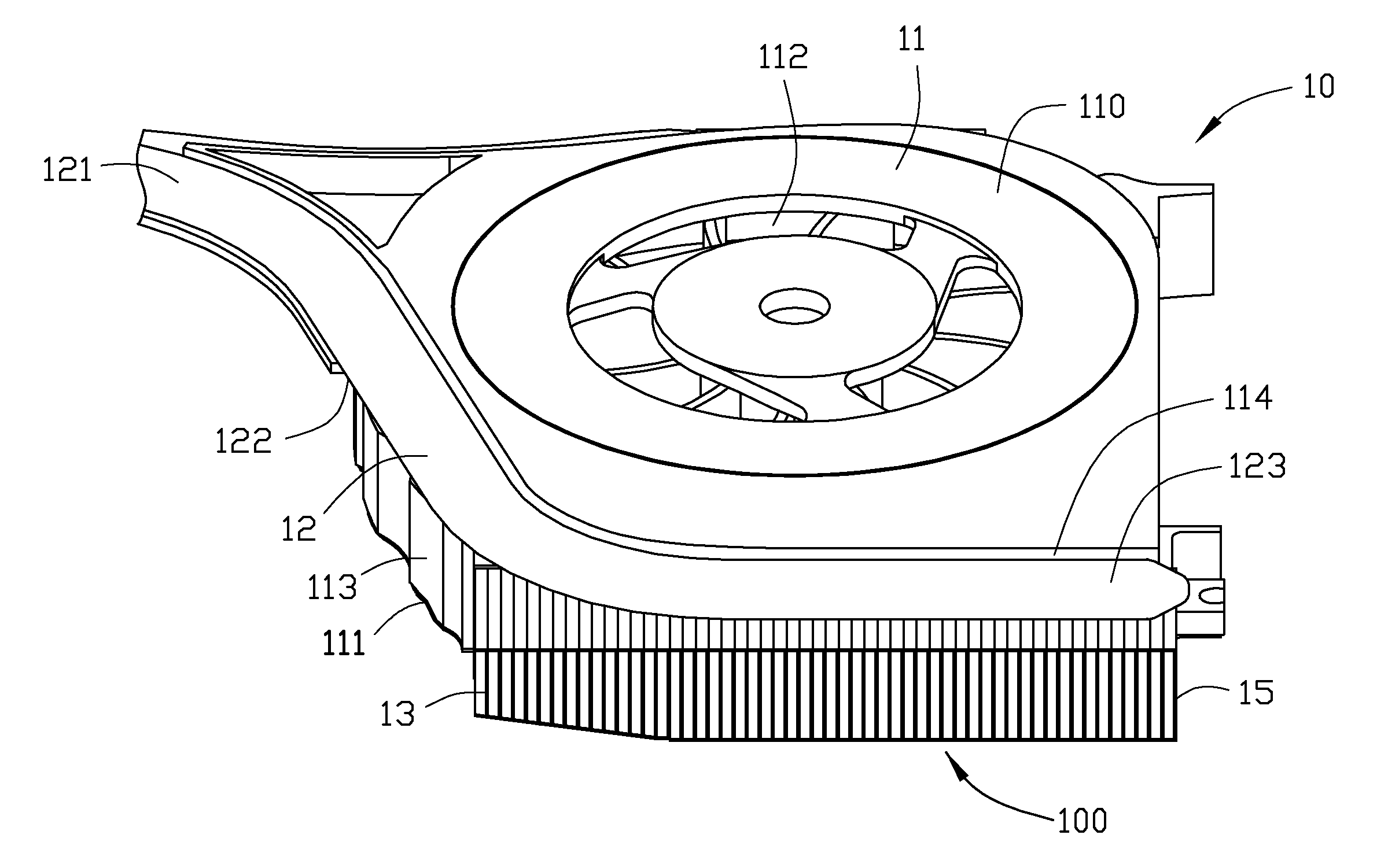

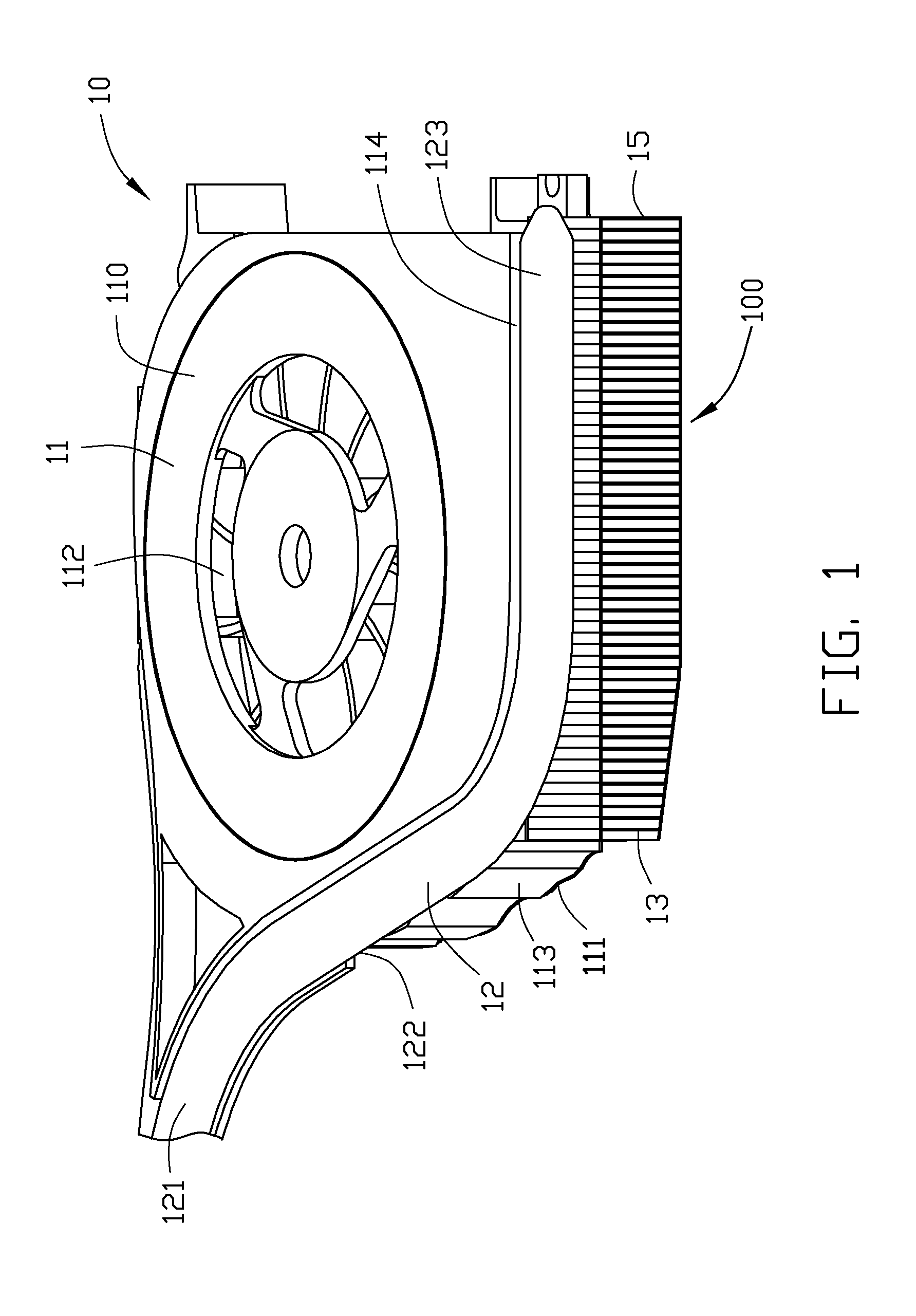

Heat dissipation module

InactiveUS20110042043A1Excessive heatingPowerful computingDigital data processing detailsSemiconductor/solid-state device detailsHeight decreaseEngineering

A heat dissipation module includes a heat pipe having a condensing section, a centrifugal fan defining an air outlet and a fin assembly. The fin assembly includes a plurality of fins stacked together and is thermally attached to the condensing section of the heat pipe. The fin assembly is located at the air outlet of the centrifugal fan. At least some fins of the fin assembly have a height decreasing along the condensing section of the heat pipe. The fin assembly defines a spared space at a bottom side of the fin assembly corresponding to the at least some fins.

Owner:HON HAI PRECISION IND CO LTD

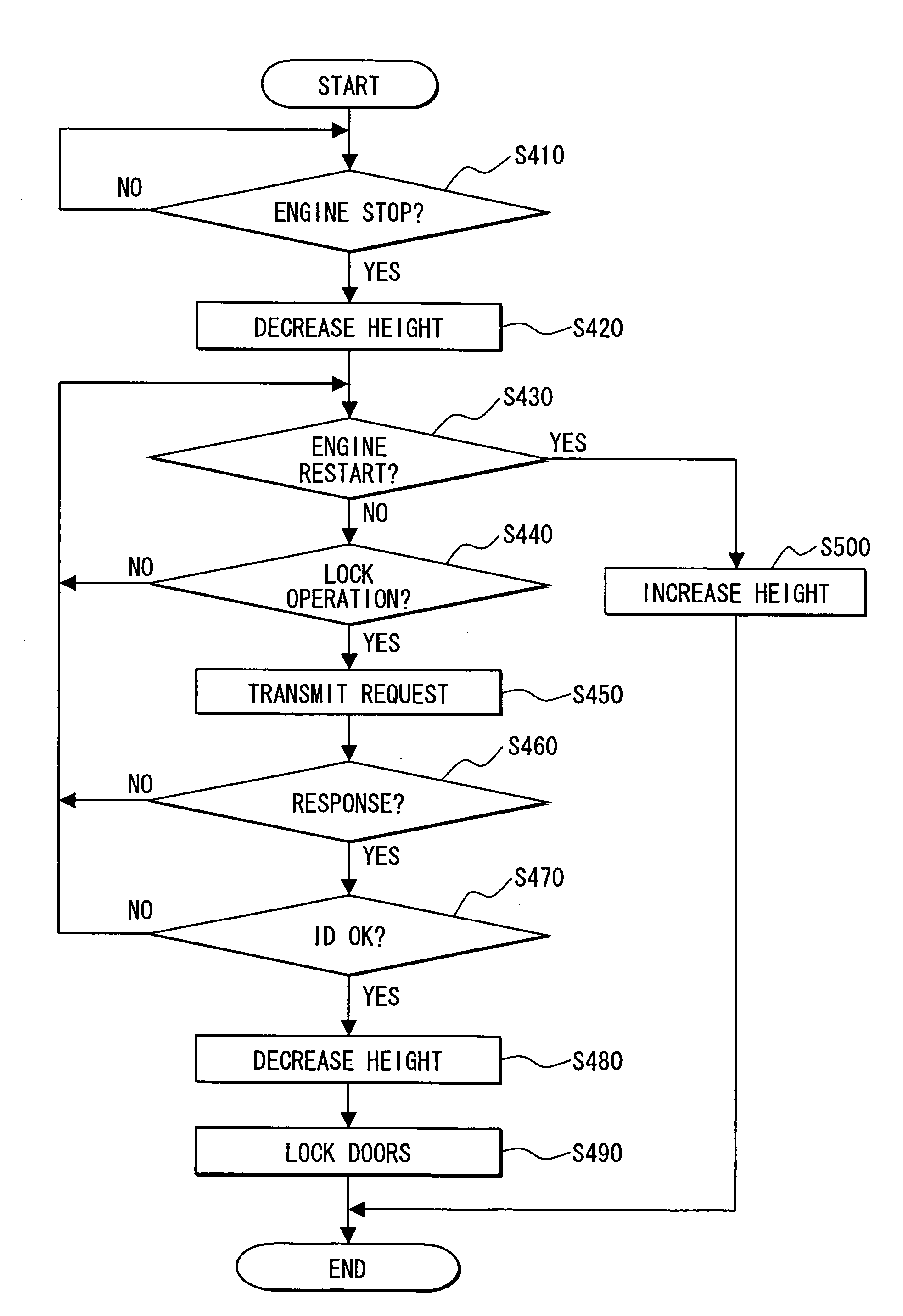

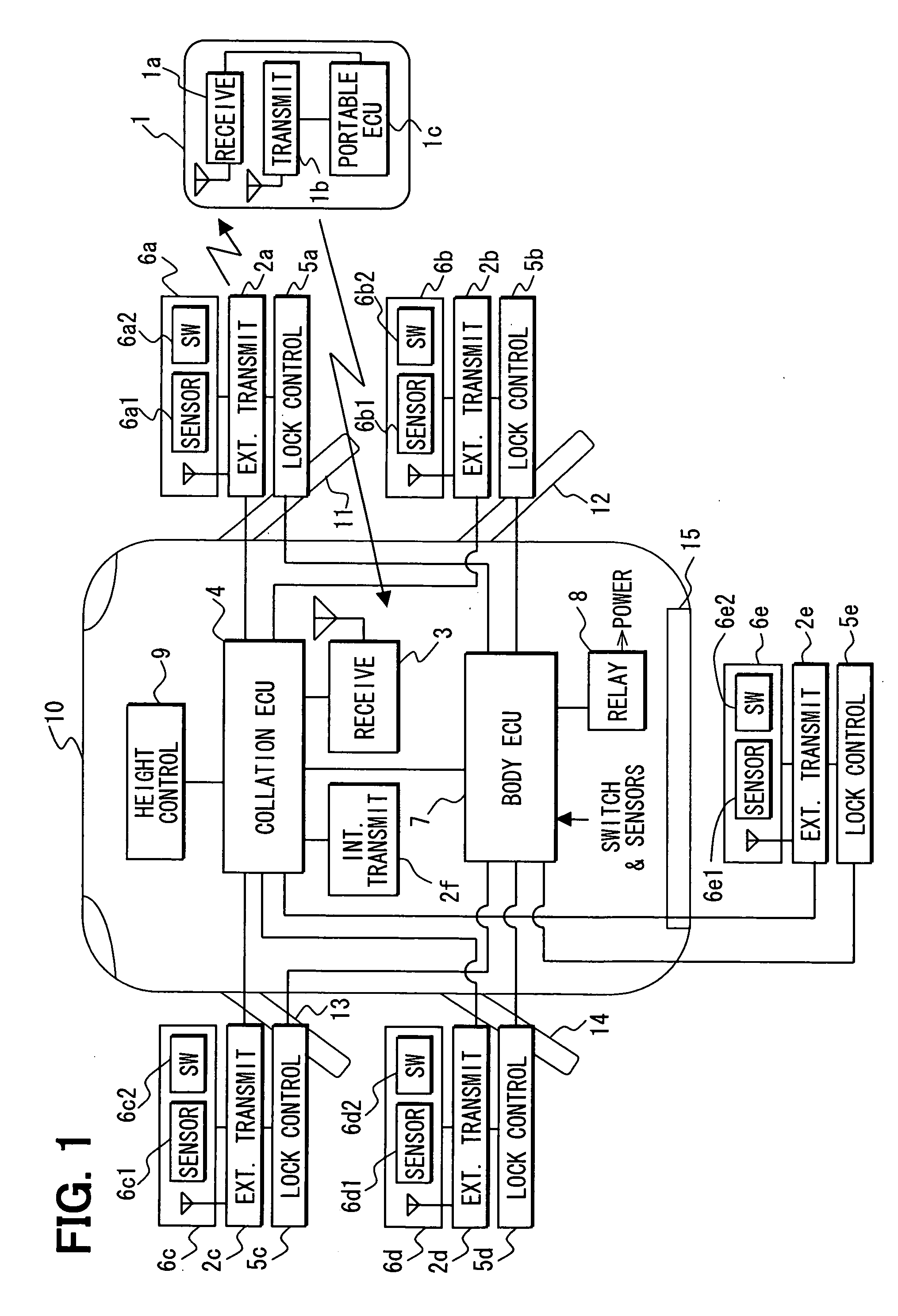

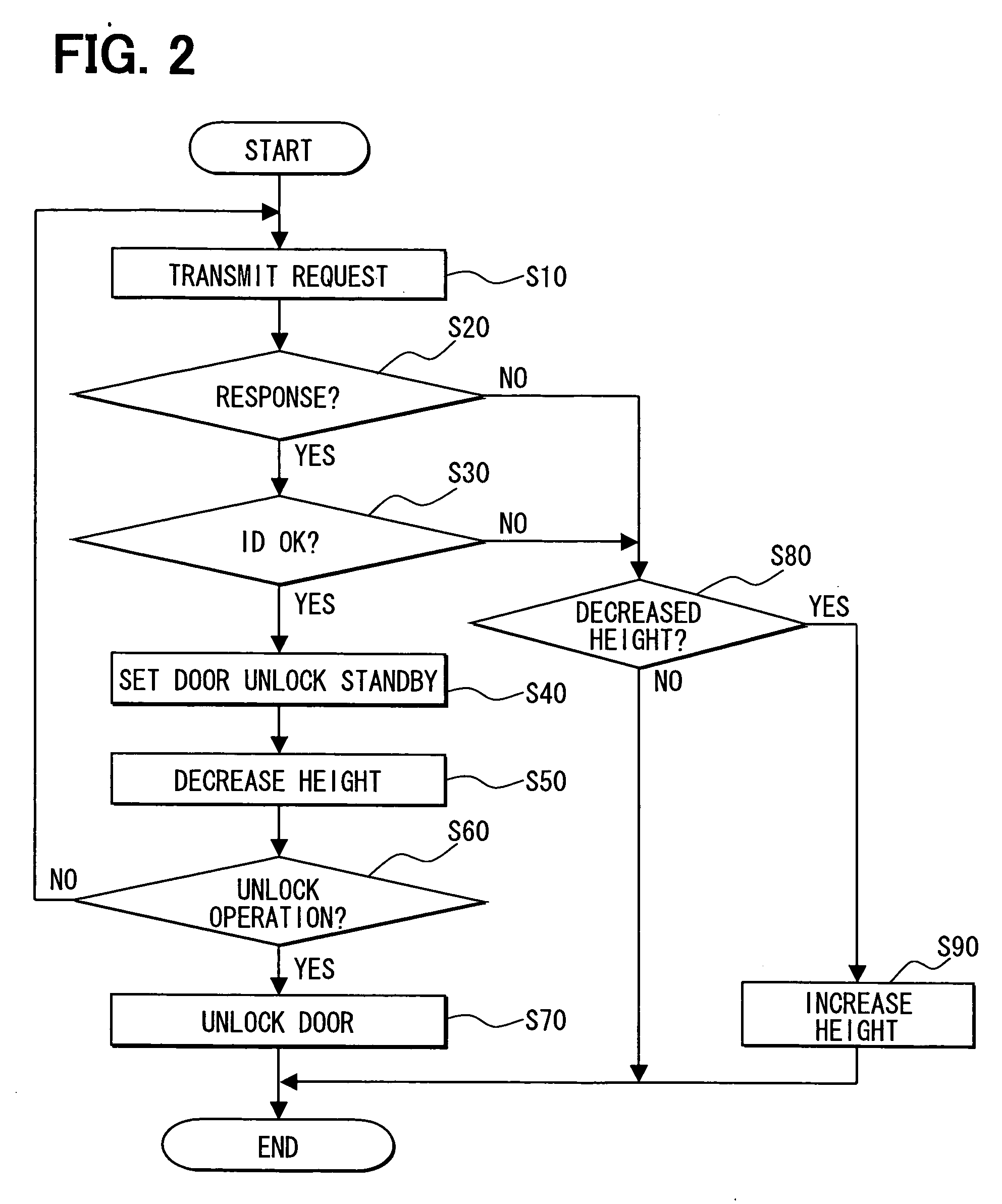

System and method for controlling vehicle equipment

InactiveUS20060284388A1Easy to getAnti-theft devicesVehicle cleaning apparatusIn vehicleHeight decrease

An in-vehicle device in a vehicle transmits a request signal and a portable device returns a response signal including an ID code. The in-vehicle device collates the ID code included in the response signal with a registration code stored therein. When the result of collating the ID code becomes OK, the in-vehicle device outputs a height decreasing signal to a vehicle height control device to decrease the height of the vehicle. Thus, the height of the vehicle is decreased at the time when a user holding the portable device gets in the vehicle or loads baggage, making it easier for users to get in the vehicle or to load baggage.

Owner:DENSO CORP

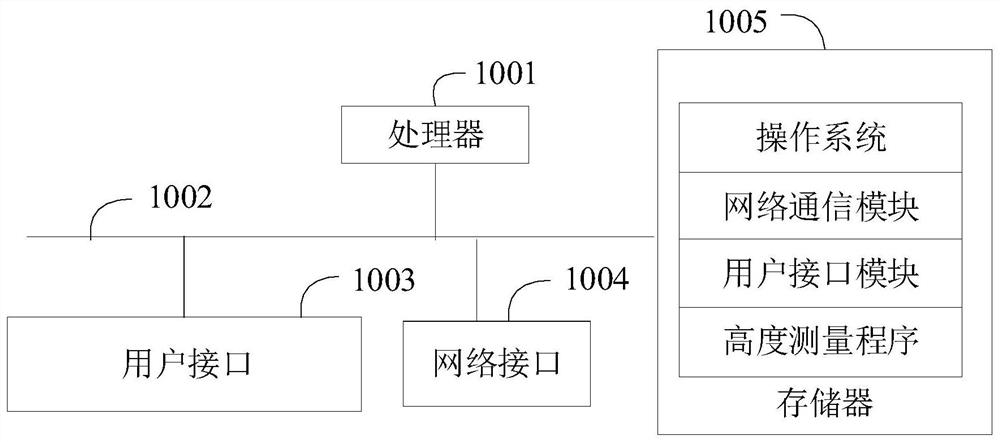

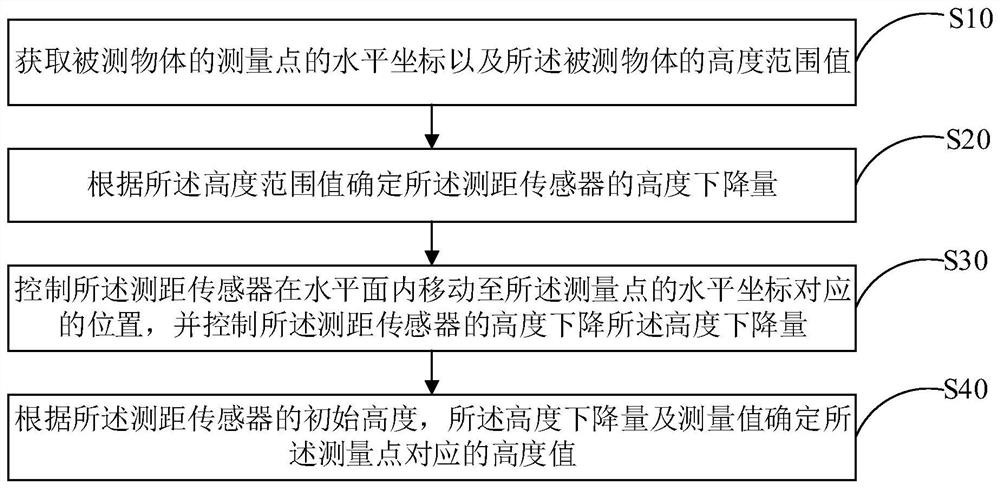

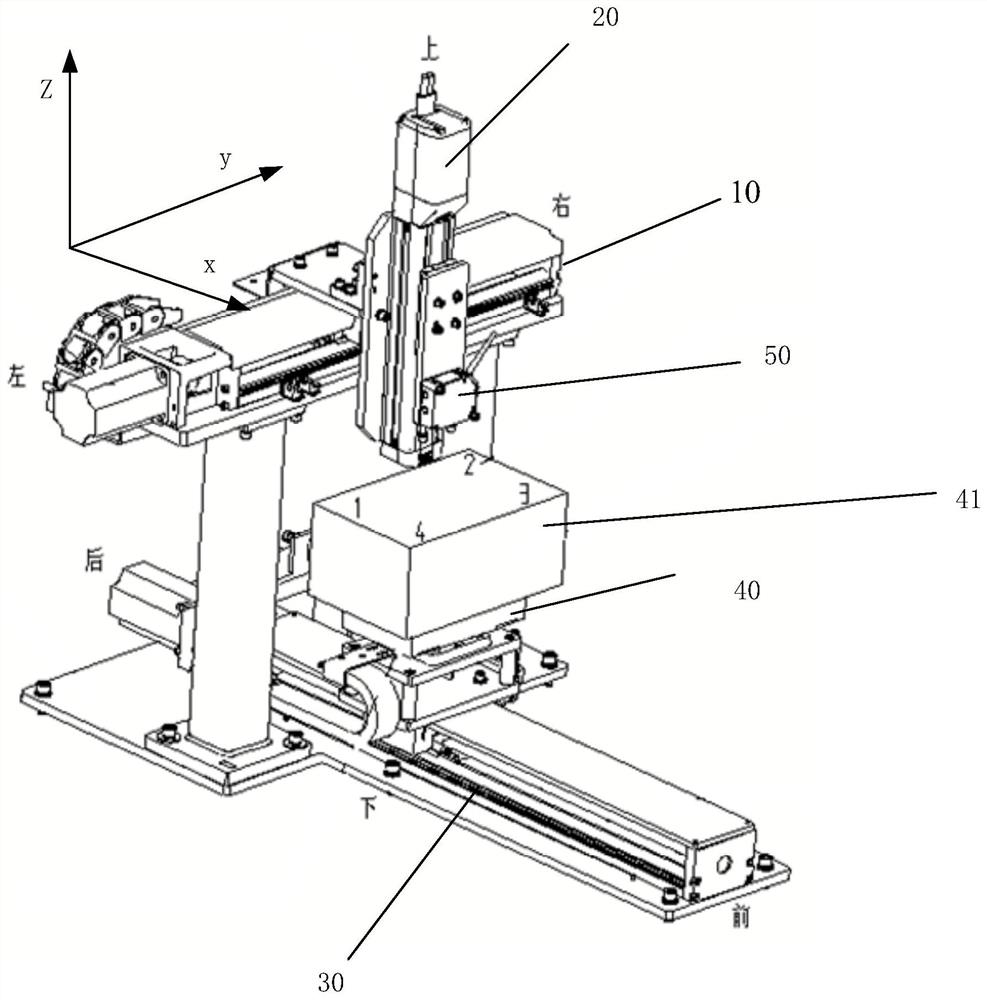

Height measurement method, height measurement equipment and storage medium

ActiveCN111928787ARealize the measurement effectImprove universalityUsing optical meansClassical mechanicsHeight decrease

The invention discloses a height measurement method. The method comprises the following steps: obtaining horizontal coordinates of a measurement point of a measured object and a height range value ofthe measured object; determining the height drop amount of the distance measuring sensor according to the height range value; controlling the distance measuring sensor to move to the position corresponding to the horizontal coordinate of the measuring point in the horizontal plane, and controlling the height of the distance measuring sensor to be decreased by the height decreasing amount; and determining a height value corresponding to the measurement point according to the initial height of the distance measurement sensor, the height drop amount and the measurement value. The invention further discloses height measurement equipment and a computer readable storage medium, and the effect of improving the universality of the height measurement scheme is achieved.

Owner:GOERTEK INC

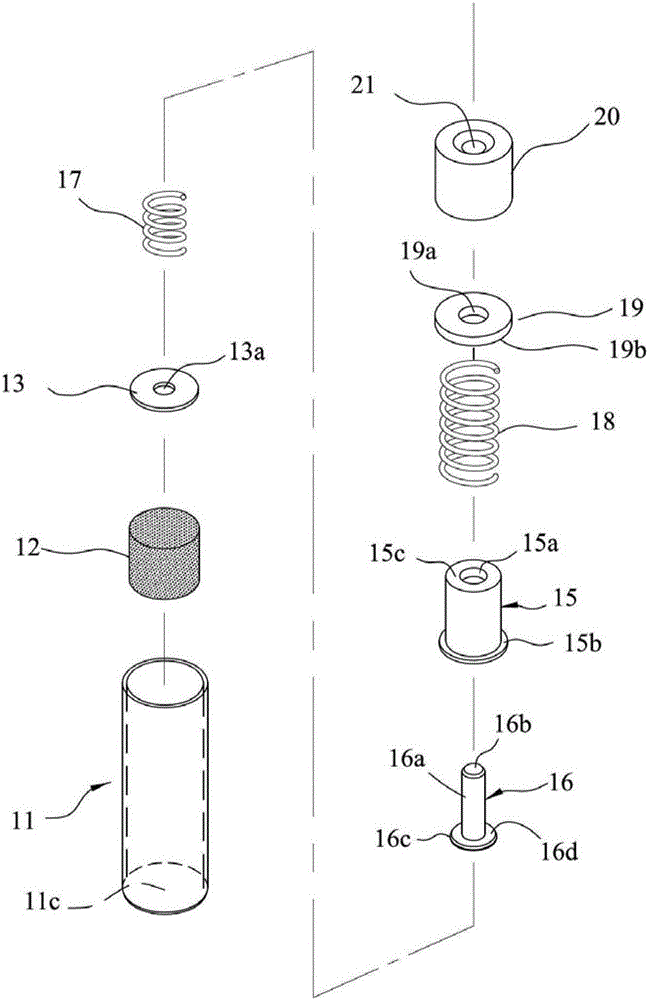

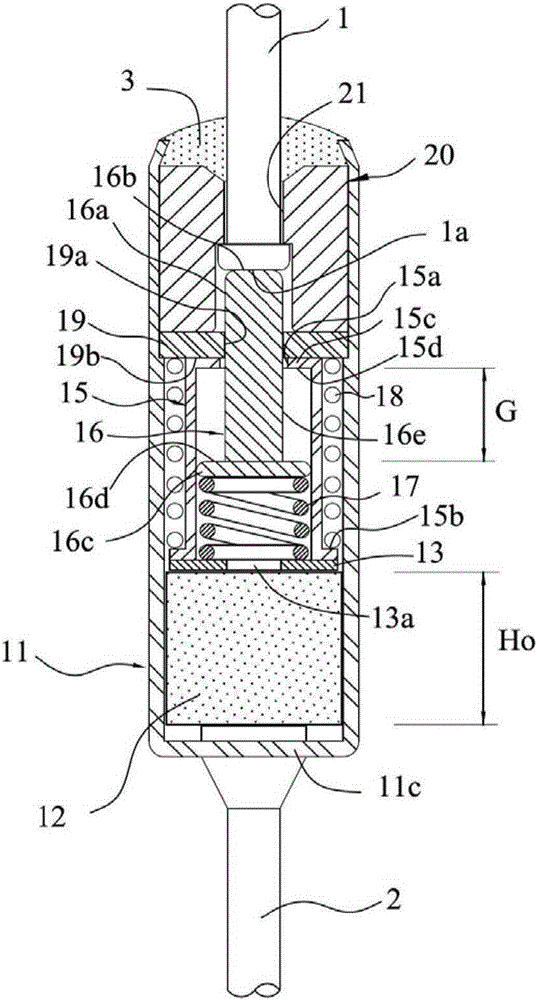

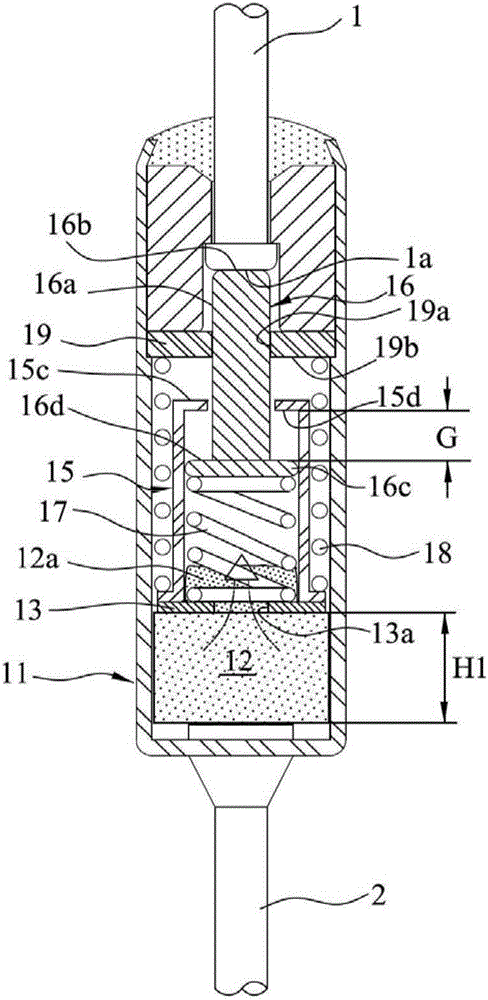

Temperature-sensitive pellet type thermal fuse

ActiveCN107437479ASeparation operation is stableRealize switch operationHeating/cooling contact switchesEmergency protective devicesHeight decreaseEngineering

The invention relates to a temperature-sensitive pellet type thermal fuse having a cylindrical metal case (11), a first lead (1) fixedly installed and insulated from the case (11) and a second lead (2) electrically connected to the case (11). A temperature-sensitive pellet (12) is installed by melting inside the case (11) and has a variable height. A moving terminal (16) is elastically coupled by a first spring (17) to the temperature-sensitive pellet (12) and an activating member (15) moves in a height decrease direction of the temperature-sensitive pellet (12) by an elastic repulsive force of a second spring (18). When the temperature-sensitive pellet (12) is melted and thereby is reduced in height, a first moving contact (16b) of the moving terminal (16) is separated from a first contact (1a) of the first lead (1).

Owner:TOYO ELECTRIC CO LTD +1

Cutting insert, cutting tool using the same, and cutting method

ActiveUS8579558B2Reduce generationSmall cutting forceWood turning toolsTransportation and packagingHeight decreaseEngineering

Owner:KYOCERA CORP

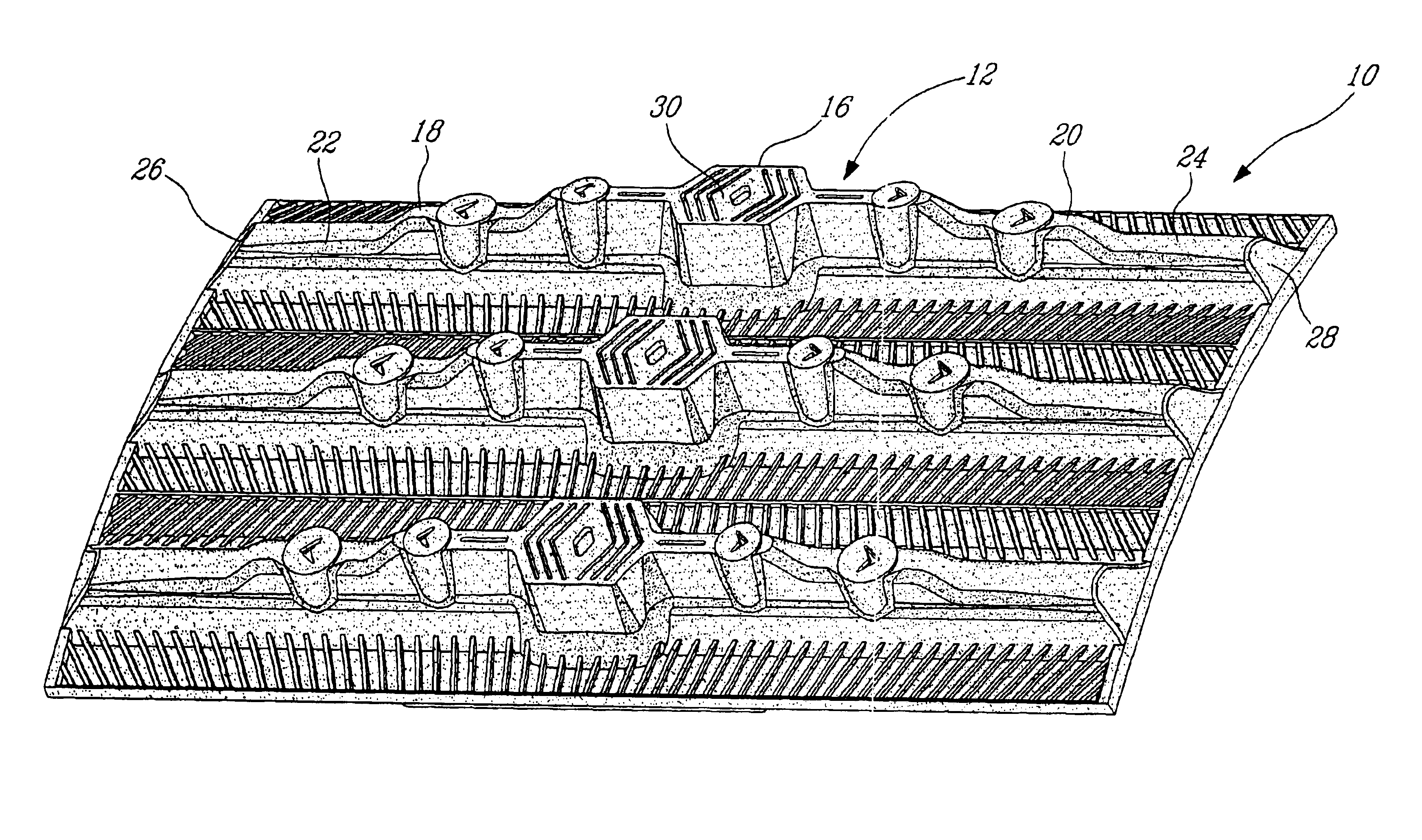

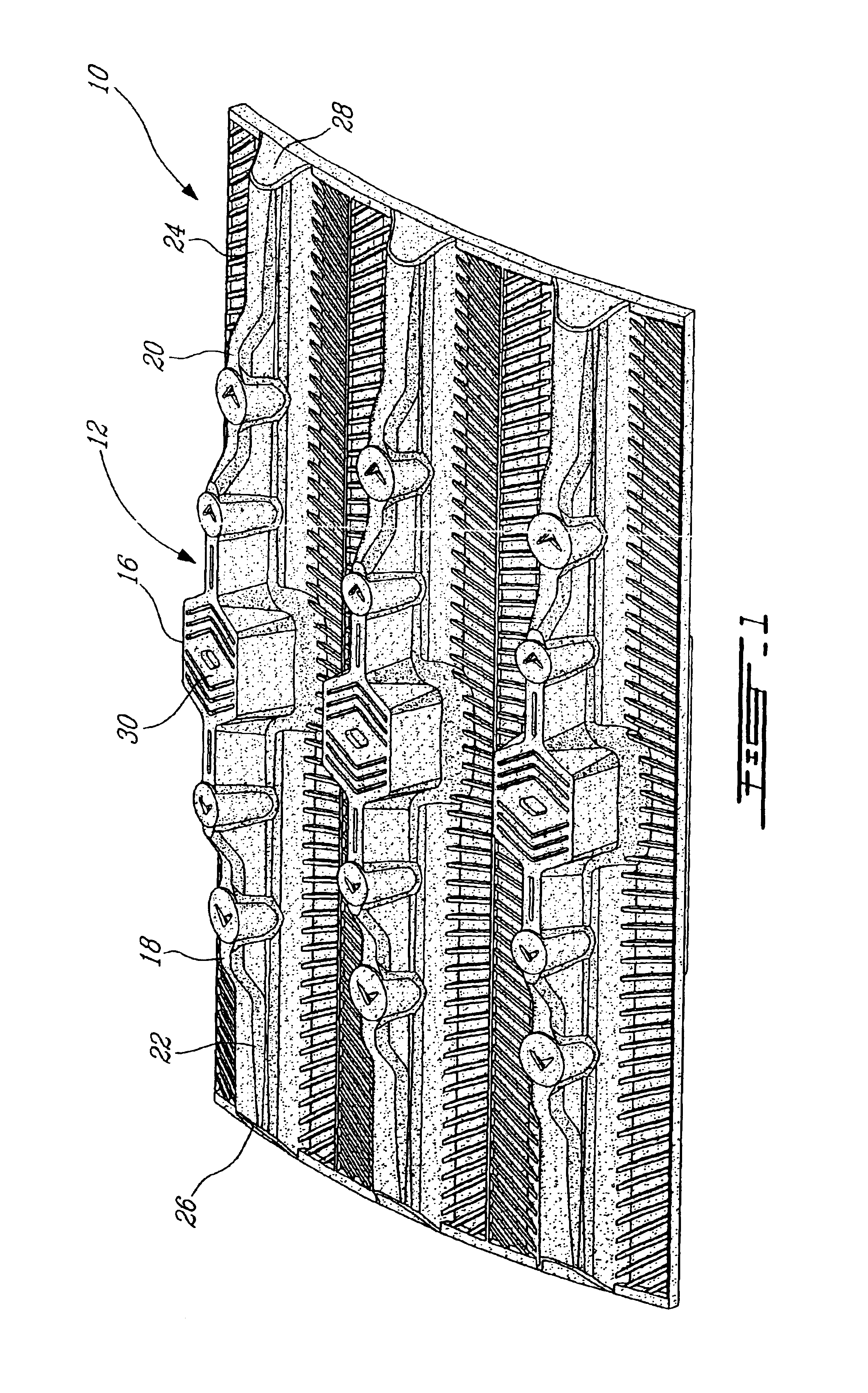

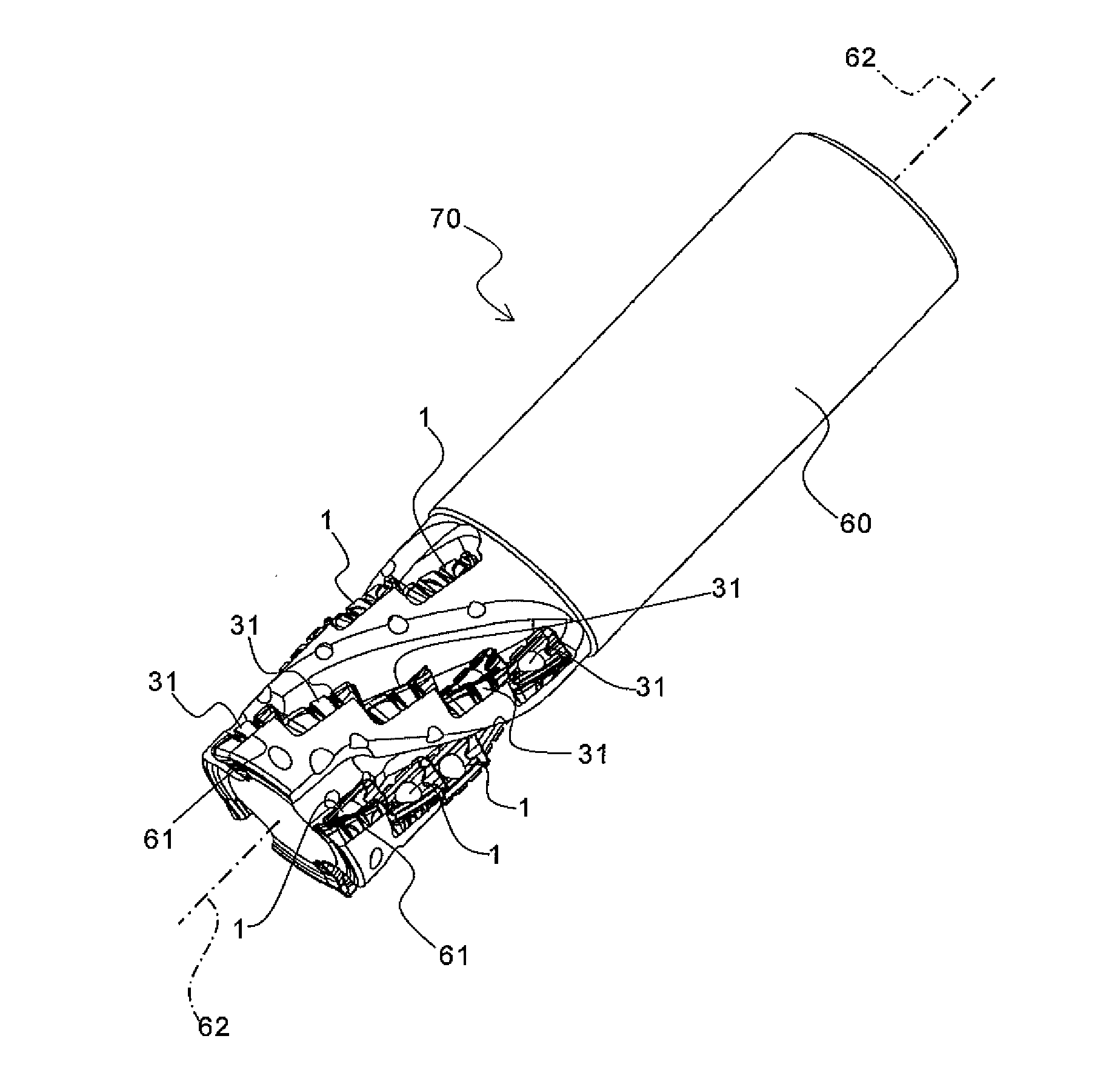

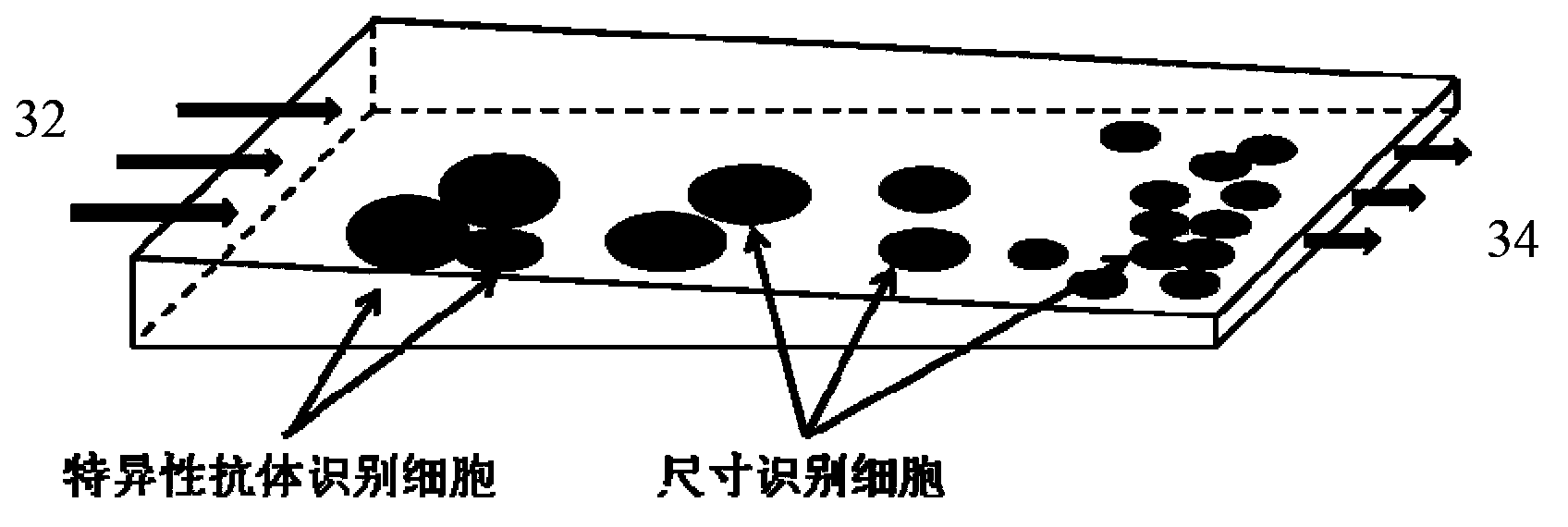

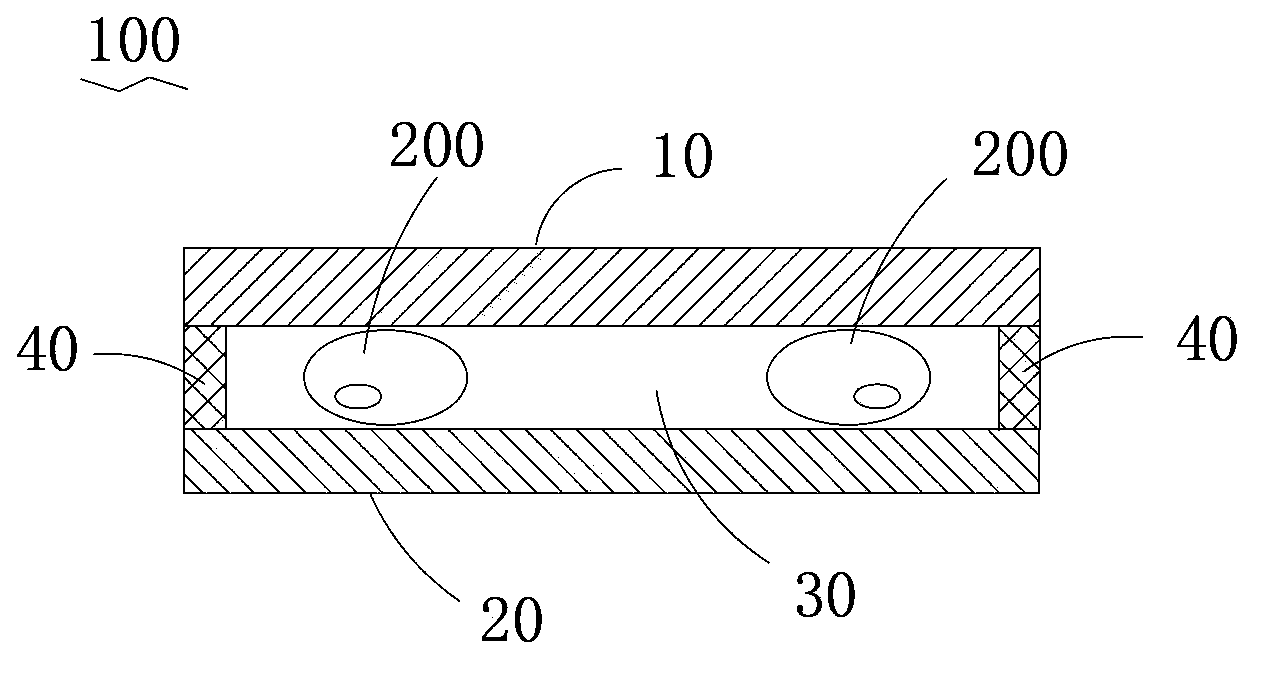

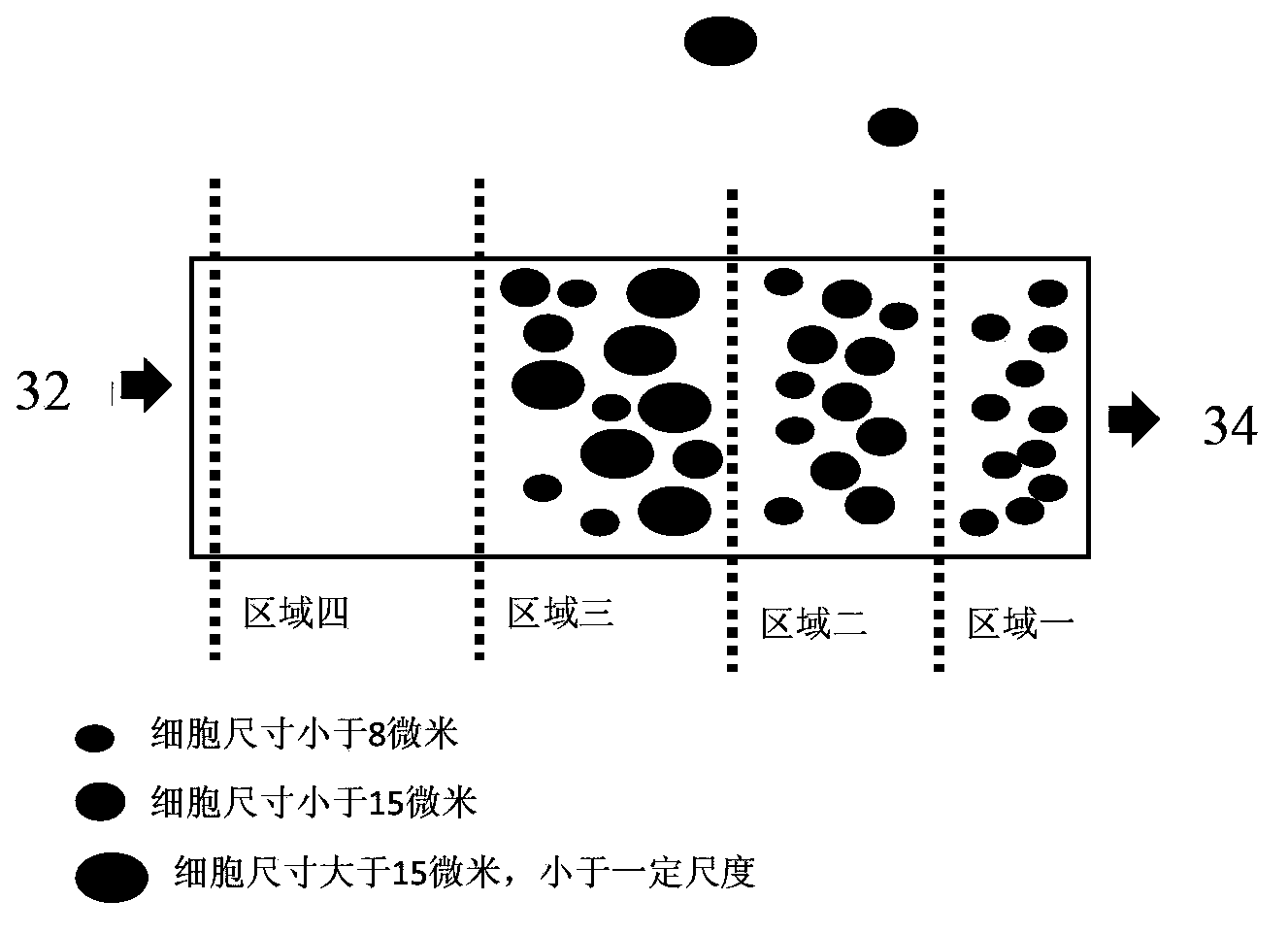

Microfluid cell capturing chip and manufacture method thereof

ActiveCN102925337BEfficient enrichmentSimple structureBioreactor/fermenter combinationsBiological substance pretreatmentsHeight decreaseEngineering

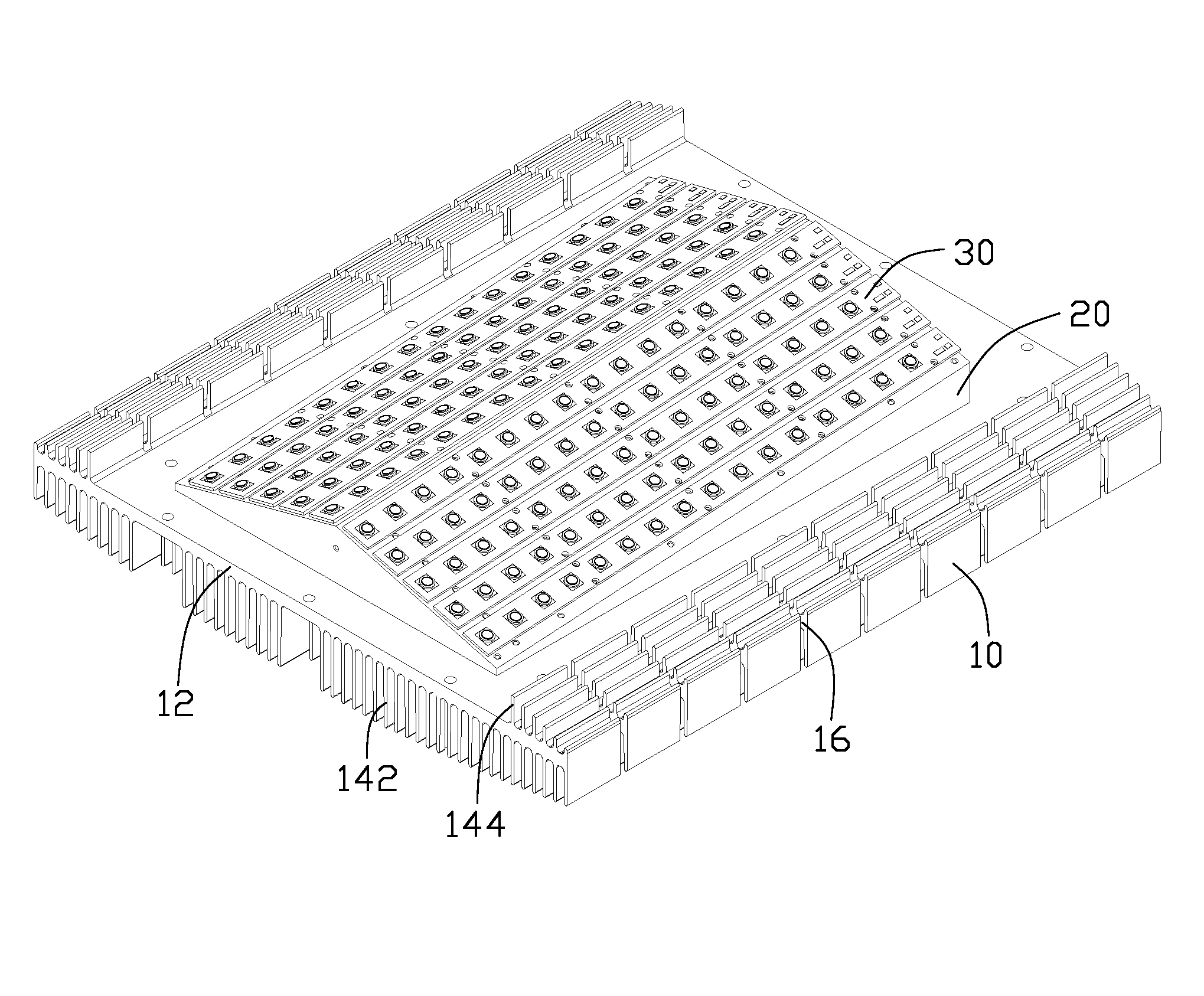

A microfluidic chip (100) for capturing cells (200) and preparing method thereof. The chip (100) comprises an upper rigid material (10) and a lower rigid material (20), a channel (30) provided between the upper rigid material (10) and the lower rigid material (20). The channel has an inlet (32) and an outlet (34). At least one of the upper rigid material (10) and the lower rigid material (20) is made of transparent material. The channel (30) has a height decreasing gradually from the inlet (32) to the outlet (34), thus a wedge shape is formed, or a portion of the channel has the wedge shape. The lowest portion of the channel (30) has a dimension approximating to or less than that of at least one of target cells. The chip (100) could quickly, effectively separate and enrich cells with various sizes and specific molecular expressions.

Owner:WUHAN YZY MEDICAL SCI & TECH

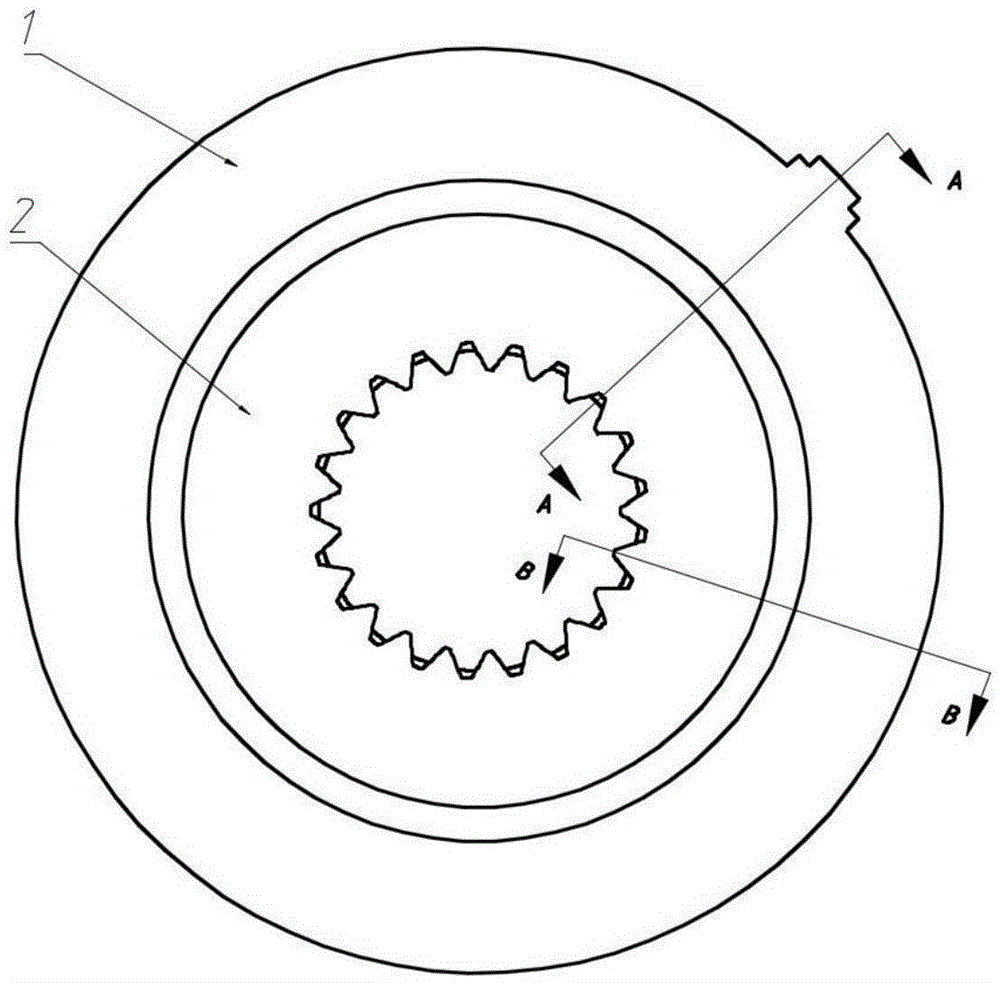

Wedge-shaped variable modulus multipore-lubricating spline shaft extrusion die with surface texture

ActiveCN105642696AReduce accumulationIncrease the diameter of the pitch circleExtrusion diesInterference fitPre stress

A wedge-shaped variable modulus multipore-lubricating spline shaft extrusion die with surface texture comprises an extrusion die and a prestress die fixing sleeve externally connected with the same, the prestress die fixing sleeve is in interference fit with the extrusion die, a seal ring is fitted to a fit position of the prestress die fixing sleeve with the extrusion die, the extrusion die includes an upper bevel segment, a middle forming segment and a wedge-shaped transition segment, tooth profile modulus of the wedge-shaped transition segment increases gradually from bottom to top, tooth thickness decreases gradually from bottom to top, tooth height decreases gradually from bottom to top, bevels of the middle forming segment and the wedge-shaped transition segment are laser nicked, and the surface texture is formed to reduce friction. Metal flow in the forming process is controlled by varying the die tooth profile modulus, so that acceptability rate of extruded spline shafts is increased.

Owner:XI AN JIAOTONG UNIV

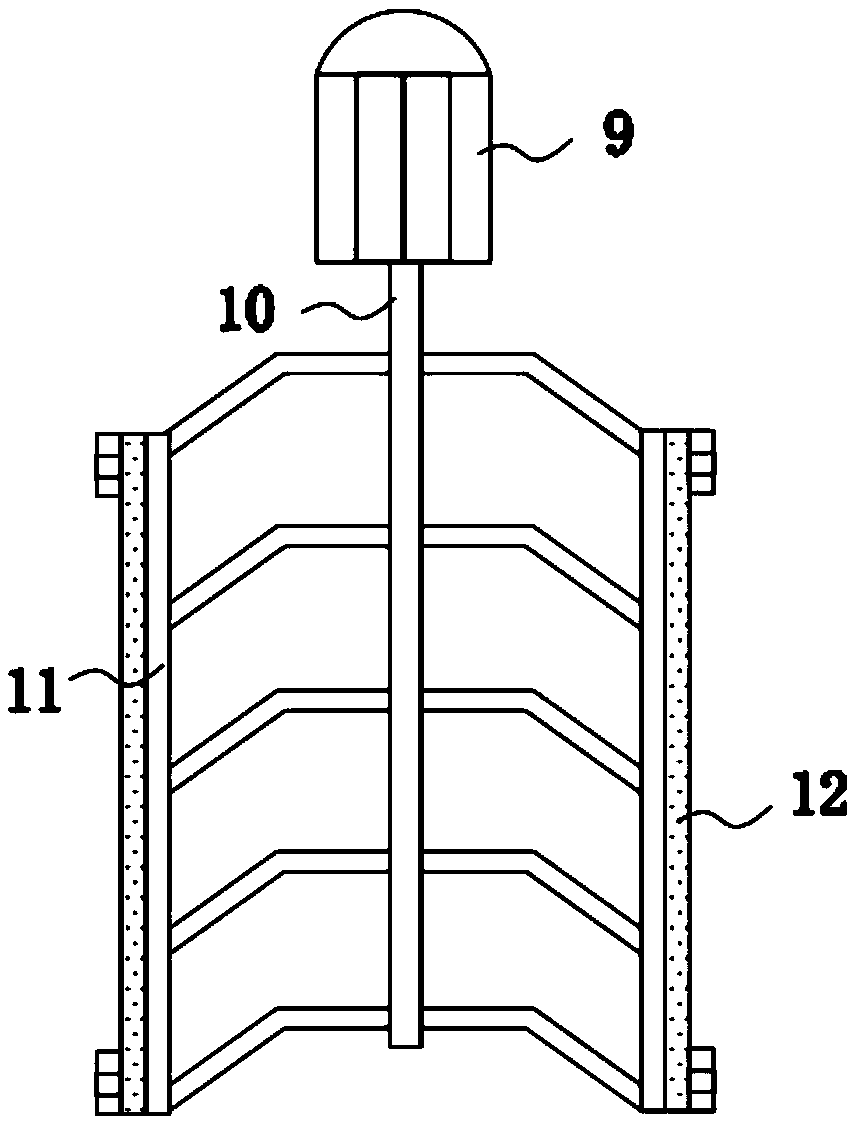

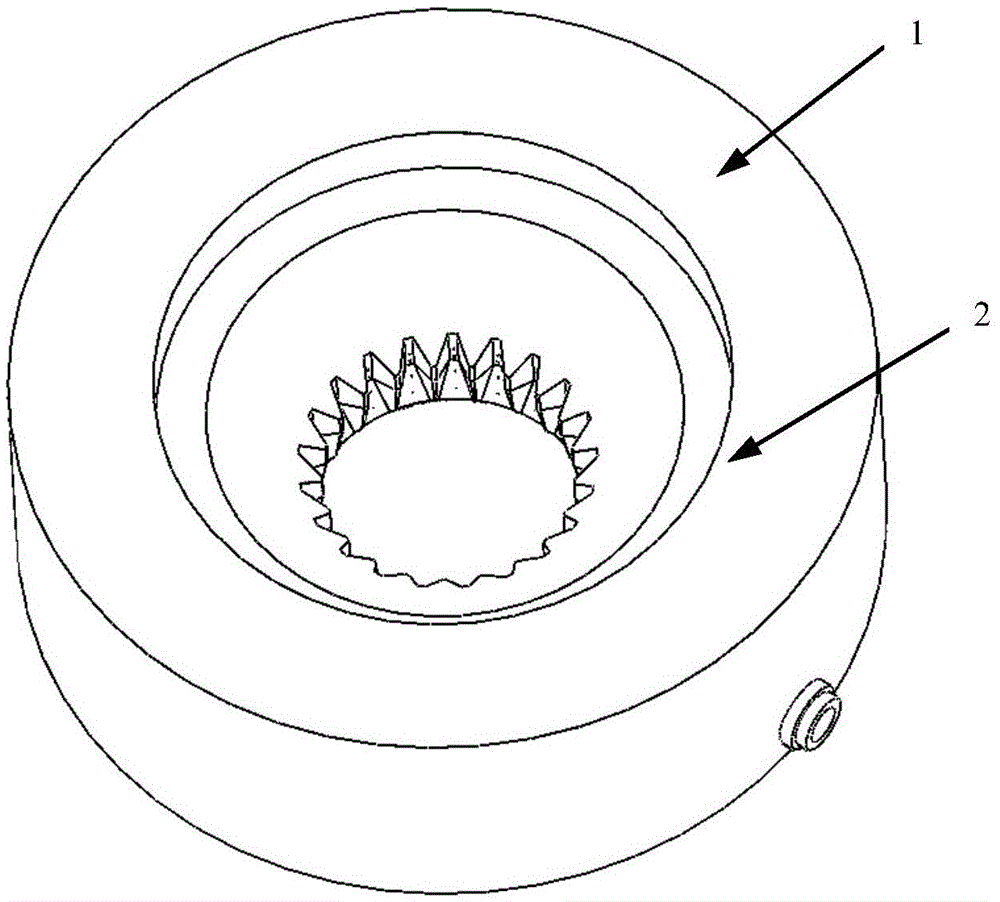

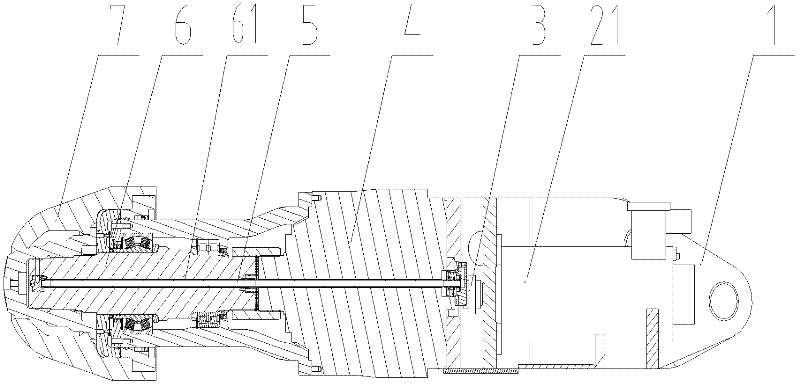

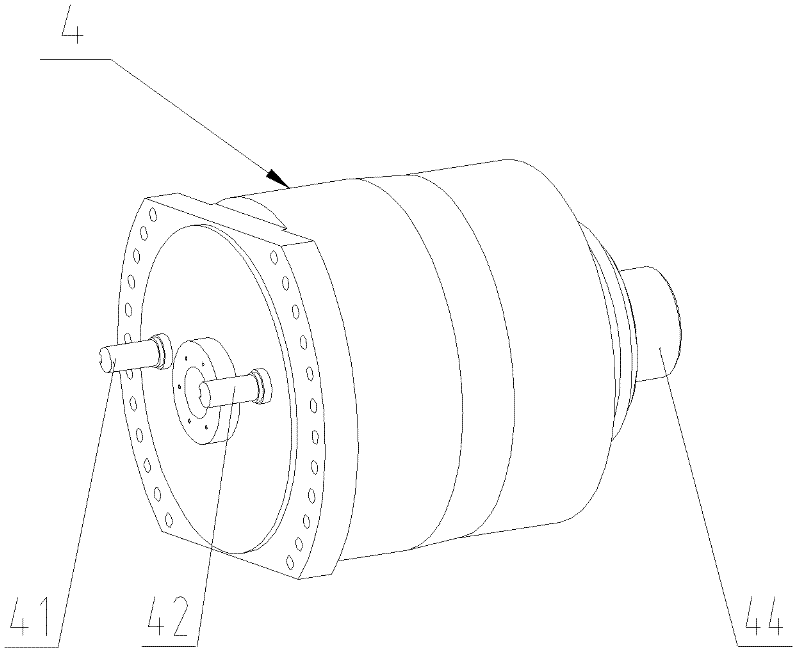

Entry-driving machine and cutting part thereof

InactiveCN102373924AOptimize space layoutOvercoming the disadvantages of excessive heightDriving meansWork performanceWater channel

The invention discloses a cutting part of an engineering machine. The cutting part comprises a cutting head, a cutting head shaft, a water pipe, a speed reducer, at least two power devices for driving the cutting head and an installation rack, wherein the installation is fixed on the power devices; the output ends of the power devices are connected with the input end of the speed reducer; and the output end of the speed reducer is in fixed connection with the cutting head through the cutting head shaft. The invention also discloses an entry-driving machine comprising the cutting part. In the cutting part of the entry-driving machine, the output shafts of at least two power devices are in corresponding connection with the input shafts of the speed reducer, the power devices drive the speed reducer to work, after speed reduction and moment increase of the speed reducer, the cutting head shaft connected with the output shaft of the speed reducer rotates, and thus the cutting head is driven to rotate. The cutting part disclosed by the invention has the characteristics that: along with the height decrease, the working performance is increased, the cutting part can work in a narrow space and the universality is significantly improved; and furthermore, by the cutting part, the arrangement of an internal spraying water channel is simplified.

Owner:SANY HEAVY EQUIP

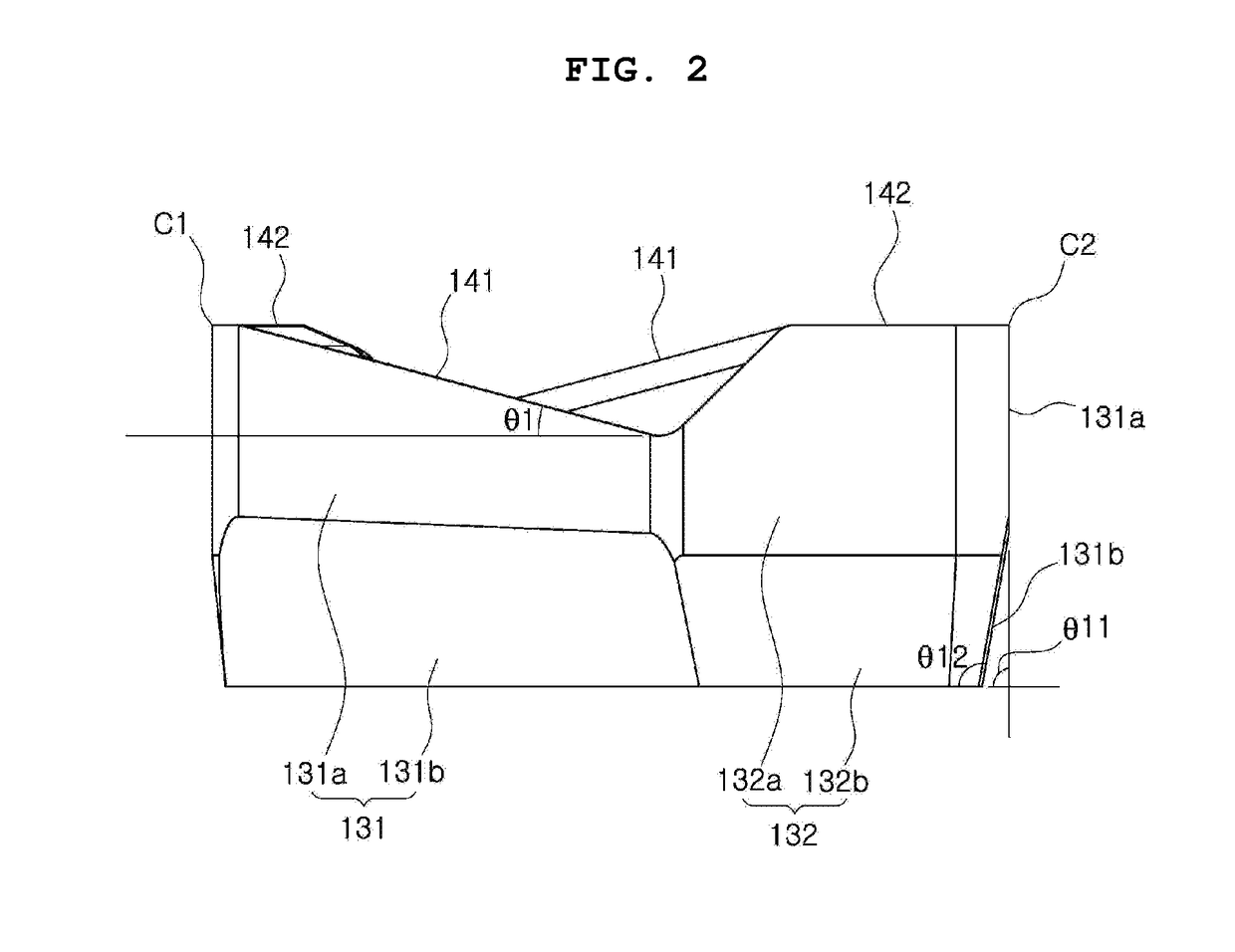

Insert and tool holder for mounting same

ActiveUS20170113286A1Enhanced couplingMinimize interferenceTransportation and packagingMilling cuttersHeight decreaseTool holder

An insert in which a cutting edge is formed only between an upper surface and a side surface. The insert comprises: three or more corners along a perimeter; a main cutting edge formed on an edge between an upper surface and a main side surface, and a sub cutting edge formed on an edge between the upper surface and a sub side surface, wherein the main cutting edge and the sub cutting edge are placed in succession between the corners; and a flat lower surface. The main cutting edge forms an inclination angle such that a height decreases gradually in a direction toward the sub cutting edge. The main side surface is formed by a first end main side surface and a second end main side surface. The sub side surface is formed by a first end sub side surface and a second end sub side surface.

Owner:KORLOY

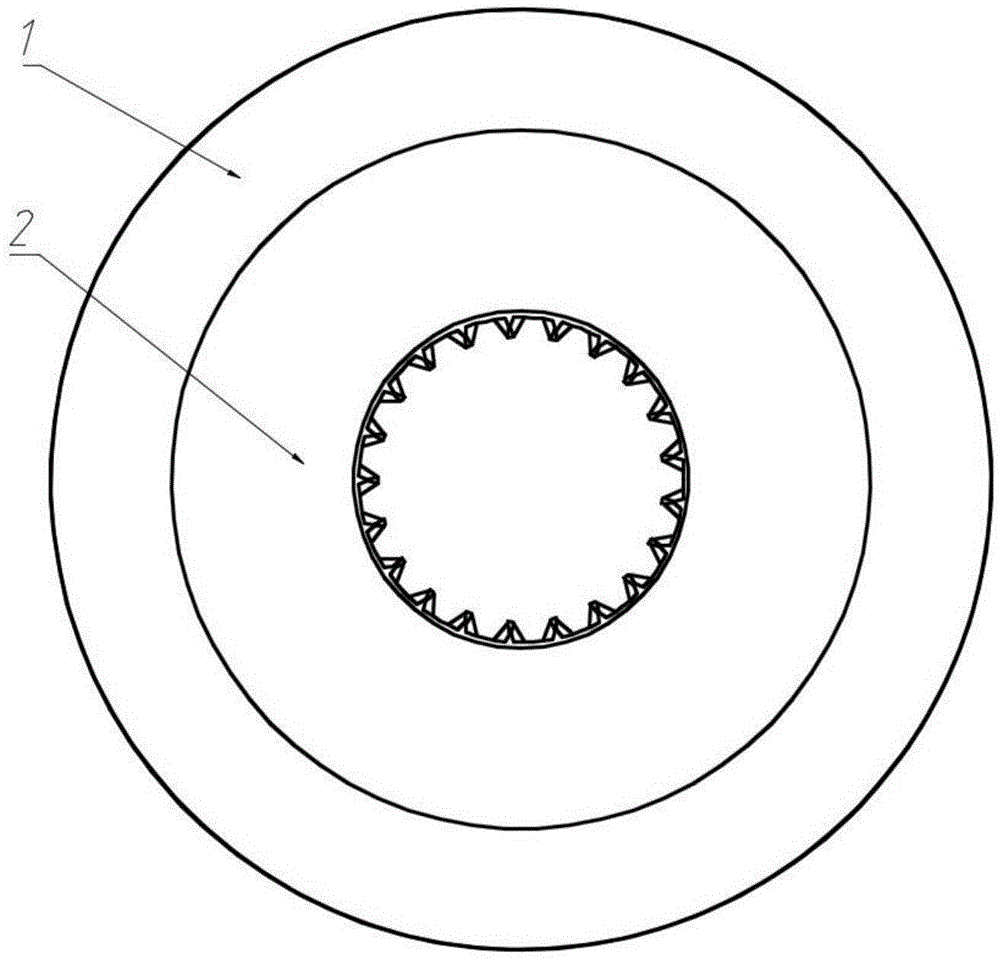

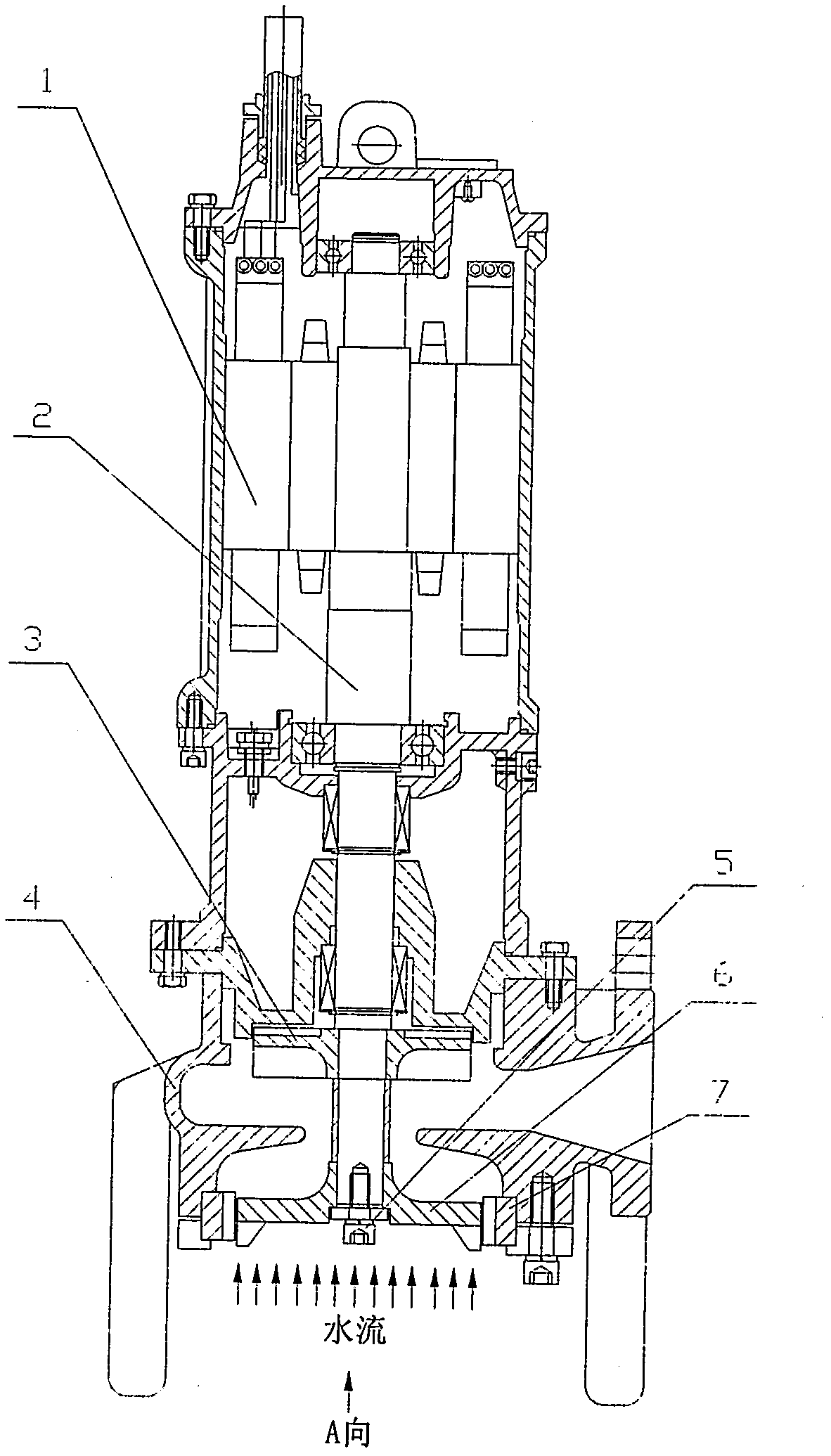

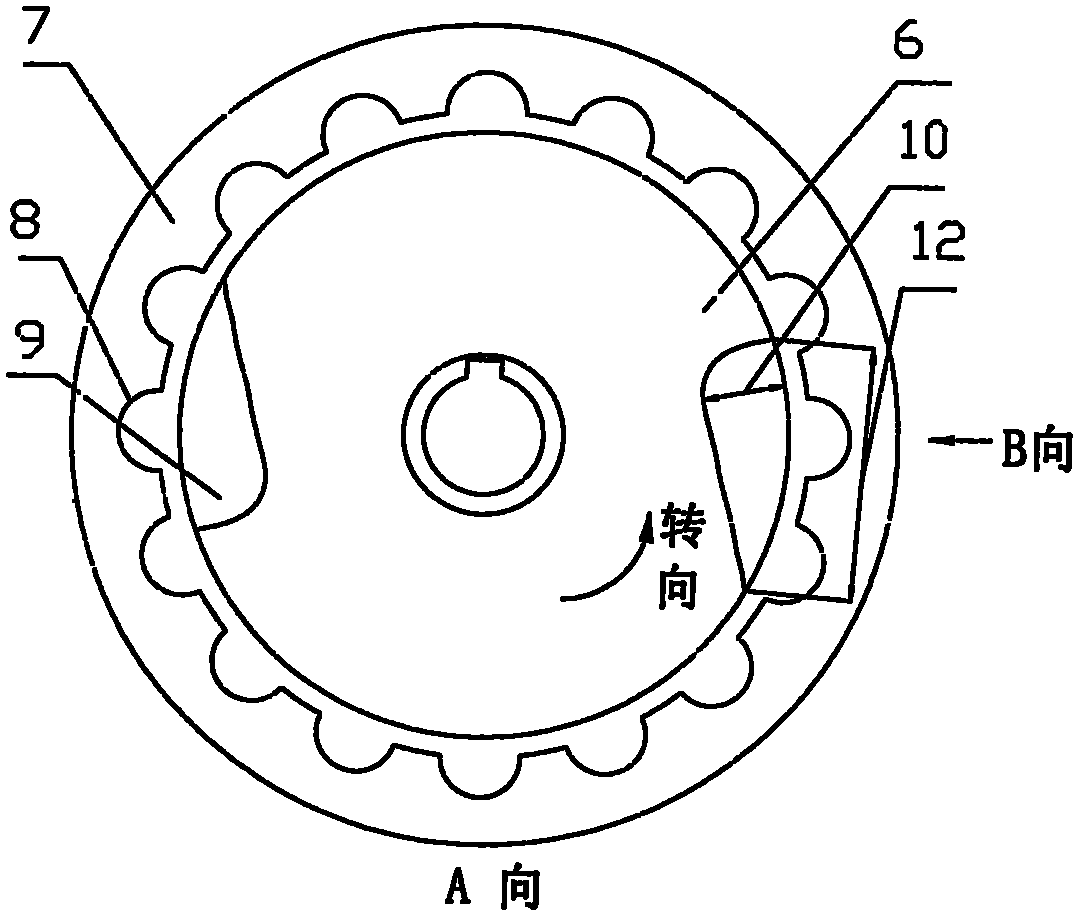

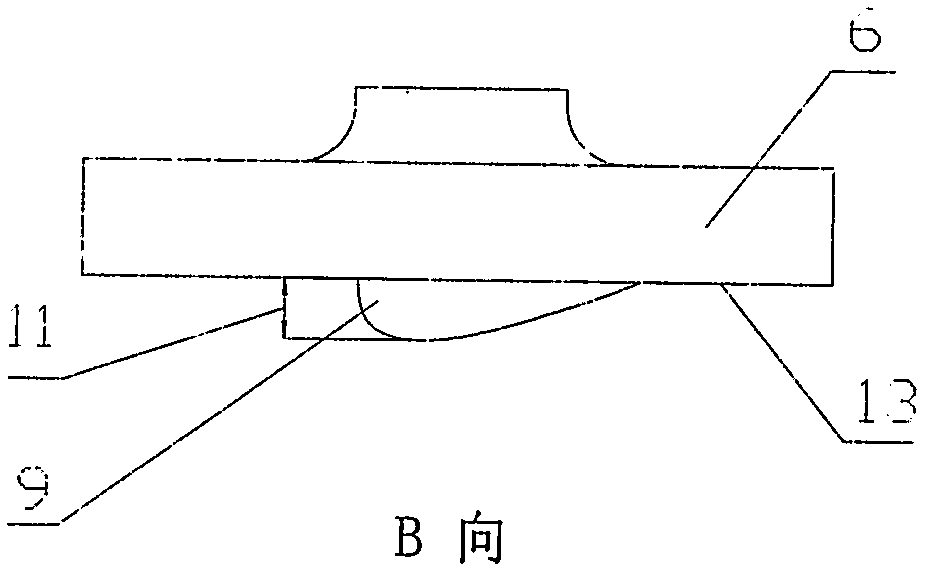

Crushing pump utilizing streamlined cutter heads

InactiveCN102434481AImprove performanceReduce hydraulic lossPump componentsPumpsImpellerHeight decrease

The invention relates to a crushing pump utilizing streamlined cutter heads. A crushing device is installed in front of an impeller inlet and substantially comprises a dynamic cutter and a static cutter. The dynamic cutter is fixed at the shaft end in front of the impeller inlet and pressed on the shaft through a fastening bolt of the shaft end to achieve axial fixing. The dynamic cutter rotates along with a pump shaft. More than one cutter head is arranged on the lower surface of the dynamic cutter close to the position of the external diameter and downwards extend for a certain height along the shaft. The cutter heads are in streamlined shapes viewed both from the axial direction and the radial direction. The cutter heads are in streamlined shapes with both the width and the height decreasing in the direction opposite to the rotating direction. The static cutter is fixed on fixed pieces such as a pump body, a pump cover or the like, a plurality of semi-circular flow channels for limiting the diameter of particles passing through are arranged on the inner circumference of the static cutter, and two sides of each flow channel form two cutting edges matched with the rotating cutter heads of the dynamic cutter to crush sundries. The dynamic cutter utilizes the streamlined cutter heads, thereby reducing flow losses and effectively improving flow situations of the inlet of the crushing pump and crushing performance of the crushing pump.

Owner:JIANGSU GUOQUAN PUMP MFG CO LTD

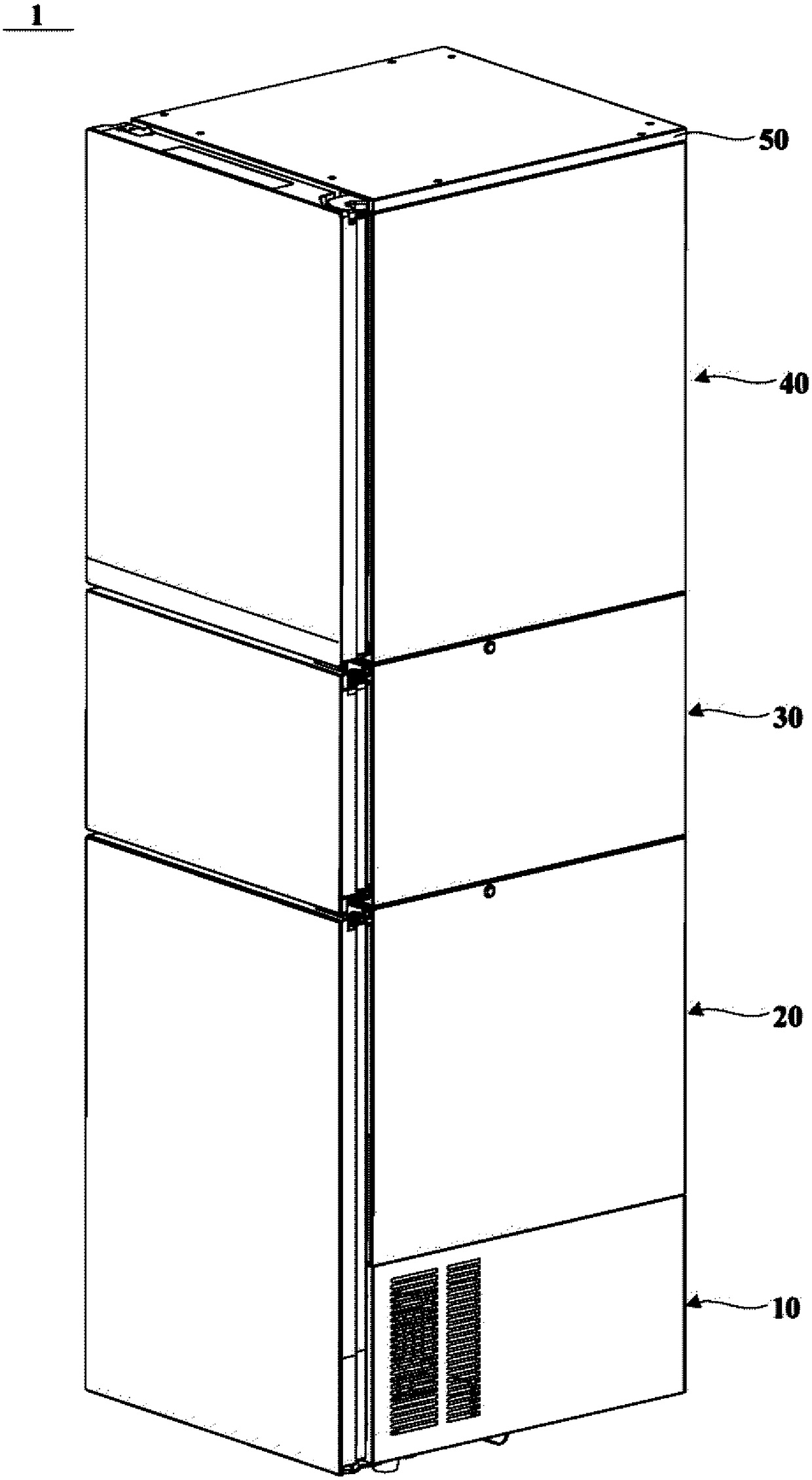

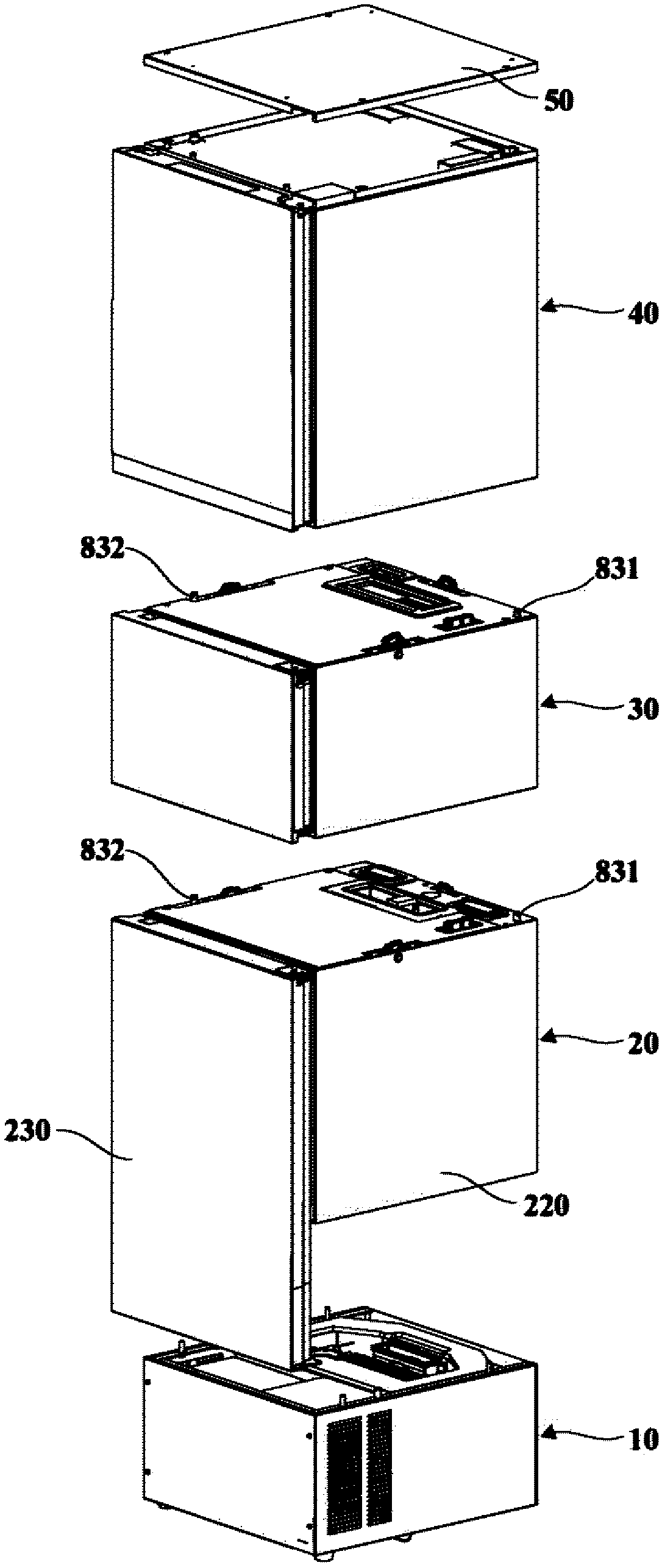

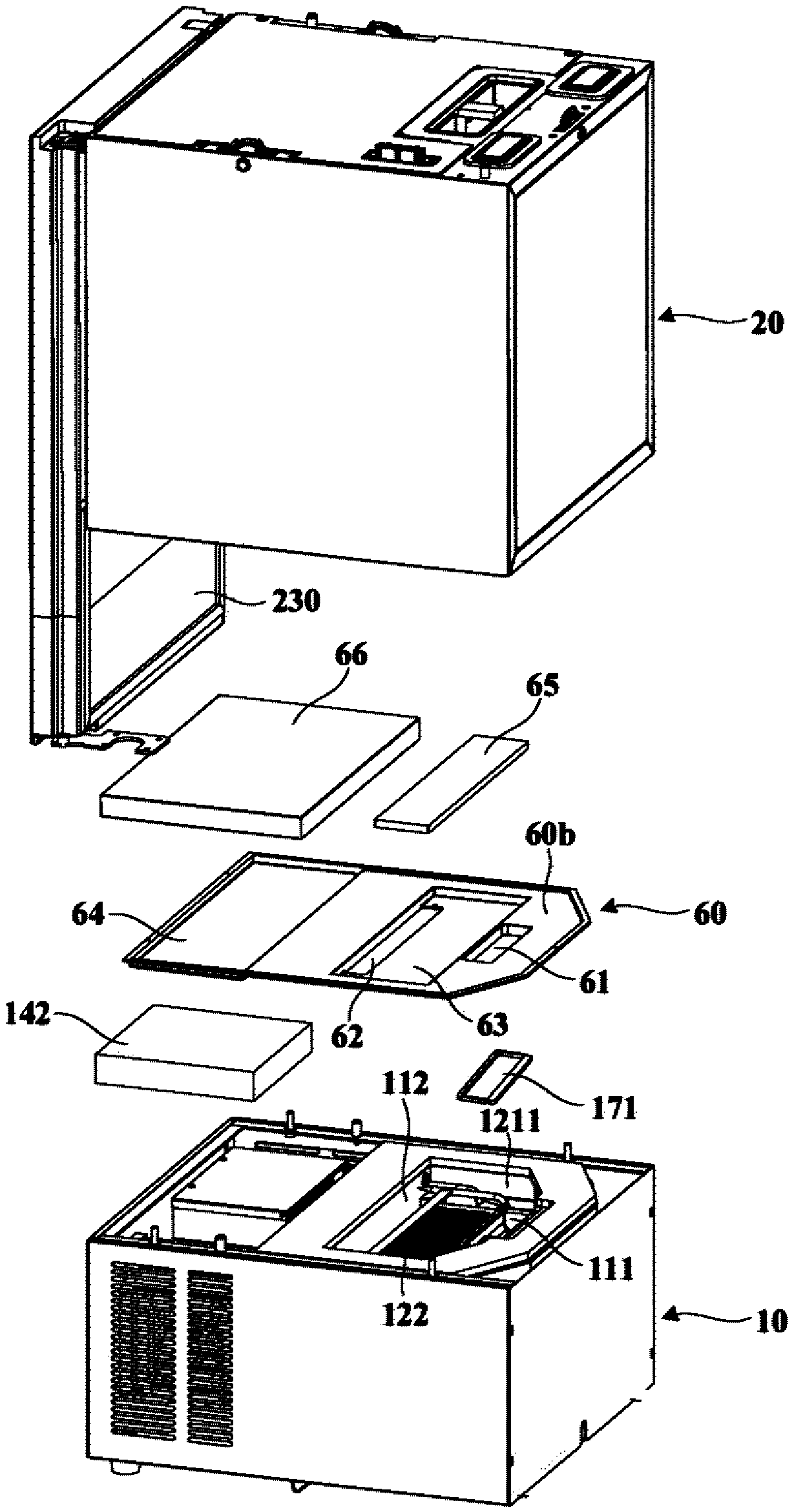

Cold storage and refrigeration device

ActiveCN108626941AReduce the overall heightIncreasing the thicknessLighting and heating apparatusDomestic refrigeratorsThermal insulationHeight decrease

The invention relates to a cold storage and refrigeration device. The cold storage and refrigeration device comprises a refrigeration module, a base layer storage module and a reuse wall panel. The refrigeration module is configured to be used for providing cooling air currents for the storage module connected to the refrigeration module in an attachment manner, and the top of the refrigeration module is open. Storage space is limited inside the base layer storage module, the bottom of the base layer storage module is open, and the base layer storage module is connected with the upper part ofthe refrigeration module in the attachment manner. The reuse wall panel is arranged between the refrigeration module and the base layer storage module, and is configured to be reused as a top plate ofthe refrigeration module and a base plate of the base layer storage module, so that the top of the refrigeration module and the bottom of the base layer storage module are sealed at the same time, the cooling air currents generated by the refrigeration module are allowed to flow to the base layer storage module, and return air currents in the base layer storage module are allowed to flow to the refrigeration module. Therefore, the height of the refrigeration module is decreased (the decrease range of the height roughly ranges from 50 millimeters to 100 millimeters), the partial space formed because of height decrease can be used for thickening a thermal insulation layer between the refrigeration module and the base layer storage module, and then, the heat preservation performance is improved.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +1

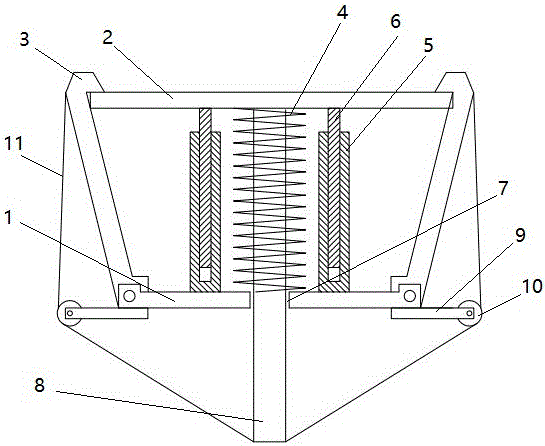

Bounce power-assisted pad for performance

ActiveCN106422158ASmall height dropLower the altitudeShock absorber matsHeight decreaseElectrical and Electronics engineering

The invention discloses a bounce power-assisted pad for performance. The bounce power-assisted pad comprises a base, an ejecting plate and a blocking hook, wherein a spring and a guide device for limiting a bouncing direction of the ejecting plate are arranged between the base and the ejecting plate; the tail end of the blocking hook is hinged with the base, and the head end of the blocking hook hooks an edge of the ejecting plate; when the blocking hook hooks the ejecting plate, the length direction and the vertical direction of the blocking hook define an outward-inclined included angle which is not less than 10 degrees. The bounce power-assistant pad for performance can reduce the height decreasing range of a performer before jumping, and reduce shooting flaws.

Owner:WUXI XINRENJU SCI & TRADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com