Ship unloading method of bridge crane at shallow water wharf

The technology of bridge crane and shallow water wharf is applied to the unloading field of bridge crane in shallow water wharf. The effect of reliability, reducing self-weight and protecting the safety of the wharf structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

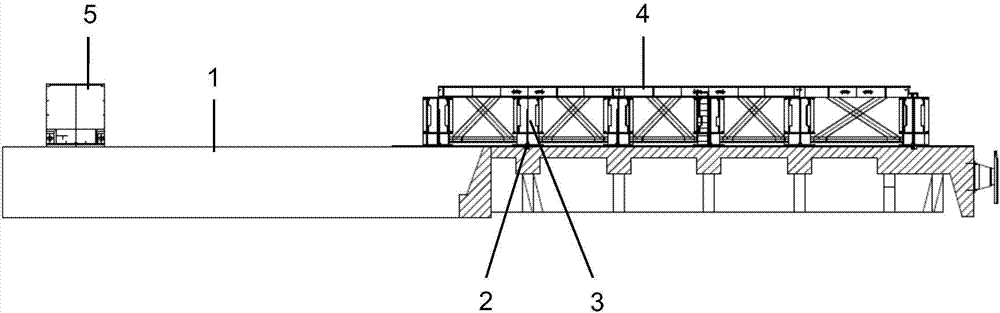

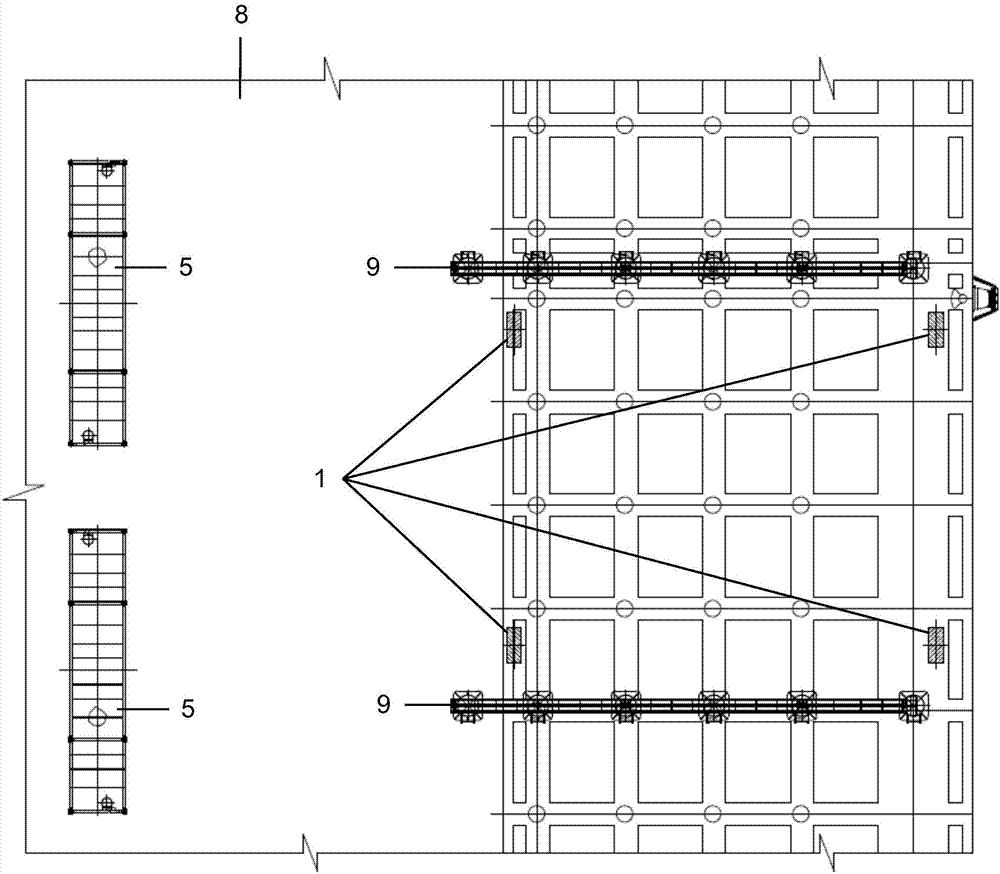

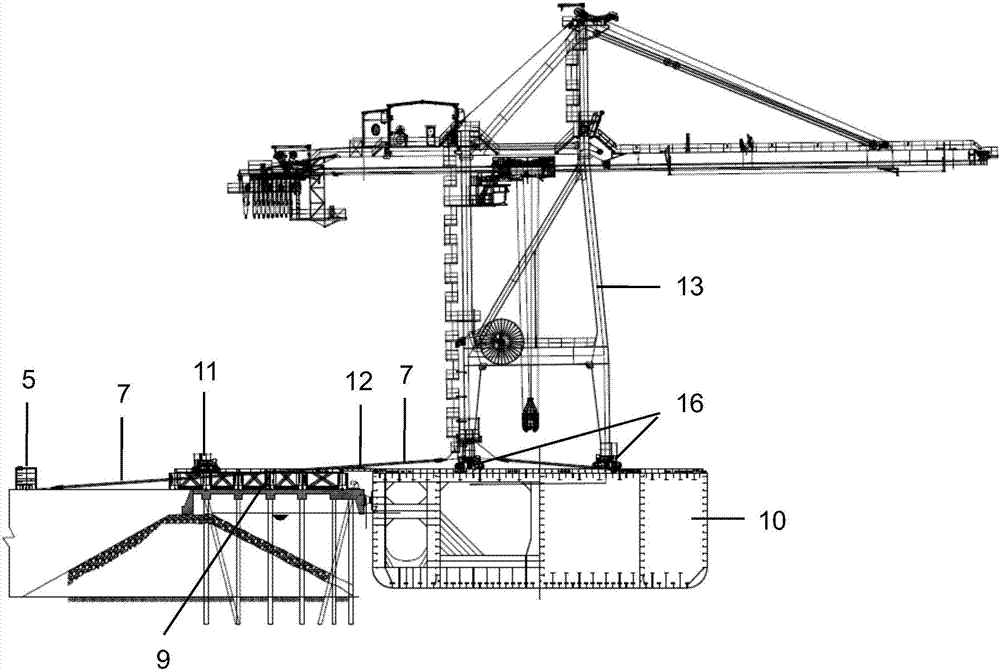

[0035] Please combine Figure 1 to Figure 7 As shown, a ship unloading method of a quay bridge provided by the present invention at a shallow water wharf comprises a jacking device 1, a support 2, a wharf pile foundation 3, a truss type deep continuous track beam 4, a ground anchor water tank 5, a bridge bridge Track beam 6, hoist and pulley block 7, lift the bridge crane 13 before shipment, remove the cart running mechanism 17 below it, install the roll-on trolley 16 at the position of the original cart running mechanism 17, and the cart running mechanism The direction of the wheels of 17 and the direction of the wheels of the roll-on trolley 16 are arranged in a 90° direction, and the specific steps are as follows:

[0036] S1. Draw a line on the shallow water wharf 8, and locate several ship unloading track beams and jacki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com