Crushing pump utilizing streamlined cutter heads

A streamlined, pulverized pump technology, applied to parts, pumps, pump elements, etc. of pumping devices used for elastic fluids, can solve problems such as cavitation of the cutter head, improper shape of the cutter head, flow disorder at the inlet of the crushed pump, etc. , to achieve the effect of reducing hydraulic loss and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

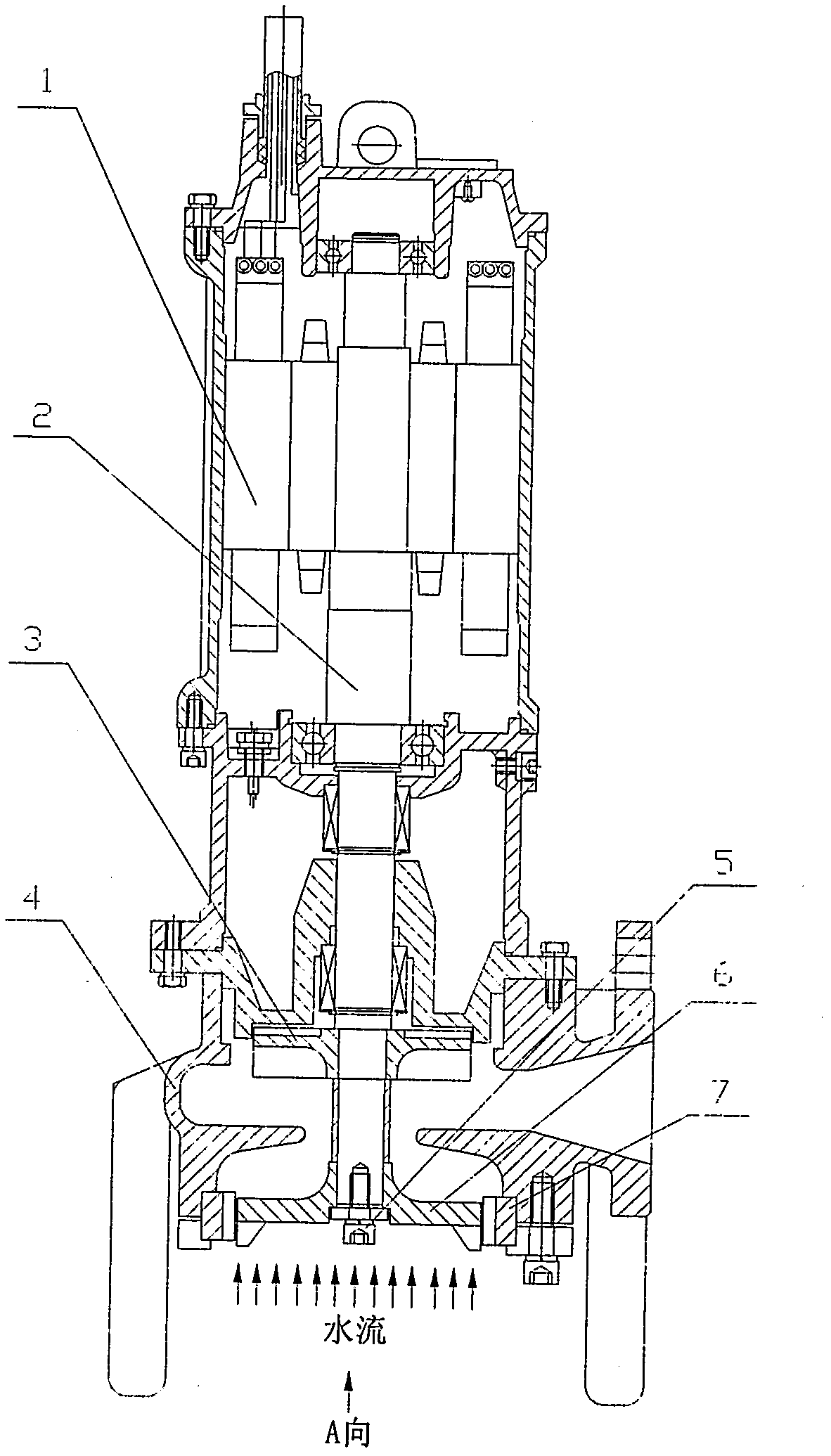

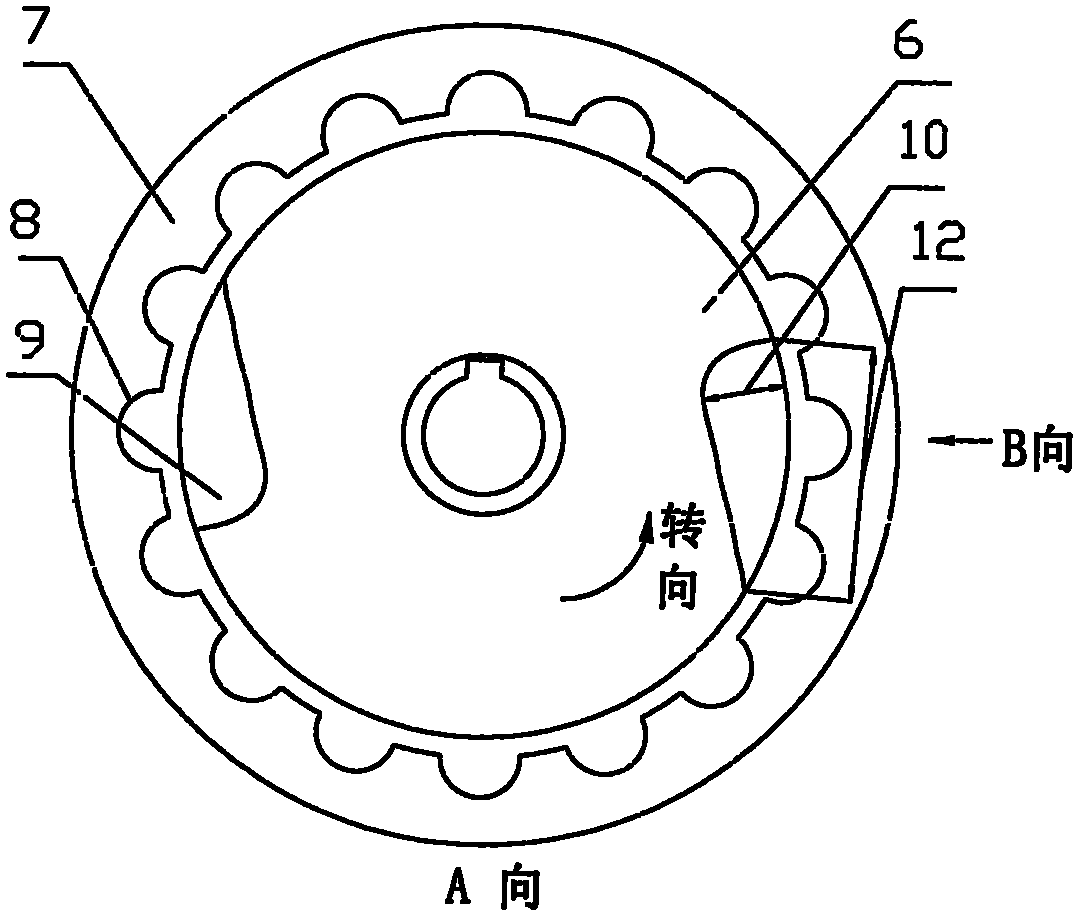

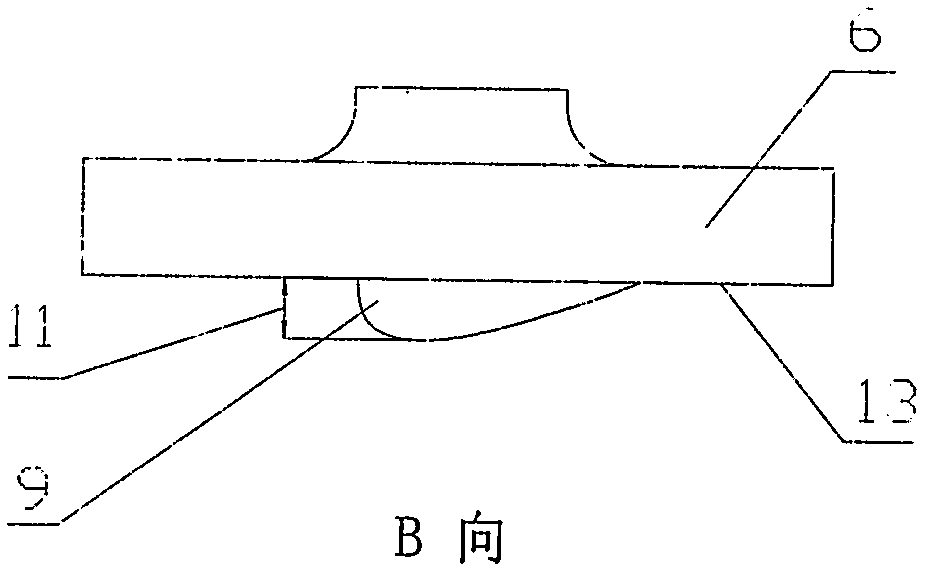

[0012] figure 1 , figure 2 and image 3 Determined to adopt the structural form of the streamline cutter head pulverizing pump in the present embodiment jointly, it is by motor (1), shaft (2), impeller (3), pump body (4), fastening bolt (5), movable cutterhead (6), static cutter head (7), semicircular runner (8), cutter head (9), cutter head width B (10), cutter head height H (11), cutter head length L (12), The lower surface of the cutter head (13) is composed of a crushing device installed before the inlet of the impeller (3), and the crushing device is mainly composed of two parts: the moving cutter head (6) and the static cutter head (7); the moving cutter head (6) Fix the shaft end before the inlet of the impeller (3), press the fastening bolt (5) on the shaft end to fix it axially on the shaft (2), and the movable cutter head (6) rotates with the shaft (2), On the lower surface (13) of the movable cutterhead (6), there is no less than one cutter head (9) near the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com