Capping beam and straining beam reverse construction method of concrete cylinder piers

A construction method and concrete technology, applied in bridges, bridge construction, bridge parts, etc., can solve problems such as difficulty in changing or partially widening construction access roads, insufficient and effective use of pier and column formwork, and increasing pier and column construction time. , to achieve the effect of saving the cost of construction measures, strong bearing capacity, and widening the construction access road

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

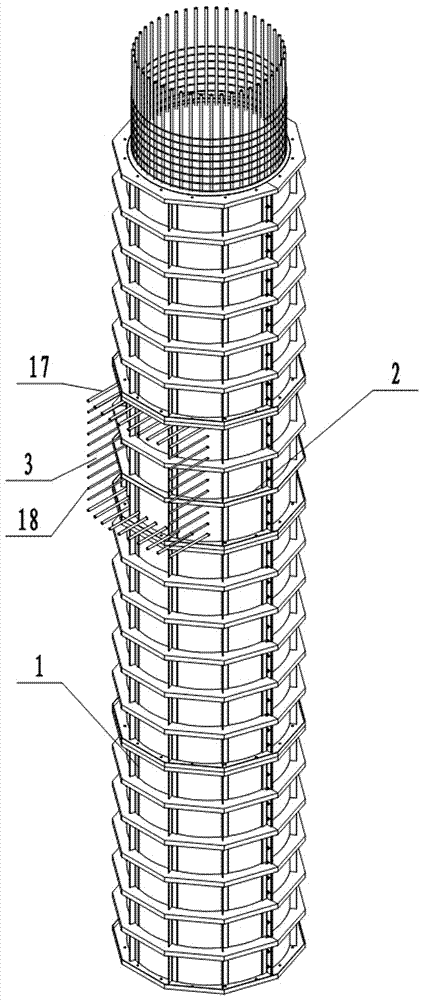

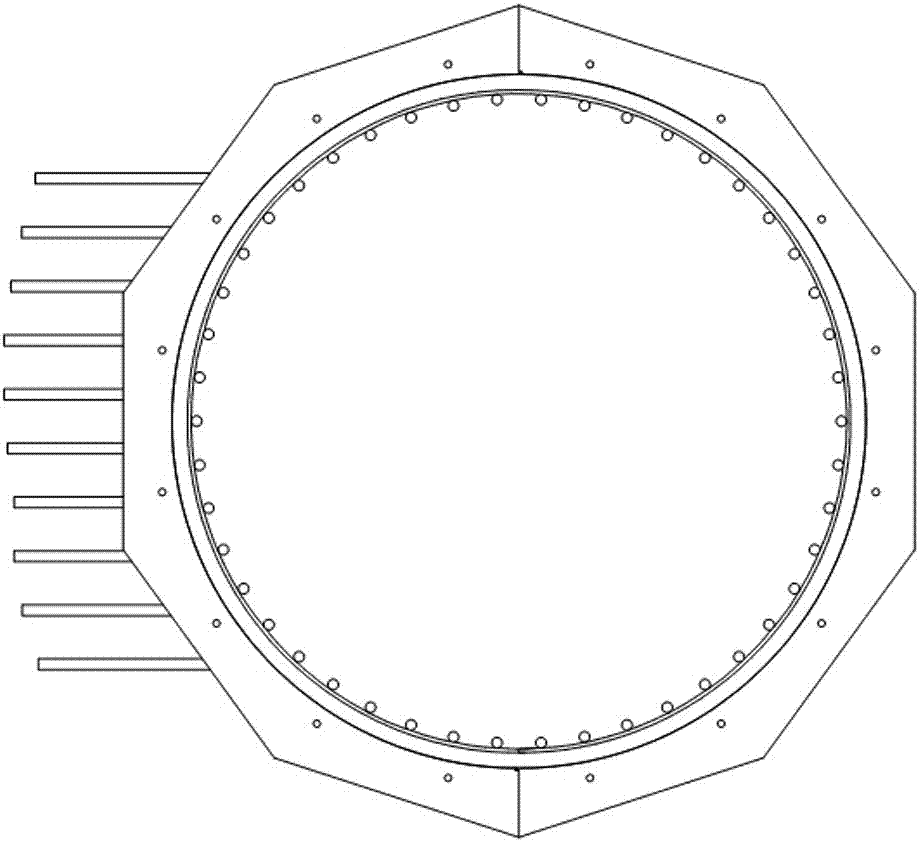

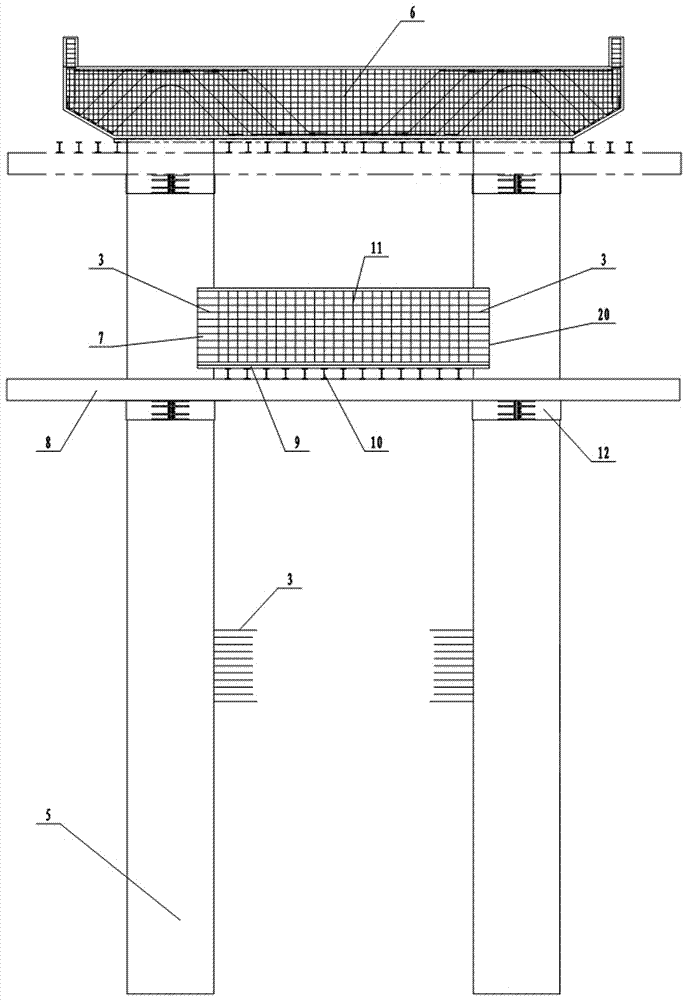

[0072] A bridge with a length of 240m is designed on a rocky half-slope. The upper structure is two sections of 4×30m prestressed concrete first simply supported and then continuous T-beam. According to the height of the pier, there are 1-3 tie beams. If traditional construction methods are used to construct pier columns, tie beams, and cover beams in sequence, some tie beams will have an impact on the original construction access road after construction, and the construction access road route needs to be re-set, and the construction access road level must be raised or widened. The original construction access road, but due to the influence of the geological environment, it is very difficult to construct the second construction access road. In addition, there are many pier columns in this bridge, and the cylindrical formwork cannot be fully and effectively used, which affects the construction progress. The pier column, tie beam, and cover beam are constructed in reverse order...

Embodiment example 2

[0074] The length of a bridge is 510m. The superstructure is 5×30m+2×30m+4×30m+3×30m+3×30m. The prestressed concrete is first simply supported and then continuous T-beam. It is φ1.8m and the height is 8.29m-30.19m According to the practice and experience of Case 1, using the material turnover in Case 1 greatly reduces the cost and saves the construction period. By adopting the invention, the construction period is greatly shortened, and the construction cost is greatly reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com