Metal wire tool for minimally invasive cutting of biological soft tissues

A biological soft tissue and metal wire technology, applied in the field of soft matter and experimental mechanics, can solve the problems of difficulty in obtaining accurate geometric samples, cumbersome operation, limited effect, etc., achieving easy production and promotion, simple production method, and reduced adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Micro-nano texturing method on the surface of molybdenum wire:

[0028] (1) Put molybdenum wire (length: 10cm, diameter: 80μm) into FeCl 3 In etchant (FeCl 3 with H 2 The mass ratio of O is 4:15, and HCl, H 3 PO 4 、H 2 o 2 , its volume ratio to water is 2:2:2:15), etched at room temperature for 5 min.

[0029] (2) Take out the molybdenum wire and ultrasonically clean it with anhydrous ethanol for 30 s to clean the residue on the surface of the molybdenum wire and dry it in the air.

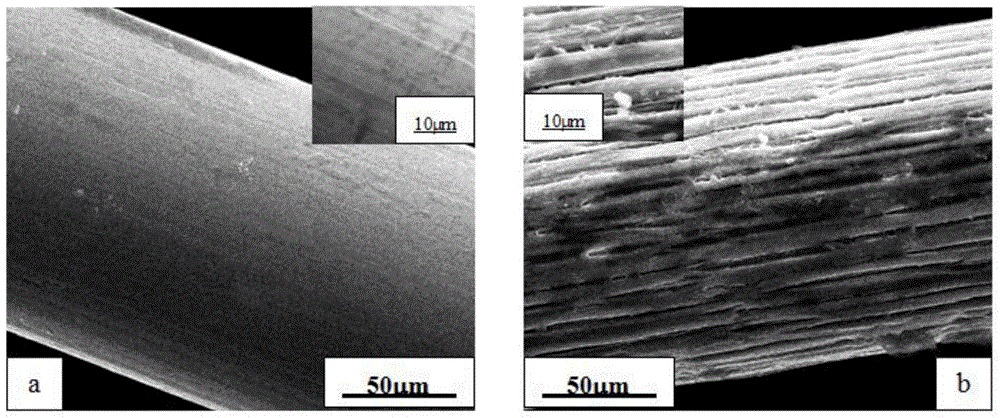

[0030] (3) Scanning electron microscope (SEM) was used to observe the surface morphology of molybdenum wire before and after etching, see attached image 3 .

[0031] (4) Measured by a contact angle measuring instrument, by adjusting the microneedle to drop 2 μl water drop on the molybdenum wire, and measure the static contact angle of the water drop on the surface of the molybdenum wire before and after etching. The static contact angle before etching is 125°; after ...

Embodiment 2

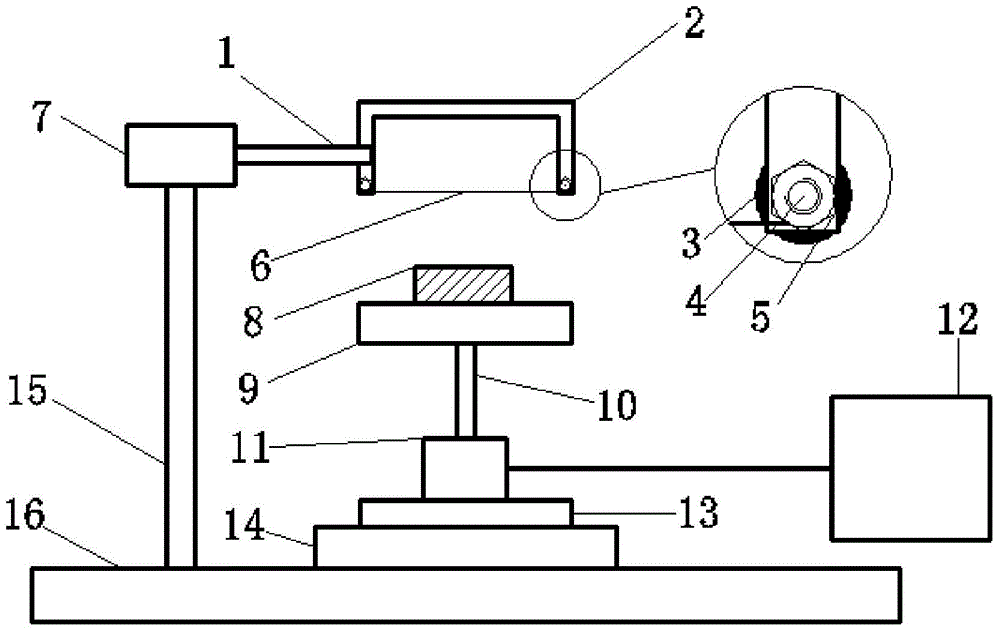

[0033] (1) Put a pair of red steel paper gaskets 3 and bolts 4 in the left and right small holes of the bow-shaped clip 2, slightly tighten the nut 5, and place the etched molybdenum wire 6 between the left and right rubber gaskets 3 and the upper ends of the bolts 4 Make a circle around and continue to screw the nut 5. Turn the nut 5 to tighten the molybdenum wire 6, and use cyanoacrylate to glue the bow clip 2 with the molybdenum wire 6 installed on the appropriate position of the handle 1. The assembled molybdenum wire cutter head is placed on the front end of the medical reciprocating saw 7, and the whole cutter is fixed on the sliding guide rail 15.

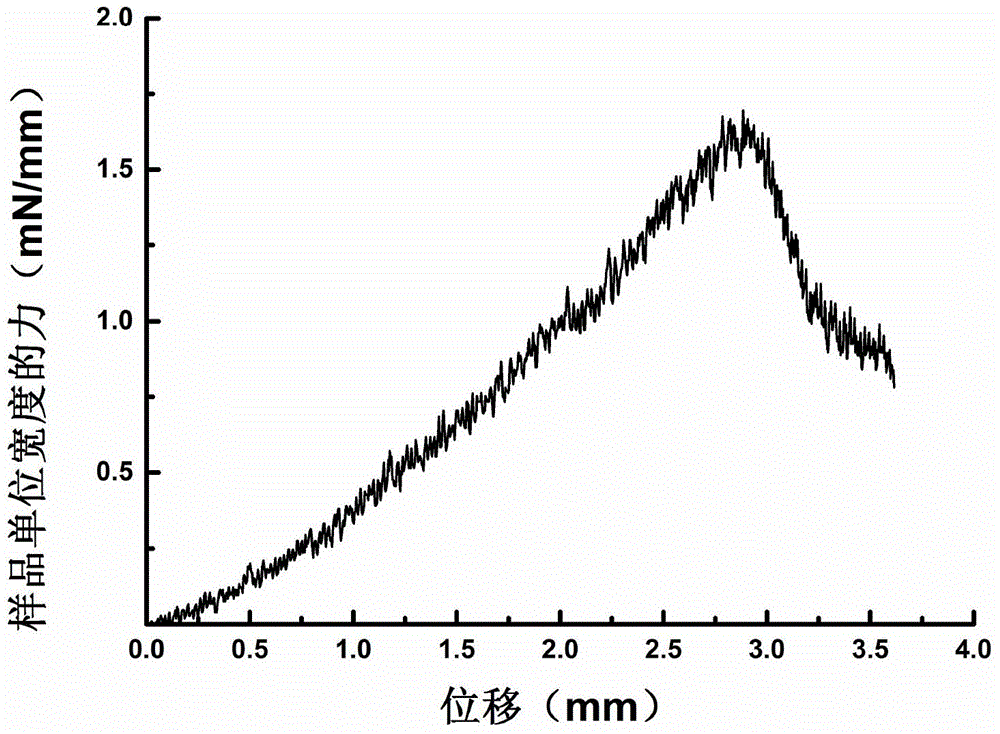

[0034] (2) Place the fresh sheep brain tissue sample 8 on the center of the circular platform 9, turn on the medical reciprocating saw 7 with an amplitude of 3 mm and a frequency of 30 Hz, drive the molybdenum wire cutter to perform reciprocating linear motion, and control the medical reciprocating saw 7 along the sliding gu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com