Differential wire conveyor for diamond wire saw cutter

A technology of diamond wire and saw cutting machine, which is applied in the direction of fine working devices, stone processing tools, stone processing equipment, etc., and can solve problems such as insufficient smoothness of the surface, poor flatness of the processed surface, and inability to meet the quality requirements of high-end product cutting surfaces, etc. , to achieve the effect of smooth cutting surface, improved surface quality and reduced cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The following are examples of the present invention, and the practical use of the present invention is not limited to the examples.

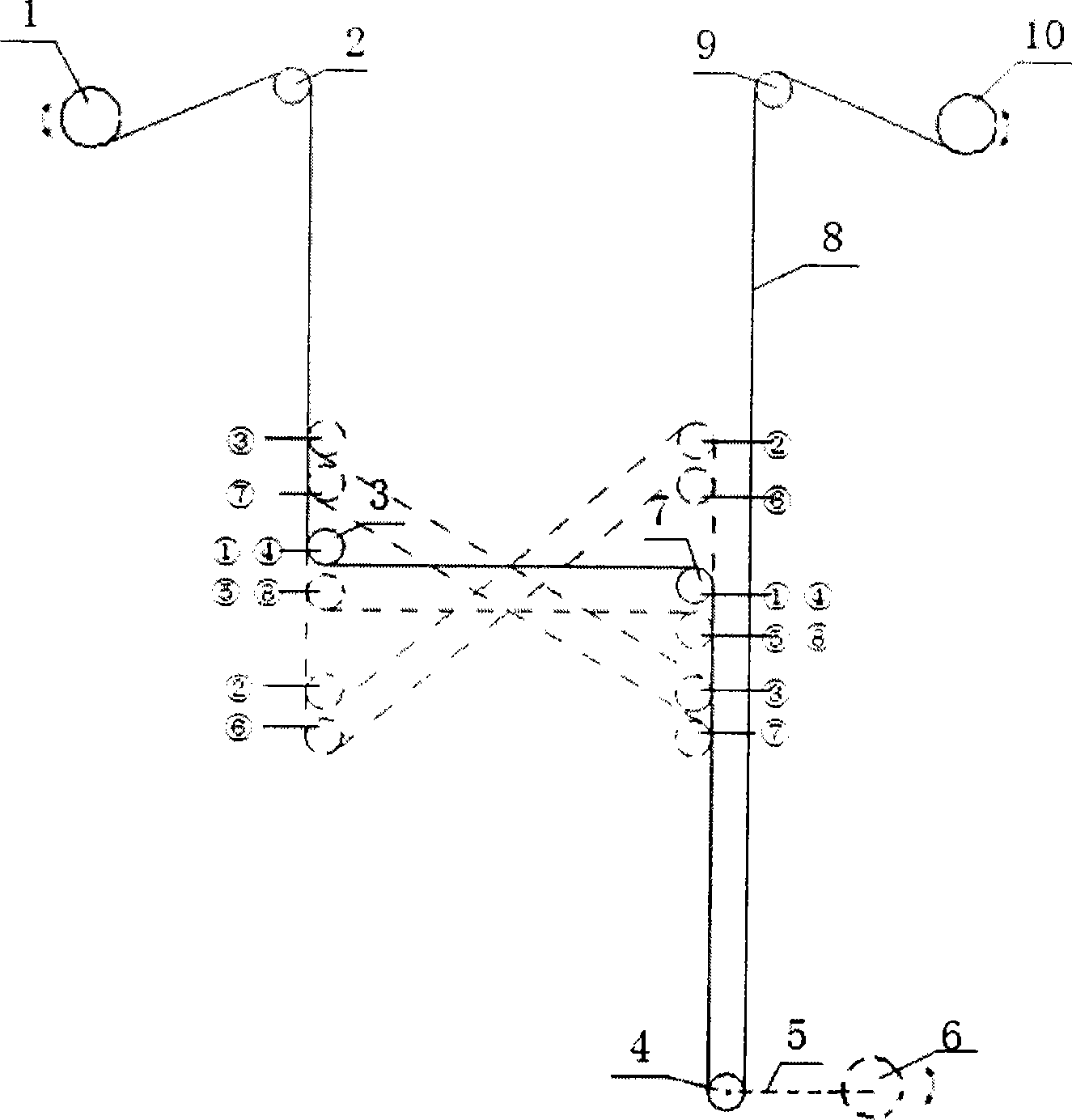

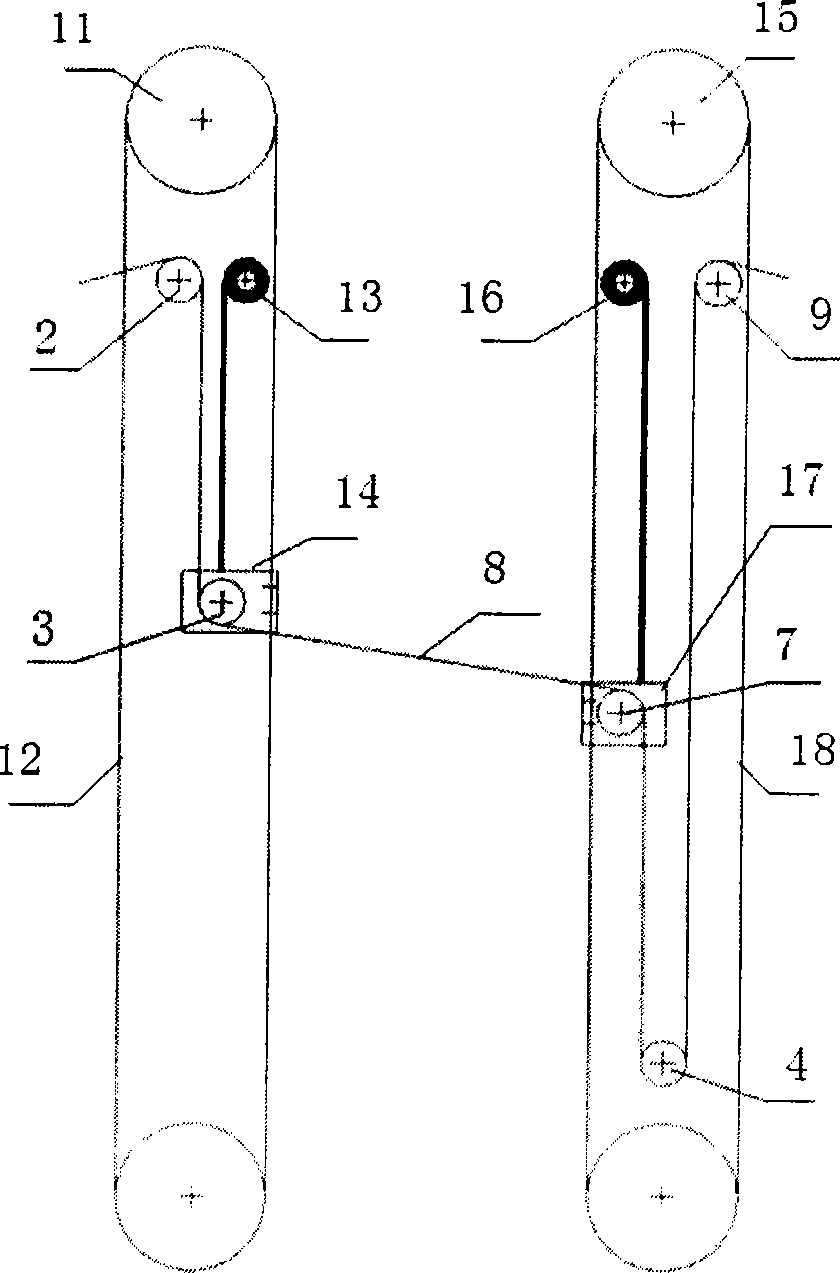

[0010] refer to figure 1 , figure 2 , In this embodiment, the differential wire moving device of the diamond wire saw cutting machine is composed of a wire (winding) cylinder 1 and 10, a wire guide wheel 2 and 9, a differential wheel 3 and 7, and a tension wheel 4. The wire-releasing (rolling wire) cylinders 1 and 10 are respectively driven by two synchronous motors to rotate in the same direction and at the same speed. When the wire feeding (rolling) cylinder 1 and 10 rotate counterclockwise, the wire (winding) cylinder 10 coils the wire, and the wire (winding) cylinder 1 releases the wire; when the wire (winding) cylinder 1 and 10 When rotating in the clockwise direction, the wire feeding (reeling) drum 1 reels the wire, and the wire feeding (reeling) drum 10 reels the wire, thereby realizing the reciprocating circulation of the wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com