Combined plating CBN grinding wheel for camshaft grinding and manufacturing method thereof

A manufacturing method and camshaft technology, which are applied to grinding devices, manufacturing tools, bonded grinding wheels, etc., can solve the problems of grinding linear speed, feed journal size, difficult to control, surface roughness, low efficiency, etc. To achieve the effect of reducing rework operations and efficient grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

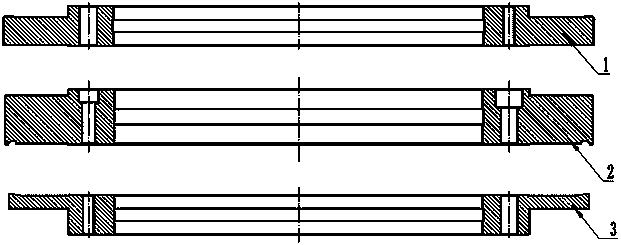

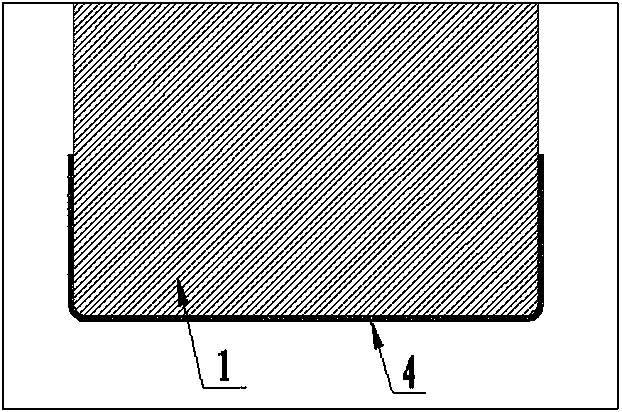

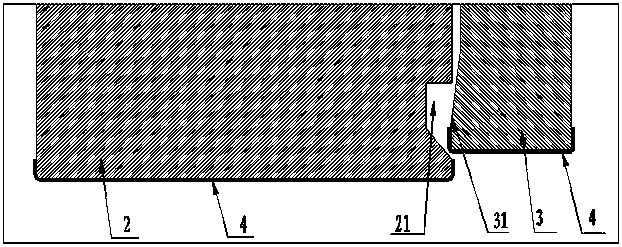

[0035] A combined electroplated CBN grinding wheel for camshaft grinding, comprising a camshaft 7, a combined electroplated CBN grinding wheel sleeved on a main shaft 8 for grinding different parts of the camshaft 7, the camshaft 7 is far away from a part of the combined electroplated CBN grinding wheel The side is top-connected with a guide wheel 6, and the combined electroplated CBN grinding wheel includes grinding wheel 2 for grinding the outer circle of the big head end and the end face, grinding wheel 3 for grinding the outer circle of the big end end, and several grinding wheels 1 for grinding the outer circle of the journal, wherein the outer circle of the big head end is ground And the profile of the end face grinding wheel 2 and the outer circular journal grinding wheel 3 of the large head end is matched. In this embodiment, there are four grinding wheels 1 for grinding outer journals, the outer diameter is 590 mm, the inner hole diameter is 370 mm, and the thickness i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com