Manufacturing method of Mg-based composite wallboard profile

A composite material and a manufacturing method technology, applied in the field of manufacturing magnesium-based composite wall plate profiles, can solve the problems of high bending and torsion of the profiles, easy to get stuck, and achieve the elimination of casting stress, elimination of intragranular segregation, and uniform structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

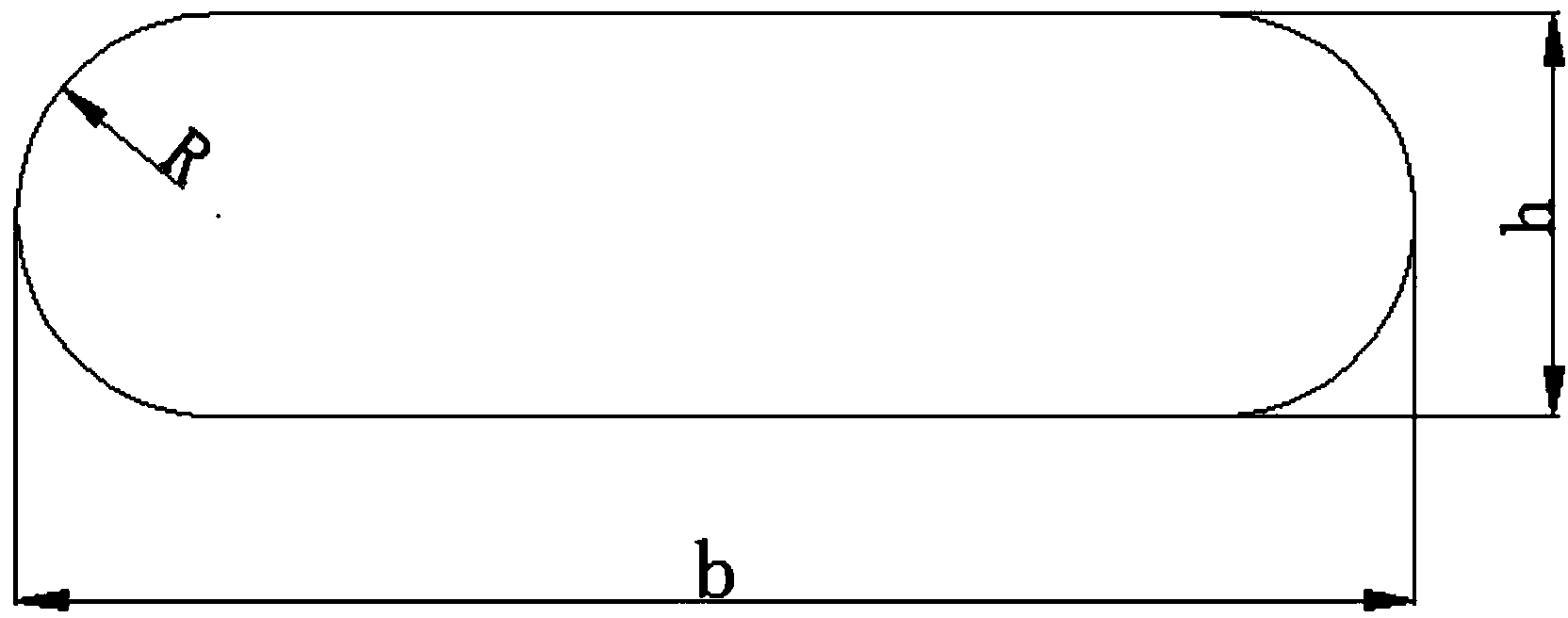

Image

Examples

specific Embodiment approach 1

[0018] Specific implementation mode one: the manufacturing method of the magnesium-based composite material wall plate profile of this implementation mode is implemented according to the following steps:

[0019] 1. According to the mass percentage of elements, Al: 0.2%, Mn: 1.3%-2.2%, Zn: 0.3%, Ce: 0.15%-0.35%, Fe: ≤0.05%, Si: ≤0.1%, Cu: ≤0.05 %, Ni: ≤0.007%, and the balance is Mg. Weigh aluminum ingots, magnesium-manganese master alloys, zinc ingots, magnesium-cerium master alloys, magnesium-iron master alloys, magnesium-silicon master alloys, copper ingots, magnesium-nickel master alloys and magnesium Ingots are used as raw materials, and the raw materials are added to a dry smelting furnace, and smelted at a temperature of 760°C to 780°C for 3.5h to 5h to obtain a magnesium alloy melt;

[0020] 2. Preheat the SiC particles, the preheating temperature is 490℃~510℃, the holding time is 1.5h~2.5h, add the preheated SiC particles into the magnesium alloy melt obtained in step ...

specific Embodiment approach 2

[0031] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, raw materials are added into a dry smelting furnace and smelted at a temperature of 770° C. for 4 hours. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0032] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the particle size of the SiC particles described in Step 2 is 5 μm˜8 μm. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com