Alloy material with high resistivity and high elongation and preparation method thereof

A technology of alloy materials and high resistivity, applied in the field of alloy materials and their preparation, to achieve the effects of subsequent processing such as drawing and rolling, excellent plastic deformation ability, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] (2) a kind of preparation method of the alloy material of high electrical resistivity, high elongation, described method step is as follows:

[0022] ①Smelting: Weigh the raw material according to the chemical composition of the high resistivity alloy material, and prepare the master alloy ingot by vacuum induction melting under the protection of argon;

[0023] ②Remelting and casting: Under the protection of argon, heat the master alloy ingot to 1400-1600°C for remelting, and prepare a high-resistivity alloy material by turning over casting, wherein the current 550A;

[0024] The vacuum degree during melting, remelting and casting is 2.0×10 -3 Pa, the size of the alloy material is 50mm×13mm×40mm.

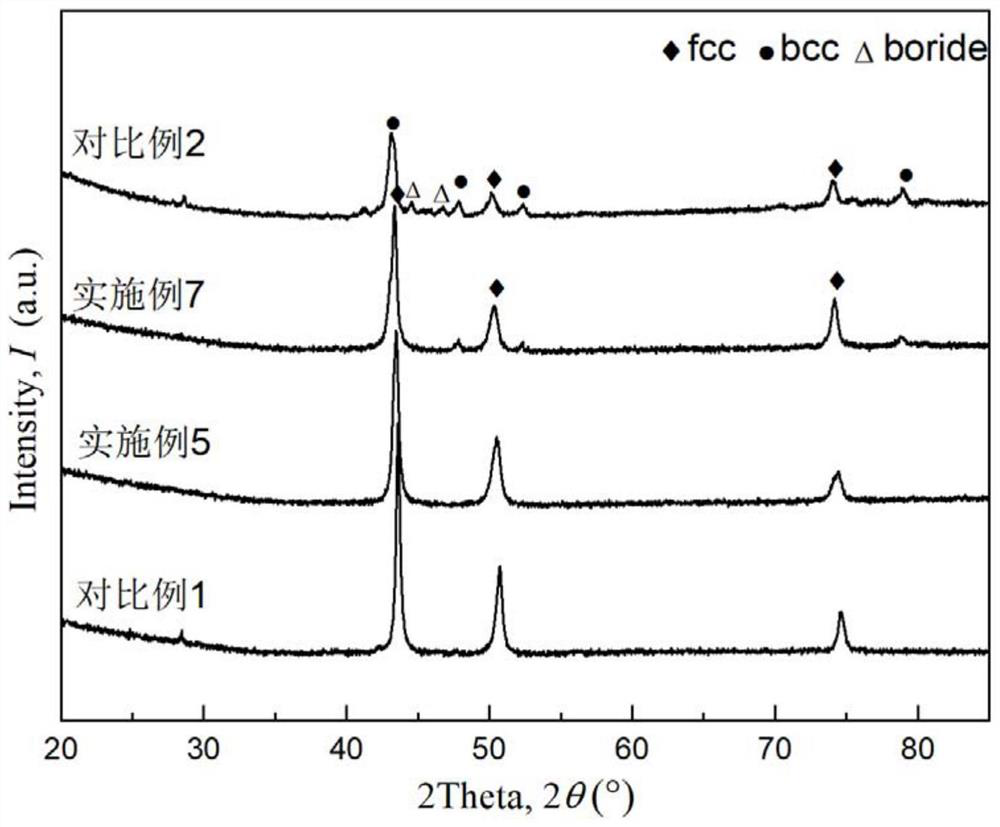

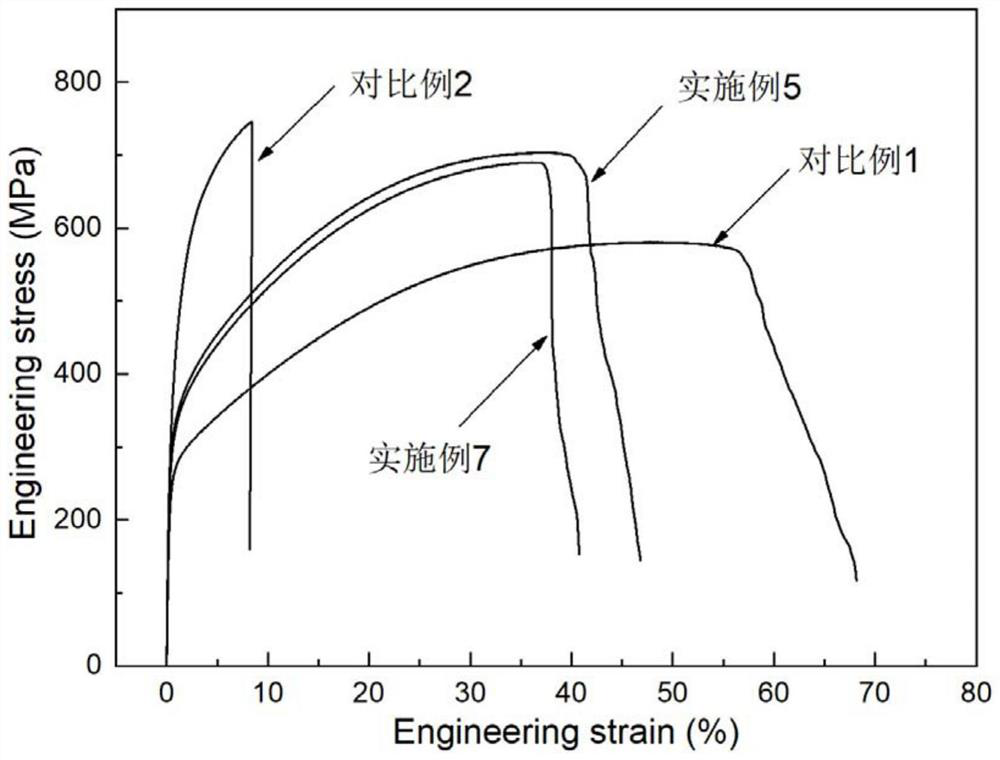

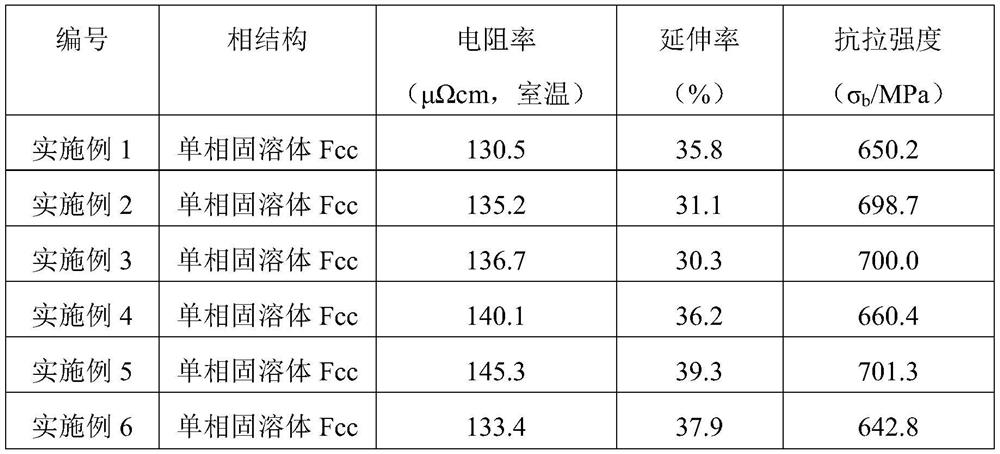

[0025] (3) The microstructure characterization, electrical resistivity and mechanical properties of the prepared alloy materials were tested under the same conditions: the phase structure used Bruker's X-ray diffractometer (D8 ADVANCE), and the test sample size was 10×10× ...

Embodiment 1

[0027] The chemical composition and mass percentage of the alloy material in this embodiment are: iron: 25%, cobalt: 14%, chromium: 10%, aluminum: 0.5%, non-metallic element silicon: 0.5% and boron: 0.5%, the balance For nickel and unavoidable impurities.

Embodiment 2

[0029] The chemical composition and mass percentage of the alloy material in this embodiment are: iron: 17%, cobalt: 25%, chromium: 18%, aluminum: 5%, silicon: 0.3%, boron: 0.8%, and the balance is nickel and unavoidable impurities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com