Gas shielded welding technology of steel for Q960 ultrahigh-strength steel structure

A gas shielded welding, ultra-high strength technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of joint performance cannot be guaranteed, no application, lack of experience, etc., to reduce hardenability and sensitivity , Avoid the effect of welding cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The features and principles of the present invention will be described in detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

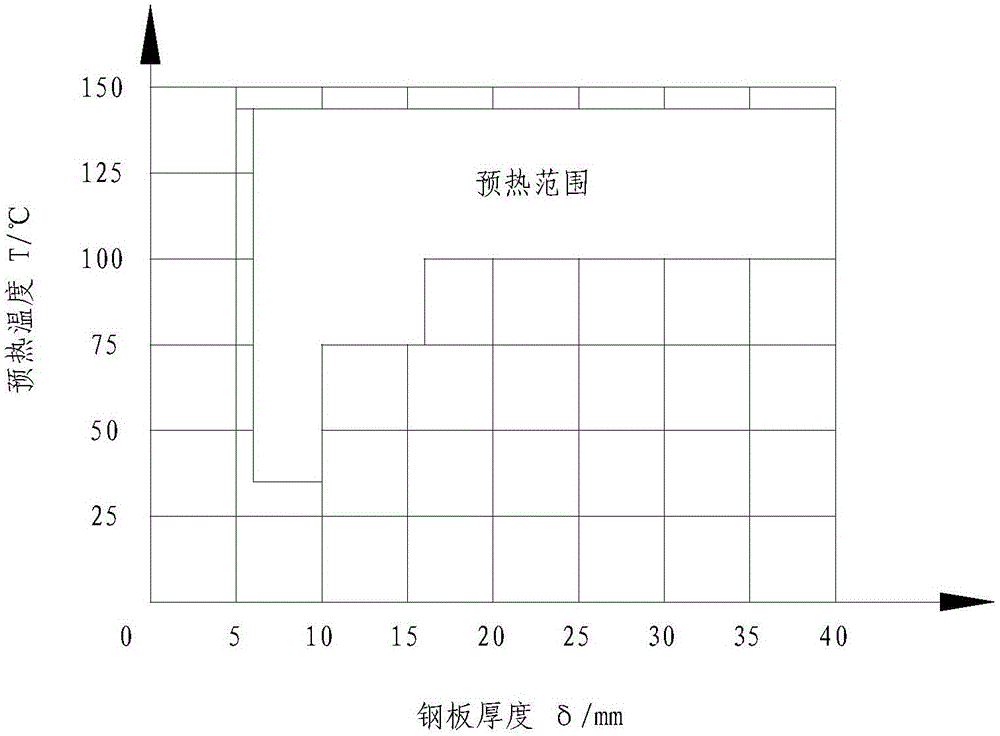

[0020] The gas-shielded welding process of the Q960 ultra-high-strength steel structural steel is characterized in that the process includes the following steps:

[0021] Pre-treat the steel plate before welding to ensure that there is no oil, moisture, rust, etc. within 50mm of the groove to be welded and both sides of the groove until the metallic luster is exposed, and ensure that there are no cracks, delamination and other defects within the cleaning range.

[0022] The diameter of solid wire welding wire is 1.2mm, and the weight percentage of its chemical composition is: C: 0.08-0.15%, Si: 0.65-0.75%, Mn: 0.75-0.80%, P: ≤0.01%, S: ≤0.008%, Cr: 0.20~0.22%, Ni: 1.25~1.30%, Cu: 0.12~0.18%, Mo: 0.25~0.28%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com