Double-phase double-lattice light high-entropy alloy and preparation method thereof

A high-entropy alloy and coherent technology, applied in the field of dual-phase dual-coherent light-weight high-entropy alloy and its preparation, can solve problems such as the incompatibility of alloy strength and plasticity, and achieve improved mechanical properties, wide application prospects, and preparation effects. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

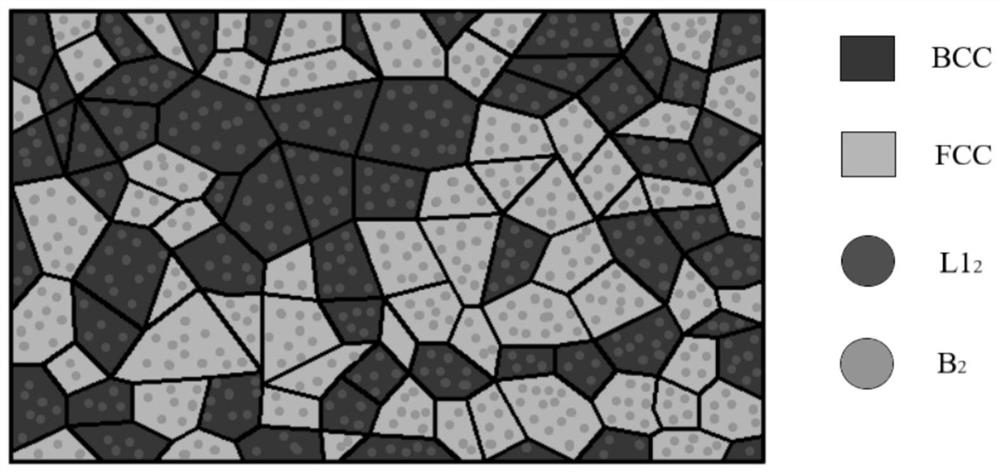

[0026] Embodiment 1: by Al 40 (TiV) 40 Si 2 The atomic mole percentage of the light high-entropy alloy is batched; the prepared raw materials are placed in the crucible according to the melting point, and the elements with high melting point are at the top, and the elements with low melting point are at the bottom. The background vacuum is 1×10 -3 Pa, under the protection of argon, the high-entropy alloy block is obtained by melting; the high-entropy alloy block is placed in a high-vacuum tube furnace, and the vacuum is evacuated to 6×10 -4 Pa, and heated to a heat treatment temperature of 900 ° C, holding time of 12 hours, cooled to room temperature with the furnace, the alloy is a FCC / BCC two-phase double-precipitation coherent structure, and the theoretical density is 4.06g / cm 3 , hardness 480HV, high temperature performance 640 ℃.

Embodiment 2

[0027] Example 2: Al 40 (TiV) 40 Si 2 The atomic mole percentage of the light high-entropy alloy is batched; the prepared raw materials are placed in the crucible according to the melting point, and the elements with high melting point are at the top, and the elements with low melting point are at the bottom. The background vacuum is 1×10 -3 Pa, under the protection of argon, the high-entropy alloy block is obtained by melting; the high-entropy alloy block is placed in a high-vacuum tube furnace, and the vacuum is evacuated to 6×10 -4 Pa, and heated to a heat treatment temperature of 900°C, holding time for 12 hours, air cooled to room temperature, the alloy is a FCC / BCC two-phase double-precipitation coherent structure, and the theoretical density is 4.06g / cm 3 , hardness 490HV, high temperature performance 620 ℃.

Embodiment 3

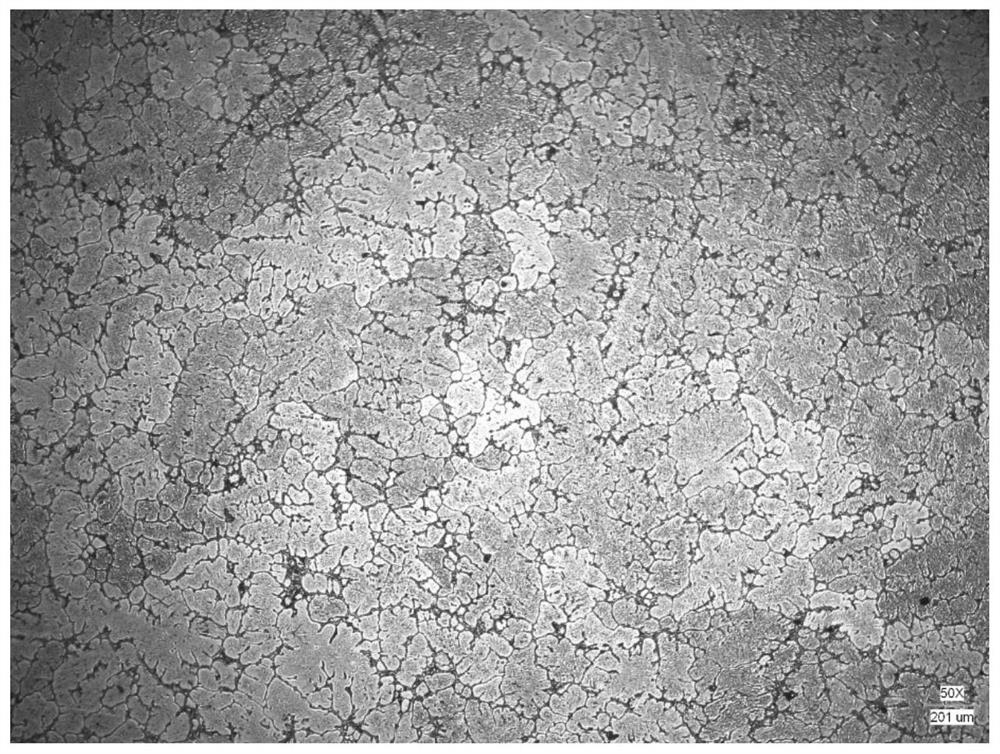

[0028] Example 3: Al 40 (TiV) 40 Si 2 The atomic mole percentage of lightweight high-entropy alloys is used for batching; the background vacuum is 1×10 -3 Pa, under the protection of argon, the high-entropy alloy block is obtained by melting; the high-entropy alloy block is placed in a high-vacuum tube furnace, and the vacuum is evacuated to 6×10 -4 Pa, and heated to a heat treatment temperature of 900°C, holding time for 12 hours, cooled to room temperature with water, the alloy is a FCC / BCC two-phase double-precipitation coherent structure, and the theoretical density is 4.06g / cm 3 , hardness 500HV, high temperature resistance 610 ℃. Such as figure 2 As shown, the alloy has a dual-phase structure and contains nanoscale precipitated phases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Theoretical density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com