One-time formed methanal-free compound panel and processing technique

A processing technology and a technology for composite boards, applied in wood processing equipment, lamination devices, lamination, etc., can solve the problems of the decline in the online pass rate of the boards and the increase in production costs, and achieve excellent surface quality, improved screw holding force, and equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

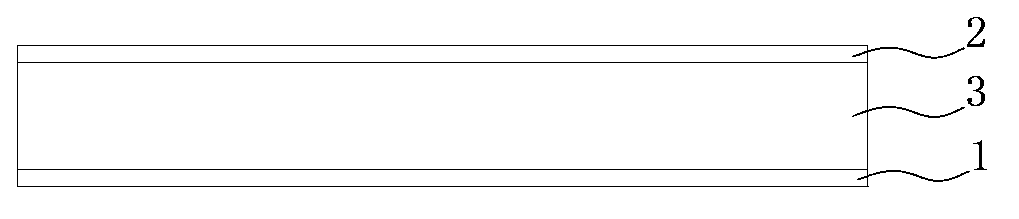

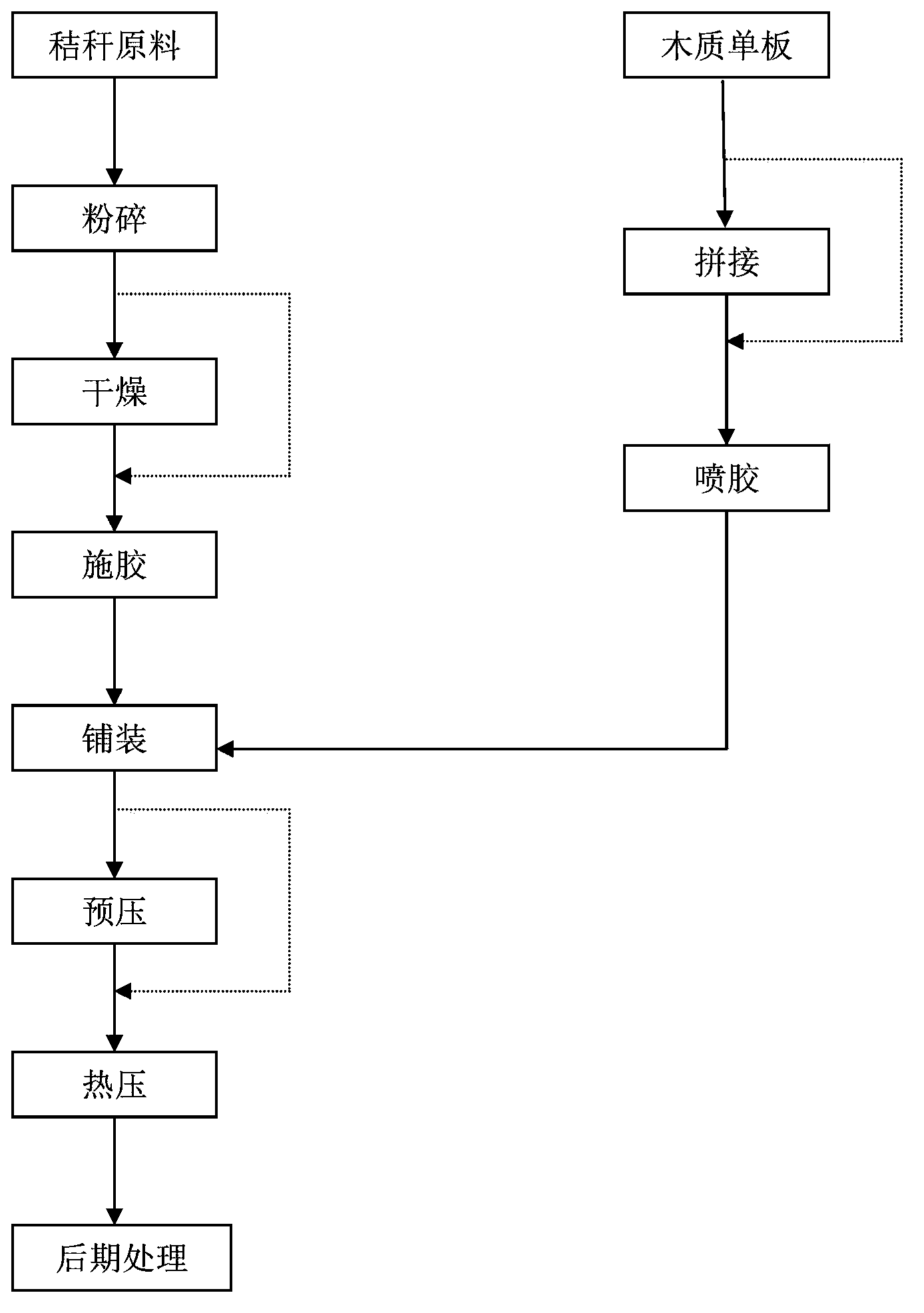

[0038] Example 1: Formaldehyde-free wheat straw board composite board formed at one time

[0039] (1) Preparation of materials:

[0040] Wheat straw (origin: Cao County, Shandong) is crushed by a crushing device (screen with 7mm square holes) to obtain wheat straw raw materials for the production of one-time formaldehyde-free composite boards, and the moisture content of the raw materials is 12.6%.

[0041] The bottom and surface wood veneers are 2mm thick fast-growing poplar veneers (origin: Caoxian, Shandong), and the moisture content of the veneers is 25%.

[0042] (2) Glue sizing: in a mixer, atomize isocyanate (pMDI) adhesive and mix evenly with wheat straw raw materials, the glue amount is 4% of the dry weight of wheat straw raw materials; spray glue on one side of poplar veneer surface , the amount of spray glue is 15g / m 2 . The adhesive used was Huntsman Suprasec 5005.

[0043] (3) Paving preload:

[0044] To manufacture 18mm thick wheat straw composite board, take ...

Embodiment 2

[0054] Example 2: Formaldehyde-free wheat straw board composite board formed at one time

[0055] (1) Material preparation:

[0056] Wheat straw (origin: Cao County, Shandong) is crushed by a crushing device (screen with 7mm square holes) to obtain wheat straw raw materials for the production of formaldehyde-free composite boards. The moisture content of the raw materials is 11.2%.

[0057] The bottom and surface wood veneers are 1.7mm thick fast-growing eucalyptus veneers (origin: Nanning, Guangxi), and the moisture content of the veneers is 19%.

[0058] (2) Glue sizing: in a mixer, atomize isocyanate (pMDI) adhesive and mix evenly with wheat straw raw materials, the amount of glue is 3.7% of the dry weight of wheat straw raw materials; eucalyptus veneer surface single-sided spray glue , the amount of spray glue is 20g / m 2 . The adhesive used was Huntsman Suprasec 5005.

[0059] (3) Pavement preloading:

[0060] To manufacture wheat straw composite panels with a thickne...

Embodiment 3

[0073] Example 3: Formaldehyde-free corn stalk board composite board formed at one time

[0074] (1) Preparation of materials:

[0075] Corn stalks (origin: Shuangcheng, Heilongjiang) were crushed by a crushing device (screen with 7mm round holes) to obtain corn stalk raw materials for the production of formaldehyde-free composite panels with a moisture content of 13.6%.

[0076] The bottom and surface wood veneers are 1.7mm thick fast-growing eucalyptus veneers (origin: Nanning, Guangxi), and the moisture content of the veneers is 19%.

[0077] (2) Glue sizing: In a mixer, atomize the isocyanate (pMDI) adhesive and mix it evenly with the corn stalk raw material, the glue amount is 3.0% of the absolute dry weight of the corn stalk raw material; spray glue on one side of the eucalyptus veneer surface , the amount of spray glue is 20g / m 2 . The adhesive used was Huntsman Suprasec 5005.

[0078] (3) Pavement preloading:

[0079] To manufacture corn stalk composite panels wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com