Patents

Literature

64results about How to "Not easy to crack and damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thin-wall tube for hollowing out concrete

InactiveCN1401865ASolve the anti-deformationImprove tensile propertiesFloorsUltimate tensile strengthHollow core

A thin-wall hollow pipe for in-situ pouring bar reinforced non-beam concrete floor is composed of pipe wall and two end plugs, and is characterized by that each end plug has at least one thin strip for improving its tension, tension and compression resistance. Its advantages are simple structure, high strength, high crack, deformation and vibration resistance and low cost.

Owner:湖南邱则有专利战略策划有限公司

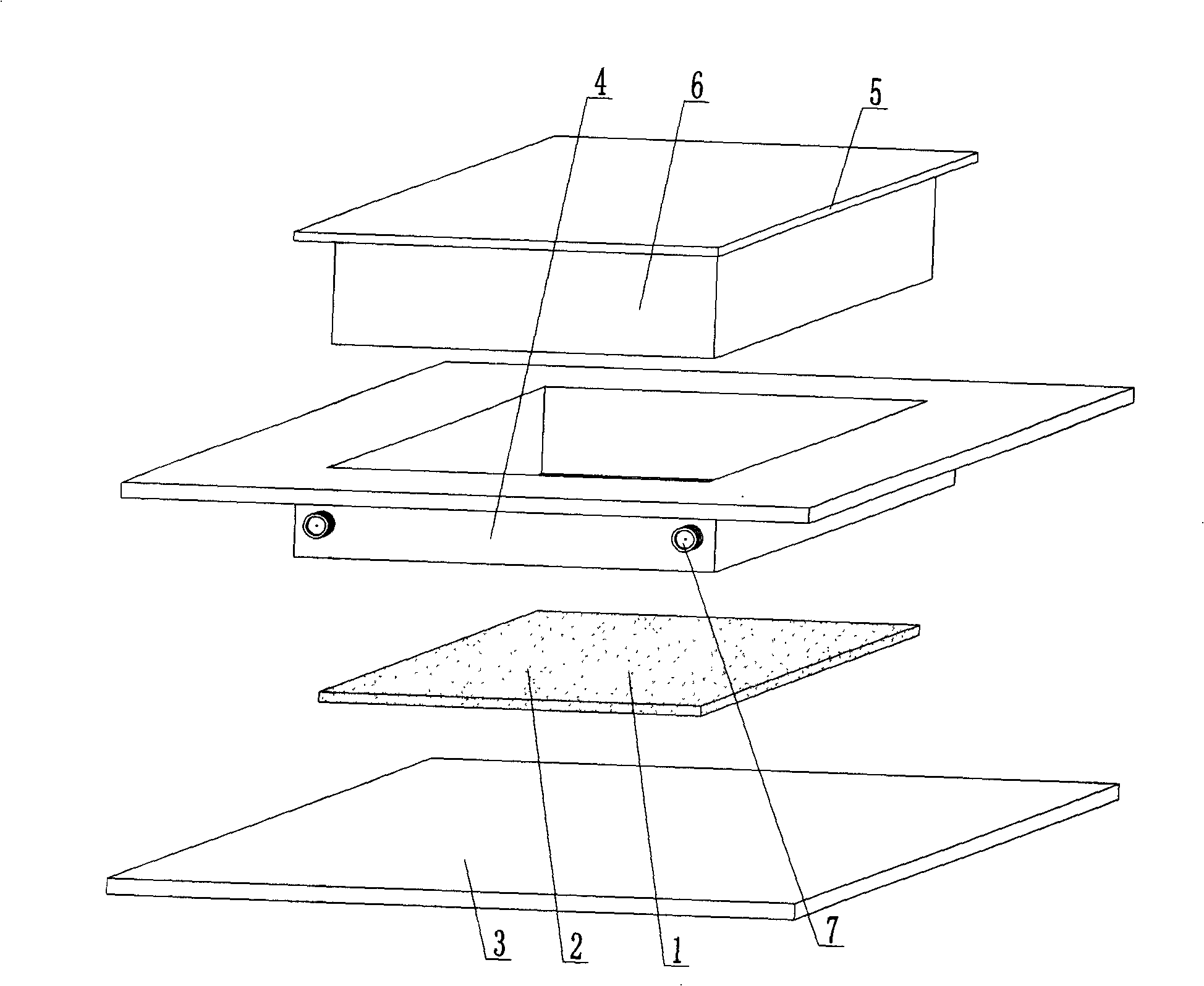

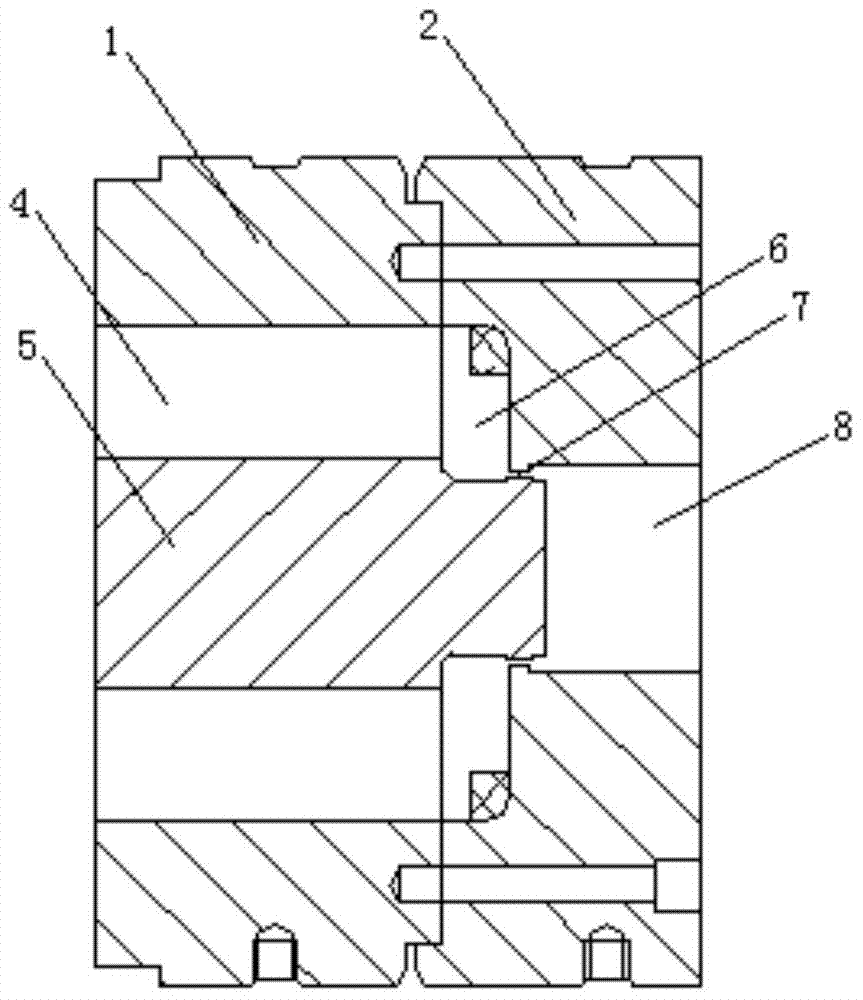

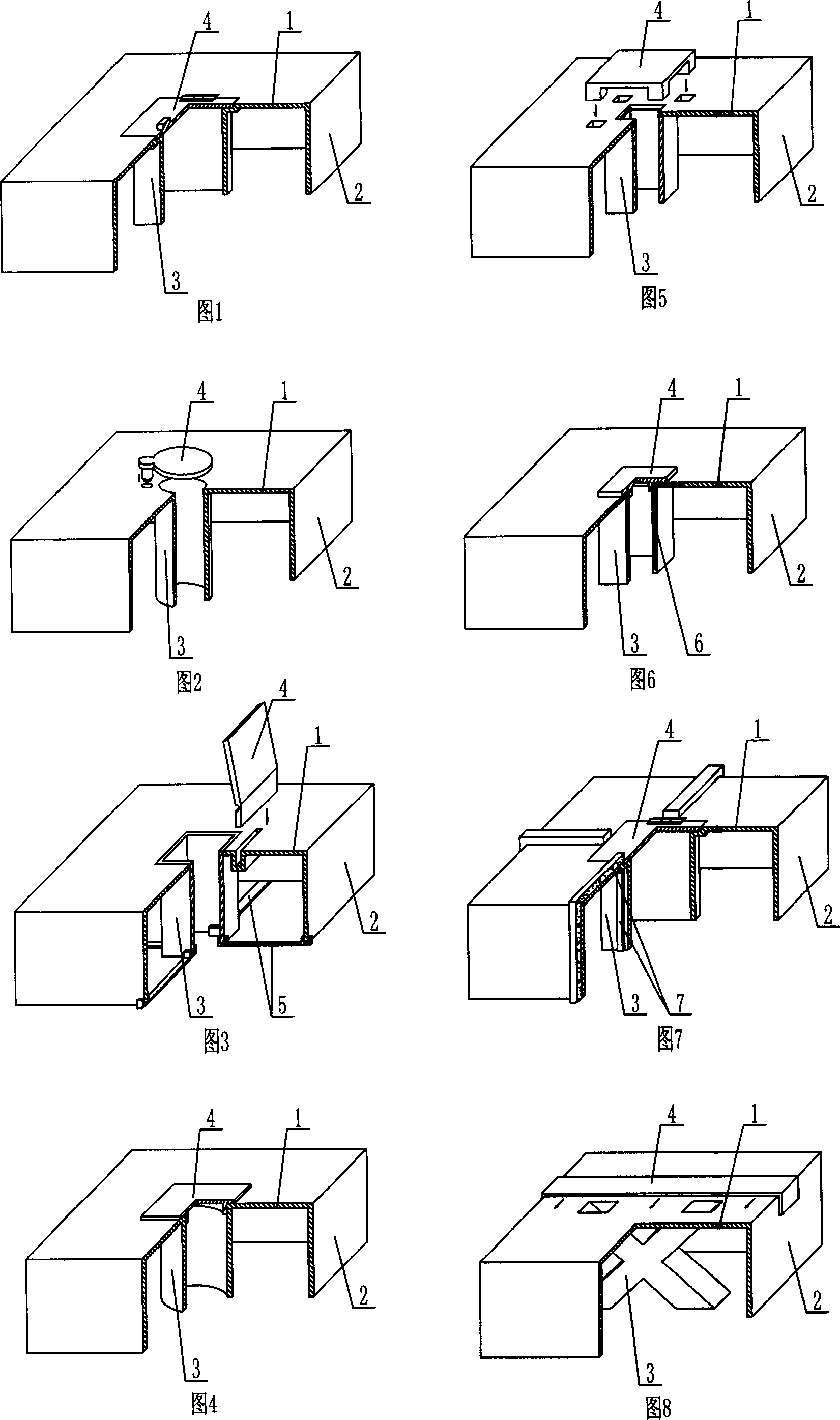

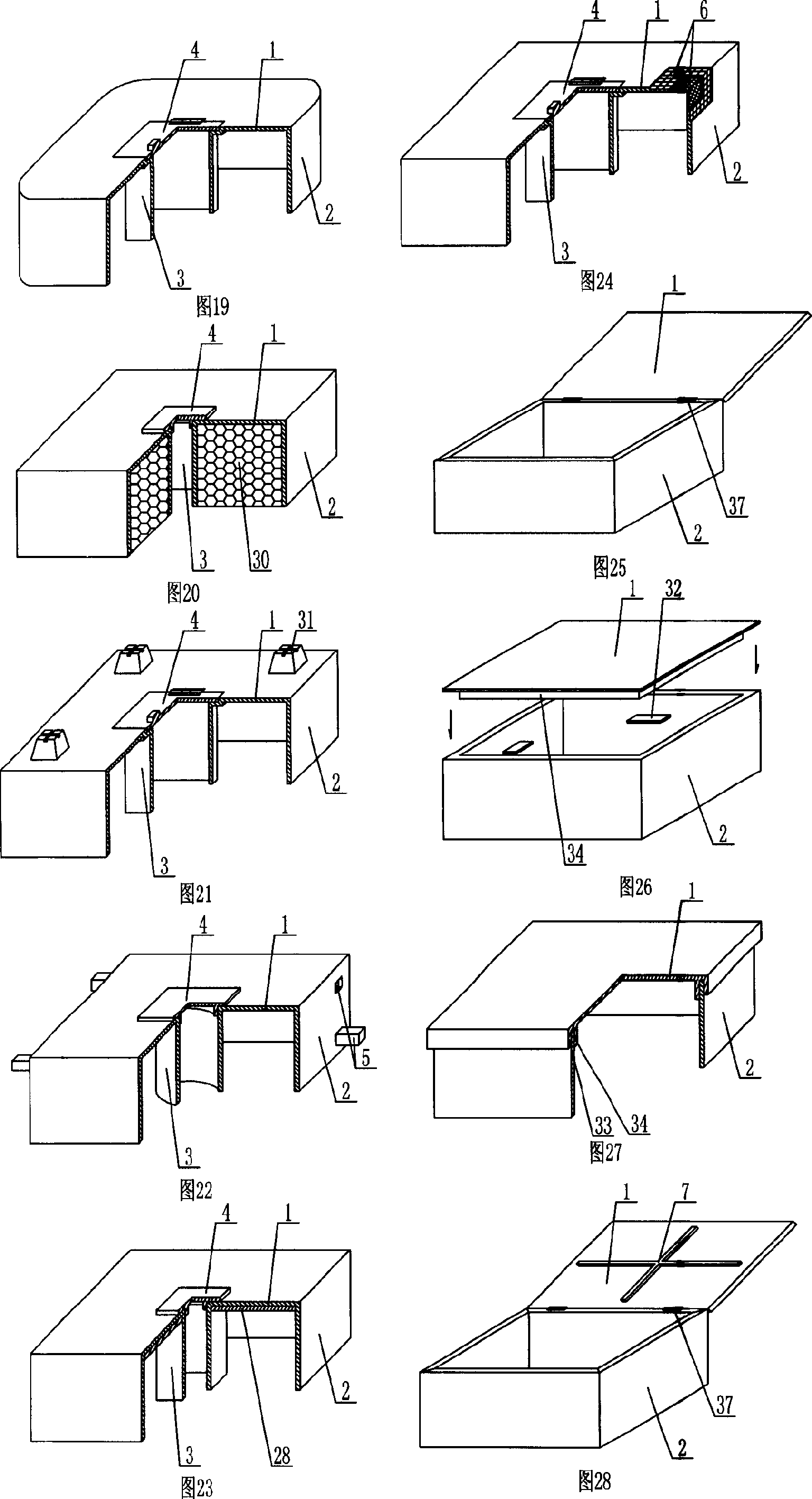

Prefabricated element for floor

InactiveCN101260712AQuality assuranceEffective dispersionFloorsCeramic shaping apparatusFloor slabReinforced concrete

The invention relates to a prefabricated component for floor slabs, comprising a prefabricated concrete plate (1). The prefabricated component is characterized in that: in the prefabricated concrete plate (1), bar reinforced concrete materials (2) are arranged on a bottom molding board (3) and inside a side mold frame (4); an upper press plate (5) which moves in the vertical direction to pressurize is arranged above the bar reinforced concrete materials (2); a pressure head (6) is arranged under the upper press plate (5); a vibrator (7) is arranged on the bottom molding board (3) or / and the upper pressure head (6) or / and the side mold frame; the prefabricated concrete plate (1) is formed by pressing of upper pressure head (6) compression or vibrating pressure head (6) compression and simultaneously by vibration of the bottom molding board (3), thereby forming a plate-shaped component formed by pressurizing and vibrating an upper splint and a lower splint of a lower mold board and the upper pressure head (6). The prefabricated component can be applied to various constructions such as cast-in-place slab floors, roofs, walls, foundation mats and road and bridge works, and is especially suitable for hollow flat slabs.

Owner:湖南邱则有专利战略策划有限公司

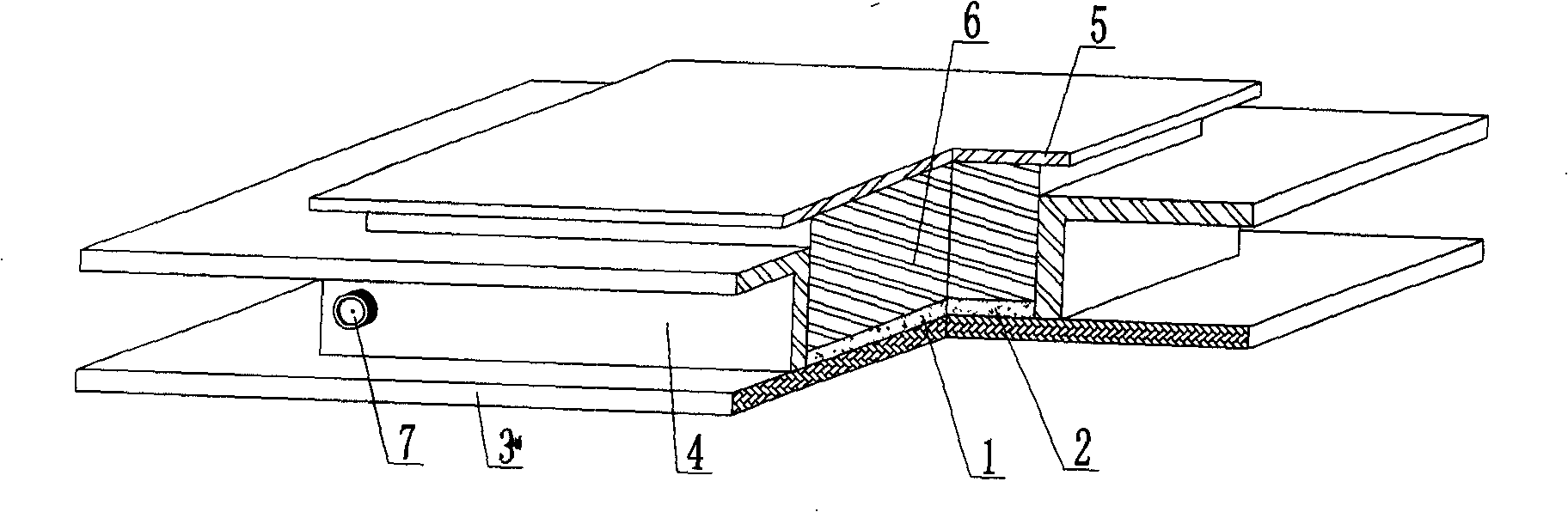

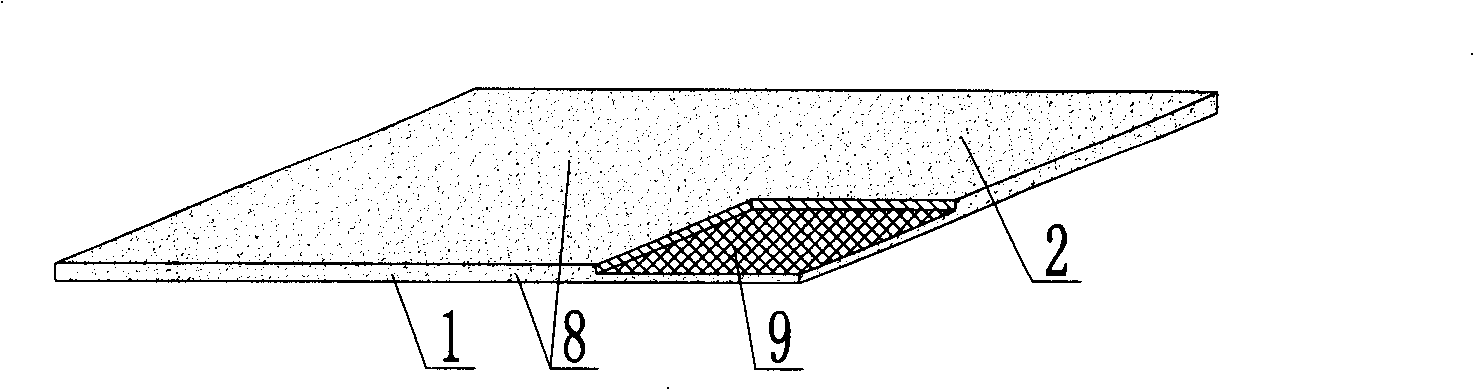

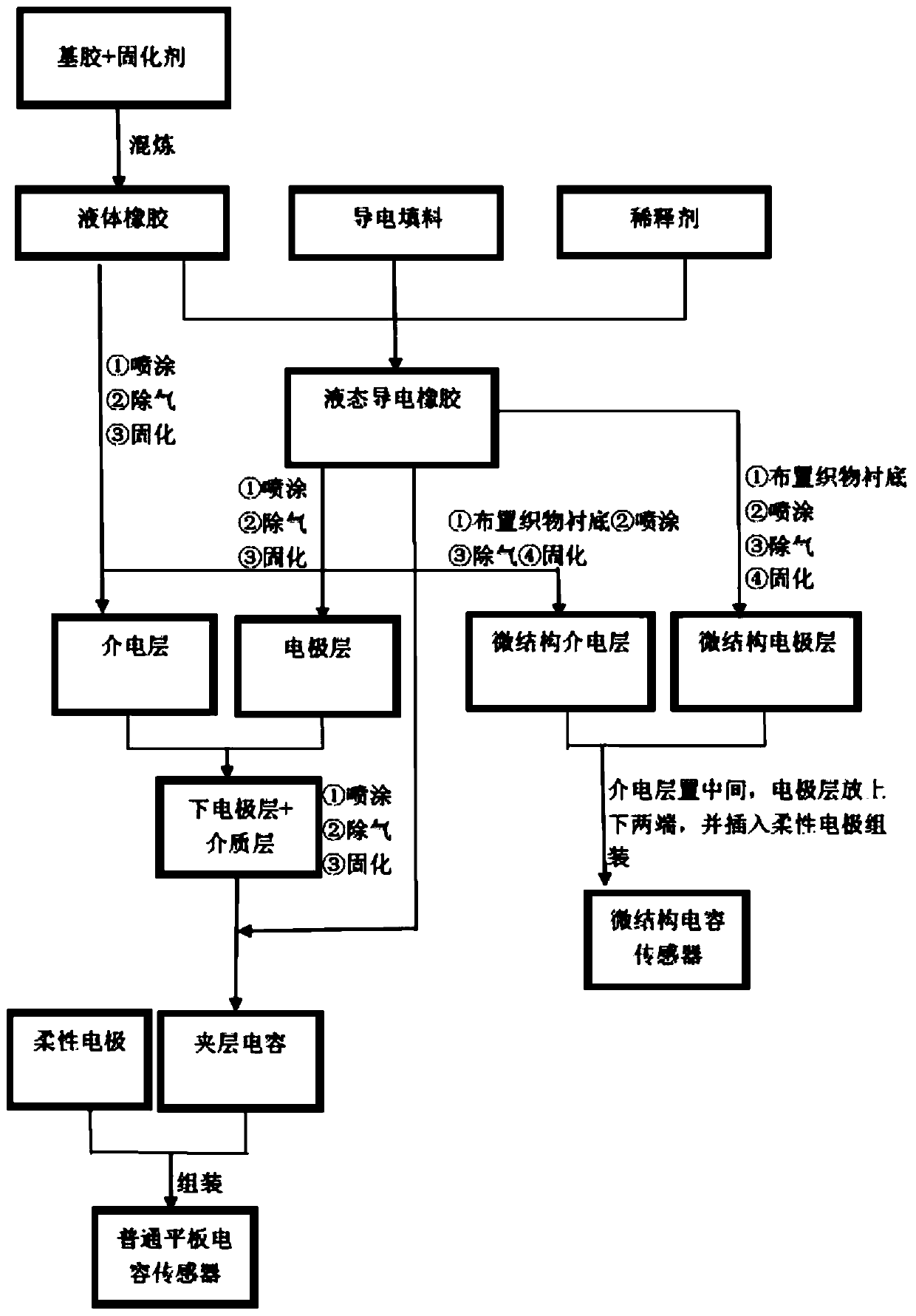

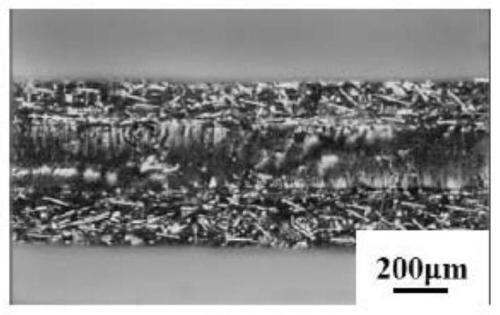

Flexible capacitive sensor based on conductive rubber

ActiveCN109883582AThe overall thickness is thinThickness securityForce measurementSignal responseDiluent

The invention provides a flexible capacitive sensor based on conductive rubber. According to the sensor, flexible conductive rubber is used as a conductive pole plate, flexible pure rubber is used asa dielectric layer, a spraying process is utilized to prepare all layers of the capacitive sensor, and a surface microstructure is used as assistance. The prepared flexible capacitive sensor makes a remarkable signal response to an external load and can be used for stretching, compression and movement tests, wherein the pure rubber of the dielectric layer is prepared by mixing 80-90wt% of liquid rubber and 10-20wt% of a curing agent; the conductive rubber is prepared by mixing 40wt%-60wt% of liquid rubber, 10-15wt% of a curing agent, 20wt%-30wt% of a conductive filler and 10-20wt% of a diluent; and through layered spraying and step-by-step or overall curing, the flexible capacitive sensor with a good mechanical signal response is obtained. According to the capacitor, the conductive pole plate layer is conductive rubber, the dielectric layer is pure liquid rubber, and therefore the capacitor is a complete flexible sensor in a true sense.

Owner:BEIJING UNIV OF TECH

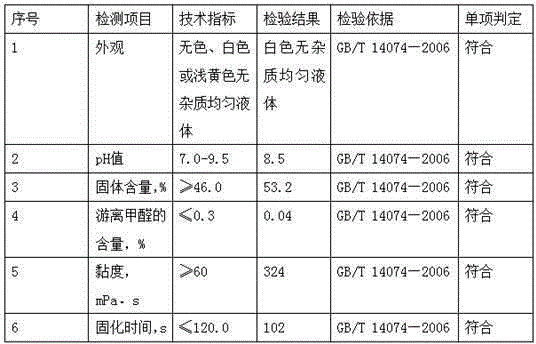

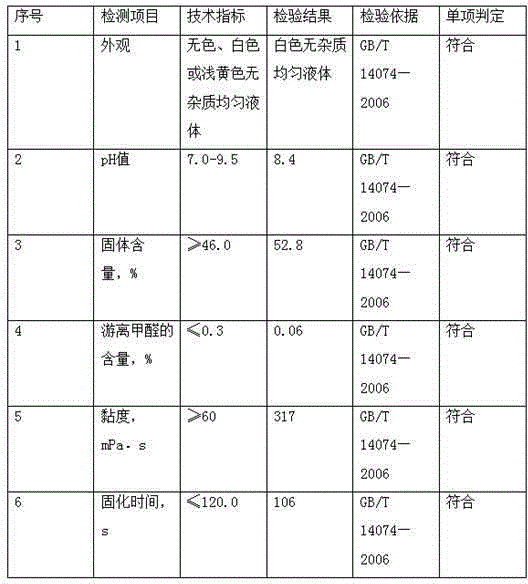

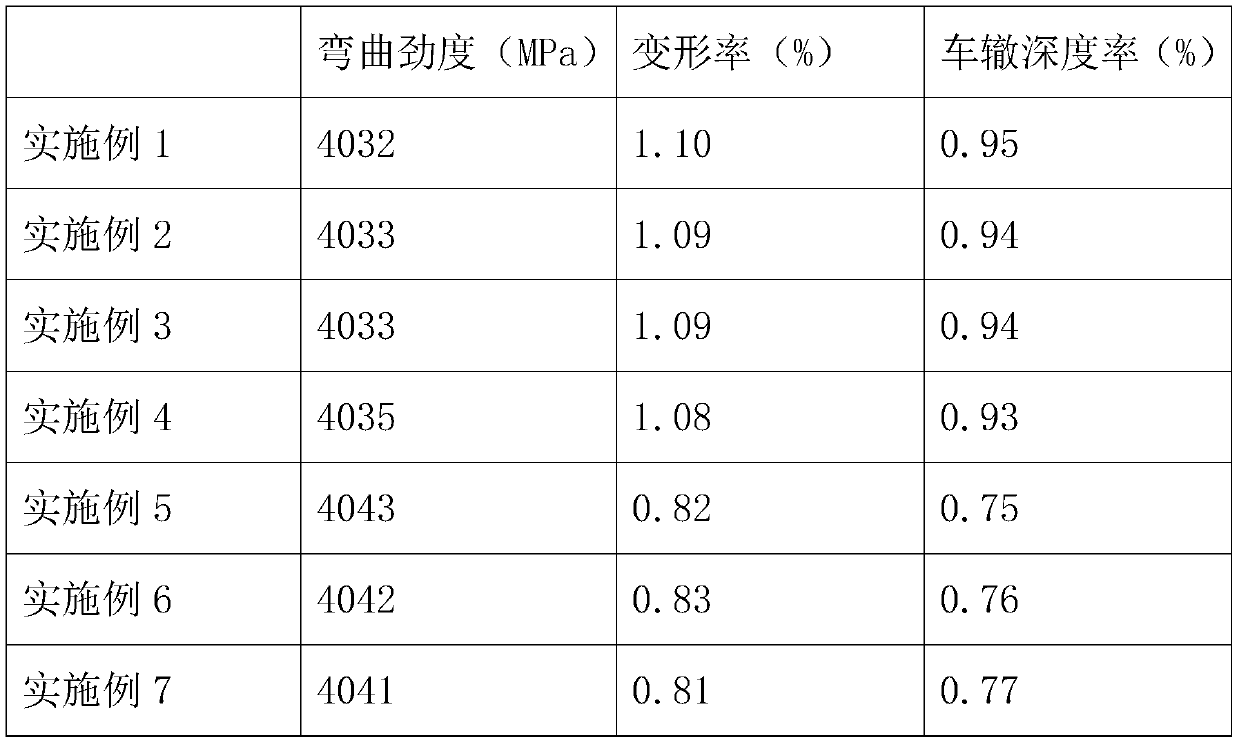

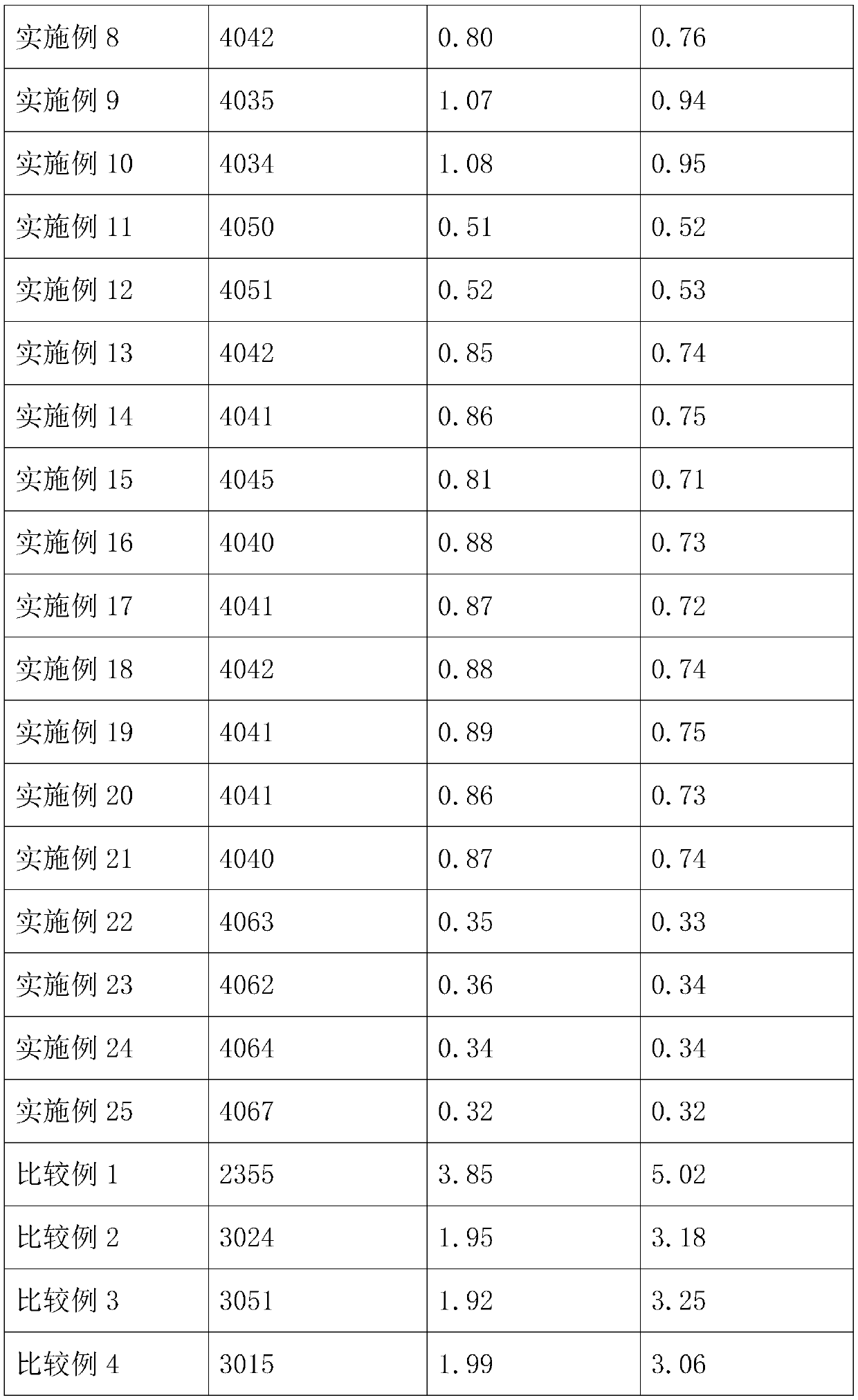

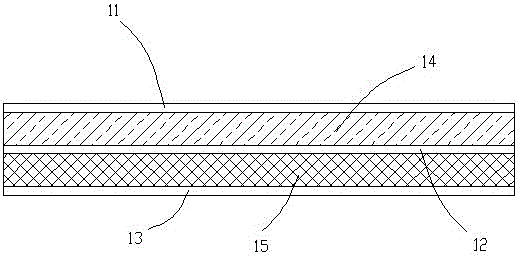

Method for manufacturing moth-proof and low-formaldehyde wardrobe plate

ActiveCN105108841AResidue reductionImprove water resistanceLaminationLamination apparatusAdhesiveMoisture resistance

The invention relates to a building material for home furnishing, in particular to a method for manufacturing a moth-proof and low-formaldehyde wardrobe plate. The method for manufacturing the moth-proof and low-formaldehyde wardrobe plate is characterized by comprising the steps of lathing a plank into pieces, conducting drying, trimming edges, applying adhesive, conducting prepressing, conducting hot-pressing, sanding cut edges, conducting moth proofing treatment, attaching abrasion resistant paper, conducting decoration veneering and sealing the edges. According to the method for manufacturing the wardrobe plate, the formaldehyde residual amount is small, an aluminum alloy frame is inlaid at the periphery of the wardrobe plate, moisture in the air can be effectively prevented from permeating the plate, the moisture resistance and water resistance of the wardrobe plate are improved, the wardrobe plate obtained through the manufacturing method has good moth prevention performance, mold prevention performance, moisture protection performance and abrasion resistant performance, the formaldehyde residual amount is small, damage to a human body is reduced, the obtained wardrobe plate is stable in quality, the dimension stability is good, the plate is not prone to being cracked, damaged or deformed, and the service life is long.

Owner:广州市艾依格家居制品有限公司

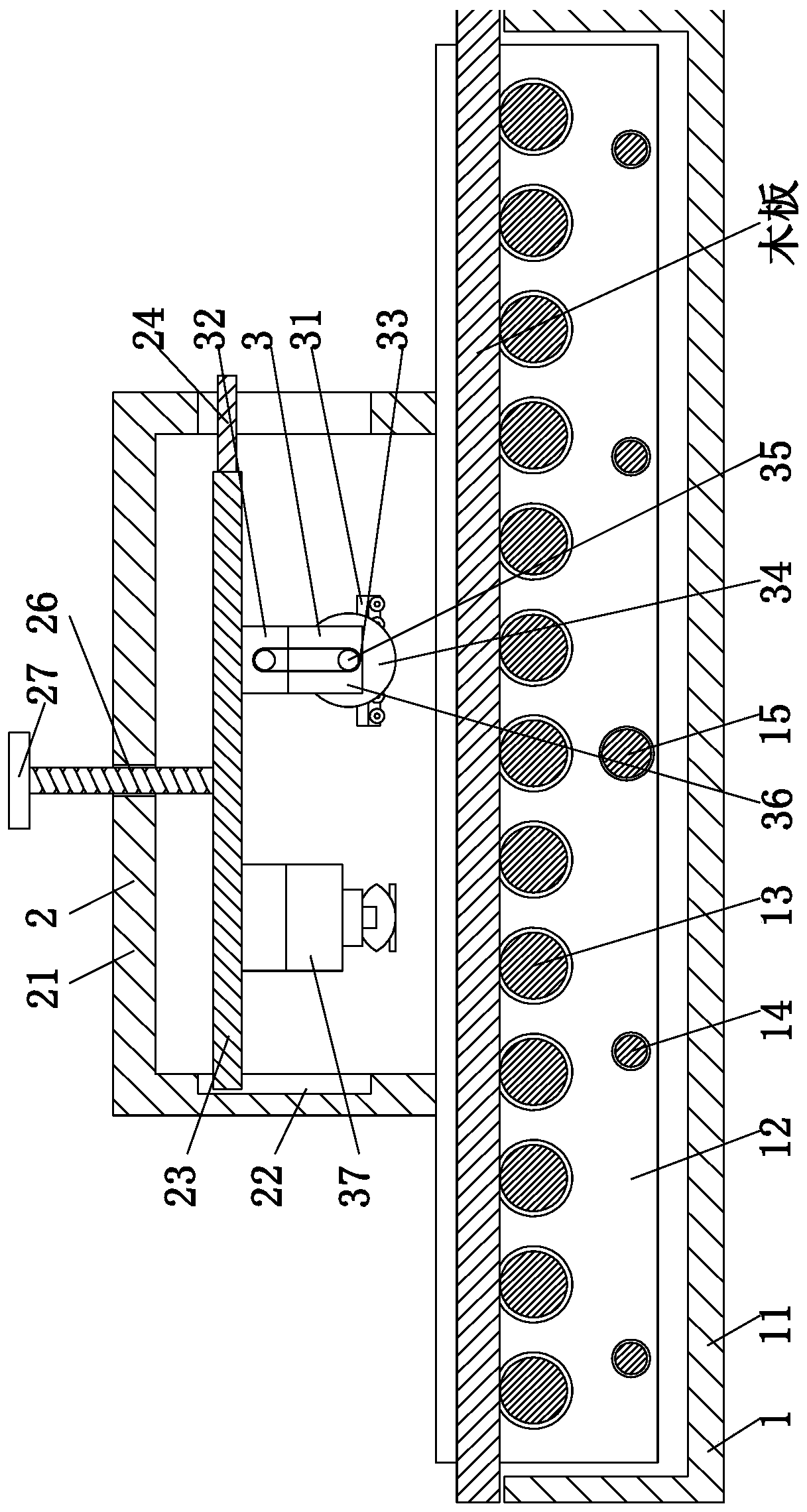

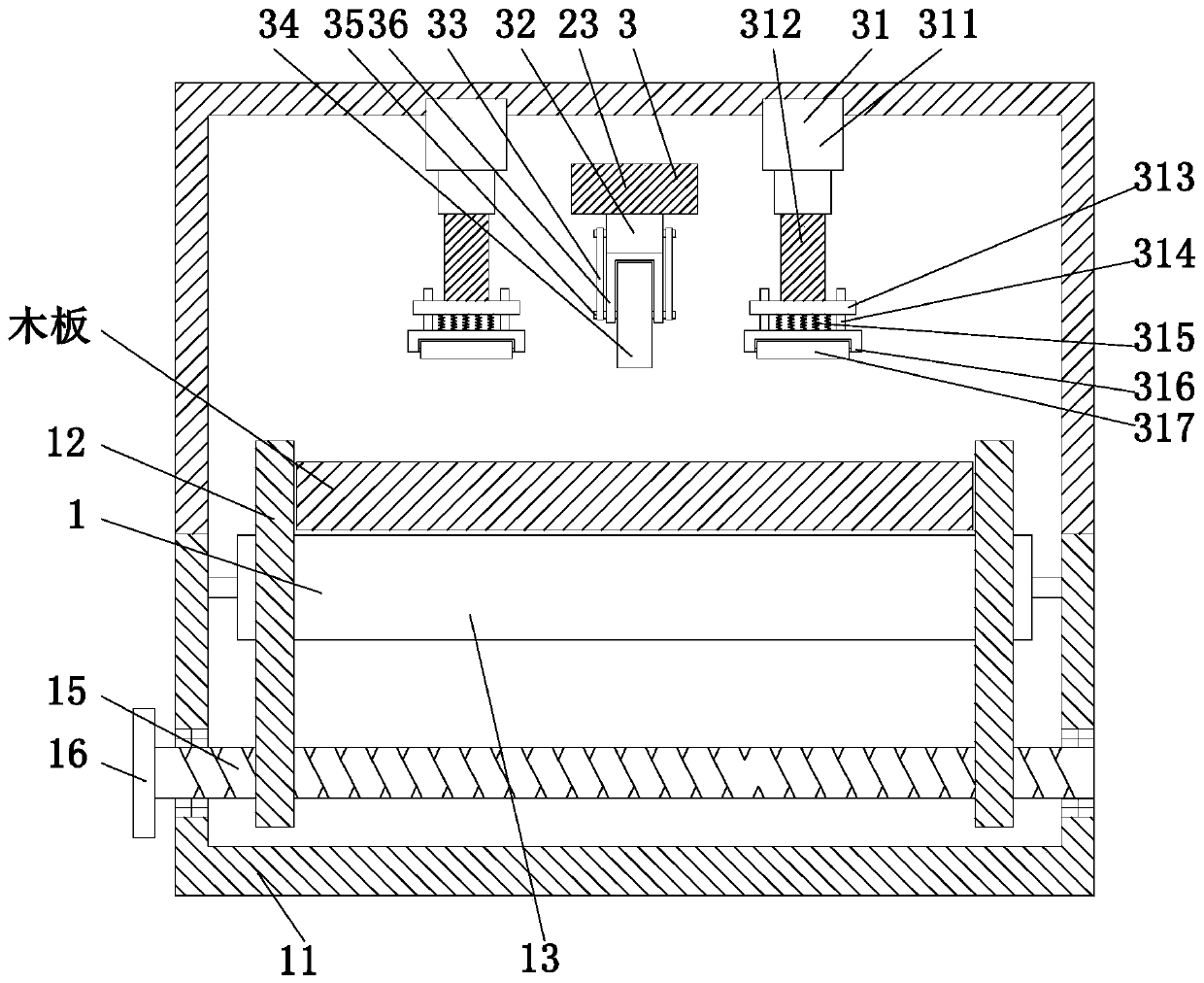

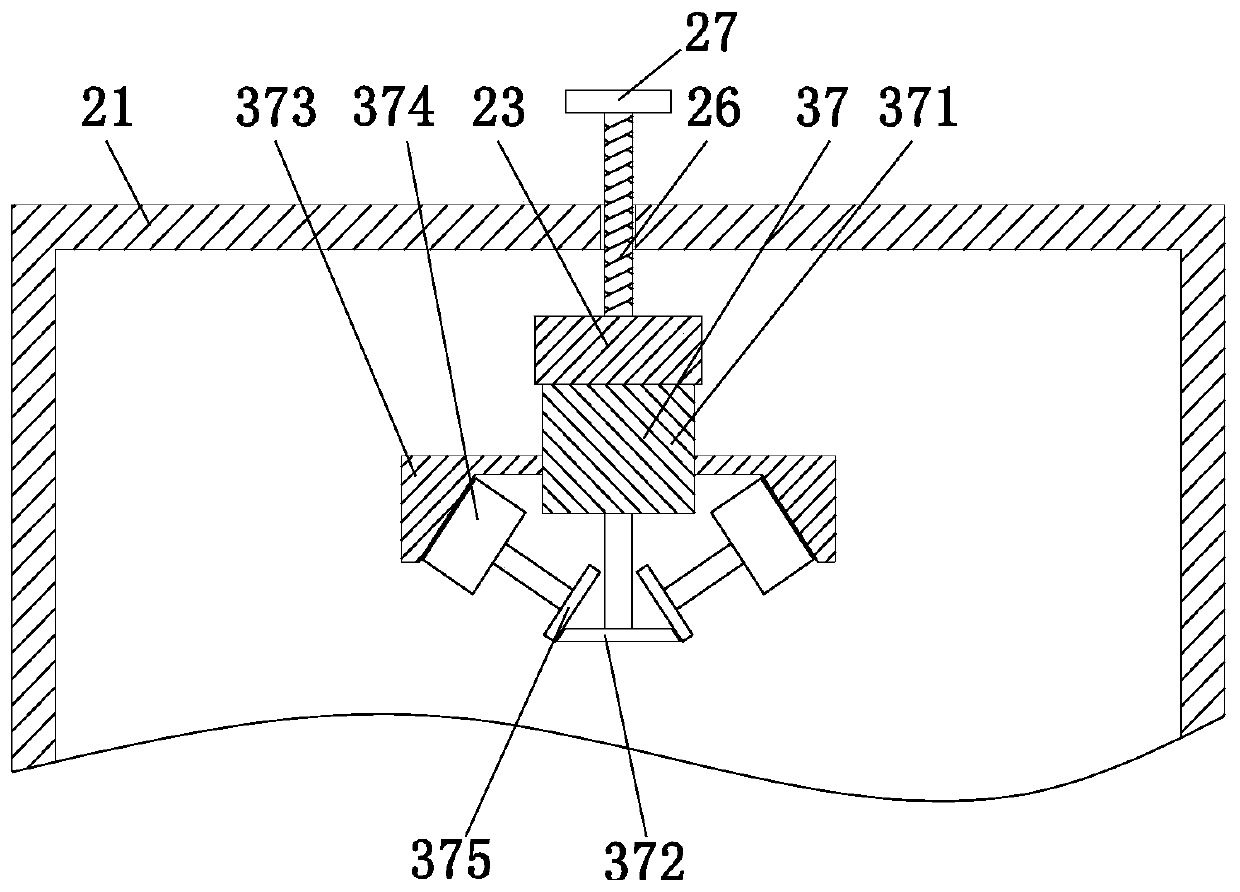

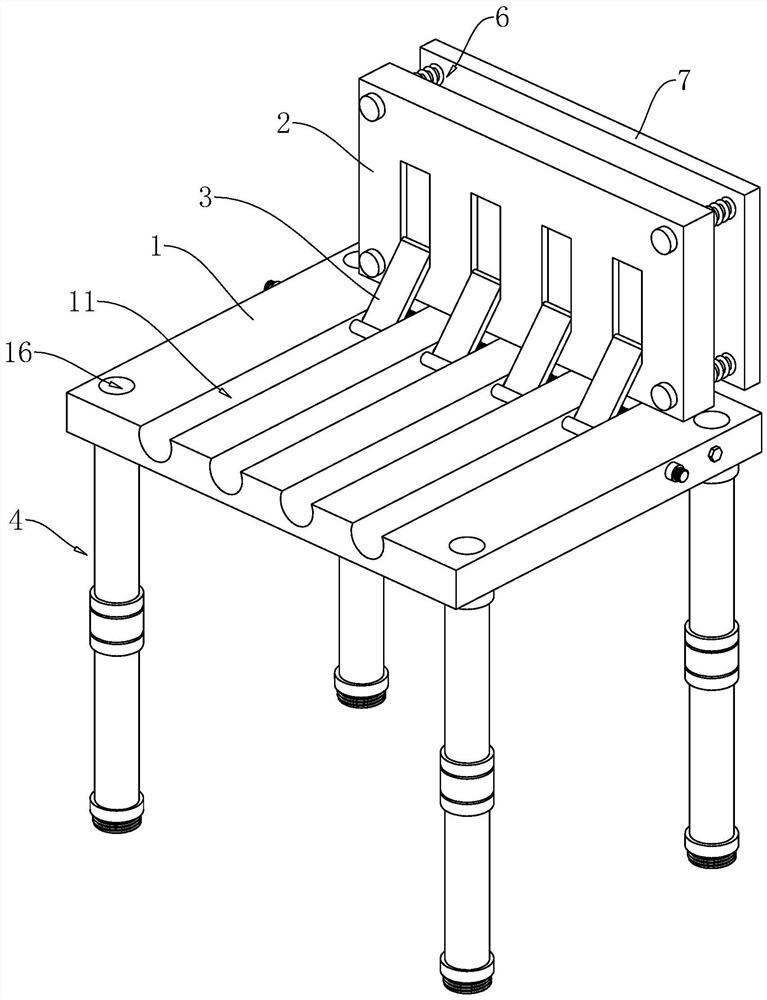

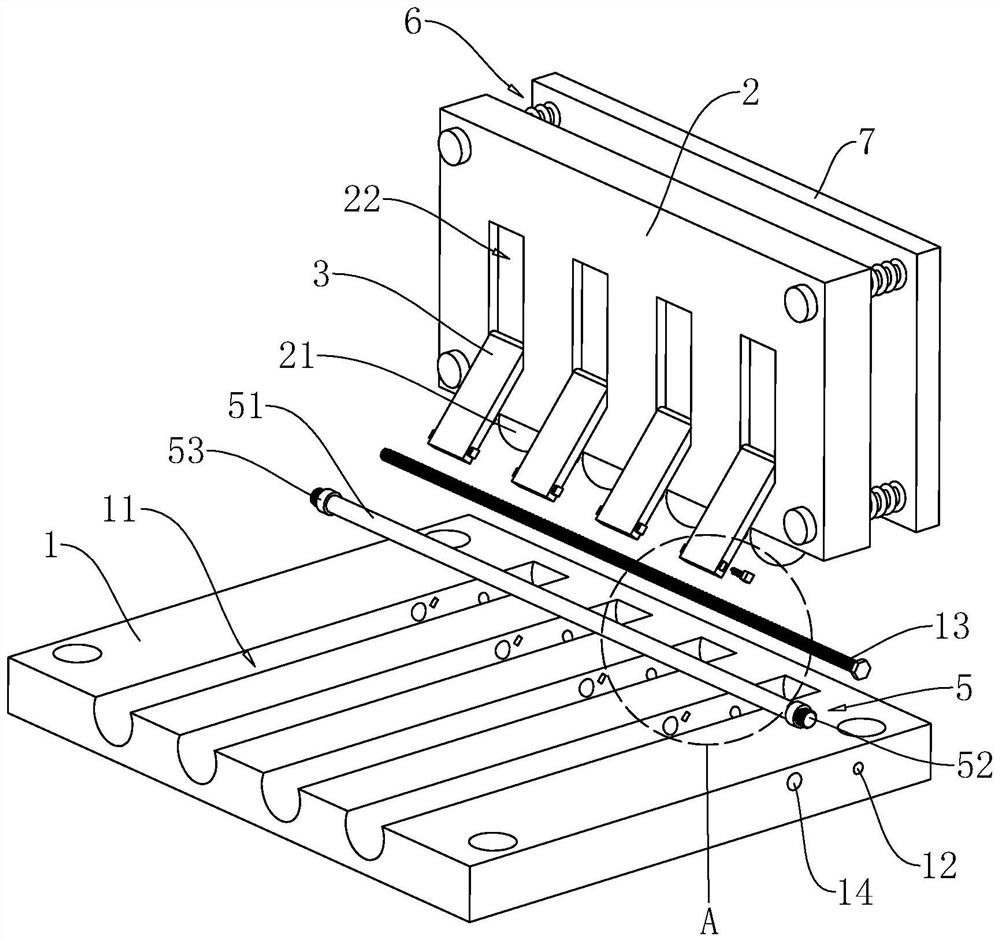

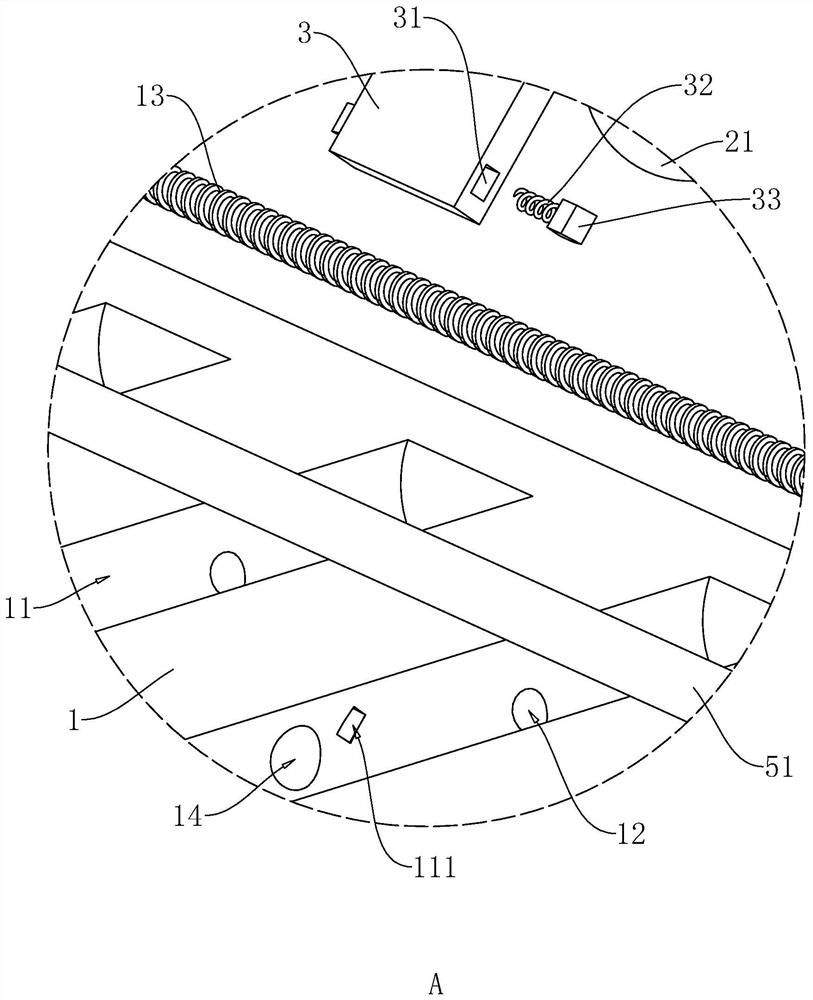

Grooving machine and method for processing shaving boards

ActiveCN110744654AQuality improvementNot easy to crack and damageWood feeding arangementsMulti-purpose machinesMechanical engineeringWood plank

The invention relates to a grooving machine and method for processing shaving boards. The grooving machine comprises a conveying device, a distance adjustment device and a grooving device. The distance adjustment device is installed on the upper end face of the conveying device. The grooving device is installed on the inner end face of the distance adjustment device. By the adoption of the grooving machine and method, the phenomena that an existing grooving machine used for processing the shaving boards adopts a one-time cutting formation technique, the boards are severely stressed in the cutting process and are likely to be cracked and damaged, and the quality of the processed shaving boards is reduced can be avoided, and the problems that the existing grooving machine used for processingthe shaving boards adopts manual conveying during cutting, and consequentially, the labor cost of workers is high, the safety risk is high, and the machining efficiency is low can be solved.

Owner:广东中泰家具集团有限公司

Method for manufacturing cabinet board

ActiveCN105082300AUniform structureSmall expansion and contractionDomestic articlesFlat articlesProcess engineeringCupboard

The invention discloses a method for manufacturing a cabinet board. The method is characterized by comprising the following steps of raw material chipping, impurity removing and screening, stewing, wax applying and hot grinding, glue applying and drying, paving and prepressing, sticking of a waterproof board and veneering and side sealing. The cabinet board manufactured with the method has the good properties of water resistance, wear resistance, fire prevention and high temperature resistance; the residual amount of formaldehyde is low, and the hurt to a human body is reduced; and the board is stable in quality, good in strength, excellent in waterproof performance, good in size stability, not prone to cracking and being damaged and long in service life.

Owner:河南瀚之源实业有限公司

Municipal asphalt concrete pavement construction method

InactiveCN111254774AImprove fatigue resistanceImproves anti-rutting performanceIn situ pavingsTriethyleneglycol dimethacrylateStructural engineering

The invention relates to the technical field of municipal construction, in particular to a municipal asphalt concrete pavement construction method. The method comprises the following steps of: S1, cleaning a roadbed; S2, laying a cushion layer: specifically, paving an asphalt gauze evenly in the clean roadbed, and spraying permeating oil to the gauze to form the cushion layer; S3, paving asphalt concrete: uniformly paving pre-mixed asphalt concrete on the cushion layer to form a pavement layer; and S4, compaction: compacting the pavement to obtain an asphalt concrete pavement. The asphalt concrete comprises the following components by mass: 5-10 parts of asphalt; 65-80 parts of coarse aggregate; 3-8 parts of fine aggregate; 8-13 parts of basalt fiber; 0.5-1 part of a coupling agent; 1-3 parts of triethylene glycol dimethacrylate; 0.5-1 part of clotrimazole; and 0.1-0.3 part of tridecyl phenyl ketone. The method has the effects of improving the anti-fatigue performance and anti-ruttingperformance of the asphalt concrete pavement.

Owner:君兆建设控股集团有限公司

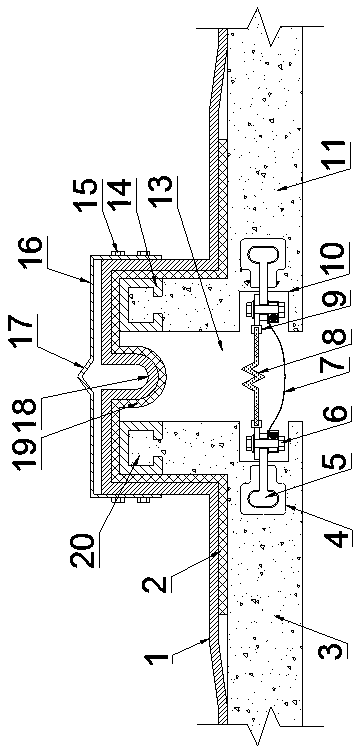

Waterproof connecting structure of deformation joint of building roof

InactiveCN108867900ALarge amount of expansion and contractionNot easy to crack and damageBuild-up roofsBuilding insulationsCushionRubber band

The invention discloses a waterproof connecting structure of a deformation joint of a building roof. The waterproof connecting structure comprises a waterproof roll layer, a fireproof rock wool layer,a waterproof elastic material connecting band, an elastic rubber band, the deformation joint and a waterproof aluminum plate. The deformation joint is arranged between a first concrete wall body anda second concrete wall body. The fireproof rock wool layer, the waterproof roll layer and the waterproof aluminum plate are sequentially laid on the top of the deformation joint from bottom to top. Prefabricated grooves are formed in the first concrete wall body and the second concrete wall body on the two sides of the deformation joint, pre-embedded anchor cables are arranged in the first concrete wall body and the second concrete wall body, locking heads are fixed into the pre-embedded anchor cables and connected with locking plates, the locking plates are arranged in the prefabricated grooves, bolt holes are formed in the locking plates, connecting bolts penetrate into the bolt holes, and the connecting bolts sequentially penetrate through clamping arms, the bolt holes of the locking plates, cushion plates and U-shaped glands from top to bottom to be connected with nuts. Assembly and disassembly are convenient, mounting and replacing of the fireproof elastic material connecting bandor the elastic rubber band are convenient, and operation is convenient.

Owner:曹文东

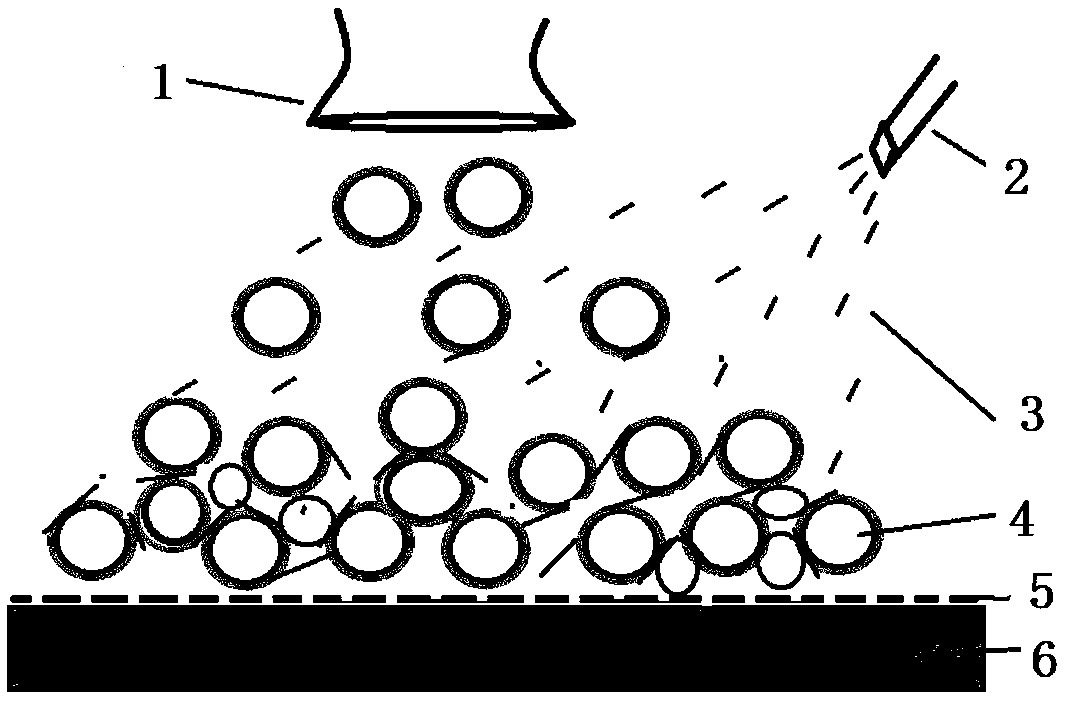

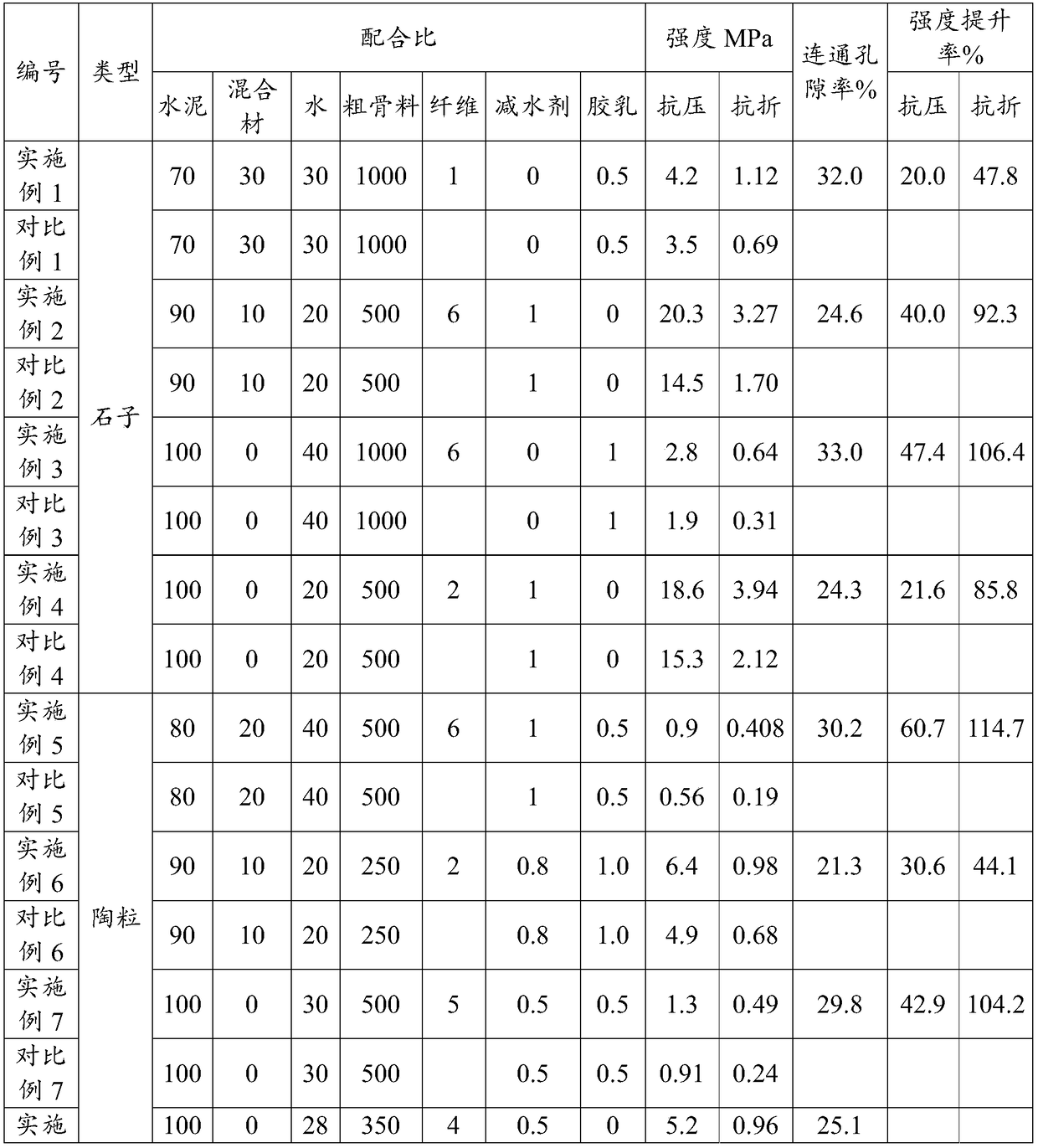

Glass fiber-reinforced vegetation form porous concrete and construction method thereof

InactiveCN108892446AImprove effective utilizationImprove performanceCeramicwareBreaking strengthGlass fiber

The invention discloses a glass fiber-reinforced vegetation form porous concrete and a construction method thereof. The construction method comprises the following steps: (1) uniformly mixing cement,water, an admixture and an aid, and preparing cement paste; (2) blending and stirring wetted coarse aggregates with the cement paste prepared in the step (1), so as to obtain coarse aggregates with the surfaces packaged with the cement paste; (3) pouring the coarse aggregates obtained in the step (2), simultaneously jetting chopped glass fibers to the surfaces of the coarse aggregates to adhere the glass fibers into the cement paste on the surfaces of the coarse aggregates, enabling the glass fibers and the coarse aggregates to simultaneously fall into a mold, and carrying out compaction and maintenance, so as to obtain the glass fiber-reinforced vegetation form porous concrete. By utilizing the construction method provided by the invention, the glass fibers with relatively high adding quantity can be added; by virtue of the jetted glass fibers, the situation that the cement paste on the surfaces of the coarse aggregates runs off downwards to block communication holes of the concrete is avoided; and the compressive strength and breaking strength of pervious concrete are remarkably improved, so that the pervious concrete is unlikely to be broken.

Owner:GUANGZHOU UNIVERSITY

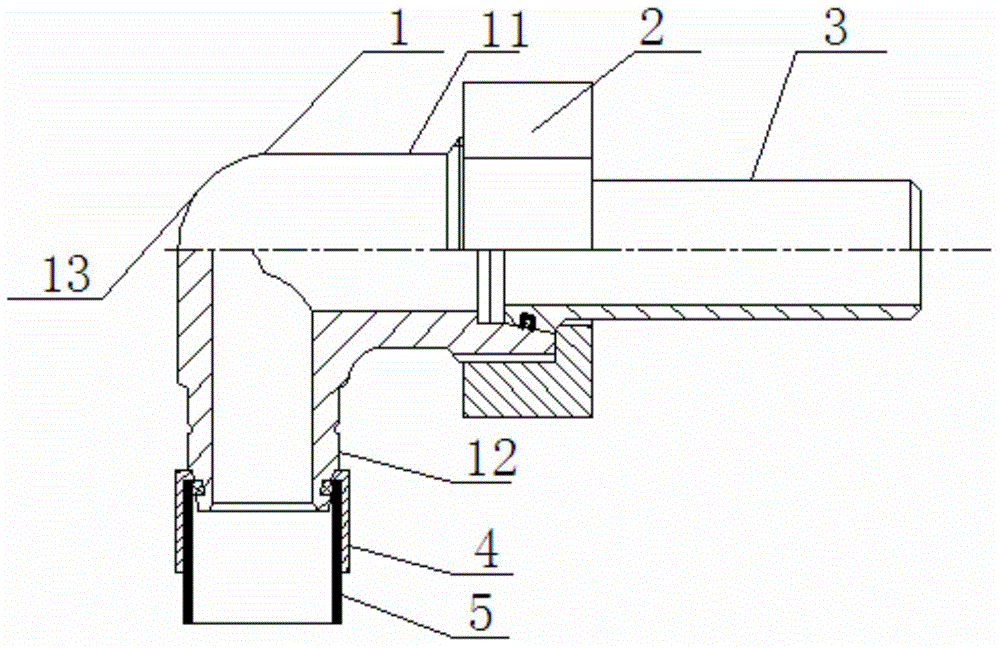

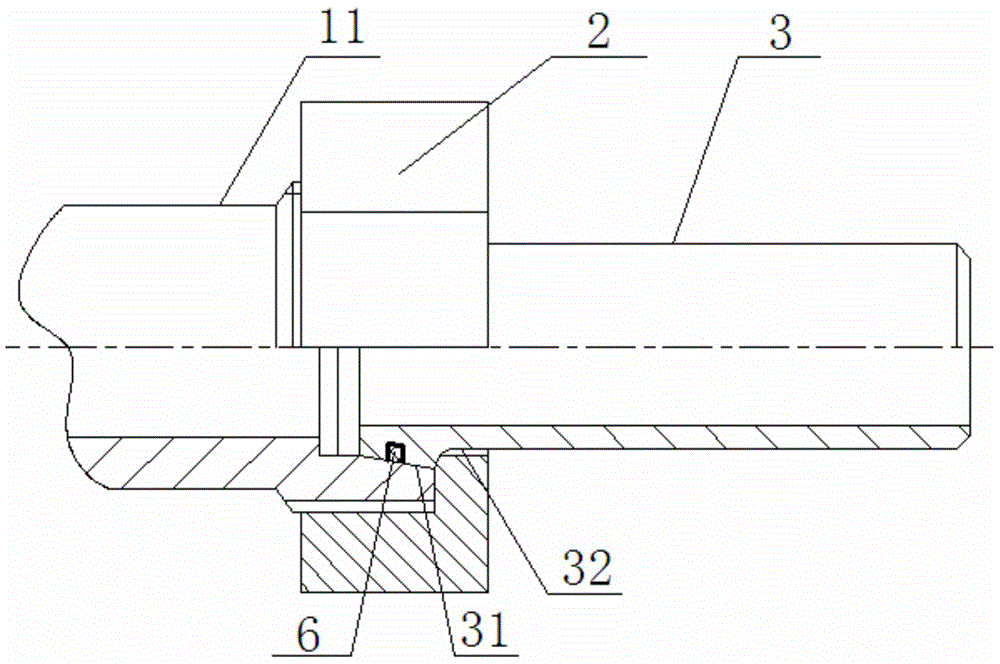

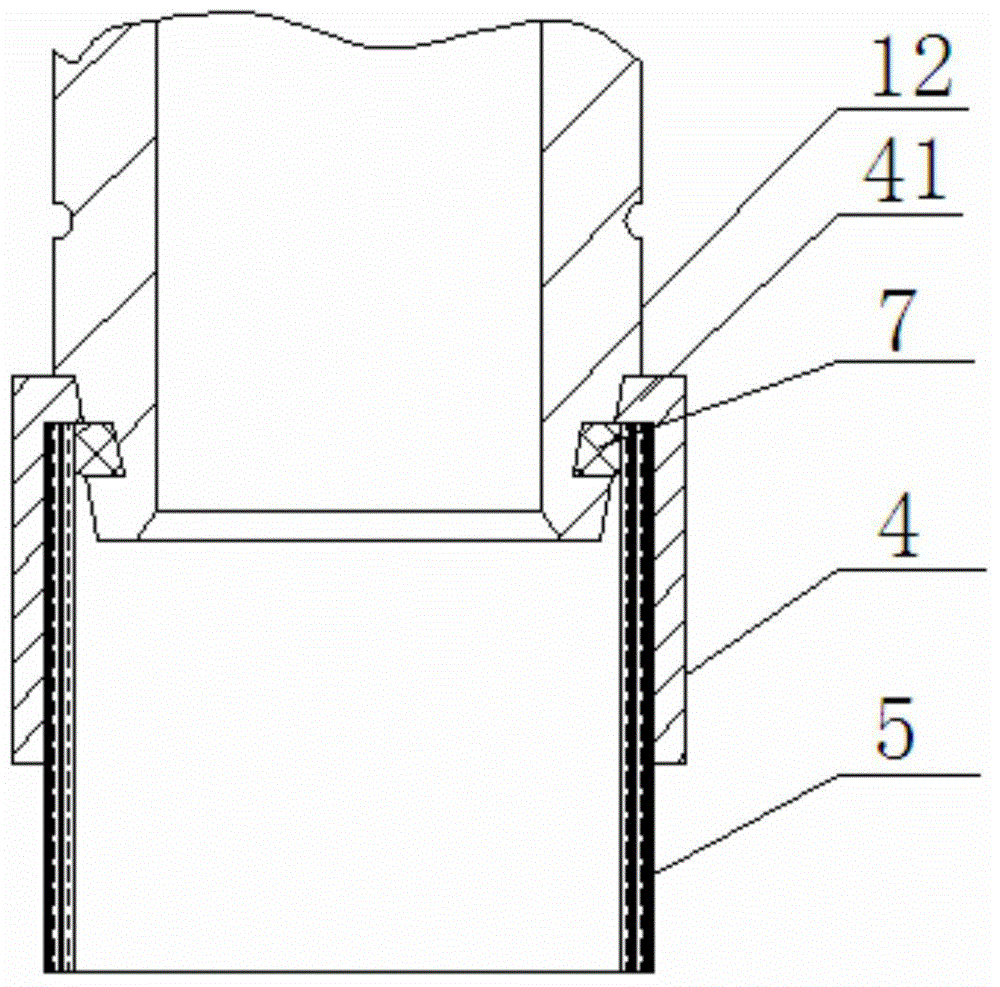

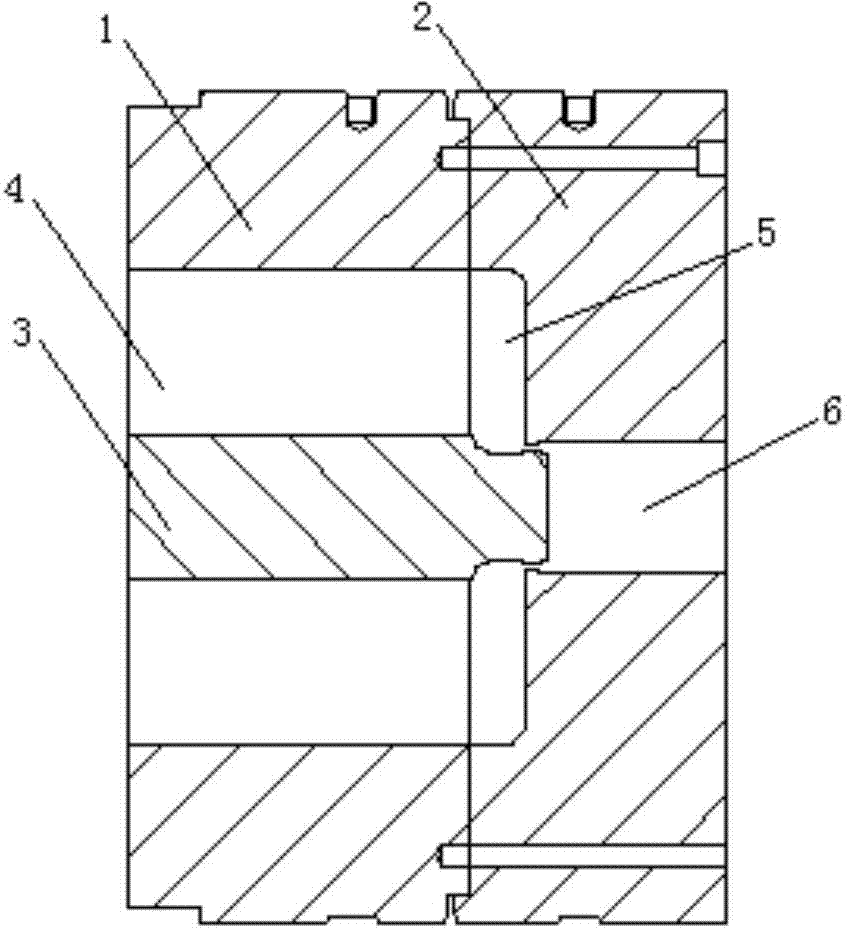

Tapered sealing pipe connector for excavator

ActiveCN104455815AImprove sealingEven by forceJoints with sealing surfacesSiphonsEngineeringExcavator

The invention discloses a tapered sealing pipe connector for an excavator. The tapered sealing pipe connector comprises a connector body, a nut, a first connection pipe, a sleeve and a second connection pipe. The connector body comprises a big pipe segment, a small pipe segment and a bent pipe segment. The connector body is formed by sequentially connecting the small pipe segment, the bent pipe segment and the big pipe segment. The small pipe segment is connected with the second connection pipe. The joint of the small pipe segment and the second connection pipe is sleeved with the sleeve. The big pipe segment is connected with the first connection pipe through the nut. The big pipe segment is a segment of straight pipe. The outer ring of the tail end of the straight pipe is provided with external threads. A tapered opening is formed in the big pipe segment. The big end of the tapered opening faces the outer end of the connector body. The first connection pipe is provided with a first O-shaped sealing ring. The small pipe segment comprises a mounting head, a groove and a ladder axial segment. According to the tapered sealing pipe connector for the excavator, through tapered sealing connection, sealing performance can be well achieved, connection can be achieved quickly and conveniently, the connection part is made to be even in stress and not prone to damage and cracking, stability is improved, service life is prolonged, airtightness is good, safety performance is high, and the tapered sealing pipe connector is convenient to assemble.

Owner:JIAXING MASTER PLUMBING

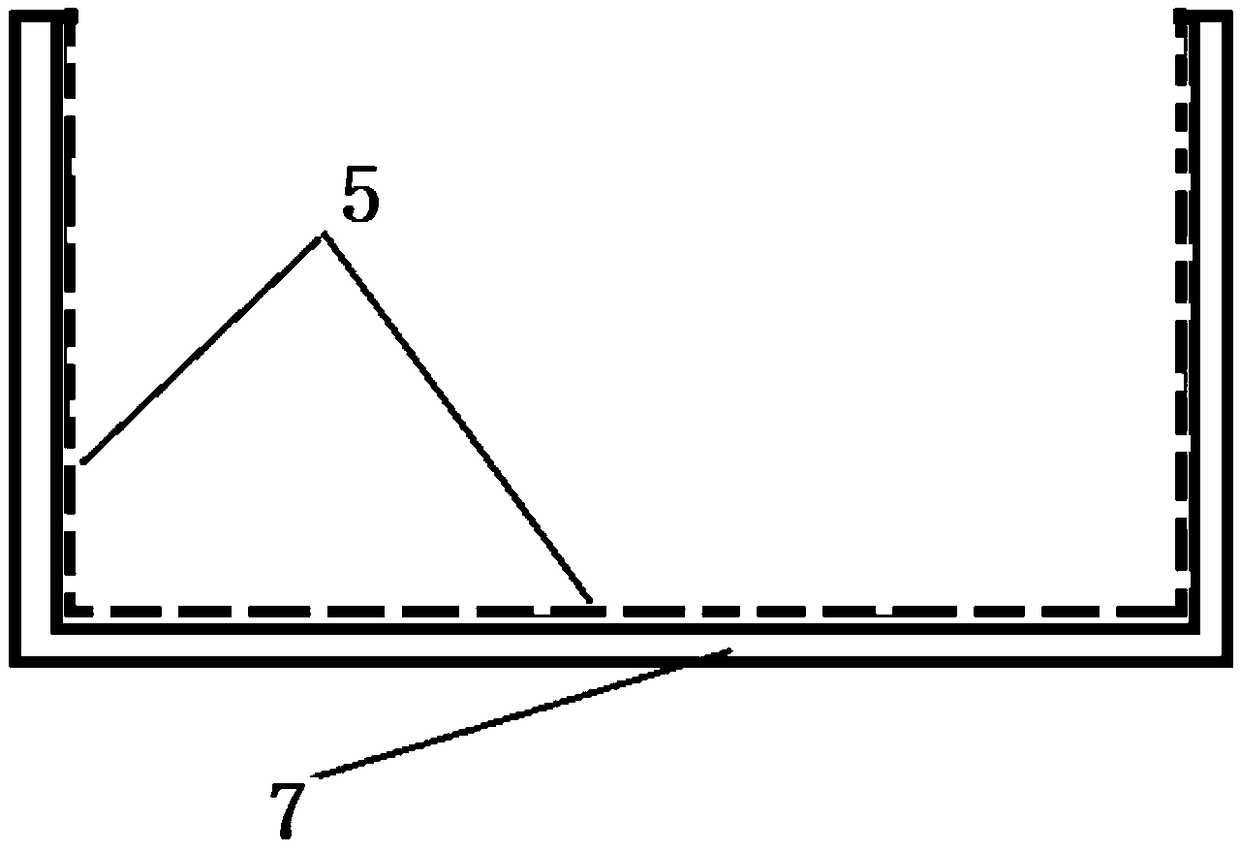

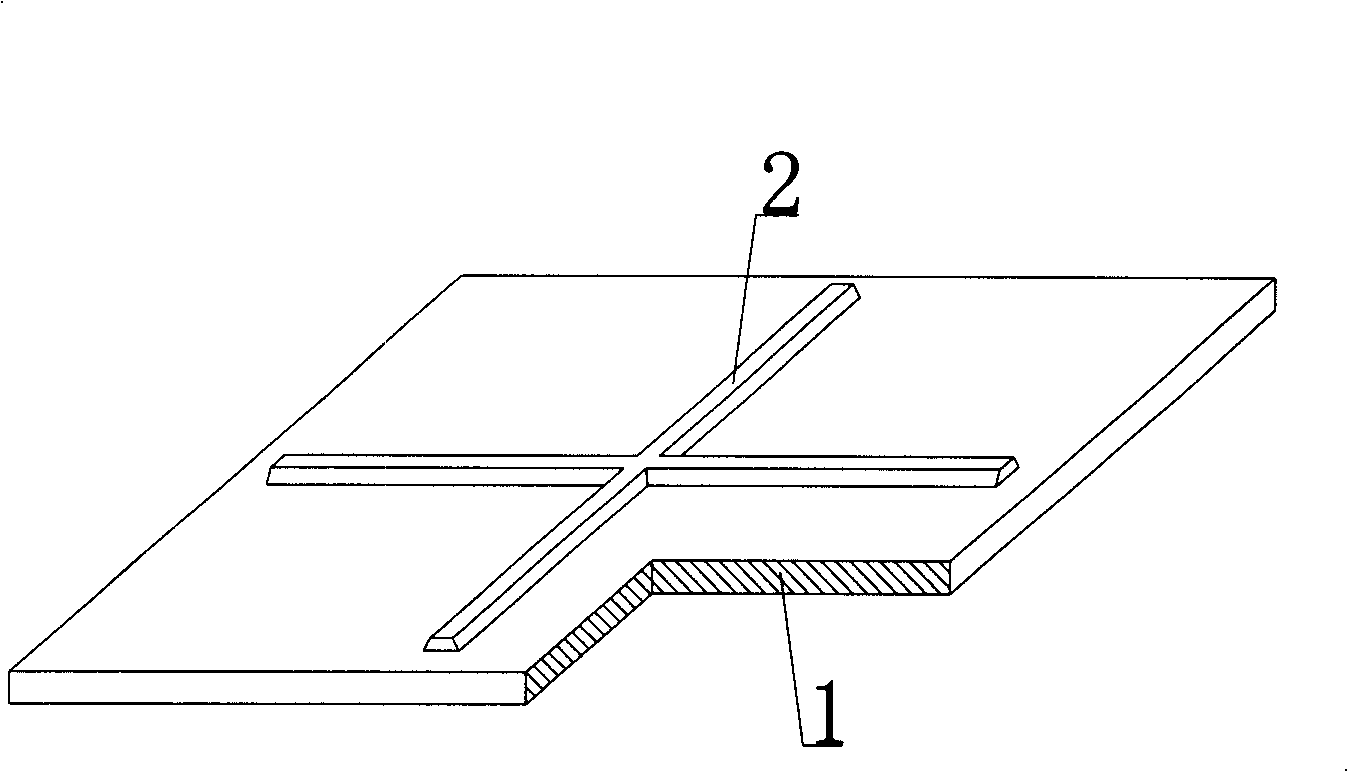

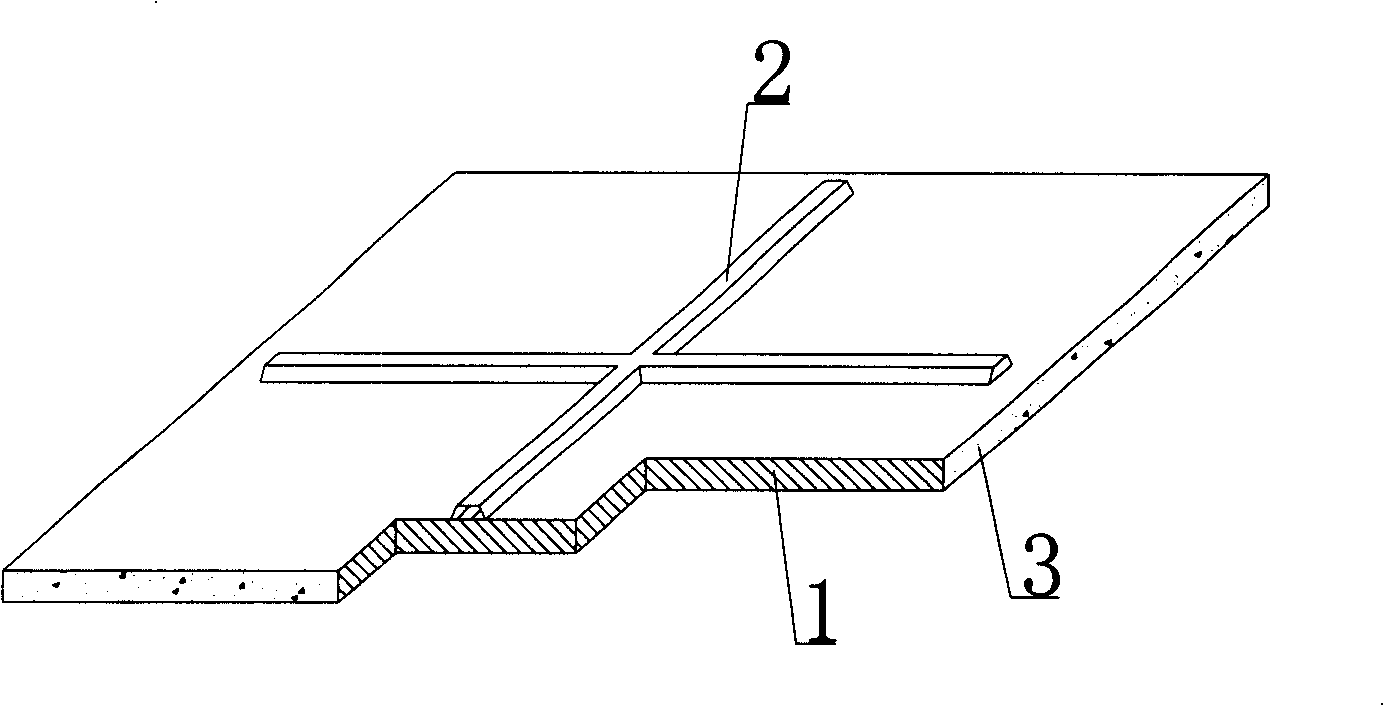

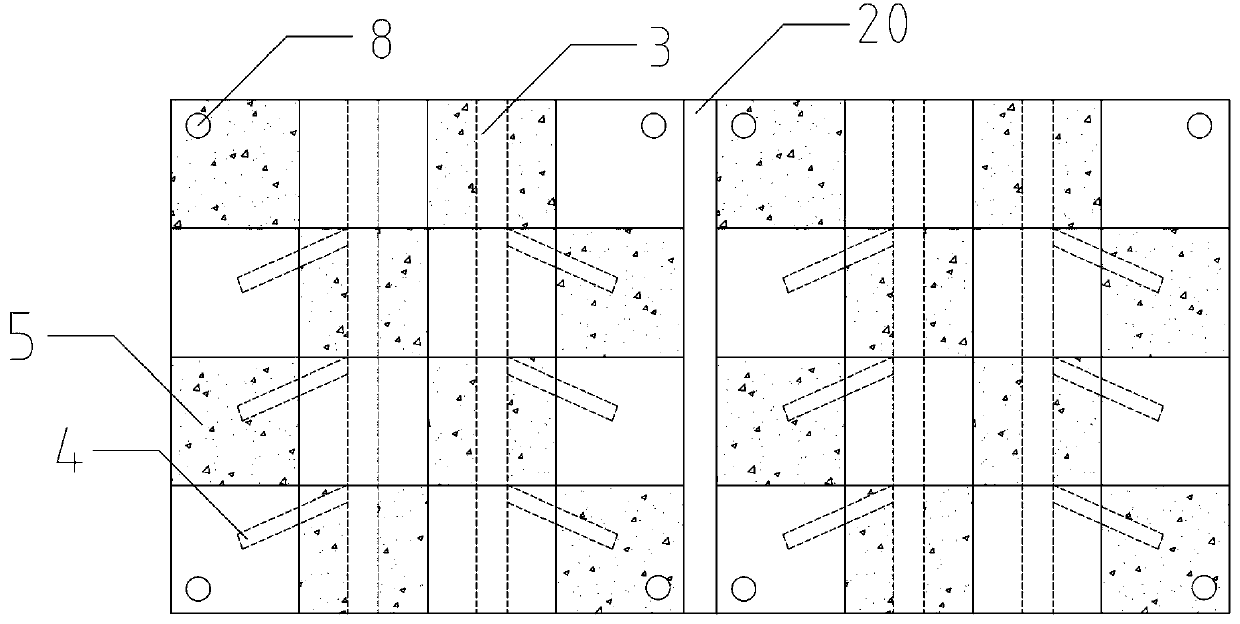

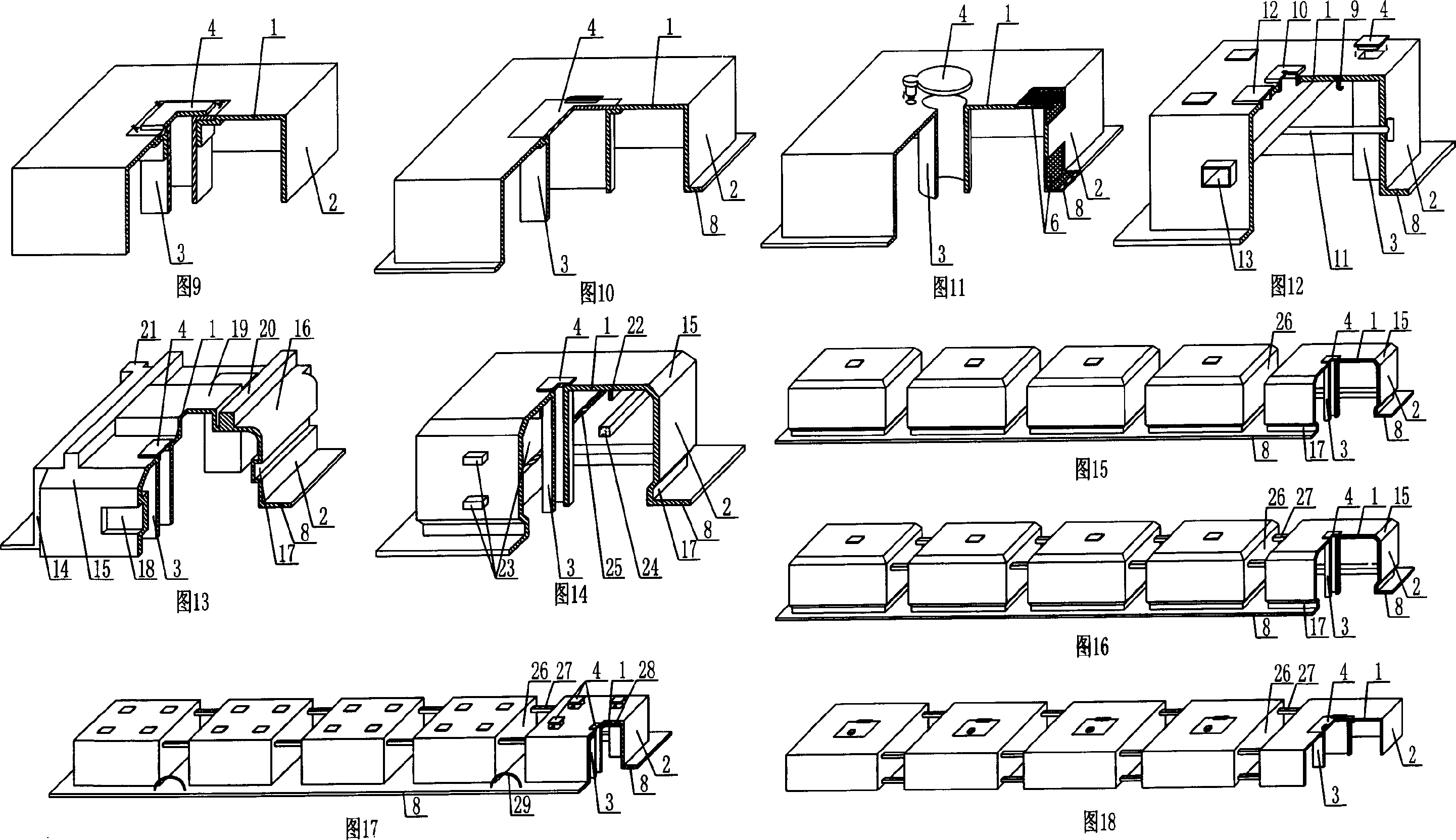

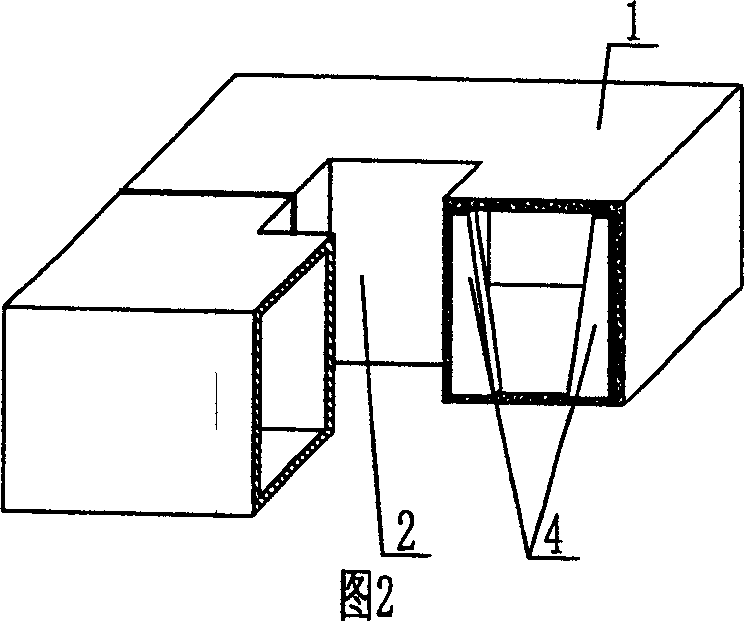

Prefabricated board for floor

InactiveCN101260722AQuality assuranceEffective dispersionCeramic shaping apparatusBuilding componentsReinforced concreteStructural engineering

The invention relates to a floor precast slab, which comprises a precast reinforced concrete board (1) and is characterized in that: a convex reinforcing rib (2) is arranged on a board surface of the precast reinforced concrete board (1) and is a reinforcing rib which is formed by compression of a reinforcing rib pressure head. The floor precast slab is suitable for various cast-in-situ concrete floors, roofs, walling, base slabs and structures of pipe bridge projects and is particularly suitable for hollow flat slabs.

Owner:邱则有

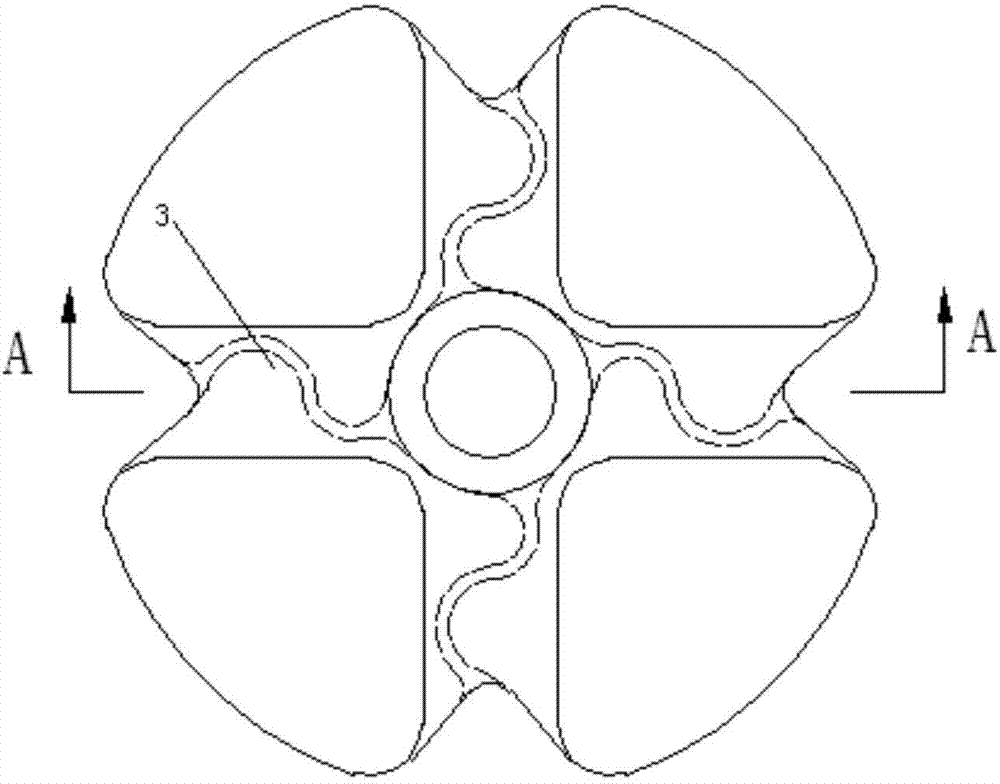

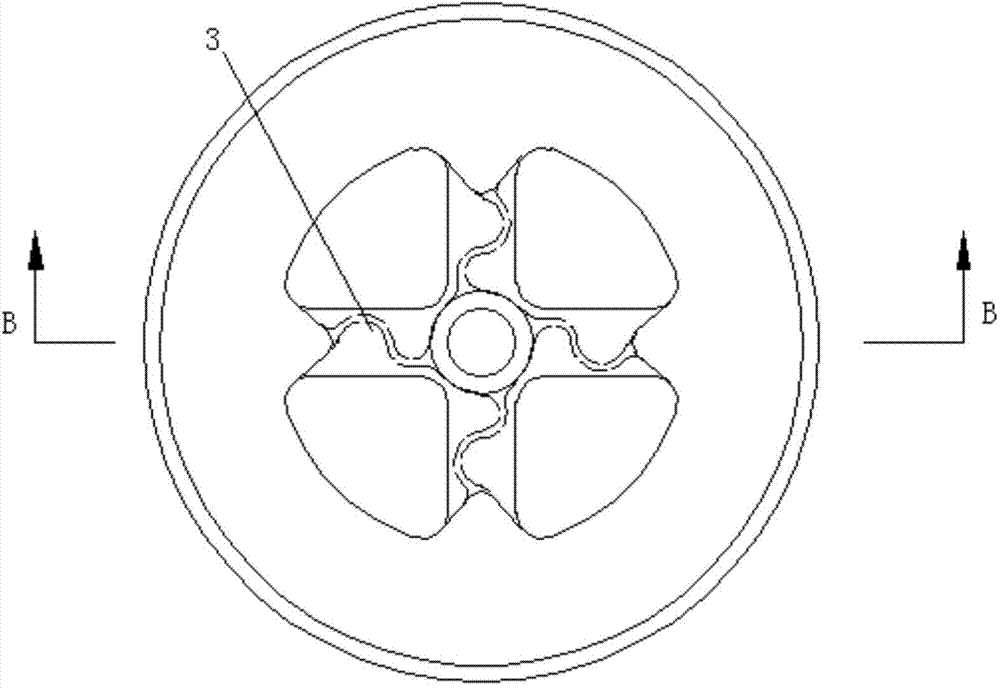

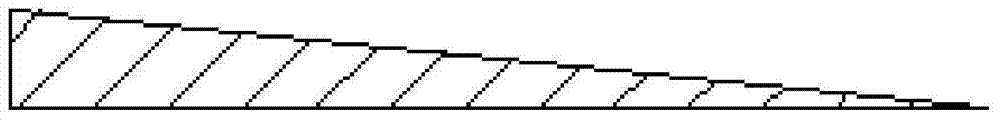

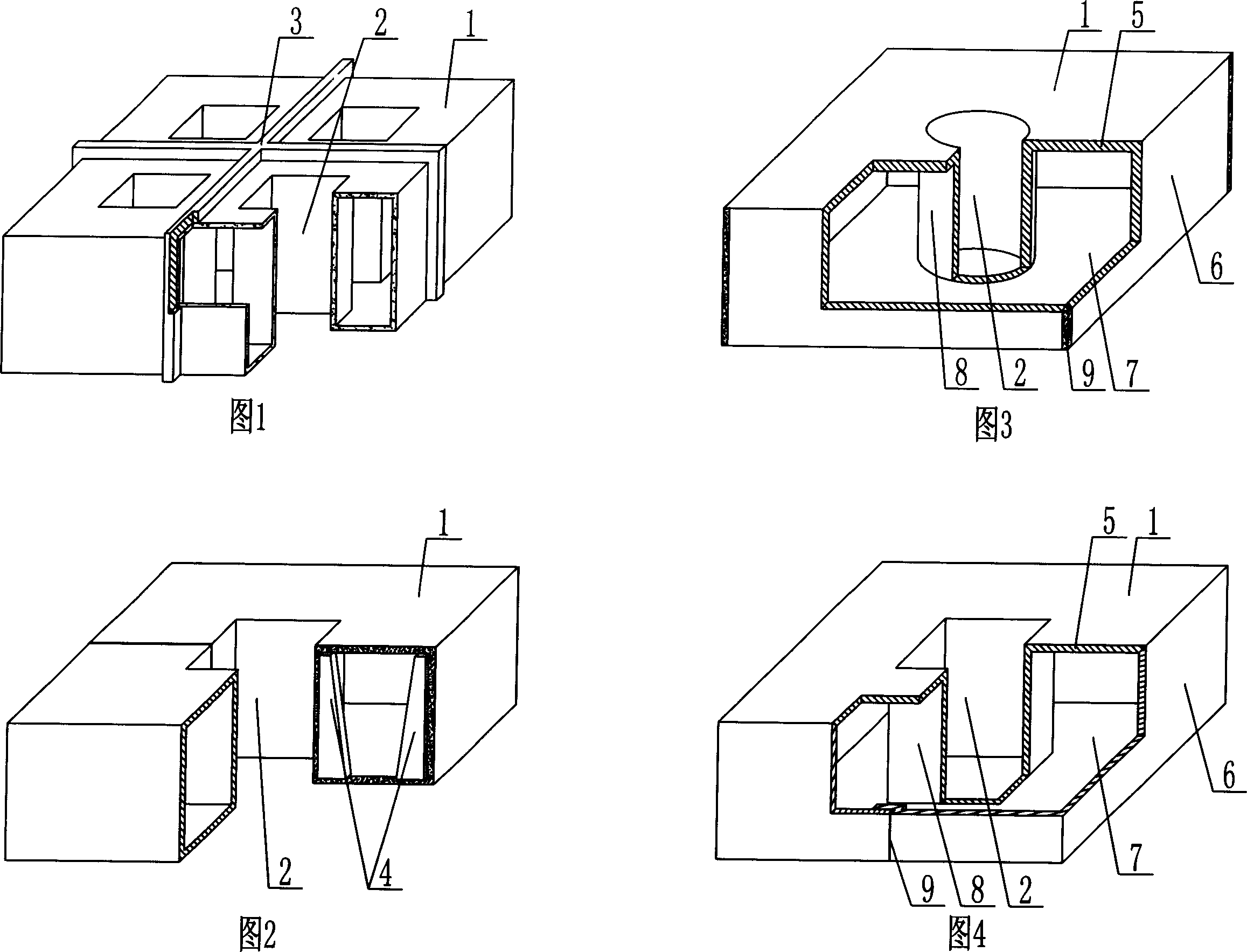

Hot extrusion die with improved structure

InactiveCN104741406AHigh strengthNot easy to crack and damageExtrusion diesCurve shapeUltimate tensile strength

The invention discloses a hot extrusion die with an improved structure. The hot extrusion die comprises an upper die and a lower die which can be superposed and connected together back and forth, wherein a guide plate is arranged at the feeding end of the upper die; multiple bridge locations are formed on the guide plate; a shunt hole is formed between every two bridge locations; a welding chamber and a discharge hole which are communicated with each other are sequentially formed from the feeding end to the discharging end of the lower die; the welding chamber is communicated with the shunt holes in the upper die; a core head of the upper die is inserted into a molding hole of the lower die; and each bridge location of the upper die extends in a curve state along the radial direction of the upper die. The bridge locations of the upper die are designed into a curve structure, and materials entering the shunt holes enter the welding chamber via the shunt holes of the curve shape and form turbulence in the welding chamber, so that the materials flowing into the welding chamber in each shunt hole are fully welded, the welding line on the surface of the product molded by the materials by virtue of the molding hole extends in a spiral curve mode, the overall strength is high, and the die is difficult to crack and damage during bending, cold-drawing and stretching.

Owner:捷安特轻合金科技(昆山)股份有限公司

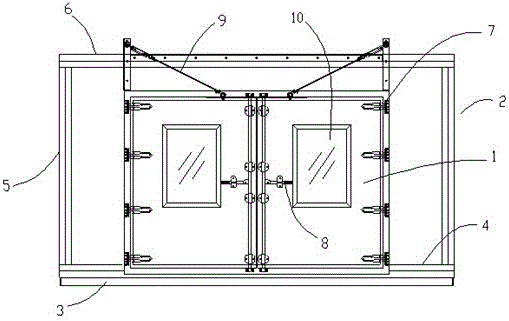

Large high-temperature-resistant storeroom and installation method thereof

InactiveCN106760696ABeautiful appearanceExtended service lifeSpecial buildingBuilding componentsSteel platesEngineering

The invention provides a large high-temperature-resistant storeroom and an installation method thereof. The large high-temperature-resistant storeroom comprises a storeroom door, a storeroom body and a base. The storeroom body is a hollow sealed cubic formed by a top panel, lateral panels and a bottom panel. The storeroom door which can be opened and closed is installed on one lateral panel. The base used for bottom leveling is arranged under the bottom panel of the storeroom body. The top panel, the lateral panels and the bottom panel of the storeroom body are each formed by splicing unit plates in a sealed mode. Each unit plate comprises a color steel plate on the surface layer, a zinc-plated plate on the middle layer and a stainless steel plate on the inner layer, wherein filling layers are arranged between the color steel plate and the zinc-plated plate and between the zinc-plated plate and the stainless steel plate. The storeroom provides a larger stable high-temperature environment which is more resistant to high temperature.

Owner:广州科灿制冷设备有限公司

Hot extrusion die with improved lower die choke flow structure

The invention discloses a hot extrusion die with an improved lower die choke flow structure. The hot extrusion die comprises an upper die and a lower die, which can be superposed and connected together back and forth, wherein a flow guide plate is arranged at a feeding end of the upper die; a plurality of bridge sites are arranged on the flow guide plate; tap holes are formed among the bridge sites; a core head is arranged at a discharge end of the upper die; a welding chamber, a molding hole and a discharge hole, which are communicated with one another, are sequentially formed in the lower die from the feeding end to the discharge end; the welding chamber is communicated with the tap hole of the upper mold; the core head of the upper mold is inserted into a molding hole of the lower mold; and a circle of spiral structure of which the axial height is gradually reduced is arranged on the bottom surface of the welding chamber of the lower mold. Welding lines on the surface of the product which is molded from the material disclosed by the invention by the molding hole are slight or even disappear; the slight welding lines also extend in a spiral curve manner; the hot extrusion die is high in overall strength, and is not easily fractured or damaged when being subjected to bending, cold drawing and stretching; and the product is high in surface accuracy and small in dimension error.

Owner:捷安特轻合金科技(昆山)股份有限公司

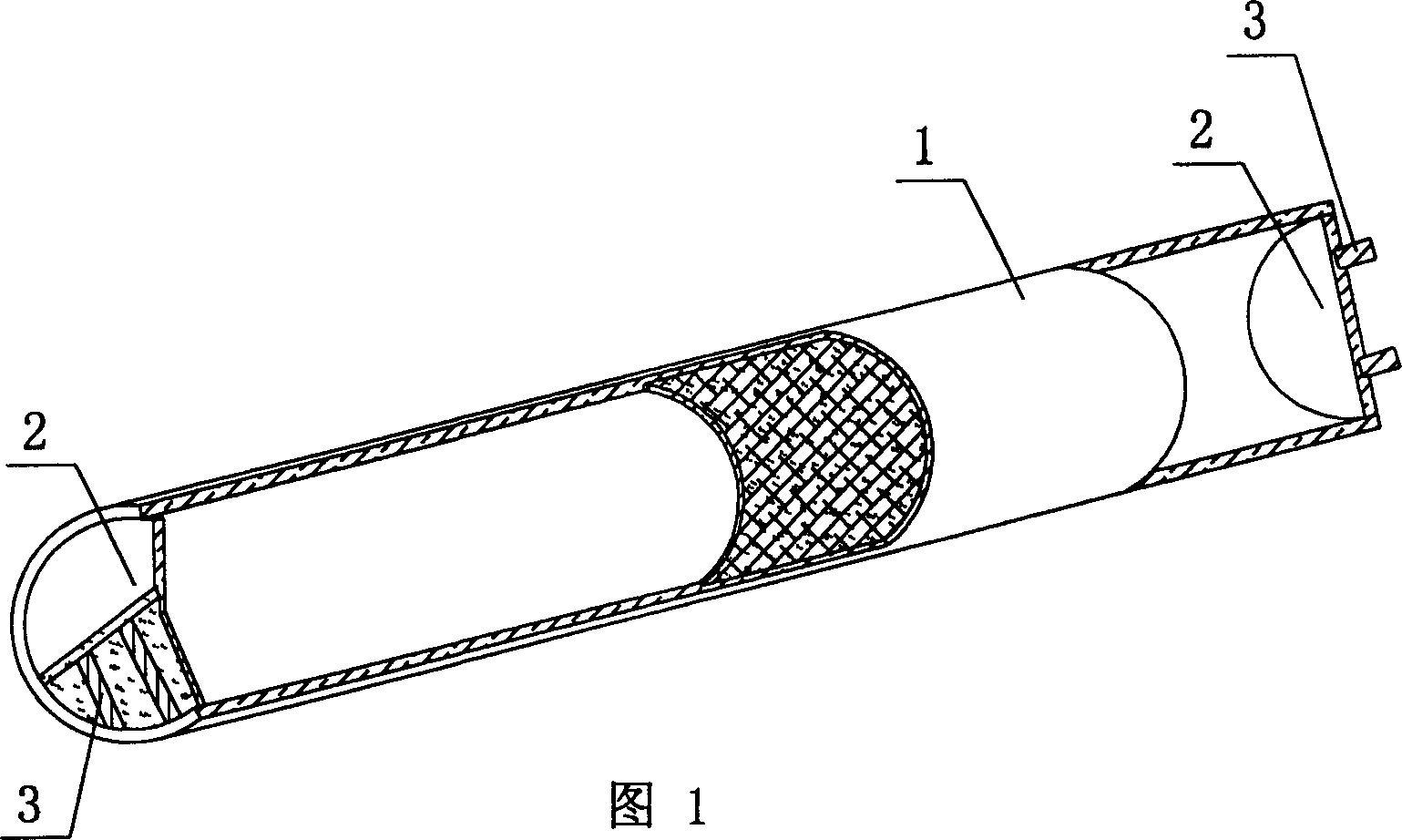

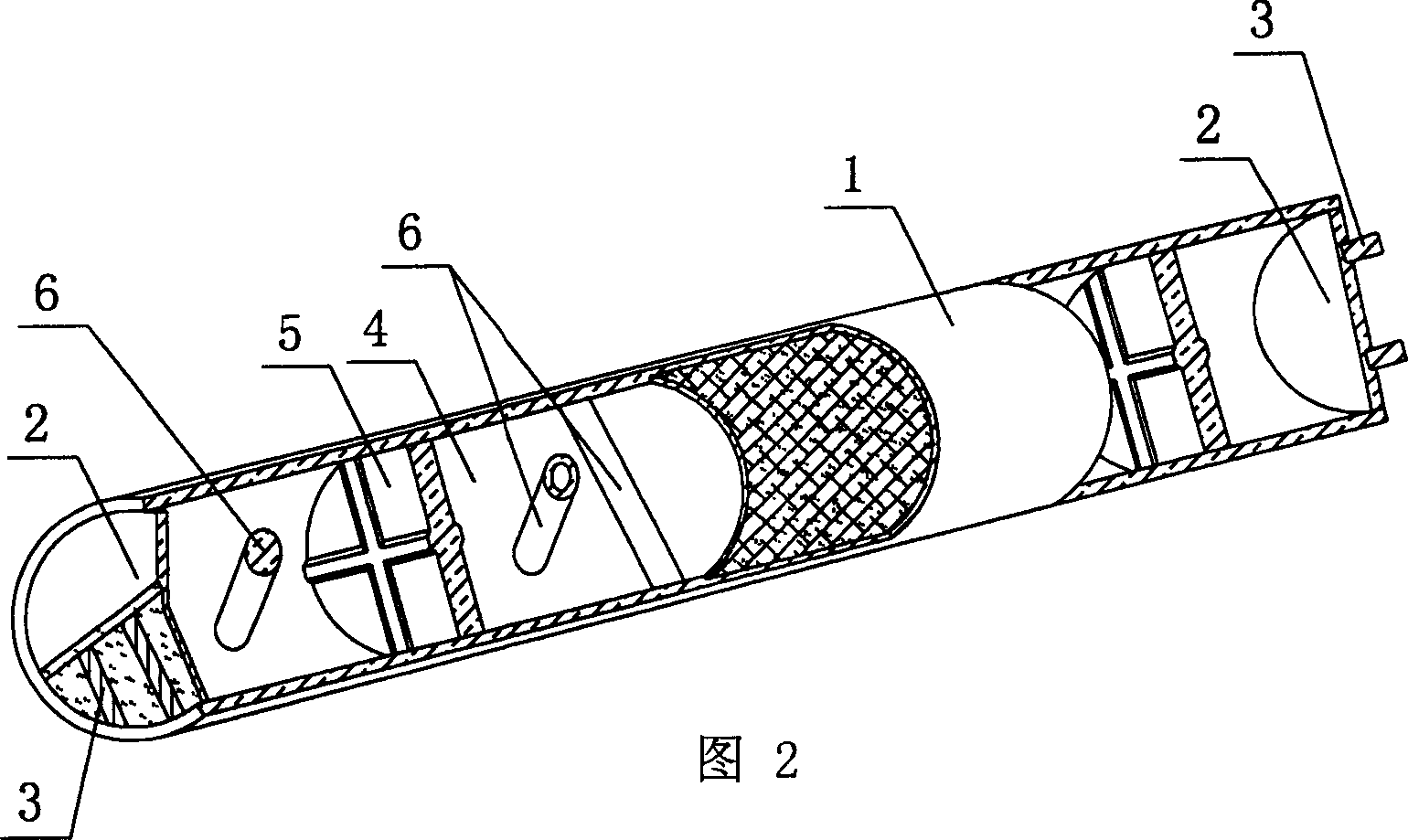

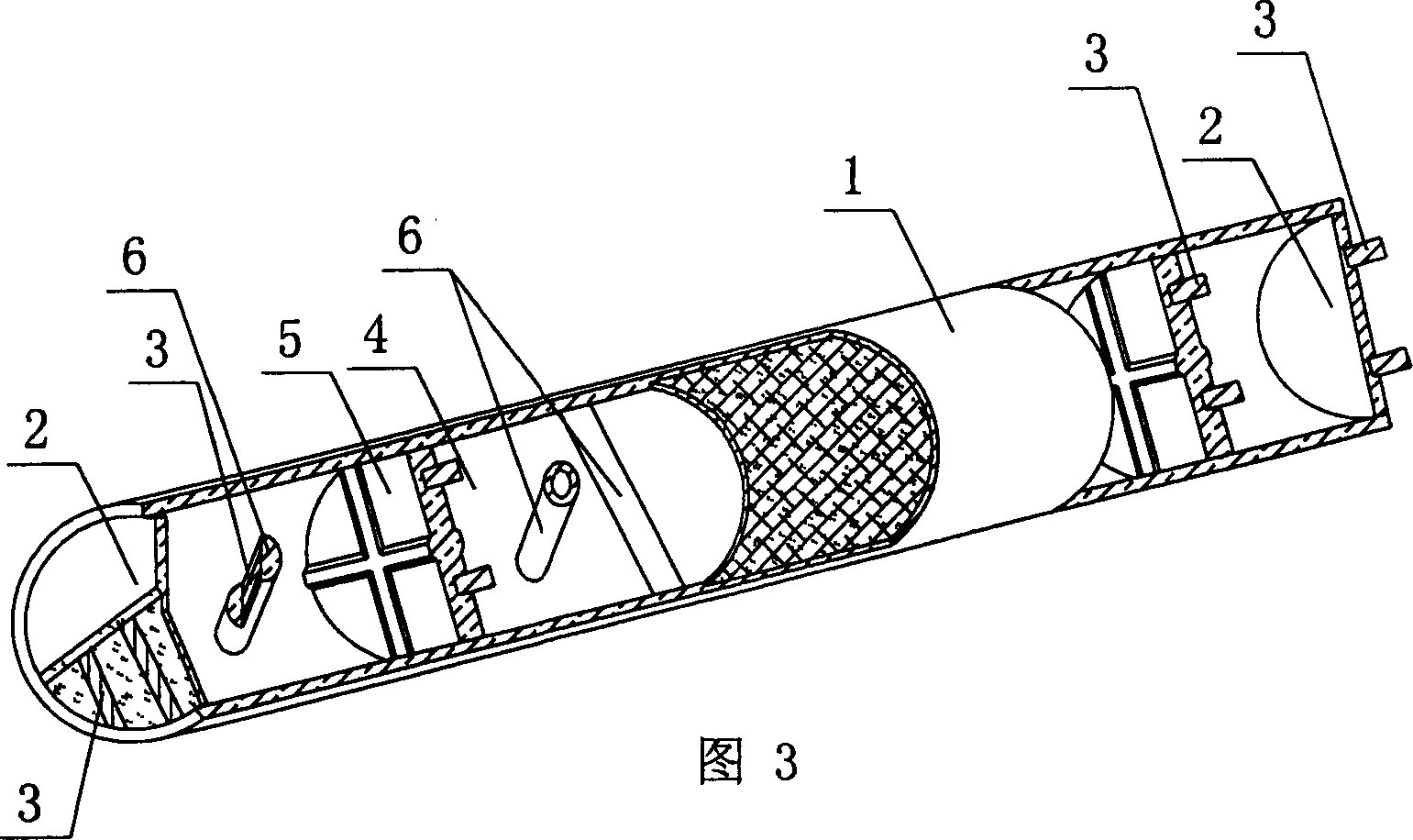

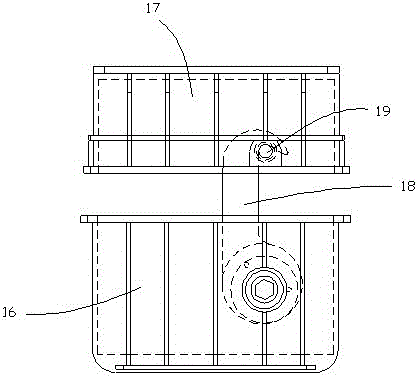

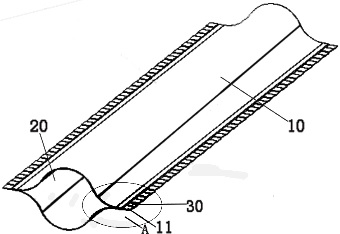

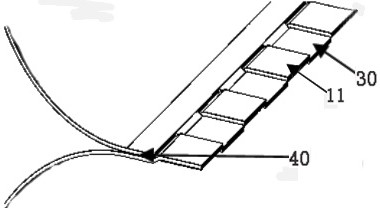

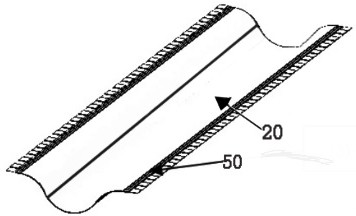

Lightweight permanent embryonic shell in use for filling concrete

InactiveCN1958994AImprove performanceNot easy to crack and damageFloorsReinforced concreteEngineering

The present invention relates to a light permanent form for filling concrete. It includes a light form body, said light form body includes upper plate, peripheric side plate and lower plate, and said upper plate, peripheric side plate and lower plate can be combined together and made into a closed hollow cavity. It is characterized by that it also includes a through hole tube, said through hole tube is placed in the closed hollow cavity of light form body, said through hole tube is a hard prefabricated tube, and is used for forming concrete pouring hole. Said light permanent form can be used for in-situ casting reinforced concrete or prestressed reinforced concrete hollow floor, roof, wall body, foundation bedplate and open-web bridge, etc.

Owner:湖南邱则有专利战略策划有限公司

Preparation process and application of photosensitive resin for 3D printing

InactiveCN109929080AImprove performanceImprove light curing efficiencyAdditive manufacturing apparatusAcetic acidPolymer science

The invention discloses a preparation process and application of photosensitive resin for 3D printing. The process comprises the following steps of: 1) weighing organic silicon resin powder, an organic solvent and a silane coupling agent in parts by weight and adding the components into a first container to be stirred and mixed in a forward and reverse rotation alternating mode, the silane coupling agent being prepared by weighing silane, alcohol, water and acetic acid in parts by weight and mixing the components; 2) adding a catalyst, mixing and stirring the components until a transparent anduniform first liquid is obtained, respectively weighing a complexing agent and metal alkoxide according to parts by weight, and adding the components into a second container, mixing and stirring themetal alkoxide and the complexing agent in a forward and reverse rotation alternating manner until a transparent and uniform second liquid is obtained; 2) adding the first liquid into a third container, pre-stirring the first liquid, adding a second liquid, mixing and stirring the first liquid and the second liquid, adding an active diluent, and mixing and stirring all the components; 3) adding aphotoinitiator into the third container, and continuously stirring the mixture to obtain the 3D printing photosensitive resin.

Owner:广东信毅新材料有限公司

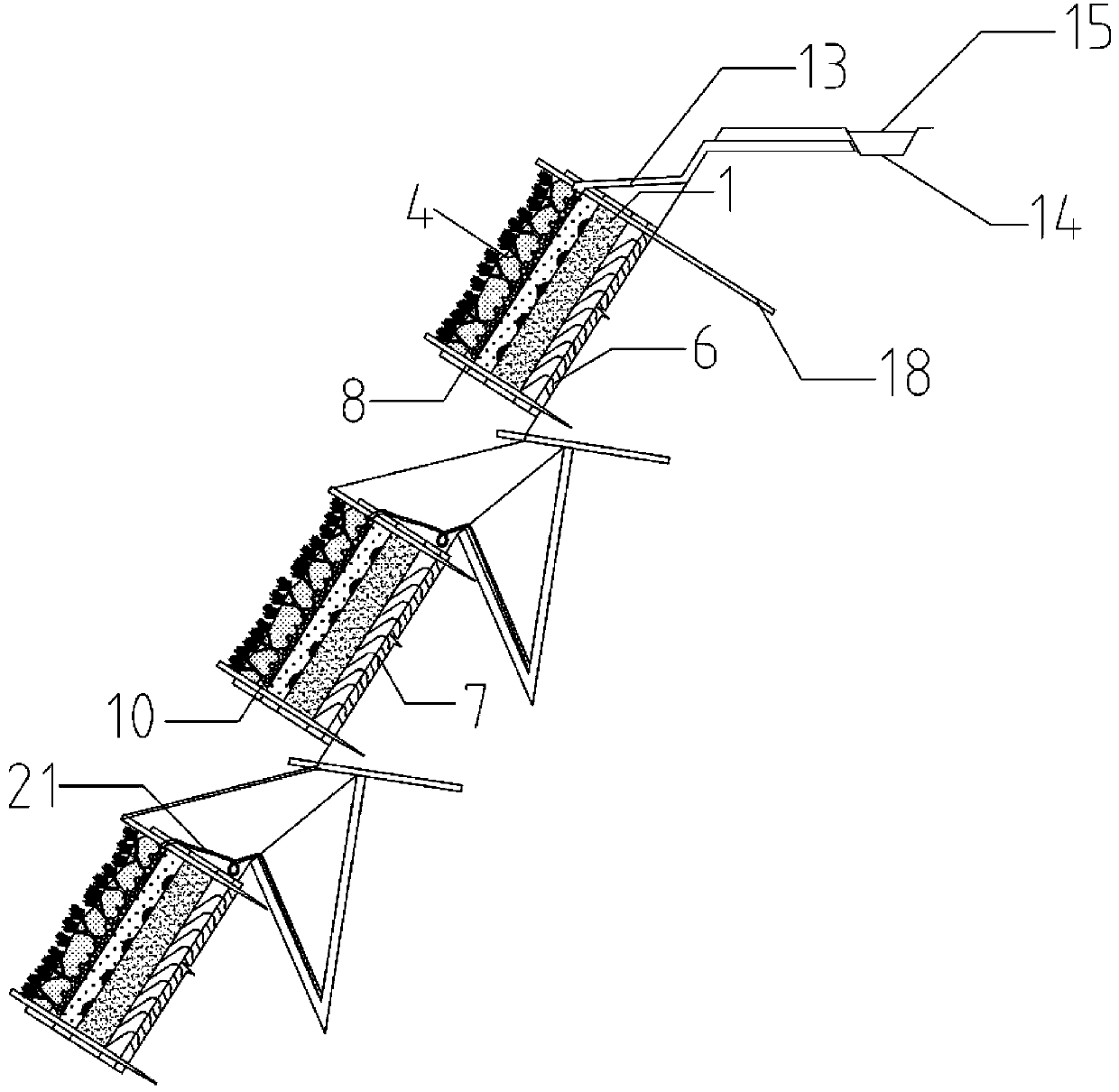

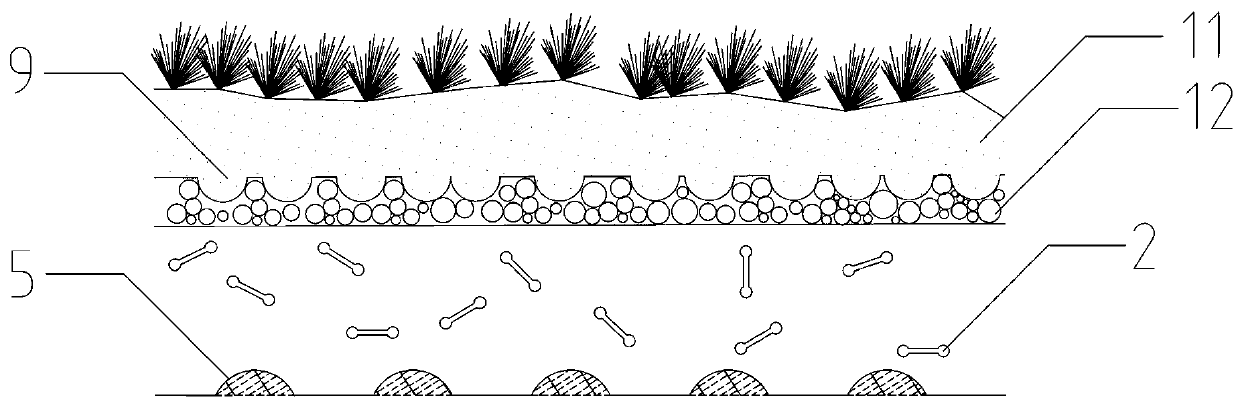

Slope ecological protection blanket structure and construction method

ActiveCN111305234AHigh breaking strengthIncrease frictionWatering devicesExcavationsWater storageEnvironmental engineering

The invention provides a slope ecological protection blanket structure and a construction method. The slope ecological protection blanket structure comprises an expansive cement blanket structure, a vegetation concrete structure, a water storage and drainage system and a fixing system. The expansive cement blanket structure, the vegetation concrete structure, the water storage and drainage systemand the fixing system form the whole slope ecological protection blanket structure which can effectively play a role in slope stabilization and water storage and drainage. All accumulated water is slope rainwater, and thus the cost of artificial water application under drought conditions is reduced.

Owner:CHINA THREE GORGES UNIV

Middle mold core for manufacturing large mold

The invention discloses a middle mold core for manufacturing a large mold. The mold core is formed by splicing various blocks. The middle mold core has the advantages that the mold core is formed by splicing the blocks into a whole, after the mold is stressed, the spliced mold core has the buffering function and has less possibility of being cracked and damaged, and the scrap rate of the mold core is reduced; and when the mold core is worn in the pressing process, only the worn blocks are required to be replaced or the blocks are required to be spliced into a full mold core so as to form a cavity, the mold core still can be utilized, and the cost is reduced.

Owner:太仓市日精模具有限公司

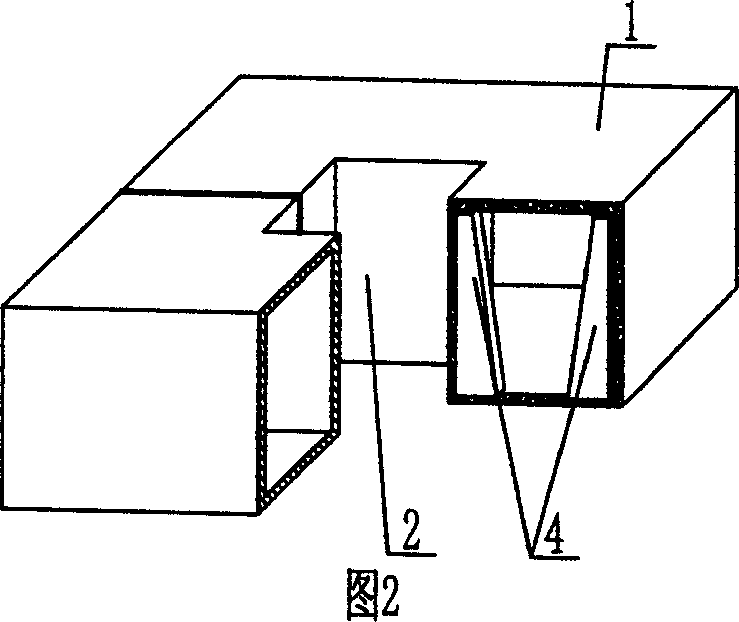

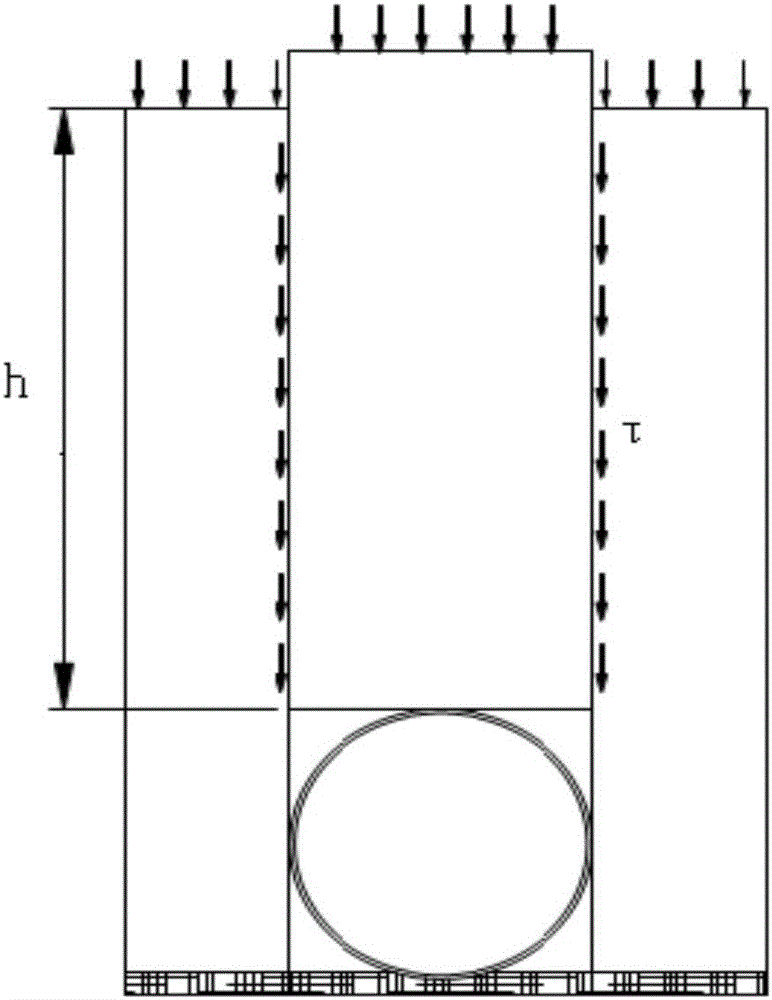

A lightweight permanent blank shell

InactiveCN101003994AImprove performanceNot easy to crack and damageFloorsReinforced concreteOptoelectronics

The present invention relates to a light permanent form for filling concrete. It includes a light form body; said light form body includes upper plate, peripheral side plate and lower plate. It is characterized by that in the light form body at least one hole is set, said hole is passed through upper and lower surfaces of said light form body, and can be used for in-situ pouring concrete. Said light permanent form is applicable to cast-in-situ reinforced concrete or prestressed reinforced concrete hollow floor, roof, wall body, foundation baseplate and open-web bridge, specially, it is applicable to hollow beamless floor.

Owner:湖南邱则有专利战略策划有限公司

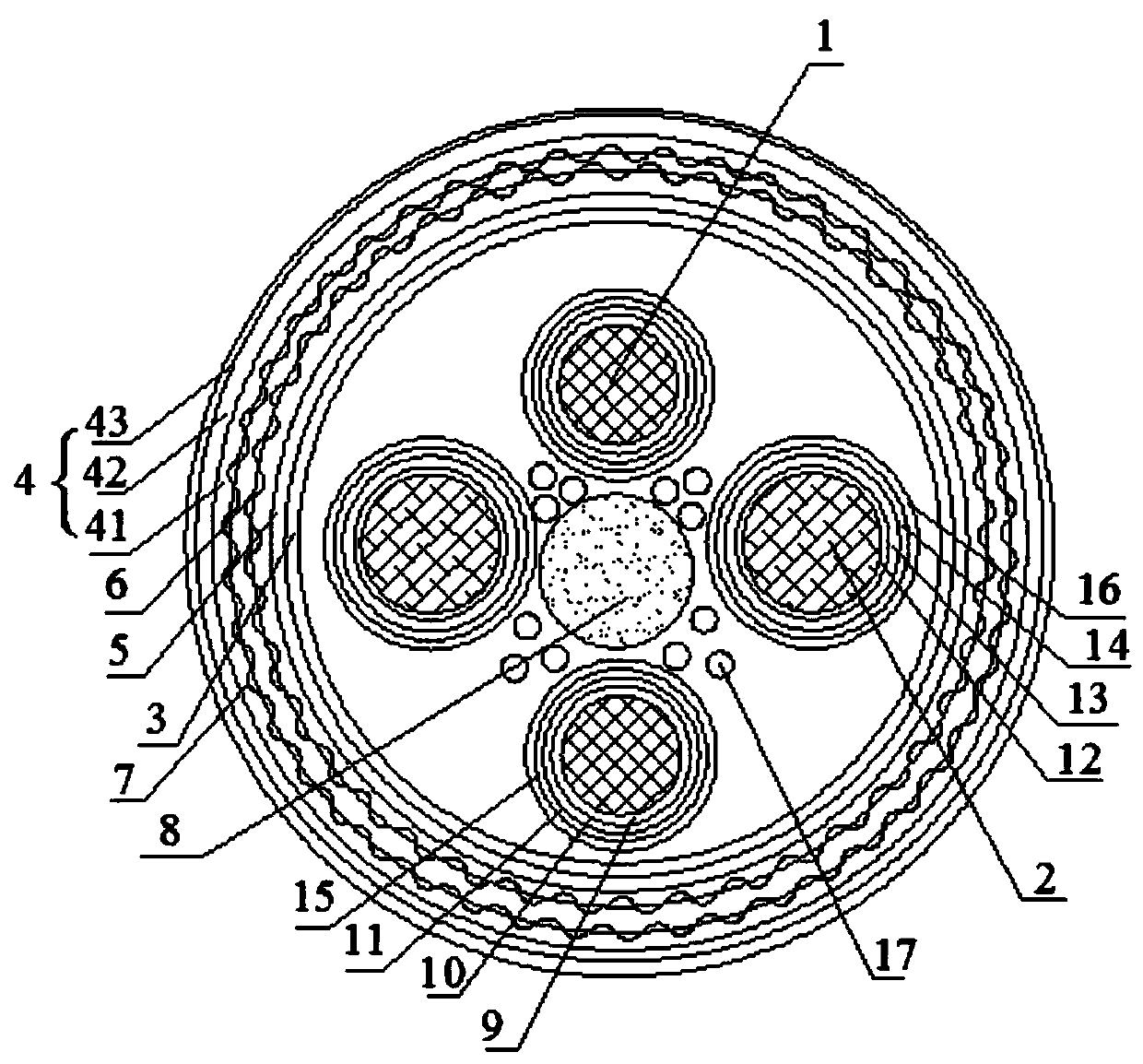

Fire-resistant and bend-resistant shielding flexible optical cable

ActiveCN108594382AGuaranteed cooling effectExtended service lifeFibre mechanical structuresFiberInsulation layer

The invention discloses a fire-resistant and bend-resistant shielding flexible optical cable which comprises two optical cable cores, two carbon fiber composite core rods, an outer shielding layer andan outer insulation layer, wherein the two optical cable cores and the two carbon fiber composite core rods are arranged in the optical cable, and the outer shielding layer and the outer insulation layer are arranged outside the optical cable. Center reinforced steel wires are arranged in the optical cable cores and the carbon fiber composite core rods, a water blocking layer, an inner cooling pipe and an outer cooling pipe are arranged between the outer shielding layer and the outer insulation layer, the outer insulation layer comprises a polytetrafluoroethylene layer, a ceramic silicon rubber layer, a high-flame-retardant halogen-free polyethylene layer which are sequentially arranged from inside to outside, the inner cooling pipe and the outer cooling pipe are made of high-molecular flexible materials, composite non-woven fabric layers, inner insulating layers and first fiber woven reinforcement layers are sequentially arranged on the outer layers of the optical cable cores, and fiber sheathes, high-temperature-resistant slip bands and second fiber woven reinforcement layers are sequentially arranged on the outer layers of the carbon fiber composite core rods. The optical cabledoes not easily crack or damage and is resistant to fire and high temperature after bearing multiple crimping and high pressure on the premise of ensuring the cooling performance and the shielding performance of the flexible optical cable.

Owner:SHENZHEN SDG INFORMATION CO LTD

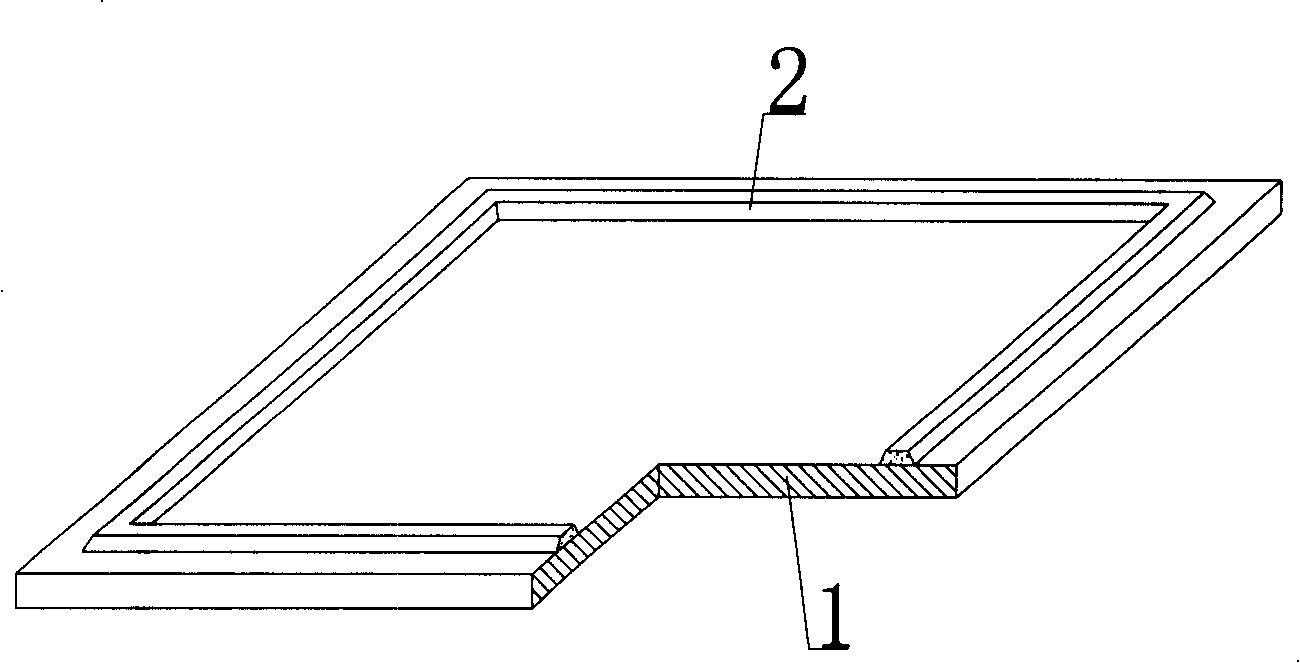

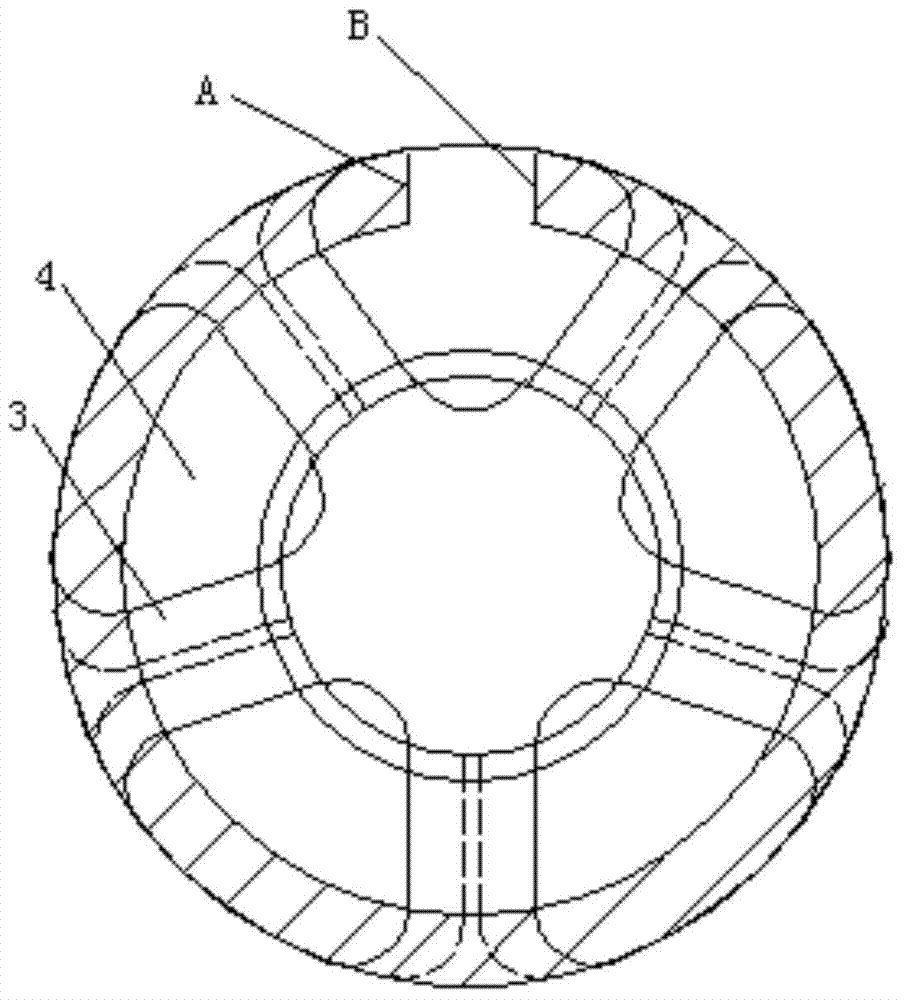

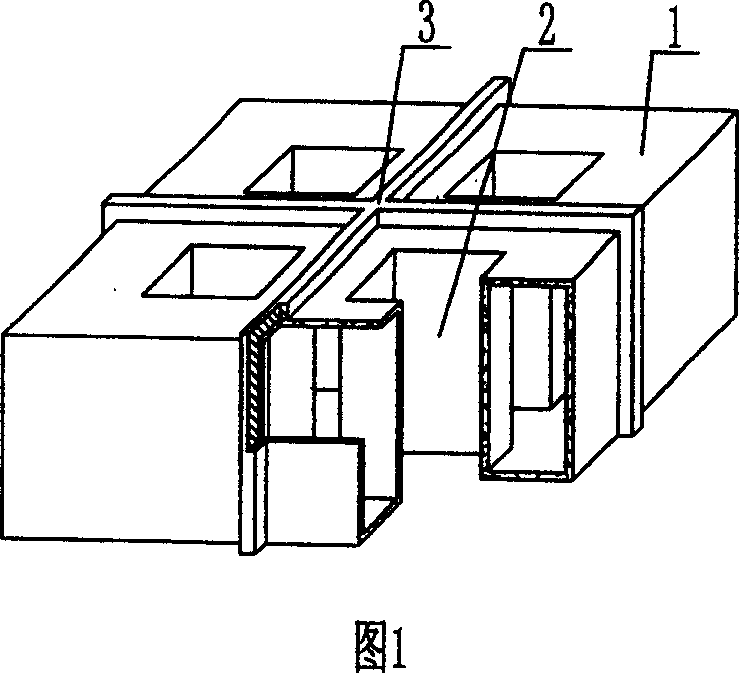

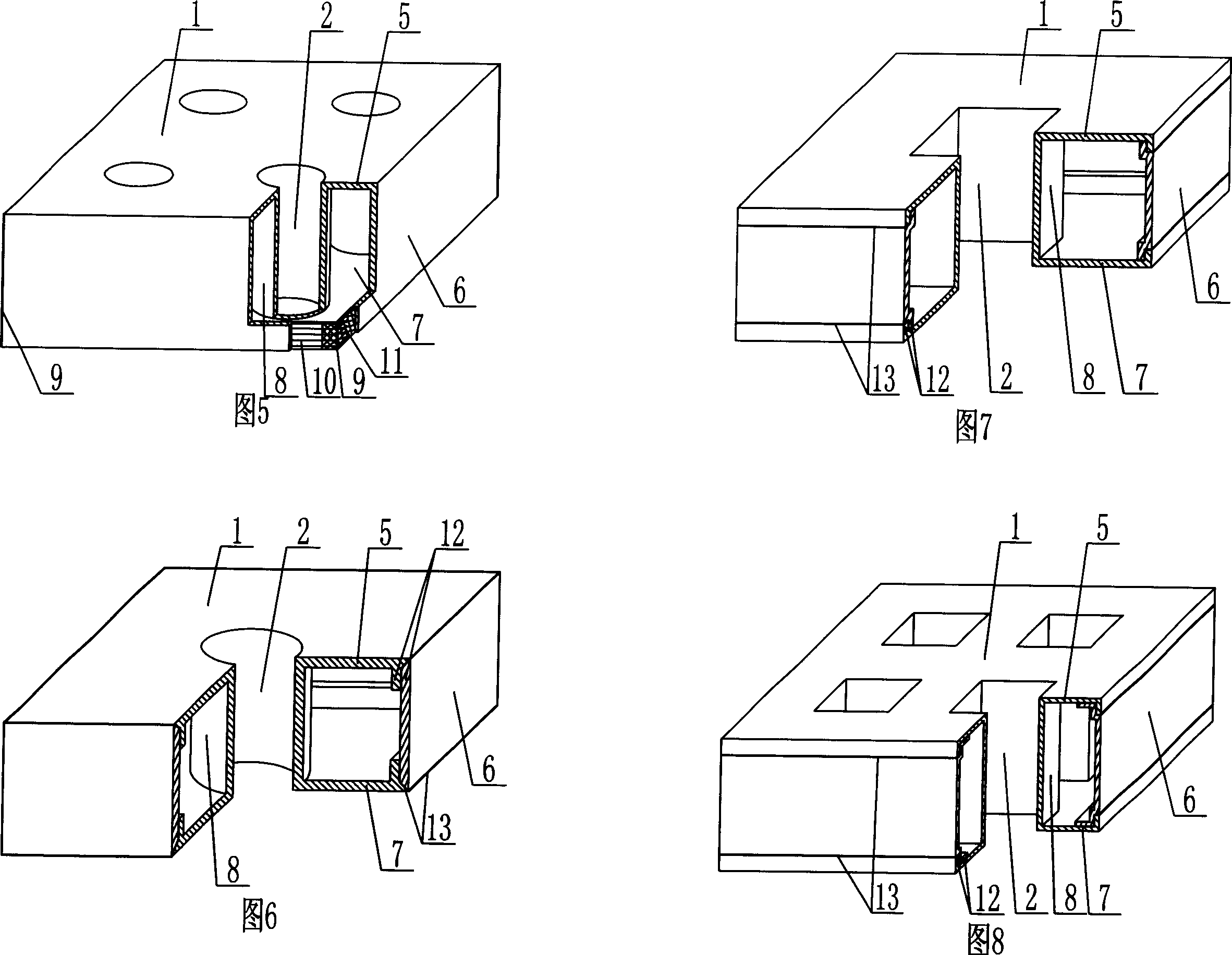

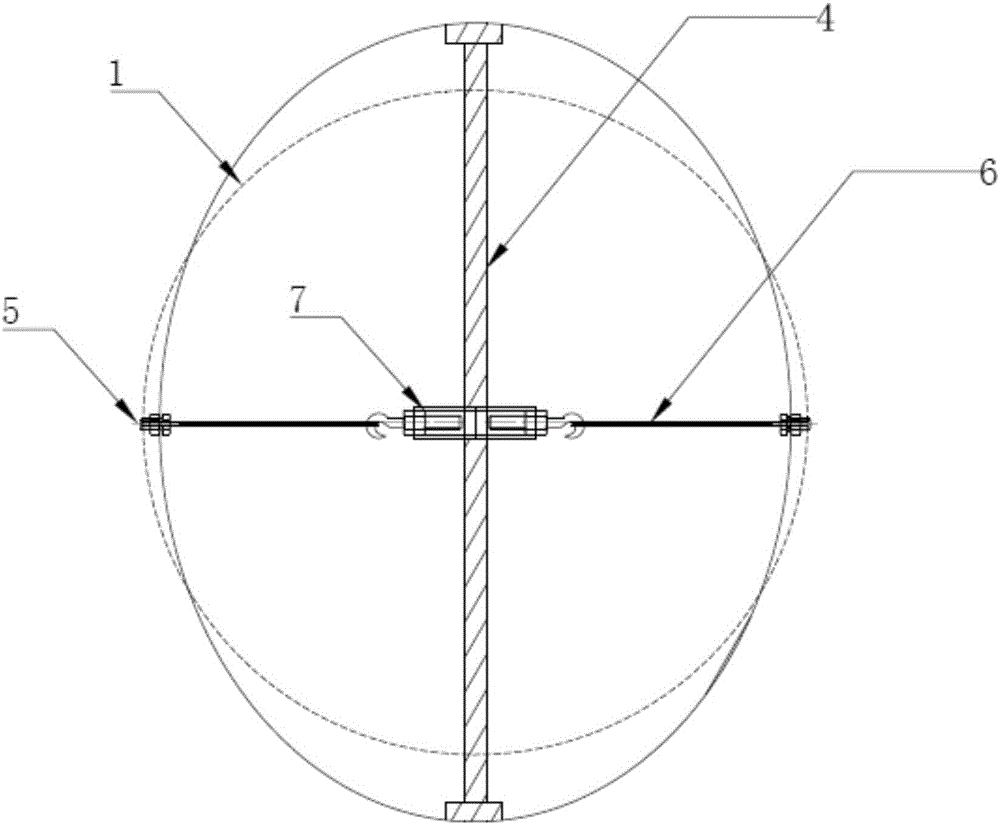

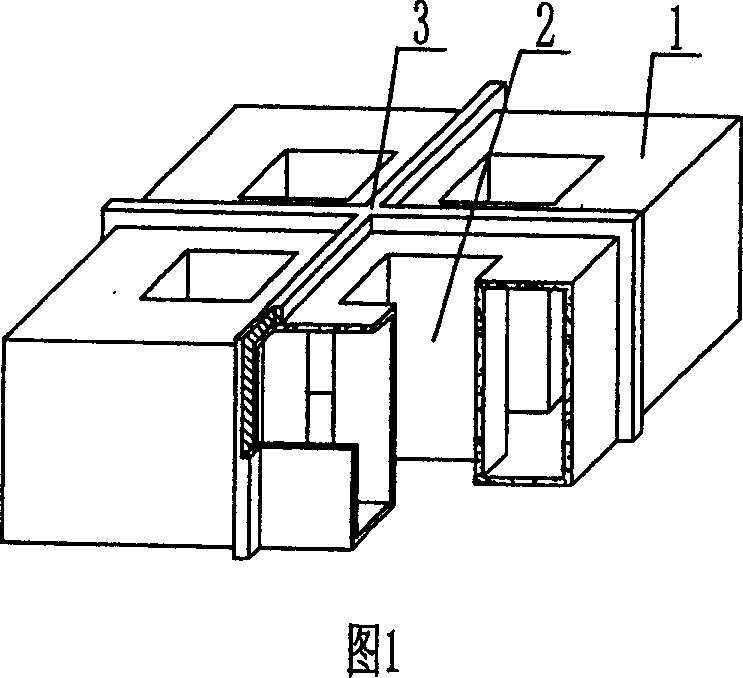

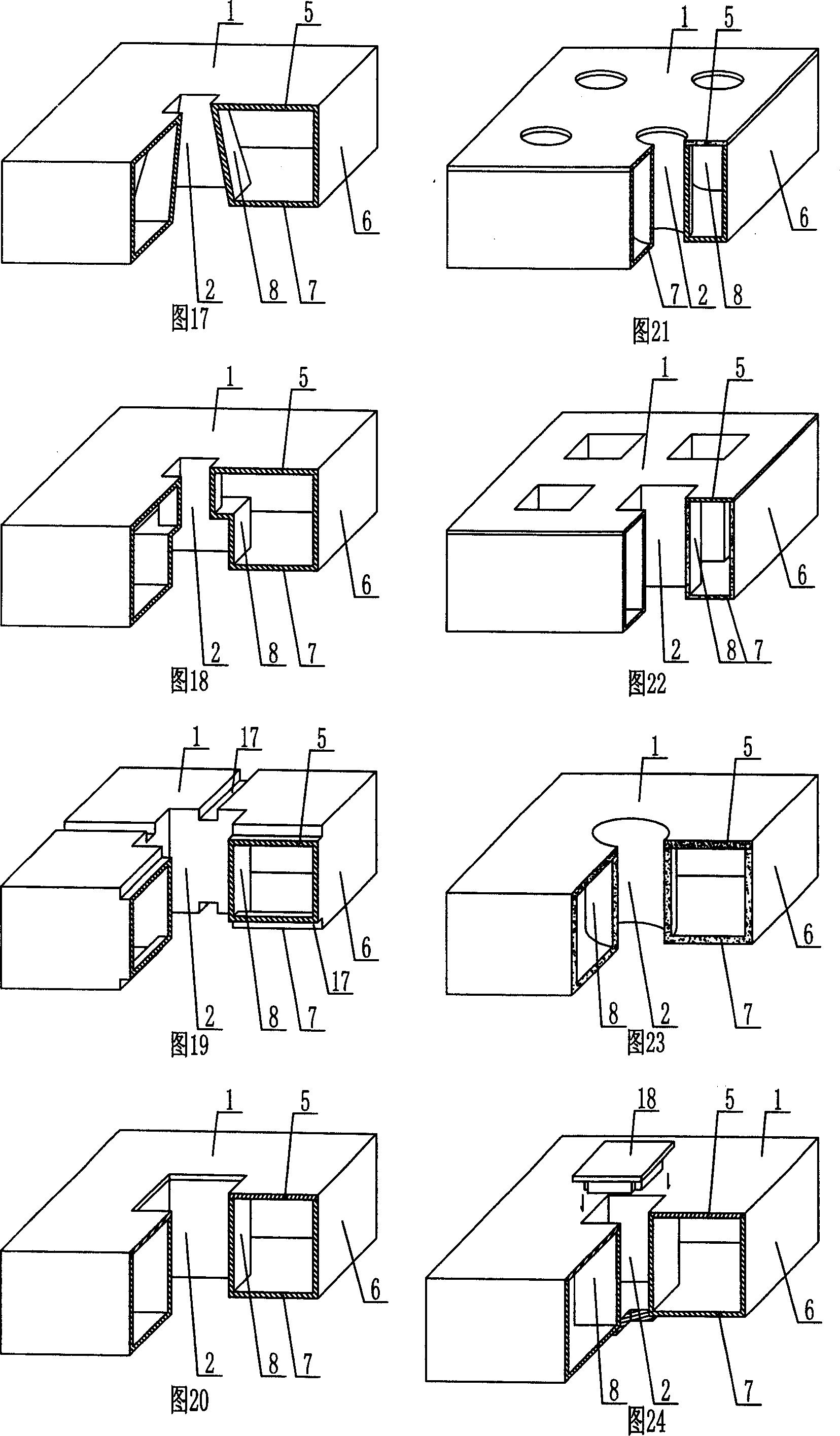

Mould-shell structural component

A mold-shell member is composed of top plate(1) and peripheral side walls(2). Said top plate(1) and peripheral side walls(2) are enclosed into an open basin-shaped member, a top plate(1) scuttle(51) is set in the middle of said basin-shaped member top plate(1), said open basin-shaped member is connected by at least two shell plates(53) at corner. It can be used for various hollow and beamless building roofs of cast-in-situ reinforced concrete or pre-stressed reinforced concrete, basic baseboard, wall and bridges.

Owner:湖南邱则有专利战略策划有限公司

Construction method of a high-fill corrugated steel pipe culvert

ActiveCN103541311BHigh compressive strengthIncrease the moment of inertia of the sectionGround-workEngineeringCulvert

Owner:NANJING LIANZHONG CONSTR ENG TECH

Building reinforcing structure and reinforcing method thereof

ActiveCN113882708ANot easy to tiltGood support and reinforcementBuilding repairsBuilding material handlingArchitectural engineeringRebar

The invention relates to the technical field of building reinforcing, and discloses a building reinforcing structure and a reinforcing method thereof. The building reinforcing structure comprises a bottom plate, a side plate connected to the upper portion of the bottom plate, a plurality of supporting plates arranged on one side of the side plate and a plurality of sets of fixing members connected to the lower portion of the bottom plate; the fixing members comprise at least two steel pipe bodies which are spliced and connected in the vertical direction, reinforcement cages arranged in the steel pipe bodies and anti-disengaging covers detachably connected to the two ends of the steel pipe bodies; the anti-disengaging covers on any two adjacent steel pipe bodies are connected through a set of installation members; the bottom plate is provided with grouting holes, the number of the grouting holes is equal to that of the fixing members, the grouting holes are formed over the fixing members in a communicating mode, and the anti-disengaging covers are provided with flow guide holes communicating with inner cavities of the steel pipe bodies. According to the building reinforcing structure and the reinforcing method thereof, concrete grout can be injected into the fixing members through the grouting holes, so that the supporting and reinforcing effect of the fixing members on the wall is improved.

Owner:浙江城颐工程设计有限公司

Pod-shaped elastic supporting rod device

ActiveCN113998149ANot easy to crack and damageReduce breakage rateCosmonautic vehiclesCosmonautic partsFiberEngineering

The invention discloses a pod-shaped elastic supporting rod device which comprises an upper pod section and a lower pod section, and the edges of the two sides of the upper pod section and the edges of the two sides of the lower pod section each comprise a bonding face and a straight face; tooth grooves which are arranged at intervals are sequentially formed in the straight surface, the tooth grooves of the upper bean pod section and the tooth grooves of the upper bean pod section are arranged in a crossed mode, a toughening type fiber sheet is arranged between every two adjacent tooth grooves, high-toughness glue is coated on the toughening type fiber sheets and the bonding surface, and the upper bean pod section and the lower bean pod section are connected in a bonding mode through the high-toughness glue. The tooth grooves which are arranged at intervals are sequentially formed in the straight faces of the upper pod section and the lower pod section, the tooth grooves of the upper pod section and the tooth grooves of the lower pod section are arranged in a crossed mode, the toughening type fiber sheets are arranged between the adjacent tooth grooves, and the toughening type fiber sheets and the bonding faces are coated with the high-toughness glue. The upper bean pod section and the lower bean pod section are bonded together through the high-toughness glue, so that when the device is flattened or curled, cracking damage is not prone to being generated, and the breakage rate is reduced; and the bearing capacity and the yield are improved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

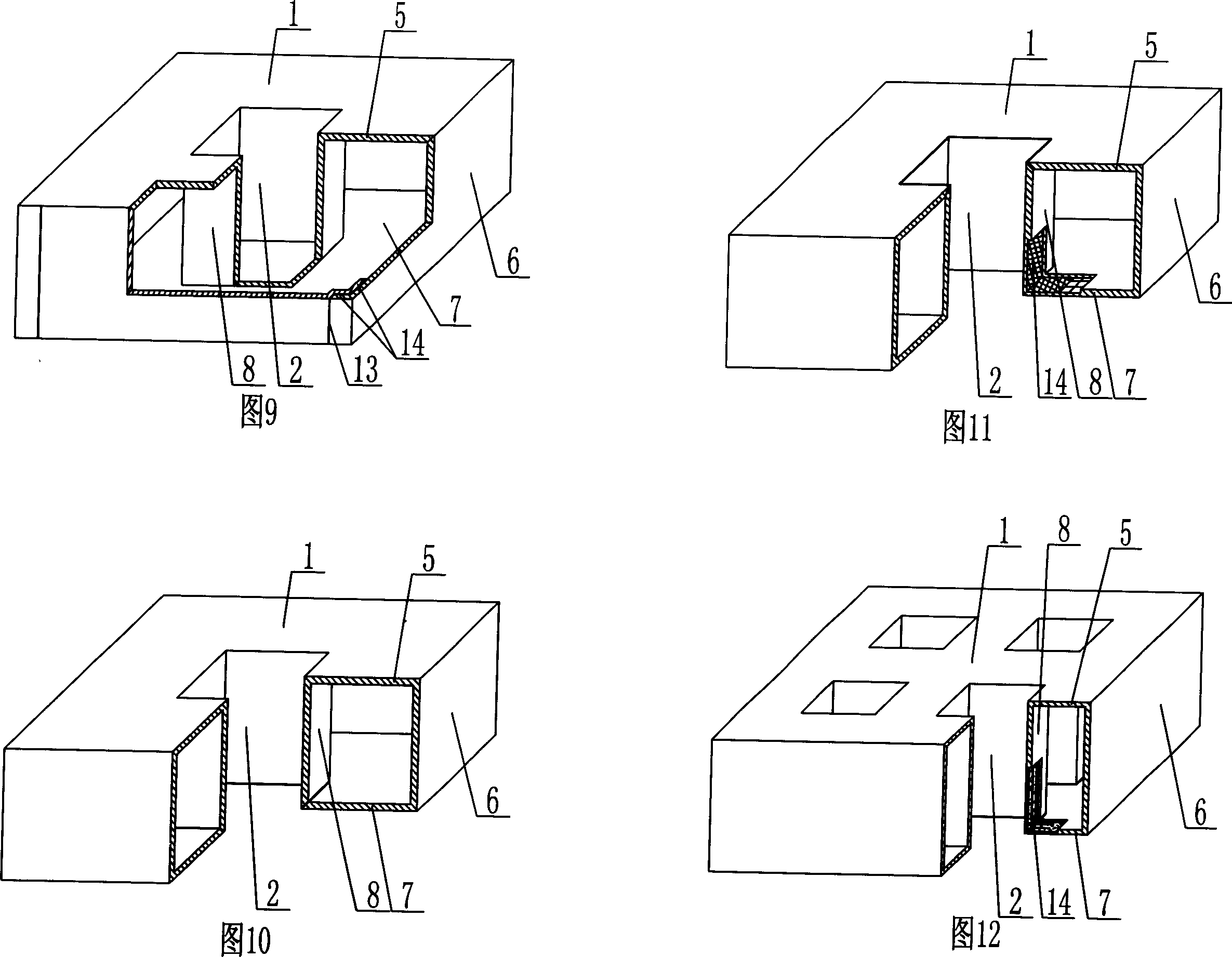

A fire-proof and bending-resistant shielded flexible optical cable

ActiveCN108594382BGuaranteed cooling effectExtended service lifeFibre mechanical structuresNonwoven fabricSilicon rubber

The invention discloses a fire-proof and bending-resistant shielded flexible optical cable, which comprises two optical cable cores and two carbon fiber composite mandrels arranged inside, an outer shielding layer and an outer insulating layer arranged outside, an optical cable core and a carbon fiber composite core There is a central reinforcing steel wire inside the rod, and a water-blocking layer, a heat-dissipating inner pipe, and a heat-dissipating outer pipe are arranged between the outer shielding layer and the outer insulating layer. The outer insulating layer includes a polytetrafluoroethylene layer, ceramic Silicone rubber layer, high flame-retardant halogen-free polyethylene layer, heat dissipation inner tube, and heat dissipation outer tube are all made of polymer flexible materials; the outer layer of the optical cable core is sequentially provided with a composite non-woven layer, an inner insulating Braided reinforcement layer; the outer layer of the carbon fiber composite mandrel is provided with a fiber sleeve, a high temperature resistant slip belt, and a second fiber braided reinforcement layer in sequence. Under the premise of ensuring the heat dissipation performance and shielding performance of the flexible optical cable, the present invention is not easy to crack and damage after being subjected to multiple crimps and relatively high pressure, and is fireproof and high temperature resistant.

Owner:SHENZHEN SDG INFORMATION CO LTD

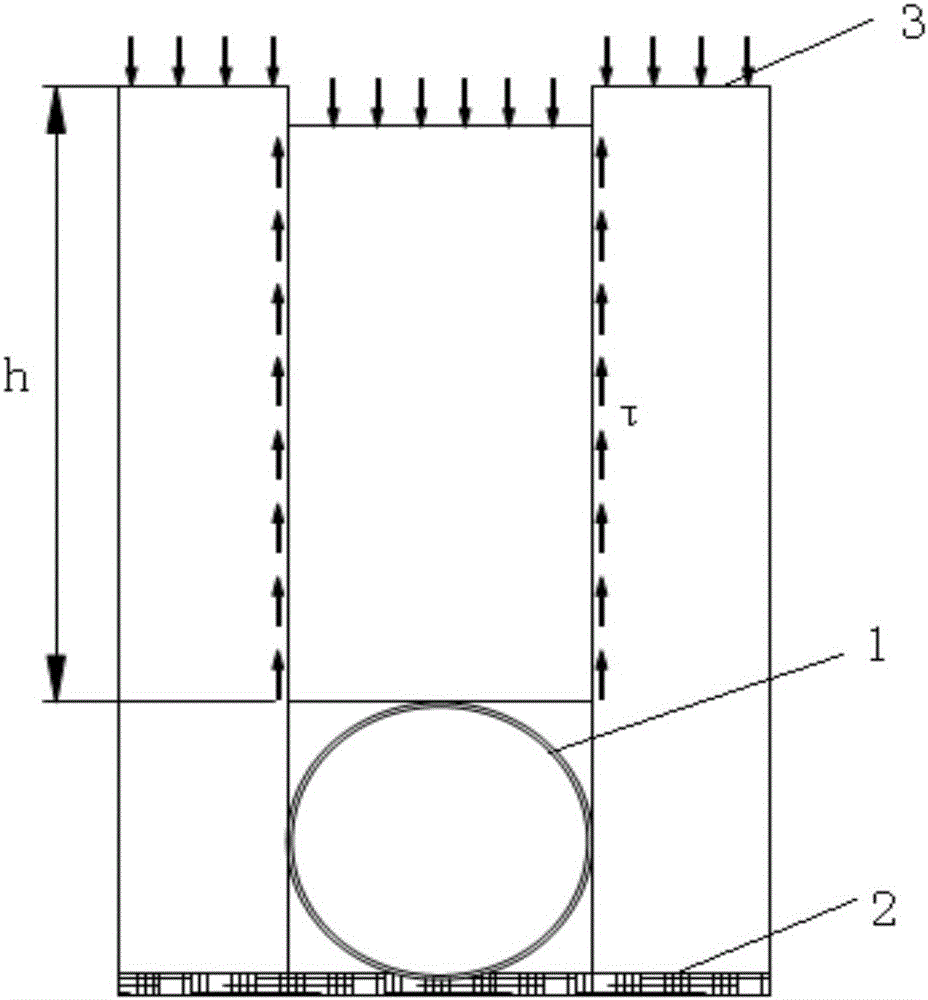

Light permanent form for concrete filling

InactiveCN1974982AEasy to pour and compactIncreased Strength and RigidityFloorsHollow coreReinforced concrete

The present invention relates to a light permanent form for filling concrete. It includes light form body. Said light form body includes upper plate, peripheral side plate and lower plate which are mutually connected together and formed into a closed hollow cavity. It is characterized by that it also includes a tube for making through hole, and said tube for making through hole is placed in the closed hollow cavity. Said light permanent form can be used for in-situ casting reinforced concrete or prestressed reinforced concrete hollow floor, roof, wall body, foundation bedplate and open-web bridge, etc.

Owner:湖南邱则有专利战略策划有限公司

Novel environment-friendly domestic garbage treatment method

InactiveCN111036650AReduce odorImprove the environmentTransportation and packagingSolid waste disposalDecompositionEnvironmental engineering

The invention relates to the technical field of garbage treatment, in particular to a novel environment-friendly domestic garbage treatment method. According to the method, domestic garbage is subjected to graded stirring treatment, according to different densities of the domestic garbage, the domestic garbage is pre-divided into two types of metal sandstone garbage and organic plastic garbage, the organic plastic garbage is preliminarily extruded and dehydrated and then sprayed with bacterial liquid for fermentation, organic perishable substances are further decomposed through bacteria in thefermentation process, the organic perishable substances can be further dried, the odor of a working workshop can be effectively reduced through fermentation and decomposition under a low water content environment, the environment of a treatment workshop is improved, organic matters in the micro-carbonized organic garbage are subjected to anaerobic pyrolysis through a pyrolysis furnace, extractedpyrolysis gas can be stored in a gas storage tank to be used as fuel gas, efficient resource conversion is carried out on the domestic garbage, and the method has a wide application prospect.

Owner:安徽家齐物业管理有限公司

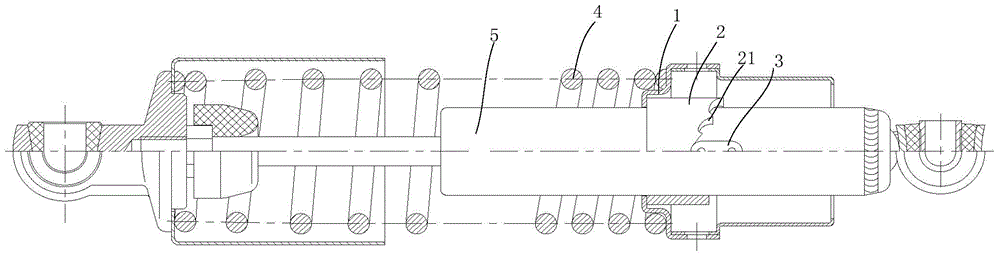

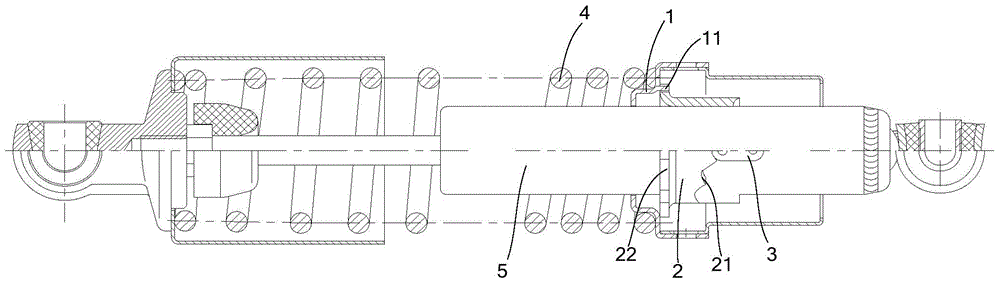

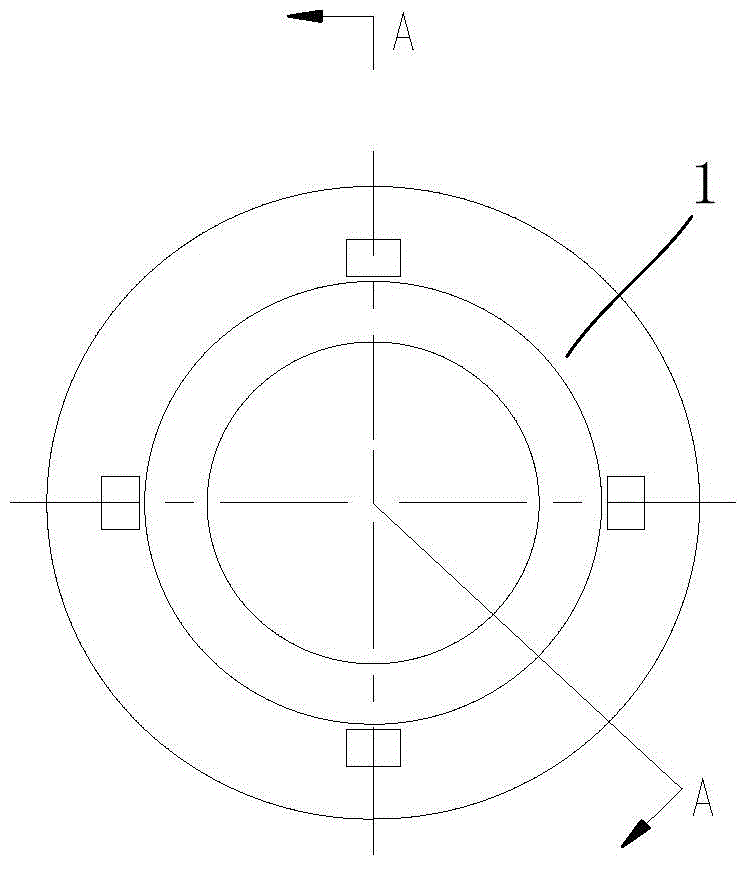

Rear shock absorption regulating structure for motorcycle and shock absorber of rear shock absorption regulating structure

InactiveCN104455158AHigh strengthNot easy to crack and damageSpringsAxle suspensionsEngineeringShock absorber

The invention provides a rear shock absorption regulating structure for a motorcycle. The rear shock absorption regulating structure comprises a lower dust cover and a tubular regulator. The regulator is made of tubes. Regulating teeth are arranged at the lower end of the regulator. A boss is arranged on the outer wall of the upper end of the regulator. The inner wall of the upper portion of the lower dust cover is supported by the boss. The invention further provides a shock absorber which comprises the rear shock absorption regulating structure for the motorcycle and further comprises a damper and an outer spring. A stroke fixing device is installed on the damper. The damper is sleeved with the regulator. The regulator is covered with the lower dust cover. The regulating teeth of the regulator are matched with the stroke fixing device. The damper is sleeved with the outer spring. The lower end of the outer spring abuts against the outer wall of the upper portion of the lower dust cover. A traditional board coiling structure is changed, the structure is integrally formed in a stamping mode through a steel pipe, the strength of the regulator is improved, and the regulator is not prone to cracking or damage. Through the cooperation of the boss and a clamping block, the regulator and the lower dust cover are installed and matched more firmly; meanwhile, the regulator can be operated through the lower dust cover conveniently and the height is regulated.

Owner:CHONGQING YAOYONG SHOCK ABSORBER

A kind of manufacturing method of sugarcane press roller

ActiveCN104087687BSatisfy acid resistanceMeet performance requirements such as juice yieldJuice extraction from sugarcaneGraphiteSugar cane

The invention aims to provide a method for manufacturing a pressing roll of a sugarcane press. The method is characterized by comprising the following process steps: (1) by adopting vermicular graphite cast iron as a raw material, casting a shell blank of the pressing roll; (2) carrying out rough turning on the top circle and two ends of the roll shell blank; (3) carrying out rough and fine boring on an inner bore of the pressing roll shell; (4) carrying out deep drilling on axial lotus holes of the pressing roll shell; (3) installing internal threads on juice blocking rings at the drilling end and tapping end of the pressing roll shell; (6) thermally sleeving the roll shell on a pressing roll shaft; (7) carrying out fine turning on the top circle and length of the pressing roll shell and turning V-shaped insections; (8) drilling slant radial juice collecting holes in the tank bottom of the V-shaped insections of the pressing roll; (9) milling large herringbone grooves in the circumference of the tooth crest of the pressing roll shell. The method provided by the invention has the advantages that the strength of the pressing roll of the sugarcane press is well satisfied; the capability and efficiency of carrying bagasse materials in the pressing process are increased; the performances of juice yield and the like of sugarcane pressing are increased.

Owner:广西南宁市中高糖机设备制造有限公司

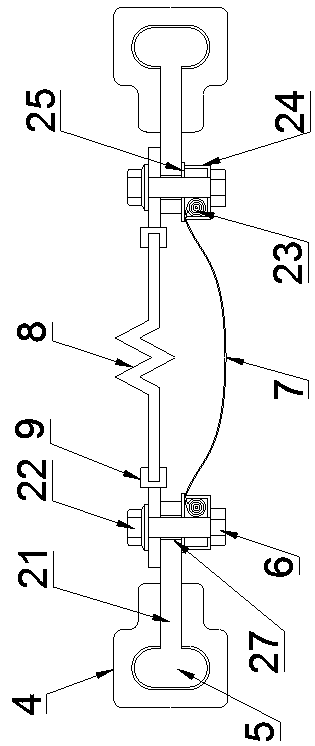

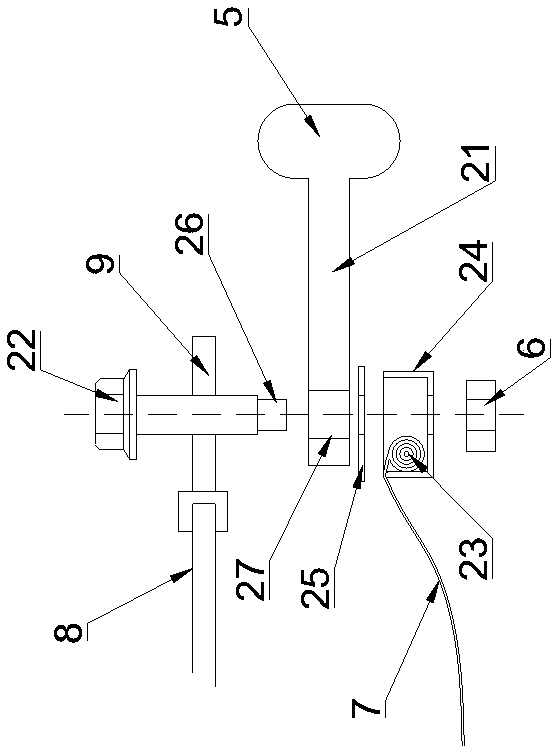

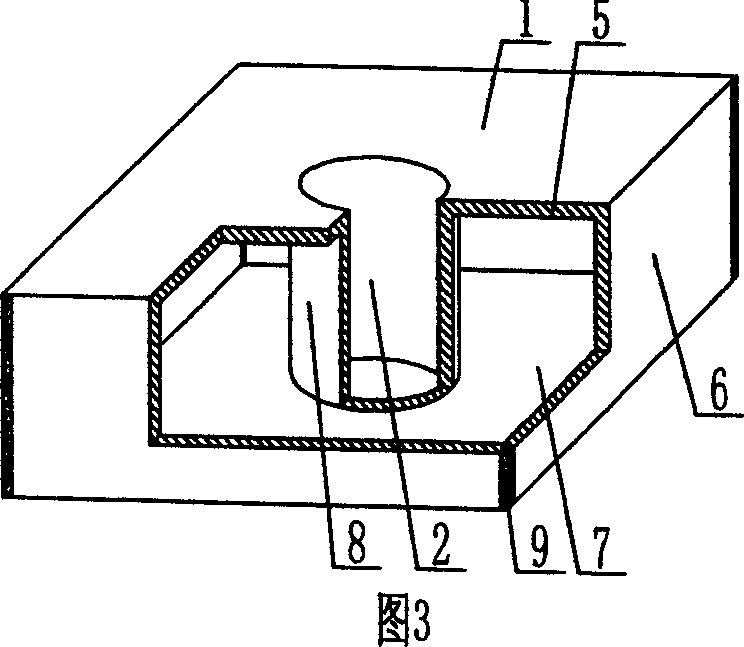

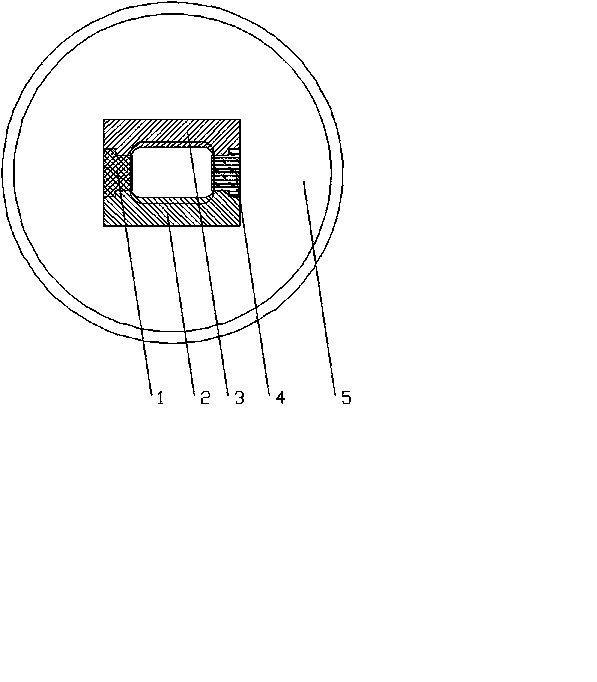

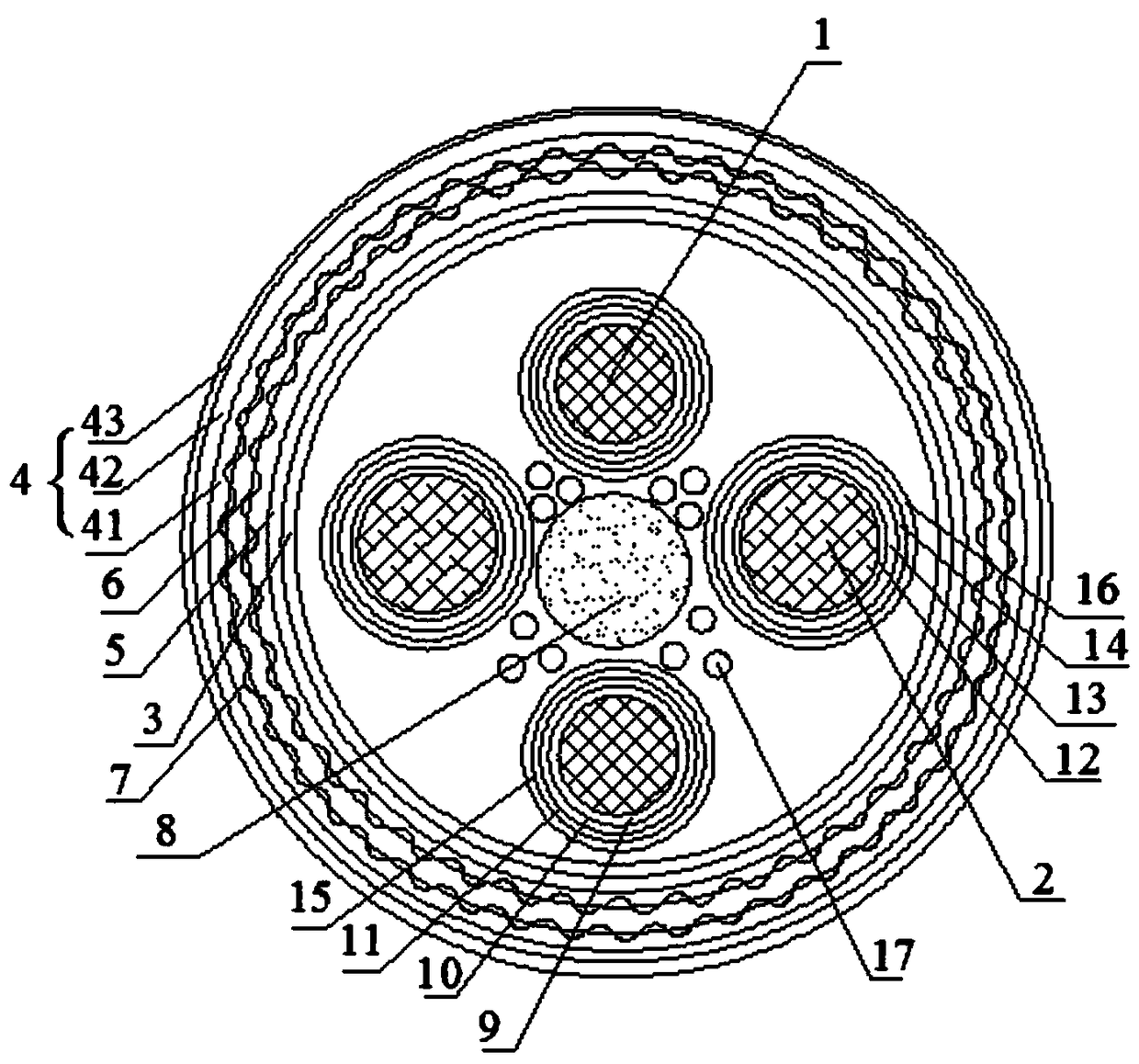

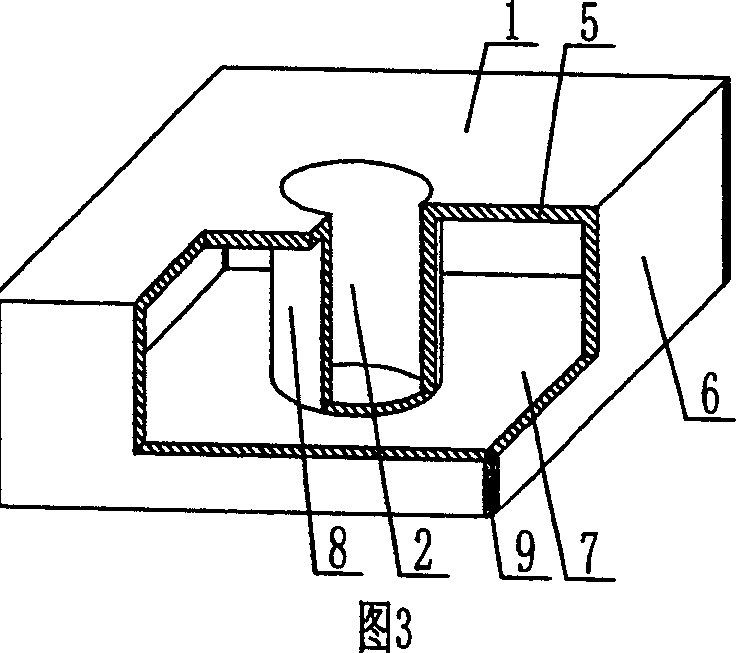

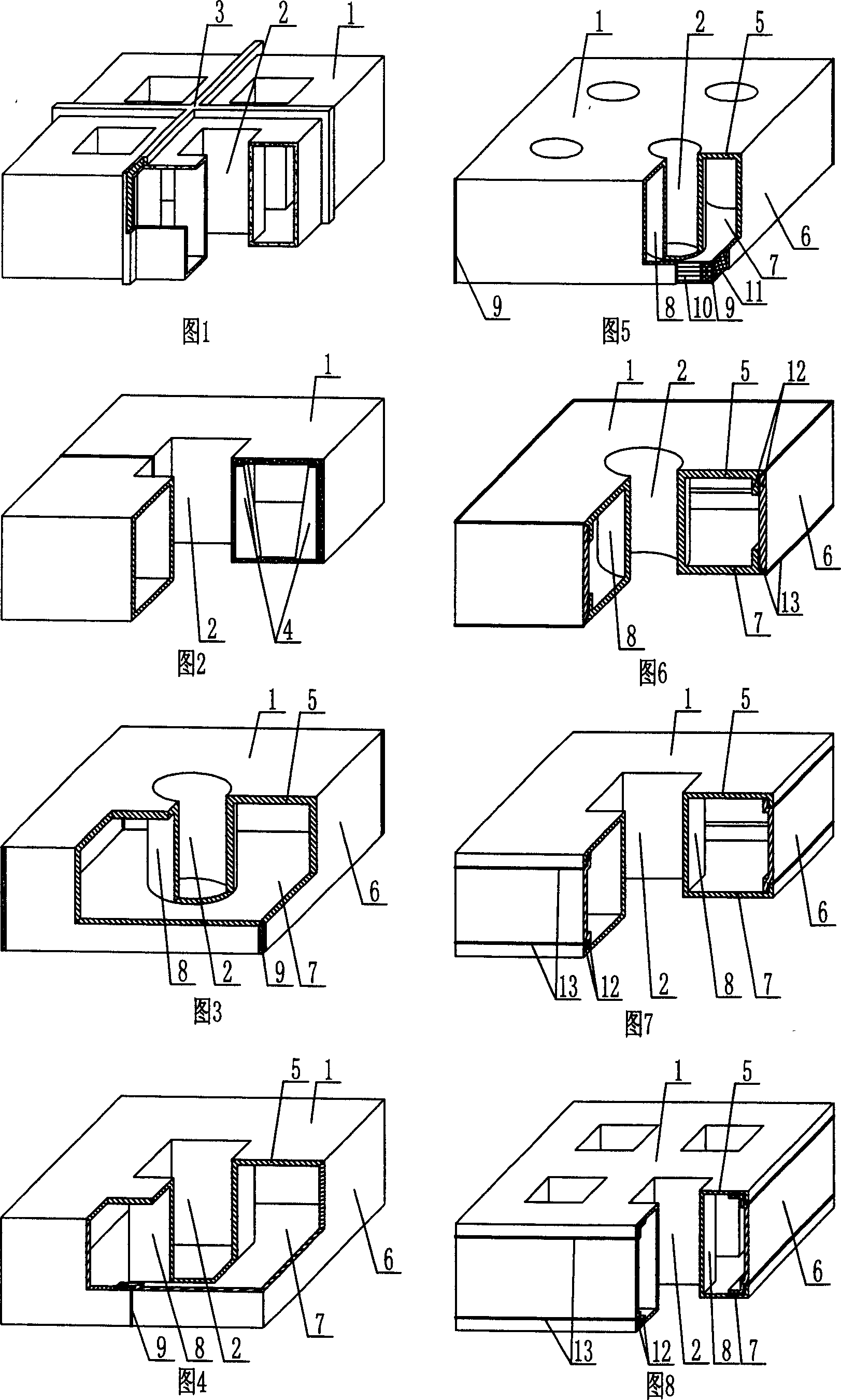

Light permanent tubing shell for filling concrete

InactiveCN1982572AImprove performanceNot easy to crack and damageFloorsReinforced concretePre stress

A light-permanent tube shell for filling concrete is composed of light tube(1), through-hole pipe(8) and hole(2) for pouring cast-in-situ concrete. Said light tube(1) is composed of top shell(5), peripheral side shells(6) and bottom shell(7), said top shell(5), peripheral side shells(6) and bottom shell(7) are enclosed into a closed cavity, through-hole pipe(8) is set inside closed cavity of said light tube(1), at least one hole(2) for pouring cast-in-situ concrete is penetrated top and bottom shells surfaces of said light tube(1),said hollow through-hole pipe(8) is integrated with bottom shell(7) to form into internal shell(21), top shell(5) is integrated with peripheral side shells(6) to form into external shell(22), and external shell(22) connects with internal shell(21) to form into tube shell. It can be used for various hollow and beamless building roofs of cast-in-situ reinforced concrete or pre-stressed reinforced concrete, basic baseboard, wall and bridges.

Owner:湖南邱则有专利战略策划有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com