Large high-temperature-resistant storeroom and installation method thereof

A high-temperature, warehouse-proof technology, applied in building types, special buildings, building components, etc., can solve the problems of cracking in the gap of the assembled board, deformation of the warehouse body, application troubles, etc., to achieve the effect of beautiful appearance and improved service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

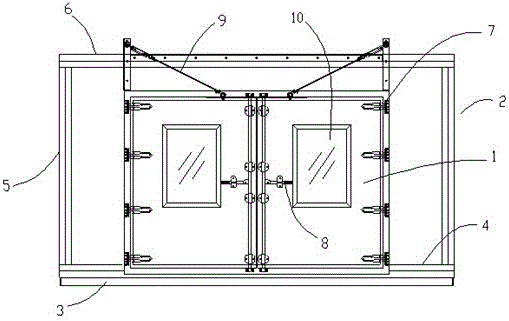

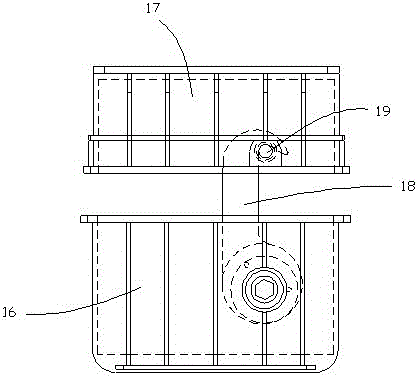

[0058] see Figure 1 to Figure 2 , this embodiment discloses a large-scale high-temperature-resistant warehouse, including: a warehouse door 1, a warehouse body 2 and a base 3; The warehouse door 1 can be opened and closed and installed on one of the side panels 5; the base 3 for bottom leveling is arranged under the bottom panel 4 of the warehouse body 2;

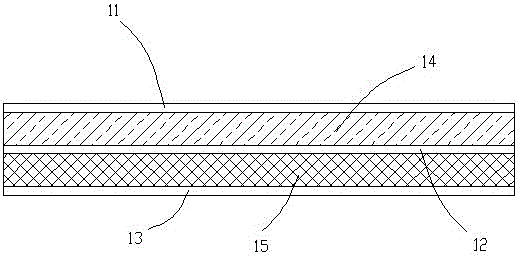

[0059] Each top panel 6, side panel 5, and bottom panel 4 of the storage body 2 are sealed and assembled by unit panels, and each unit panel is composed of a color steel plate 11 on the surface, a galvanized sheet 12 on the middle layer, and a stainless steel plate on the inner layer. 13, a filling layer is provided between the color steel plate 11 and the galvanized plate 12, and between the galvanized plate 12 and the stainless steel plate 13.

[0060] The present invention changes the traditional one-piece structure of the storage body 2, but adopts an assembled structure of unit plates, which lays the foundation for m...

Embodiment 2

[0070] The present invention also provides a method for installing a large-scale high-temperature-resistant warehouse, which includes the following steps:

[0071] S01. Install the base 3 at the assembly site, and perform leveling according to the bottom surface of the assembly site to ensure that the upper surface of the base 3 is set horizontally; the leveling of the base 3 can overcome the uneven bottom surface of the installation site and provide a stable level for the storage body 2. premise.

[0072] S02. Assemble and splice each unit board according to the drawing to form the bottom panel 4, side panel 5 and top panel 6 of the storage body 2 respectively, and reserve a vacancy for installing the storage door 1 on the side panel 5 according to the drawing. The warehouse body 2 is a six-sided airtight space, and ensuring its firmness and airtightness is a prerequisite for realizing a warehouse with a large volume, high firmness, and high-temperature operation.

[0073] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com