Grooving machine and method for processing shaving boards

A particleboard and slotting machine technology, which is applied in slotting machines, processing machines for manufacturing flat surfaces, and mortise-cutting machines, etc., can solve the problems of high labor cost, reduced particleboard quality, damage and cracking of wood boards, etc. High quality, reduce labor cost, not easy to damage and crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in a variety of different ways defined and covered by the claims.

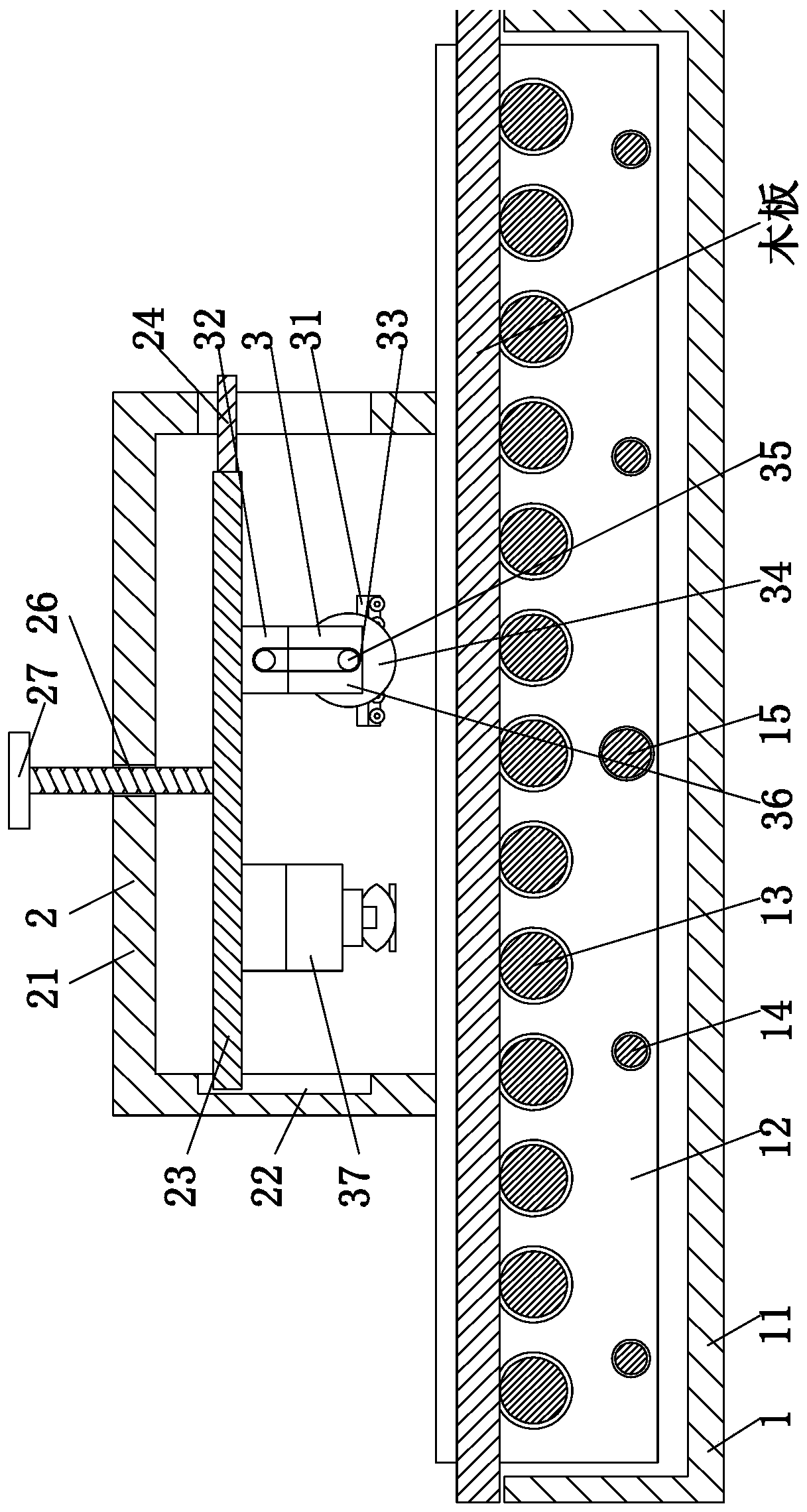

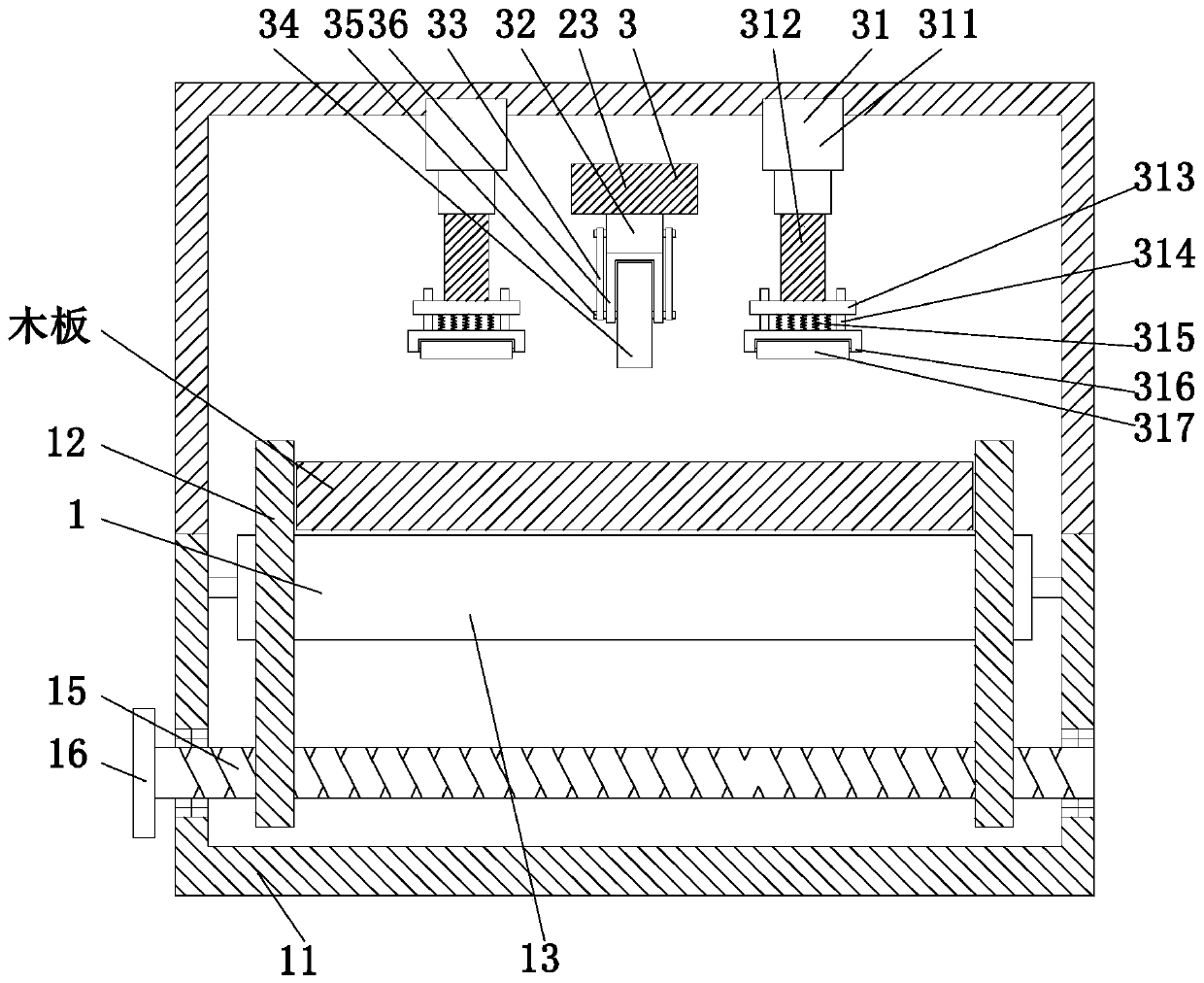

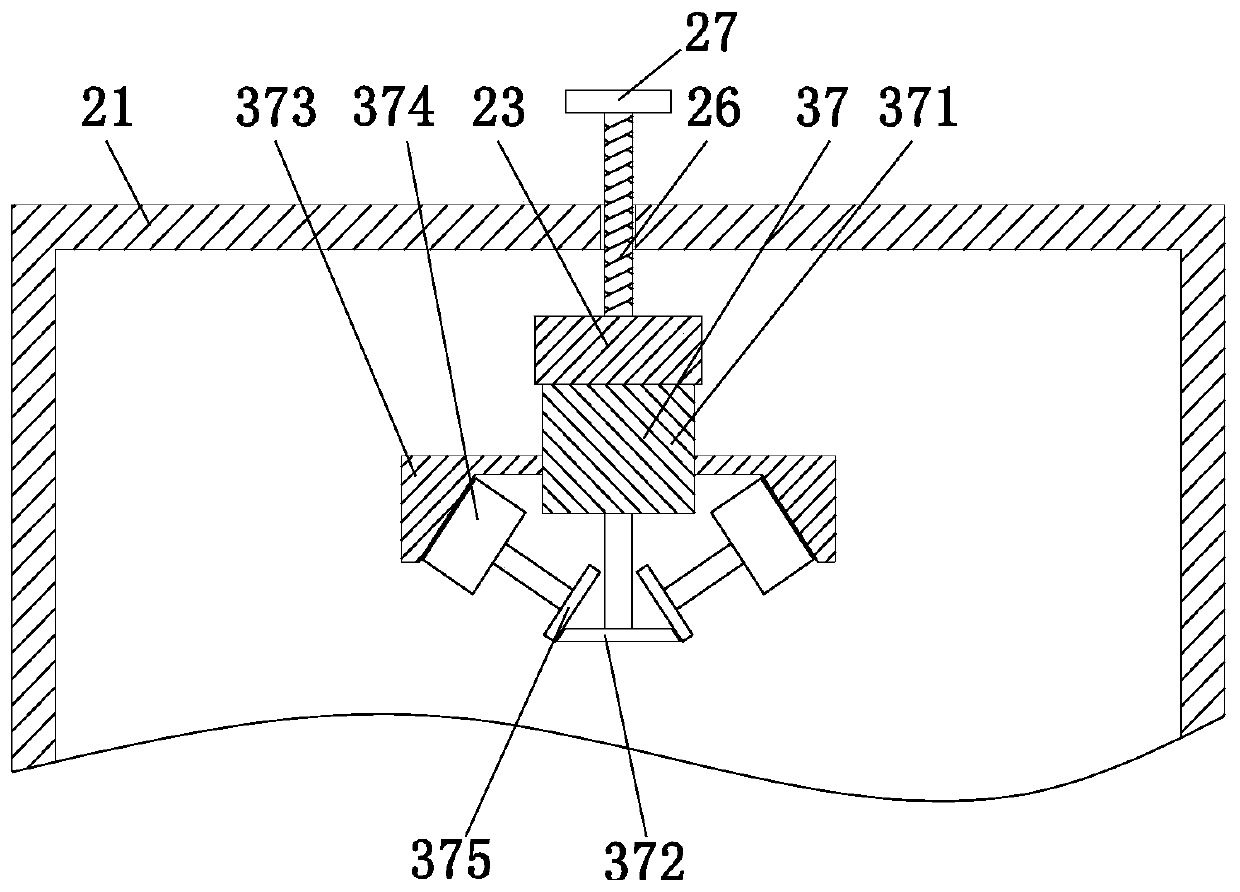

[0032] Such as Figure 1 to Figure 4 A slotting machine for processing particleboard is shown, comprising a conveying device 1, a distance adjusting device 2 and a grooving device 3. The upper end of the conveying device 1 is equipped with a distance adjusting device 2, and the inner end of the distance adjusting device 2 is installed There are slotting device 3.

[0033] The conveying device 1 includes a support frame 11, a fixed plate 12, a conveying roller 13, a limit rod 14, a two-way screw 15 and a turntable 16. The support frame 11 is uniformly installed with conveying rollers 13 through bearings. The lower side of the conveying roller 13 is evenly installed with a limit bar 14 which is connected to the support frame 11 by a fixed method. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com