Glass fiber-reinforced vegetation form porous concrete and construction method thereof

A porous concrete and glass fiber technology, applied in other household appliances, ceramic products, household appliances, etc., can solve the problems of reduced fiber reinforcement efficiency, large water absorption, difficult to wrap fiber cement slurry, etc., to improve flexural strength and resistance. The effect of high compressive strength, high effective utilization, and not easy to crack and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

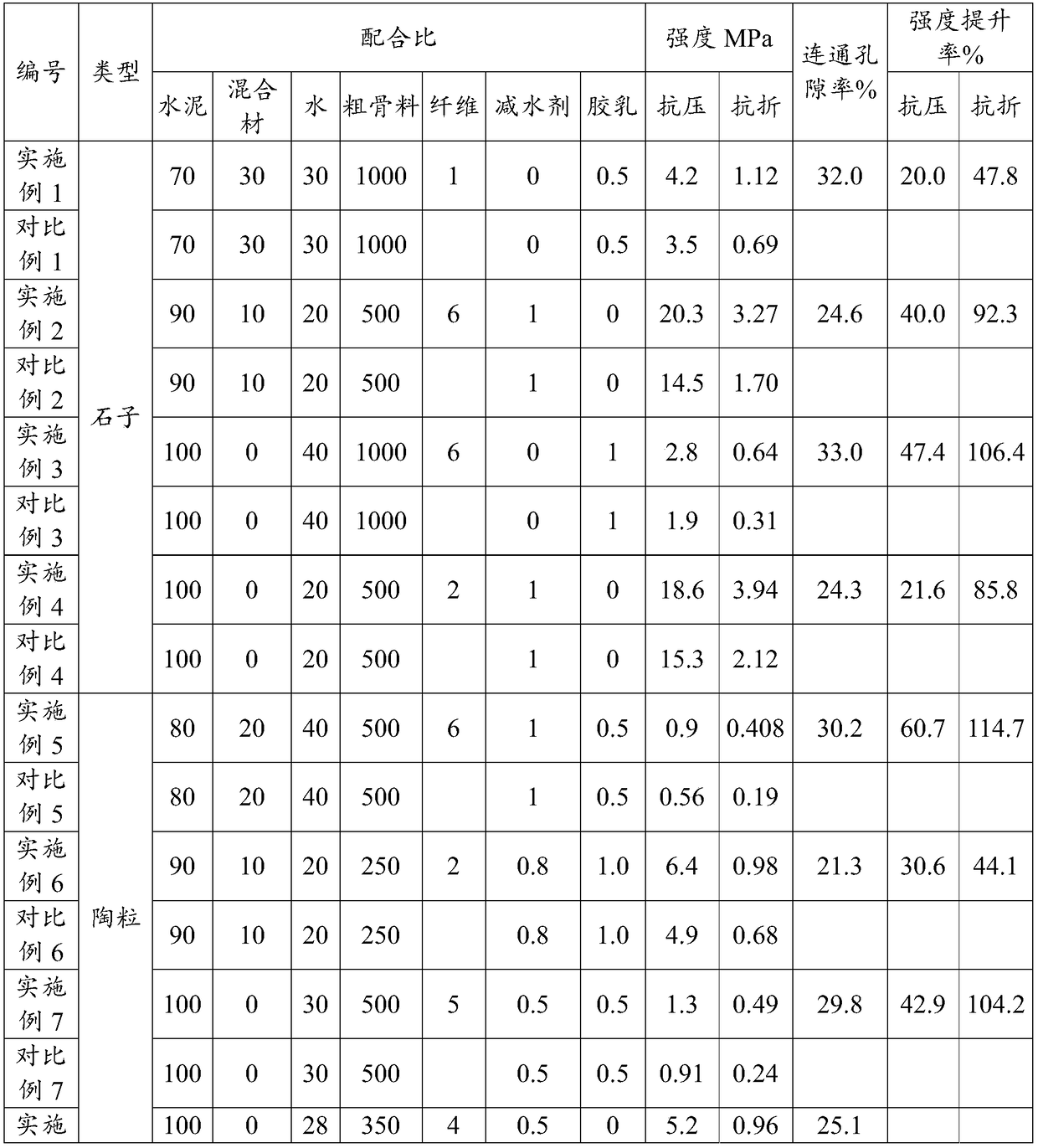

[0028] An embodiment of the glass fiber-reinforced plant-growing porous concrete of the present invention, the glass fiber-reinforced plant-growing porous concrete described in this embodiment comprises the following components by weight:

[0029] 100 parts of cementitious material (70 parts of Portland cement, 30 parts of fly ash), 1 part of glass fiber (10-40mm in length), 1000 parts of stone, 30 parts of water, 0 part of water reducer, 1 part of latex powder .

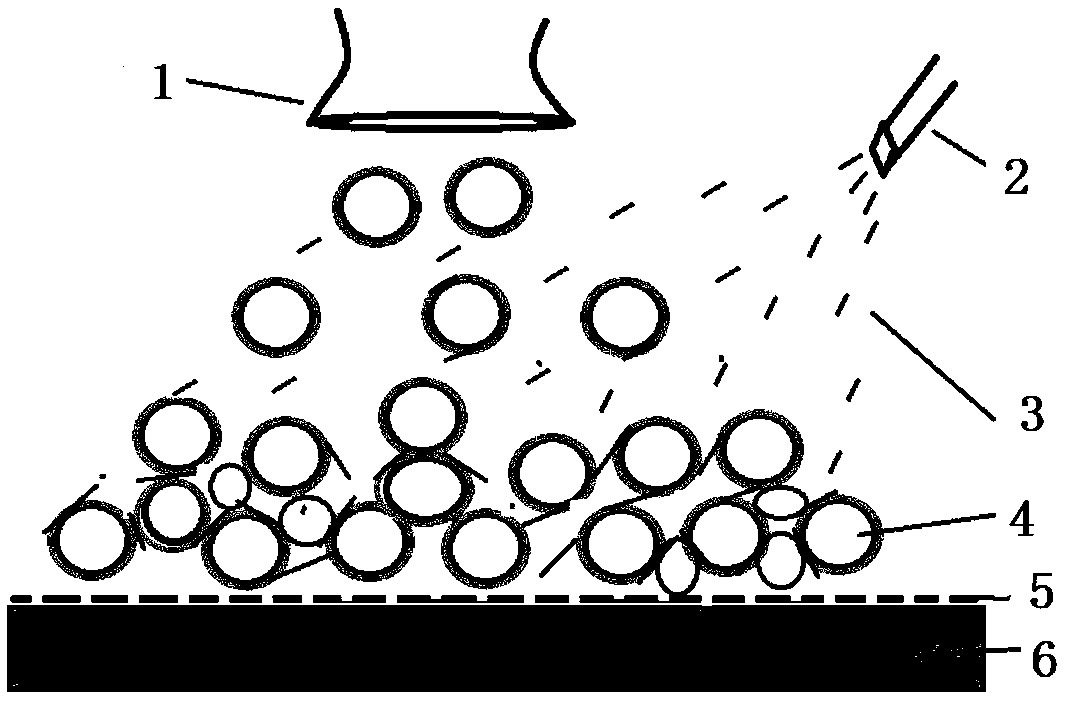

[0030] The construction method of glass fiber reinforced plant-growing type porous concrete described in this embodiment is as attached figure 1 shown, including the following steps:

[0031] (1) Treat the base layer well, and place the fiber mesh cloth on the base layer of the concrete to be poured;

[0032] (2) Blend the single-grain coarse aggregate (if it is ceramsite, it must be pre-wetted) and part of the mixing water to make the coarse aggregate wet;

[0033] (3) Then add cement, water and other components...

Embodiment 2

[0038] An embodiment of the glass fiber-reinforced plant-growing porous concrete of the present invention, the glass fiber-reinforced plant-growing porous concrete described in this embodiment comprises the following components by weight:

[0039] 100 parts of cementitious material (90 parts of Portland cement, 10 parts of granulated blast furnace slag), 6 parts of glass fiber (10-40 mm in length), 500 parts of stone, 20 parts of water, 1 part of water reducer, latex powder 0 share.

[0040] The construction method of glass fiber reinforced plant-growing type porous concrete described in this embodiment is as attached figure 1 shown, including the following steps:

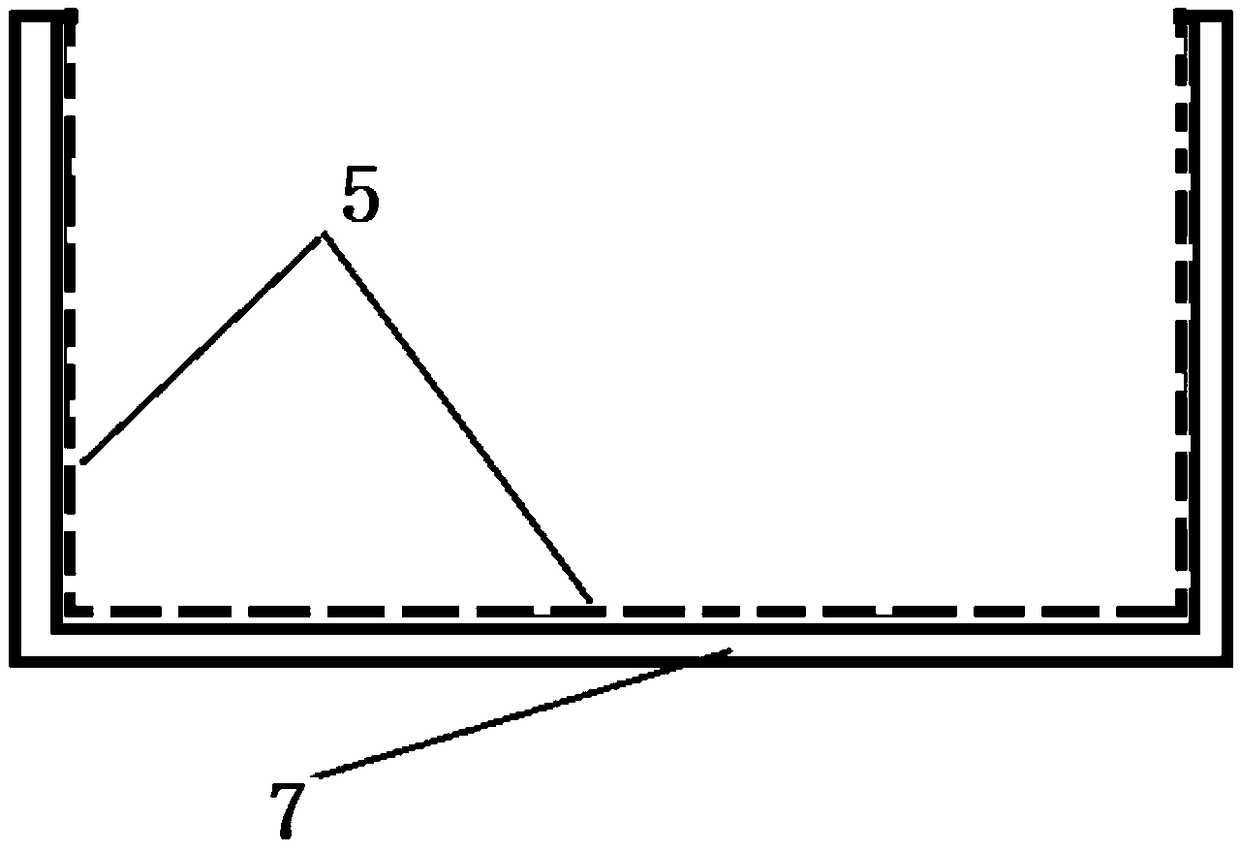

[0041] (1) Prepare the template, place the cut fiber grid cloth on the bottom of the template and turn it around (such as figure 2 shown);

[0042] (2) Blend the single-grain coarse aggregate (if it is ceramsite, it must be pre-wetted) and part of the mixing water to make the coarse aggregate wet;

[0043] (3)...

Embodiment 3

[0048] An embodiment of the glass fiber-reinforced plant-growing porous concrete of the present invention, the glass fiber-reinforced plant-growing porous concrete described in this embodiment comprises the following components by weight:

[0049]100 parts of sulfoaluminate cement, 6 parts of glass fiber (10-40 mm in length), 1000 parts of stone, 40 parts of water, 0 part of water reducer, and 1 part of latex powder.

[0050] The construction method of the glass fiber reinforced plant-growing porous concrete described in this embodiment is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com