Hot extrusion die with improved lower die choke flow structure

A hot extrusion die and structural improvement technology, applied in the direction of metal extrusion die, etc., can solve the problems of product cracking and damage, affecting product strength, small material flow, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

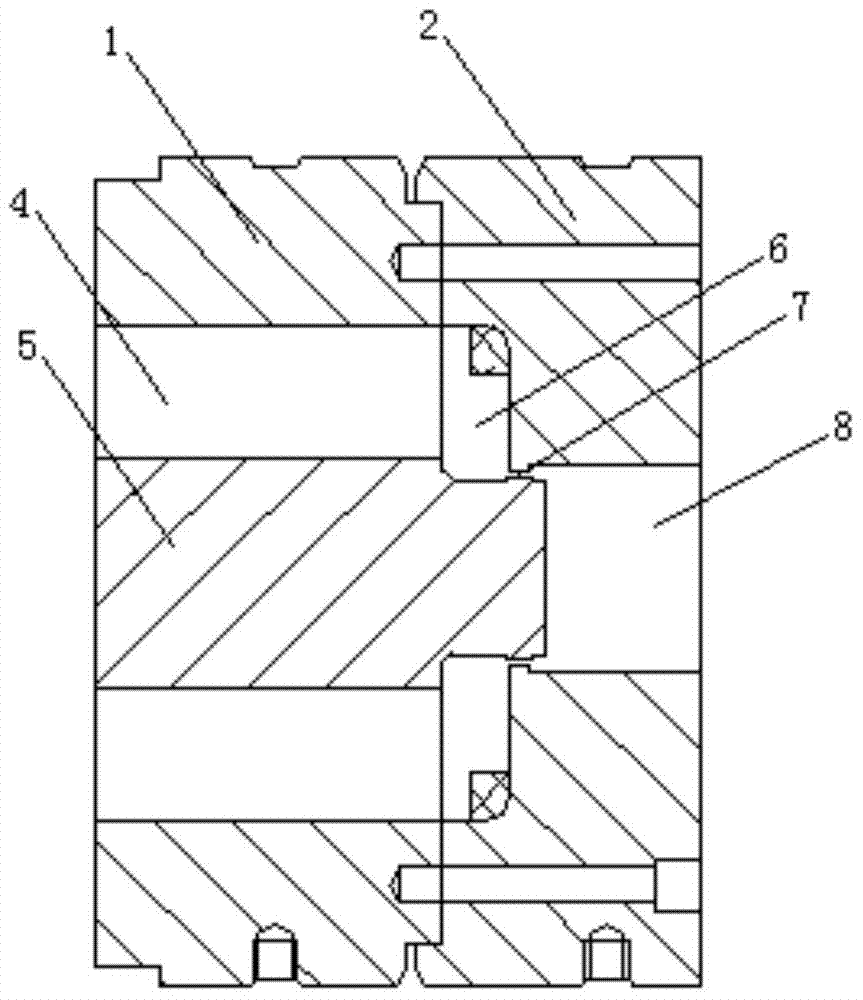

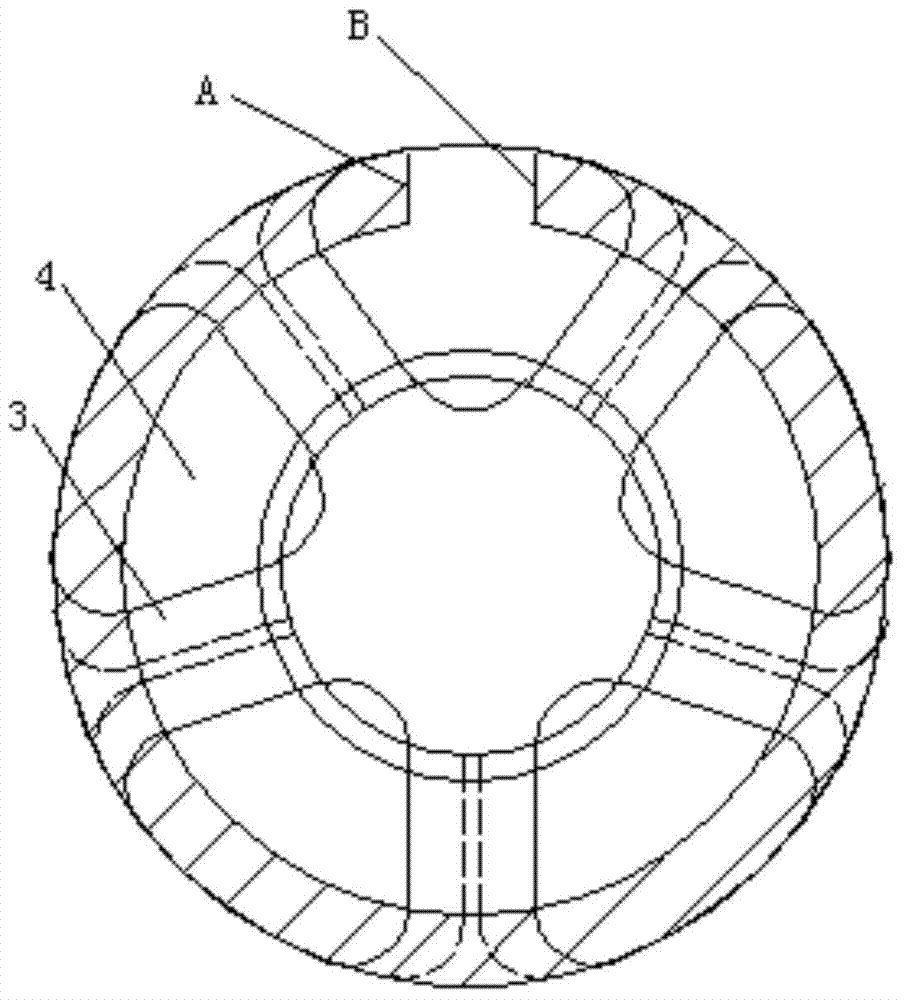

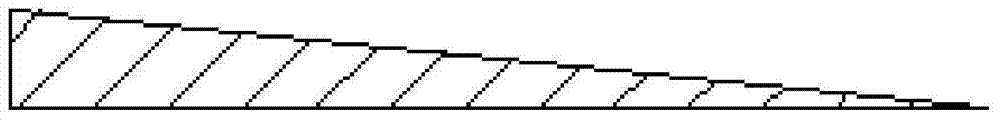

[0012] Embodiment: A hot extrusion die with an improved flow resistance structure of the lower die, including an upper die 1 and a lower die 2 that can be superimposed and connected together. There are a number of bridge positions 3, and split holes 4 are formed between each bridge position. The discharge end of the upper die 1 is provided with a core head 5, and the lower die 2 is sequentially provided with connected welding chambers 6, The forming hole 7 and the discharge hole 8, the welding chamber 6 communicates with the split hole 4 of the upper mold 1, the core head 5 of the upper mold 1 is inserted in the forming hole 7 of the lower mold 2, and the lower mold 2 is welded The bottom surface of the welding chamber 6 is provided with a circle of spiral structure whose axial height gradually decreases. By setting the spiral structure on the inner bottom surface of the welding chamber 6, the material entering the welding chamber 6 from the split hole 4 is rotated at a high sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com