A lightweight permanent blank shell

A permanent tire, lightweight technology, applied in building components, floors, buildings, etc., can solve the problems of high cost, low production efficiency, low strength of formwork components, etc., to achieve the effect of not easy to crack and damage, and improve the overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

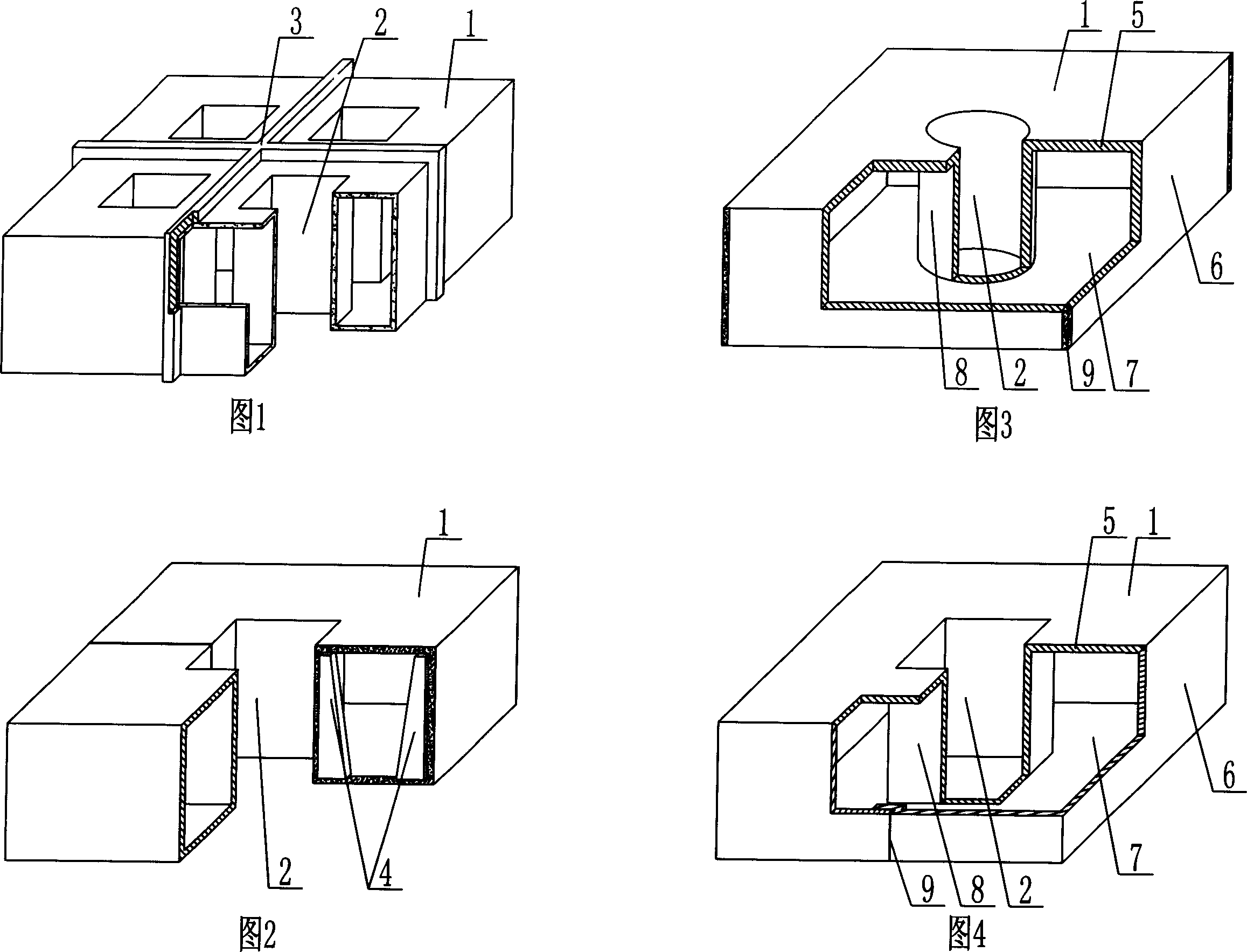

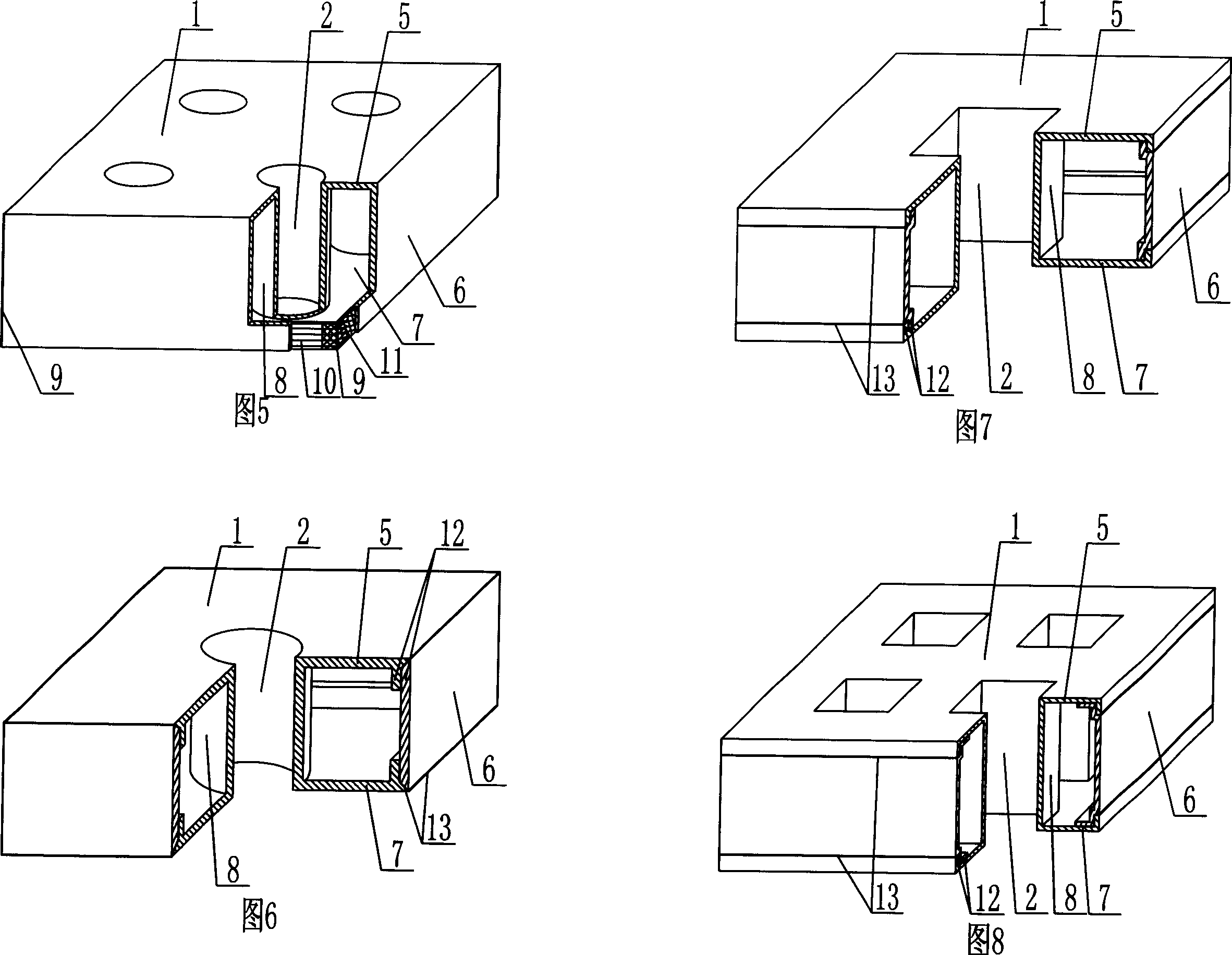

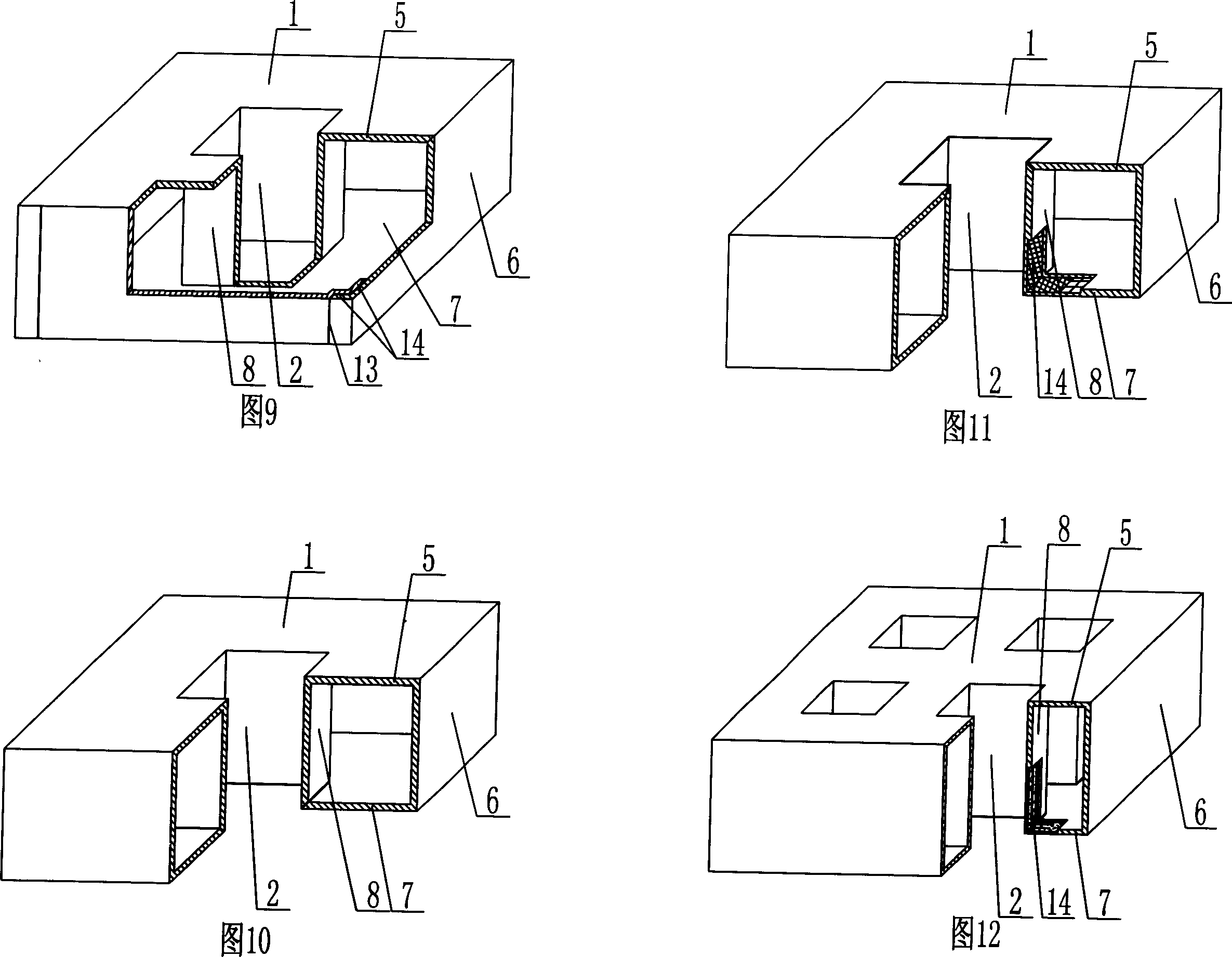

[0073] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0074] As shown in the drawings, the present invention includes a lightweight carcass 1, which includes an upper shell 5, surrounding side shells 6, and a lower shell 7, and is characterized in that there is at least one cast-in-place concrete pouring in the lightweight carcass 1 Holes 2 are used to penetrate the upper and lower shell surfaces of the lightweight carcass 1. The holes 2 are open at both ends of the surface. There is a closed wall between the openings of the two ends of the hole 2. The closed wall is separated from the inner cavity of the lightweight hollow member. , at least one outer wall is formed by cementing two embryo body edges in a wet embryo state, under the cemented embryo edges there is a support member 4 superimposed on the embryo edges. As shown in Figure 2, its lightweight permanent carcass includes a lightweight carcass 1, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com