Thin-wall tube for hollowing out concrete

A thin-walled tube, hollow technology, used in building components, floors, buildings, etc., can solve problems such as damage, affecting the service life of the floor, and cracking of plugs, achieving easy cracking and damage, simple structure, and good anti-vibration performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

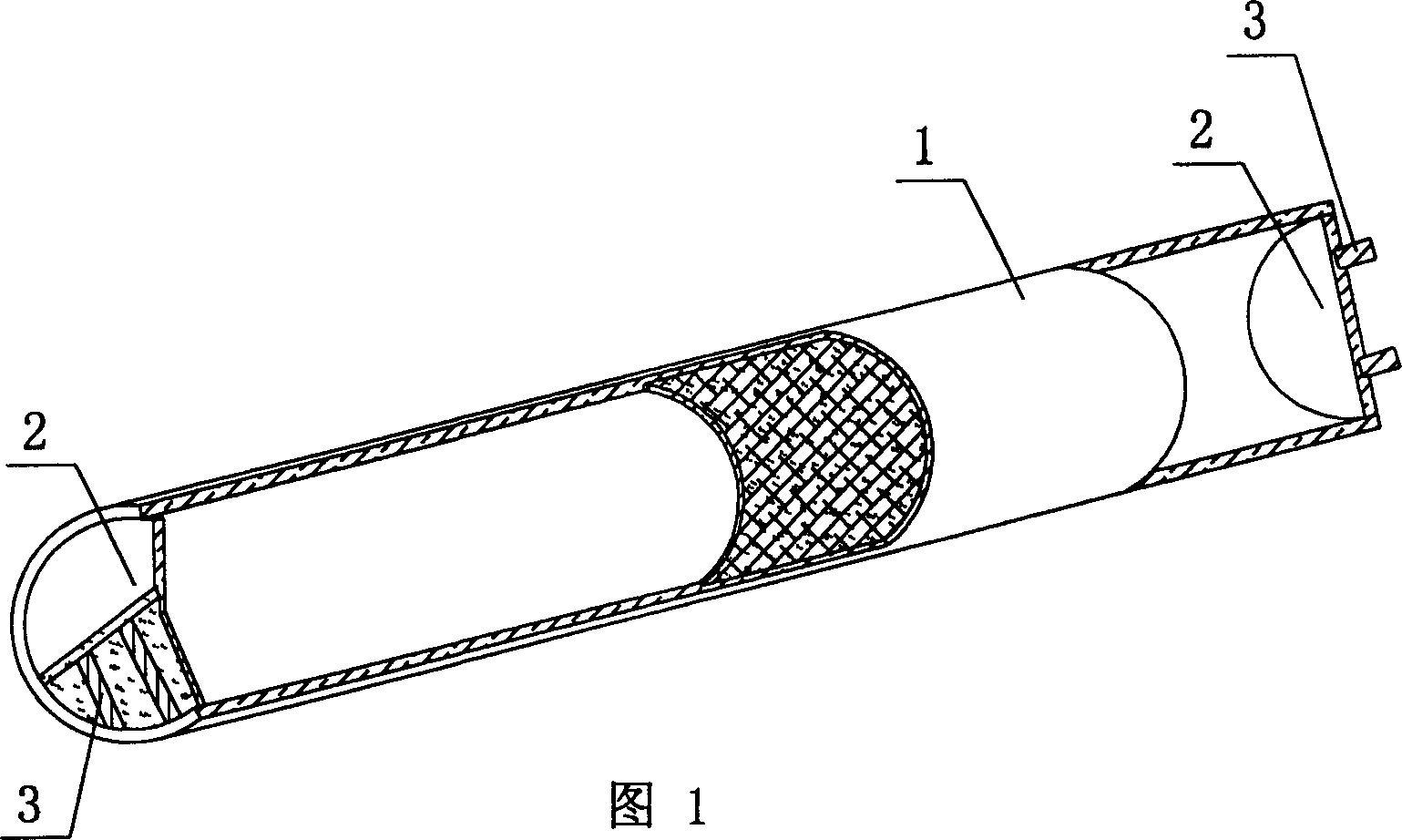

[0048] As shown in the drawings, the present invention includes a pipe wall 1 and two plugs 2, and is characterized in that at least one thin strip 3 is clamped inside the plugs 2. Fig. 1 is a schematic structural diagram of Embodiment 1 of the present invention. In each accompanying drawing, 1 is a pipe wall, 2 is a plug, and 3 is a thin strip, and those with the same number have the same description. In Fig. 1, two thin strips 3 are clamped in the plug 2.

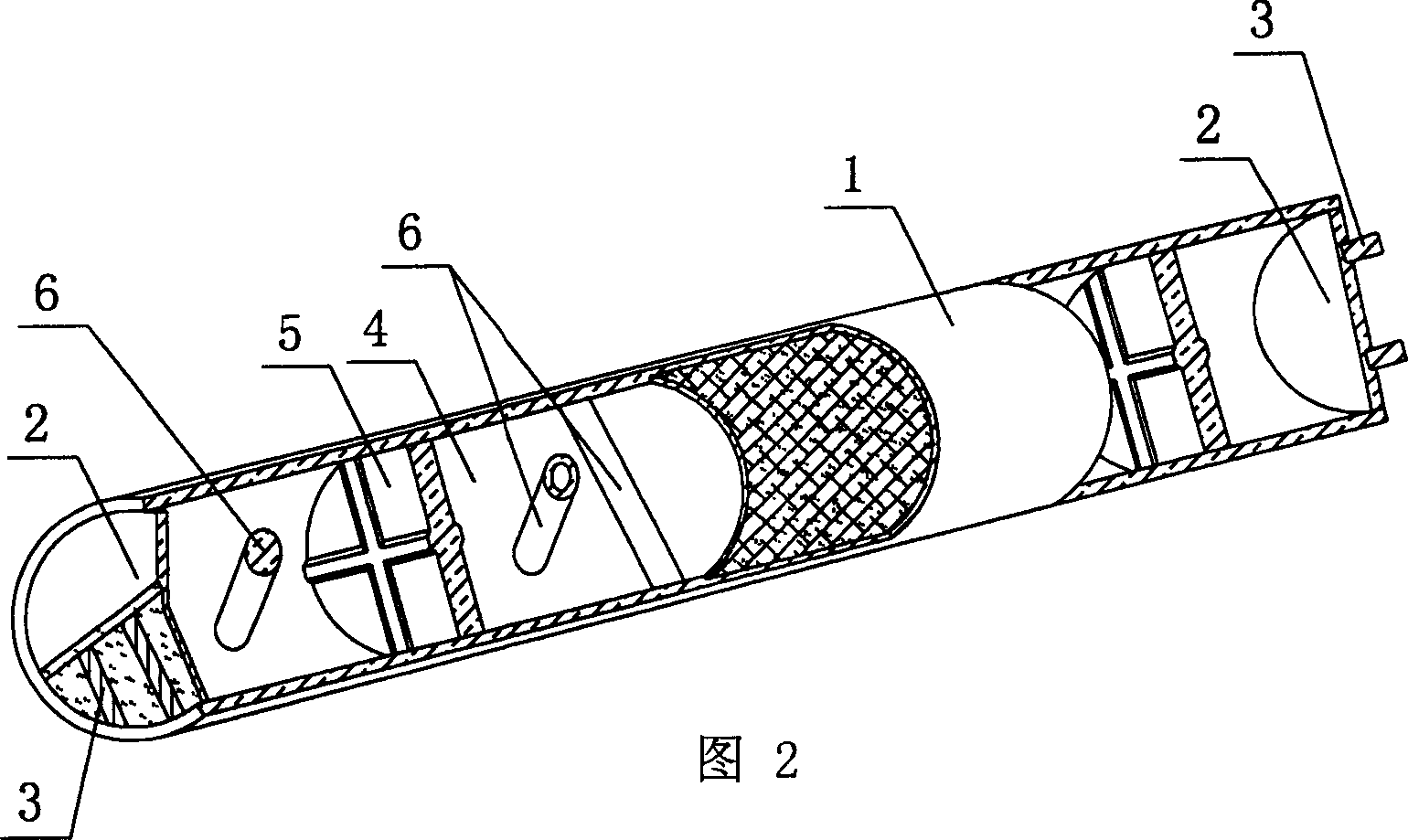

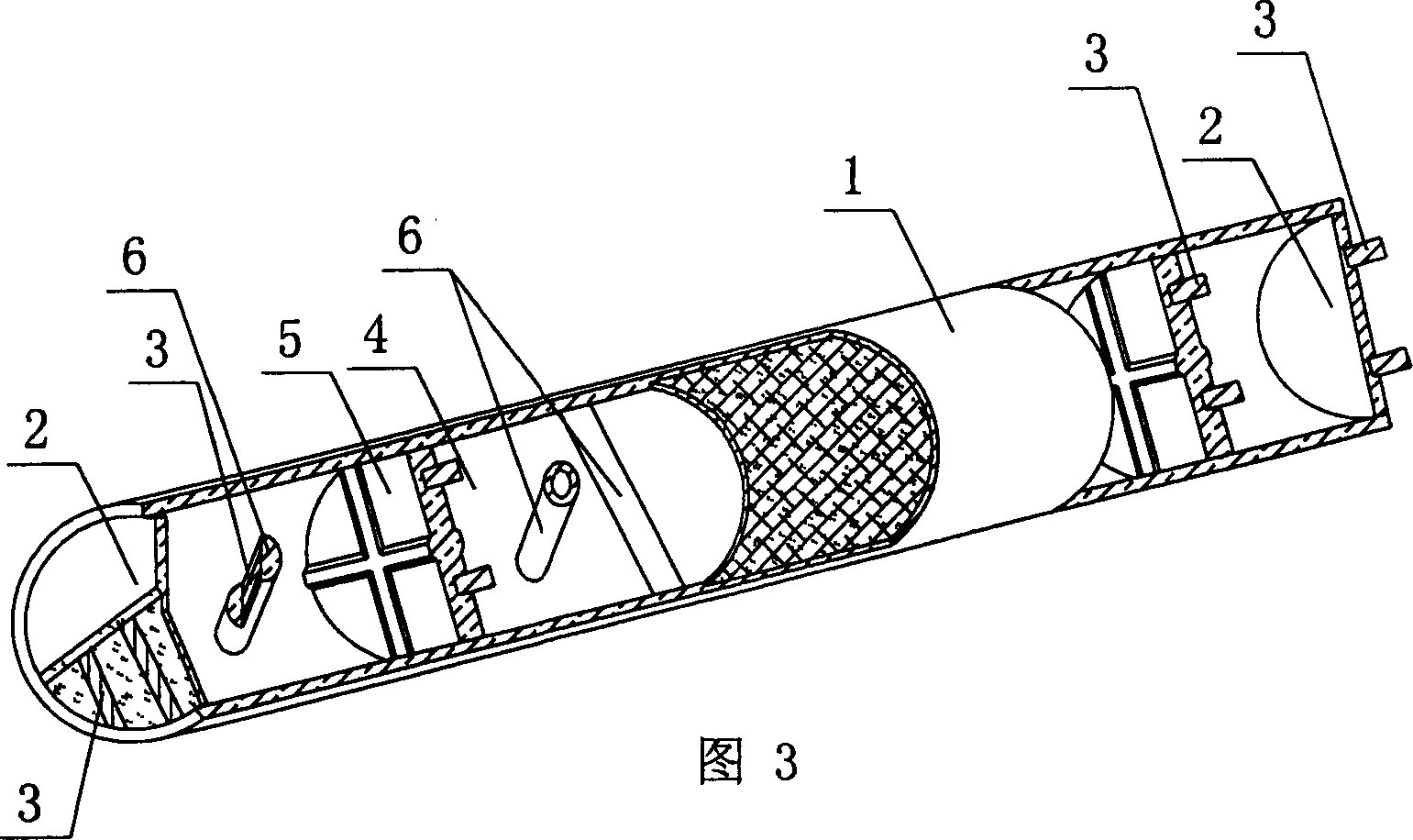

[0049] The present invention is also characterized in that a stiffening rib 5 or a stiffening rod 6 or both are arranged in the closed cavity 4 surrounded by the pipe wall 1 and the two plugs 2 . FIG. 2 is a schematic structural view of Embodiment 2 of the present invention, in which a solid stiffener 5 , a hollow stiffener 6 and a solid stiffener 6 are arranged in the cavity 4 .

[0050] The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com