Round heat treatment tray made of high precision cast stainless steel

A stainless steel, high-precision technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of poor deformation and oxidation resistance, general strength and oxidation resistance, and unsatisfactory performance of the tray, etc. Good oxidation performance, solve the effect of poor deformation resistance and oxidation performance, improve quality and benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

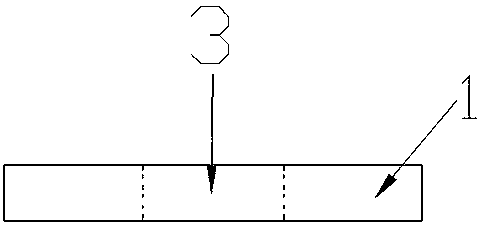

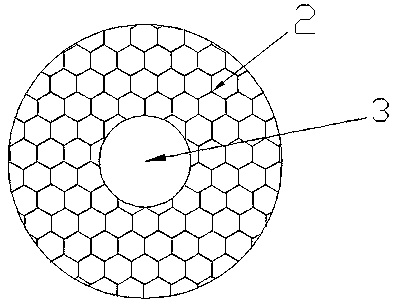

[0010] A stainless steel circular heat treatment pan, which improves the raw material composition of the heat treatment pan. The steel contains a certain amount of carbon, high chromium content and a small amount of silicon and nitrogen. The diameter of the circular bearing plate is about 150cm-170cm. There are several hollow hexagons (2) on the bearing plate. The side length of the hexagons (2) is about 10cm, and the height is about 25cm. It is networked on the bearing plate. Structural distribution; in the center of the load plate there is a hollow cylinder (3). The hollow cylinder (3) has a diameter of 30-40 cm and a height of about 25 cm. It can be superimposed with multiple trays for heat treatment at the same time. Finally, the heat-treated trays are electrolytically polished to prevent rust and deformation of the trays.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com