Tapered sealing pipe connector for excavator

A technology for sealing pipes and excavators, which is applied in the direction of sealing surface connections, pipes/pipe joints/fittings, elbows, etc. It can solve the problems of insufficient sealing of joints, inconvenient disassembly and assembly, and poor versatility, so as to achieve sealing performance and connection Fast and convenient, the effect of increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

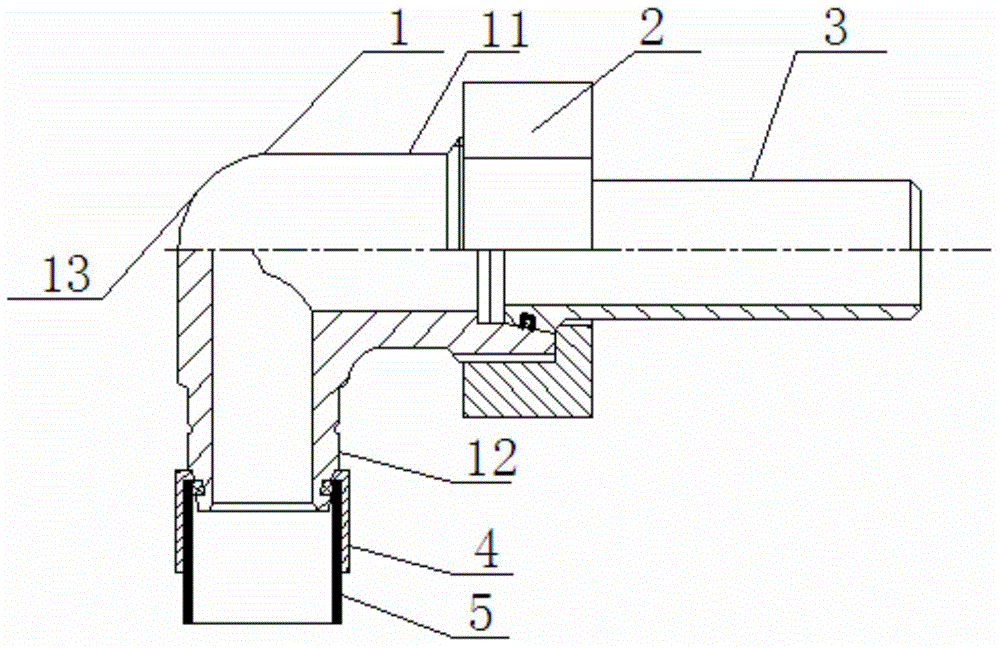

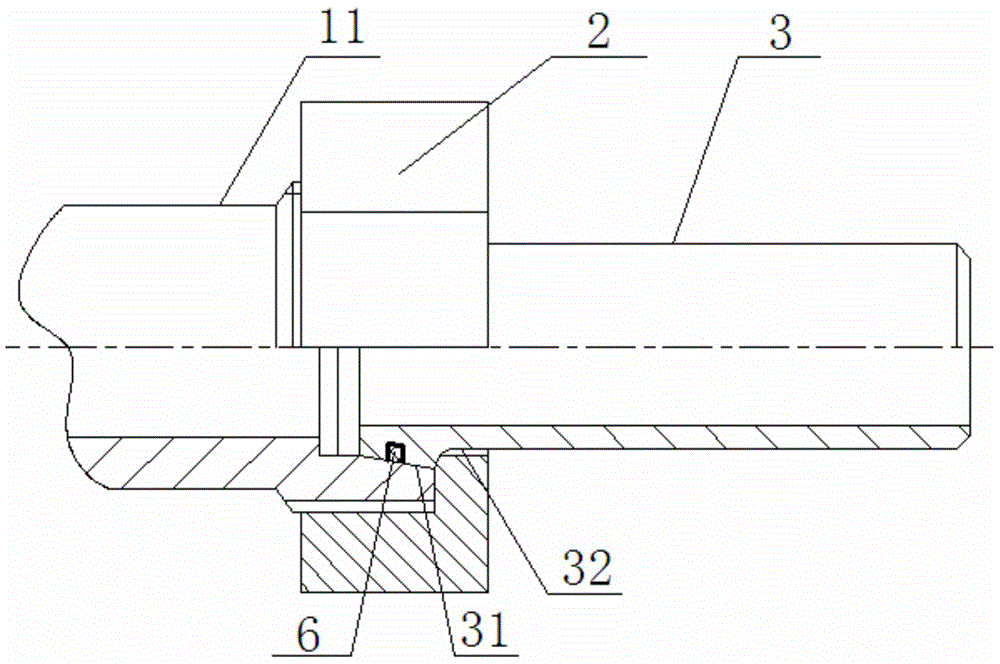

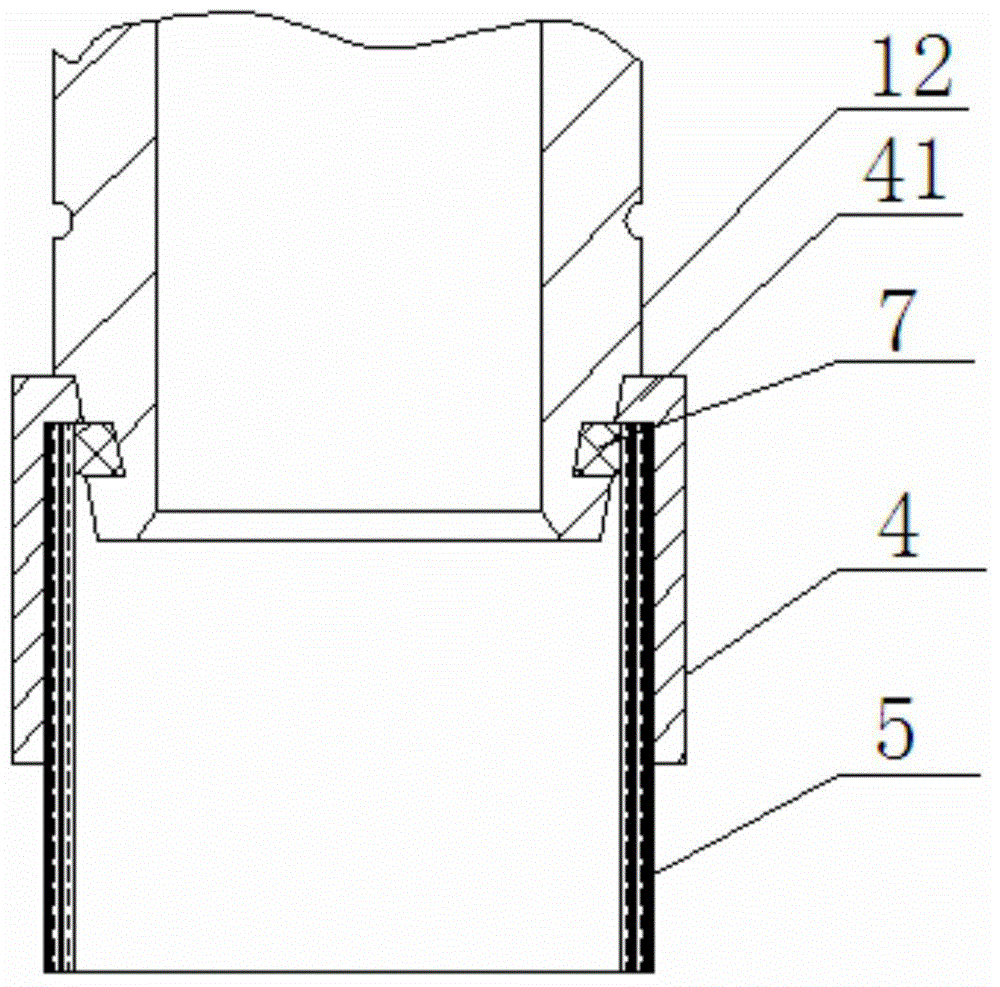

[0023] refer to Figure 1 to Figure 6 , the present invention includes a joint body 1, a nut 2, a first connecting pipe 3, a casing 4 and a second connecting pipe 5, the joint body 1 includes a large pipe section 11, a small pipe section 12, and an elbow section 13, and the joint body 1 is sequentially composed of The small pipe section 12, the curved pipe section 13, and the large pipe section 11 are connected; the small pipe section 12 is connected with the second connecting pipe 5, and the joint between the small pipe section 12 and the second connecting pipe 5 is covered with a casing 4; the large pipe section 11 is connected with the first connecting pipe 3 through the nut 2; the large pipe section 11 is a straight pipe, the outer ring of the end of the straight pipe is provided with an external thread 111, and a tapered opening 112 is opened in the large pipe section 11, and the tapered opening 112 The large end opens to the outer end of the joint body 1 , and the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com