Patents

Literature

53results about How to "Large amount of expansion and contraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

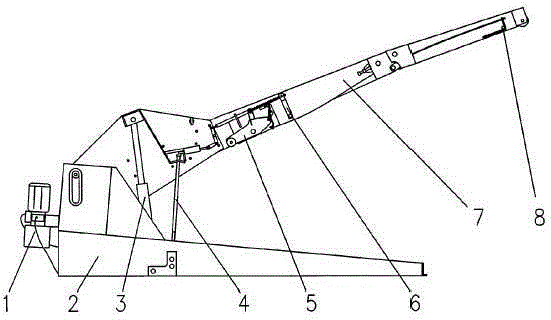

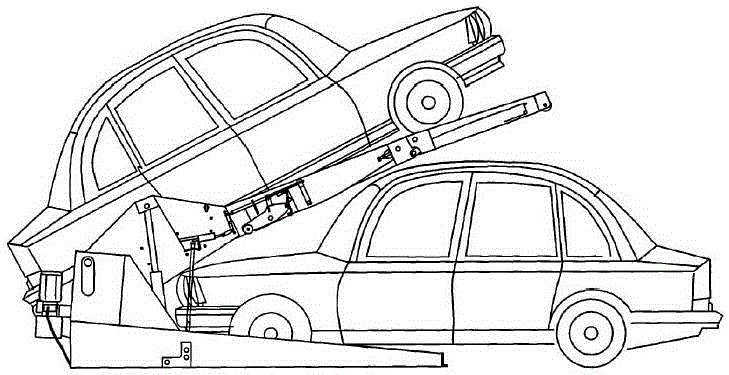

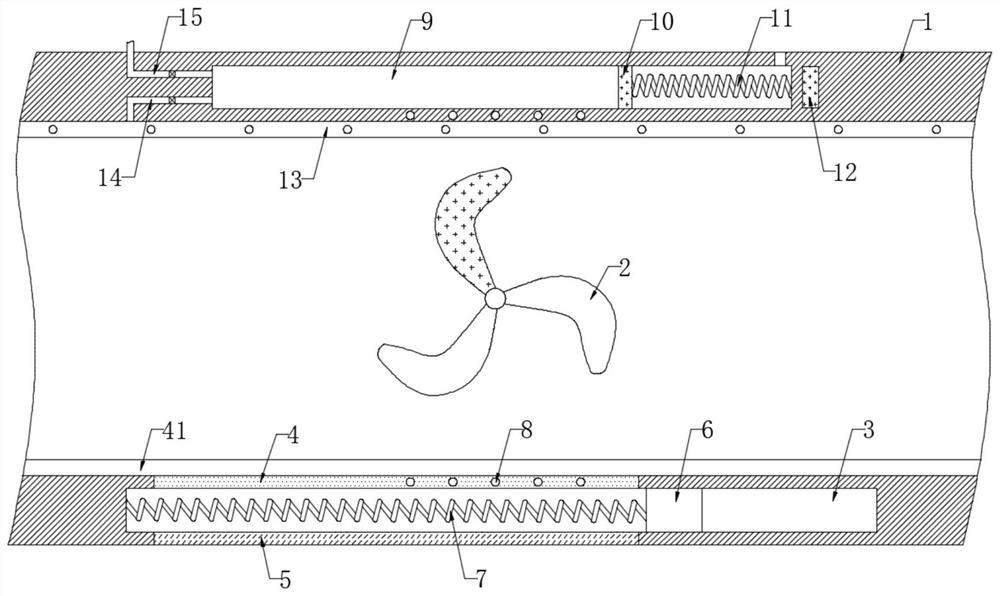

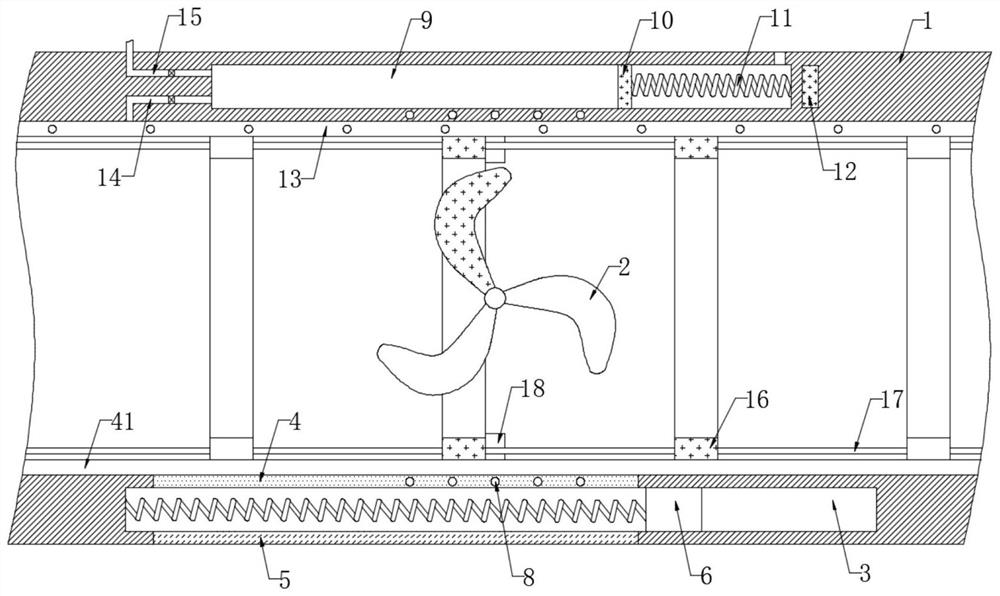

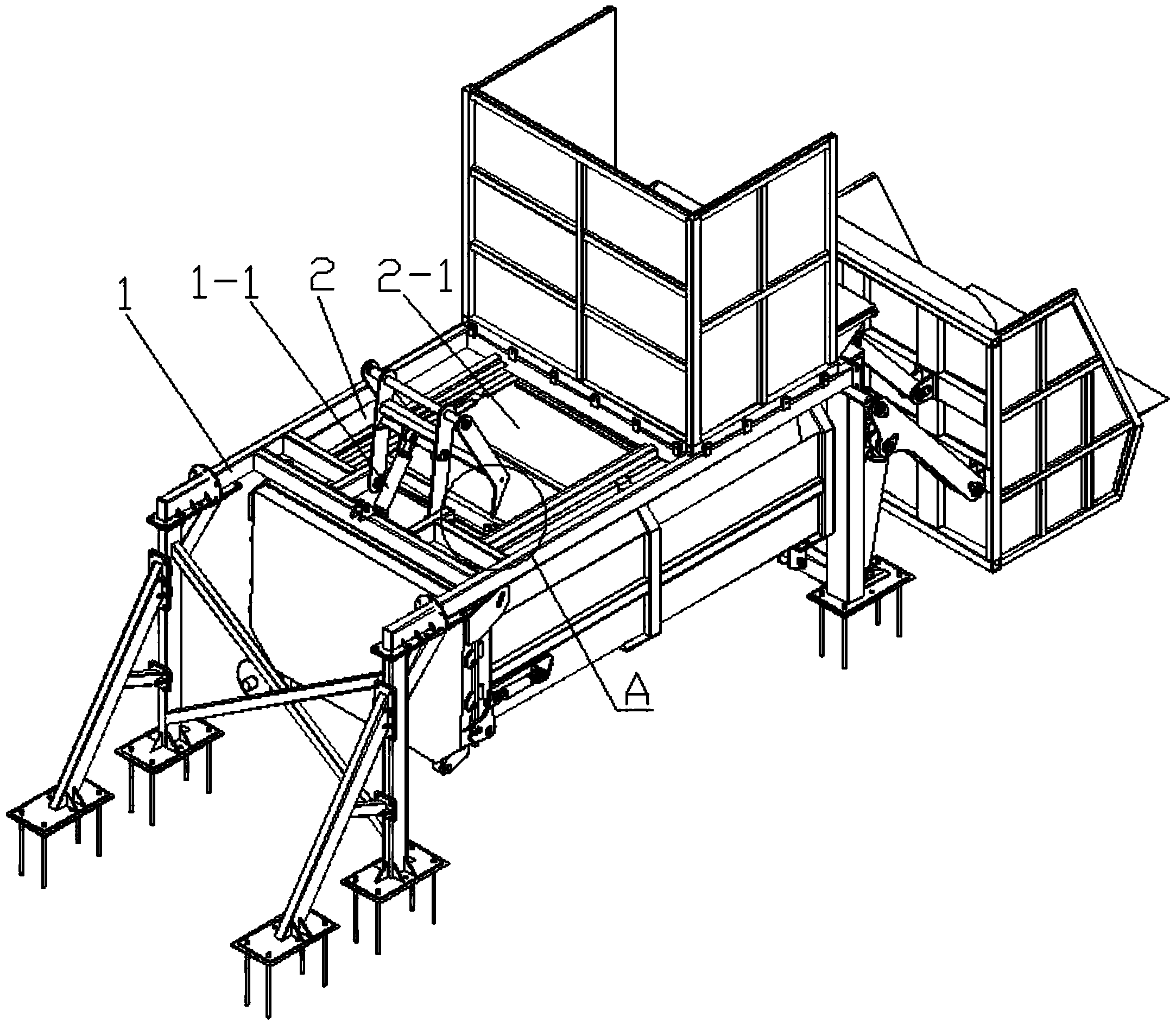

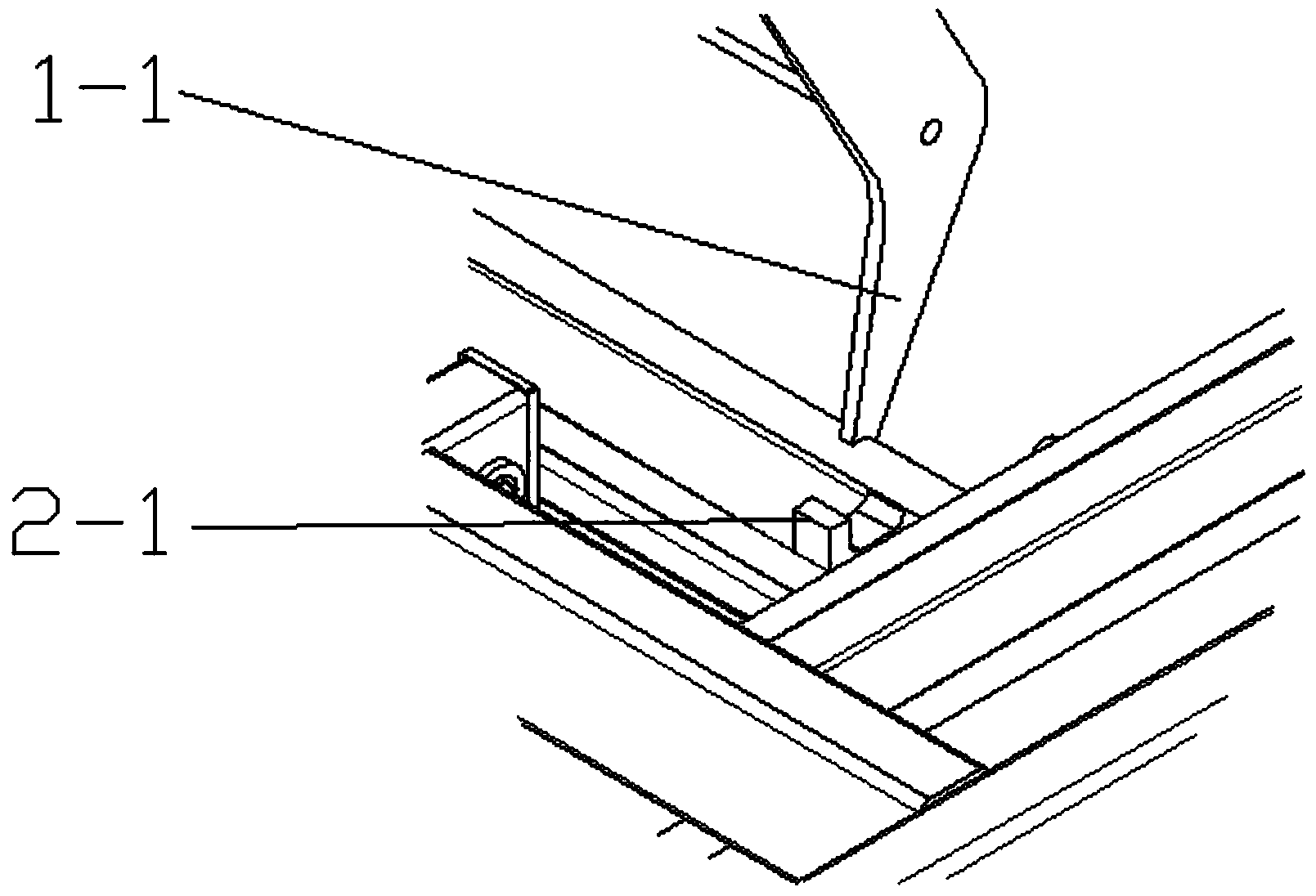

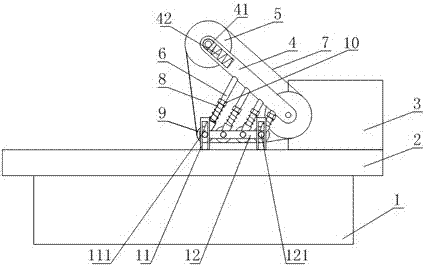

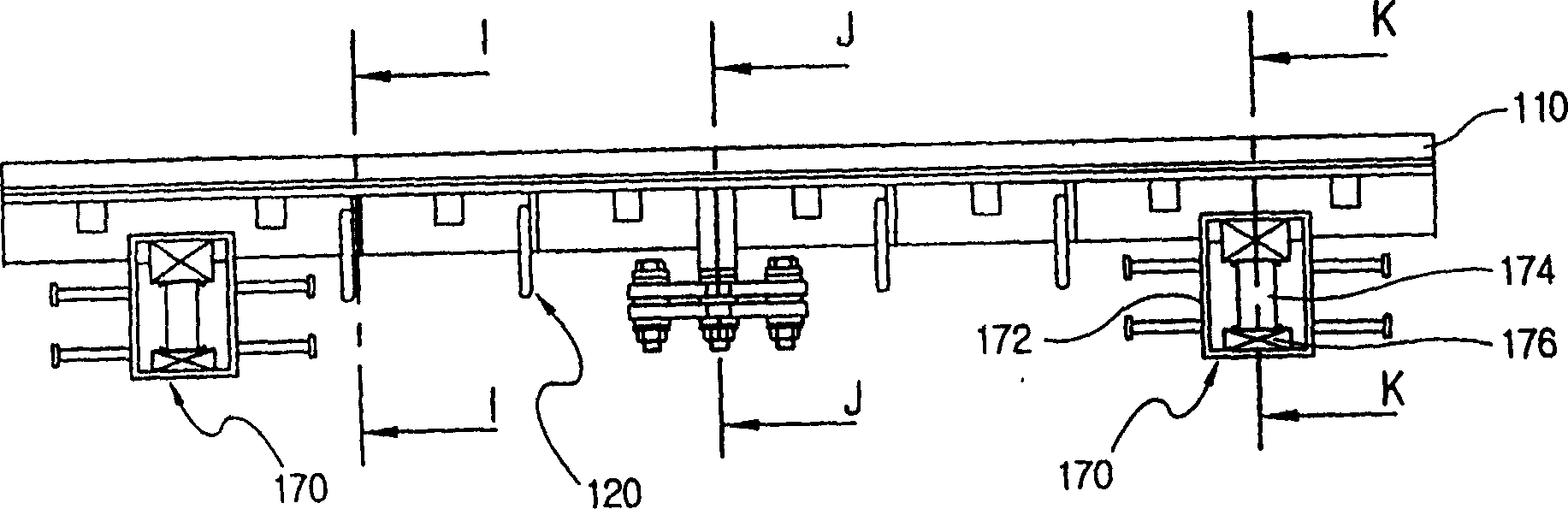

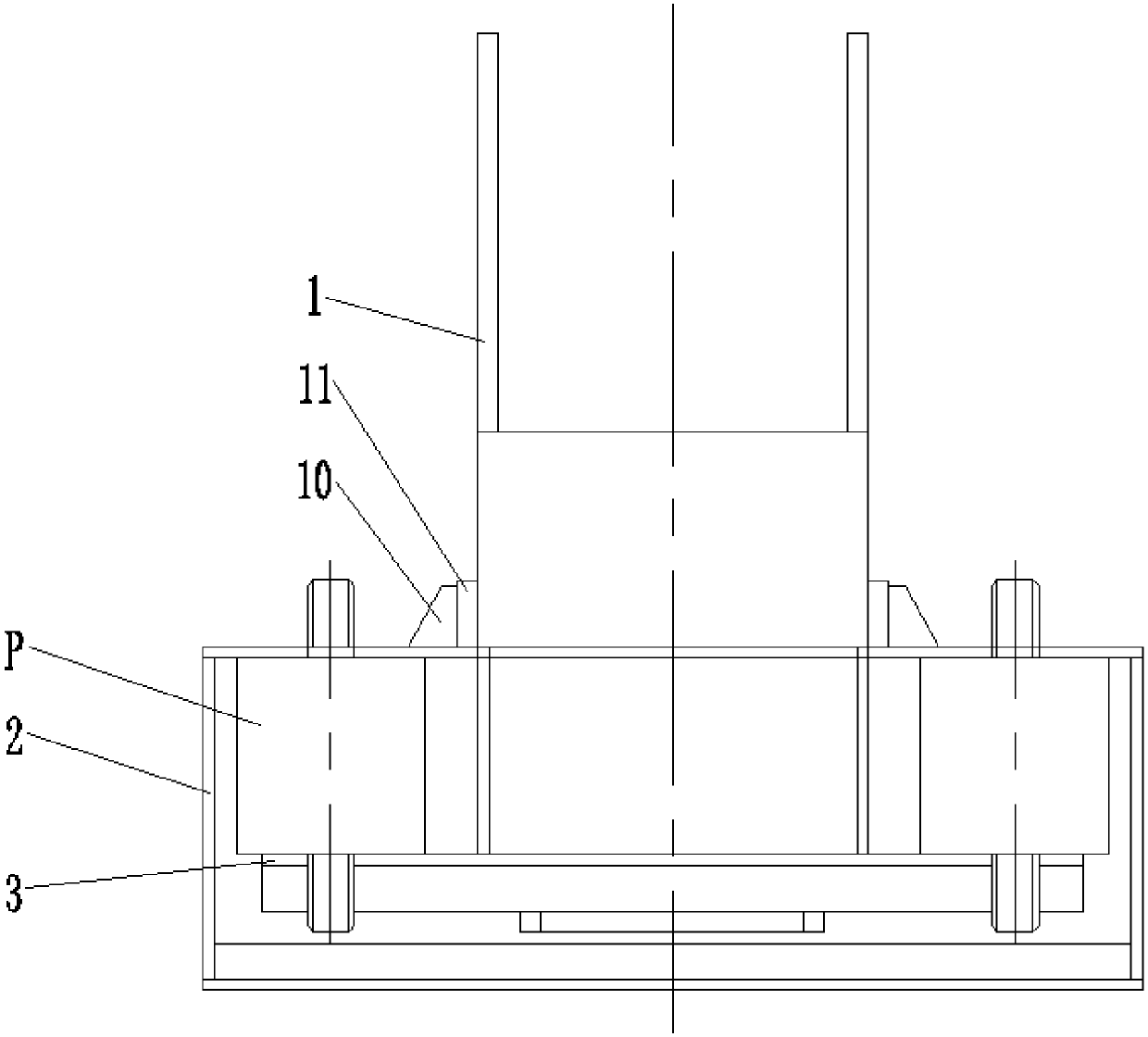

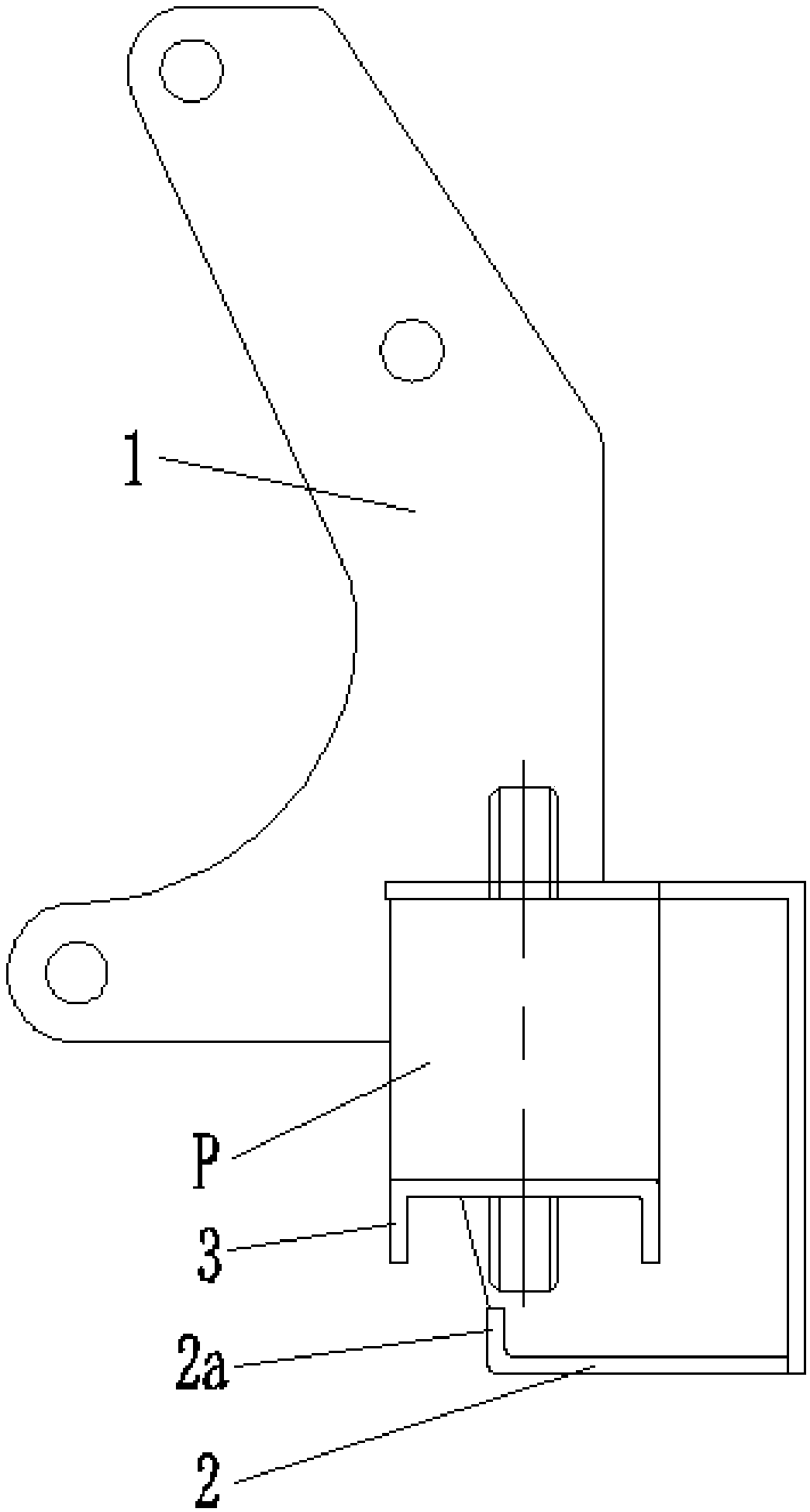

Side movement type parking system

The invention belongs to the technical field of vehicle parking, and particularly discloses a side movement type parking system. The system comprises a supporting frame and a bracket used for supporting a vehicle, wherein the supporting frame is pivoted to the bracket, the supporting frame is located below the bracket, and a supporting hydraulic cylinder is arranged between the supporting frame and the bracket; a cylinder tube of the supporting hydraulic cylinder is hinged to the supporting frame, a piston rod of the supporting hydraulic cylinder is hinged to the bracket, and a hydraulic station is arranged on the supporting frame and connected with the supporting hydraulic cylinder through a first hydraulic pipe. The system further comprises a telescopic mechanism, wherein the telescopic mechanism comprises a power part, a telescopic part and a fixed block fixed to the ground, the power part, the telescopic part and the fixed block are sequentially connected, the power part is fixed in the supporting frame, and the supporting frame is located within the projected area of the bracket in the horizontal plane. The system has the advantages of being high in adaptability in a parking lot, and capable of improving the parking rate of the parking lot.

Owner:杨自忠

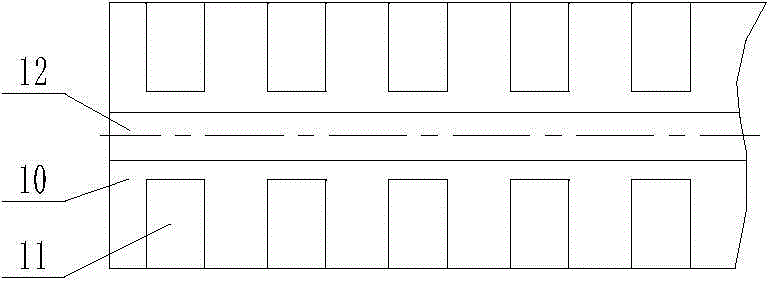

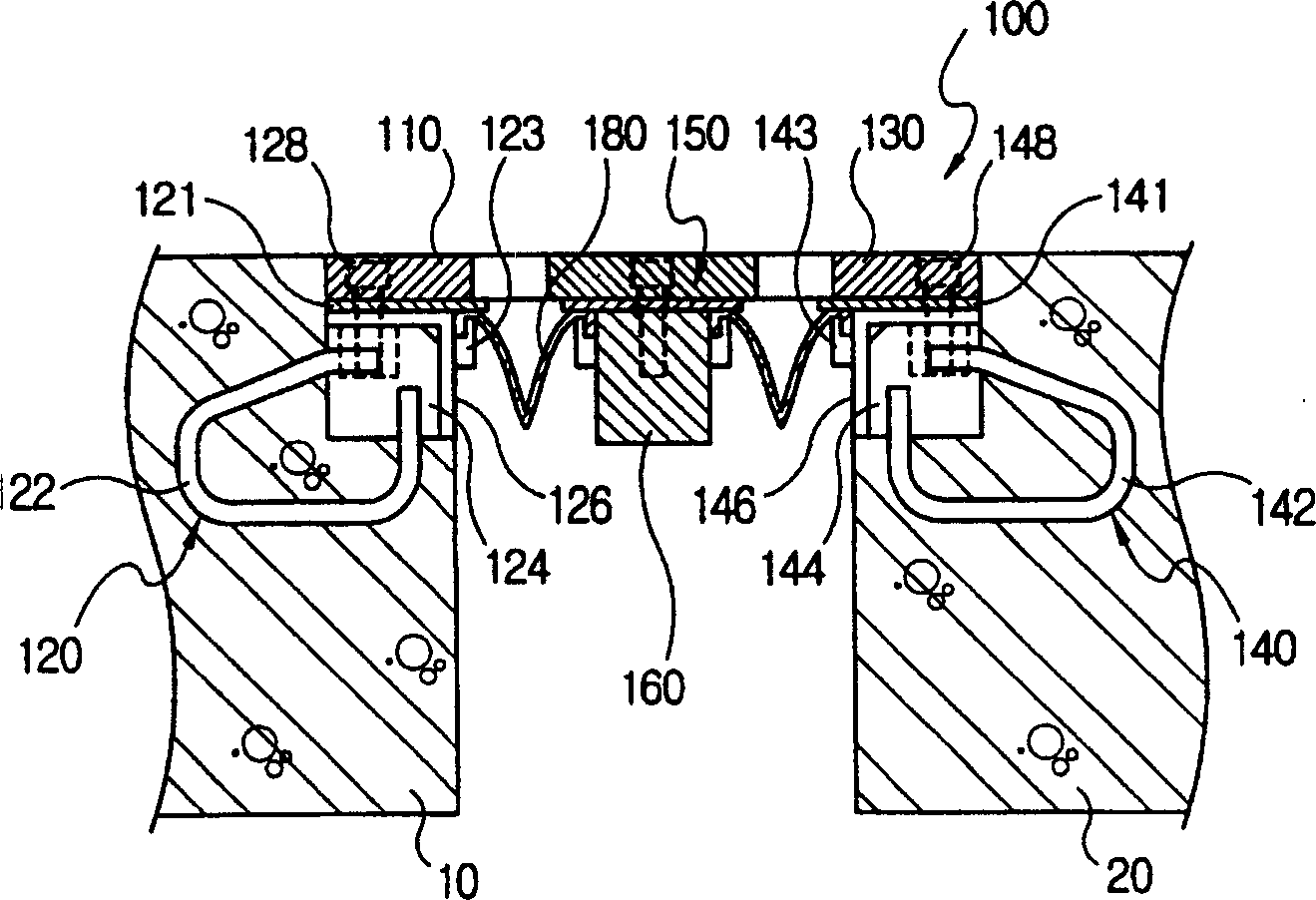

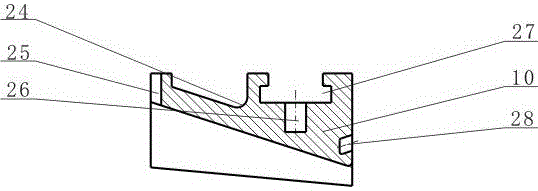

Train run-through channel

InactiveCN101844565AImprove the operating environmentGuaranteed uptimeAxle-box lubricationRailway bodiesEngineeringMechanical engineering

The invention discloses a train run-through channel. The train run-through channel comprises a mounting frame assembly, a shed cloth assembly, a side guard plate assembly, a pedal assembly, a cab apron assembly and a top plate assembly; wherein the cab apron assembly comprises a cab apron and a link mechanism, the link mechanism is fixedly arranged on the cab apron, and the four corners of the cab apron are in folder structure with the corner tilted. The train run-through channel of the invention has simple structure, so that the train can be in better train operational environment while passing a curve with less radius and train operation effect is ensured.

Owner:CRRC TANGSHAN CO LTD

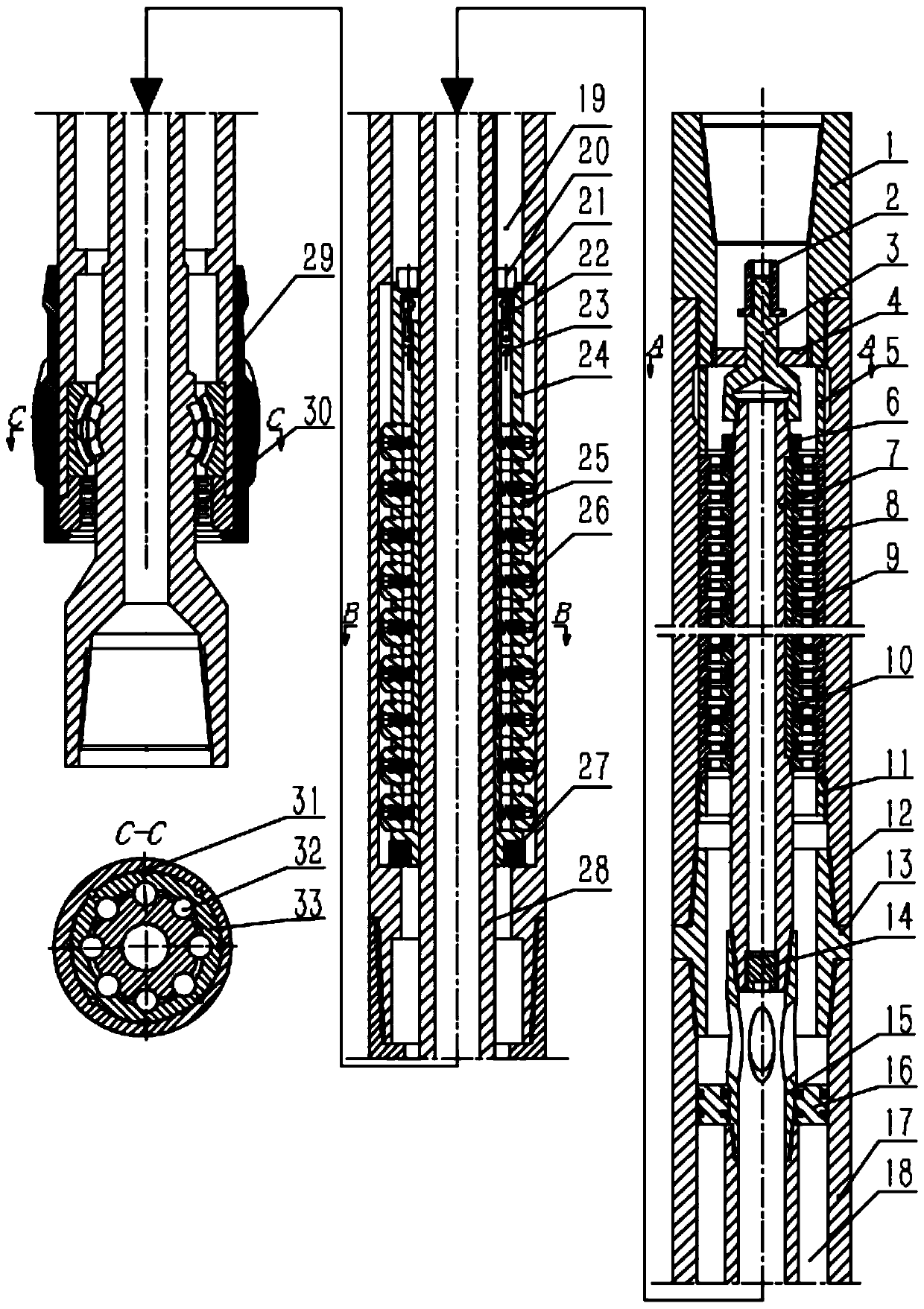

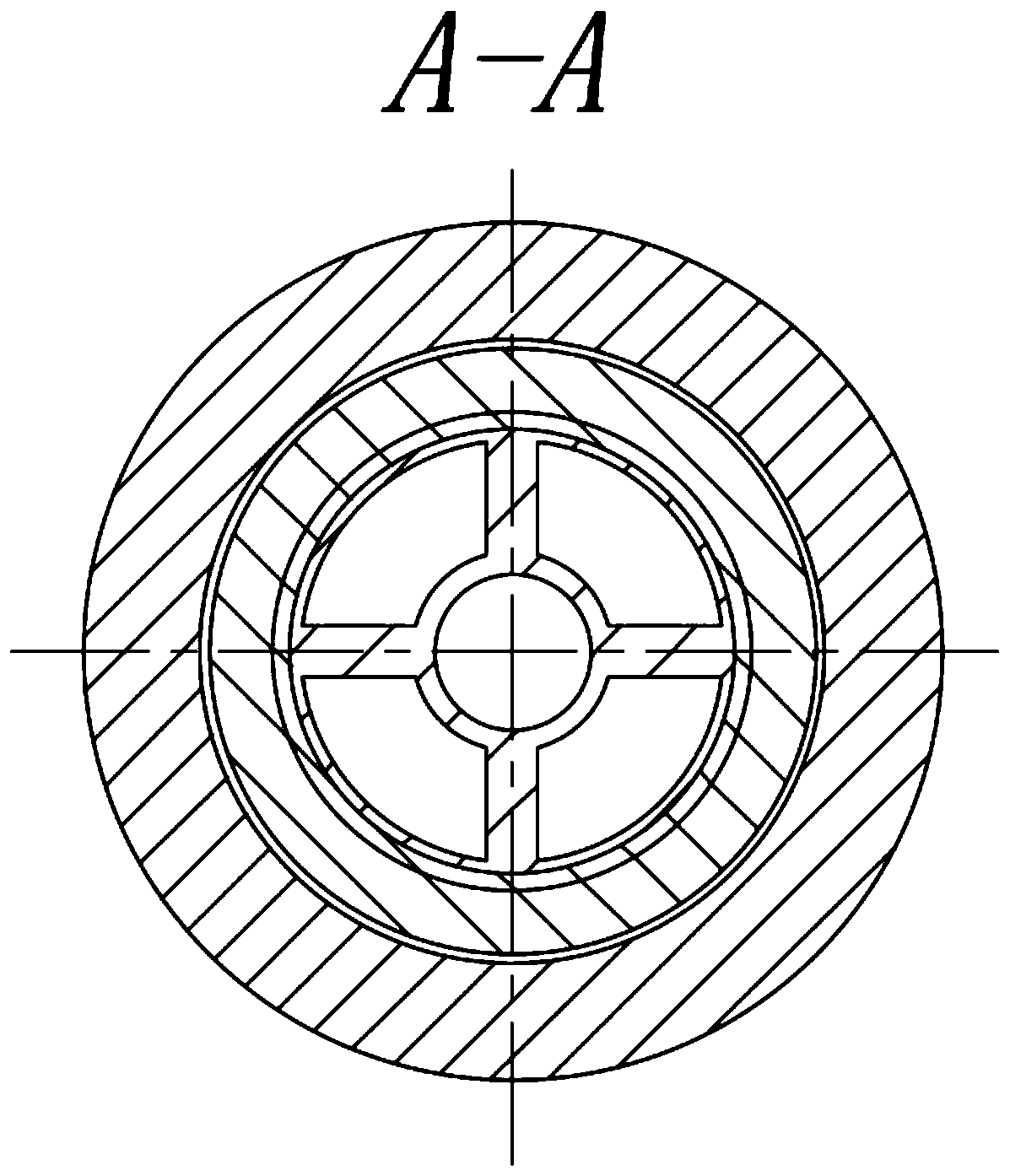

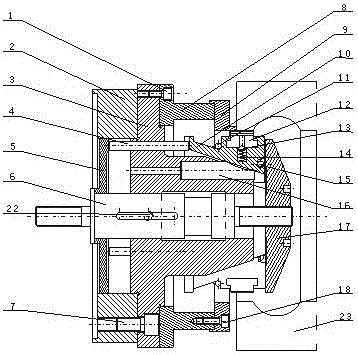

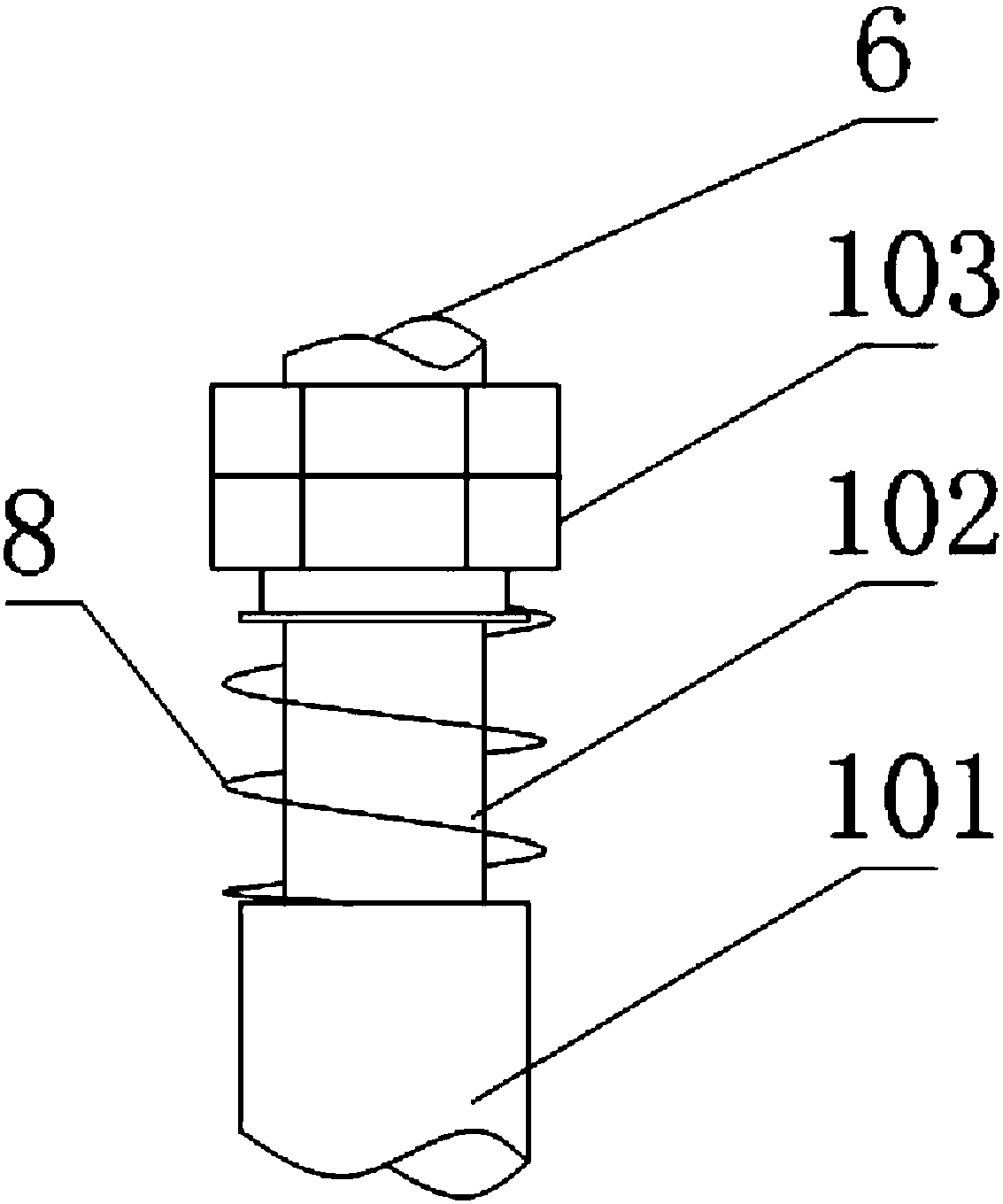

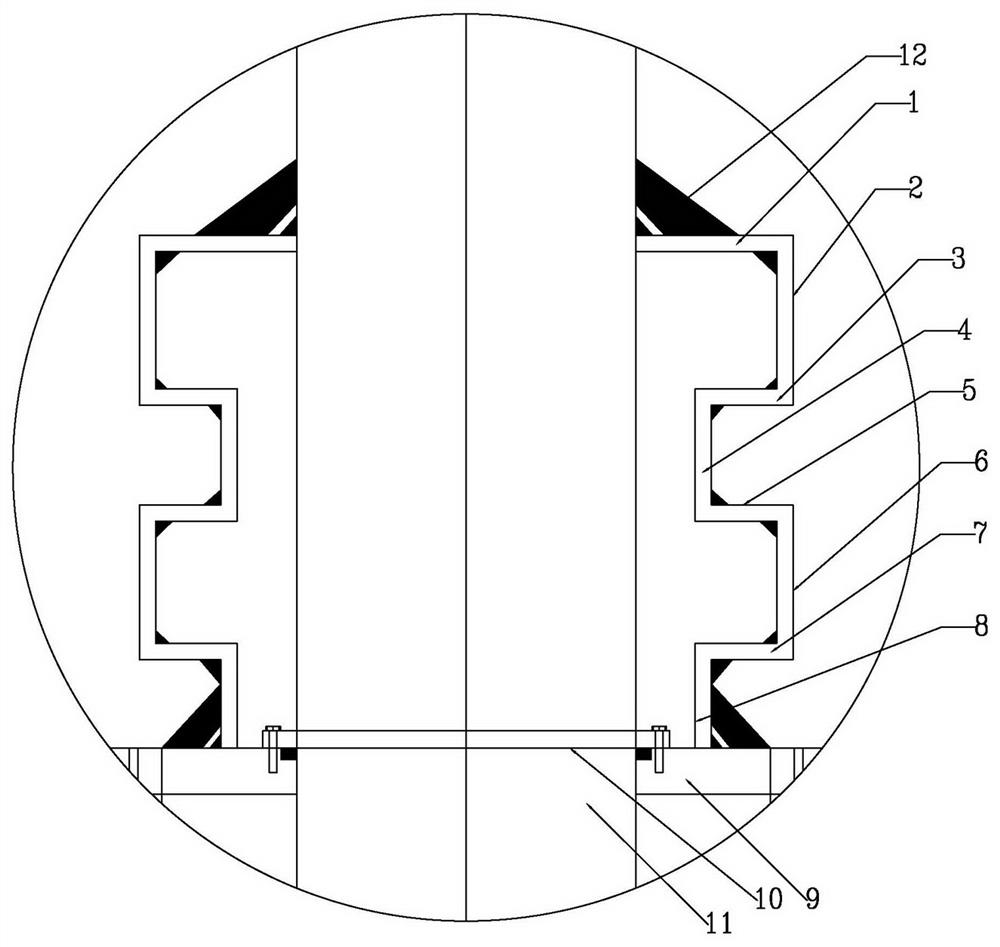

Static directional hydraulic rotary steering tool

InactiveCN110410008ATo achieve the role of torque transmissionLarge amount of expansion and contractionDirectional drillingPistonDrill bit

The invention relates to a static directional hydraulic rotary steering tool which is formed by three parts: a turbine motor assembly, a guide mechanism and a torque transmission mechanism. The staticdirectional hydraulic rotary steering tool has the technical scheme that six high-temperature-resistant pressure-resistant pistons are uniformly distributed on the circumference; during control, thethree connected pistons push oil liquid, and the three opposite pistons pull the oil liquid, so that a spindle is deviated toward one direction under the actions of the pistons, and a lower drill bitcan accurately guide under the control so as to drill toward a target position; nine rows of pistons are arranged in the radial direction, and 54 pistons are arranged in total, so that a sufficient force is provided for deviating the spindle; when the pistons reach to the limiting position, a horizontal included angle formed between a deflection point and a deflection center is 1.16 degrees; in order to ensure the stable operation of the pistons, six direct-current servo motors are uniformly distributed on the upper parts of the pistons at 60-degree angles, and a plum coupling device is connected under each servo motor; and a screw rod is connected under each coupling device, so that the rotation movement produced by the servo motors is changed into the radial movement through the screw rods.

Owner:SOUTHWEST PETROLEUM UNIV

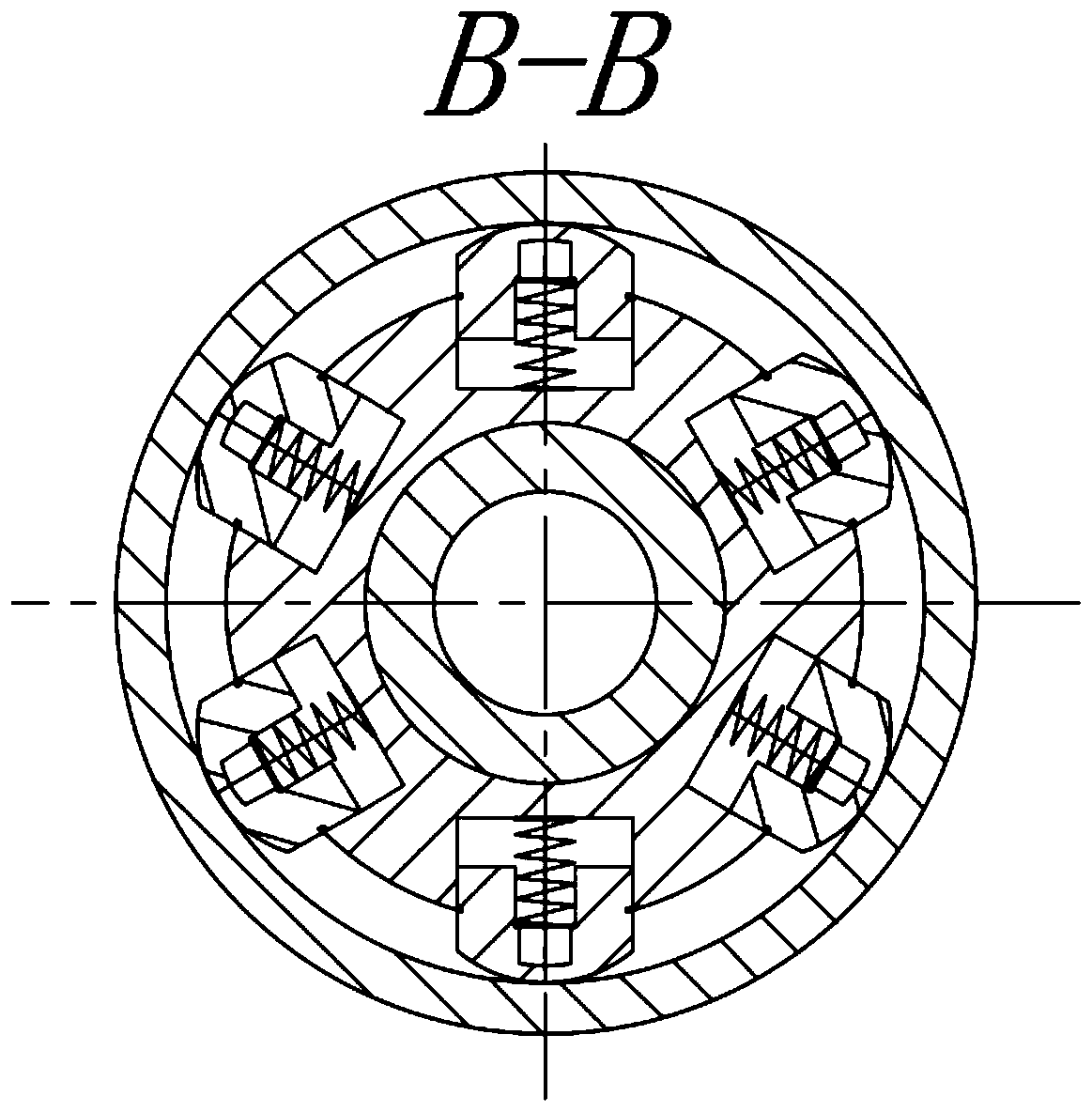

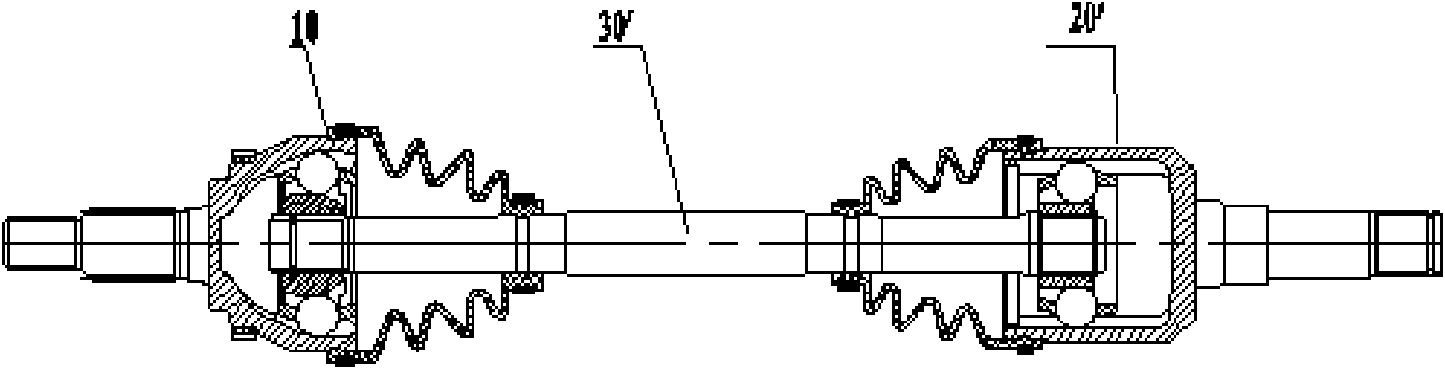

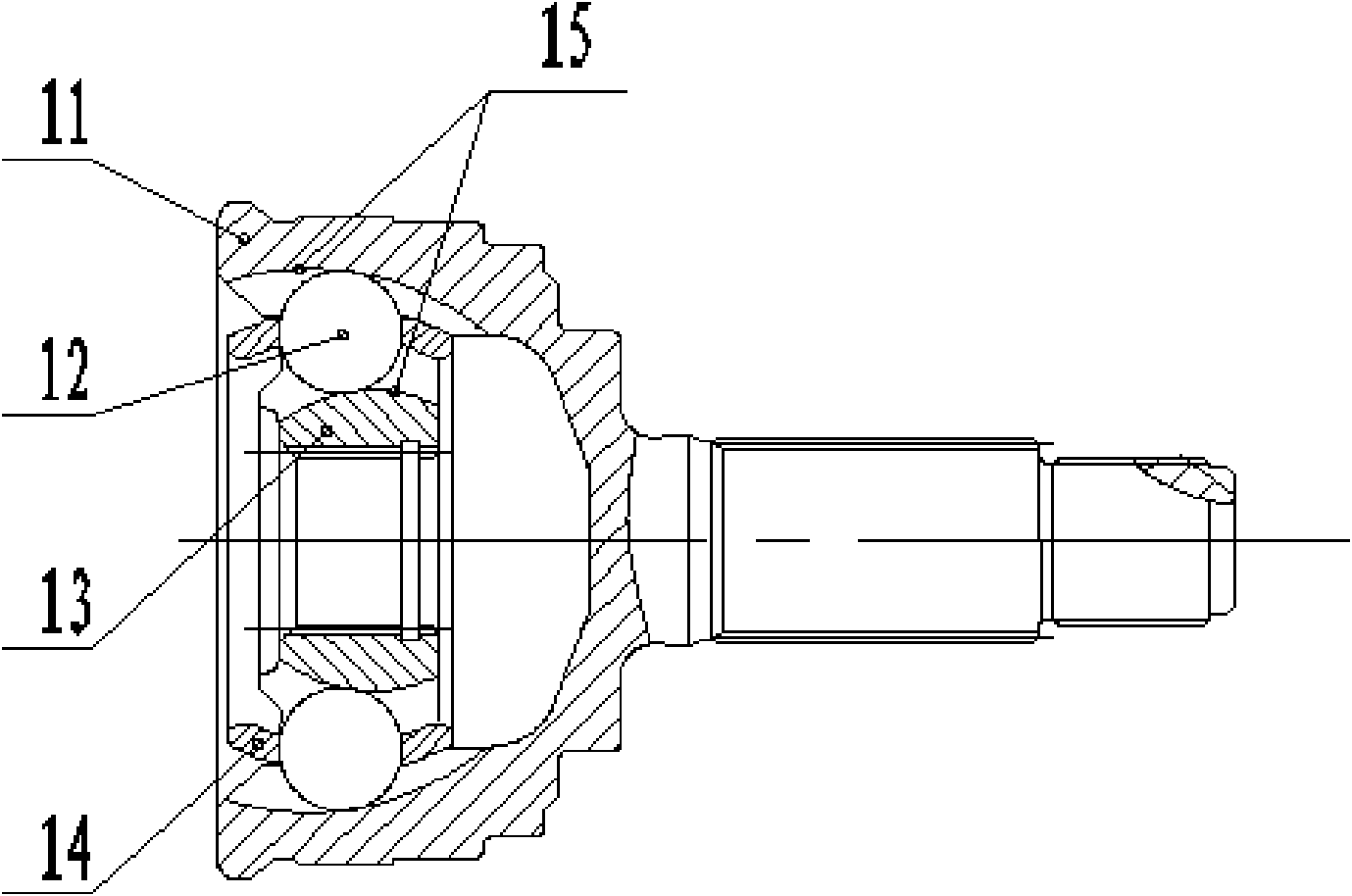

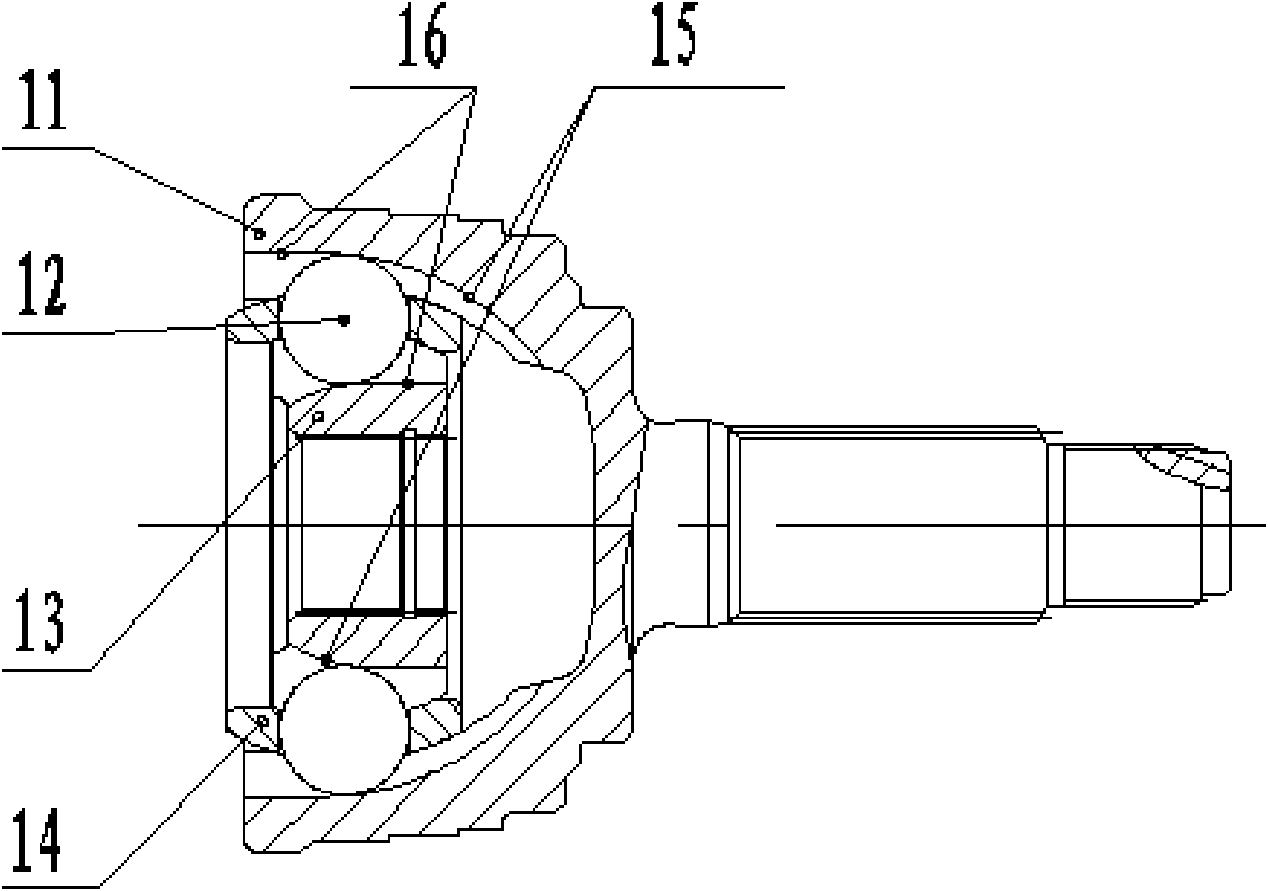

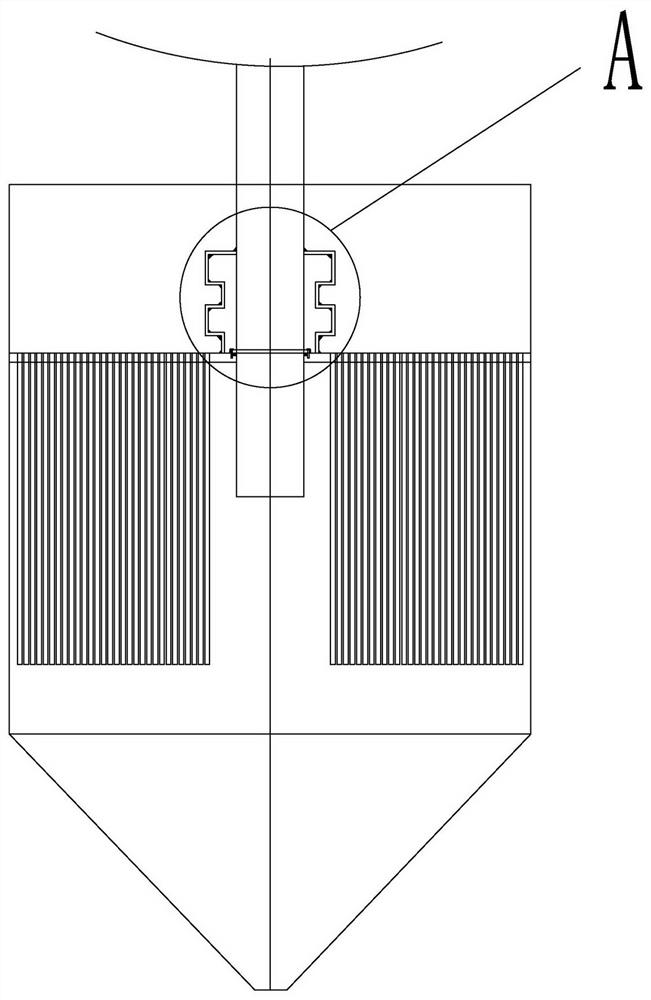

Constant-speed transmission shaft with telescopic middle shaft

ActiveCN101876351AWill not affect the relationshipSuitable for useYielding couplingDrive wheelUniversal joint

The invention relates to front and rear wheel transmission shafts of a car or other mechanical transmission equipment, in particular to a middle shaft structure of a front wheel driving shaft for a car, aiming to provide a constant-speed transmission shaft with a telescopic middle shaft with favorable lubricating condition and excellent sliding performance. The constant-speed transmission shaft with a telescopic middle shaft is provided with a constant-speed universal joint of a driving wheel end center fixing type, a constant-speed universal joint of a gearbox end center fixing type and a middle shaft, wherein the middle shaft comprises a middle shaft sleeve, a middle shaft core, a retainer and rolling pieces, the middle shaft sleeve is sleeved on the middle shaft core, mutually matched grooves are respectively and evenly distributed on the periphery of the inner surface of the middle shaft sleeve and the periphery of the outer surface of the middle shaft core, the rolling pieces are arranged in the grooves between the middle shaft sleeve and the middle shaft core, and the mutual relative positions of the rolling pieces are fixed by the retainer. The middle shaft of the invention comprises the middle shaft sleeve, the middle shaft core, the retainer and the rolling pieces and has excellent transmission performance.

Owner:常州超宇机械制造有限公司

Automobile exhaust pipe with refrigerating and cooling function

InactiveCN112459866AExtended service lifeReduce the temperatureInternal combustion piston enginesExhaust apparatusImpellerExhaust pipe

The invention discloses an automobile exhaust pipe with the refrigerating and cooling function. The automobile exhaust pipe comprises a pipe body, a plurality of impellers are rotatably connected to the inner wall of the pipe body through a rotating shaft, a plurality of heat absorption cavities are evenly formed in the inner wall of the pipe body, and first conductive plates communicating with the inner wall of the pipe body are fixedly connected to the inner walls of the multiple heat absorption cavities; and second conductive plates communicating with the side wall of the pipe body are fixedly connected to the inner walls of the multiple heat absorption cavities, conductive blocks are slidably connected into the heat absorption cavities, and the side walls of the conductive blocks are elastically connected with the inner walls of the heat absorption cavities through conductive springs. When circuits between the first conductive plates and the second conductive plates are conducted,a Peltier effect occurs, so that the first conductive plates serve as heat absorption ends, the second conductive plates serve as heat release ends, continuous heat absorption is performed on the interior of the pipe body, the temperature in the pipe body and the temperature in tail gas are reduced, the service life of the pipe body is prolonged, and meanwhile, the greenhouse effect is reduced.

Owner:德清县高桥绢纺厂

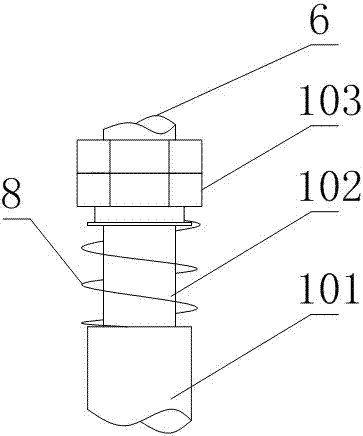

Temperature control extension tube

ActiveCN104989868AControl the stretch lengthLarge amount of expansion and contractionOperating means/releasing devices for valvesTemperature controlCellular material

The invention relates to a temperature control extension tube. The temperature control extension tube comprises a corrugated tube, and thermal conductive plates are arranged on the two sides of the corrugated tube; and a shaft is connected between the thermal conductive plates and comprises a bendable bimetallic strip and a straight rod. The inner wall of the corrugated tube is wrapped with a capillary cellular material, the corrugated tube and the thermal conductive plates are sealed, and the corrugated tube is filled with a thermal conductive medium and is pumped to be at negative pressure. By means of the temperature control extension tube, heat can be conducted, a temperature control tube is extendable, the extension amount is large, the size of the temperature control extension tube can be large or small, the structure is simple, and application is wide.

Owner:门立山

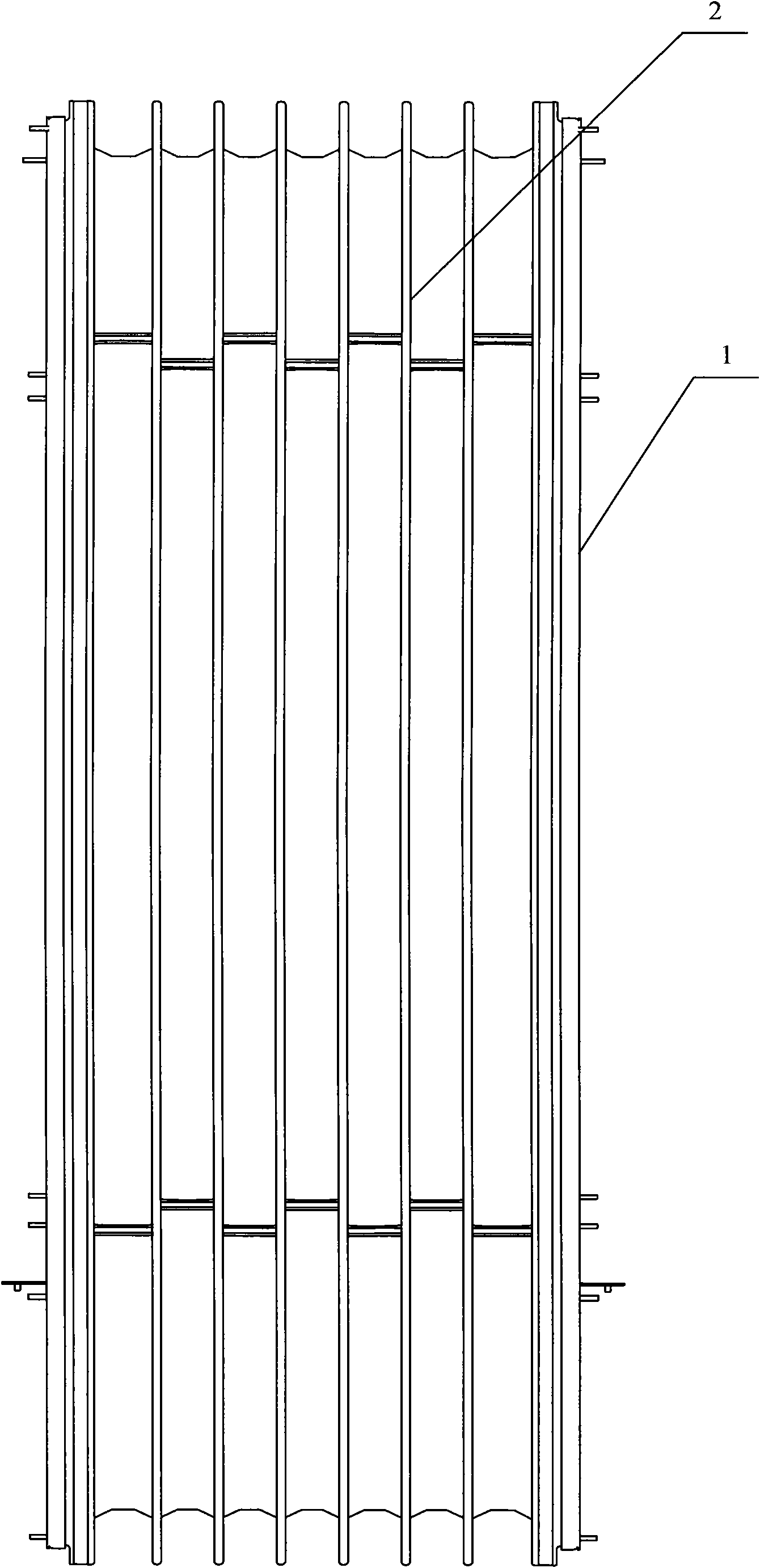

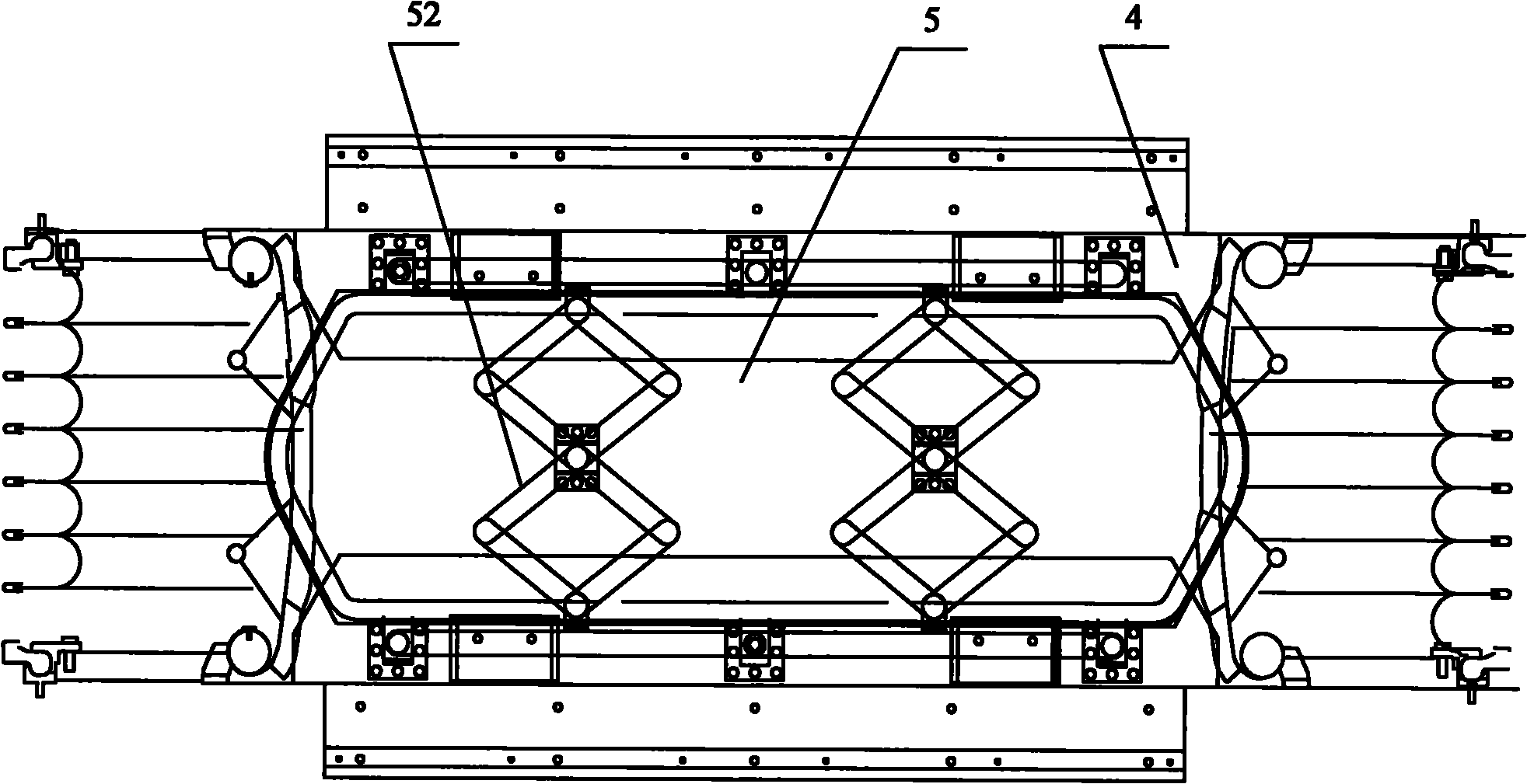

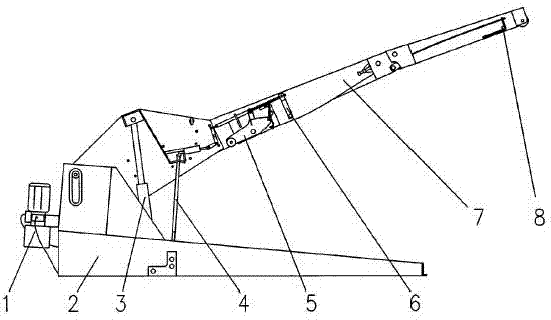

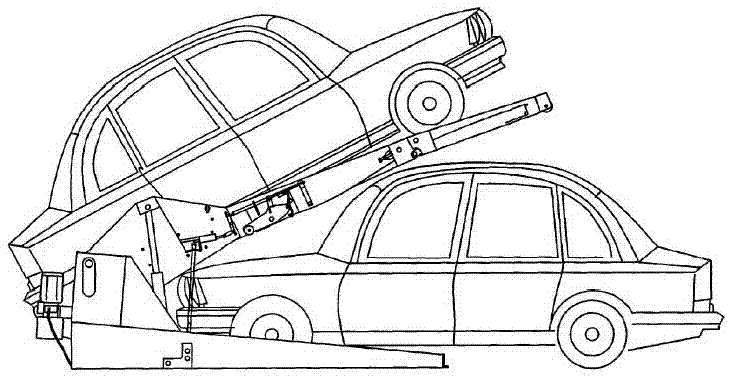

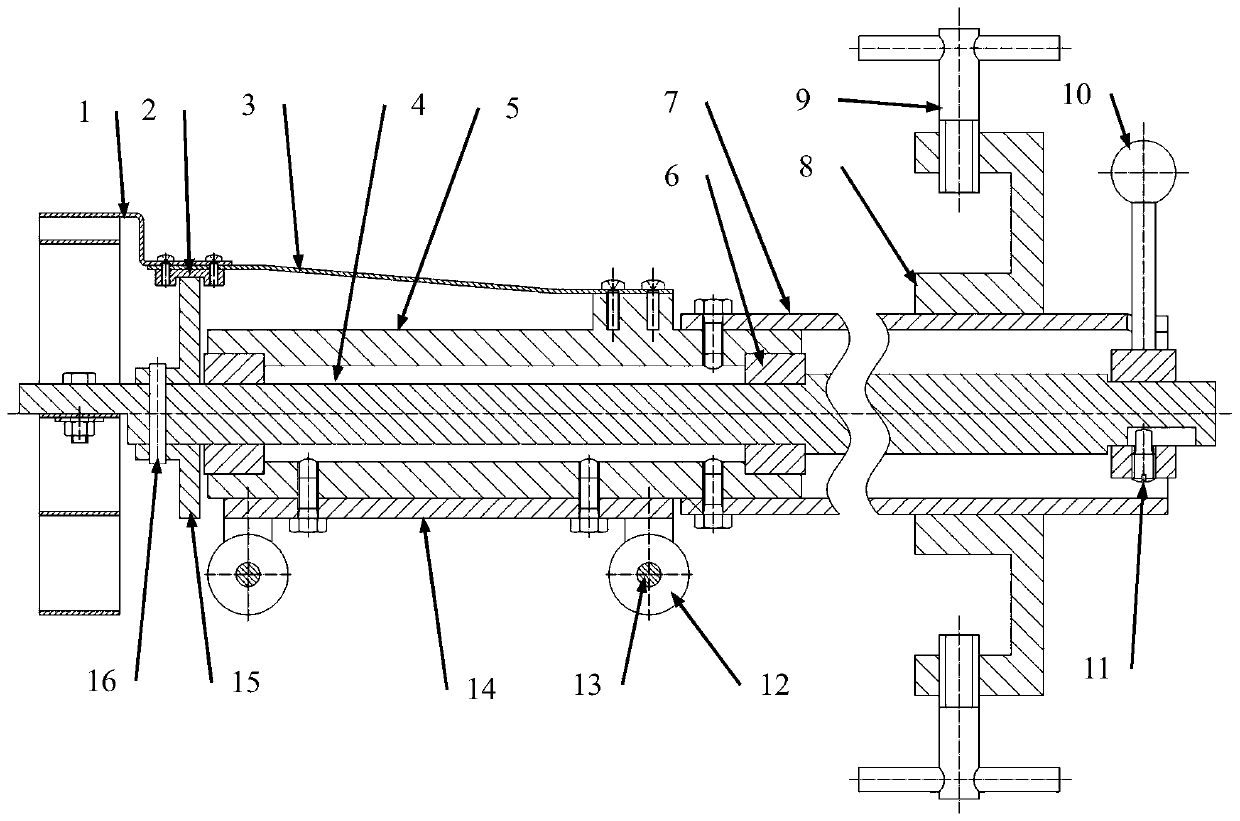

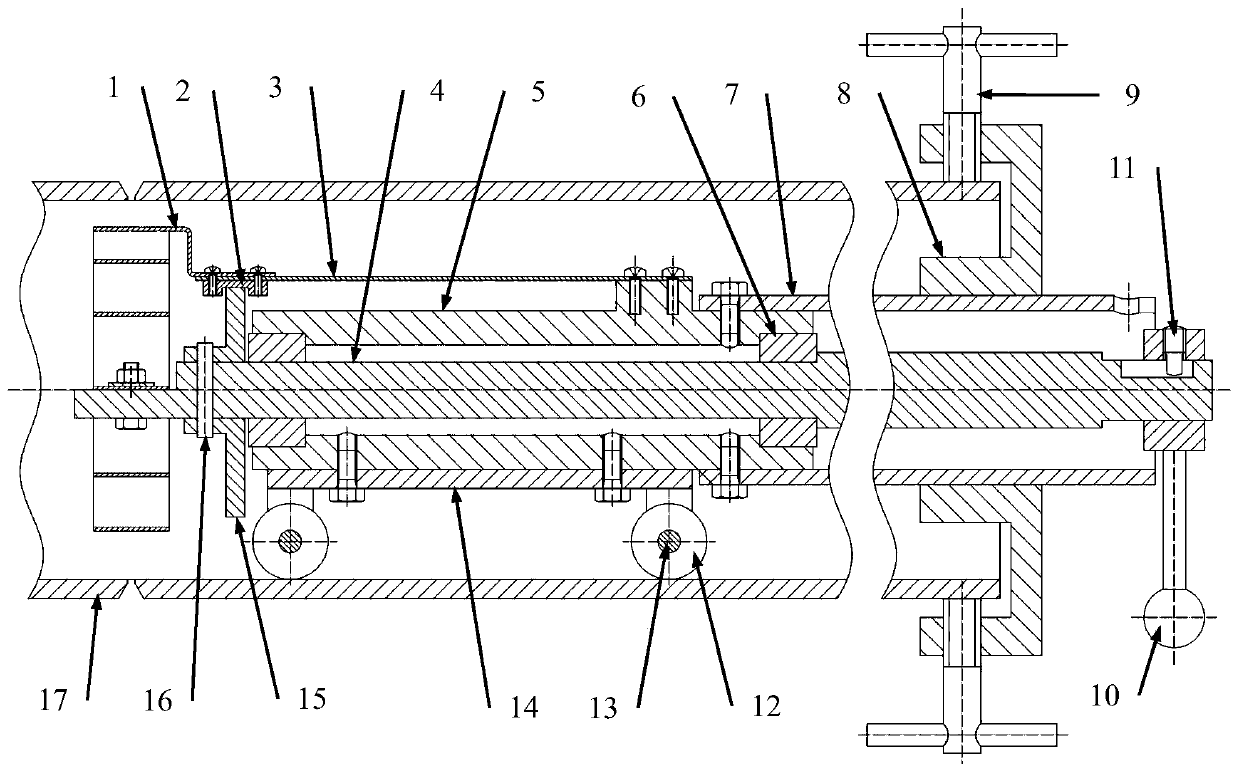

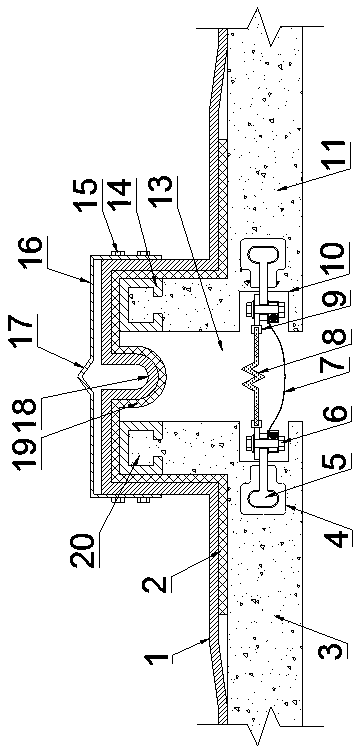

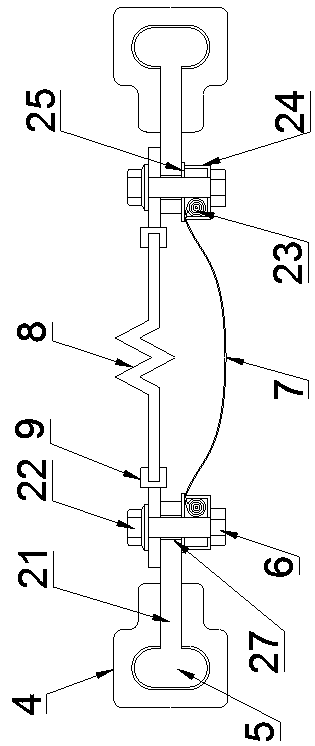

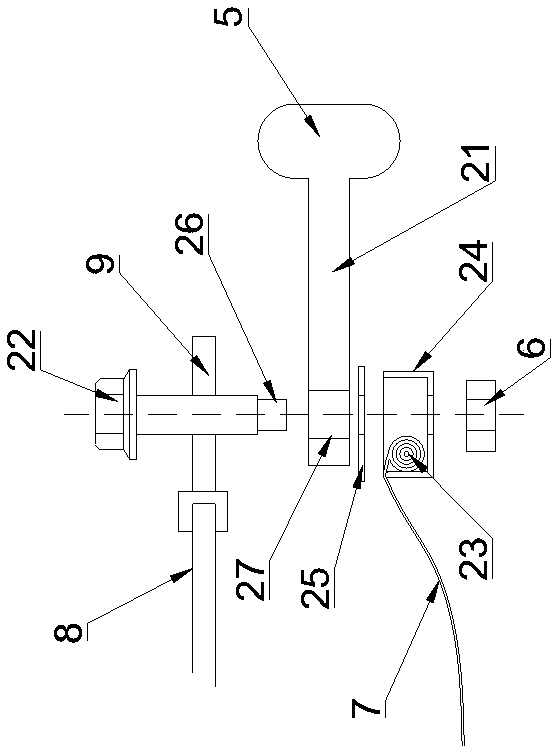

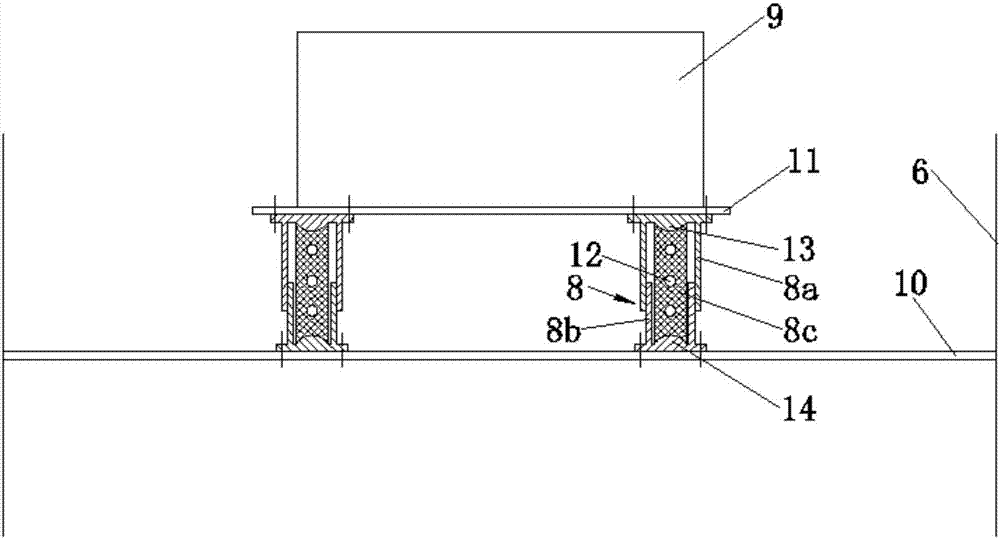

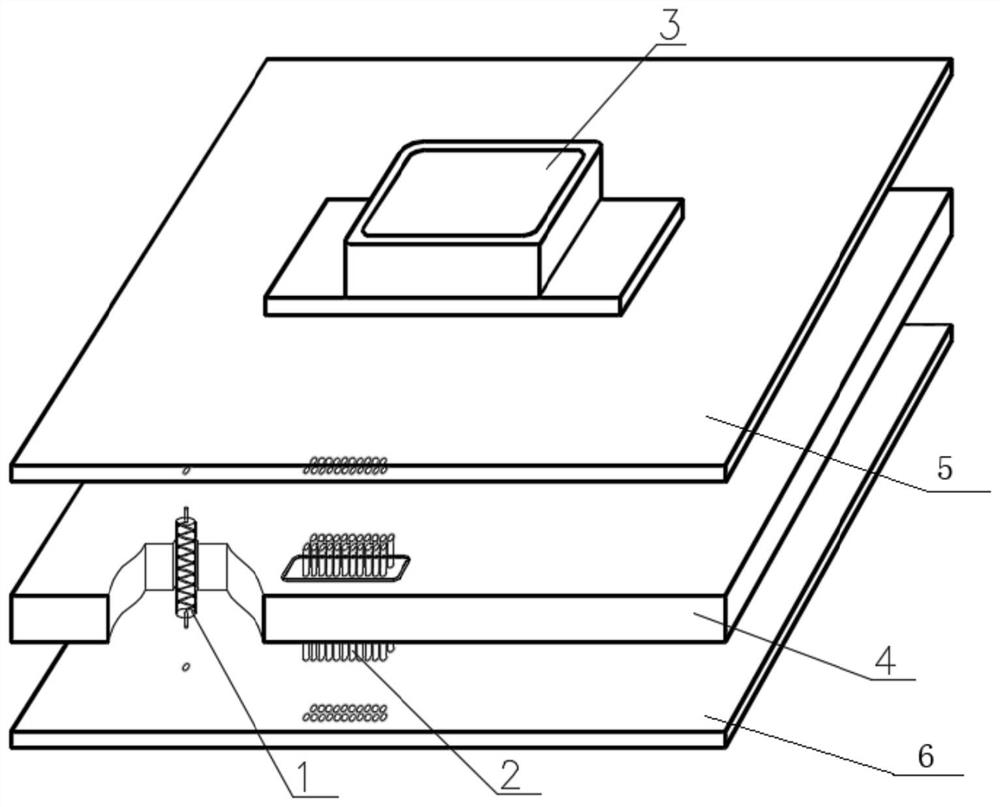

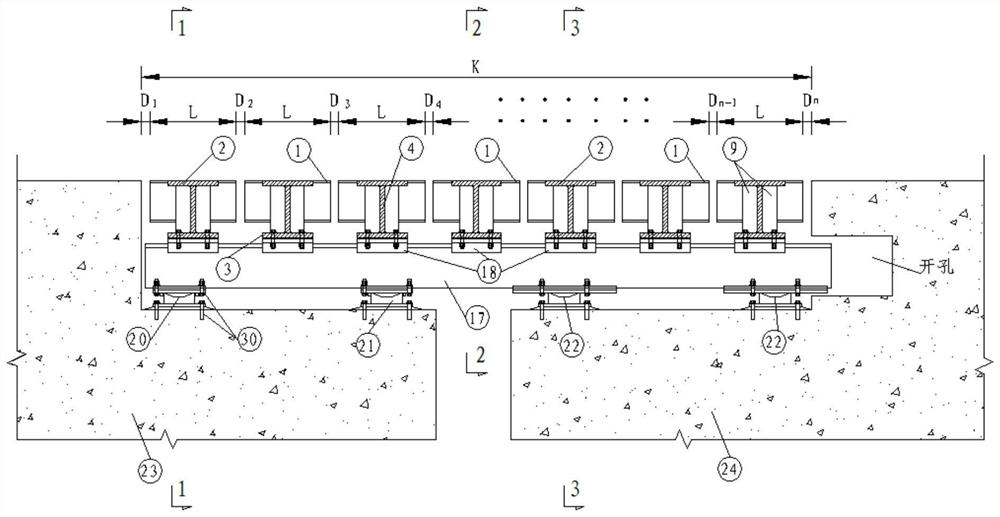

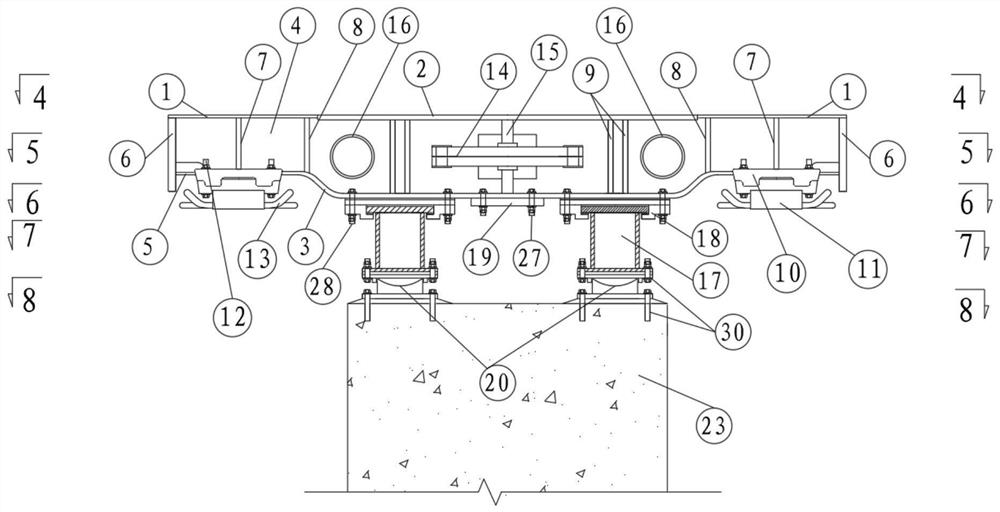

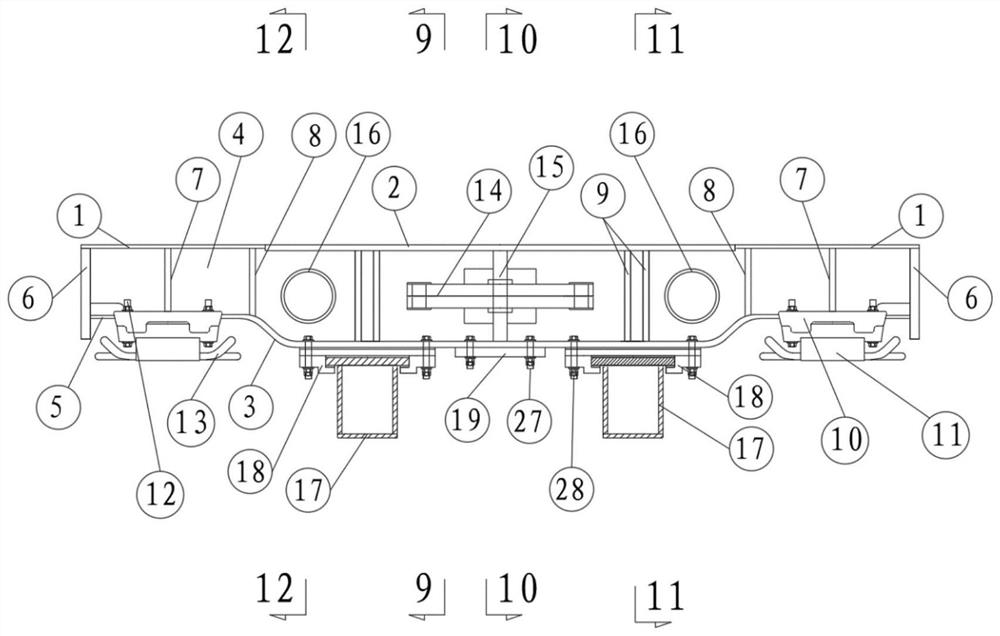

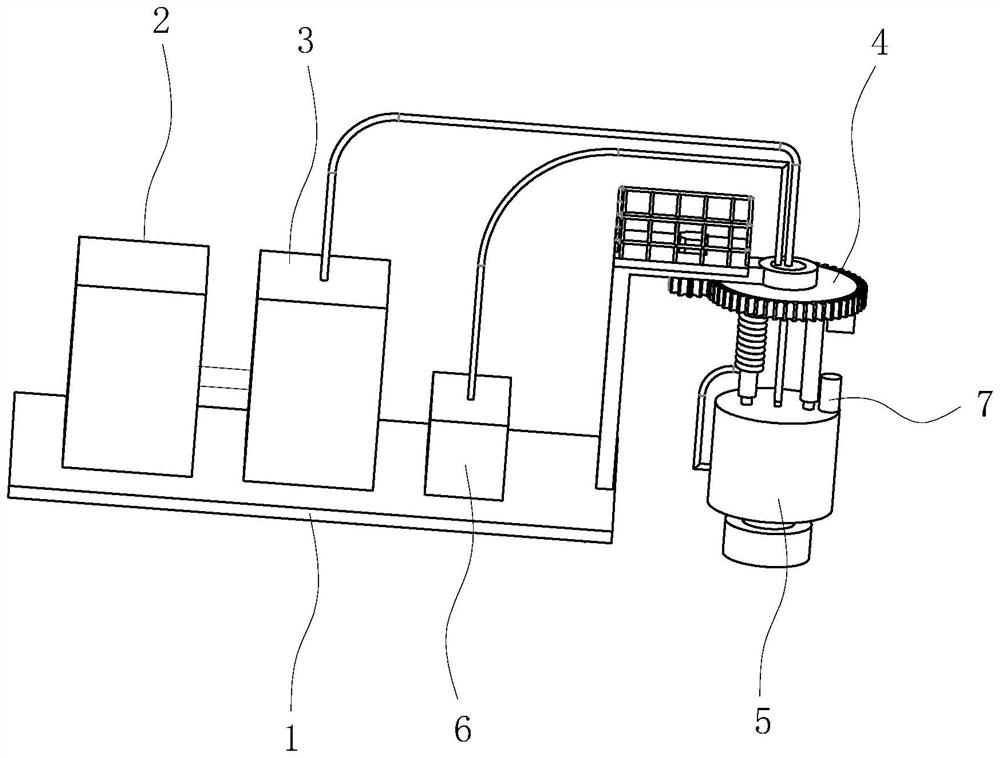

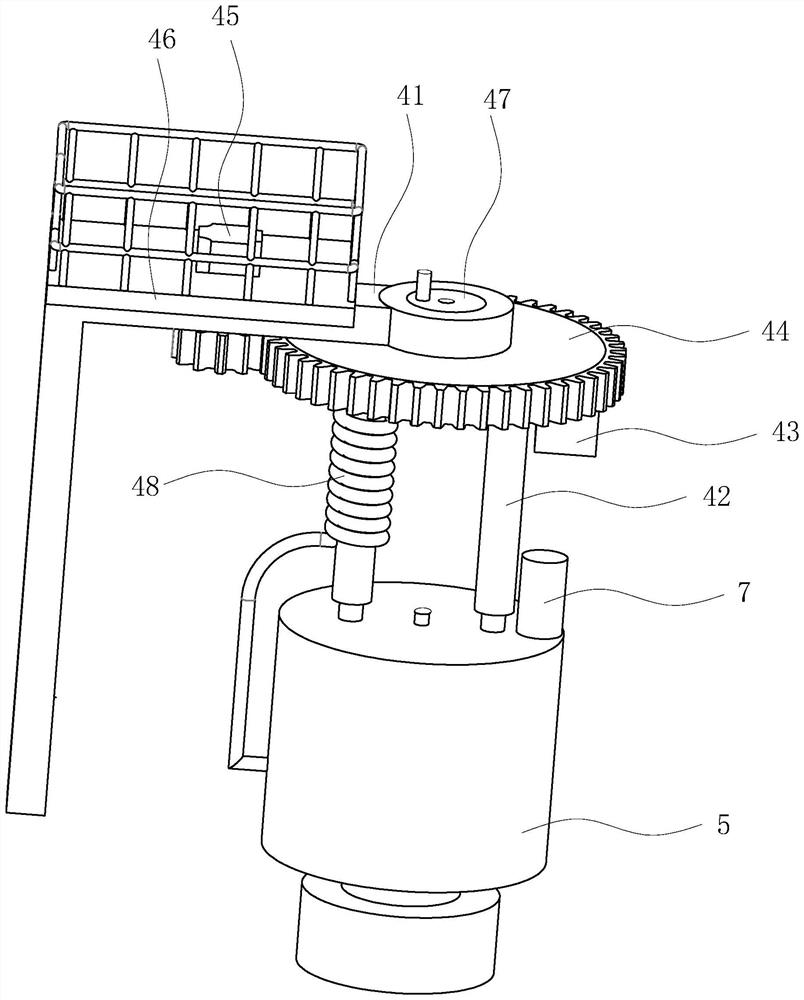

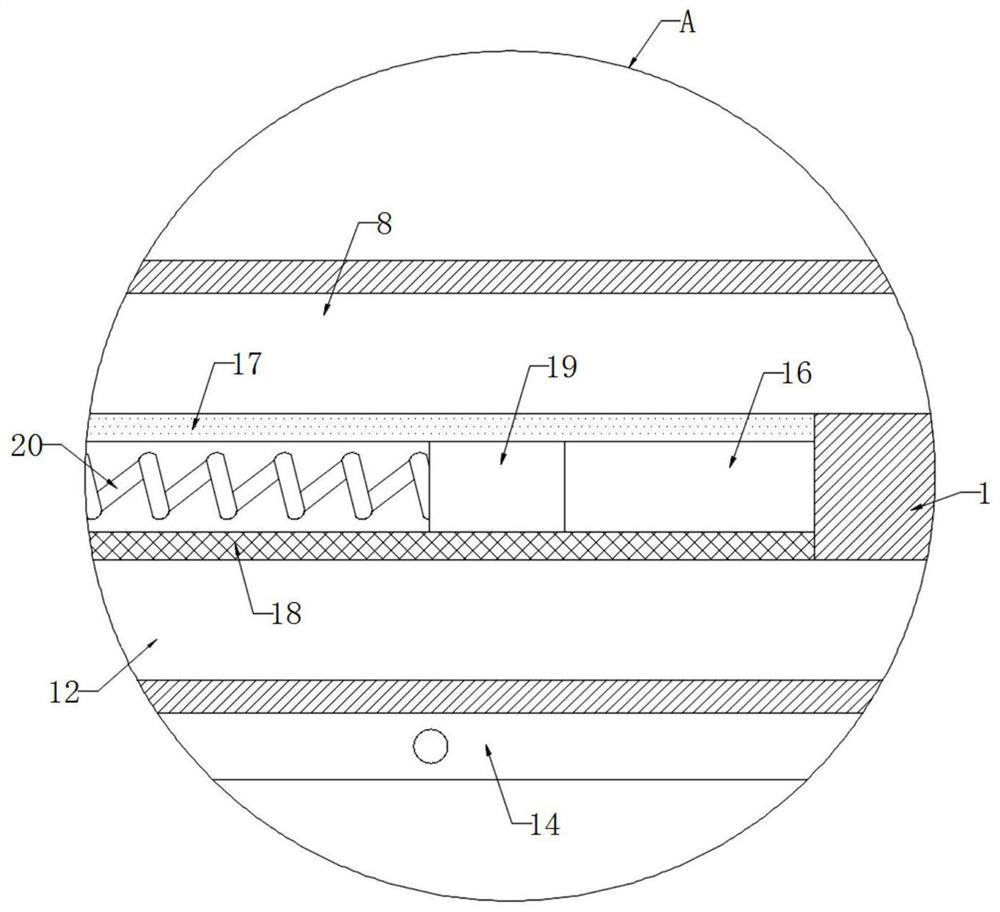

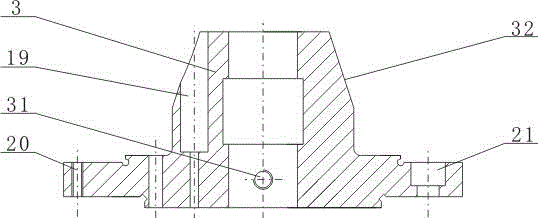

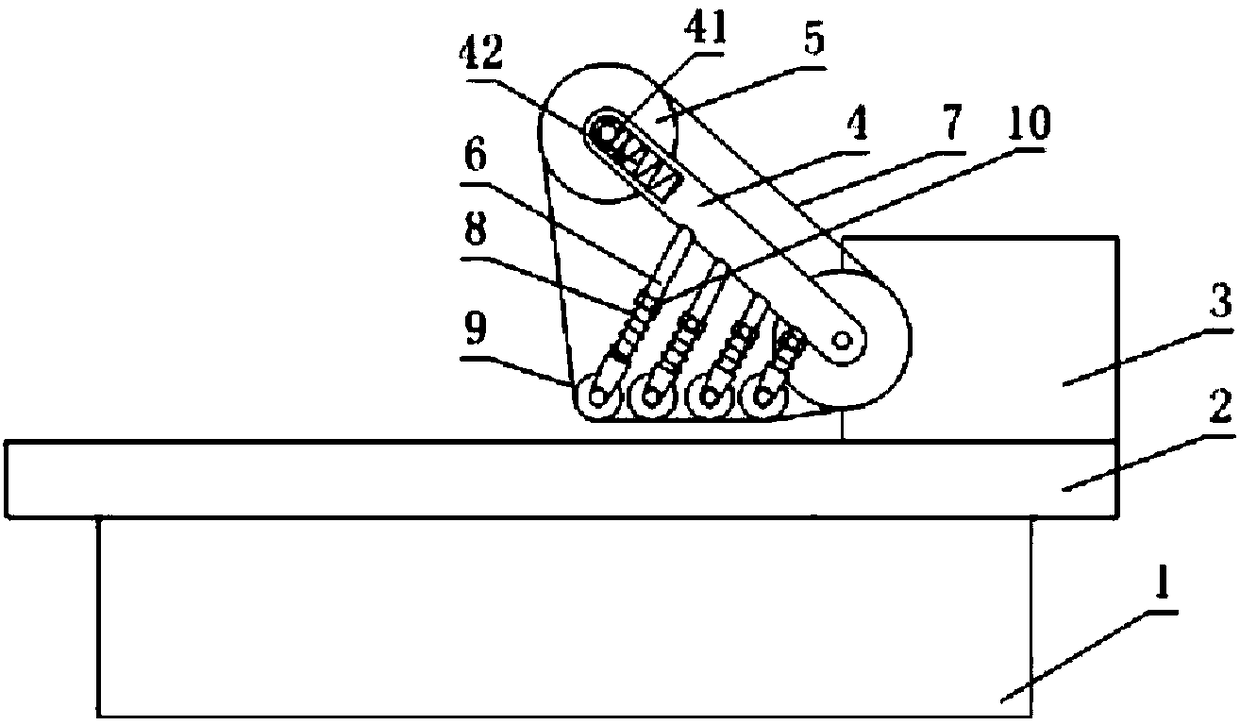

side shift parking system

ActiveCN105201249BLarge amount of expansion and contractionSmall footprintParkingsHydraulic cylinderProject area

This patent belongs to the technical field of car parking, and specifically discloses a side-moving parking system. The side-moving parking system includes a support frame and a bracket for supporting the car. The support frame and the bracket are pivotally connected. The support frame Located below the bracket, a supporting hydraulic cylinder is provided between the supporting frame and the bracket, the cylinder barrel of the supporting hydraulic cylinder is hinged with the supporting frame, the piston rod of the supporting hydraulic cylinder is hinged with the bracket, and the supporting frame is provided with The hydraulic station, the hydraulic station is connected to the supporting hydraulic cylinder through the first hydraulic pipe, and also includes a telescopic mechanism, which includes sequentially connected power parts, telescopic parts and fixed blocks for fixing on the ground, and the power parts are fixed on the support In the frame, the support frame is located in the projected area of the bracket on the horizontal plane. The side-moving parking system has the characteristics of strong adaptability in the parking lot and improving the parking rate of the parking lot.

Owner:杨自忠

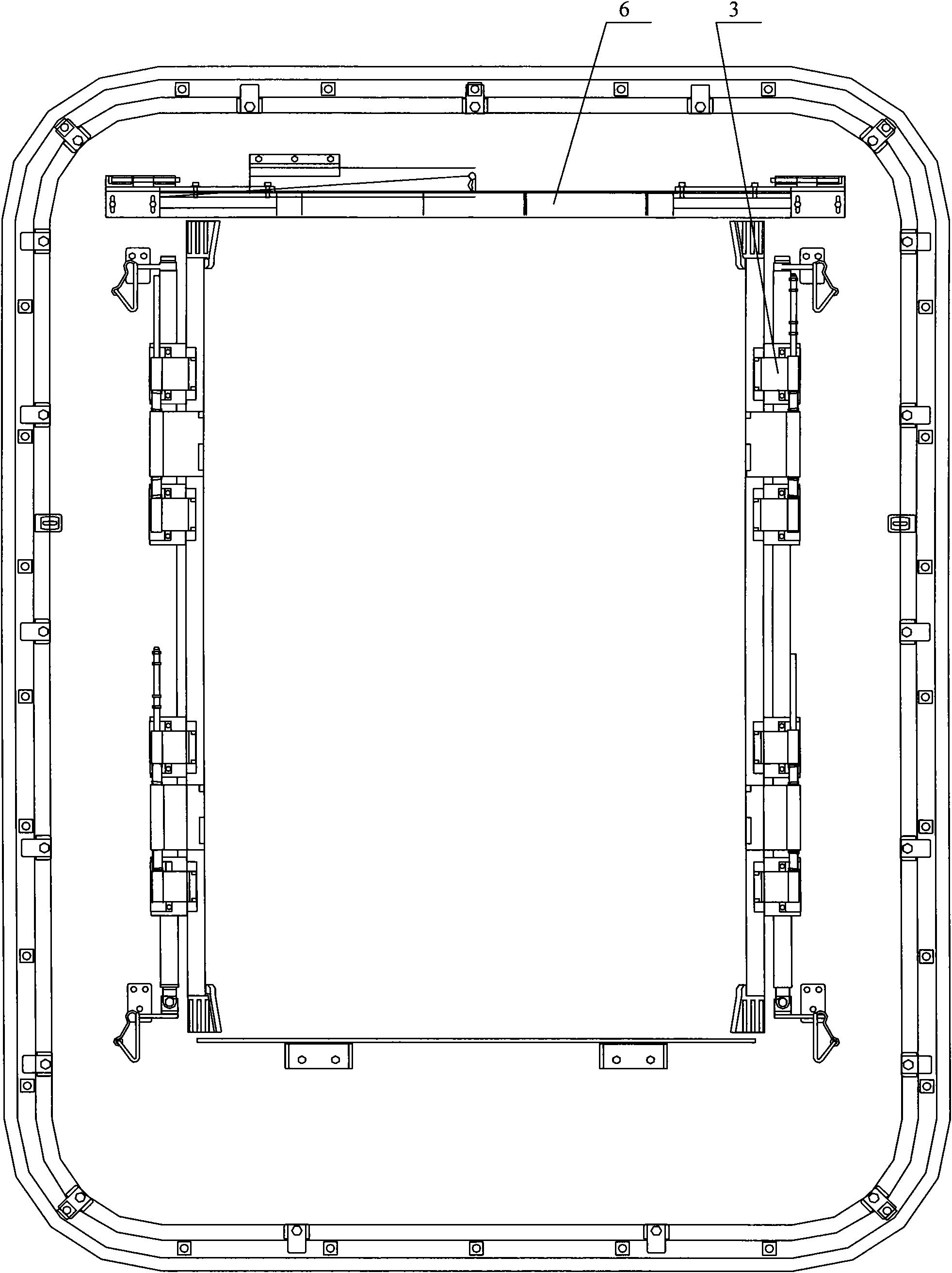

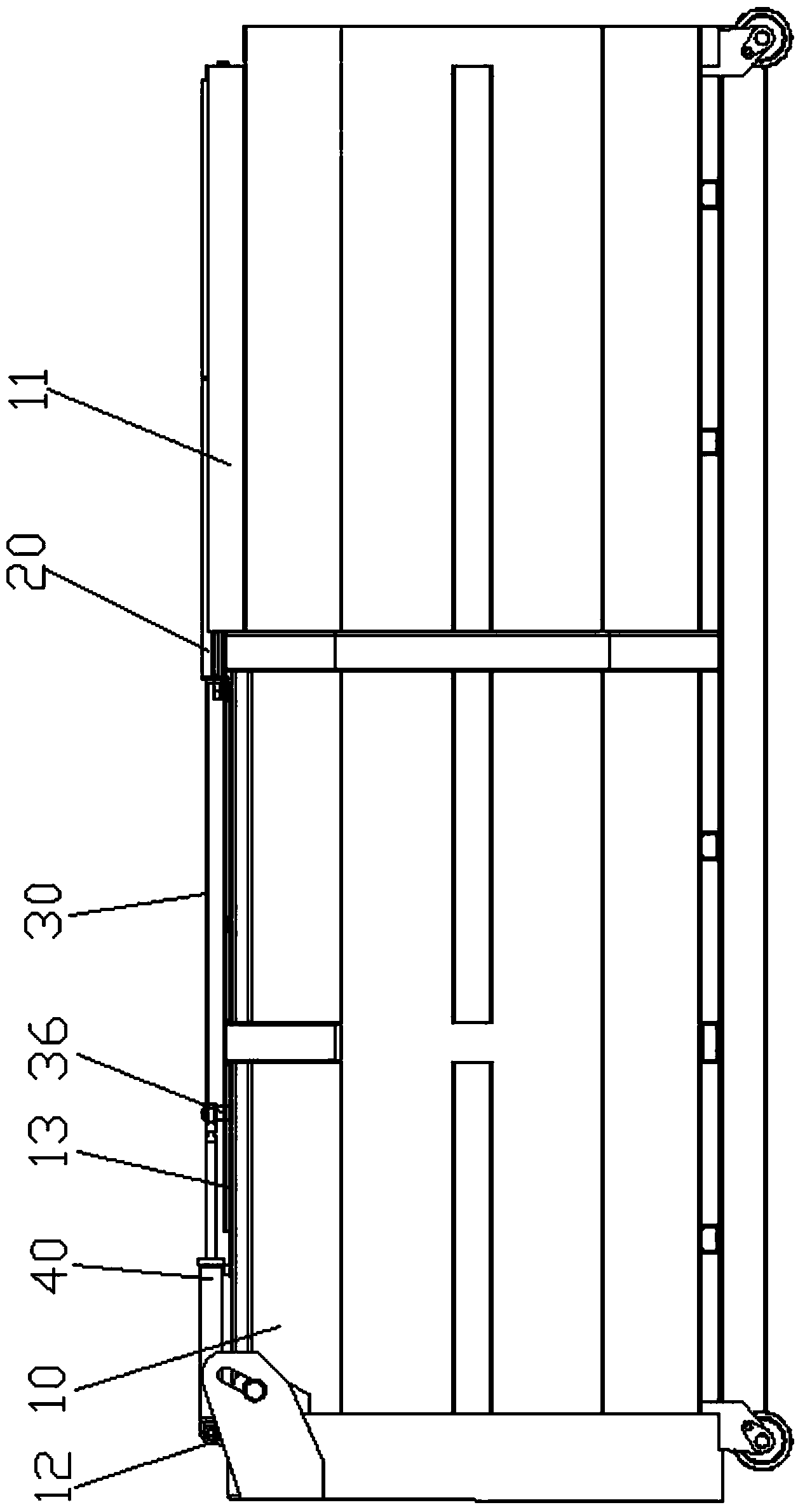

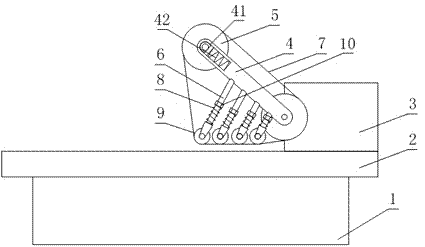

Door locking mechanism for garbage transfer box

InactiveCN103950662ALarge open spaceLow costLarge containersRefuse receptaclesHinge angleEngineering

The invention relates to a door locking mechanism, in particular to a door locking mechanism for a garbage transfer box, which comprises a box body (10) and an upper door plate (20), guide rails (11) are arranged at the two ends of the upper side of the box body (10), and the upper door plate (20) is clamped in the guide rails (11) and can slide along the guide rails (11). The door locking mechanism is further provided with a telescopic hinge (30) and a hydraulic cylinder (40), a hinged base (12) is arranged at one end of the box body (10) away from a feeding port, the cylinder head of the hydraulic cylinder (40) is hinged with the base (12), a piston rod of the hydraulic cylinder (40) is hinged with the telescopic hinge (30), and one end of the telescopic hinge (30) is connected with the upper door plate (20). The door locking mechanism has the benefits that the upper door plate is horizontally pushed in a way that the hydraulic cylinder is matched with the telescopic hinge to further open and close the feeding port, a larger opening space is realized by a smaller space, and the door plate can be reliably locked.

Owner:XUZHOU TIANJIU HEAVY IND

Aluminum product machining equipment

InactiveCN105437029AReduce dependenceLarge amount of expansion and contractionBelt grinding machinesEngineeringMachining

The invention discloses aluminum product machining equipment which comprises a machine base. The machine base is provided with a working table and a driving part. The aluminum product machining equipment further comprises two main belt pulleys, and a grinding belt winds across the two main belt pulleys. The aluminum product machining equipment also comprises auxiliary belt pulleys, springs, deformation adjusting parts and second belt pulley rods. In the acting process of the deformation adjusting parts, the end, arranged on the corresponding second belt pulley rod in a sleeving mode, of each spring is adjustable in position in the length direction of the second belt pulley rod, and each auxiliary belt pulley is fixed to the other end of the corresponding spring. The side faces of the auxiliary belt pulleys make contact with the side face of the grinding belt, the axes of the auxiliary belt pulleys and the axes of the main belt pulleys are parallel, and the distance between each auxiliary belt pulley and the working table is smaller than the distance between each main belt pulley and the working table. The axes of the springs intersect with the table top of the working table. A first belt pulley rod is further provided with an adjusting groove, and a compression spring is arranged in the adjusting groove. According to the aluminum product machining equipment, reliance of work of drawing equipment on real-time manual control can be weakened, and the aluminum product machining equipment is suitable for carrying out drawing machining on aluminum plates with poor surface quality.

Owner:成都金科达铝业有限公司

Wind-up attaching type gasket device for pipeline welding

ActiveCN110076485AReduce radial sizeLarge amount of expansion and contractionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSmall caliber

The invention discloses a wind-up attaching type gasket device for pipeline welding, and mainly aims to provide a pipeline welding auxiliary tool used during welding of pipelines with medium and smallcalibers and used for improving the welding quality. The wind-up attaching type gasket device for pipeline welding is characterized by comprising a sheet gasket which is made of copper alloy and areused for plugging a pipeline welding groove, a sliding pad, an elastic sheet, a gasket guide wheel, a long shaft, a guide wheel pin, a support barrel, two bearings, a wheel support, a small wheel, a pin shaft, a connecting barrel, a swing handle, a torque screw, a fixing frame and a T-shaped screw. According to the gasket device, the radial size is relatively small, the wind-up gasket is utilizedto be expanded to attach on the inner wall of a steel pipe so as to achieve the purpose of plugging the welding groove so that the gasket device can be applied into medium-and-small-caliber pipeline welding construction, and the gasket device is simple in structure and convenient to use.

Owner:大庆市庆东鸿运科技有限公司

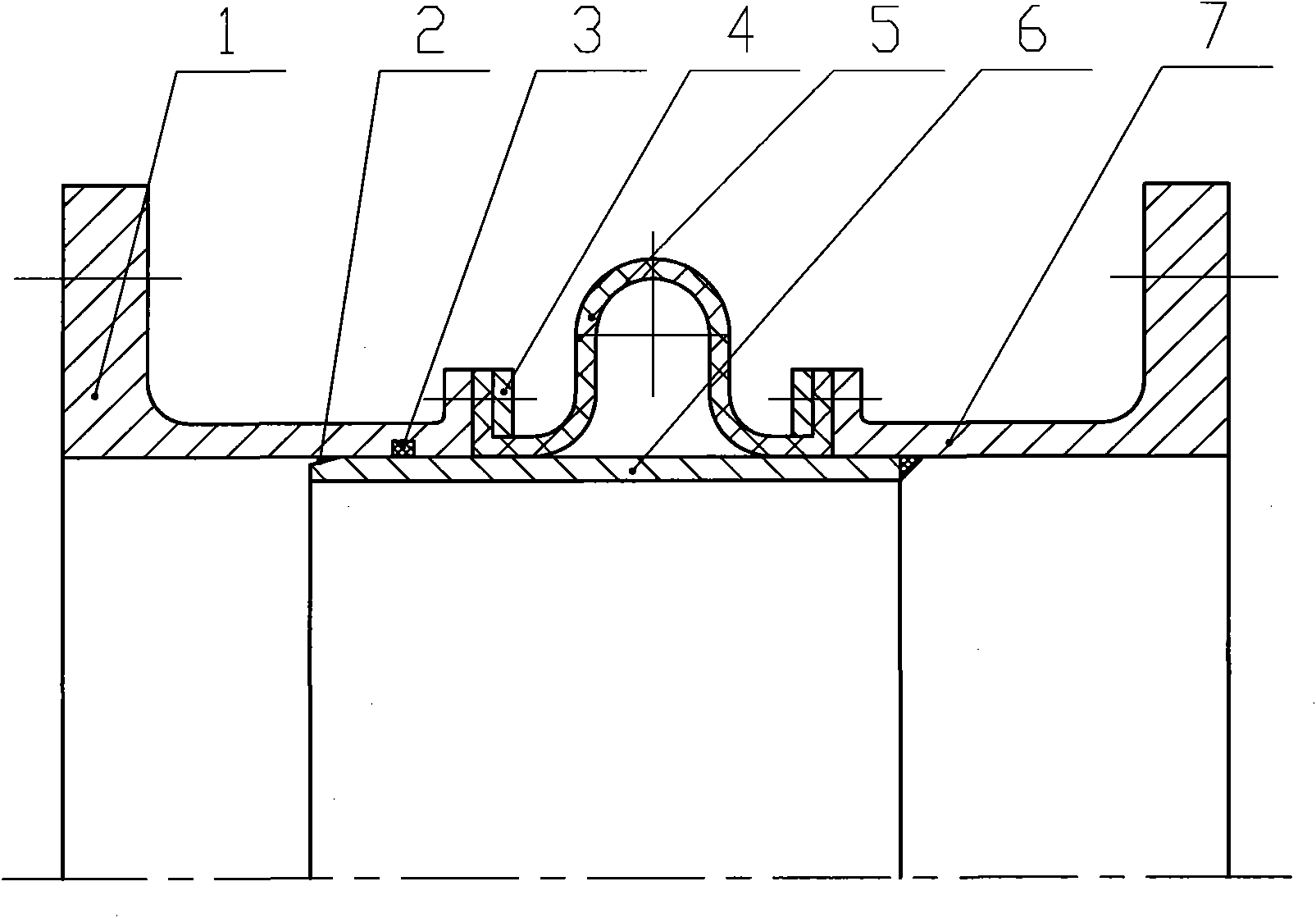

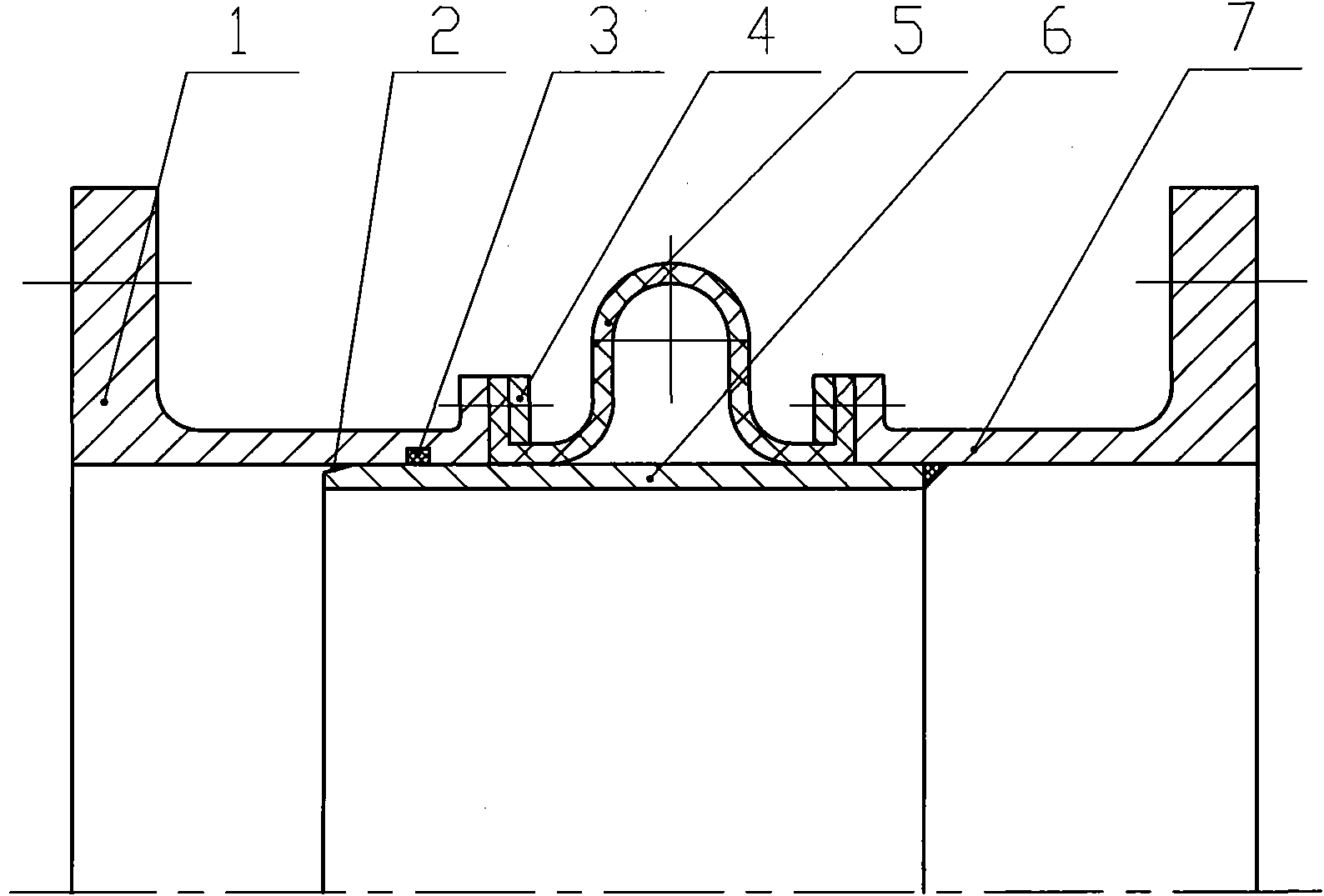

Waterproof connecting structure of deformation joint of building roof

InactiveCN108867900ALarge amount of expansion and contractionNot easy to crack and damageBuild-up roofsBuilding insulationsCushionRubber band

The invention discloses a waterproof connecting structure of a deformation joint of a building roof. The waterproof connecting structure comprises a waterproof roll layer, a fireproof rock wool layer,a waterproof elastic material connecting band, an elastic rubber band, the deformation joint and a waterproof aluminum plate. The deformation joint is arranged between a first concrete wall body anda second concrete wall body. The fireproof rock wool layer, the waterproof roll layer and the waterproof aluminum plate are sequentially laid on the top of the deformation joint from bottom to top. Prefabricated grooves are formed in the first concrete wall body and the second concrete wall body on the two sides of the deformation joint, pre-embedded anchor cables are arranged in the first concrete wall body and the second concrete wall body, locking heads are fixed into the pre-embedded anchor cables and connected with locking plates, the locking plates are arranged in the prefabricated grooves, bolt holes are formed in the locking plates, connecting bolts penetrate into the bolt holes, and the connecting bolts sequentially penetrate through clamping arms, the bolt holes of the locking plates, cushion plates and U-shaped glands from top to bottom to be connected with nuts. Assembly and disassembly are convenient, mounting and replacing of the fireproof elastic material connecting bandor the elastic rubber band are convenient, and operation is convenient.

Owner:曹文东

Expansion joint with bellows

InactiveCN101936440ASimple structureLarge amount of expansion and contractionPipeline expansion-compensationEngineeringExpansion joint

The invention provides an expansion joint with bellows, which comprises a left short tube and a right short tube. A rubber bellows is installed between the left short tube and the right short tube, and the rubber bellows is connected with the left short tube and the right short tube through flanges. The back face of the rubber bellows is provided with a cushion block, a bush is welded on the right short tube, an O-ring seal is installed between the left short tube and the bush, and the end part of the bush is provided with a guide angle. The invention has the advantages of simple structure, large expansion amount, reliable sealing and long service life.

Owner:倪静丰

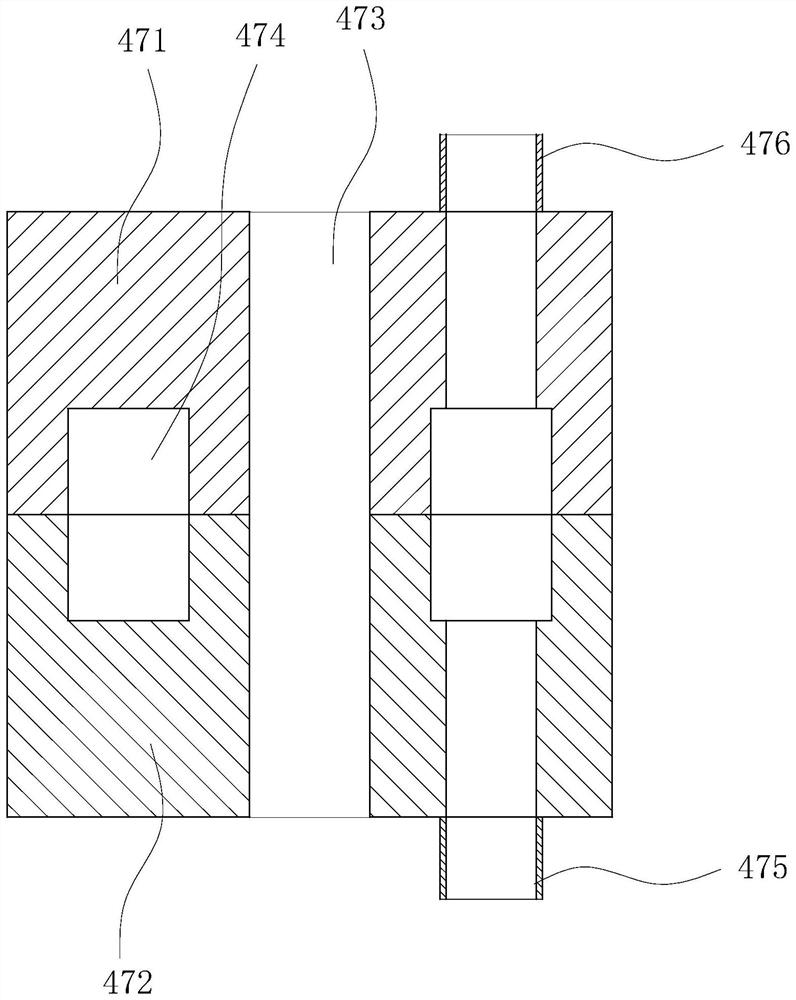

Clamping mechanism and clamping device

ActiveCN113997101AImprove versatilitySave layout spaceWork holdersPositioning apparatusMechanical engineeringPhysics

Owner:TONGJI UNIV

Aluminum plate surface processing device

InactiveCN105345627BReduce dependenceLarge amount of expansion and contractionBelt grinding machinesEngineeringTime control

The invention discloses a device for processing the surface of an aluminum plate. The device comprises a machine base. A workbench and a driving part are arranged on the machine base. The device further comprises two main belt wheels, and a grinding belt is wound around the two main belt wheels. The device further comprises auxiliary belt wheels, springs, deformation adjusting parts and second belt wheel rods. The side faces of the auxiliary belt wheels make contact with the side face of the grinding belt, and the axes of the auxiliary belt wheels are parallel to the axes of the main belt wheels. The distances between the auxiliary belt wheels and the workbench are smaller than the distances between the main belt wheels and the workbench, and the axes of the springs intersect with the tabletop of the workbench. An adjusting groove is further formed in a first belt wheel rod, and a compression spring is arranged in the adjusting groove. More than one auxiliary belt wheel is arranged. The device further comprises guide blocks and a linkage rod which are used for limiting the relative positions of all the auxiliary belt wheels. Dependence of work of wiredrawing equipment on manual real-time control can be relieved, the device is suitable for conducting wiredrawing on the aluminum plate with poor surface quality, and processing efficiency is high.

Owner:成都金科达铝业有限公司

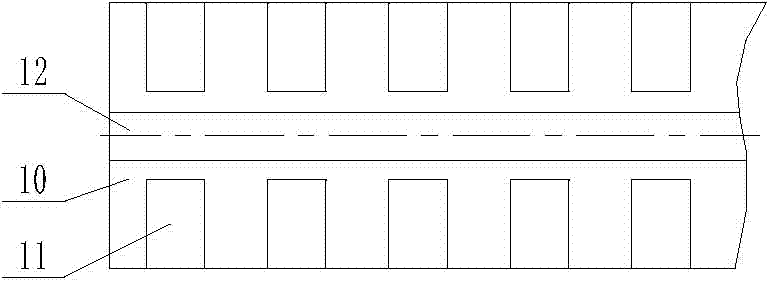

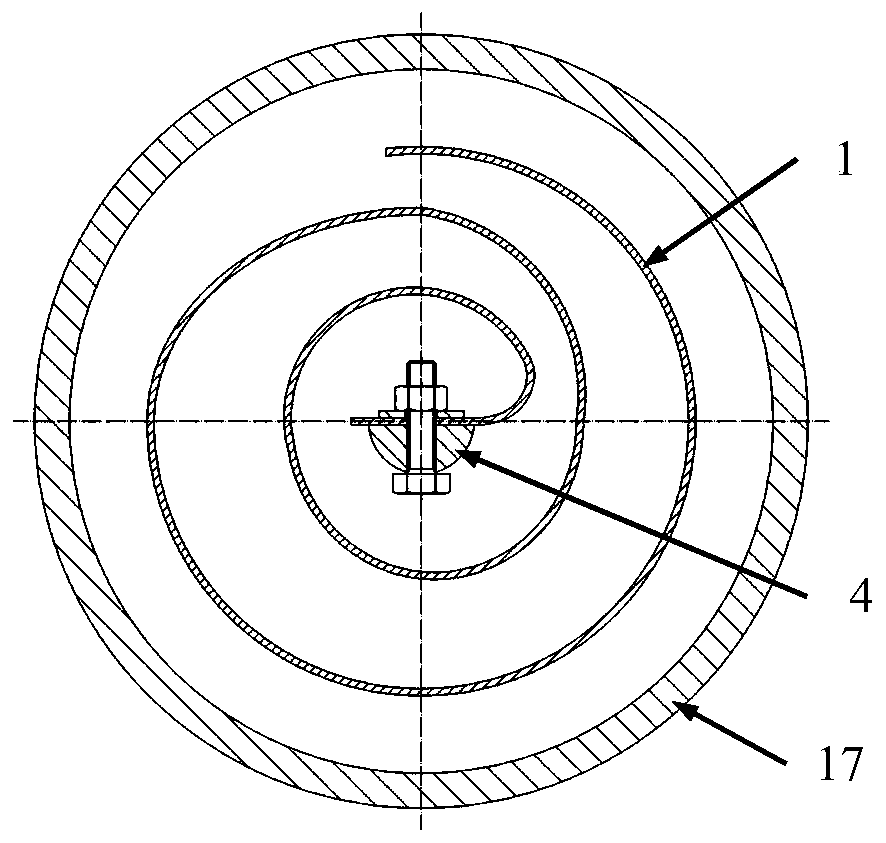

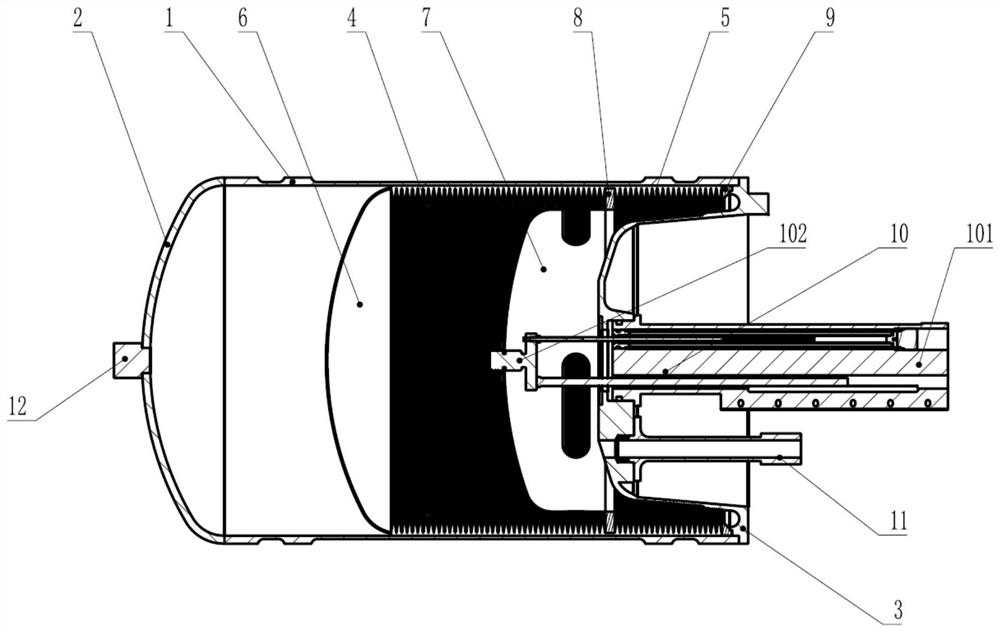

Two-stage corrugated pipe type pressure vessel capable of displaying volume

PendingCN112746993ARealize the function of storing liquidSmall measuring rangeFluid-pressure actuator testingAccumulator installationsPressure stabilizationStructural engineering

The invention belongs to the field of hydraulic pressure, and relates to a two-stage corrugated pipe type pressure vessel capable of displaying volume. The pressure vessel comprises an outer cylinder (1), a convex seal head (2), a concave end cover (3), a primary corrugated pipe (4), a secondary corrugated pipe (5), a primary convex cover (6), a secondary convex cover (7), a connecting seat (8), a connecting flange (9), an indicating device (10), an oil inlet / outlet (11) and an inflation valve (12). The pressure vessel is suitable for the fields of pressure accumulators, pressurizing oil tanks and the like needing volume compensation and pressure stabilization, has the characteristics of small volume, high volume utilization rate, large expansion and contraction amount, strong volume compensation capability and good oil supply, and is low in manufacturing cost, high in material utilization rate, less in welding seam quantity and good in reliability. Meanwhile, a measuring range of an indicating device is shortened by adopting a primary corrugated pipe and a secondary corrugated pipe, and the overall size is shortened.

Owner:JINCHENG NANJING ELECTROMECHANICAL HYDRAULIC PRESSURE ENG RES CENT AVIATION IND OF CHINA

Compound expansion joint

InactiveCN1724813ALarge amount of expansion and contractionEasy constructionBridge structural detailsEngineeringExpansion joint

Owner:DAEBONG MACHINERY IND

Agricultural unmanned pesticide sprayer

InactiveCN107873682AEasy to shapeImprove aestheticsAircraft componentsConstruction fastening devicesAttitude indicatorSprayer

The invention discloses an agricultural unmanned pesticide sprayer. An opening in the top of a main engine room is buckled with a main engine room cover; the center of the main engine room cover is embedded with a lockset; the lower end of a lock cylinder is fixedly provided with a following block; four suspended ends of the following block respectively correspond to four guide blocks; each guideblock is provided with a lock rod; the outer ends of the lock rods penetrate through guide holes correspondingly formed in the guide blocks and can extend in elastic lock folders arranged on the innerwall of the top end of the main engine room; and an attitude indicator is located in an equipment room, the bottom of the attitude indictor is provided with a locating plate, positions, close to fourcorners, at the bottom of the locating plate are supported on a partition plate by dampers, and the damper comprises an upper guide cylinder, a lower guide cylinder and a rubber column. By using theagricultural unmanned pesticide sprayer, the locking reliability of the main engine room cover on the main engine room can be guaranteed, and the agricultural unmanned pesticide sprayer is convenient,fast and labor-saving; and the attitude indicator is supported by the four dampers distributed in a rectangle, so that not only is the mounting firmness of the attitude indicator guaranteed, but alsoinfluences of airborne vibration to the attitude indicator can be effectively reduced, and furthermore, the reliability of the attitude indicator is guaranteed.

Owner:刘福珍

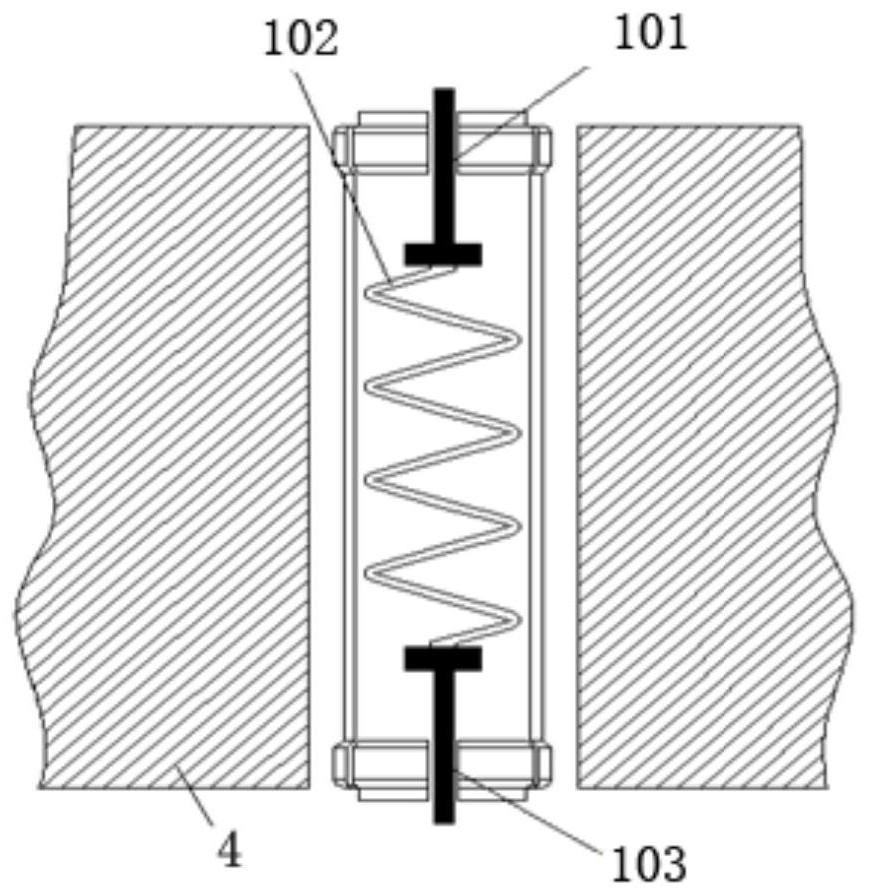

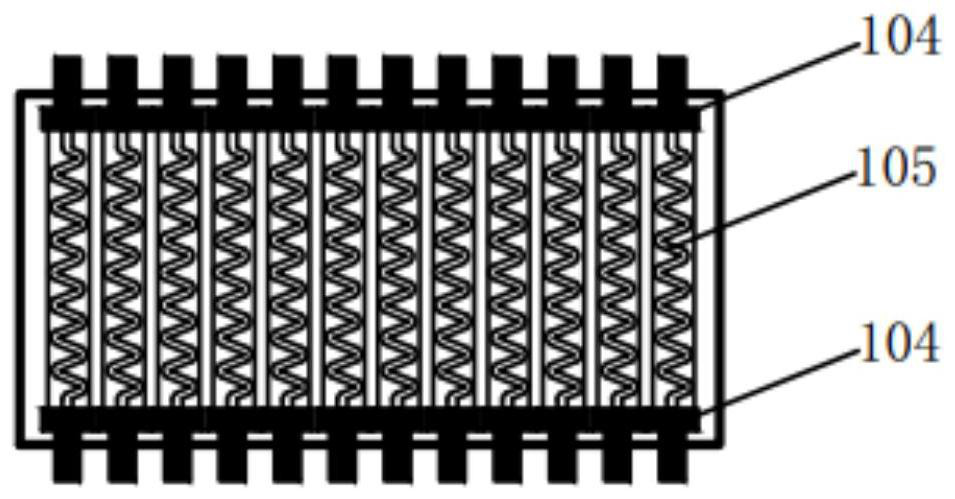

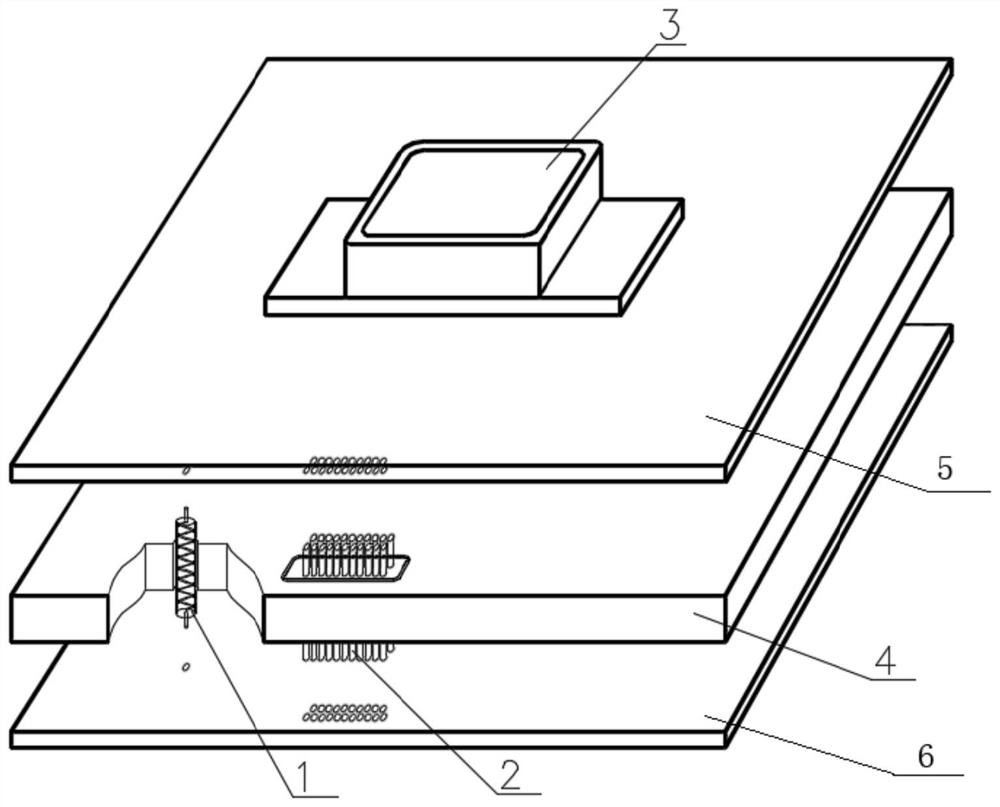

Method for realizing interconnection between microwave signal boards and interconnected microwave signal boards

ActiveCN113488754ACompact structurePass on advantagesWaveguidesCoupling devicesComposite substrateExternal connection

The invention relates to the field of active phased arrays, and discloses a method for realizing interconnection between a microwave signal board and an interconnected microwave signal board. The method comprises the following steps: arranging an interlayer adapter board for supporting a composite substrate at a middle position between an upper composite substrate and a lower composite substrate which are adjacent to each other, and forming a limiting hole for limiting the spring connecting structure in the interlayer adapter board; arranging a separable spring connecting structure between the adjacent upper and lower composite substrates, arranging the spring connecting structure in the limiting hole, and arranging metal bonding pads at the positions, corresponding to the spring connecting structure, of the adjacent upper and lower composite substrates; extruding the adjacent upper and lower composite substrates, and enabling the spring connecting structures to be in contact with the metal bonding pads on the upper and lower composite substrates to realize interconnection; and after interconnection is completed, arranging a high and low frequency mixed joint assembly used for external connection on the upper composite substrate. According to the invention, longitudinal interconnection between boards of 10 mm or above can be realized, and the expansibility is high.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

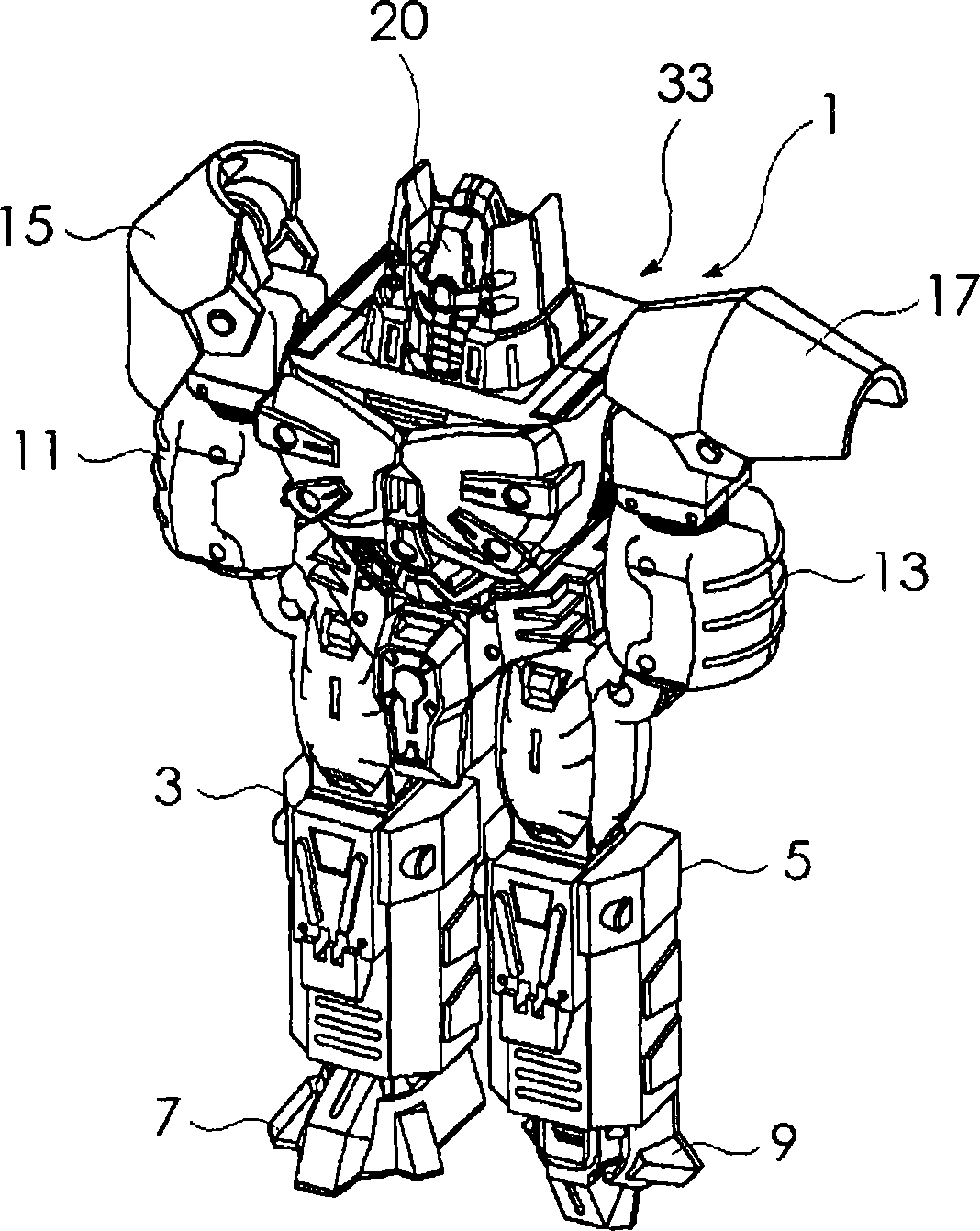

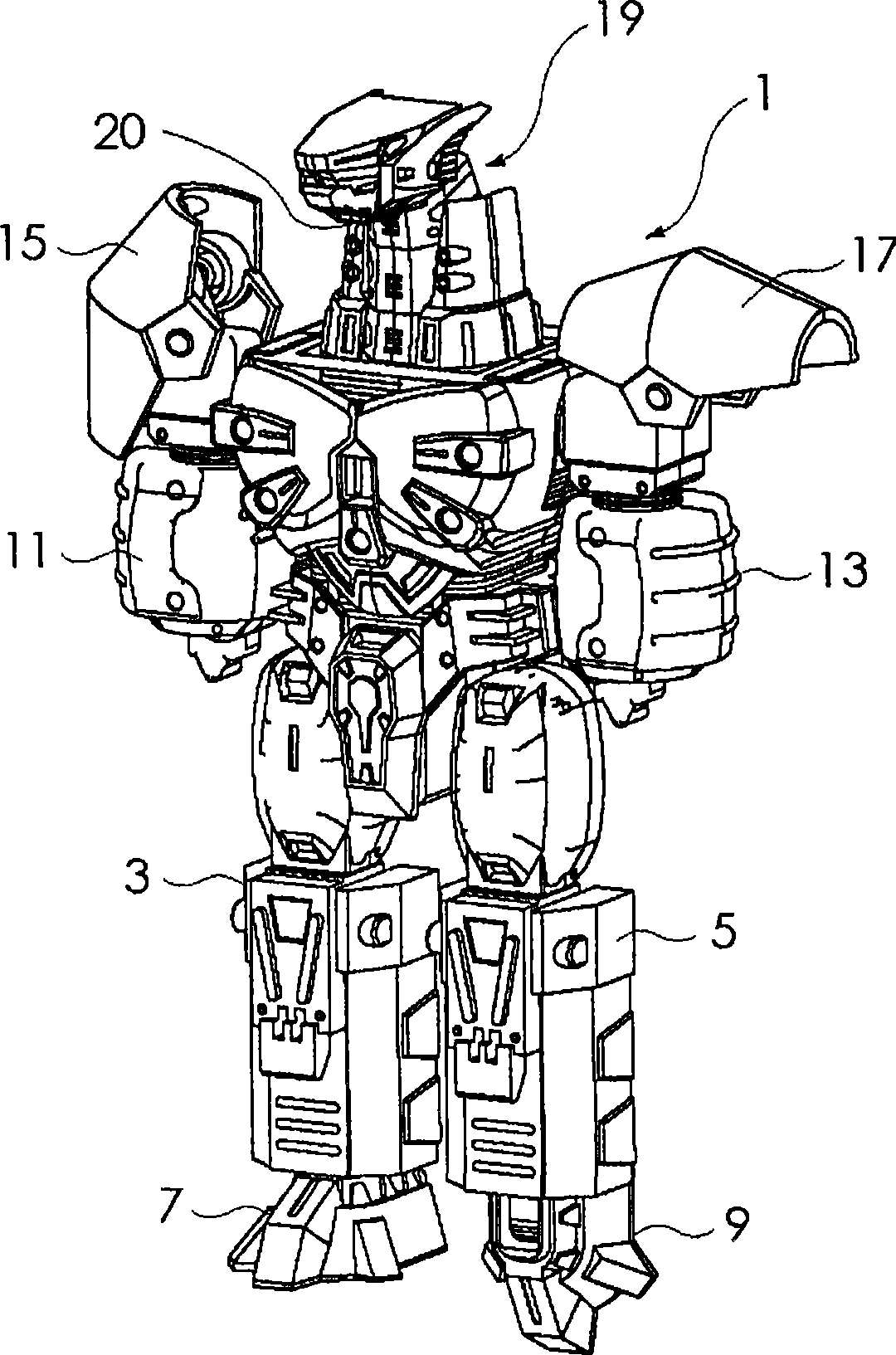

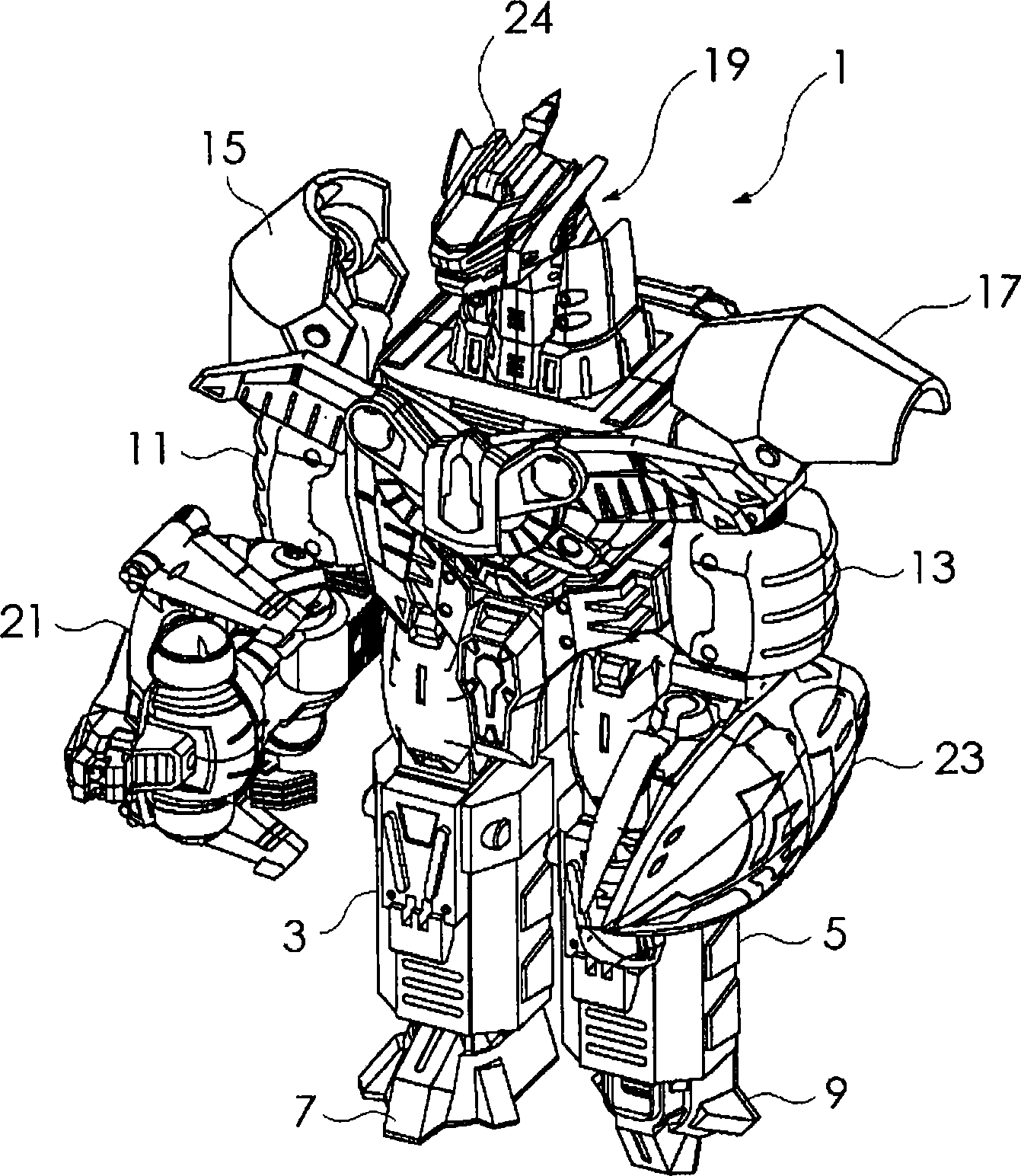

Transformable toy

InactiveCN1894013ALarge amount of expansion and contractionDollsSelf-moving toy figuresEngineeringMechanical engineering

The present invention provides a shape-changing toy capable of imparting unexpected shape changes to the shape-morphing toy. The neck (19) is configured to expand and contract in the direction in which the first to fourth members (35) to (41) are arranged. The first part (35) is fixed on the fixed part of the shape deformation toy. The first part (35) and the second part (37) are connected by a sliding connection mechanism. The second member (37) is fitted inside the first member (35). Connect the second to fourth parts (37) to (41) through a rotary connection mechanism, and accommodate all or most of the second to fourth parts (37) to (41) in the first part (35) internal.

Owner:KONAMI DIGITAL ENTERTAINMENT CO LTD

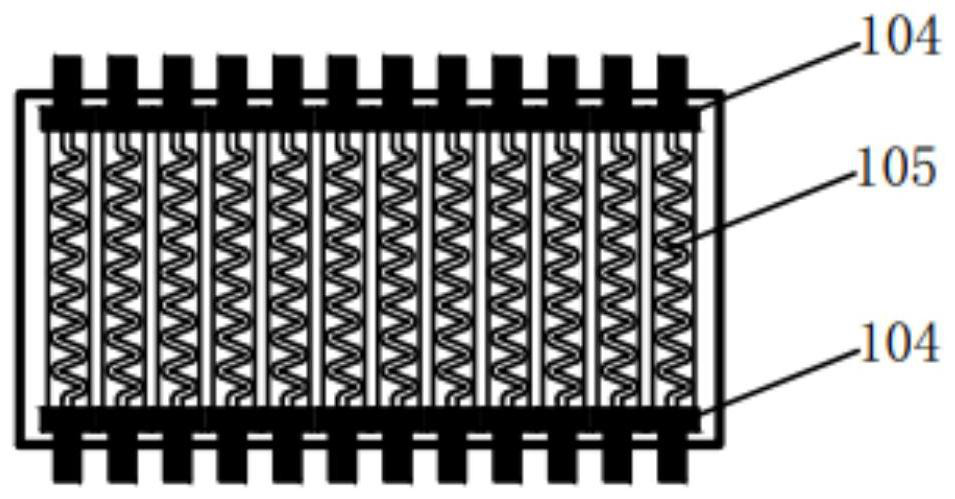

Long stator module of high-speed maglev bridge large-displacement telescopic device

ActiveCN112482211ALongitudinal displacement and expansionSmall structureRailway tracksBridge structural detailsStator coilControl theory

The invention discloses a long stator module of a high-speed maglev bridge large-displacement telescopic device, which constructs a unique long stator track unit module system including a cross beam unit and a long stator track assembly to realize segmentation of a stator core and continuous scalability of a long stator coil. The long stator module can adapt to suspension, guiding and traction driving of a high-speed maglev train and traveling of emergency traveling wheels at the same time; a brand-new longitudinal limiting system, a connecting rod system and a spring system are further designed in the long stator module to be in close fit with a longitudinal beam system and a fastener system of a large-displacement telescopic device, and large-displacement telescopic of high-speed maglevtraffic is achieved. The long stator module is not only suitable for a superposed beam scheme, but also suitable for a pure track beam scheme or a bridge scheme of paving track plates on a bridge; thestructural body is small in size, clear in structural stress and good in durability; through the synergistic effect of the connecting rod system and the spring system, the longitudinal gaps between any two long stator track unit module systems can be equal in any telescopic state.

Owner:CHINA RAILWAY MAGLEV TRANSPORTATION INVESTMENT CONSTR CO LTD +1

A kind of pneumatic centrifugal spray construction inspection well repair equipment, engineering vehicle and repair method

ActiveCN114439009BAvoid swingingSwing don't worryArtificial islandsFoundation repairRotary stageElectric machinery

Owner:广东银浩智能技术有限公司

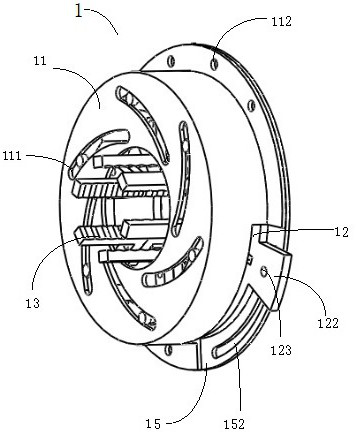

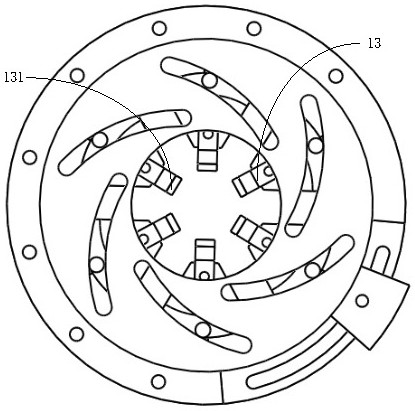

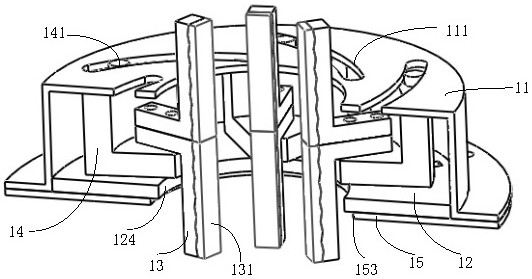

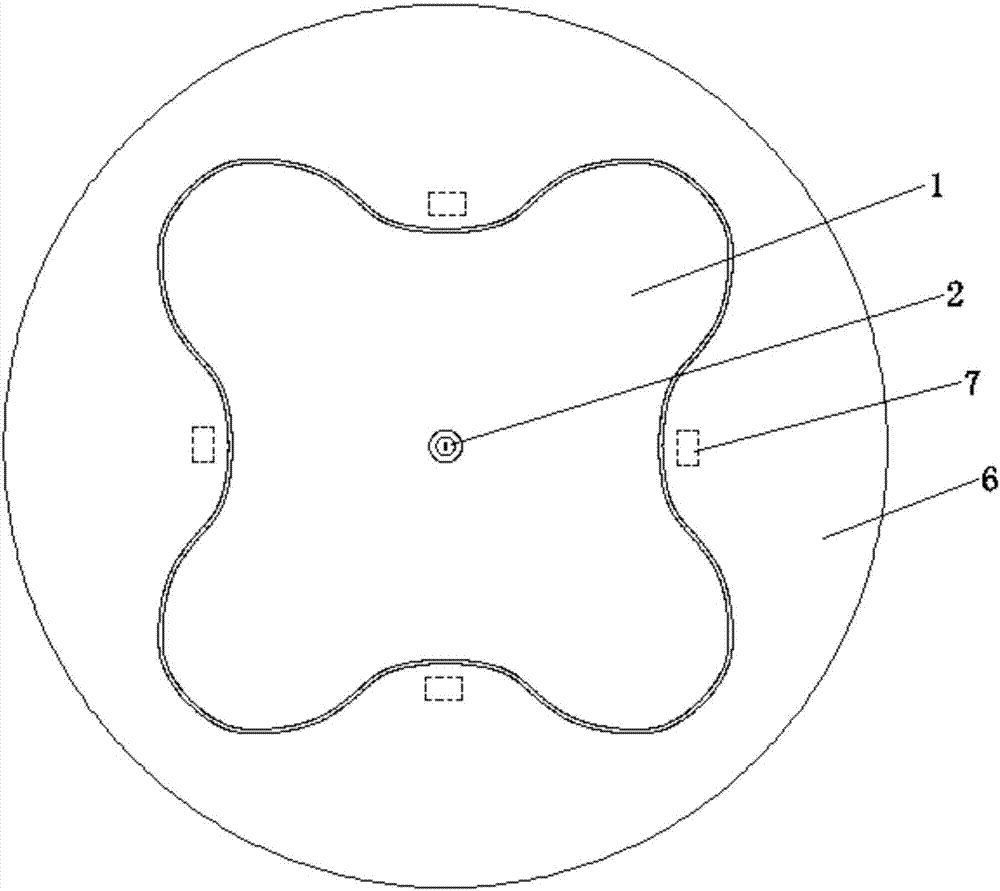

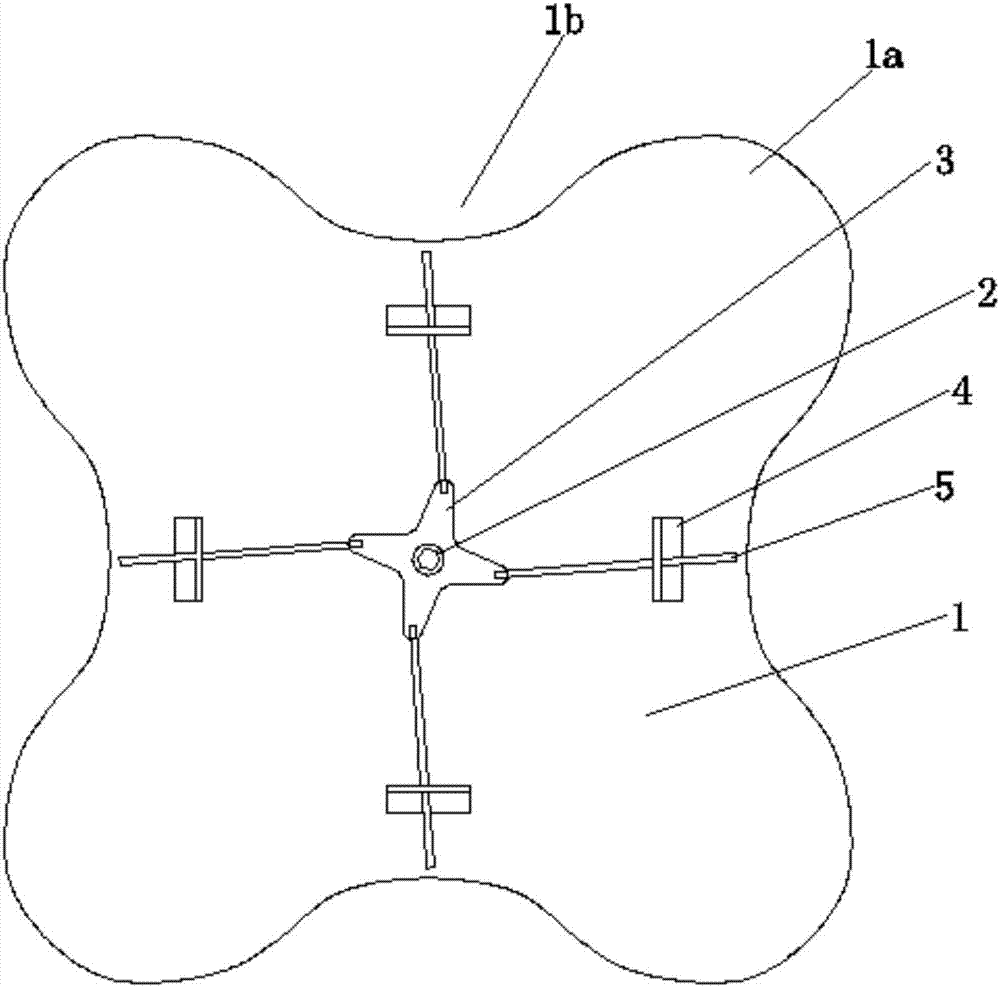

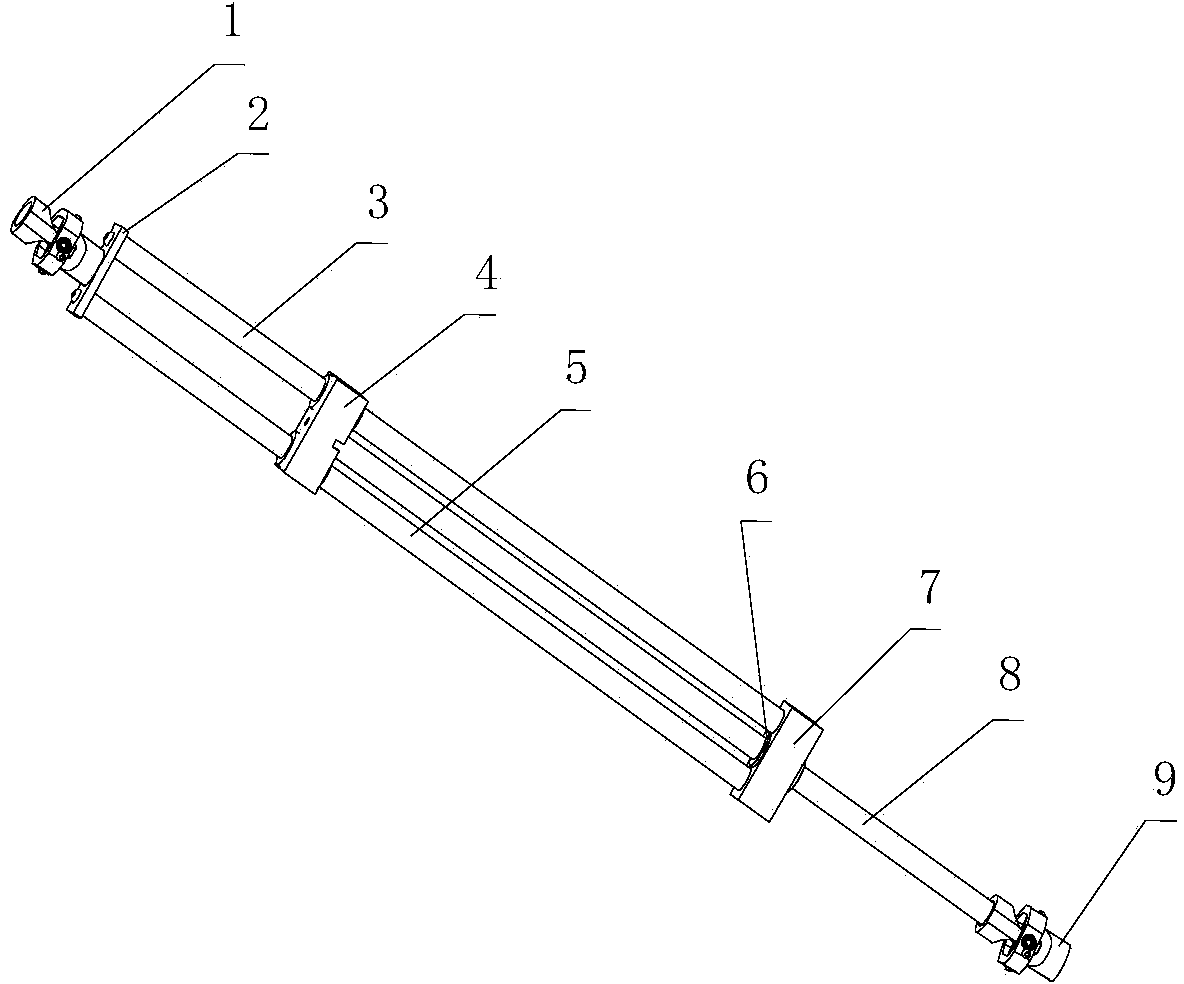

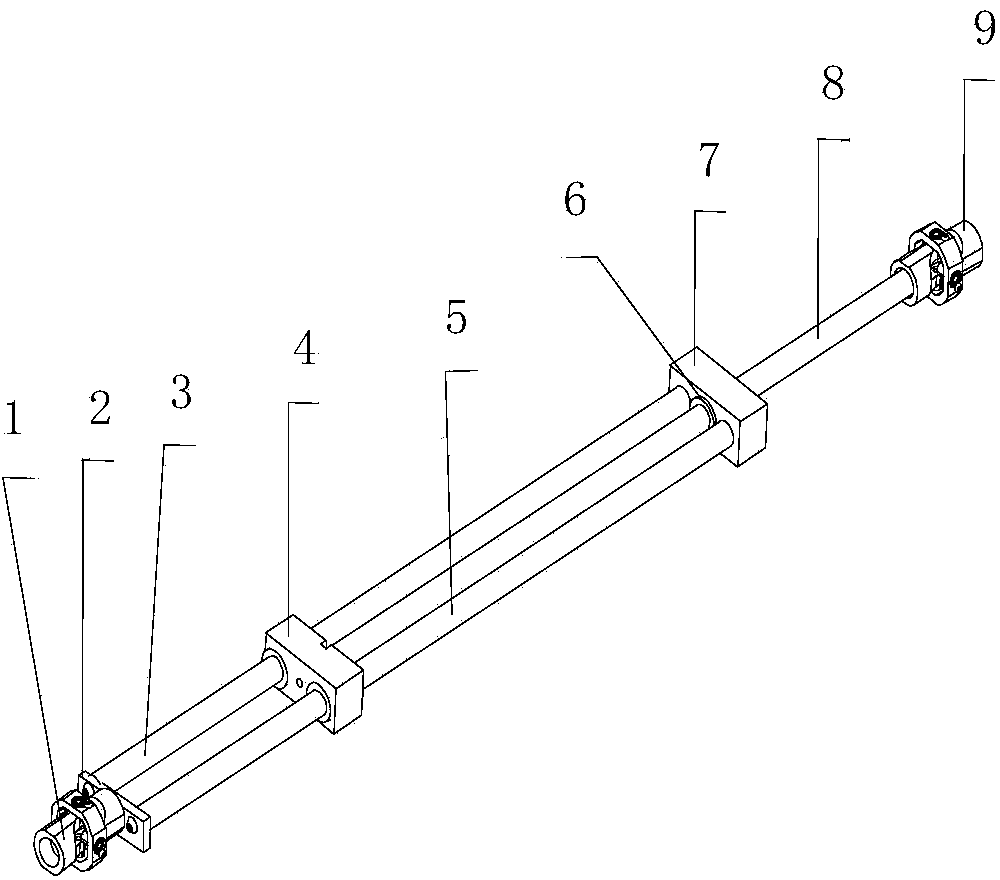

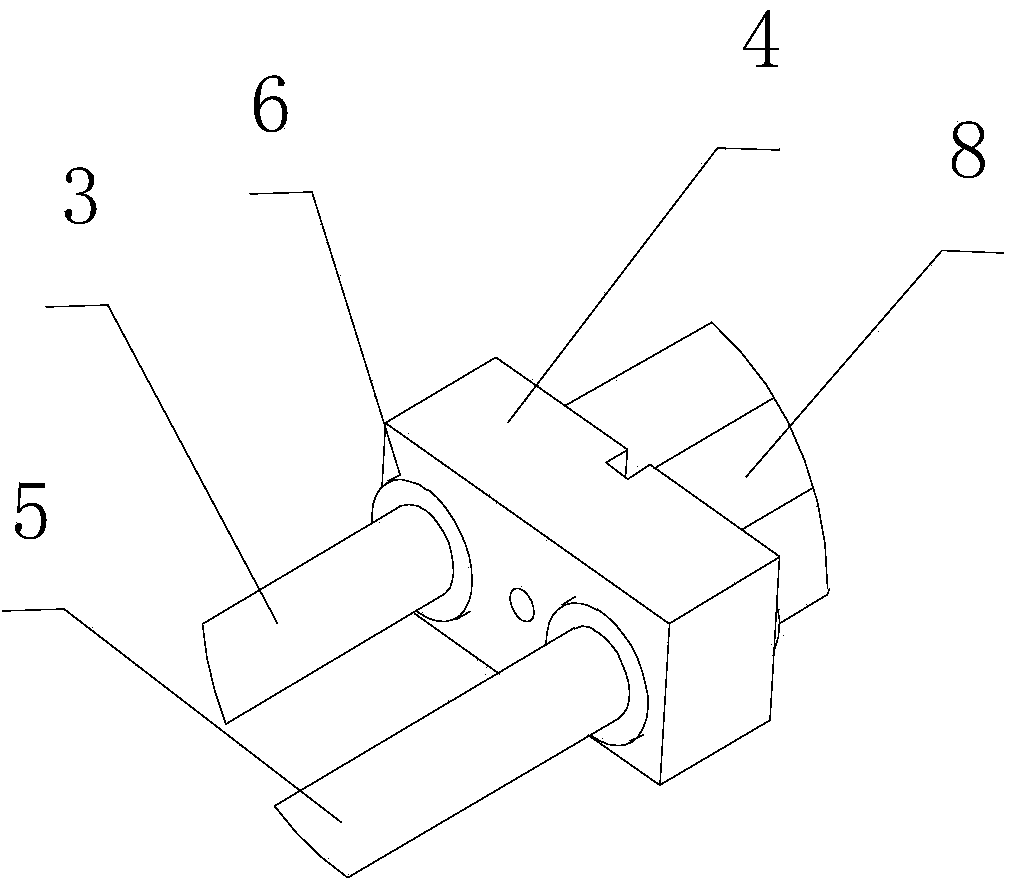

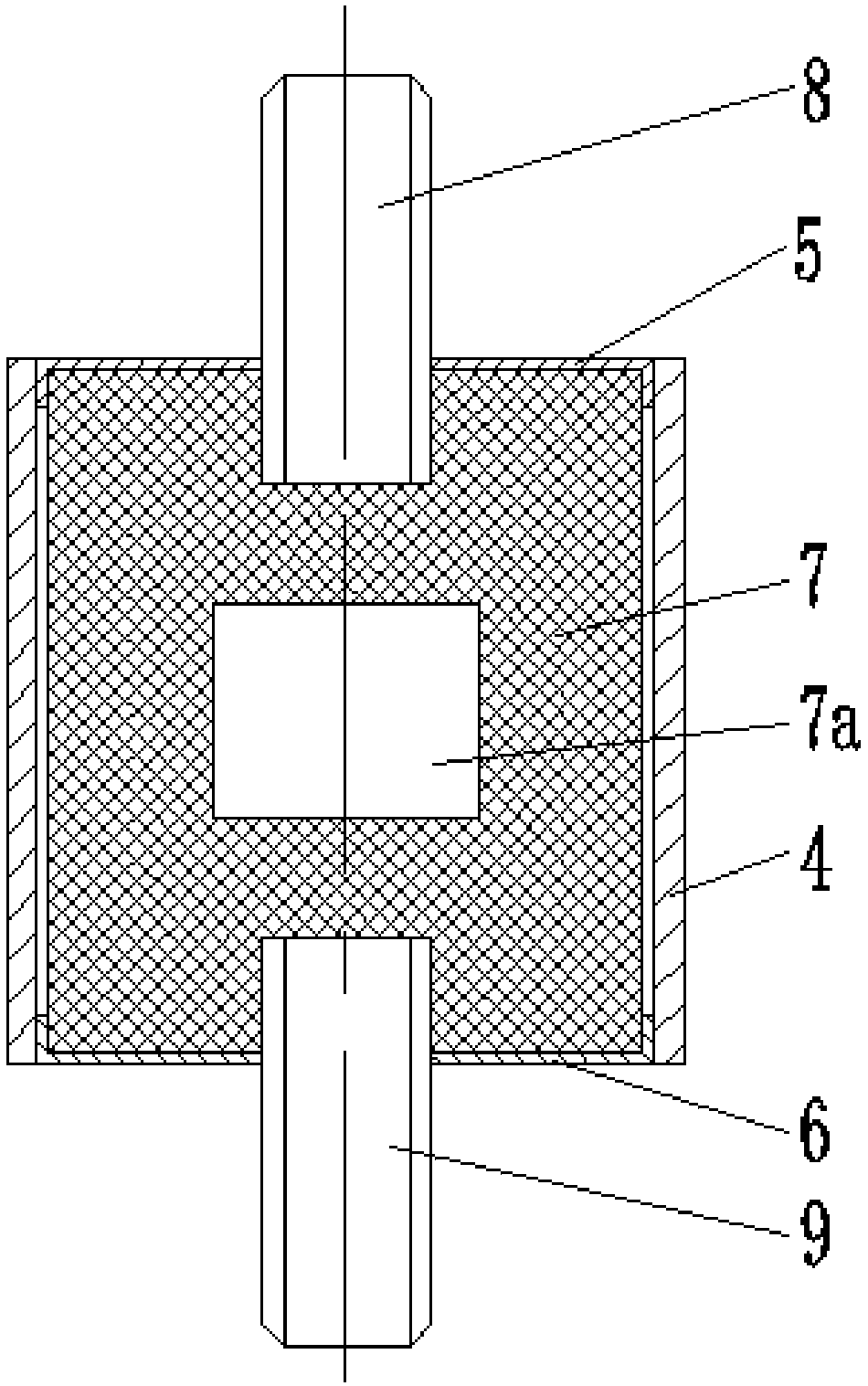

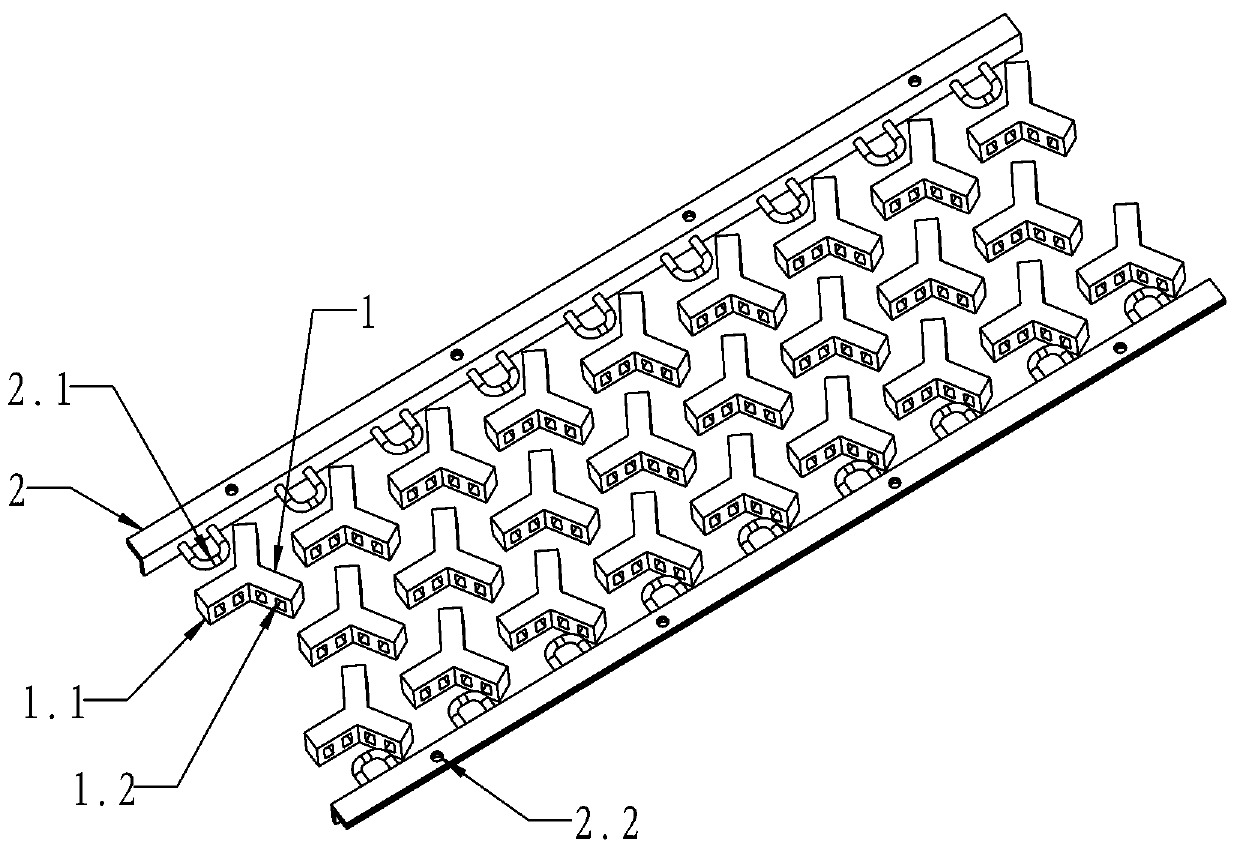

Large telescopic double-cross joint rotation shaft of parallel robot

InactiveCN103802102AReduce resistanceLarge amount of expansion and contractionProgramme-controlled manipulatorArmsRolling resistanceOptical axis

The invention discloses a large telescopic double-cross joint rotation shaft of a parallel robot. The large telescopic double-cross joint rotation shaft of the parallel robot is mainly composed of three parts, namely the upper cross cardan joint (1), the lower cross joint (9) and the middle telescopic rod assembly. The large telescopic double-cross joint rotation shaft is characterized in that the telescopic rod assembly comprises a connection top plate (2), a first hollow optical shaft (3), a second hollow optical shaft (5), a third hollow optical shaft (8), a linear bearing (6), a middle connection plate (4) and a lower connection plate (7). The first hollow optical shaft (3) and the second hollow optical shaft (5) are fixed between the connection top plate (2) and the lower connection plate (7) in parallel. One end of the third hollow optical shaft (8) is fixed to the center of the middle connection plate (4) and the other end of the third hollow optical shaft (8) and the lower cross joint (9) are fixed together. As the hollow optical shafts and the linear bearing are adopted, the overall telescopic amount is large, rolling friction is adopted in the linear bearing and resistance is greatly lowered.

Owner:QINGDAO PHAESTUS IS ENG CO LTD

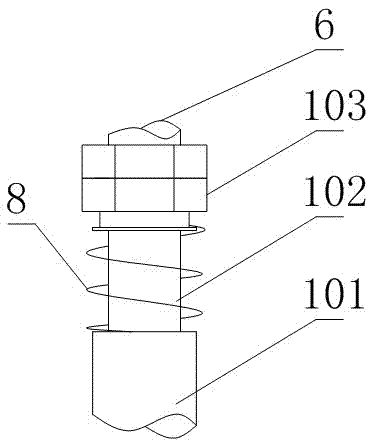

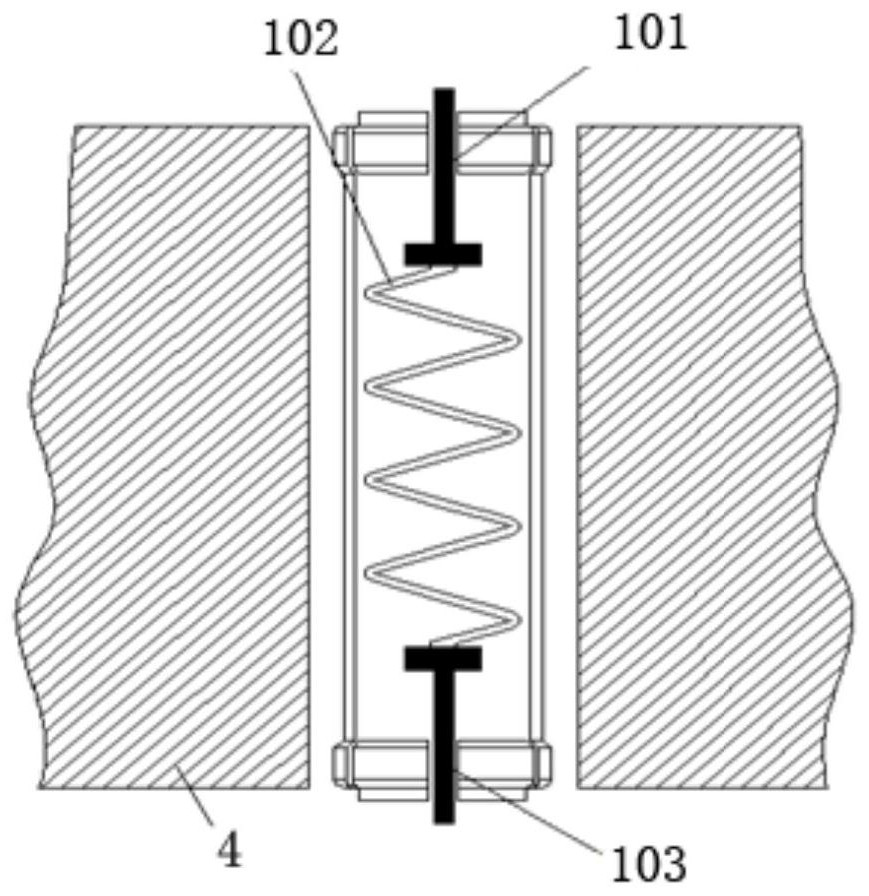

Agricultural quadricycle shock absorber

InactiveCN107588145AEasy to assembleReduce the amount of swingSpringsJet propulsion mountingAgricultural engineeringShock absorber

The invention discloses an agricultural quadricycle shock absorber. The shock absorber is composed of an outer cylinder, an upper cover, a lower cover, a rubber column, an upper stud and a lower stud,wherein the outer cylinder is of a circular sleeve structure with two open ends; the rubber column is arranged in the outer cylinder; a circle of gap is reserved between the rubber column and the outer cylinder; the top of the rubber column is fixedly provided with the upper cover; the upper cover and the outer cylinder are fixed together; the lower end of the upper stud extends into and is fixedat the upper end of the rubber column; the lower cover is fixed on the bottom of the rubber column; the lower cover and the outer cylinder are fixed together; and the upper end of the lower stud extends into and is fixed at the lower end of the rubber column. The agricultural quadricycle shock absorber disclosed by the invention is simple in structure, easy to assemble with few components, low incost and good in shock absorbing effect, can reduce vehicle body vibration, lower abnormal sound, greatly improves the driving comfort, and effectively reduces the left-right oscillating quantity ofan engine.

Owner:刘福珍

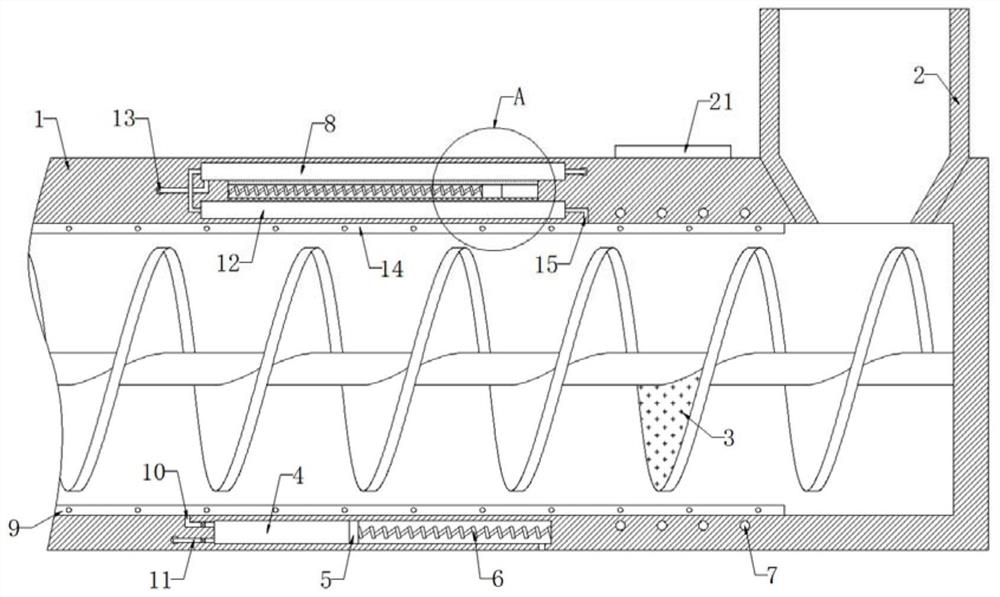

Self-drying system for plastic bag film blowing extruder

The invention discloses a self-drying system for a plastic bag film blowing extruder. The self-drying system comprises a machine body, a feeding box is fixedly connected to the upper end of the machine body, an extrusion plate is rotatably connected to the inner wall of the machine body through a rotating shaft, an air suction cavity is formed in the lower end of the machine body, a sliding plug is slidably connected to the inner wall of the air suction cavity in a sealed mode, the side wall of the sliding plug is elastically connected with the inner wall of the air suction cavity through a first conductive spring, an air suction pipe is fixedly connected to the bottom in the machine body, the inner wall of the air suction cavity is connected with the inner wall of the air suction pipe through a one-way air inlet pipe, and a refrigerating cavity is formed in the upper end of the machine body. According to the self-drying system for the plastic bag film blowing extruder, when a circuit between a first current-conducting plate and a second current-conducting plate is conducted, the first current-conducting plate serves as a heat absorption end, the second current-conducting plate serves as a heat release end, then heat can be absorbed in the refrigeration cavity, the interior of the heating cavity can be heated, hot air entering the refrigeration cavity is dried, the treated air enters the heating cavity to be heated, and then the air flows into the machine body again, so that the steam in the machine body is discharged.

Owner:武汉积墨包装印刷有限公司

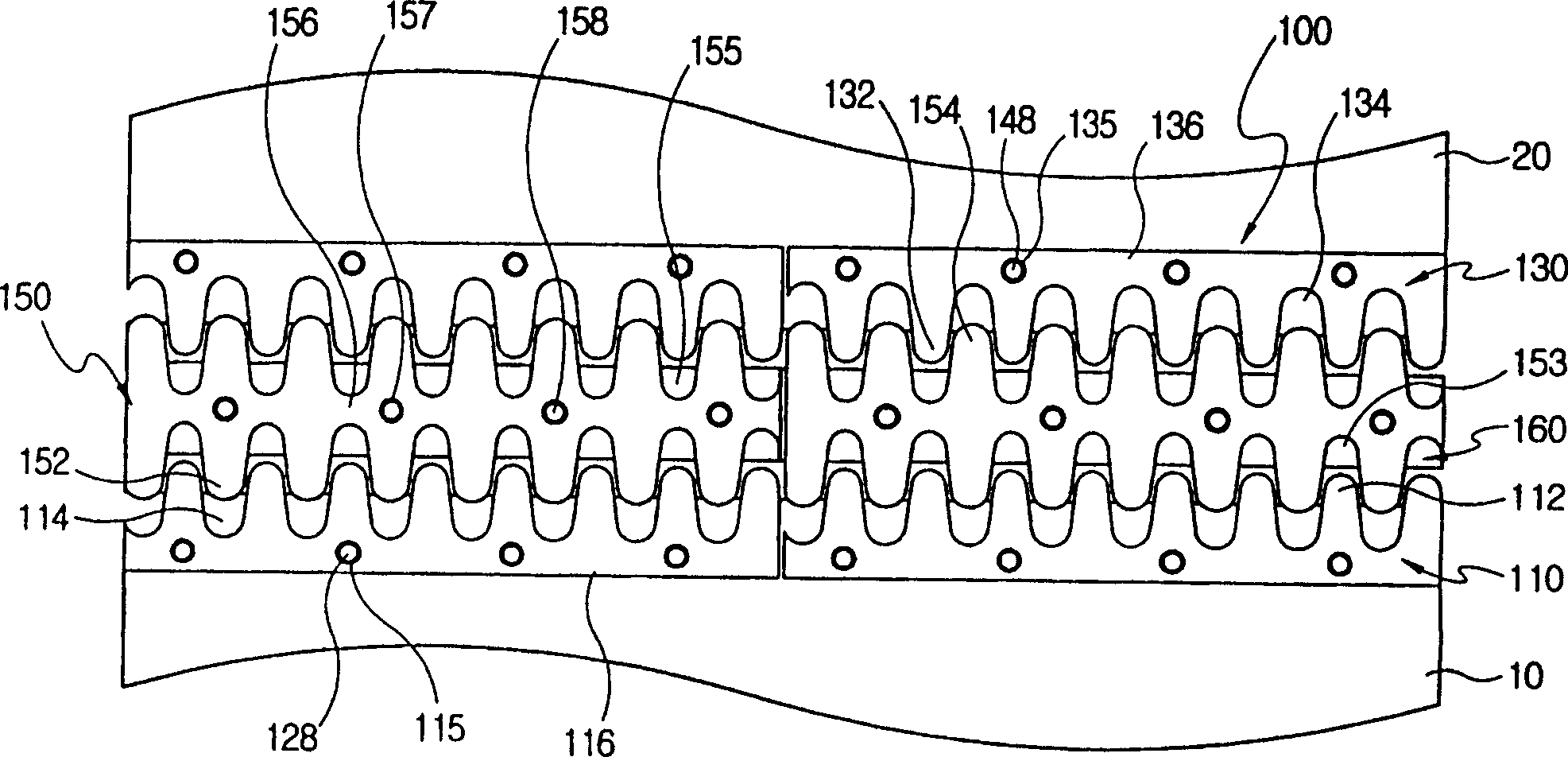

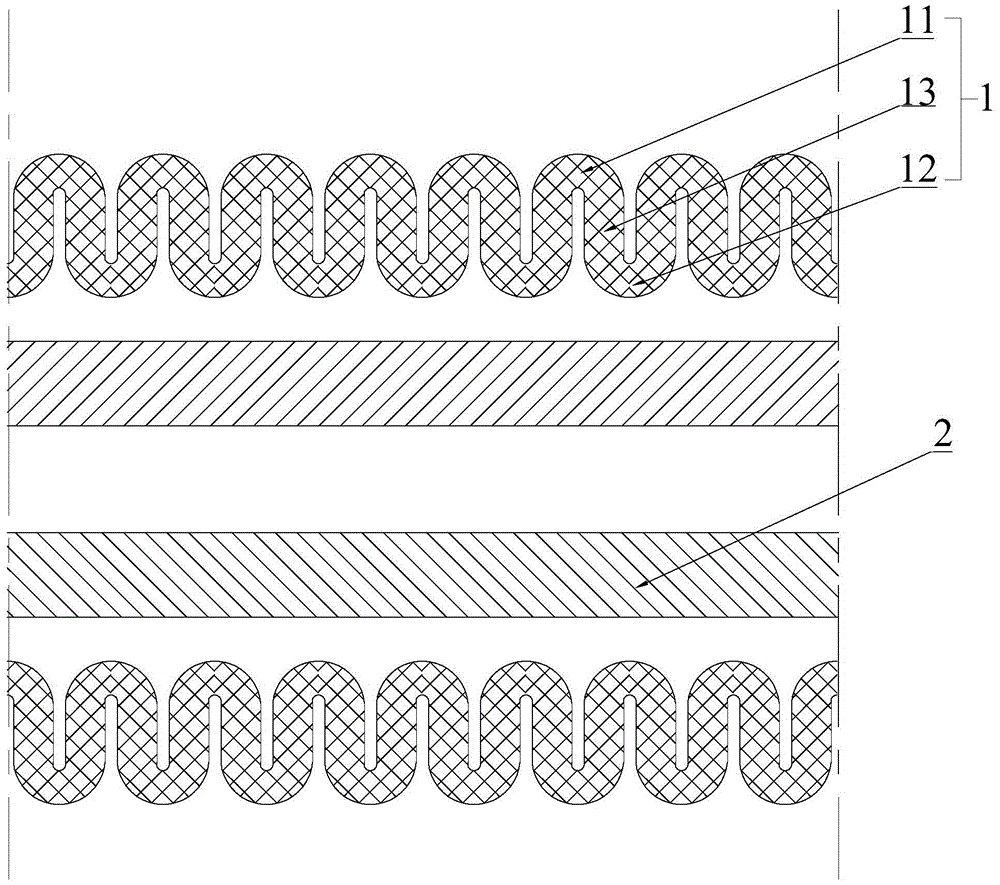

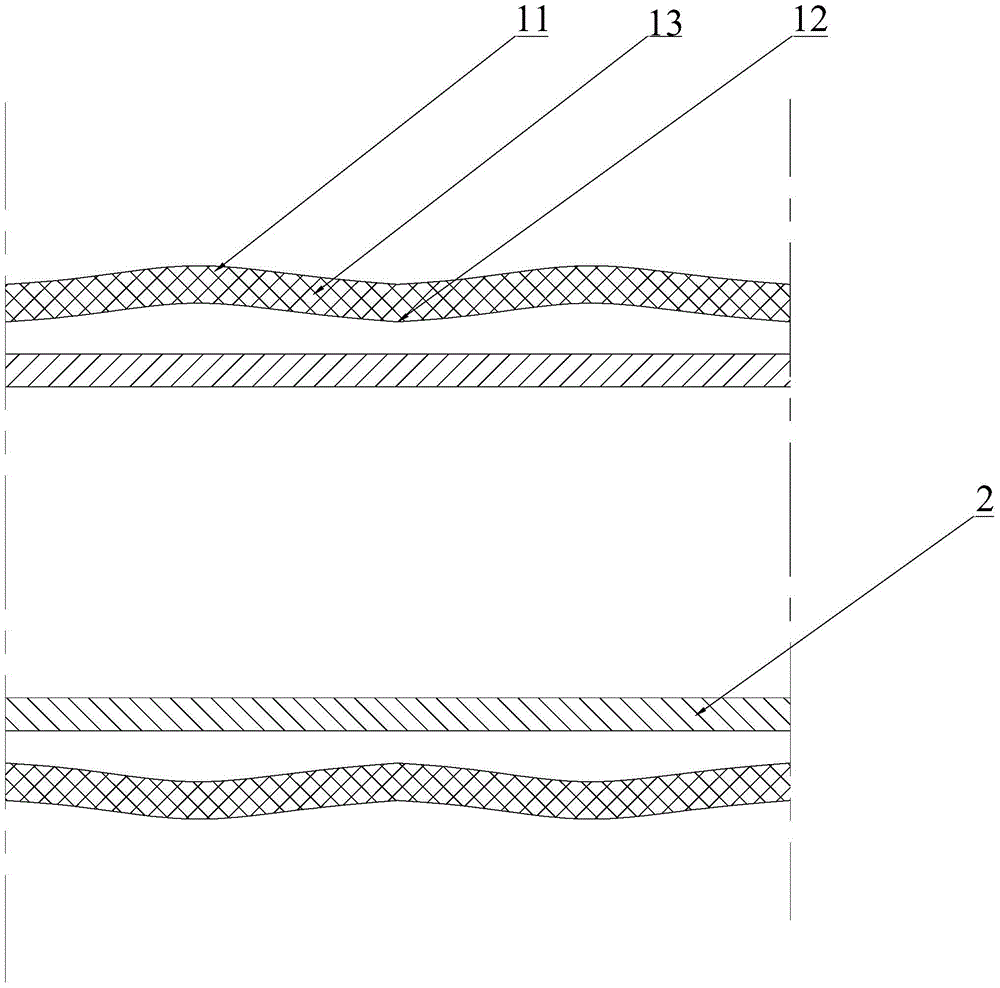

Pipe material, pipe material manufacturing method and telescopic water pipe

ActiveCN105465501BImprove structural strengthUniform shape deformationPipeline expansion-compensationFlexible pipesWrinkle skinUltimate tensile strength

The invention discloses a pipe, a method for making the pipe and a telescopic water pipe, aiming to provide a pipe that can be stretched, has a uniform structure, and does not produce wrinkle angles when stretching. In the state of natural shrinkage of the pipe body, the pipe wall integrally extends outwards with several flexible convex rings, and in the state of natural shrinkage of the pipe body, the pipe wall integrally extends inward with several flexible concave rings. The pipe body of this structure can be uniform When deforming and shrinking, the outer wall of the pipe is composed of a number of flexible convex ring outer walls, and the inner wall is composed of a number of flexible concave ring inner walls. Or the skin, when stretched, the pipe is approximately tubular, that is, there are tiny wavy structures on the inner and outer walls, which can effectively buffer the force on the inner and outer walls of the pipe, so that the pipe has good structural strength and uniform shape deformation, and has a good application market.

Owner:NINGBO FENGYUAN IMPORT & EXPORT CO LTD

A self-aligning fixture for clamping precision forgings

ActiveCN103009161BGuaranteed clamping accuracyHigh clamping accuracyPositioning apparatusMetal-working holdersMachine toolMachining

The invention relates to a centering clamp for clamping a precision forged piece, relating to the field of machining. According to the invention, a centering claw is arranged at an end part of a seat frame body, is simultaneously provided with a clamping claw and is driven by a pull rod to move left and right so as to clamp a workpiece tightly, and furthermore, an automatic centering effect is achieved by the reasonable rotation of the centering claw and a centering pin together in a pin hole of the seat frame body. According to the invention, the clamping claw is convenient to detach, accurate in positioning, large in expansion / contraction quantity, and capable of clamping precision and rough forged pieces, meanwhile, the clamping precision of the clamp can be guaranteed because the jitter of the seat frame body of the clamp is measurable and controllable when the seat frame body is connected to a machine tool, and the centering clamp has the characteristics of compact structure, equal-division property and firmness for clamping, strong centering capacity, high clamping precision, convenience for regulation, simplicity for replacement of quick-wear parts, long service life and the like, is greatly reduced in use cost during actual production, and is suitable for large-range popularization and application.

Owner:LUOYANG LUOLING BEARING SCI & TECH

Method for realizing interconnection between microwave signal boards and interconnected microwave signal board

ActiveCN113488754BPass on advantagesCompact structureWaveguidesCoupling devicesComposite substrateInterconnection

The invention relates to the field of active phased arrays, and discloses a method for realizing interconnection between microwave signal boards and an interconnected microwave signal board. The interlayer adapter board is provided with a limit hole for limiting the spring connection structure; a separable spring connection structure is arranged between the adjacent upper and lower composite substrates to connect all the The spring connection structure is arranged in the limit hole, and metal pads are arranged at the positions of the adjacent upper and lower composite substrates corresponding to the spring connection structure; the adjacent upper and lower composite substrates are squeezed, and the The spring connection structure is in contact with the metal pads on the upper and lower composite substrates to realize interconnection; after the interconnection is completed, a high and low frequency mixed joint assembly for external connection is arranged on the upper composite substrate. The present invention can realize the vertical interconnection between boards of more than 10 mm, and has high expansibility.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

Aluminum product machining device

InactiveCN108466146AAdjust the amount of initial compressionLarge amount of expansion and contractionBelt grinding machinesEngineeringMachining

The invention discloses an aluminum product machining device. The aluminum product machining device comprises a machine base, a worktable and a drive part are arranged on the machine base, two main belt wheels are further included, a grinding belt is wound on the two main belt wheels, auxiliary belt wheels, springs, deformation adjusting parts and second belt wheel rods are further included, in the action process of the deformation adjusting parts, the springs are arranged at one ends of the second belt wheel rods in a sleeving manner and are adjustable in the length direction of the second belt wheel rods, the auxiliary belt wheels are fixed to the other ends of the springs, the side faces of the auxiliary belt wheels make contact with the side face of the grinding belt, the auxiliary belt wheels are parallel to the axes of the main belt wheels, the distance between the auxiliary belt wheels and the worktable is smaller than that of the main belt wheels and the worktable, the axes ofthe springs are crossed with the table board of the worktable, an adjusting groove is formed in a first belt wheel rod, and a compression spring is arranged in the adjusting groove. The dependency ofwork of a wire drawing device on manual real-time operation can be weakened, and an aluminum plate with the poor surface quality can be subjected to wire drawing machining.

Owner:梁延津

Bag dedusting coal gas guide-in pipe sealing structure of Ouye furnace

PendingCN111850220AEasy to makeLarge amount of expansion and contractionShaft furnaceWaste heat treatmentDust controlStructural engineering

The invention discloses a bag dedusting coal gas guide-in pipe sealing structure of an Ouye furnace. The sealing structure mainly comprises an annular plate (1), a cylindrical pipe (2), an annular plate (3), a cylindrical pipe (4), an annular plate (5), an cylindrical pipe (6), an annular plate (7), an cylindrical pipe (8), a pattern partition board (9), a padding and gland seal (10), a crude gasguide-in pipe (11) and reinforcing rib plates (12). The cylindrical pipe (2) is cylindrical. The upper portion of the cylindrical pipe (2) is assembled and welded to the annular plate (1). The annularplate (3) is manufactured in sequence. The inner diameter of the annular plate (3) is 80 mm greater than the outer diameter of a crude gas pipe. The outer circumference of the annular plate (3) is welded and connected to the lower portion of the cylindrical pipe (2). The inner circumference of the annular plate (3) is welded and connected to the upper portion of the cylindrical pipe (2). The annular plate (3), the cylindrical pipe (4), the annular plate (5) and the cylindrical pipe (6) are manufactured in sequence. The annular plate (1), the cylindrical pipe (2), the annular plate (3), the cylindrical pipe (4), the annular plate (5) and the cylindrical pipe (6) constitute a pi-type compensator. The annular plate (7) and the cylindrical pipe (8) constitute an L-type compensator.

Owner:XINJIANG BAYI IRON & STEEL

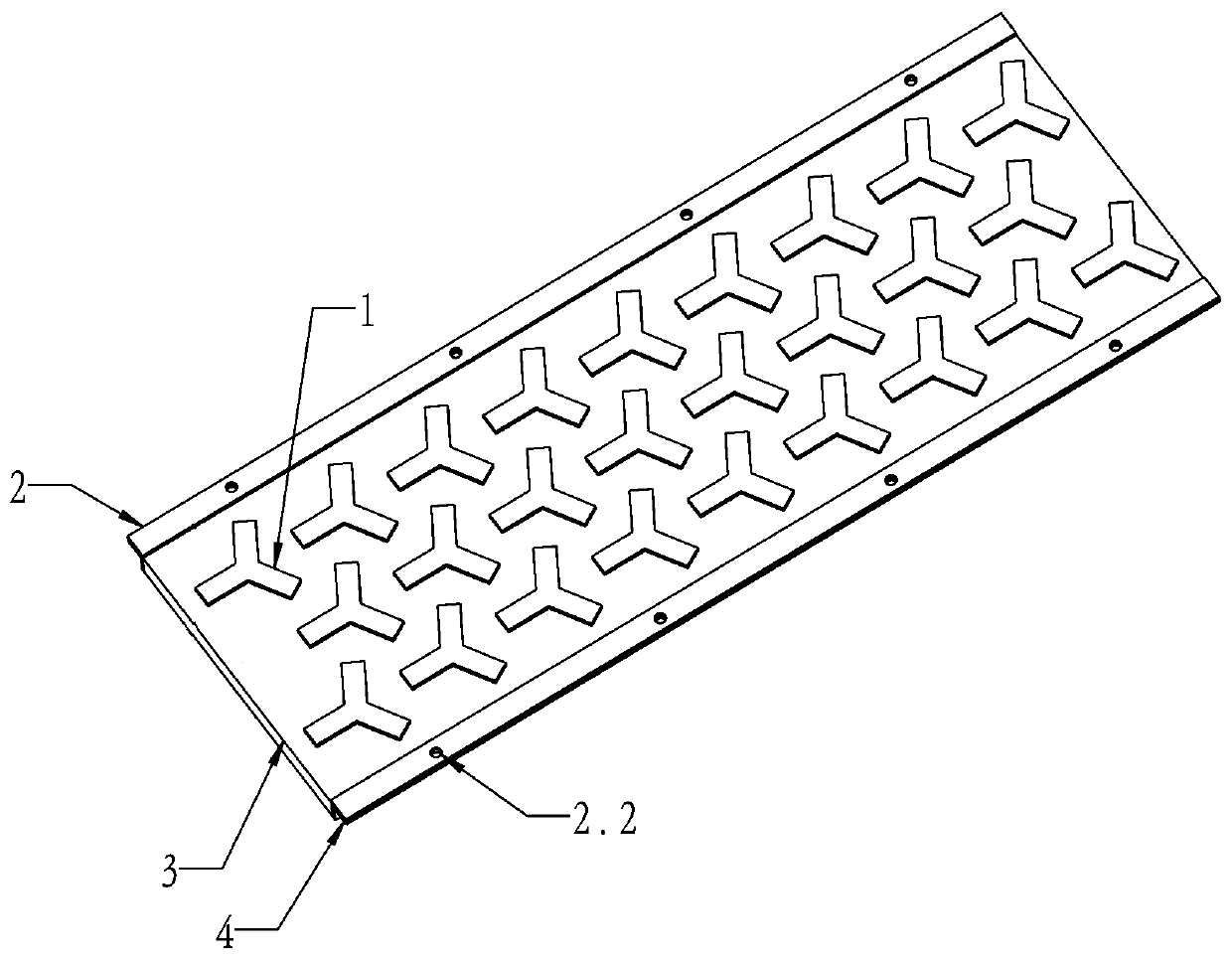

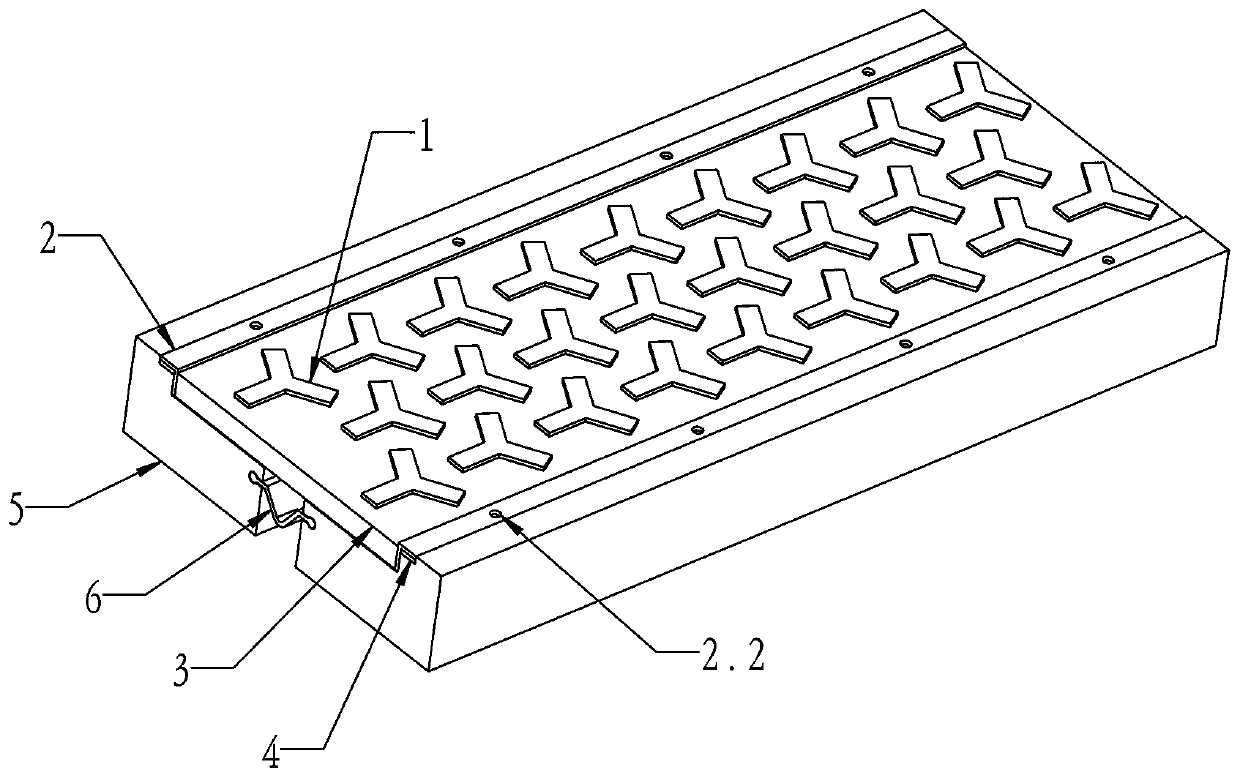

Array Bridge Expansion Joints

ActiveCN106869020BGuaranteed load capacityLarge amount of expansion and contractionBridge structural detailsRoad surfaceExpansion joint

Disclosed is an array type bridge expansion joint. Functions of bearing and pavement smoothing of the bridge seamless type expansion joint are assigned to equal-height blocks, and functions of expansion deformation and water stopping are assigned to a padding block. The equal-height blocks are arranged in the padding block in an array mode. The heights of the tops of the equal-height blocks of the expansion joint are the same with that of pavement. Bearing blocks, made of rigid materials and bearing the high pressure of wheels, of the equal-height blocks not only can guarantee the bearing capacity of the expansion joint but also can guarantee the smoothness of the pavement. Padding is connected on the peripheries of the equal-height blocks and forms the whole padding block, and the padding block is made of plastic or elastic materials and plays a role in bonding and filling of the expansion joint and connection of the bearing blocks. The padding does not take the effect of pressure bearing anymore, so that the selectivity of the formula of the padding is wide, and the padding only bears deformation of the expansion joint and stops water. The equal-height blocks can improve the smoothness of the expansion joints of the same types. The padding does not bear the pressure so that the expansion amount of the expansion joint can be increased.

Owner:河北万亿交通设施有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com