Bag dedusting coal gas guide-in pipe sealing structure of Ouye furnace

A technology of bag dust removal and sealing structure, which is applied to furnaces, shaft furnaces, furnace components, etc., and can solve the problems that the inlet pipe and flower partitions cannot be effectively sealed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

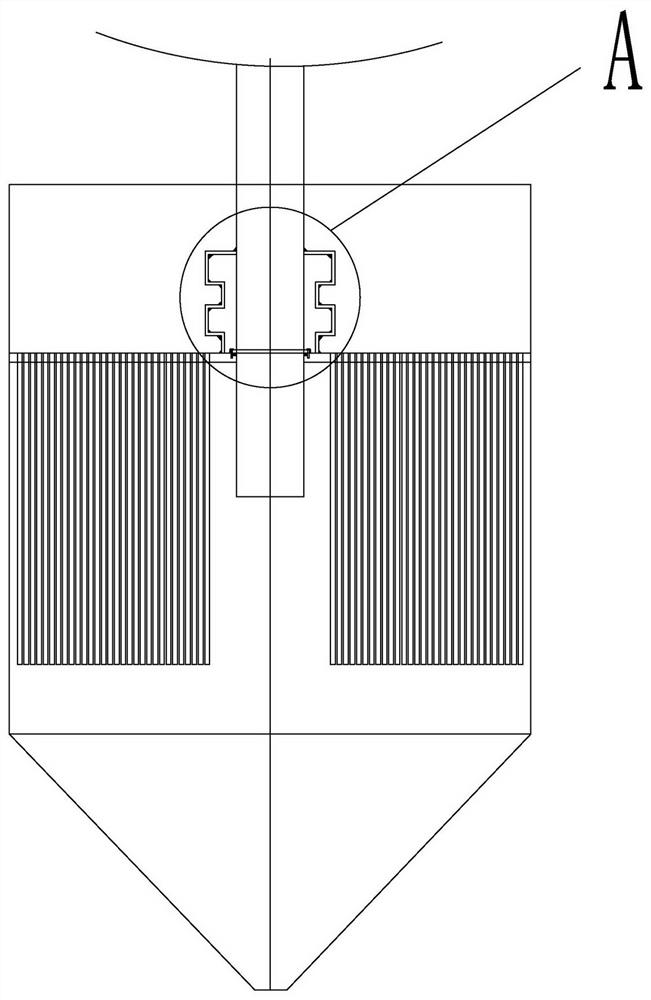

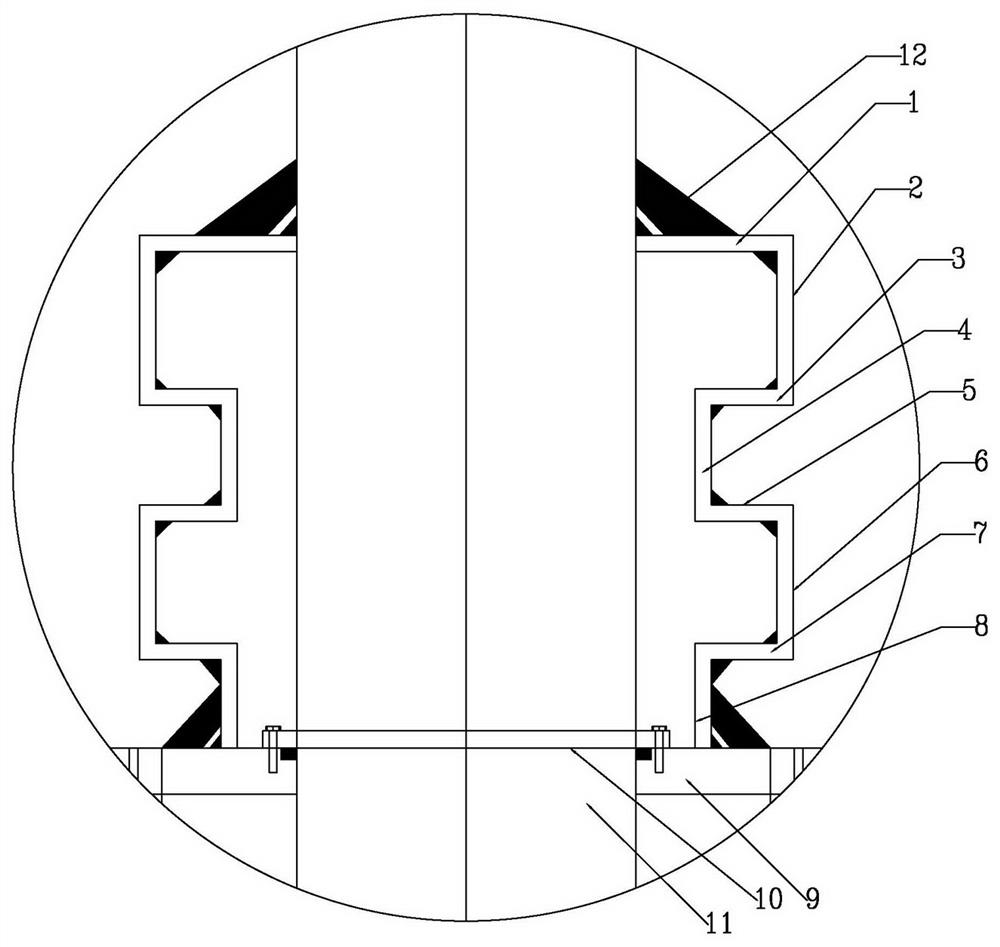

[0010] A gas inlet pipe sealing structure for Ouyeel furnace bag dust removal, such as figure 1 , figure 2 As shown, it mainly includes: circular plate 1, cylindrical tube 2, circular plate 3, cylindrical tube 4, circular plate 5, cylindrical tube 6, circular plate 7, cylindrical tube 8, flower partition 9, packing and pressing Cover seal 10, raw gas inlet pipe 11, reinforcement plate 12; cylindrical pipe 2 is cylindrical in shape, and its upper part is assembled and welded with circular plate 1 to form a triangular weld. The thickness of the weld seam is not less than the wall thickness of the cylindrical pipe. Ring plate 3, its inner diameter is 80 mm larger than the outer diameter of the raw gas pipeline, its outer circumference is welded to the lower part of the cylindrical tube 2, and its inner circumference is welded to the upper part of the cylindrical tube 2, and the ring plate 3, cylindrical tube 4, and ring plate are sequentially produced 5. Cylindrical tube 6, cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com