Automobile exhaust pipe with refrigerating and cooling function

A technology for exhaust pipes and automobiles, which is applied in the direction of exhaust devices, mechanical equipment, engine components, etc. It can solve the problems of rising exhaust pipes, affecting people's normal life, and affecting the service life of exhaust pipes, so as to increase the amount of pumped water. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

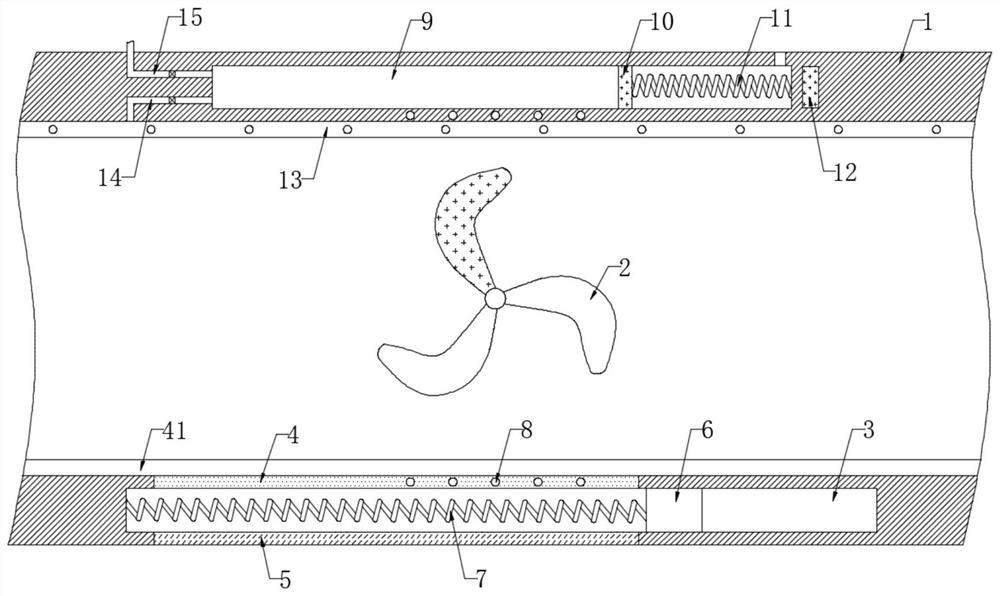

[0022] refer to figure 1 , an automobile exhaust pipe with cooling and cooling functions, comprising a pipe body 1, the inner wall of the pipe body 1 is connected with a plurality of impellers 2 through rotating shafts, the inner wall of the pipe body 1 is uniformly provided with a plurality of heat-absorbing cavities 3, and a plurality of The inner wall of the heat-absorbing chamber 3 is fixedly connected with the first conductive plate 4 communicating with the inner wall of the pipe body 1, the inner wall of the pipe body 1 is fixedly connected with the heat-absorbing plate 41 in contact with the first conductive plate 4, and the inner walls of the multiple heat-absorbing chambers 3 are fixedly connected There is a second conductive plate 5 communicating with the side wall of the pipe body 1 , a conductive block 6 is slidably connected in the heat-absorbing chamber 3 , and the side wall of the conductive block 6 is elastically connected to the inner wall of the heat-absorbing...

Embodiment 2

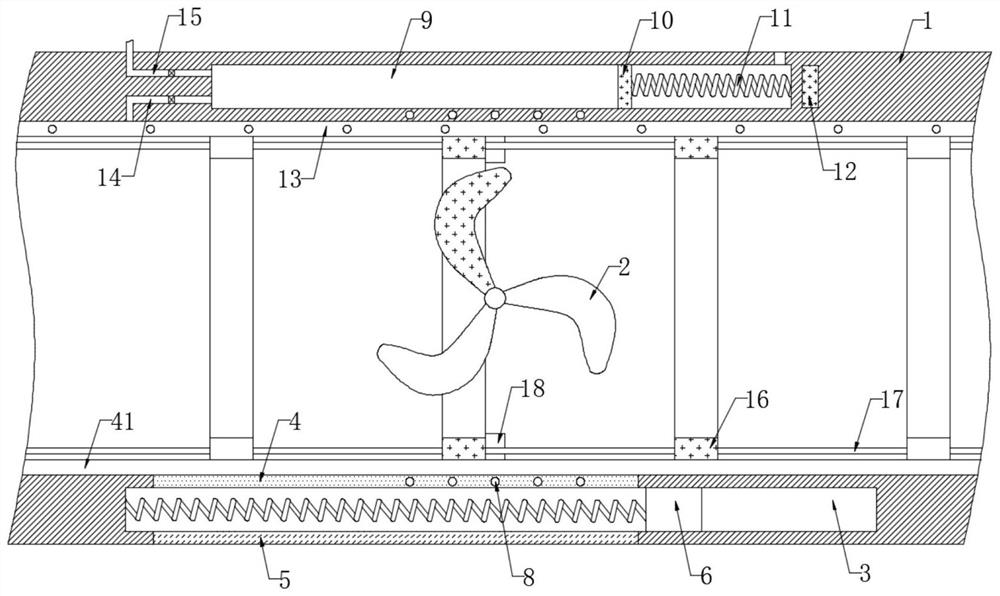

[0031] refer to figure 2, the difference from the first embodiment is that the inner wall of the pipe body 1 is slidingly connected with a plurality of scraper rings 16, and the plurality of scraper rings 16 are fixedly connected by a fixed rod 17, and the two scraper rings 16 close to the impeller 2 are made of magnetic materials The inner wall of the pipe body 1 is located at the axis of the impeller 2 and is fixedly connected with two partitions 18 symmetrically.

[0032] In this embodiment, the rotation of the impeller 2 makes the impeller 2 made of magnetic material alternately close to the two adjacent scraper rings 16, so that the scraper ring 16 drives the rest of the scraper rings 16 through the fixed rod 17 under the action of the magnetic attraction force of the impeller 2. A plurality of scraper rings 16 slide on the inner wall of the pipe body 1 to scrape off impurities in the pipe body 1 to avoid blockage of the pipe body 1 caused by carbon deposits in the pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com