Wind-up attaching type gasket device for pipeline welding

A liner and pipeline technology, applied in the field of pipeline welding auxiliary tools, can solve the problems of many gaps, narrow radial space, poor sealing effect, etc., and achieve the effects of convenient operation, large expansion and contraction, and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

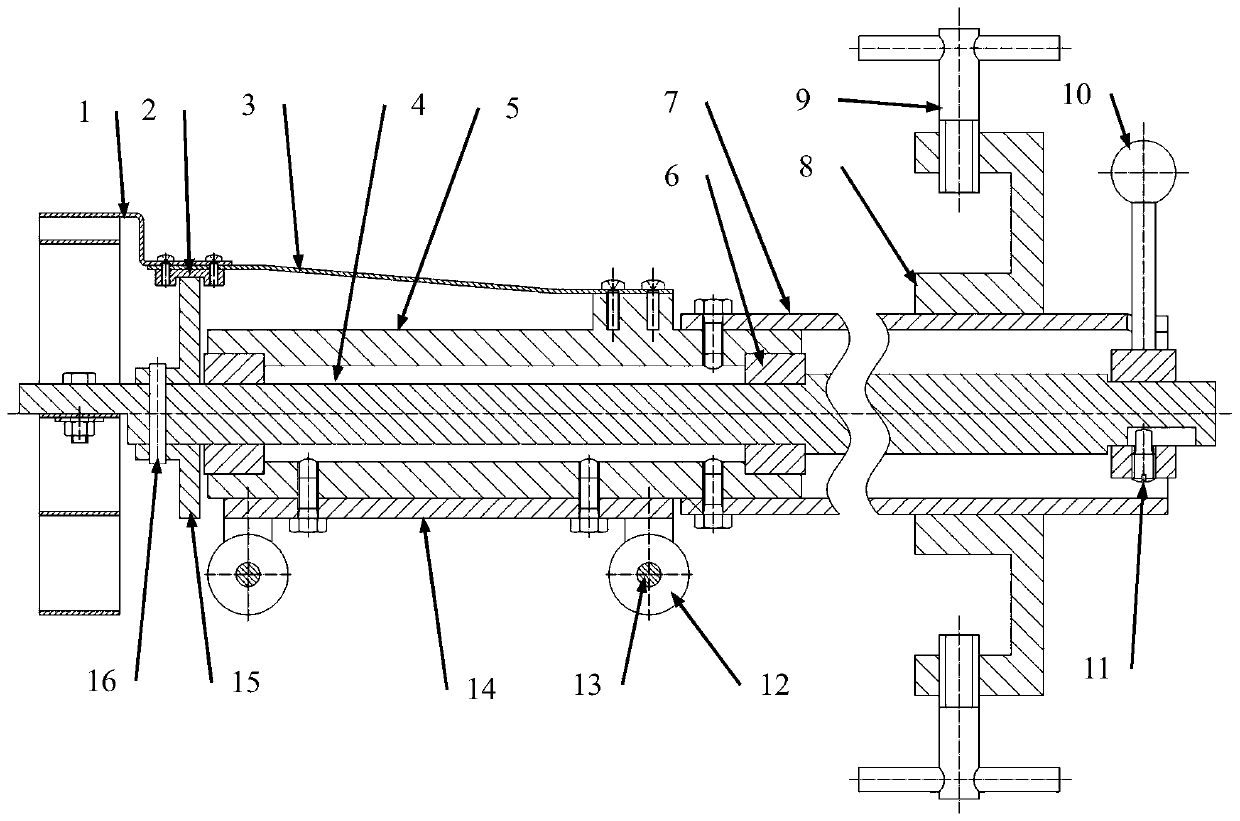

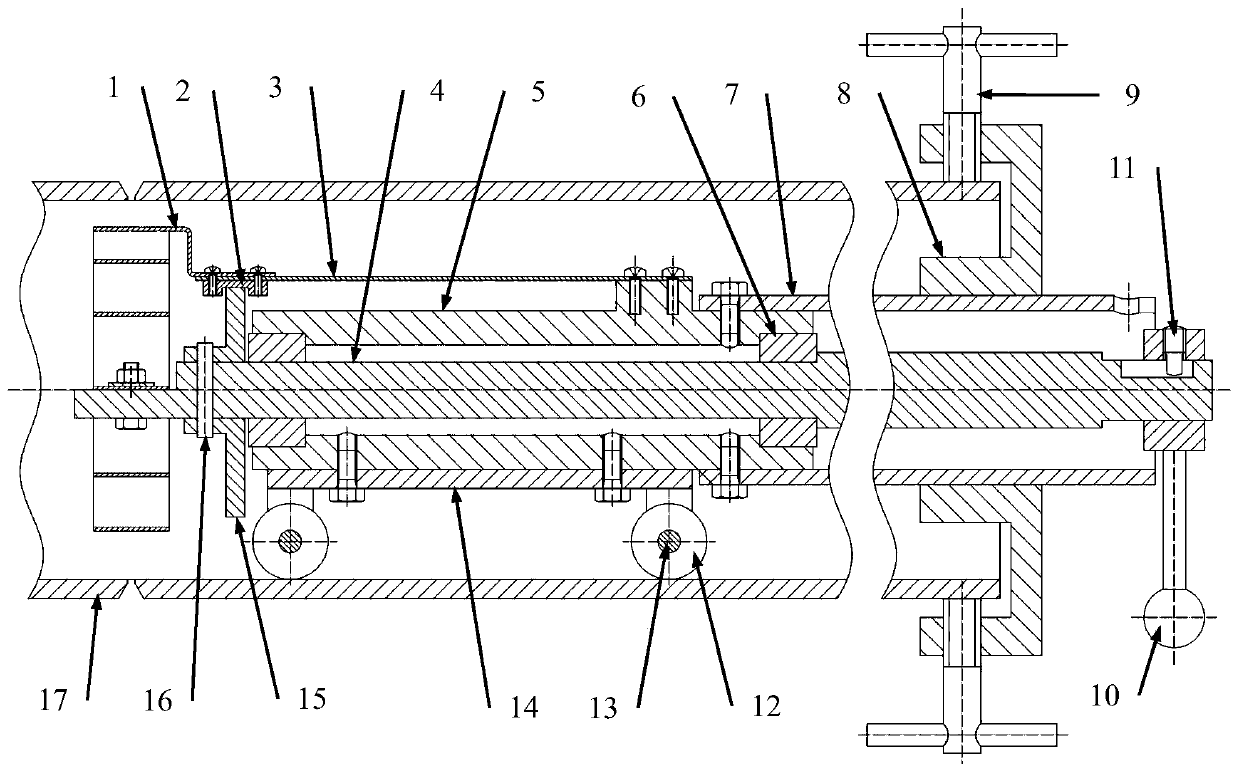

[0052] The present invention will be further described below in conjunction with accompanying drawing:

[0053] The technical solution adopted by the present invention to solve its technical problems is: the device consists of a liner, a sliding pad, an elastic sheet, a liner guide wheel, a major shaft, a guide wheel pin, a bracket tube, a bearing, a wheel bracket, a small wheel, and a pin shaft , connecting barrel, swing handle, torque screw, fixing frame, T-shaped screw.

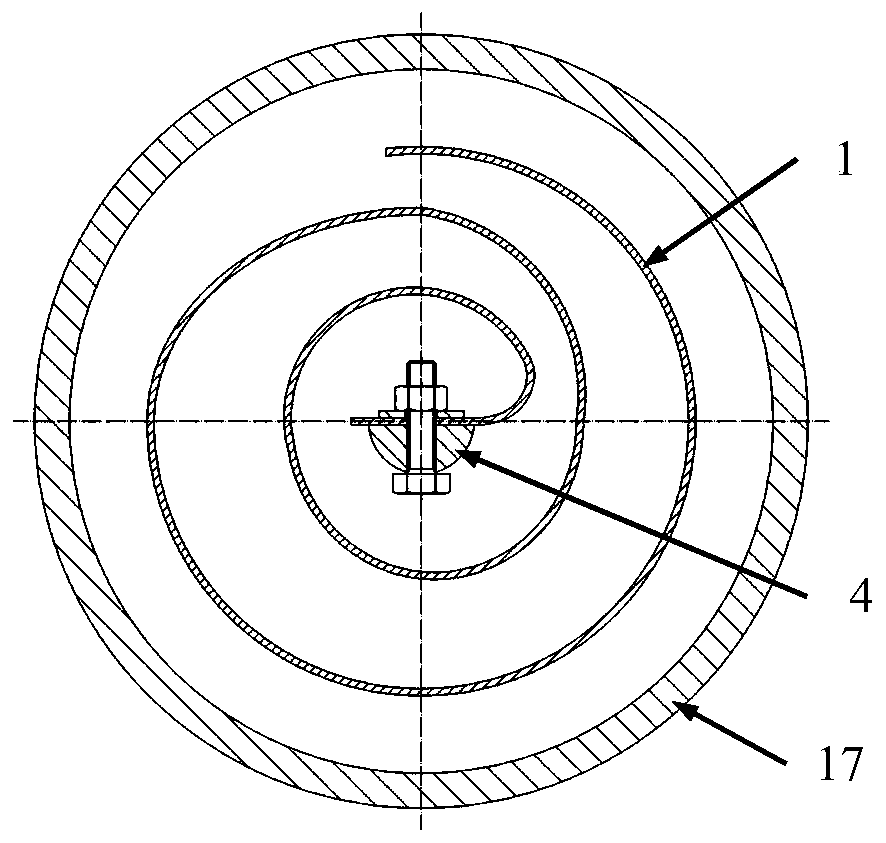

[0054] The liner is a copper alloy sheet, and a thin layer of ceramic coating is plasma-sprayed on the outer surface to improve the anti-burning performance; the liner is shaped like a clockwork, and is used to seal the welding groove of the pipeline. A small hole is processed on the inner side of the spring of the gasket, and it is installed on the front end of the long shaft through bolts and nuts; the outer side of the gasket is extended axially for a small section, and two small holes are processed, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com