Aluminum product machining equipment

A processing equipment, aluminum technology, applied in the field of aluminum processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

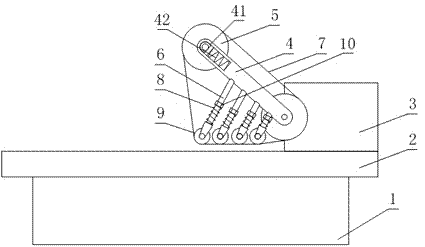

[0022] Such as figure 1 and figure 2 As shown, the aluminum material processing equipment includes a machine base 1 on which a workbench 2 and a driving part 3 are arranged, and also includes two main pulleys 5, one of which is connected to the driving part 3 On the other hand, the other main pulley 5 is connected with the machine base 1 through the first pulley rod 4, and the two main pulleys 5 are wound with a grinding belt 7, and also include a secondary pulley 9, a spring 8, a deformation adjustment part 10 and the second pulley rod 6, the second pulley rod 6 is fixedly connected to the first pulley rod 4 or the base 1, and one end of the spring 8 is sleeved on the second pulley rod 6, the deformation The adjusting part 10 is arranged on the second pulley rod 6, and one end of the spring 8 sleeved on the second pulley rod 6 is in contact with the deformation adjusting part 10. During the operation of the deformation adjusting part 10, the spring 8 is sleeved on the One ...

Embodiment 2

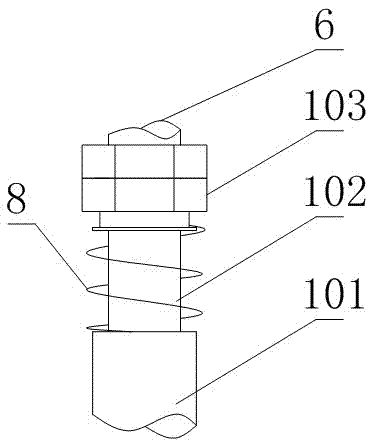

[0026] Such as figure 1 and figure 2 As shown, this embodiment is further limited on the basis of Embodiment 1: as a specific technical solution to achieve the above invention, it also includes a sleeve 101 hingedly connected to the secondary pulley 9 wheel shaft, the second belt The wheel rod 6 is also provided with a threaded segment, and the deformation adjusting part 10 is two nuts 103 threaded on the above threaded segment, and one end of the second pulley rod 6 is connected to the first pulley rod 4, the second pulley rod 6 is also provided with a guide rod segment 102 between the deformation adjustment part 10 and the free end of the second pulley rod 6, the sleeve 101 is clearance fit with the guide rod segment 102, and the spring 8 is sheathed on the guide rod section 102, and the two ends of the spring 8 are respectively in contact with the deformation adjusting part 10 and the ends of the guide rod section 102. The above two threads can be fixed on the second pul...

Embodiment 3

[0030] Such as figure 1 and figure 2 As shown, this embodiment is further limited on the basis of any one of the technical solutions provided by the above embodiments: in the above structure, the workbench 2 is used to place the workpiece, and in order to facilitate the position adjustment of the workpiece, there is also a A position adjustment unit is provided, the output end of the position adjustment unit is connected with the workbench 2 to adjust the position of the workbench 2 in the three directions of X, Y and Z, and the three directions of X, Y and Z are respectively connected with the space Cartesian coordinate system Different directions among the three directions.

[0031] A specific embodiment of the seat that facilitates the position adjustment of the workpiece, the position adjustment component in the position adjustment part is a threaded rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com