Clamping mechanism and clamping device

A technology of clamping mechanism and clamping parts, which is applied in the direction of workpiece clamping device, positioning device, clamping, etc., and can solve the problems of complex structure of clamping device, complex structure of clamping mechanism, low efficiency of clamping and releasing operations, etc. , to achieve the effect of improving the efficiency of clamping and releasing operations, saving layout space, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

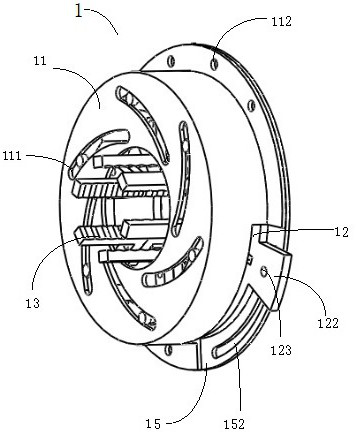

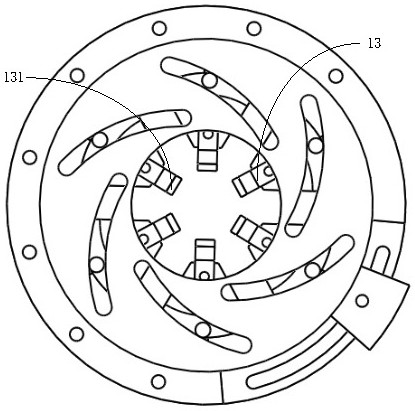

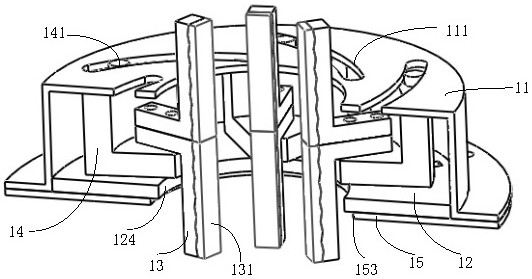

[0065] Such as figure 1 , figure 2 As shown, the clamping mechanism includes a fixed base 15. The fixed base 15 is provided with a guide seat 12 and a dial 11. The guide seat 12 is provided with clamping jaws distributed along the circumference. The radial guides of the circumference of each clamping jaw are assembled on On the guide seat 12, in this embodiment, the fixed base 15 is a bottom cover plate.

[0066] Such as image 3 , Figure 6 As shown, the dial 11 is a cover structure with a cylindrical circumferential side wall, the side of the dial 11 facing the bottom cover is an opening, the edge of the opening is provided with a flange, and the flange is provided with a flange The hole 112 is used for fixed connection with the bottom cover, so that the dial 11 is fixed on the bottom cover, and the bottom cover covers the opening side of the cover structure. The dial 11 has a through dial center hole 114 , and the dial center hole 114 runs through the dial surface of t...

Embodiment 2

[0081] The difference between this embodiment and embodiment 1 is that the clamping surface of the clamping head of the jaw in embodiment 1 is a plane, and in this embodiment, as Figure 10 As shown, the clamping surface of the clamping head 13 of the jaws is an arc surface. After each jaw clamps the clamped part, the clamping surface of each jaw forms a circle to adapt to the clamping of the cylindrical rod.

Embodiment 3

[0083] The difference between this embodiment and embodiment 1 is that the clamping surface of the jaws in embodiment 1 is a plane, and the structure of each jaw is the same, and in this embodiment, such as Figure 11 and Figure 12 As shown, the clamping mechanism is used to clamp a square bar, and the structure of each clamping jaw is different. The clamping mechanism includes an edge clamping jaw for clamping the edge of the clamped piece and a clamping jaw for clamping the clamped piece. For the side jaws on the side, the clamping surface of the chuck of the side jaws is a plane, and the clamping surface of the chuck of the edge jaws is an L-shaped surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com