Patents

Literature

36results about How to "Improve light curing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Visible-light-curing vinyl ester resin composite prepreg, and preparation method and application method thereof

The invention particularly provides a visible-light-quick-curing vinyl ester resin composite prepreg, and a preparation method and application method thereof, belonging to the field of repair of a fiber-reinforced resin-base structure with certain thickness. A special vinyl ester resin is used as a matrix; the proper visible light initiator, thermal initiator and other aids are selected to constitute the light-thermal composite initiation system; magnesium oxide is used as a thickener; different types of fabrics are selected as fiber-reinforcing materials according to performance requirements; and a proper composite technique is utilized to prepare the composite prepreg with certain thickness. The visible-light-curing prepreg material can be cured within 5 minutes under the single-side irradiation of visible light, and the once-time photocuring thickness can reach 10mm or above, thereby basically solving the problems of poor operability, poor safety and insufficient film thickness under ultraviolet light. The visible-light-curing prepreg can be subjected to mass application in the field of structure repair.

Owner:四川远鸣科技有限公司

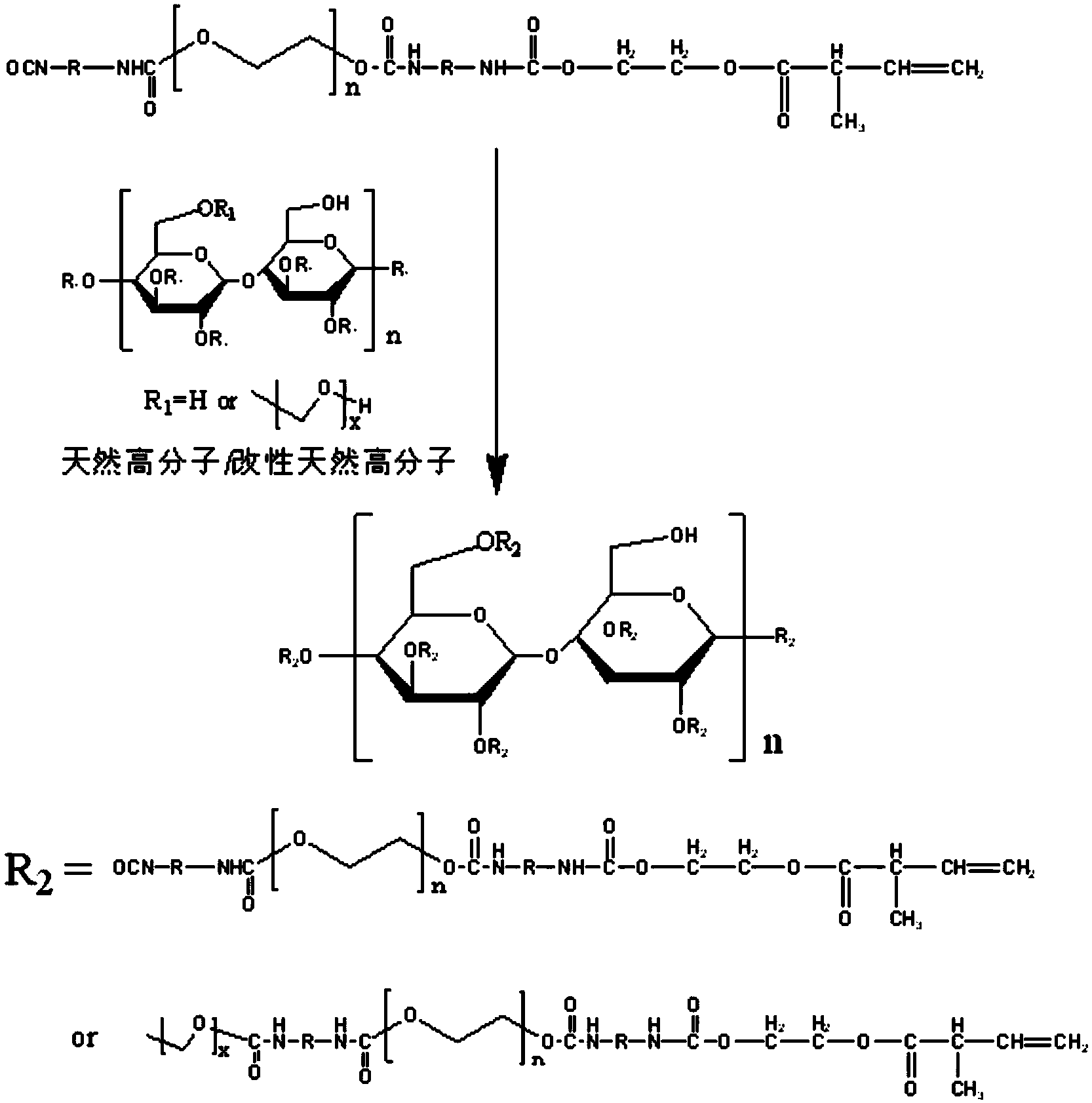

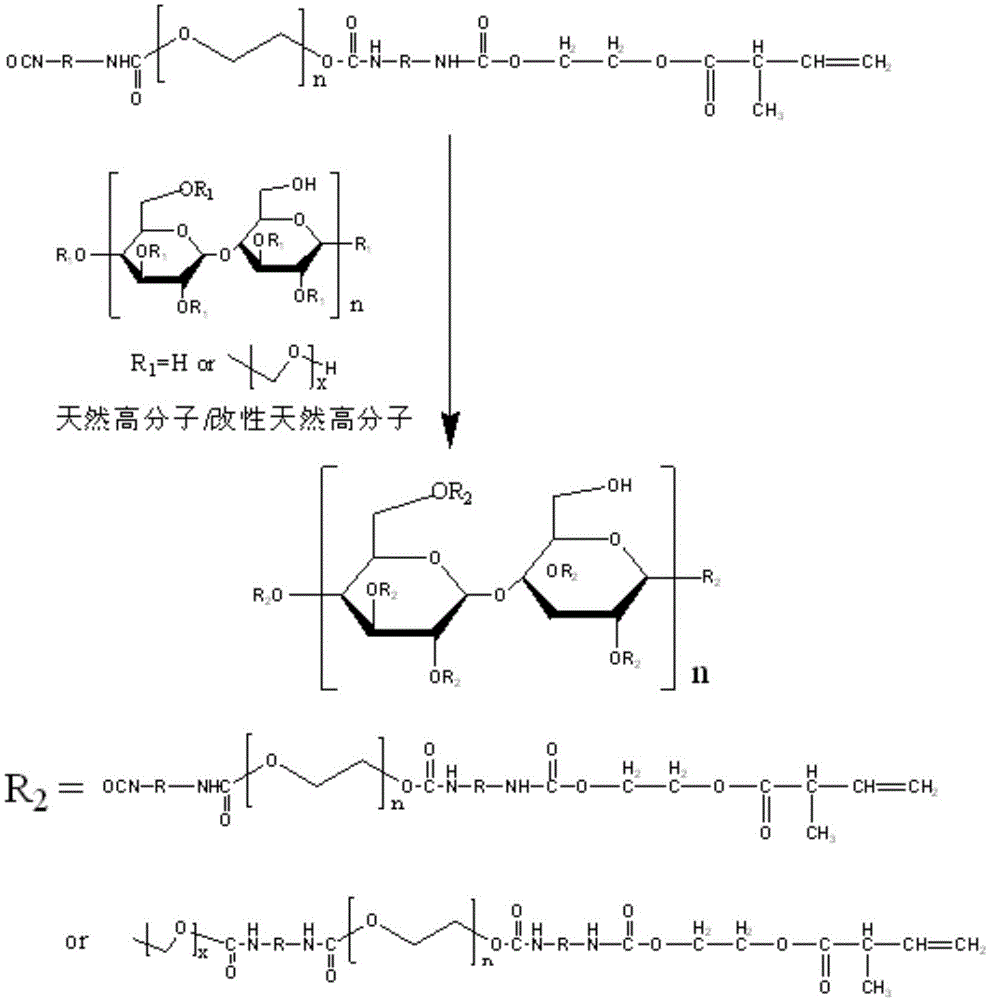

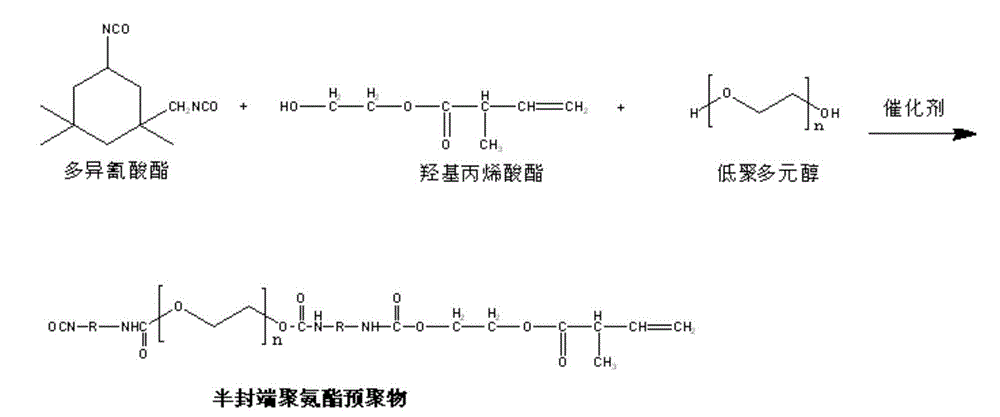

Method for preparing natural polymer matrix light-cured resin

The invention discloses a method for preparing a natural polymer matrix light-cured resin. The method comprises the following steps: (1) leading polyisocyanate, oligomer polyol and hydroxyl-containing acrylate to react according to a certain molar ratio to prepare a semi-end-blocked prepolymer; (2) dispersing a natural polymer nano-material in a solvent, and adding the semi-end-blocked prepolymer prepared in the step 1 to obtain a full-end-blocked prepolymer; (3) mixing the full-end-blocked prepolymer and a photo-initiator to prepare the natural polymer matrix resin with excellent performance under ultraviolet radiation. The method adopts the natural polymer material as a raw material, and has the advantages that: the prepared light-cured resin has high molecular weight and viscosity, the interaction and coagulation strength among resin molecules can be enhanced, the photo-crosslinking reaction efficiency can be improved, the strength and attachment performance of a curing film can be improved, the cost is low, the process is simple and controllable, and the product is more environment-friendly.

Owner:HUAZHONG AGRI UNIV

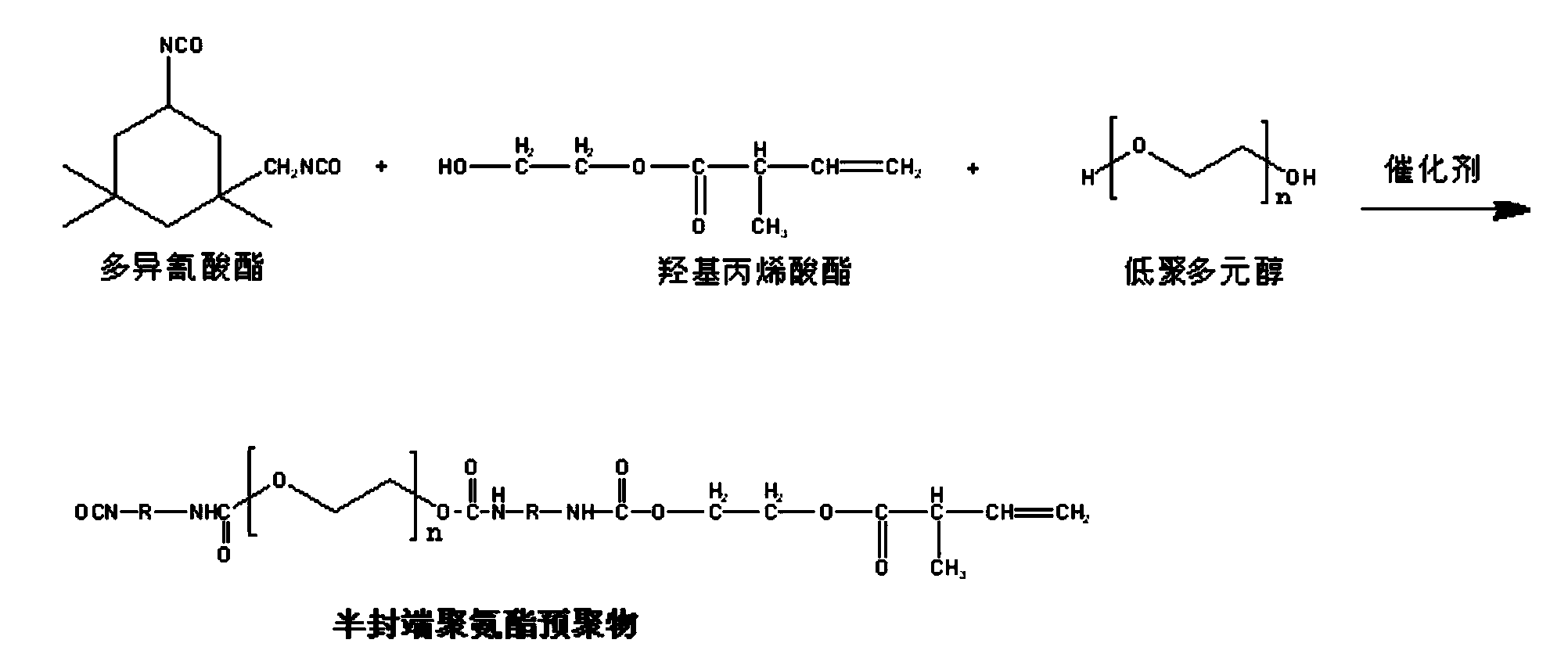

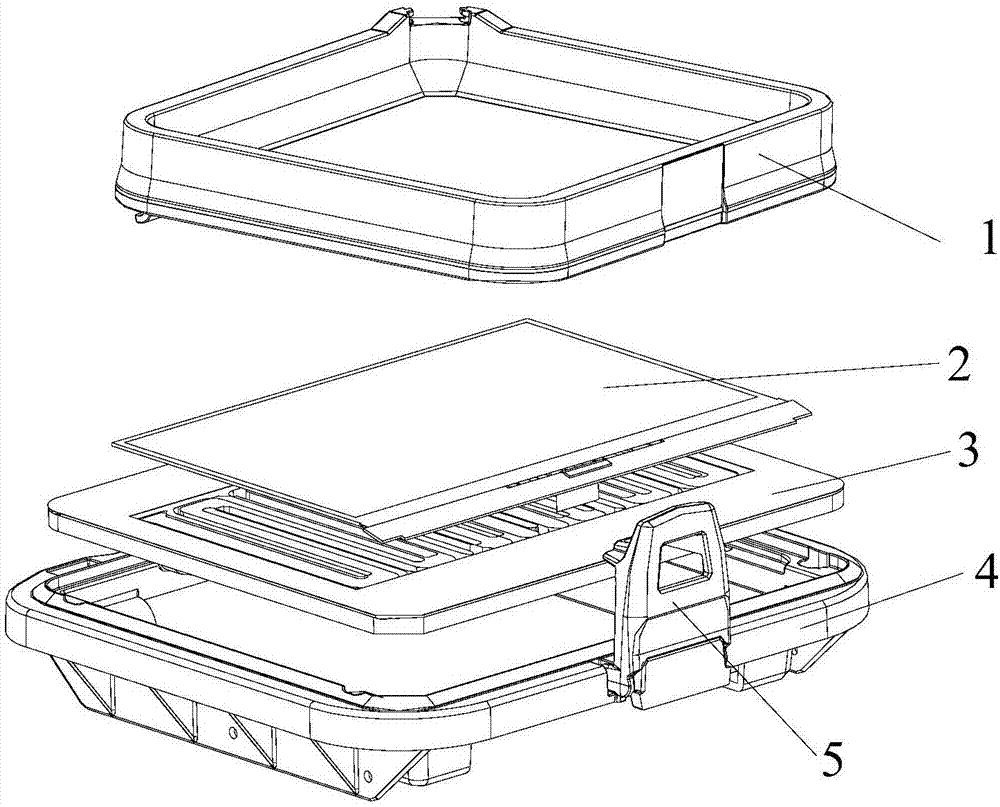

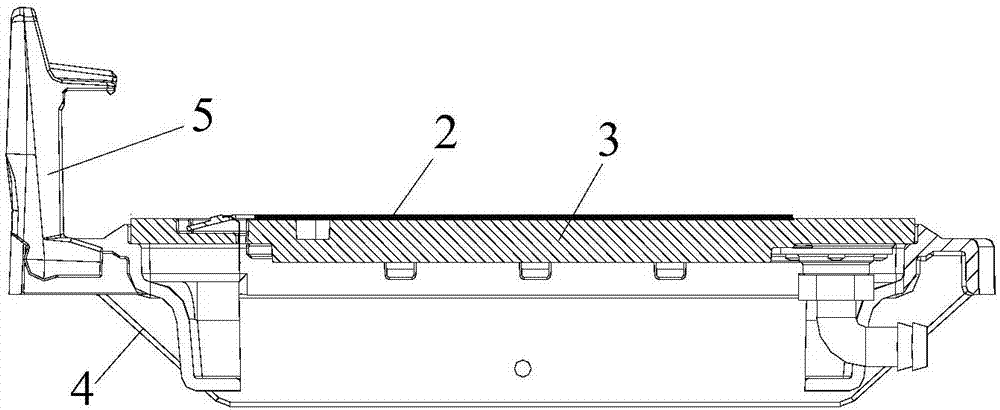

Photo-curing 3D printer and resin tank assembly and printing method thereof

InactiveCN106945281AQuick responseIncrease brightnessManufacturing enclosures3D object support structuresImage resolutionEngineering

The invention relates to a photo-curing 3D printer and a resin tank assembly and a printing method thereof. The resin tank assembly comprises a tank body (1) used for containing a resin material and with the light-transmitting tank bottom and a mounting seat (4) used for detachably mounting the tank body (1). An OLED screen (2) is arranged between the tank body (1) and the mounting seat (4). The self-luminous OLED screen has the advantages of being high in response speed, capable of emitting light with a simple driving circuit, simple in manufacture procedure and the like at the same time, besides, according to the OLED screen, in the displaying aspect, luminance is high, the response speed is high, and the image is stable and high in resolution, therefore, the photo-curing 3D printer and the resin tank assembly thereof adopt the OLED screen to supply a light source, and complex light path arrangement is avoided; and the 3D printing method is conducted by utilizing the photo-curing 3D printer, so that the manufacturing cost is relatively low, delayed time at the time of printing is reduced, the photo-curing efficiency is improved, and accordingly the printing efficiency is improved.

Owner:GOLD ARRAY TECH BEIJING LLC

Metal printing UV varnish and coating method thereof

InactiveCN107227100AImprove protectionHigh glossPretreated surfacesPolyurea/polyurethane coatingsTripropylene glycolPolymer science

The invention relates to the field of printing, and discloses a metal printing UV varnish and a coating method thereof. The UV varnish comprises the following components in percentage by mass: 30-60% of photocuring resin prepolymer, 30-60% of active monomer, 5-15% of photoinitiator and 0-15% of additive. The photocuring resin prepolymer is composed of at least one of a modified epoxy acrylic resin, a modified polyurethane acrylic resin and diallyl phthalate. The active monomer is composed of at least one of ethoxy acrylate, hexanediol diacrylate, acryloylmorpholine, trihydroxy acrylate, hydroxyethyl methacrylate and tripropylene glycol diacrylate. The UV varnish has the advantages of favorable leveling property, favorable gloss, favorable adhesive force and high photocuring efficiency. When being matched with the specific coating method disclosed by the invention, the UV varnish can not easily produce blisters, cratering, particles or other apparent defects.

Owner:HANGZHOU CPMC

Ultraviolet-cured biomass methacrylate and/or acrylate prepolymer and preparation method thereof

InactiveCN107057029AThe synthesis method is simple and controllableLow viscosityPolyureas/polyurethane adhesivesInksPolymer sciencePtru catalyst

The invention belongs to the technical fields of ultraviolet curing and polymerization and discloses an ultraviolet-cured biomass methacrylate and / or acrylate prepolymer and a preparation method thereof. The preparation method comprises the following steps: firstly synthesizing a diisocyanate prepolymer (I) from hydroxypropyl methacrylate or hydroxypropyl acrylate substances and diisocyanate under the actions of dimethylformamide (DMF) and a nitrogen protecting catalyst; and reacting by virtue of biomass cardanol and 4-chloro-1,3-butanediol under the action of strong base so as to generate diol (II), and reacting by virtue of diol (II) and synthesized diisocyanate prepolymer (I) so as to generate the ultraviolet-cured biomass methacrylate and / or acrylate prepolymer. The prepared ultraviolet-cured prepolymer has high light curing efficiency and good wear resistance and thermal stability, is adjustable in product viscosity and can be applied to the fields of ultraviolet-cured coatings, ink, adhesives and the like.

Owner:FOSHAN CENT FOR FUNCTIONAL POLYMER MATERIALS & FINE CHEM

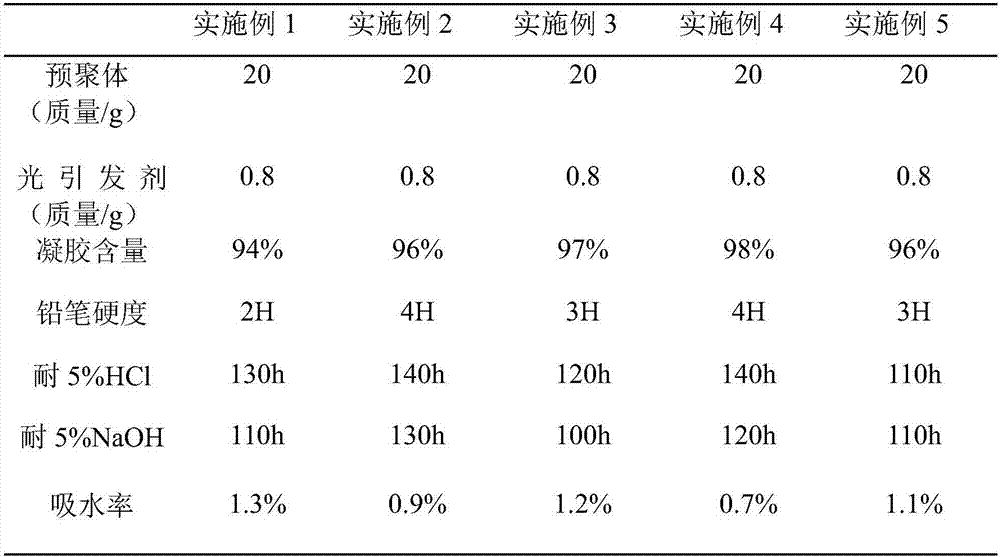

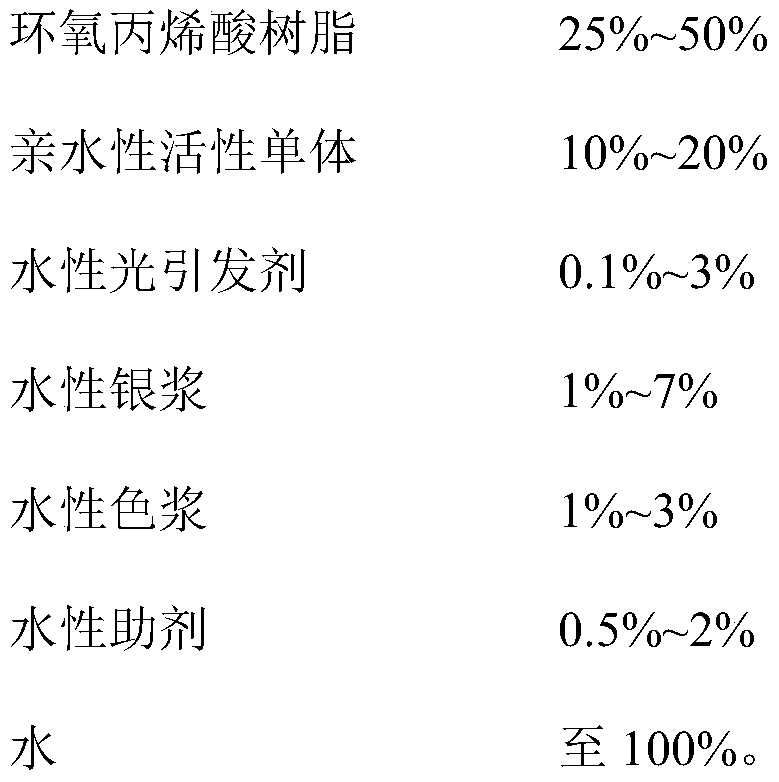

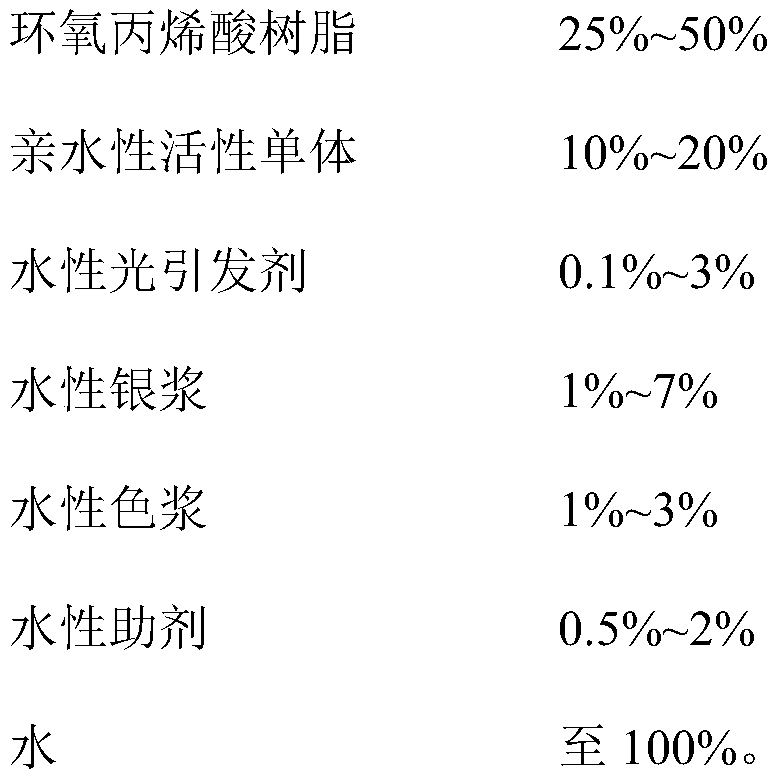

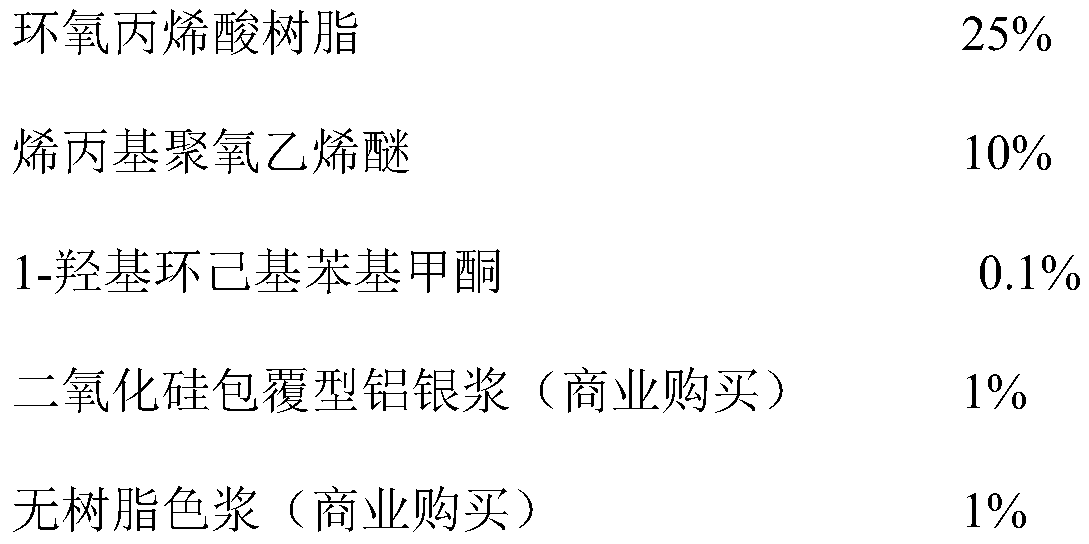

Water-based one-coating UV-cured epoxy acrylate coating and preparation method thereof

ActiveCN111253837AFast curingFully cross-linked and curedPolyether coatingsEpoxy resin coatingsSilver pastePolymer science

The invention belongs to the technical field of coatings, and discloses a water-based one-coating UV-cured epoxy acrylate coating and a preparation method thereof. The coating comprises the followingcomponents in percentage by mass: 25%-50% of epoxy acrylic resin, 10%-20% of a hydrophilic active monomer, 0.1%-3% of a water-based photoinitiator, 1%-7% of water-based silver paste, 1%-3% of water-based color paste, 0.5%-2% of a water-based additive and the balance of water, totaling 100%. By adopting a specific catalyst and a polymerization inhibitor, a paint film can be quickly cured at one time, and the cross-linking curing of the paint film is more sufficient; and a specific hydrophilic functional monomer is adopted, so that the stability of the water-based paint is further improved.

Owner:GUANGDONG RITOP FINE CHEM

LED light curing device

ActiveCN114833974AShorten the lengthIncrease the lengthLighting support devicesSpectral modifiersMechanical engineeringMaterials science

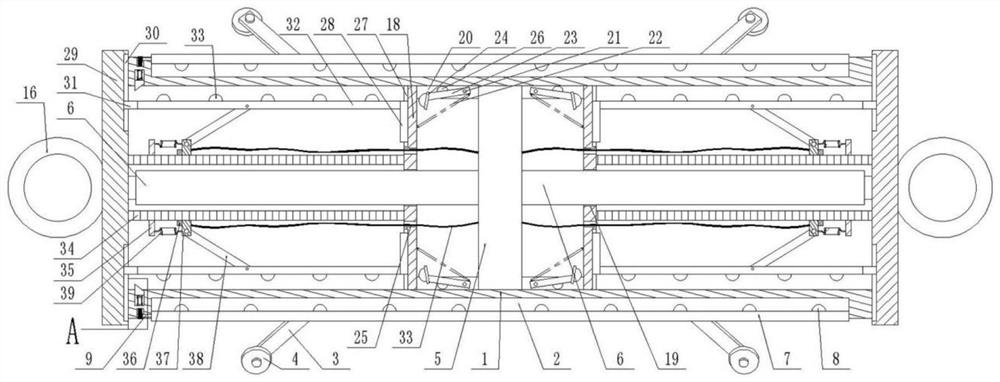

The invention relates to the technical field of trenchless pipeline repair, in particular to an LED light curing device. Comprising a cylinder body, a plurality of long grooves are evenly formed in the outer edge of the cylinder body, rotating rods are rotationally arranged in the long grooves, a plurality of LED light curing lamps are evenly distributed and fixed to the end faces, facing the axis of the cylinder body, of the rotating rods, and a driving device used for driving the rotating rods to rotate is arranged on the cylinder body on the left sides of the long grooves; movable sleeves are slidably arranged in the barrel on the left side and the right side of the inner plate, transverse telescopic cylinders are fixed to the left side and the right side of the inner plate, the sealing plate is fixedly connected with telescopic rods of the telescopic cylinders, a plurality of movable rods are arranged between the sealing plate and the movable sleeves, and a plurality of LED light curing lamps are evenly distributed and fixed to the sides, facing the inner edge of the barrel, of the movable rods. The LED light curing device is simple in structure and convenient to operate, the overall length of the curing device can be reduced, meanwhile, an LED light curing lamp is effectively protected, and the LED light curing lamp is prevented from being damaged in the process of mounting or dismounting the curing device.

Owner:河南兴兴管道工程技术有限公司

Preparation process and application of photosensitive resin for 3D printing

InactiveCN109929080AImprove performanceImprove light curing efficiencyAdditive manufacturing apparatusAcetic acidPolymer science

The invention discloses a preparation process and application of photosensitive resin for 3D printing. The process comprises the following steps of: 1) weighing organic silicon resin powder, an organic solvent and a silane coupling agent in parts by weight and adding the components into a first container to be stirred and mixed in a forward and reverse rotation alternating mode, the silane coupling agent being prepared by weighing silane, alcohol, water and acetic acid in parts by weight and mixing the components; 2) adding a catalyst, mixing and stirring the components until a transparent anduniform first liquid is obtained, respectively weighing a complexing agent and metal alkoxide according to parts by weight, and adding the components into a second container, mixing and stirring themetal alkoxide and the complexing agent in a forward and reverse rotation alternating manner until a transparent and uniform second liquid is obtained; 2) adding the first liquid into a third container, pre-stirring the first liquid, adding a second liquid, mixing and stirring the first liquid and the second liquid, adding an active diluent, and mixing and stirring all the components; 3) adding aphotoinitiator into the third container, and continuously stirring the mixture to obtain the 3D printing photosensitive resin.

Owner:广东信毅新材料有限公司

Environment-friendly and energy-saving UV (Ultraviolet) printing ink

InactiveCN106833110AImprove light curing efficiencyHigh hiding powerInksDiphenylphosphine oxideEngineering

The invention discloses environment-friendly and energy-saving UV (Ultraviolet) printing ink. The environment-friendly and energy-saving UV printing ink is prepared by mixing resin, 2,4,6 (trimethylbenzoyl)diphenylphosphine oxide, an aminoethylaminopropyl trimethoxysilane coupling agent, organic pigment, filling, a de-foaming agent and a flatting agent. The environment-friendly and energy-saving UV printing ink disclosed by the invention is high in UV light curing efficiency; the light curing time is about 5s and a post-heating process is not needed; environmental friendliness and energy saving are realized: the UV printing ink is applied to a colored crystal industry and the energy consumption is greatly reduced; and the utilization time is short, so that the energy consumption is greatly reduced. A cured film has high covering power, the rigidity of 3H and excellent wearing resistance and adhesive force; and after an adhesion test, the environment-friendly and energy-saving UV printing ink is 100% not released. The environment-friendly and energy-saving UV printing ink has excellent water resistance; a formula contains no volatile organic solvents and no irritating odor, and a screen is not plugged in a screen-printing process; and the reproducibility of screen points is good and convenience is provided for manufacturing a high-precision pattern. The environment-friendly and energy-saving UV printing ink is especially suitable for printing a glass substrate.

Owner:江世妹

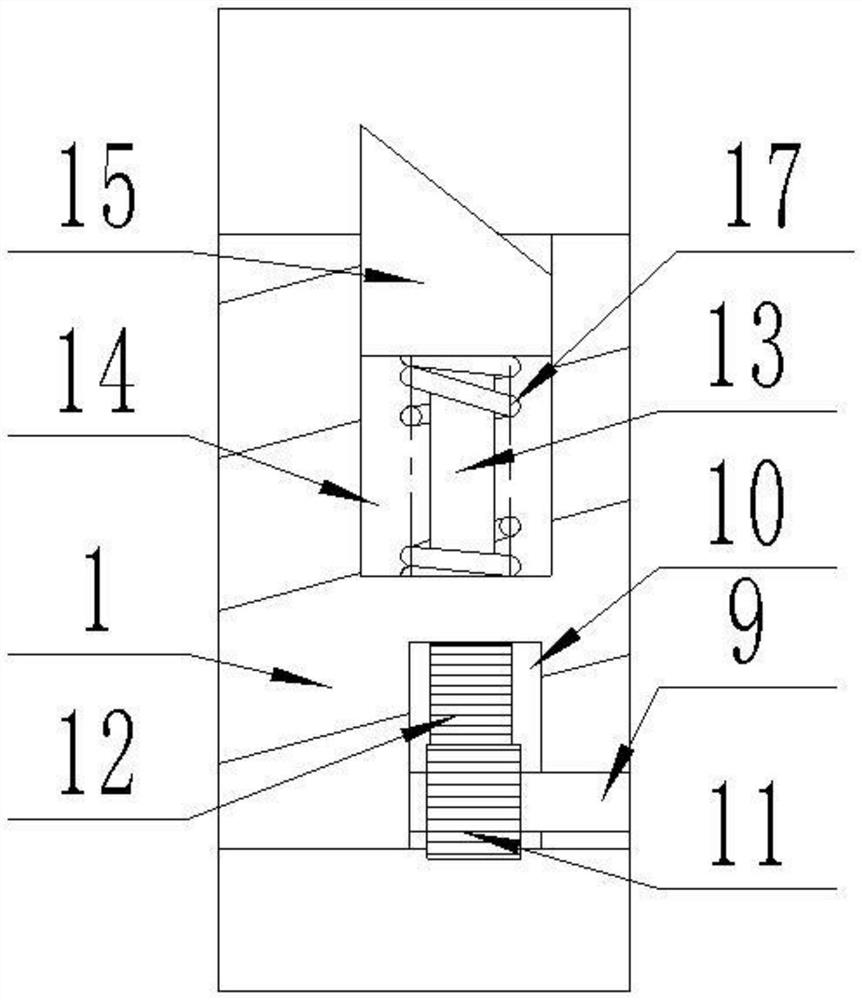

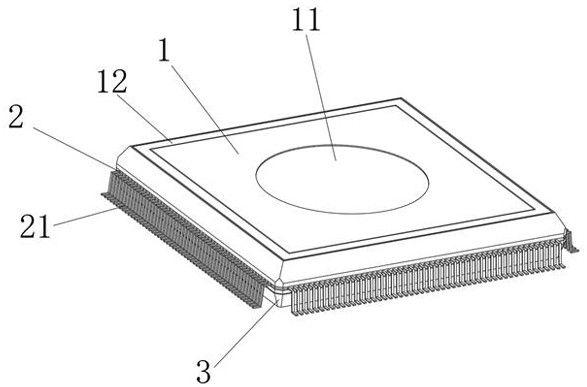

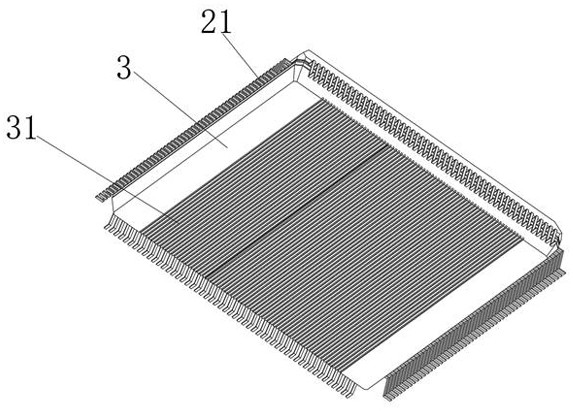

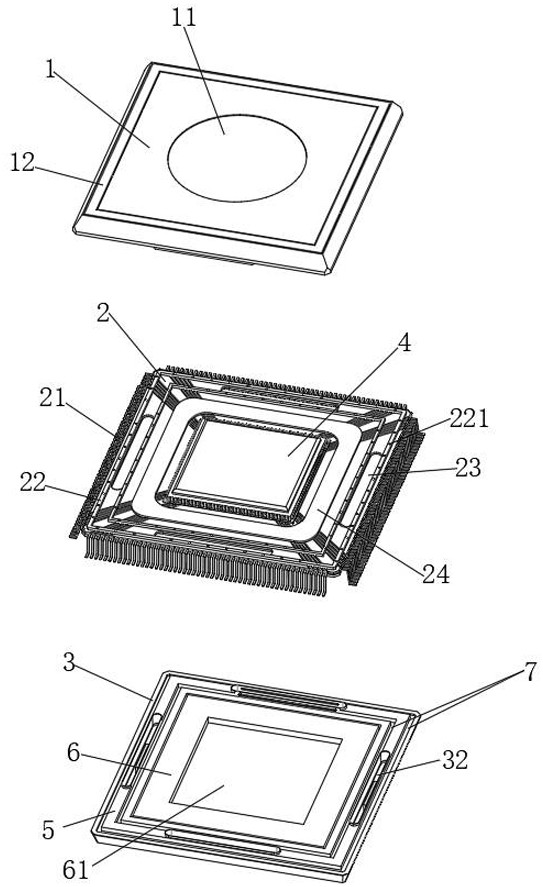

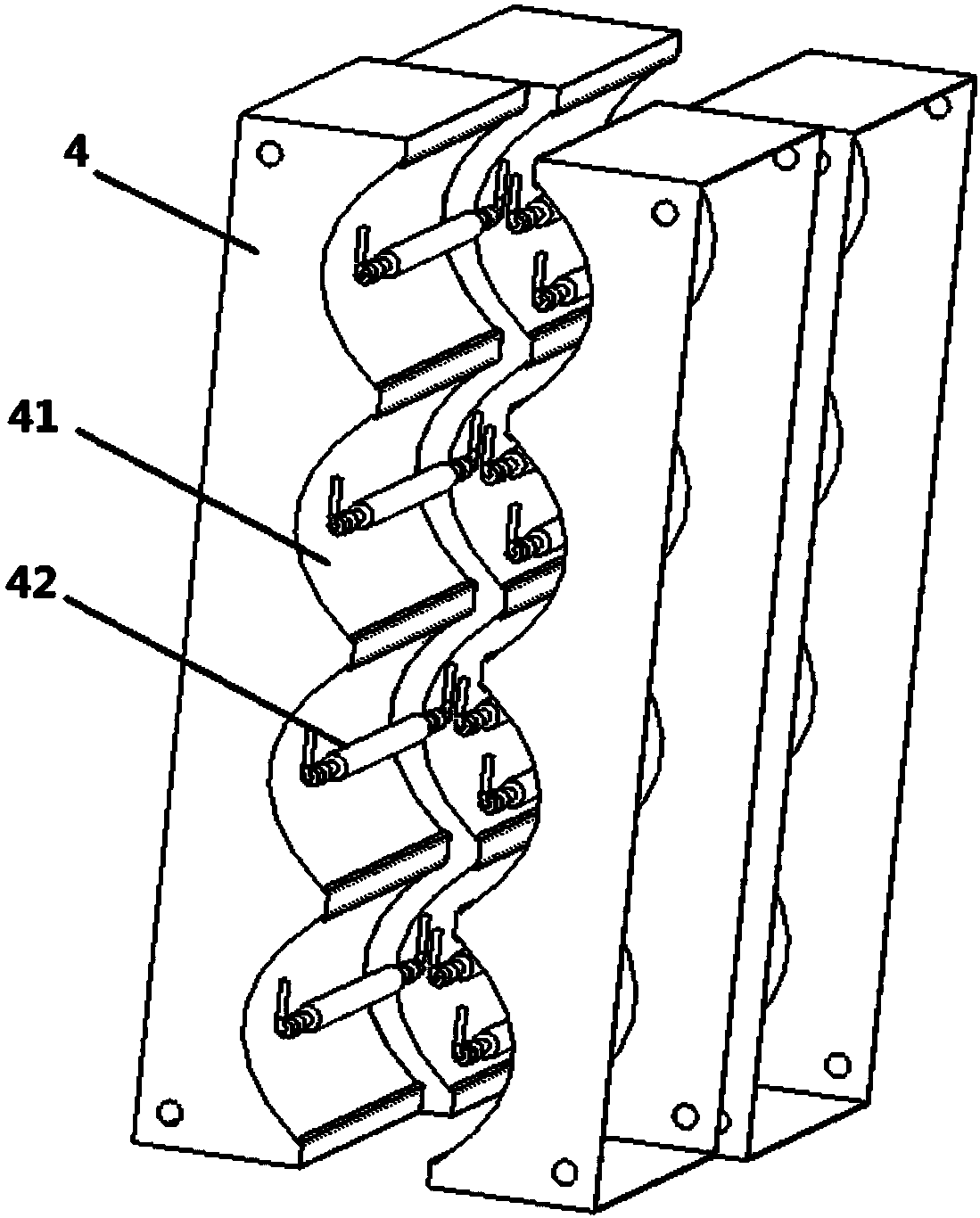

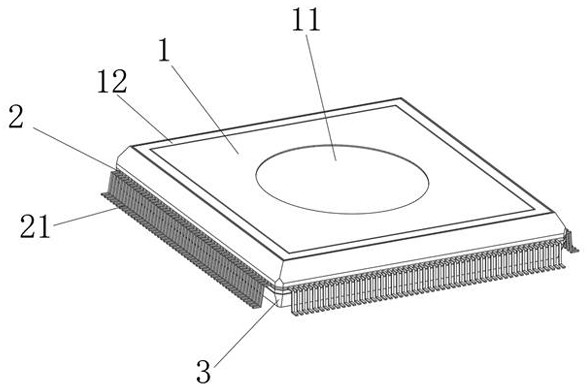

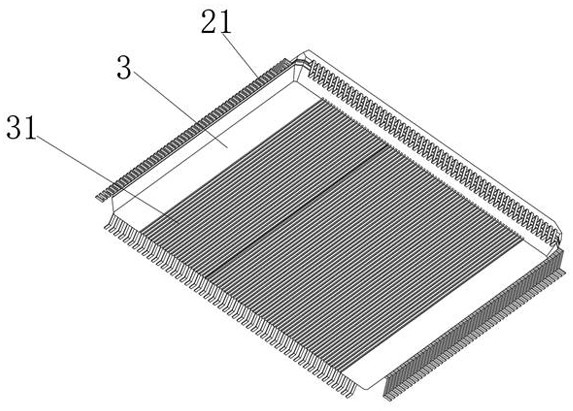

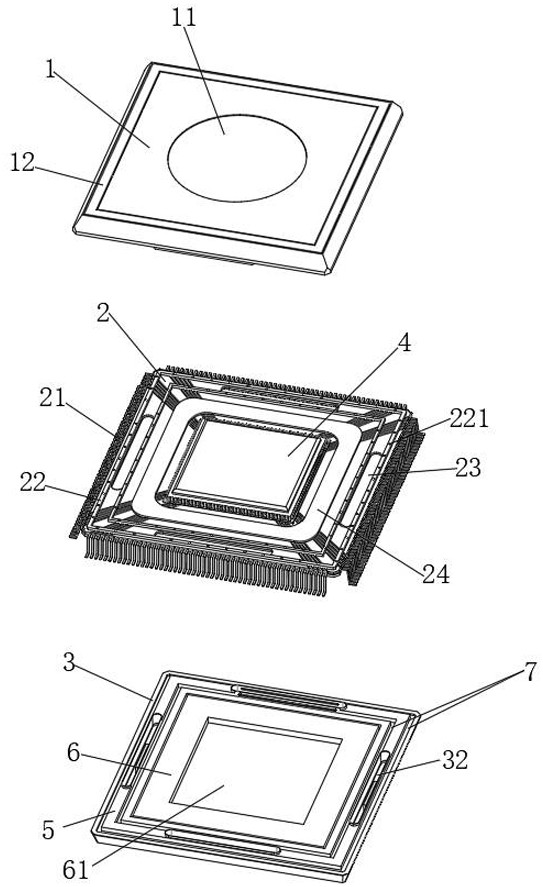

High-precision integrated circuit chip packaging device and packaging process thereof

ActiveCN114220773AQuick seal connectionShorten light curing timeNon-rotating vibration suppressionSemiconductor/solid-state device detailsLight guideMechanical engineering

The high-precision integrated circuit chip packaging device comprises an upper shell, a lower shell and a lining plate, a chip is fixed to the lining plate, the opposite sides of the upper shell and the lower shell are each provided with a second light guide frame, the inner side and the outer side of a frame body of each second light guide frame are each provided with a gluing groove, and the gluing grooves are formed in the inner side and the outer side of the frame body of each second light guide frame. The second light guide frame of the upper shell is provided with four folding blocks, the four folding blocks are evenly distributed at equal angles, the top ends of the folding blocks extend to penetrate through the upper shell and are fixedly provided with a first light guide frame, and the second light guide frame of the lower shell is provided with folding grooves matched with the folding blocks. And the packaging structure can be completely disassembled after being packaged, is convenient to maintain and reuse, is simple in process, effectively reduces the manufacturing cost, has market prospects and is suitable for popularization.

Owner:江苏高格芯微电子有限公司

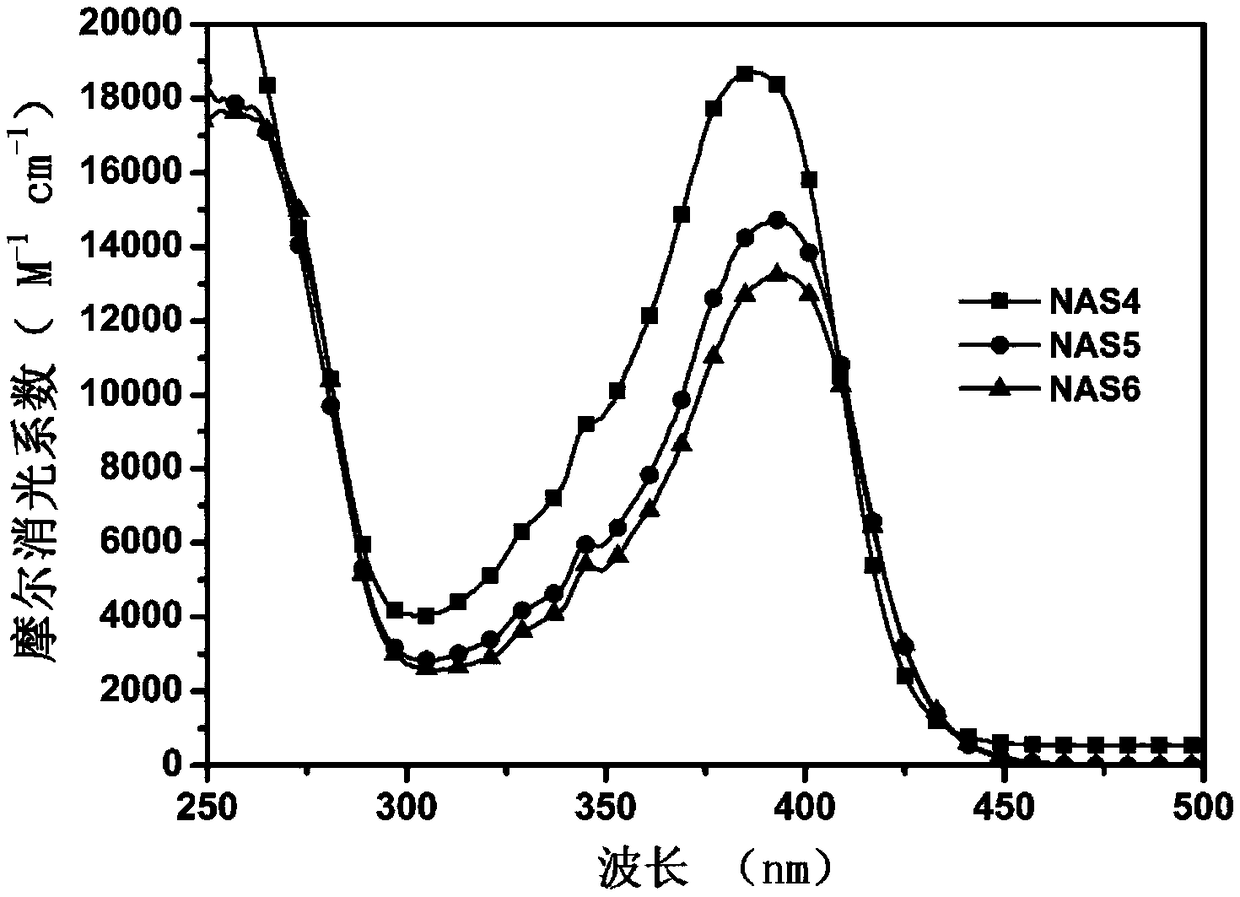

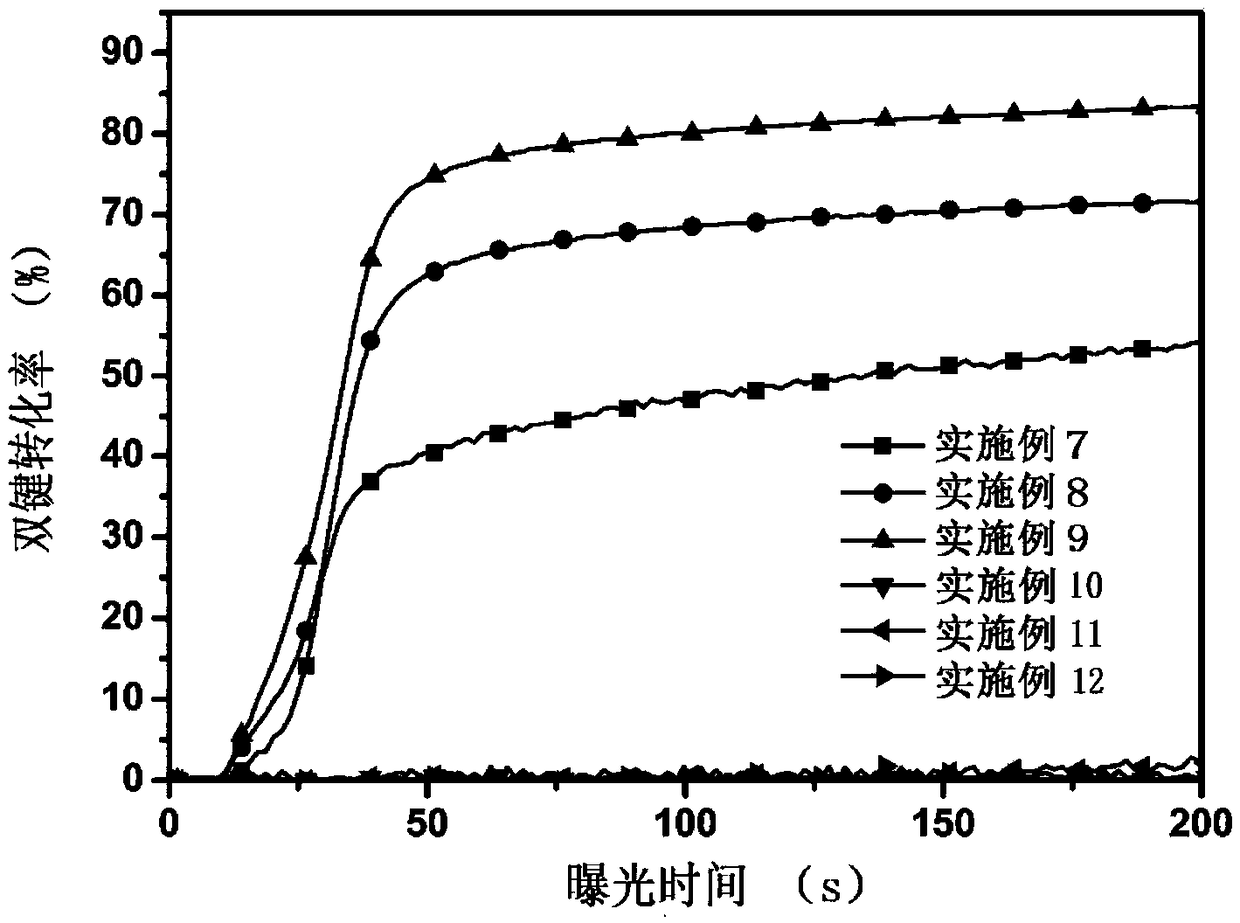

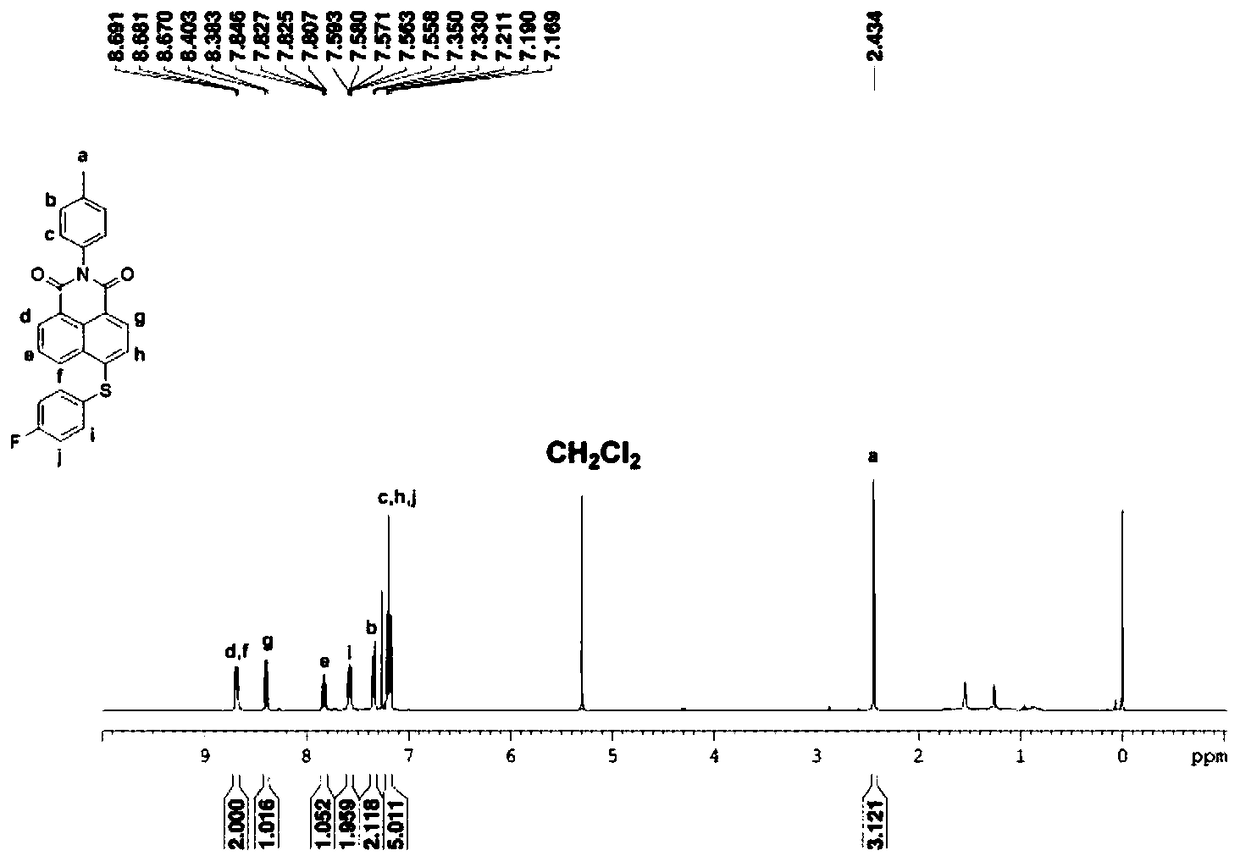

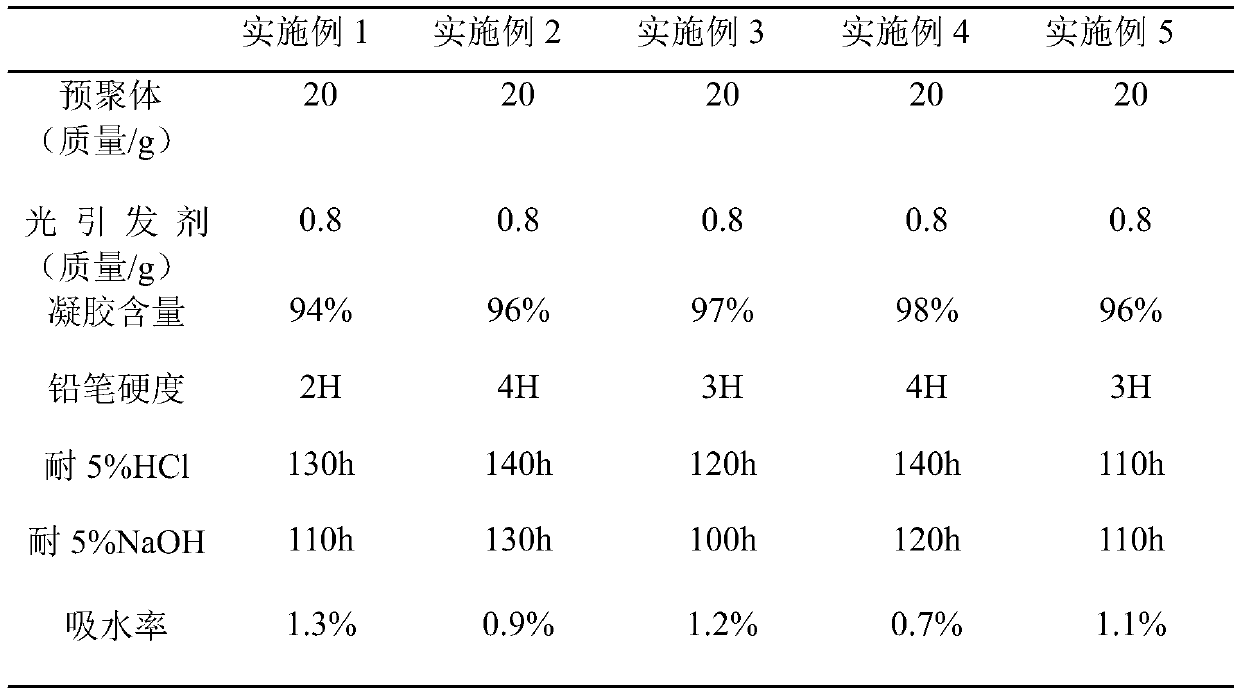

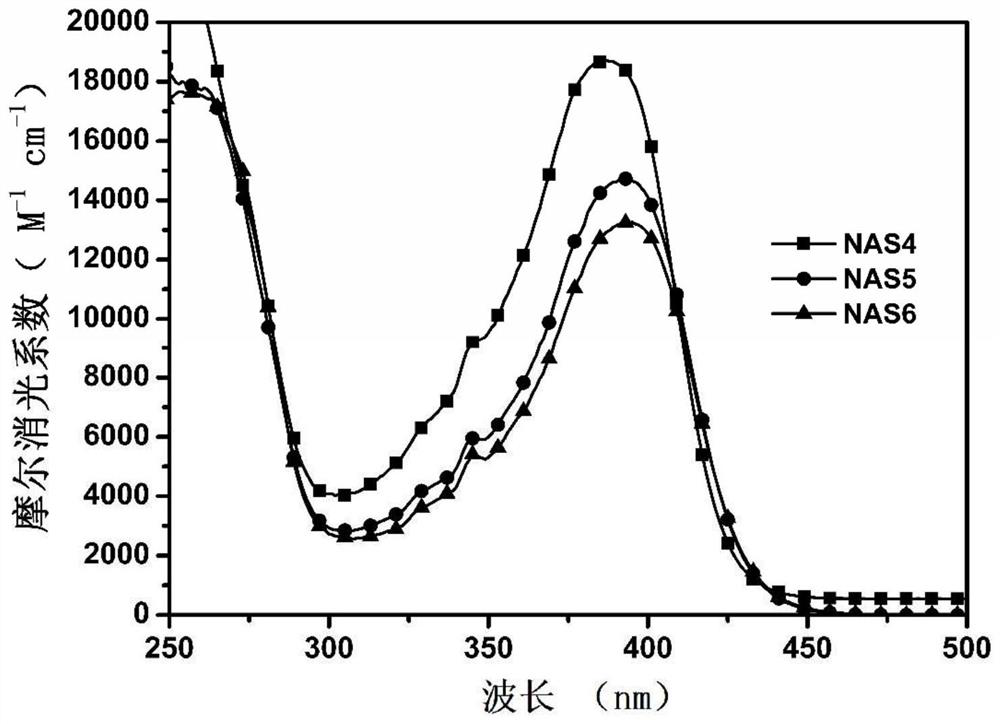

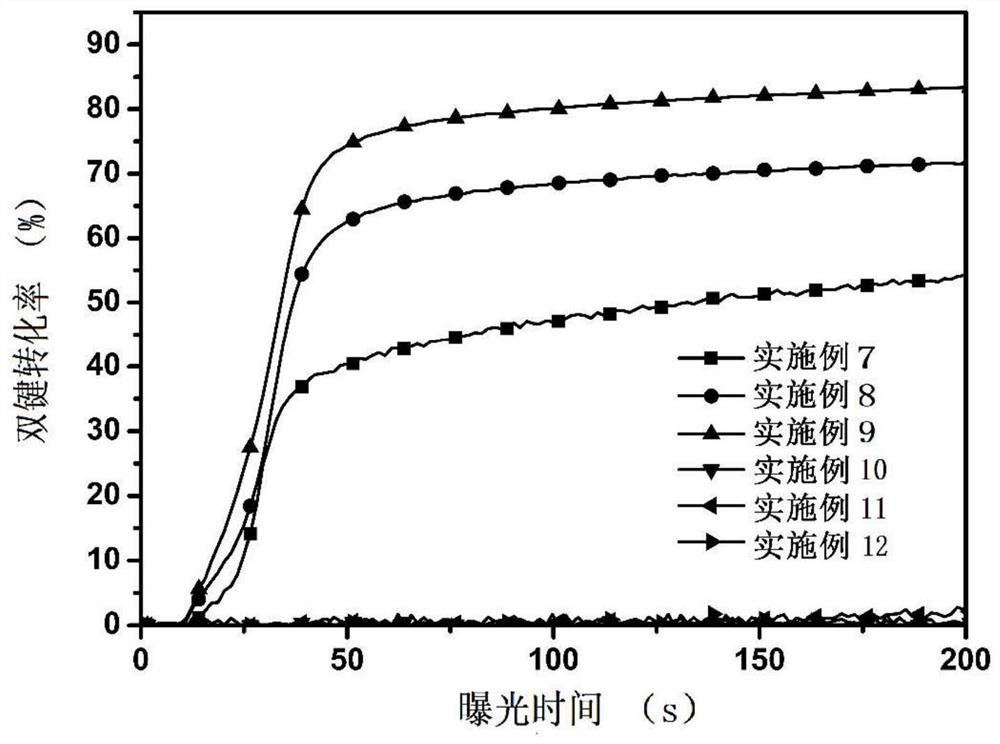

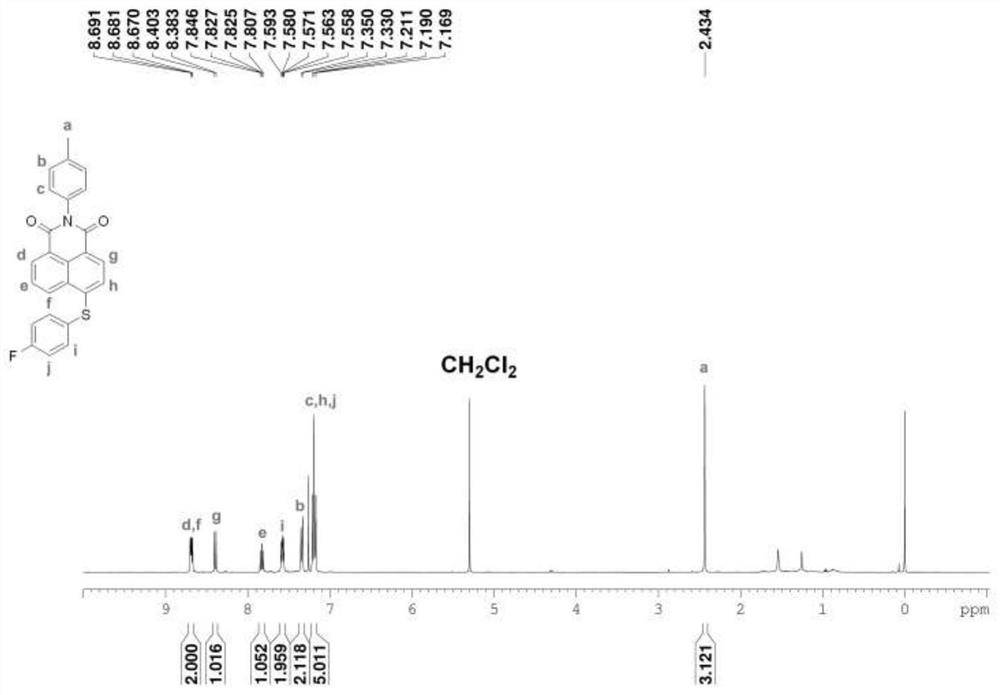

Naphthalimide aromatic sulfide photoinitiator for UV-LED photocuring and preparation method and application thereof

ActiveCN109400530AUV absorption wavelength extensionImprove light curing efficiencyOrganic chemistryUltraviolet absorptionStructural formula

The invention discloses a naphthalimide aromatic sulfide photoinitiator for UV-LED photocuring and relates to the field of light-sensing polymers. The photoinitiator herein is provided based on the problem that an existing photoinitiator has poor initiating property under irradiation of an UV-LED light source and has a chemical structural formula shown in the description, wherein R1 is selected from C1-C16 aliphatic hydrocarbon group, aralkyl or phenyl; R2 is selected independently from hydrogen, alkyl, alkoxy, acyl, halogen atom, and nitryl. The invention also provides a preparation method ofthe photoinitiator herein and application of the photoinitiator in a photocuring system. The photoinitiator herein and its preparation method and application have the advantages that ultraviolet absorption wavelength of the photoinitiator prepared herein is evidently extended, the photoinitiator has high photocuring efficiency under the action of a UV-LED light source, and the photoinitiator is helpful for the development of UV-LED photocuring industry.

Owner:安庆北化大科技园有限公司

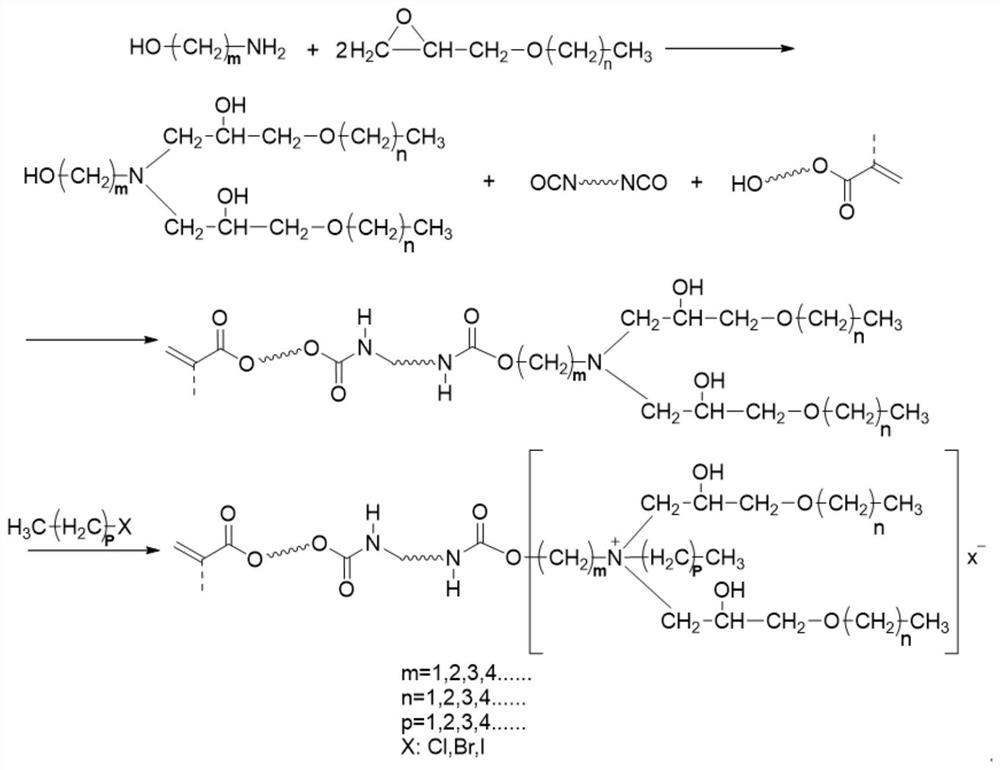

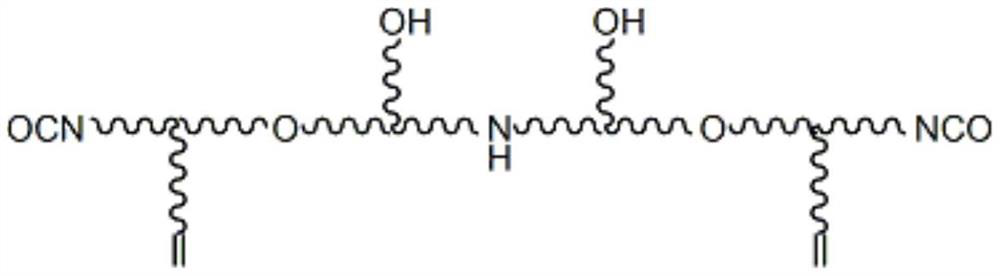

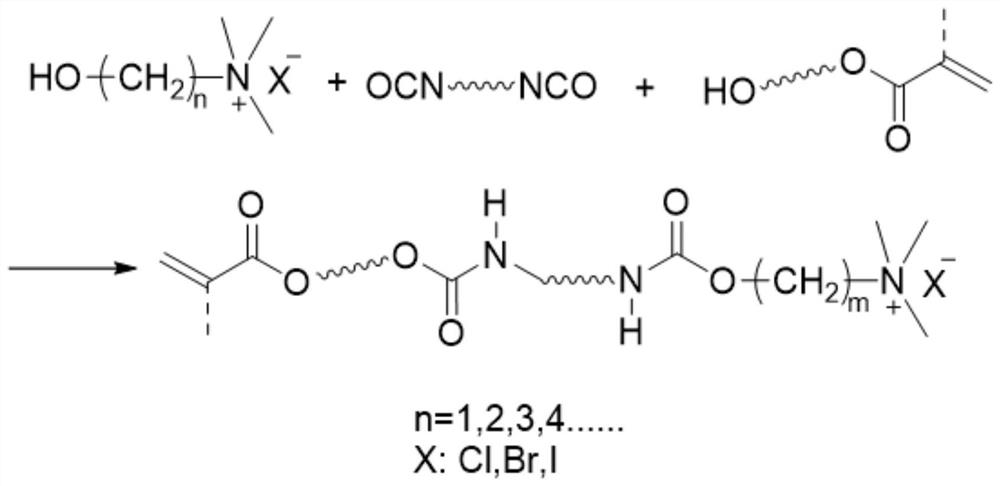

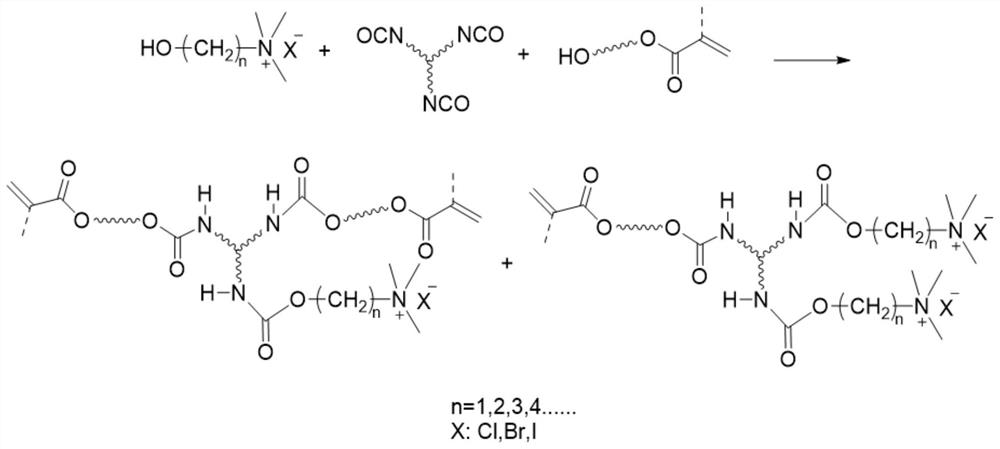

Solvent-free ultraviolet curing quaternary ammonium salt resin and preparation method thereof

The invention provides solvent-free ultraviolet curing quaternary ammonium salt resin and a preparation method thereof. The preparation method comprises the following steps of: firstly carrying out ring-opening reaction on hydroxyalkylamine and alkyl glycidyl ether, then reacting with polyisocyanate and hydroxyl acrylate, and finally reacting with halogenated alkane to obtain the solvent-free ultraviolet curing quaternary ammonium salt resin. Raw materials are cheap and easy to obtain, reaction conditions are mild, no solvent participates in the reaction process, and operation is simple. The quaternary ammonium salt resin has the characteristics of good anti-fog performance and rapid photocuring.

Owner:南京润奥新材料科技有限公司

A kind of composite material prepreg for ultraviolet curing structure repair and preparation method thereof

The invention provides a composite material prepreg for repairing glass fiber-reinforced resin-based structures with a certain thickness of ultraviolet light rapid curing and a preparation method thereof. This method uses ordinary free radical curable resin as the matrix, selects appropriate photoinitiators, thermal initiators and other additives to form a "light-thermal composite initiation system", uses glass fiber fabrics as reinforcing materials, and adopts appropriate composite processes. into a composite material prepreg with a certain thickness. The prepreg can be fully cured within 10 minutes by irradiating one side of ultraviolet light, and the thickness of one-time photocuring can reach more than 15mm. The invention solves the technical problem that the current ultraviolet light cannot cure large-thickness (10-15mm and above) composite material structural parts at one time, and makes the curing of the composite material prepreg more convenient and efficient. This light-curing resin and its composite materials have shown great application prospects and market potential in some specific fields such as trenchless repair of municipal drainage pipes.

Owner:WUHAN UNIV OF TECH

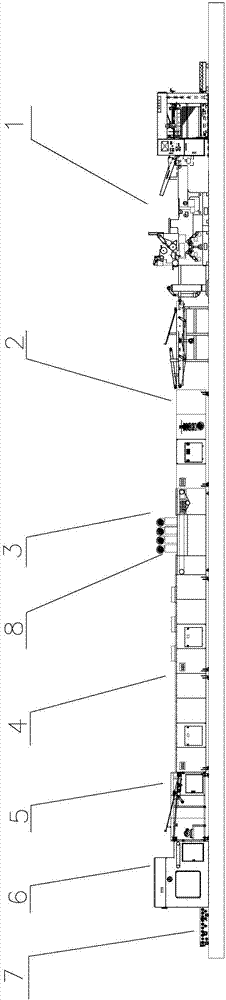

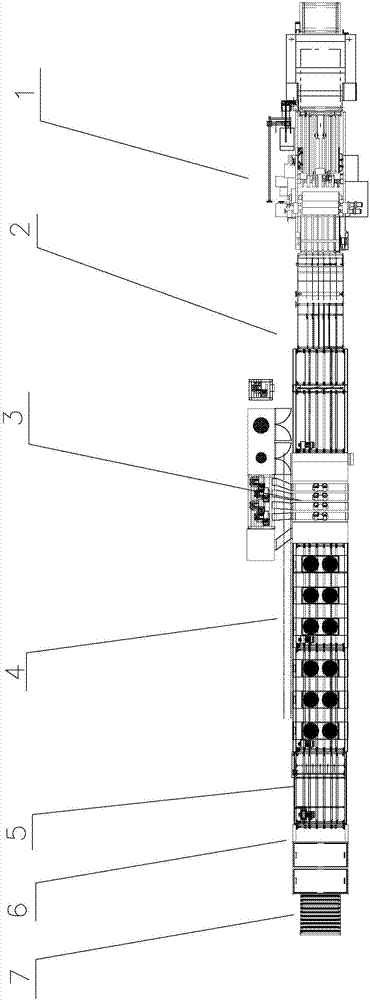

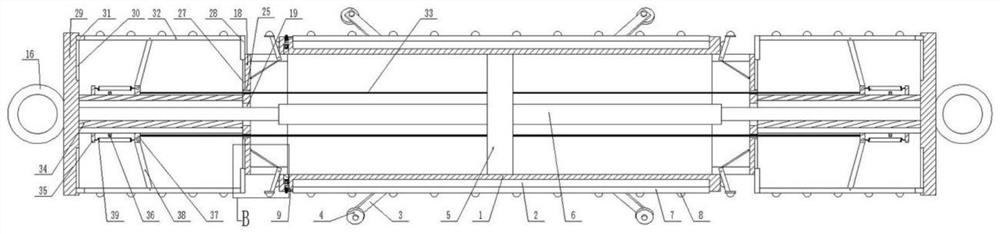

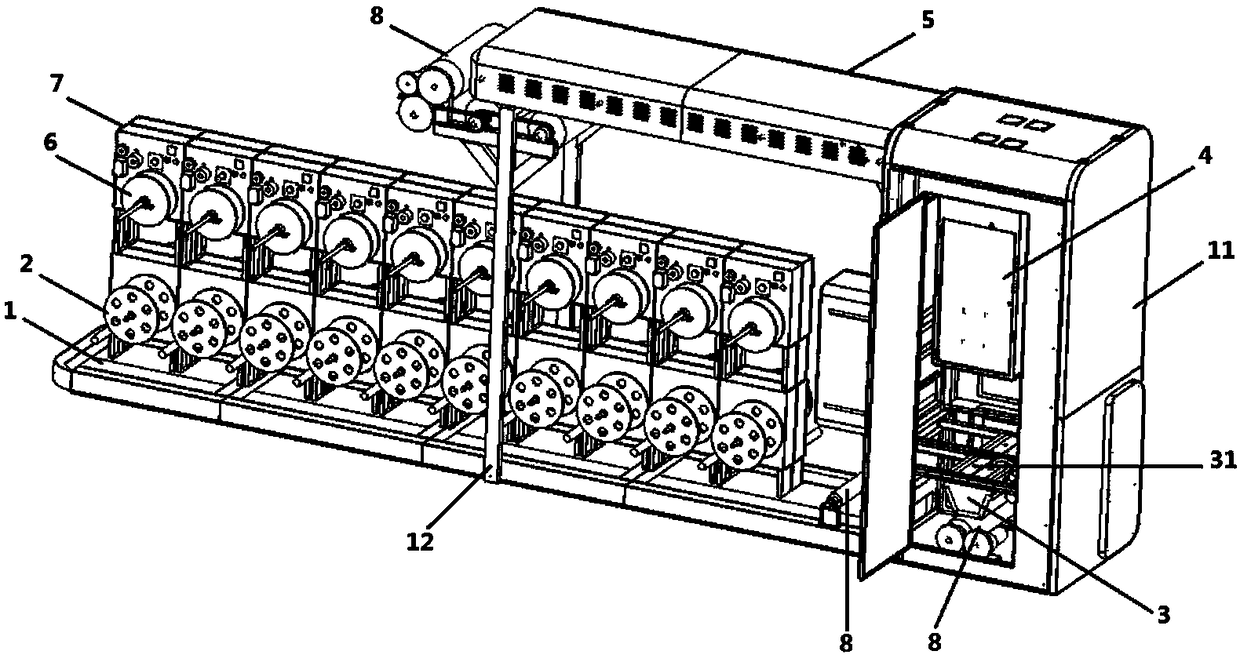

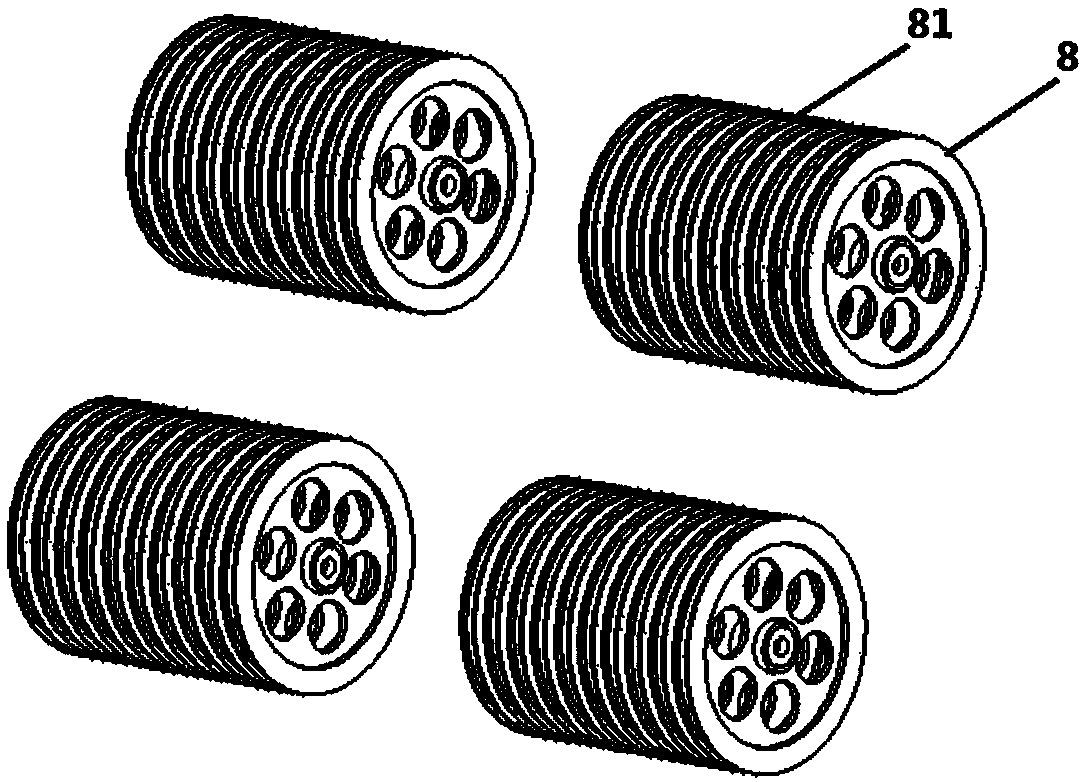

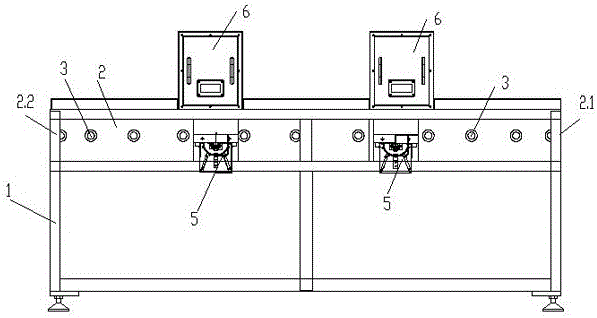

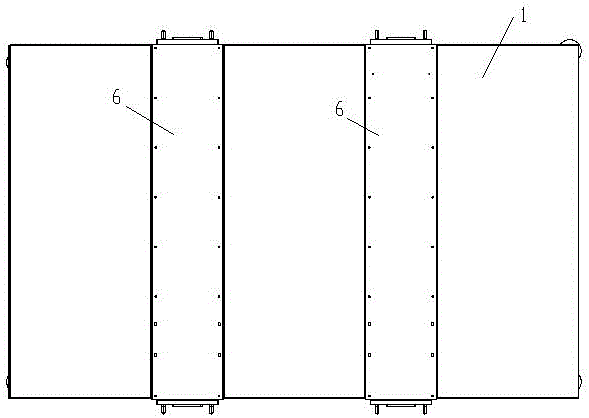

Equipment for simultaneously producing multiple glass fiber insulation pipes

InactiveCN108461235AReduce the temperatureReduce intensityInsulating bodiesGlass fiberUltraviolet lights

The invention discloses equipment for simultaneously producing multiple glass fiber insulation pipes, and belongs to the field of production equipment of the glass fiber insulation pipes. The equipment comprises a rack, wherein a pay-off device, a heating coating device, a light source curing device, a curing device after heating and a take-up device are sequentially arranged on the rack, a guideroller is further arranged on the rack and is used for guiding the glass fiber insulation pipes, the light source curing device comprises one or more groups of light reflection plates which are arranged oppositely, one or more light reflection surfaces are arranged on each light reflection plate and are sunken to form arc shapes, the positions of the light reflection surfaces on the same group oflight reflection plates are in one-to-one correspondence, and a linear ultraviolet light source is arranged in front of each arc light reflection surface and is parallel to a focus line of the light reflection surface. By the equipment, the limitation of production numbers by traditional equipment is broken through, the number of the glass fiber insulation pipes which can be theoretically and simultaneously produced is not limited according to equipment width, numbers of wiring walls and reasonable design of a take-up driving force, and the production efficiency is greatly improved.

Owner:安徽腾拓新材料科技有限公司

UV thermal expansion coating liquid composition and lithium battery thermal runaway protection patch

InactiveCN114410192AOvercome the effects of absorbing UV lightImprove light curing efficiencyFireproof paintsSecondary cellsThermal dilatationGlass fiber

The invention relates to the technical field of materials and lithium batteries, in particular to a UV thermal expansion coating liquid composition and a lithium battery thermal runaway protection patch, and the UV thermal expansion coating liquid composition is prepared by taking free radical curing type resin as a matrix, preferably selecting a proper intumescent flame retardant, and matching with a photoinitiator, a thermal initiator and other auxiliaries. The invention also provides a patch formed by taking the coating liquid composition and glass fibers with a certain thickness as reinforcing materials, the patch is used for replacing a fireproof felt for lithium battery thermal runaway protection at present, not only has the flame retardant effect of the fireproof felt, but also can foam and expand in volume at high temperature or flame, and an expansion layer has dual effects of heat insulation and flame retardance. The patch is moderate in hardness, convenient to lay and simple to operate, can be cured within 10 minutes through ultraviolet single-side irradiation, can be formed at a time, and saves the construction period.

Owner:江苏新澄瑞材料科技有限公司

A high-efficiency uv curing adhesive

ActiveCN108276948BImprove aging resistanceImprove toughnessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer science(Hydroxyethyl)methacrylate

The invention discloses a high-efficiency ultraviolet (UV) curing adhesive. The UV curing adhesive consists of the following components in percentage by mass: 60-75% of a polyurethane acrylate prepolymer, 10-20% of an isobornyl acrylate prepolymer, 5-20% of hydroxyethyl methacrylate, 5-15% of an active boron silicon tackifier, 1-5% of 1-hydroxy-cyclohexyl-phenyl ketone, 1-5% of 2,2-dimethoxy-2-phenylacetophenone, 0-2% of an adhesion promoter, 0-2% of a stabilizer, 0.5-1% of a polymerization inhibitor and 0-2% of a leveling agent. The UV curing adhesive has the following beneficial effects: (1)the ultraviolet curing band is narrow; (2) the photo-curing efficiency is high; (3) the aging resistance of cured resin is excellent; and (4) the cured product has good toughness.

Owner:NINGBO KLITE ELECTRIC MFG

A kind of preparation method of natural macromolecule-based photocurable resin

ActiveCN103554393BOvercome defects such as poor adhesionOvercome defects such as poor surface mechanical propertiesPolymer scienceSolvent

The invention discloses a method for preparing a natural polymer matrix light-cured resin. The method comprises the following steps: (1) leading polyisocyanate, oligomer polyol and hydroxyl-containing acrylate to react according to a certain molar ratio to prepare a semi-end-blocked prepolymer; (2) dispersing a natural polymer nano-material in a solvent, and adding the semi-end-blocked prepolymer prepared in the step 1 to obtain a full-end-blocked prepolymer; (3) mixing the full-end-blocked prepolymer and a photo-initiator to prepare the natural polymer matrix resin with excellent performance under ultraviolet radiation. The method adopts the natural polymer material as a raw material, and has the advantages that: the prepared light-cured resin has high molecular weight and viscosity, the interaction and coagulation strength among resin molecules can be enhanced, the photo-crosslinking reaction efficiency can be improved, the strength and attachment performance of a curing film can be improved, the cost is low, the process is simple and controllable, and the product is more environment-friendly.

Owner:HUAZHONG AGRI UNIV

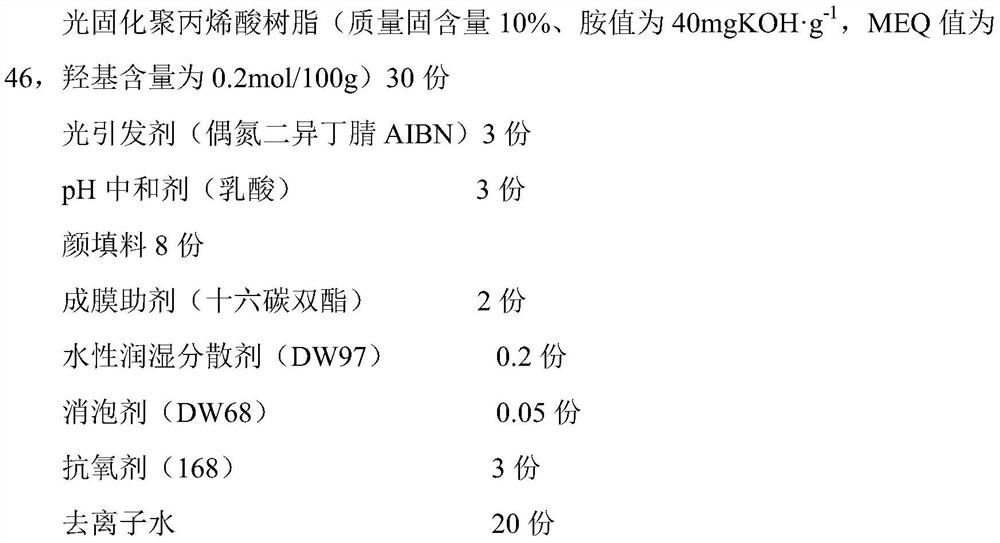

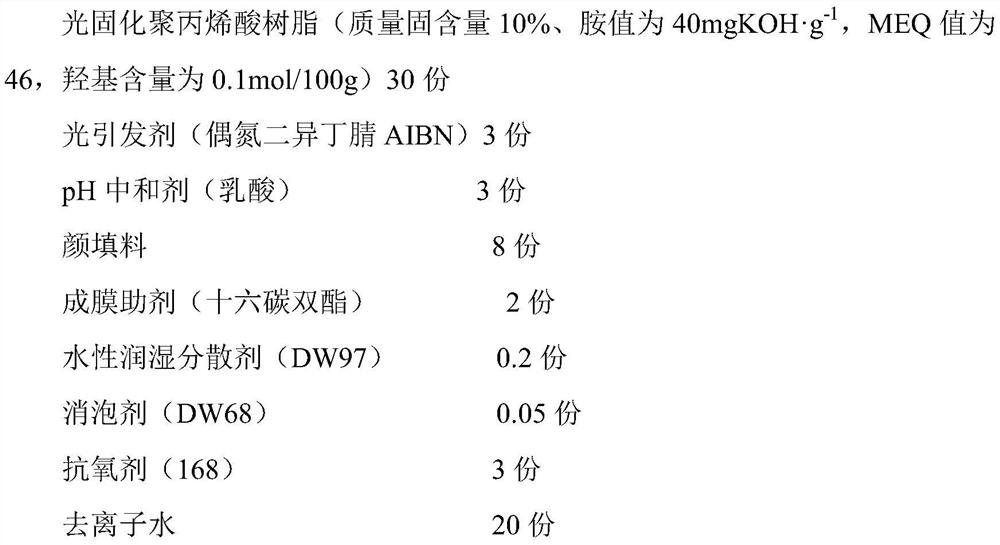

A kind of ultraviolet curing cathodic electrophoretic coating for multi-material metal collinear coating and preparation method thereof

ActiveCN111073431BImprove adhesionStrong adhesionAnti-corrosive paintsPaints for electrolytic applicationsElectrophoresesPolymer science

The invention relates to an ultraviolet-curable cathodic electrophoretic coating for multi-material metal collinear coating and a preparation method thereof. Film resin, to solve the problem of unbalanced paint film adhesion, film thickness and appearance quality on the surface of common cathodic electrophoretic coatings when cold-rolled sheets, galvanized sheets, aluminum alloy sheets and other multi-metal body bodies are collinearly coated, which cannot meet the requirements of the paint at the same time. The problem of film performance index requirements, as well as the problem of stickiness and uneven thickness of conventional UV-curable paint film, meet the needs of lightweight multi-material car body high-quality coating protection.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

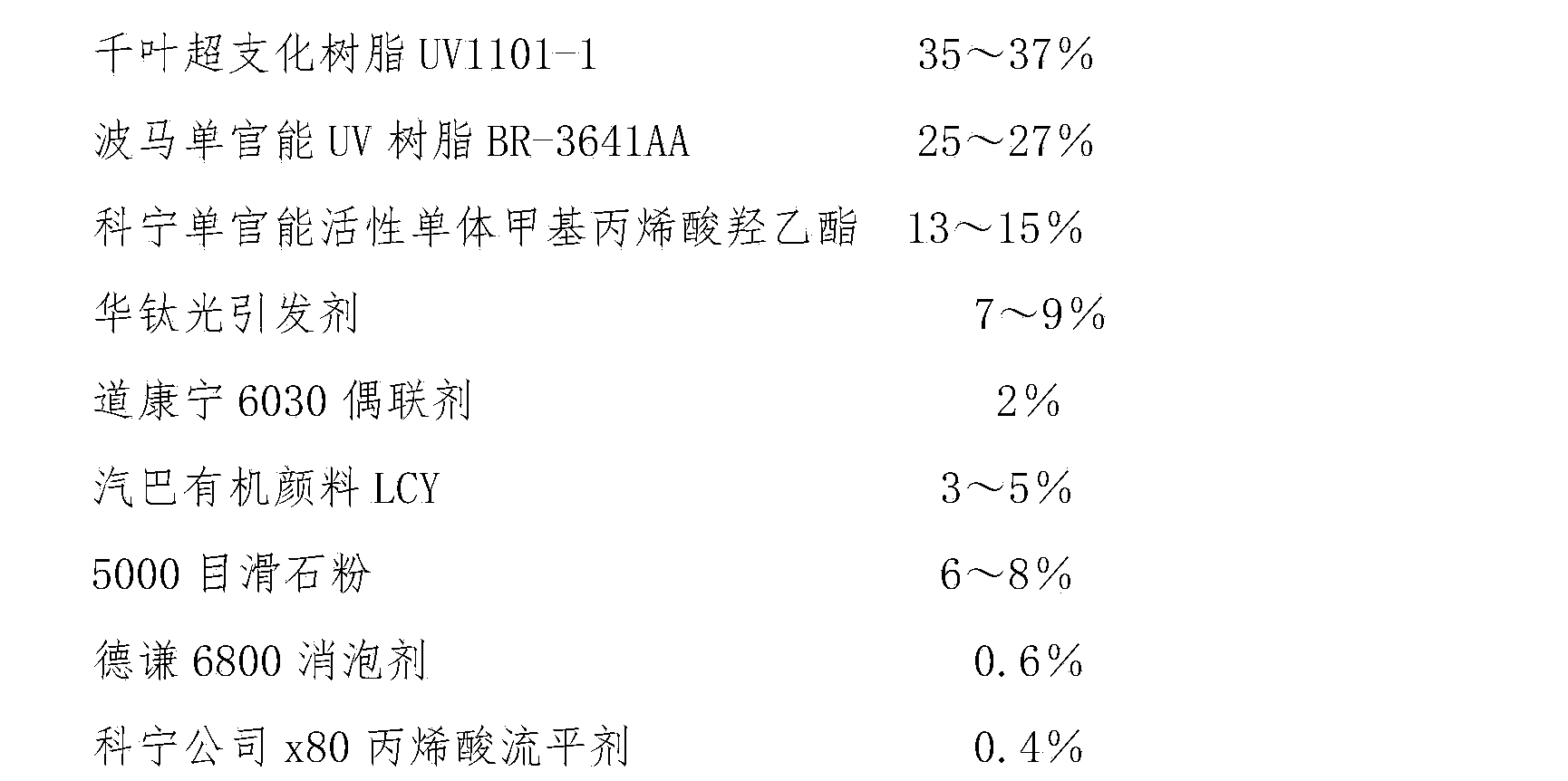

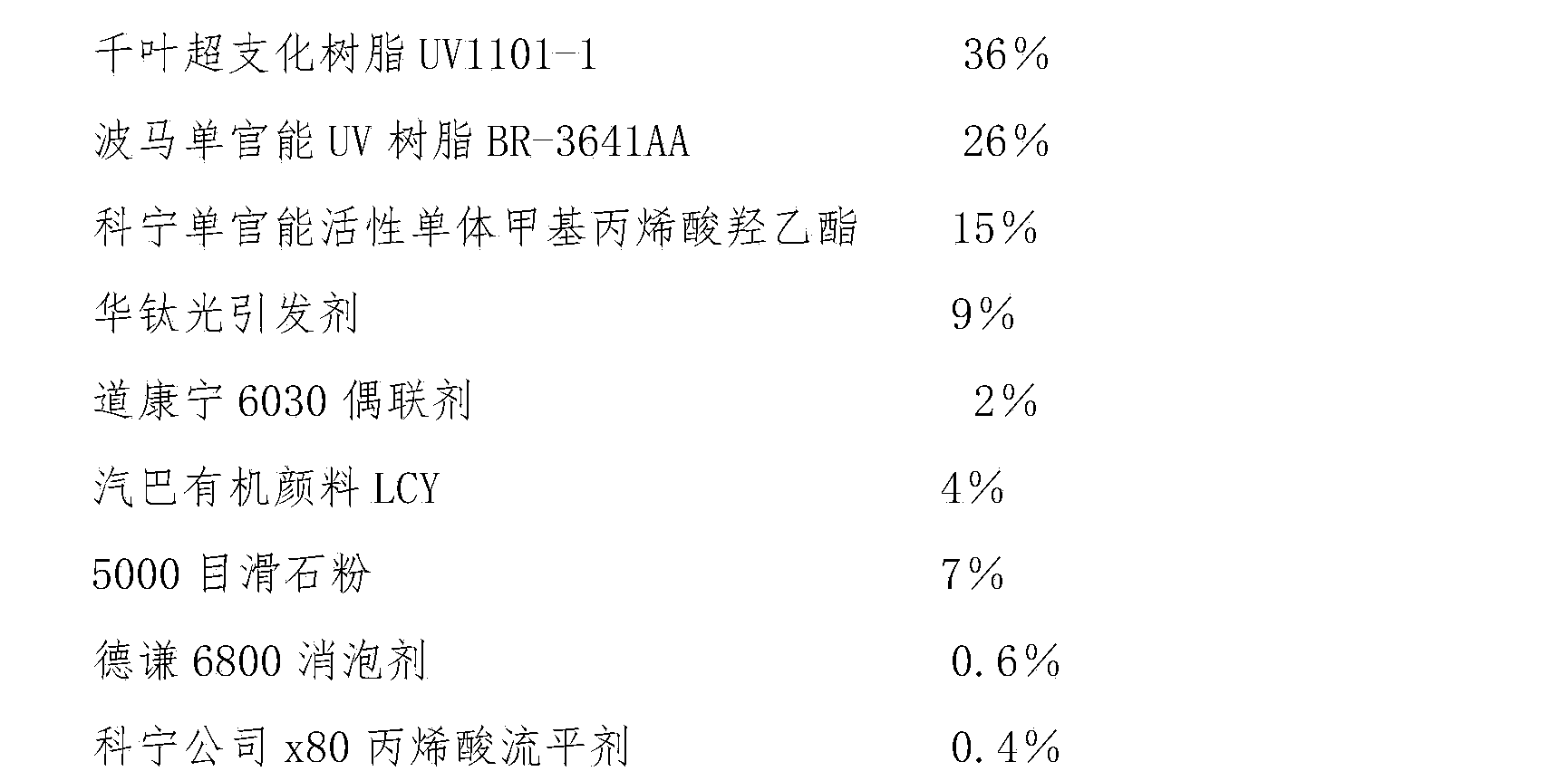

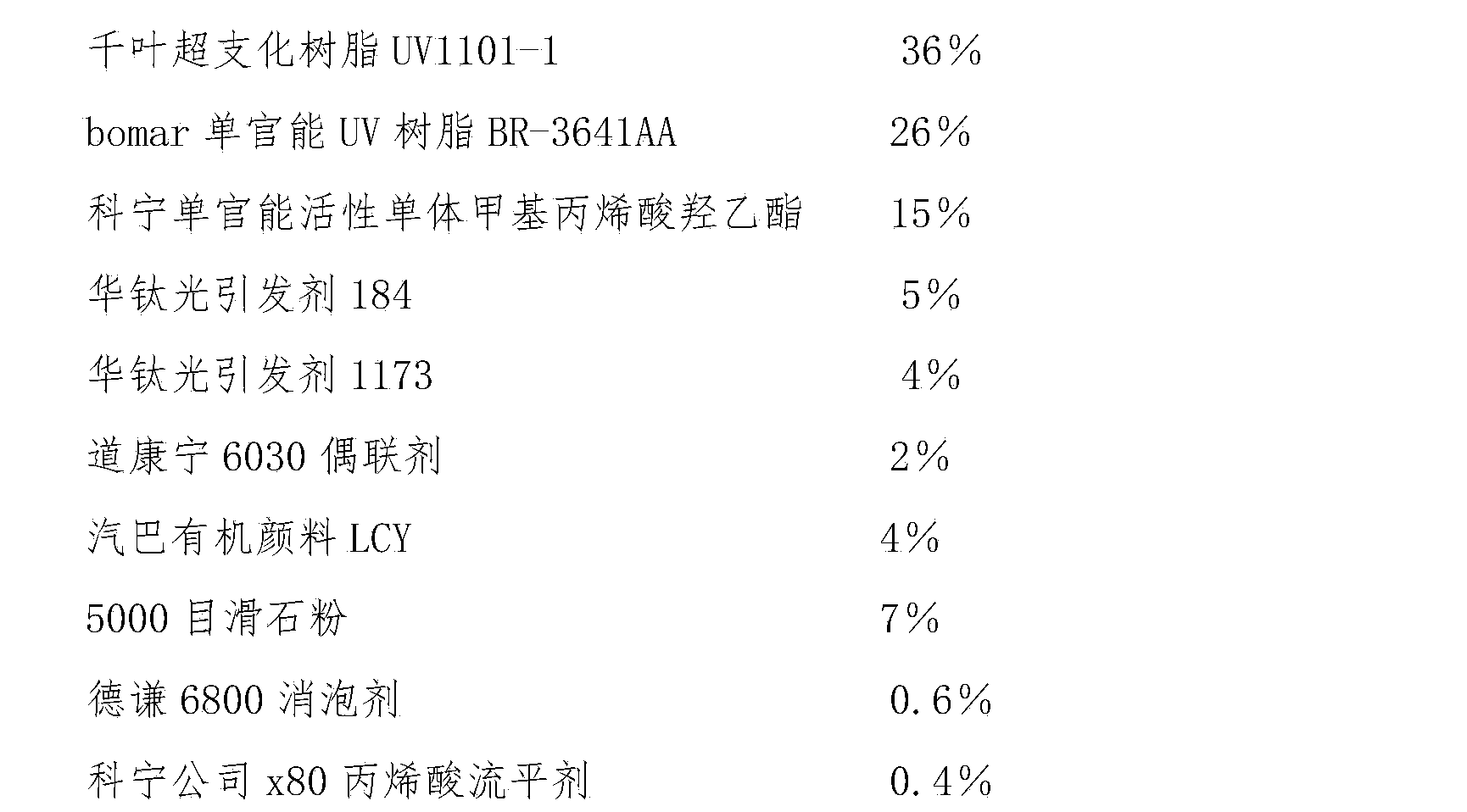

UV ink for glass base material printing and preparation method thereof

ActiveCN102702852BImprove light curing efficiencyReduce energy consumptionInksWeather resistance(Hydroxyethyl)methacrylate

The invention relates to UV (ultraviolet) ink for glass base material printing and a preparation method thereof. The UV ink for glass base material printing is composed of the following components by mass percent: 35-37% of Chiba hyperbranched resin UV1101-1, 25-27% of Poma monofunctional UV resin BR-3641AA, and 13-15% of Kening monofunctional active monomer hydroxyethyl methacrylate, 7-9% of Huatai photoinitiator, 2% of Dow Corning 6030 coupling agent, 3-5% of Ciba organic pigment LCY, 6-8% of 5000-mesh talcum, 0.6% of Deqian 6800 defoaming agent, and 0.4% of Kening Corporation x80 acrylic acid leveling agent. The UV ink has the advantages of good adhesive force with glass base material, good weather resistance and excellent overall performance.

Owner:中山市中益油墨涂料有限公司

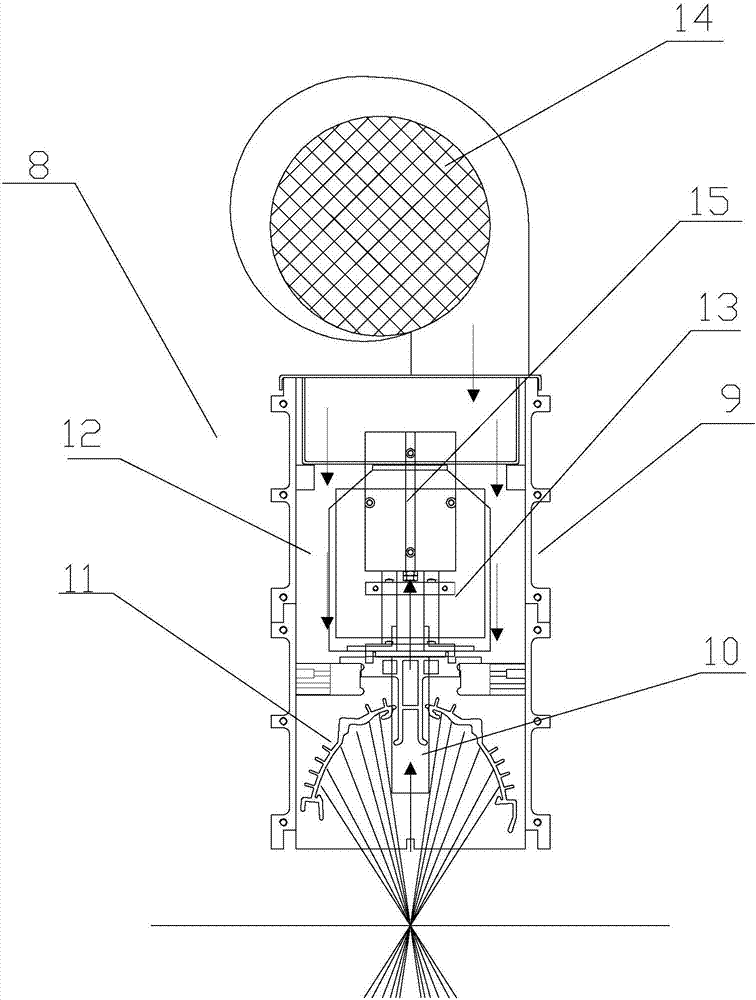

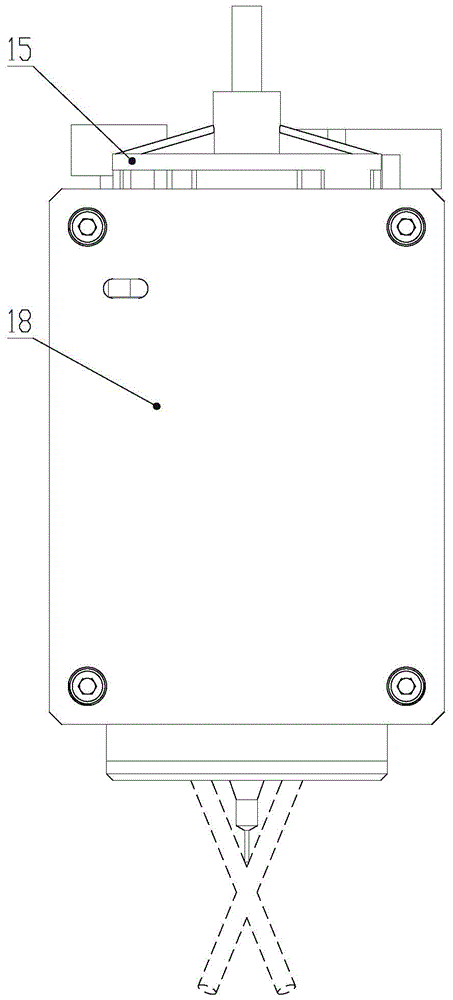

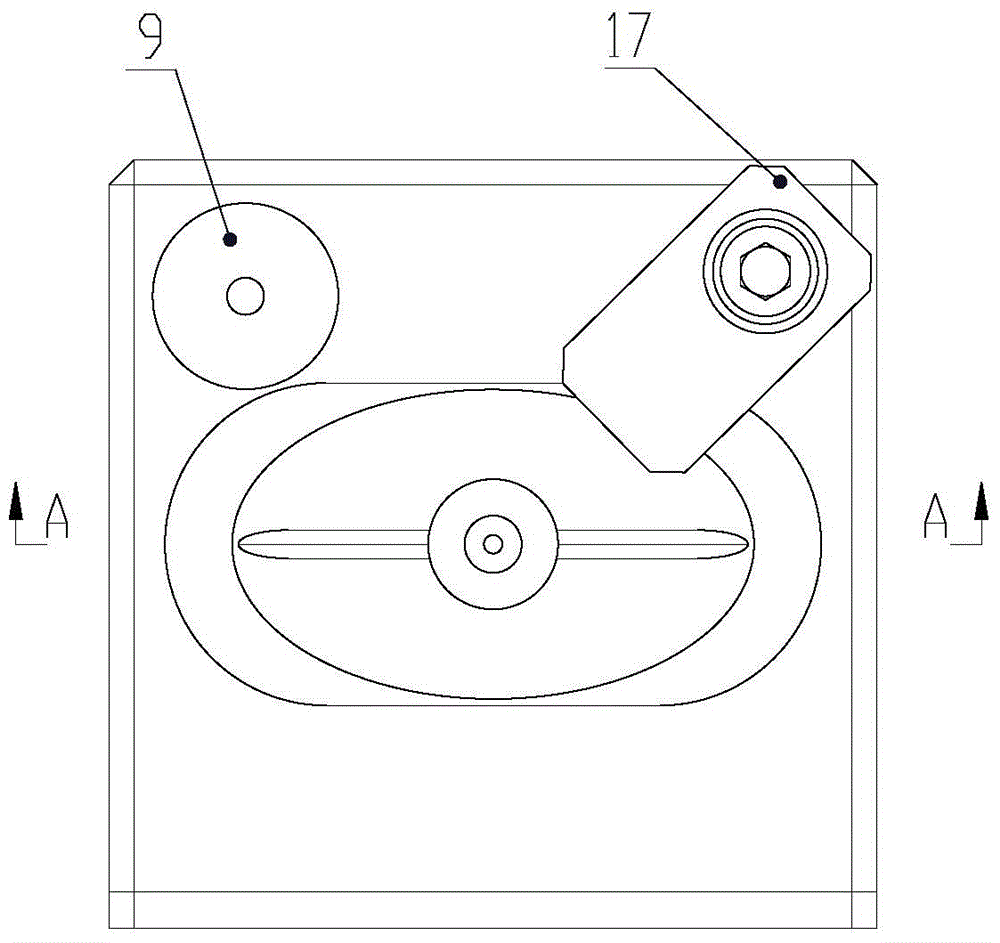

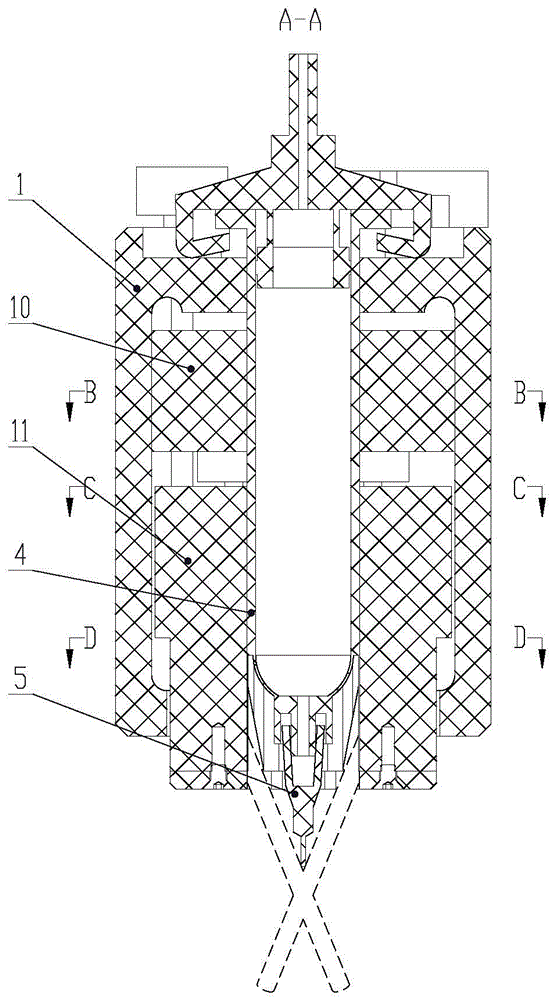

A fast photocuring nozzle for 3D printing equipment

ActiveCN104859149BCompact structureImprove light curing efficiencyApplying layer meansHigh power lasersAdhesive

The invention discloses a rapid photocuring spray head for a 3D printing device. The spray head mainly comprises a photocuring spray head shell, a charging barrel part, a point light source part and a reflector angle frame lifting part. The charging barrel part mainly comprises a charging barrel, an adhesive dispensing needle connected to the bottom end of the charging barrel, and a charging barrel cover arranged at the top end of the charging barrel. The point light source part mainly comprises laser point light sources, a light source fixing frame, a reflector fixing frame and reflector angle frames. The reflector angle frame lifting part mainly comprises a lead screw, an adjustment rotary knob, a slideway, a sliding block and a nut. The photocuring spray head has the advantages of being small and exquisite in structure and high in photocuring efficiency. Due to the fact that the high-power laser light sources are arranged in the spray head, laser light is converged at the position of a discharge outlet of the spray head through the reflection of reflectors. In this way, it is guaranteed that high-power laser with the corresponding wavelength is available for radiation at the discharging moment, and rapid curing of photocuring materials is achieved.

Owner:REGENOVO BIOTECH

Anti-fogging polyurethane acrylate resin and preparation method thereof

InactiveCN112300359AImprove light curing efficiencyGood anti-fog performanceIsocyanatePolymer chemistry

The invention provides an anti-fogging polyurethane acrylate resin and a preparation method thereof. The preparation method comprises the following steps of: reacting polyisocyanate with hydroxyl-terminated acrylate, and then reacting with hydroxyl-terminated quaternary ammonium salt to obtain the anti-fogging polyurethane acrylate resin. The raw materials are cheap and easy to obtain, and the manufacturing process is simple. The polyurethane acrylate resin has the characteristics of good anti-fog performance and rapid photocuring.

Owner:南京山维新材料科技有限公司

A high-precision integrated circuit chip packaging device and its packaging process

ActiveCN114220773BQuick seal connectionShorten light curing timeNon-rotating vibration suppressionSemiconductor/solid-state device detailsLight guideShock resistance

The invention discloses a high-precision integrated circuit chip packaging device and its packaging technology, comprising an upper case, a lower case and a liner, a chip is fixed on the liner, and the opposite sides of the upper case and the lower case are There is a second light guide frame, the inner and outer sides of the second light guide frame are provided with glued grooves, and the second light guide frame of the upper shell is provided with a mating block, and the four mating blocks are equiangularly divided. Arrangement, the top of the mating block extends through the upper case and is fixed with the first light guide frame, and the second light guide frame of the lower case is provided with a mating groove that matches the mating block. The structure of the present invention is simple , high packaging efficiency, strong heat dissipation and shock resistance of the packaging structure, and can be completely disassembled after packaging, easy to maintain and reuse, simple process, effectively reducing manufacturing costs, has market prospects, and is suitable for promotion.

Owner:江苏高格芯微电子有限公司

A kind of ultraviolet light curing biomass methacrylate and/or acrylate prepolymer and preparation method thereof

InactiveCN107057029BThe synthesis method is simple and controllableLow viscosityPolyureas/polyurethane adhesivesInksPolymer sciencePtru catalyst

The invention belongs to the technical fields of ultraviolet curing and polymerization and discloses an ultraviolet-cured biomass methacrylate and / or acrylate prepolymer and a preparation method thereof. The preparation method comprises the following steps: firstly synthesizing a diisocyanate prepolymer (I) from hydroxypropyl methacrylate or hydroxypropyl acrylate substances and diisocyanate under the actions of dimethylformamide (DMF) and a nitrogen protecting catalyst; and reacting by virtue of biomass cardanol and 4-chloro-1,3-butanediol under the action of strong base so as to generate diol (II), and reacting by virtue of diol (II) and synthesized diisocyanate prepolymer (I) so as to generate the ultraviolet-cured biomass methacrylate and / or acrylate prepolymer. The prepared ultraviolet-cured prepolymer has high light curing efficiency and good wear resistance and thermal stability, is adjustable in product viscosity and can be applied to the fields of ultraviolet-cured coatings, ink, adhesives and the like.

Owner:FOSHAN CENT FOR FUNCTIONAL POLYMER MATERIALS & FINE CHEM

Naphthalimide aryl sulfide type photoinitiator suitable for uv-led light curing, preparation method and application

ActiveCN109400530BUV absorption wavelength extensionImprove light curing efficiencyOrganic chemistryAcyl groupUltraviolet absorption

Owner:安庆北化大科技园有限公司

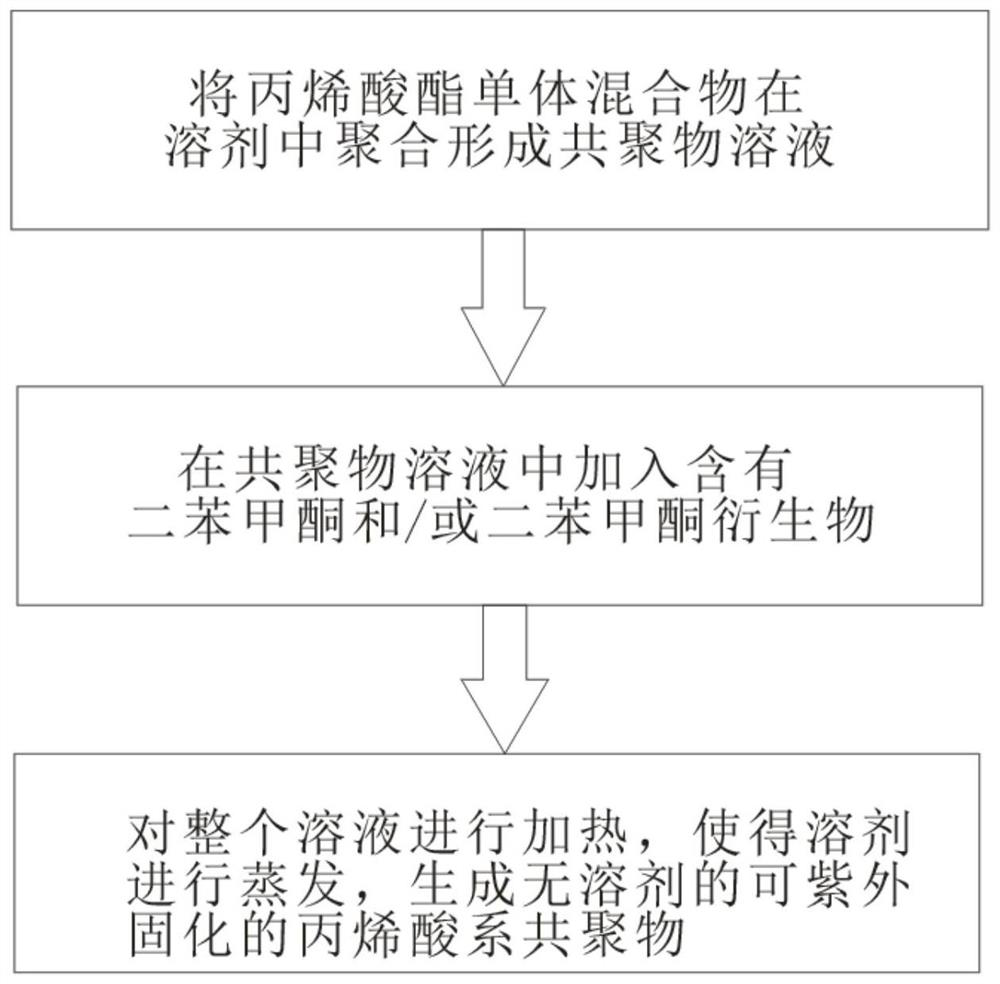

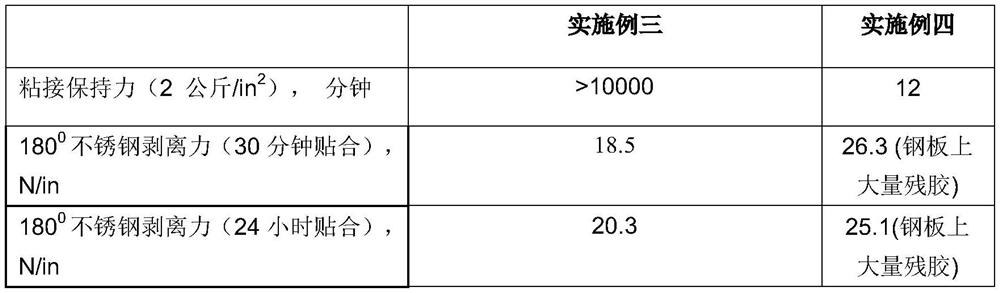

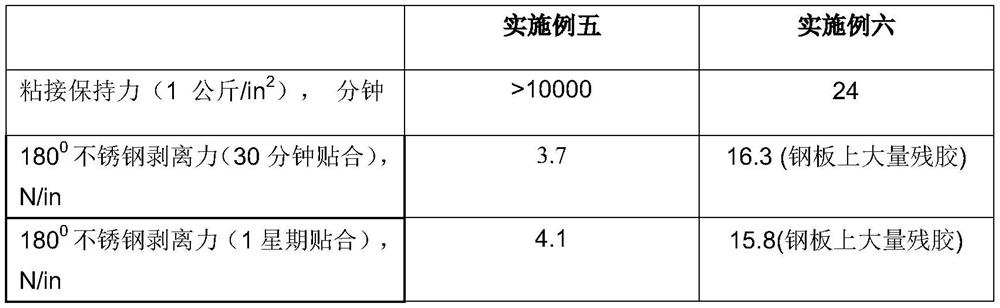

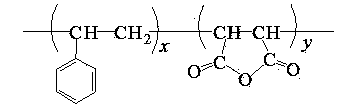

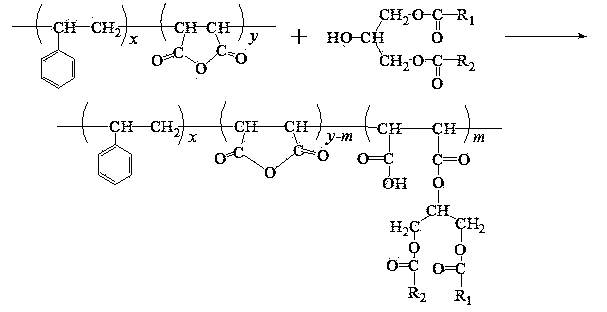

Preparation method and application of ultraviolet-curable acrylic copolymer

PendingCN114106234ALittle effect of oxygenIncrease reaction rateNon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceUV curing

The invention discloses a preparation method of an ultraviolet-curable acrylic copolymer. The preparation method comprises the following steps: S1, polymerizing an acrylate monomer mixture in a solvent to form a copolymer solution; s2, adding benzophenone and / or a benzophenone derivative into the copolymer solution; and S3, heating the whole solution to evaporate the solvent so as to generate the solvent-free ultraviolet-curable acrylic copolymer. According to the present invention, the advantages of the existing UV light curing technology are maintained, the production process of the UV curing pressure-sensitive adhesive is simplified, the performance of the pressure-sensitive adhesive and the thermal stability of the product during the hot melting production process are effectively improved, and the benzophenone or the derivative thereof is introduced so as to improve the product quality of the acrylate copolymer.

Owner:SHENZHEN LIHE BOHUI PHOTOSENSITIVE MATERIAL CO LTD

Ultraviolet (UV) curing adhesive with high strength and high toughness

InactiveCN109852328ANarrow curing bandImprove light curing efficiencyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesUltravioletTackifier

The invention discloses an ultraviolet (UV) curing adhesive with high strength and high toughness. The curing adhesive consists of the following components in percentage by mass: 60-75% of a polyurethane acrylate prepolymer, 10-20% of an isobornyl acrylate prepolymer, 5-20% of hydroxyethyl methylacrylate, 5-15% of an active boron silicon tackifier, 1-5% of 1-hydroxy-cyclohexyl-phenyl methanone, 1-5% of 2,2-dimethoxy-2-phenylacetophenone, 0-2% of an adhesion promoter, 0-2% of a stabilizer, 0.5-1% of a polymerization inhibitor and 0-2% of a flatting agent. The preparation method disclosed by theinvention has the following beneficial effects: (1) the ultraviolet curing wave band is narrow; (2) light curing efficiency is high; (3) aging resistance is excellent after the resin is cured; and (4) toughness of the cured product is good.

Owner:广州聚达光电有限公司

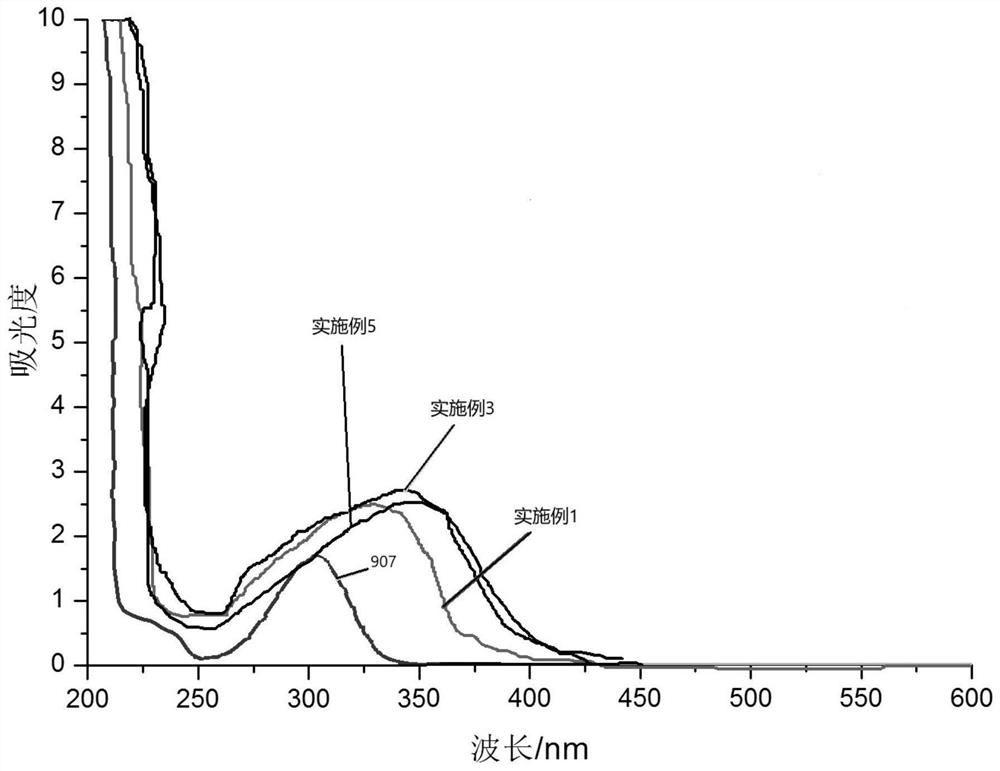

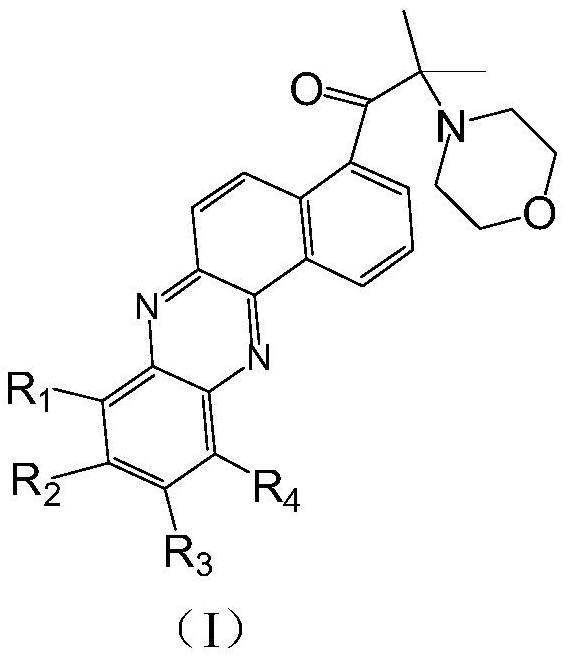

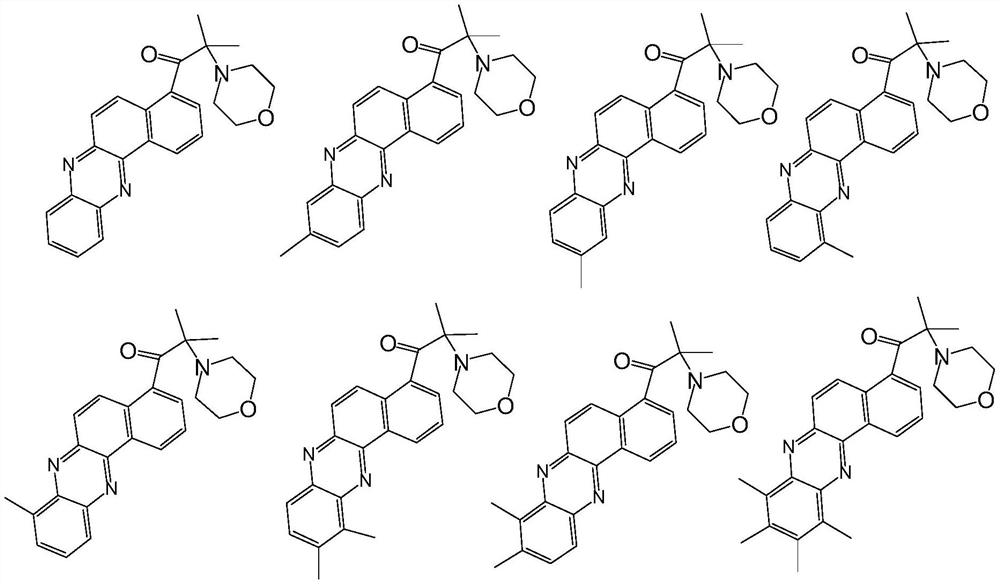

Phenazine derivative-series photoinitiator as well as preparation method and application thereof

ActiveCN112707870AImprove matchImprove light absorption efficiencyOrganic chemistryMorpholinePhenazine

The invention relates to a phenazine derivative-series photoinitiator as well as a preparation method and application thereof. The phenazine derivative-series photoinitiator comprises a phenonaphthazine group and a 2-methyl-2-morpholinyl-acetonyl group connected to the benzene ring of the phenonaphthazine group. Compared with a photoinitiator 907, the absorption wavelength of the phenazine derivative-series photoinitiator undergoes red shift, so the phenazine derivative-series photoinitiator has higher matching degree with the emission wavelength of a UV-LED, and light absorption efficiency is obviously improved; and the phenonaphthazine group in the phenazine derivative-series photoinitiator is an electron-rich group, and interacts with the 2-methyl-2-morpholinyl-acetonyl group to make the phenazine derivative-series photoinitiator have high curing efficiency, and a migration rate in the use process is obviously reduced, so the application range of the phenazine derivative-series photoinitiator is obviously broadened.

Owner:TIANJIN JIURI NEW MATERIALS CO LTD

Method for preparing photocurable resin from animal and vegetable triglyceride and photocurable resin prepared by method

Owner:GUANGDONG BOSSIN NOVEL MATERIALS TECH CO LTD

A kind of adenine enhanced degradable soft tissue adhesive and its preparation and use method

ActiveCN110680951BReduce the use effectWell mixedSurgical adhesivesPolymer scienceUltraviolet lights

Owner:XI AN JIAOTONG UNIV

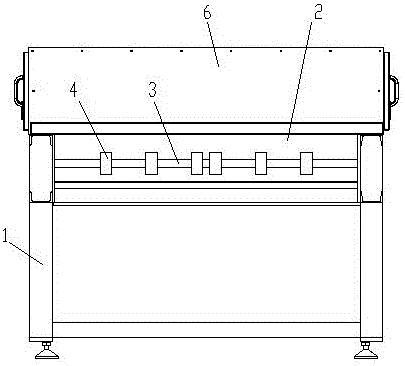

Light reflection single-box UV curing machine

PendingCN106000826AImprove light curing efficiencyOvercome Surface AgingPretreated surfacesCoatingsUV curingStructural engineering

A light reflection single-box UV curing machine comprises a rack. A conveying bin is arranged at the position, close to the top end, of the rack. A feeding opening and a discharging opening are formed in the left side and the right side of the conveying bin. A plurality of conveying shafts are arranged in the conveying bin in the horizontal direction side by side at intervals. The conveying shafts are sleeved with wear-resisting sleeves. UV lamps are arranged between the adjacent conveying shafts. UV boxes are arranged at the positions, right opposite to the upper portions of the UV lamps, of the top end of the conveying bin. Each UV lamp comprises a mounting support, a lampshade arranged on the support in a covering manner, a vertical UV lamp tube arranged in the center of the support and a hemispherical reflector arranged below the UV lamp tube. The height of the UV lamp tubes and the height of the hemispherical reflectors are smaller than the horizontal height of the conveying shafts. The structure of the UV lamps is improved, the incident angles and the arrangement positions of the UV lamps are changed, and therefore the light curing efficiency is greatly improved, and the problems that UV ink (gloss ink) surface layer aging, closing, embrittlement and the like happen, meanwhile, the adhesive force of ink (gloss ink) is poor, and the overprint interlayer binding force is poor are effectively solved.

Owner:YIXING FUSHENG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com