Method for preparing natural polymer matrix light-cured resin

A natural polymer, curing resin technology, applied in the field of photocurable materials, can solve problems such as deficiencies, and achieve the effects of improving comprehensive performance, improving photocrosslinking reaction efficiency, and enhancing interaction and coalescence strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

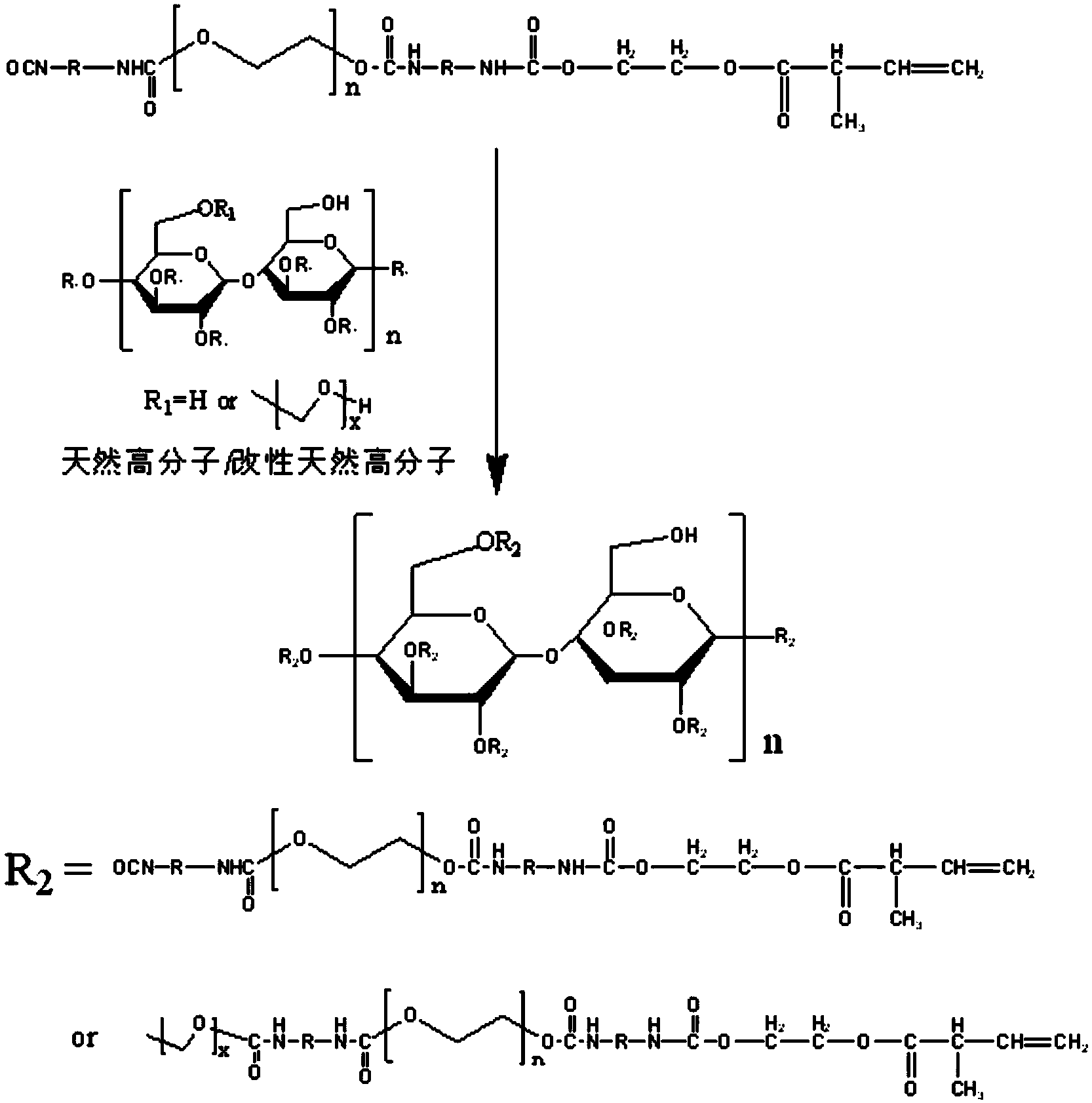

Method used

Image

Examples

Embodiment 1

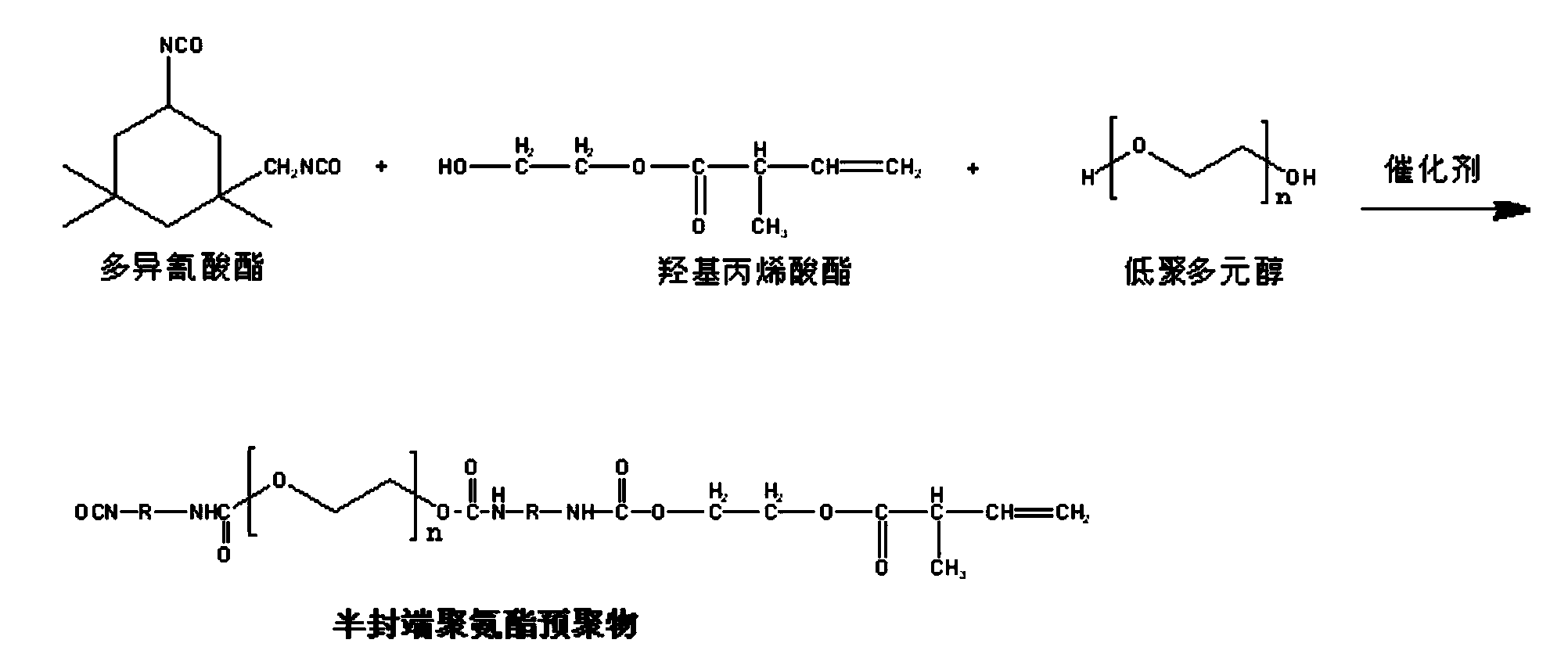

[0034] A preparation method of a natural polymer-based photocurable resin, comprising the following steps:

[0035] 1) Using butyl acetate as the reaction solvent and dibutyltin dilaurate as the catalyst, fully react isophorone diisocyanate (IPDI) and polyethylene glycol (PEG400), and then add hydroquinone (blocking Polymerization agent) and hydroxyethyl methacrylate (HEMA) are fully reacted to obtain semi-terminated polyurethane prepolymer. The specific operations are as follows:

[0036] Add 0.2mol isophorone diisocyanate (IPDI) and 15ml butyl acetate to a 250ml four-necked flask equipped with a stirrer, a thermometer and a condensation reflux tube, add 0.1mol dropwise with a dropping funnel while stirring at room temperature, and remove by molecular sieve Polyethylene glycol (PEG400) in water and 0.4229g dibutyltin dilaurate (0.5% of the total mass of isophorone diisocyanate and PEG400) were added dropwise and reacted at 80°C for 3 hours; 0.013g of hydroquinone (accounting...

Embodiment 2

[0042] A preparation method of a natural polymer-based photocurable resin, comprising the following steps:

[0043]1) Using ethyl acetate as the reaction solvent and stannous octoate as the catalyst, fully react dimethylene phenyl diisocyanate and polytetrahydrofuran diol 1400, and then add p-methoxyphenol (polymerization inhibitor) and methyl alcohol. Hydroxypropyl acrylate is fully reacted to obtain a semi-terminated polyurethane prepolymer, and the specific operations are as follows:

[0044] In a 500ml four-necked flask equipped with a stirrer, a thermometer and a condensing reflux tube, 0.2mol of dimethylene phenyl diisocyanate and 15ml of ethyl acetate were added, and 0.1 mol of water removed by molecular sieve was added dropwise with a dropping funnel while stirring at room temperature. mol polytetrahydrofuran diol 1400 and 1.2432g stannous octoate (accounting for 0.7% of the total mass of dimethylene phenyl diisocyanate and polytetrahydrofuran diol), react at 40 ° C fo...

Embodiment 3

[0053] A preparation method of a natural polymer-based photocurable resin, comprising the following steps:

[0054] 1) Using propyl acetate as the reaction solvent and dibutyltin dilaurate as the catalyst, fully react isophorone diisocyanate (IPDI) and polyethylene glycol (PEG600), and then add hydroquinone (blocking polymerizing agent) and hydroxyethyl acrylate to fully react to obtain a semi-terminated polyurethane prepolymer. The specific operations are as follows:

[0055] Add 0.2mol isophorone diisocyanate (IPDI) and 15ml propyl acetate to a 250ml four-necked flask equipped with a stirrer, a thermometer and a condensing reflux tube, and use a dropping funnel to drop the water-removed molecular sieve solution at room temperature while stirring. Polyethylene glycol (PEG600) 0.1mol and 0.6275g dibutyltin dilaurate (accounting for 0.6% of the total mass of isophorone diisocyanate and PEG400.), react at 40°C after the dropwise addition; 0.0413 g of hydroquinone (accounting fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com