A kind of adenine enhanced degradable soft tissue adhesive and its preparation and use method

A technology of adenine and soft tissue, applied in surgical adhesives, application, surgery, etc., can solve the problem of low adhesion strength, achieve high glass transition temperature, improve degradation performance, and excellent degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Concrete preparation process comprises the following steps:

[0048] Step 1: PPF and PPF-DA are accurately weighed with a double bond ratio of 1:2 and placed in a round bottom flask containing 20mL-25mL of dichloromethane.

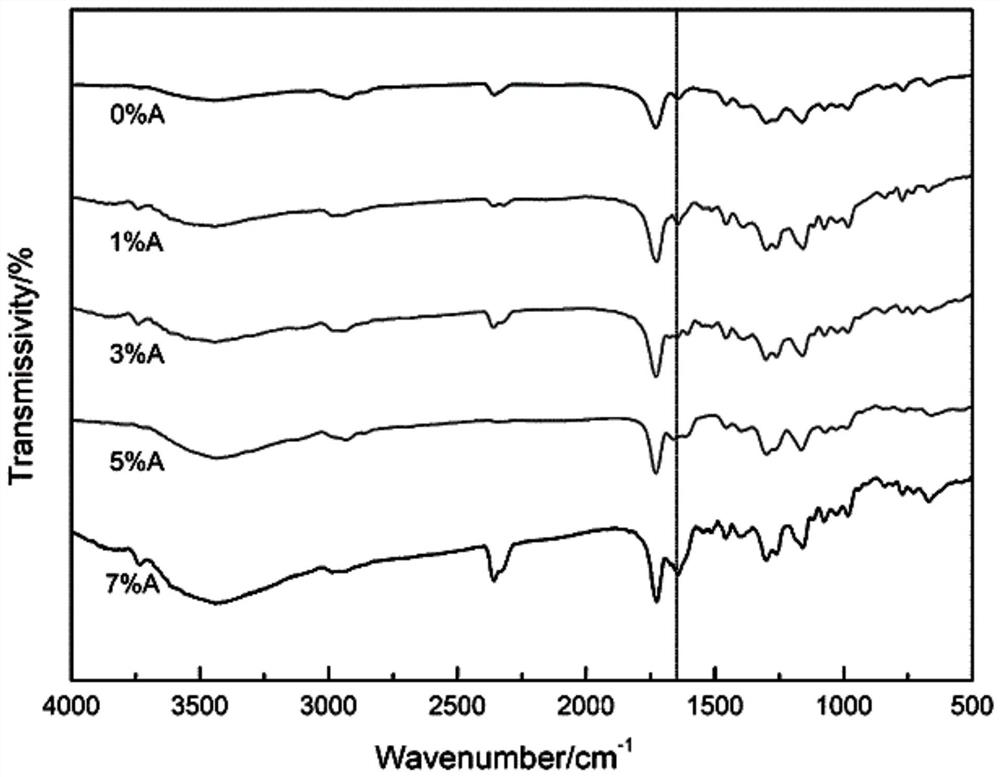

[0049] Step 2, add adenine with a mass ratio of 1%-7% of the total mass of PPF, PPF-DA and adenine to the mixed system obtained in step 1, and stir with a magnetic stirrer for 0.5h to completely dissolve PPF and PPF-DA , adenine is diffusely distributed, and mixture A is obtained.

[0050] Step 3, under vacuum condition, the dichloromethane solvent in the mixture A was removed by rotary evaporation. The rotary evaporation time is 0.67h-0.75h, the temperature is 30°C-35°C, the vacuum degree is not higher than 0.09MPa, and the mixture B is obtained. During the rotary evaporation, the temperature is gradually raised from 30°C to 35°C.

[0051] Step 4, adding the photoinitiator BAPO solution whose mass proportion is 1.5% of the total mass of the mixtu...

Embodiment 1

[0058] Put PPF and PPF-DA at a double bond ratio of 1:2 and a mass ratio of 1:2.08, accurately weigh 0.48g of PPF, and place 1g of PPF-DA in a round-bottomed flask containing 20mL of dichloromethane. Take adenine 0.0149g with an analytical balance and place it in the above-mentioned PPF and PPF-DA mixed system (the quality of adenine in this embodiment is 1% of the total mass of PPF, PPF-DA and adenine), place the round bottom flask Stir with a magnetic stirrer at a speed of 400r / min for 0.5h to completely dissolve PPF and PPF-DA, and adenine is dispersed in the mixed solution. Under vacuum conditions not higher than 0.09MPa, set the temperature of the rotary evaporator water bath to 30°C, keep it for 13 minutes, raise it to 33°C, keep it for 13 minutes, finally raise it to 35°C, keep it for 14 minutes, and rotate it together 0.67h to remove dichloromethane solvent. Using a pipette gun, pipette 224 μL of the 0.1 g / mL photoinitiator BAPO solution into the above-mentioned round...

Embodiment 2

[0060] Put PPF and PPF-DA at a double bond ratio of 1:2 and a mass ratio of 1:2.08, accurately weigh 0.48g of PPF, and place 1g of PPF-DA in a round-bottomed flask containing 20mL of dichloromethane. Take adenine 0.0458g with an analytical balance and place it in the above-mentioned PPF and PPF-DA mixed system (the quality of adenine in this embodiment is 3% of the total mass of PPF, PPF-DA and adenine), and place the round bottom flask Stir with a magnetic stirrer at a speed of 400r / min for 0.5h to completely dissolve PPF and PPF-DA, and adenine is dispersed in the mixed solution. Under vacuum conditions not higher than 0.09MPa, set the temperature of the rotary evaporator water bath to 30°C, keep it for 13 minutes, raise it to 33°C, keep it for 13 minutes, finally raise it to 35°C, keep it for 14 minutes, and rotate it together 0.67h to remove dichloromethane solvent. Using a pipette gun, pipette 229 μL of the 0.1 g / mL photoinitiator BAPO solution into the above-mentioned r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com