Ultraviolet-cured biomass methacrylate and/or acrylate prepolymer and preparation method thereof

A technology of methacrylate and hydroxymethacrylate, applied in the field of ultraviolet light curing biomass methacrylate and/or acrylate prepolymer and its preparation, can solve the problem of reducing the mechanical properties and optical properties of the consolidated body , increase cost, poor flexibility and other problems, to achieve the effect of simple and controllable synthesis method, reducing use, increasing flexibility and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

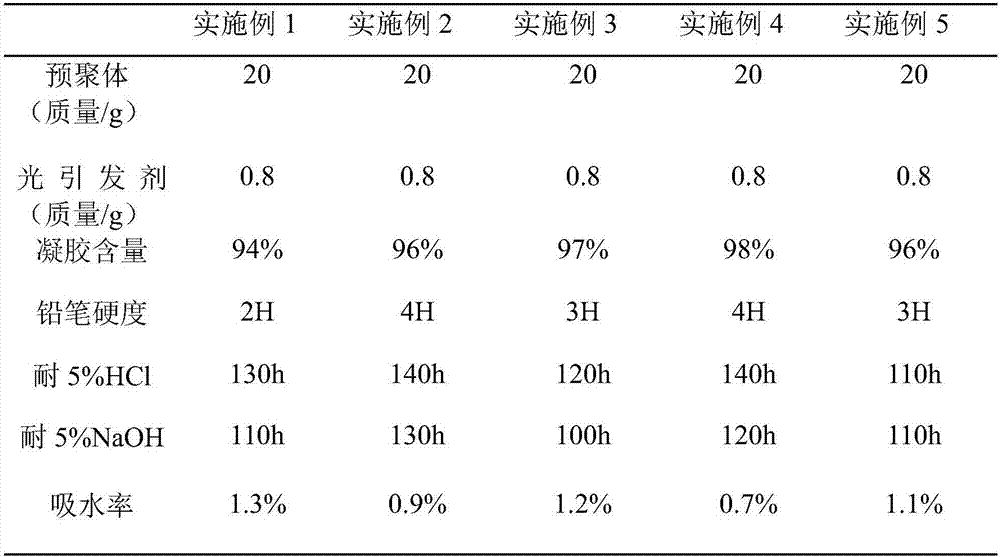

Examples

Embodiment 1

[0032] 1. Mix 18.8g of m-xylylene diisocyanate and 0.16g of dibutyltin dilaurate, blow in nitrogen, keep the temperature at 5°C, and slowly add it dropwise to 13.0ml containing 30ml of DMF under magnetic stirring. g of hydroxybutyl methacrylate solution, the dropwise addition time is 1.5h, the dropwise addition is completed and reacted for 4h, and then the temperature is raised to 25° C., and reacted for 3h to obtain a prepolymer (I) of one-end-blocked diisocyanate.

[0033] 2. Mix 13.5g of cardanol, 10.9g of 4-chloro-1,3-butanediol and 30ml of absolute ethanol, and maintain the temperature at 70°C under magnetic stirring, and add dropwise 19g of 20% hydroxide by mass fraction Add sodium for 1 hour, react for 18 hours; cool, filter the precipitated salt, wash with distilled water, and distill ethanol and water under reduced pressure at 65°C to synthesize cardanol etherified diol (II).

[0034] 3. above-mentioned prepolymer (I) is mixed with 0.16g drop dibutyltin dilaurate, und...

Embodiment 2

[0036] 1. Mix 25.0g of diphenylmethylene diisocyanate and 0.16g of stannous octoate drops, pass nitrogen gas, keep the temperature at 0°C, and slowly add dropwise to 12.4g of 27ml of DMF under the condition of magnetic stirring The hydroxypropyl acrylate solution was added dropwise for 1 hour. After the dropwise addition, the reaction was carried out for 3 hours, and then the temperature was raised to 20° C., and the reaction was carried out for 4 hours to obtain a prepolymer (I) of diisocyanate blocked at one end.

[0037] 2. Mix 13.2g of cardanol, 10.2g of 4-chloro-1,3-butanediol and 32.1ml of absolute ethanol, under magnetic stirring, keep the temperature at 65°C, add dropwise 23.5g of 15 % sodium hydroxide, dropwise time is 0.5h, react for 20h; cool, filter the precipitated salt, wash with distilled water, distill ethanol and water under reduced pressure at 60°C to synthesize cardanol etherified diol (II).

[0038] 3. Mix the above-mentioned prepolymer (I) with 0.16g drops...

Embodiment 3

[0040] 1. Mix 26.2g of dicyclohexylmethane diisocyanate and 0.16g of bis(dodecylsulfide) dibutyltin, feed nitrogen, maintain the temperature at 10°C, and slowly Add dropwise to 11.7g of hydroxyethyl methacrylate solution containing 31ml of DMF for 2 hours. After the dropwise addition, react for 5 hours, then raise the temperature to 30°C and react for 2 hours to obtain a prepolymerized diisocyanate with one end blocked. Object (I).

[0041] 2. Mix 15.6g of cardanol, 13.3g of 4-chloro-1,3-butanediol and 31.9ml of absolute ethanol, under magnetic stirring, keep the temperature at 75°C, add dropwise 19.7g of 25% mass fraction Add sodium hydroxide for 1.5 hours, react for 15 hours; cool, filter the precipitated salt, wash with distilled water, and distill ethanol and water under reduced pressure at 70°C to synthesize cardanol etherified diol (II).

[0042] 3. Mix the above-mentioned prepolymer (I) with 0.16 drops of dibutyltin di(dodecylsulfide), under the state of magnetic stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com