Patents

Literature

34results about How to "Quick seal connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

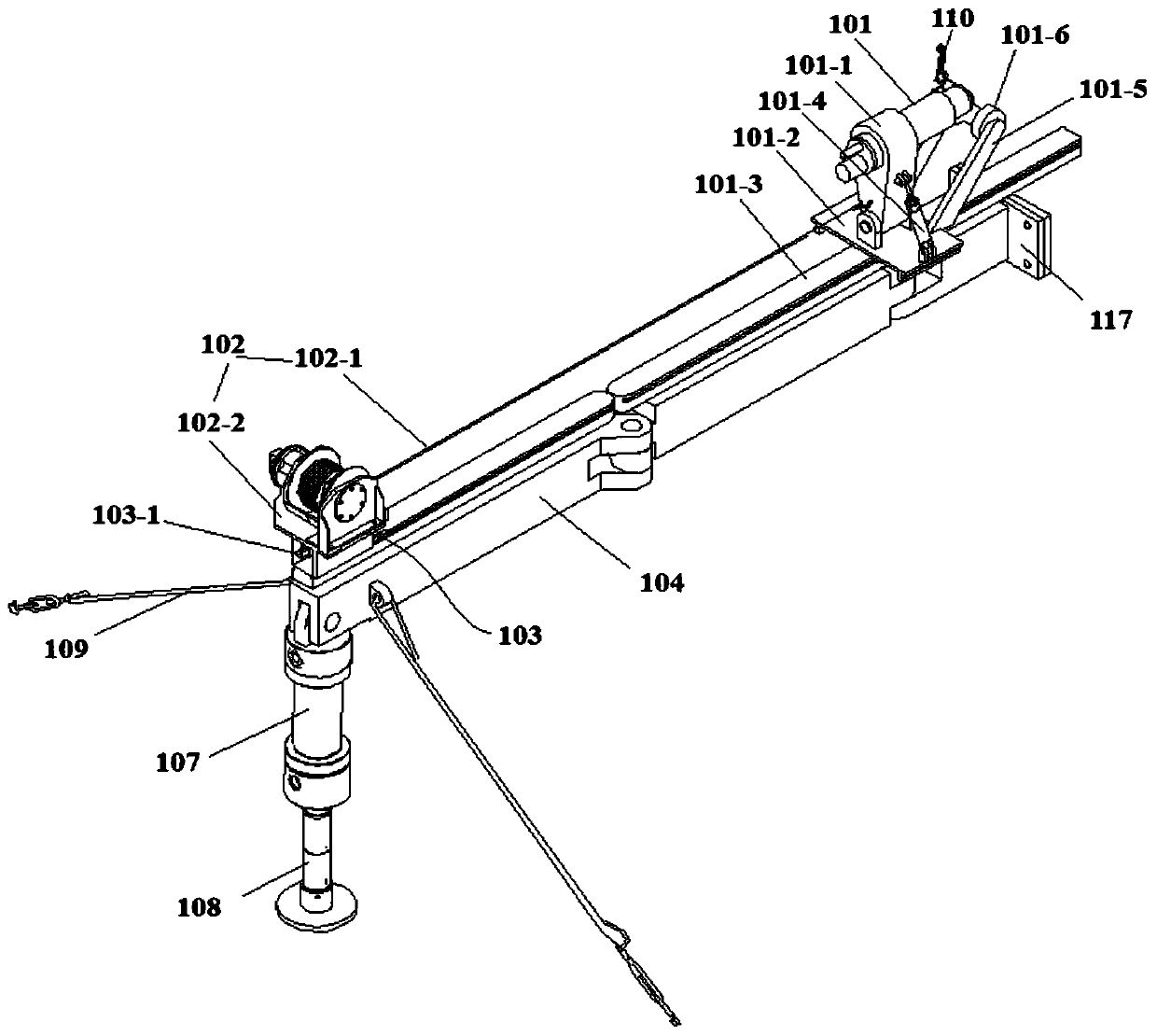

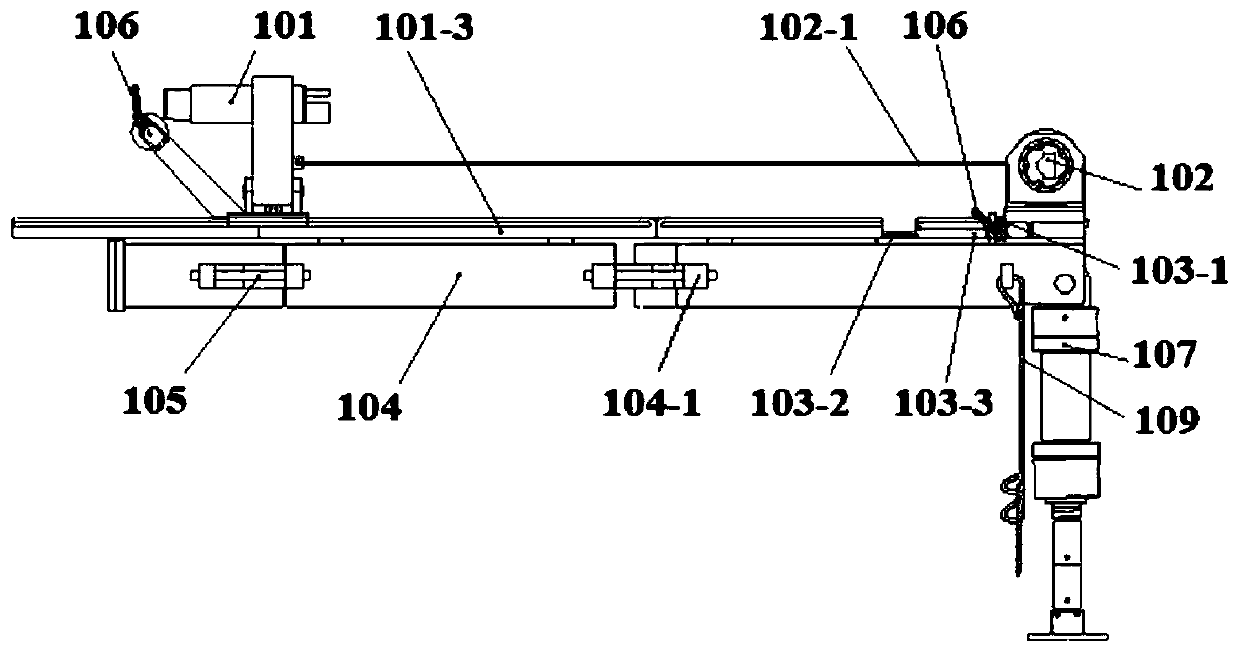

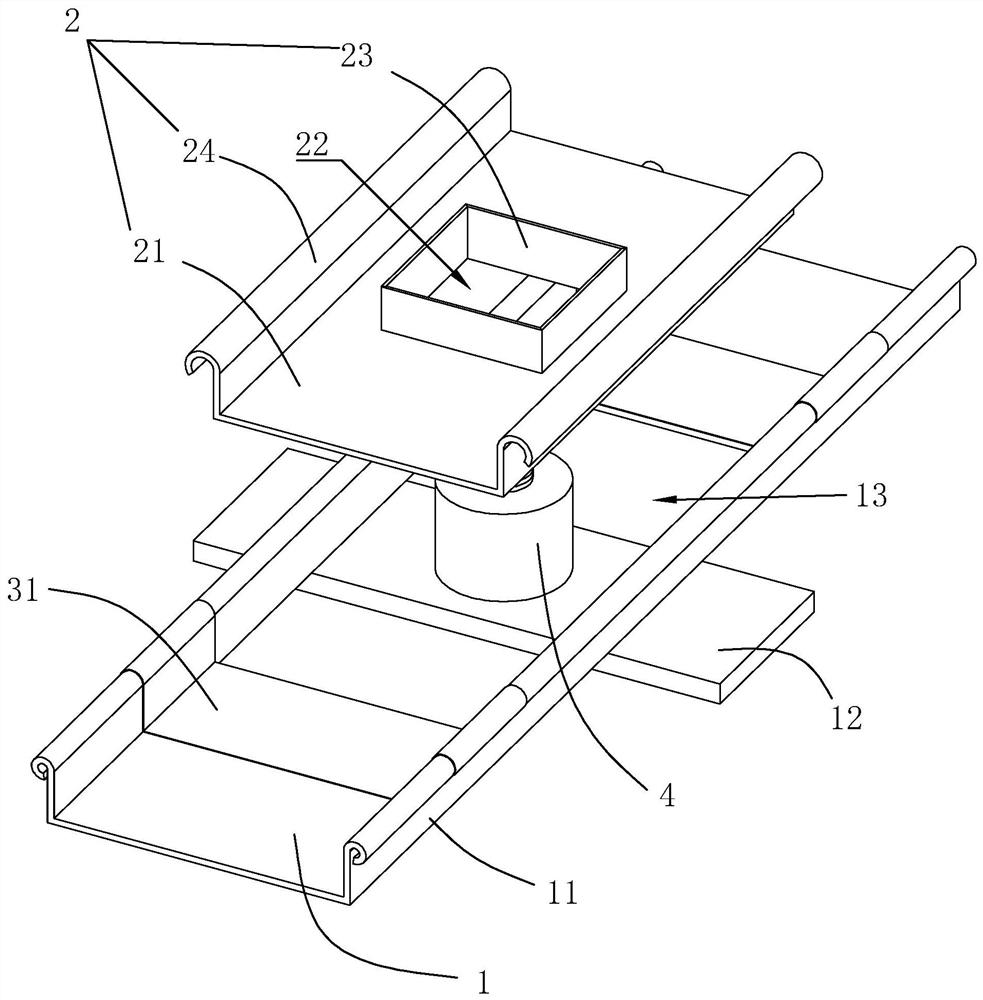

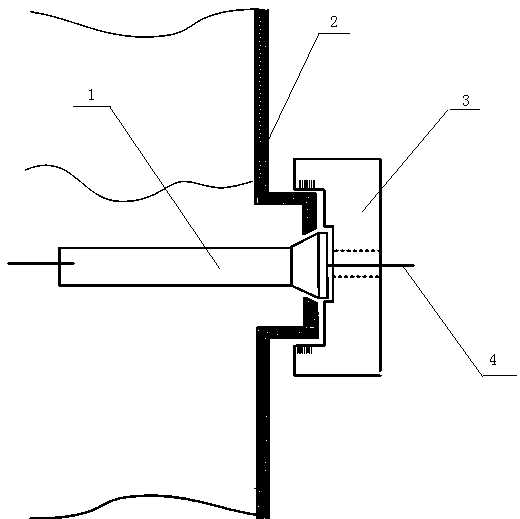

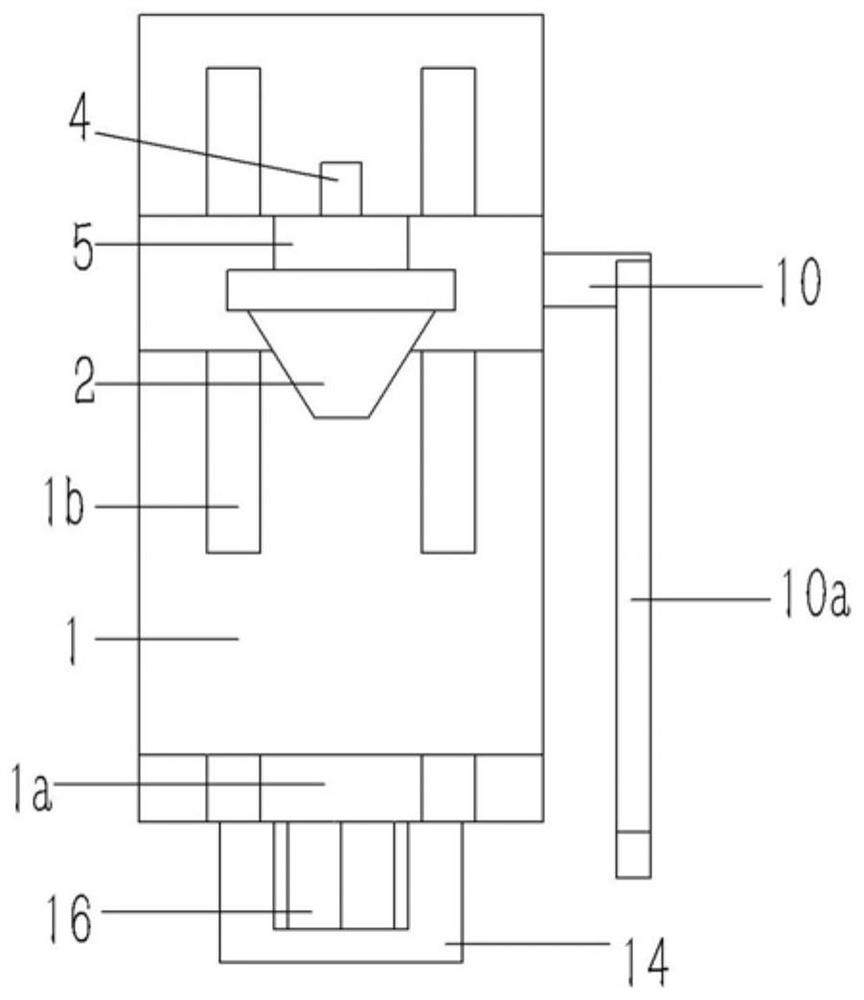

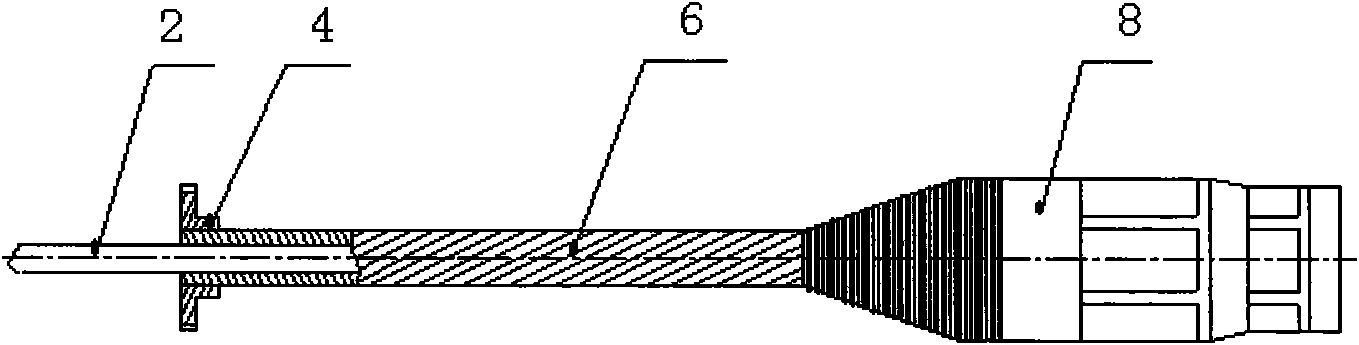

Automatic assembling and disassembling drill rod for mining drilling machine, water feeder unit, device and construction method

ActiveCN109736728AImprove automationCompact structureDrilling rodsDirectional drillingEngineeringWinch

The invention discloses an automatic assembling and disassembling drill rod for a mining drilling machine, a water feeder unit, a device and a construction method. Included are a water feeder support,a hydraulic winch connected with the water feeder support to pull the water feeder support to separate a water feeder from a drill rod, and a pushing unit located between the water feeder support andthe hydraulic winch to push the water feeder support to enable the water feeder to be connected with the drill rod. The water feeder support is movably installed on a water feeder guide rail througha movable plate; and the water feeder guide rail is arranged on a guide rail support. The hydraulic winch is mounted on a guide rail support; a steel wire rope of the hydraulic winch is connected withthe water feeder support; and a pushing unit is arranged on the guide rail support between the water feeder guide rail and the hydraulic winch, and can push the water feeder support to move along thewater feeder guide rail. The technical problems of a power head rear rod adding mode and automatic assembling and disassembling of a medium drill rod and long drill rod in a coal mine underground directional drilling process are solved, instant assembly and disassembly of the water feeder and the drill rod can be achieved, and the drilling efficiency can be effectively improved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

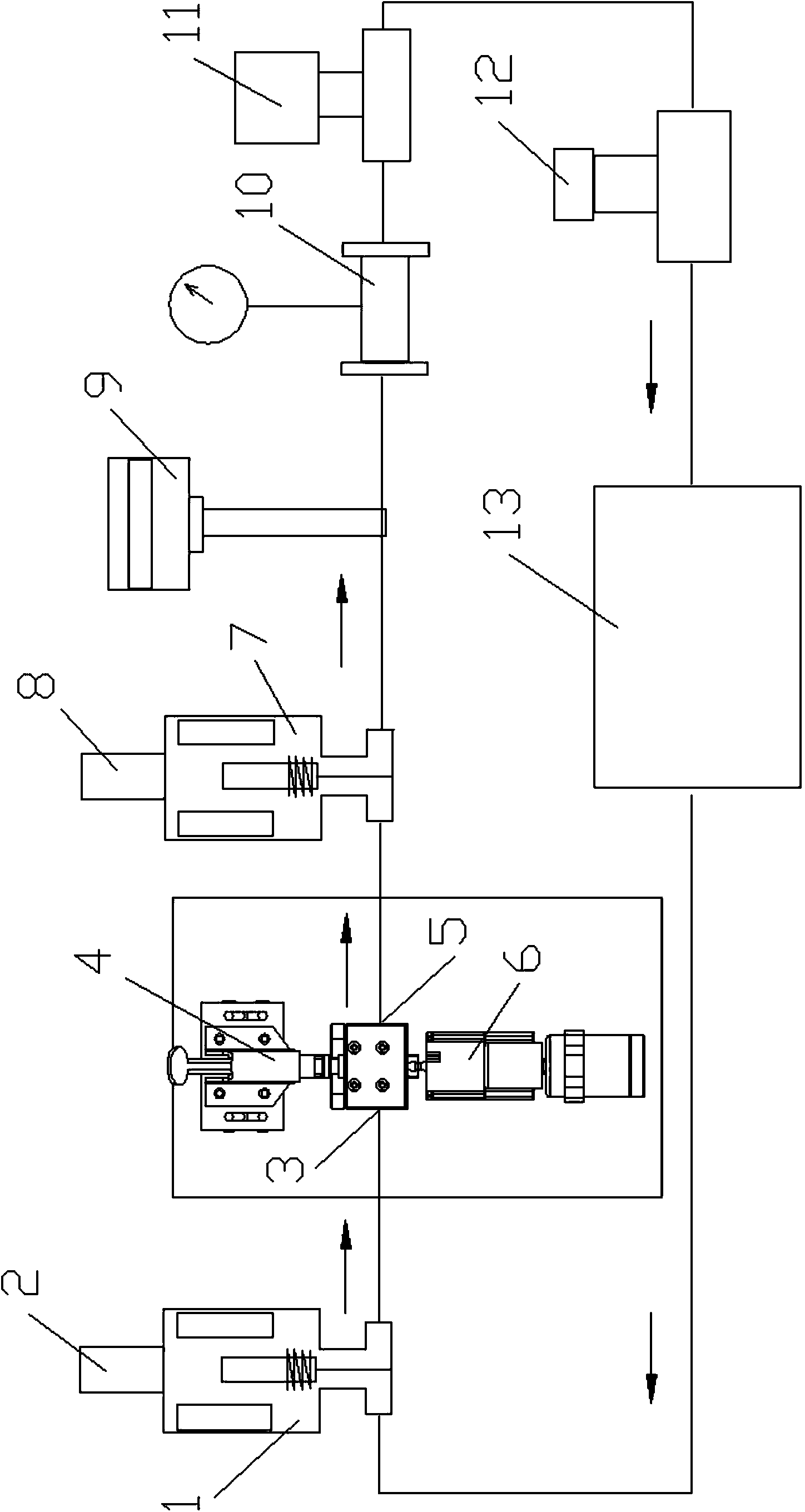

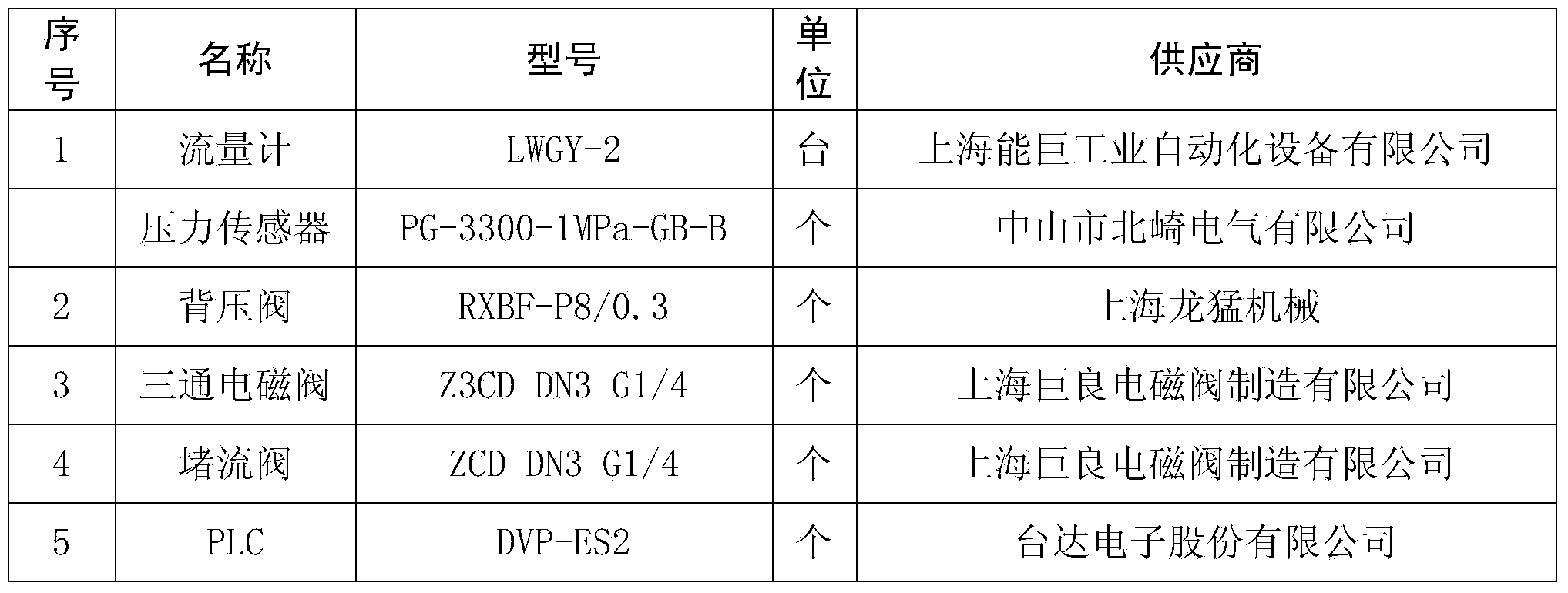

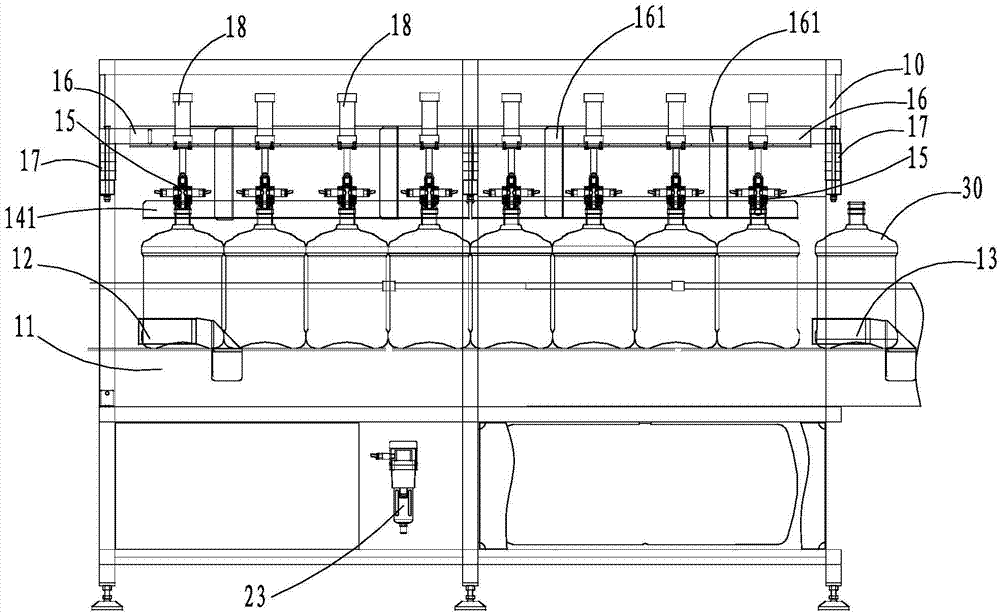

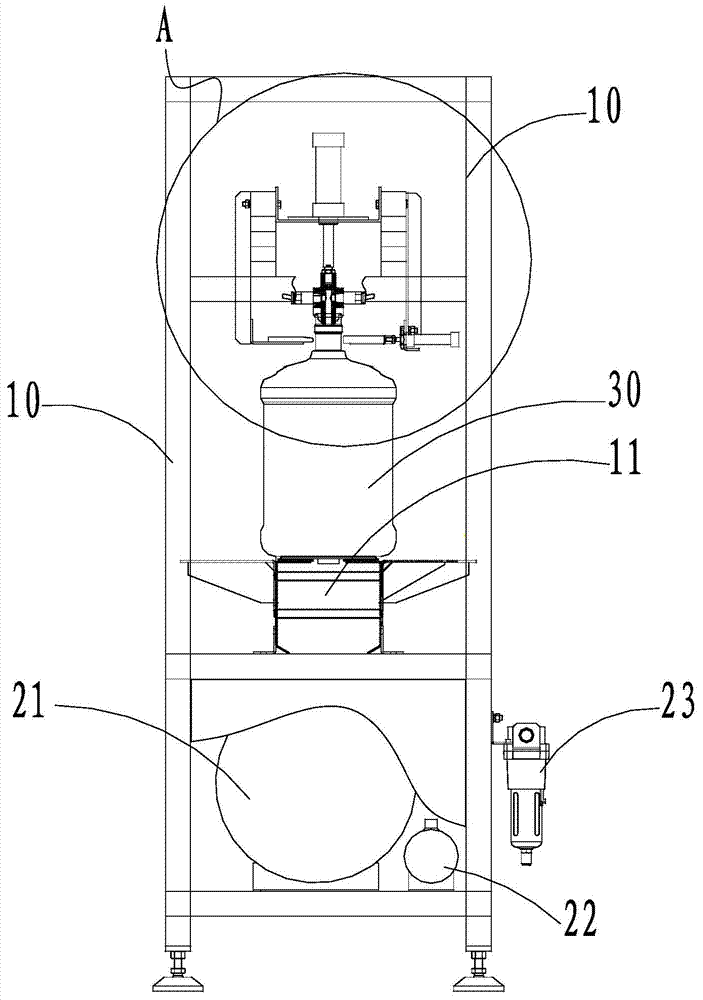

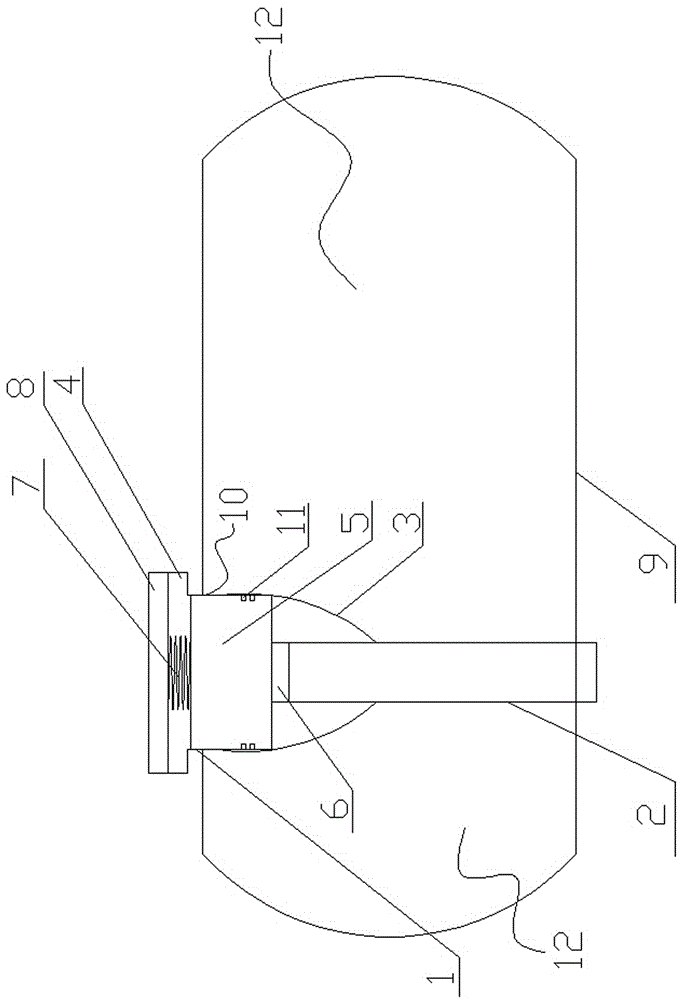

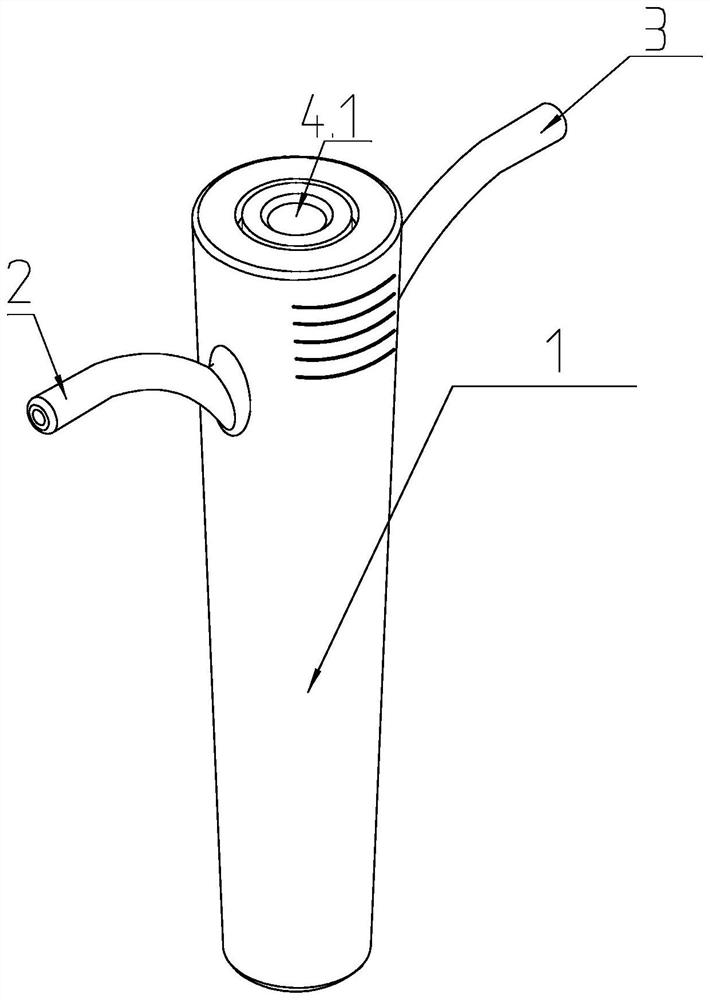

Water pump comprehensive automatic test system

InactiveCN104061150AGood sealingLower skill requirementsPump testingPositive-displacement liquid enginesElectric machineryCombined test

A water pump comprehensive automatic test system is characterized by comprising a water inlet end three-way solenoid valve (1), a water pump comprehensive test fast assembling clamp (4), a to-be-tested water pump (6), a water outlet end three-way solenoid valve (7), a flow sensor (10), a flow blocking valve (11), a back pressure regulating valve (12) and a circulation water tank (13). The water pump comprehensive automatic test system has the advantages that the to-be-tested water pump is arranged in a clamp body, fast sealing connection of a water inlet and a water outlet of the water pump and a measurement water channel is achieved rapidly by operators through a fast clamping mechanism, a circuit between a water pump motor and a test power supply is switched on synchronously, and the clamping efficiency of the to-be-tested water pump is improved.

Owner:CHANGZHOU HAOSHENG MOTOR +1

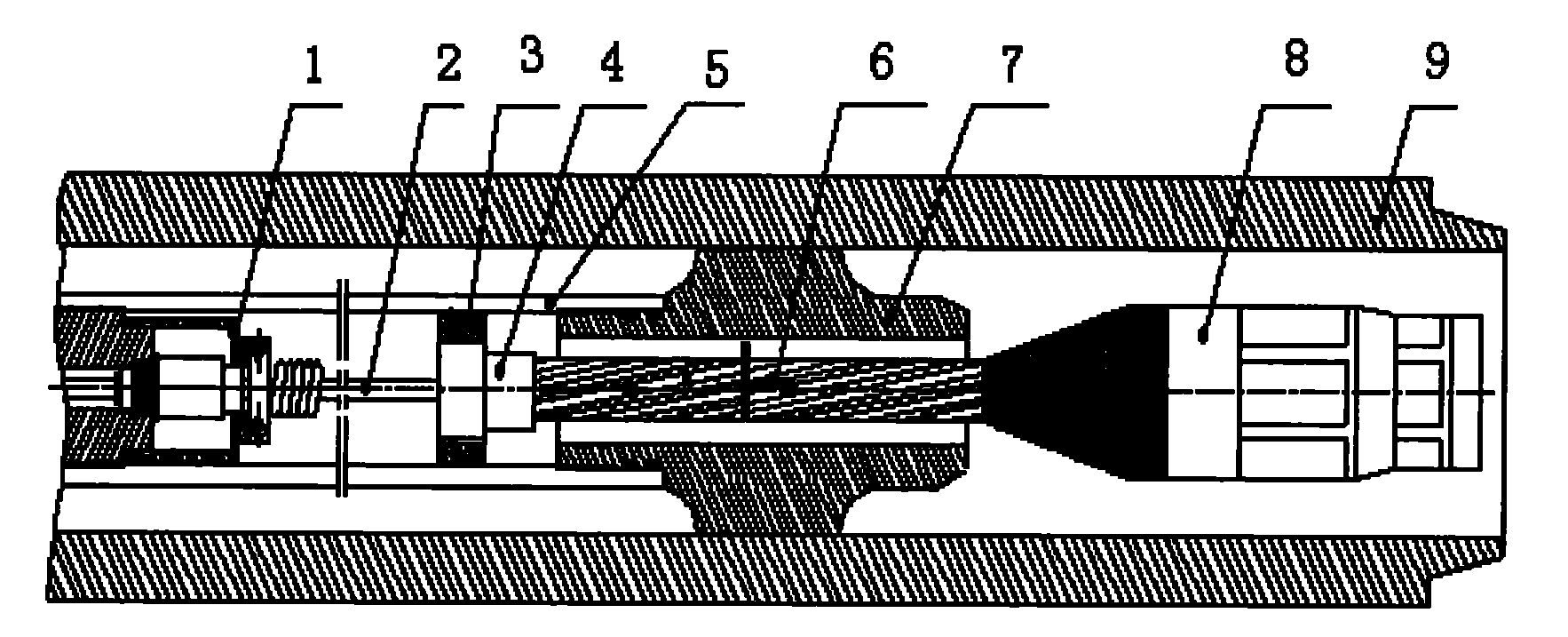

Flexible connection device of logging-while-drilling instrument

ActiveCN102400671AReduce connection difficultySatisfy data transmissionSurveyData transmissionEngineering

The invention relates to a flexible connection device of a logging-while-drilling instrument. The flexible connection device consists of a cable fixing box, a cable, a limiting sleeve, a fixed block, a flexible telescopic rod, a centralizing joint, a flexible connector shell and a quick plug, wherein the centralizing joint is positioned in a central hole of a drilling rod, and the outer diameter of the centralizing joint is matched with that of the central hole of the drilling rod; the flexible connector shell is positioned in the central hole of the drilling rod, and the lower end is fixed on the centralizing joint; the cable fixing box is positioned at the inner upper end of the flexible connector shell; a pressing plate is arranged on the cable fixing box; the upper end of the cable is fixed by using the pressing plate; the limiting sleeve is positioned inside the flexible connector shell and outside the central hole of the centralizing joint and connected with an upper end face of the fixed block; a lower end face of the fixed block is connected with the flexible telescopic rod; the flexible telescopic rod passes through the central hole of the centralizing joint and is connected with the quick plug; and the lower end of the cable passes through the limiting sleeve, the fixed block and the central hole of the flexible telescopic rod and is connected with the quick plug. By adoption of the flexible connection device, data transmission and up-down power supplying can be realized. With near-term well-site actual operation, the flexible connection device is extremely low in fault rate and good in effect.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

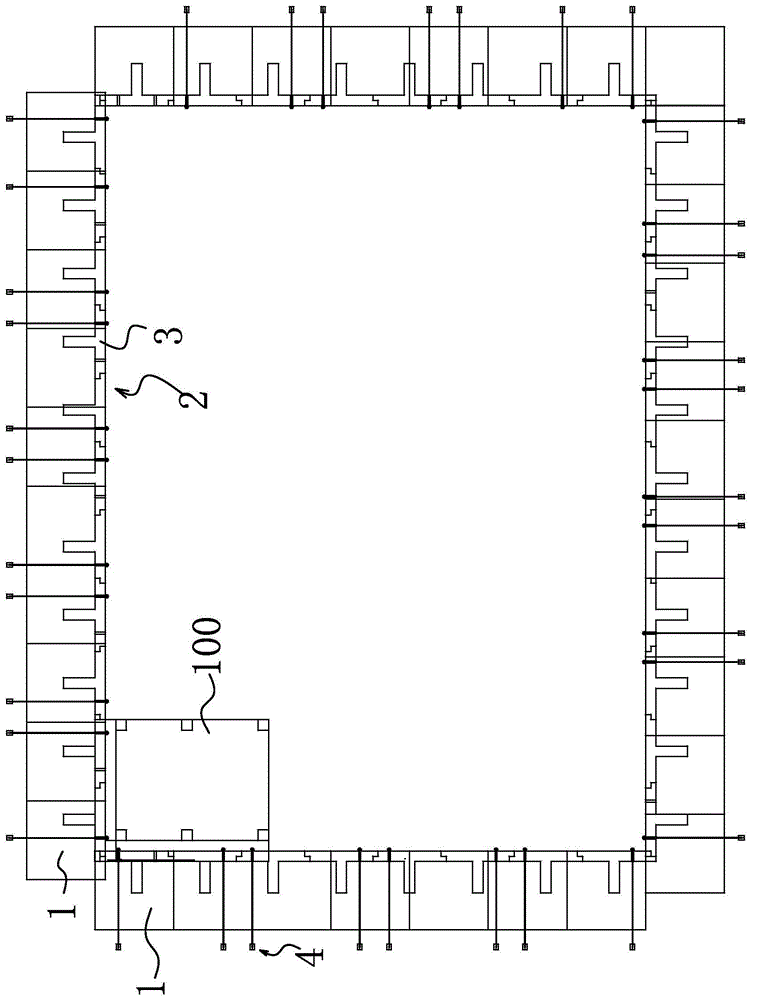

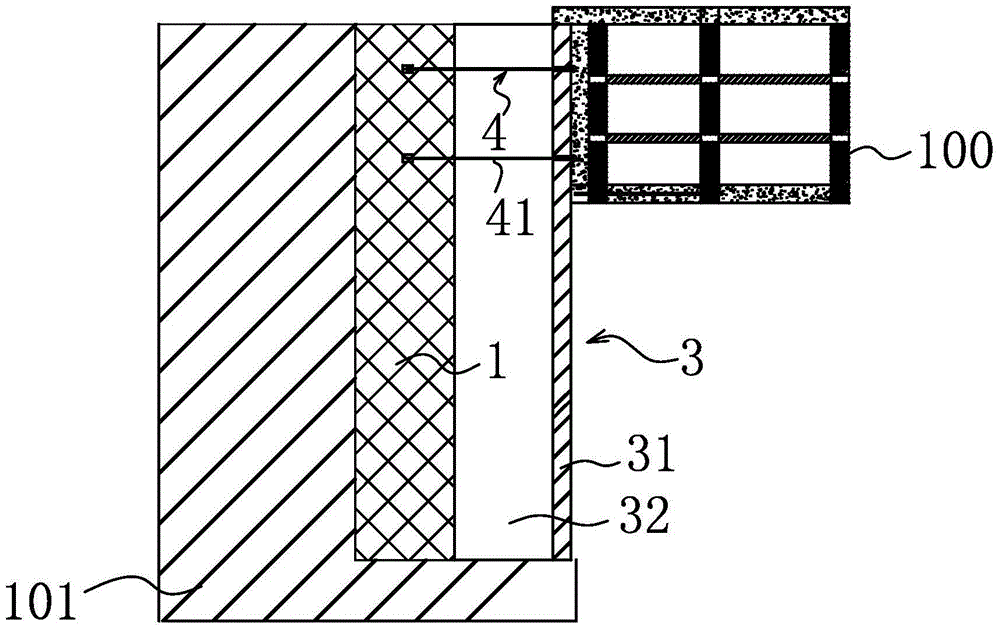

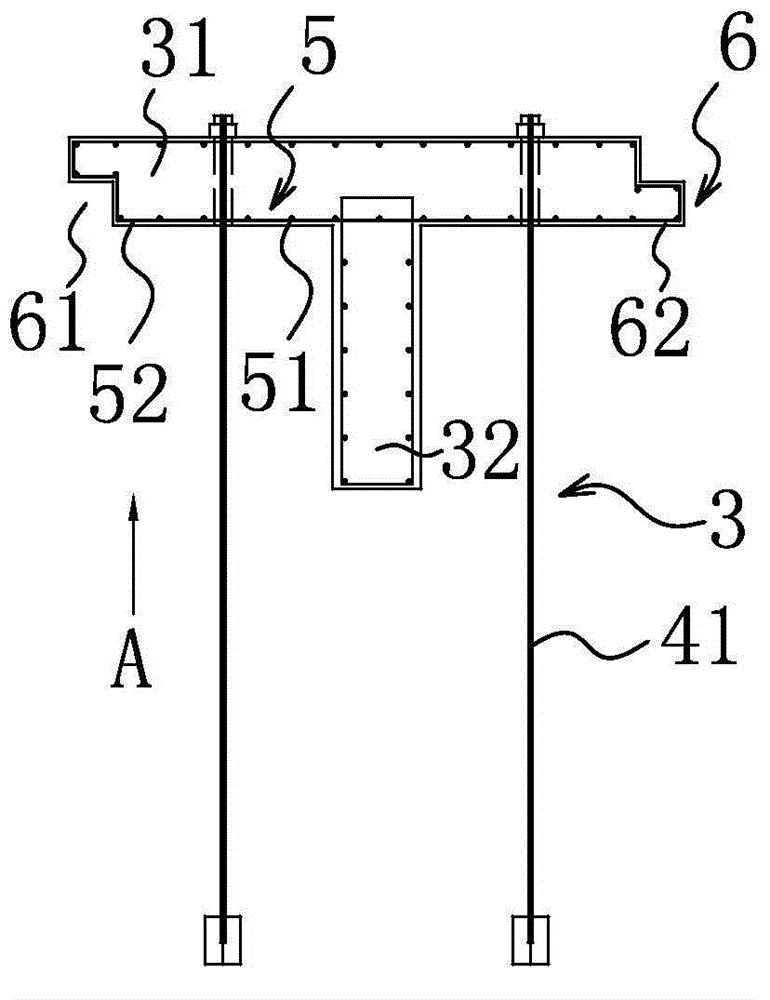

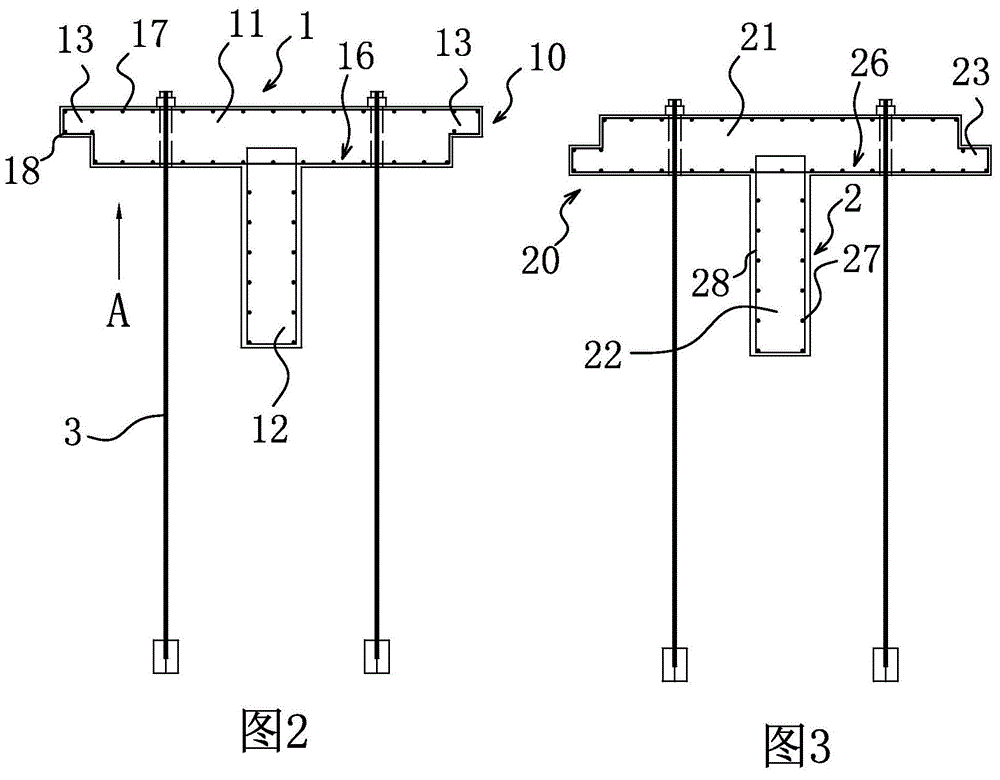

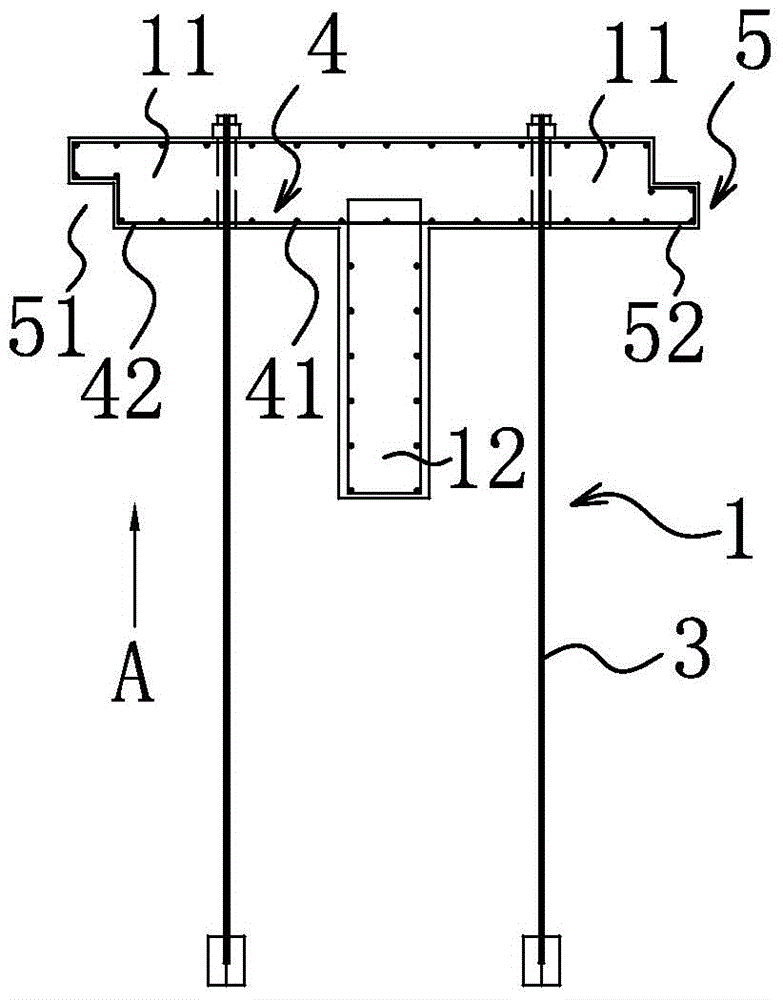

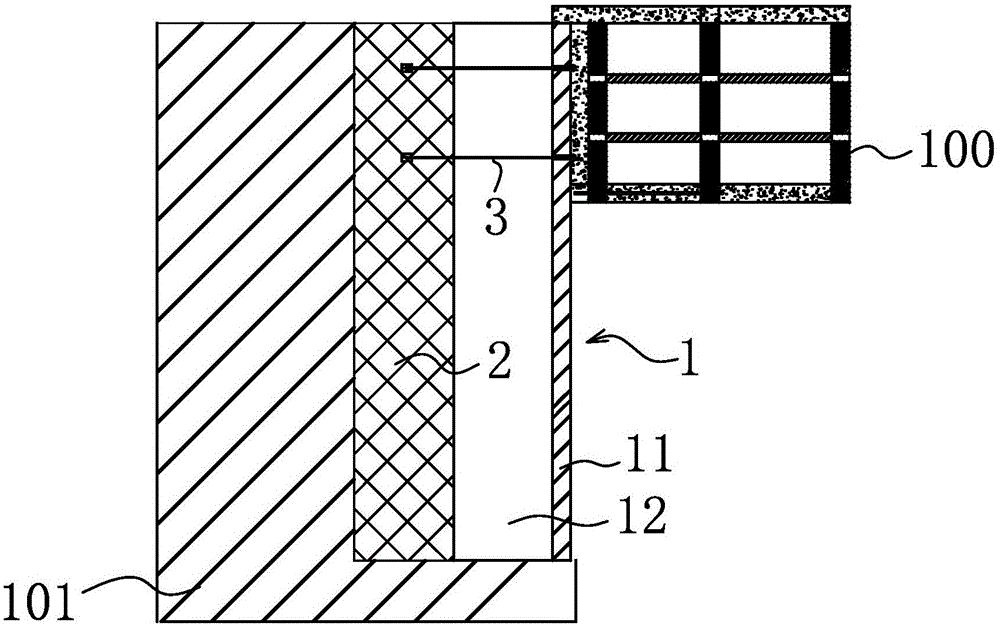

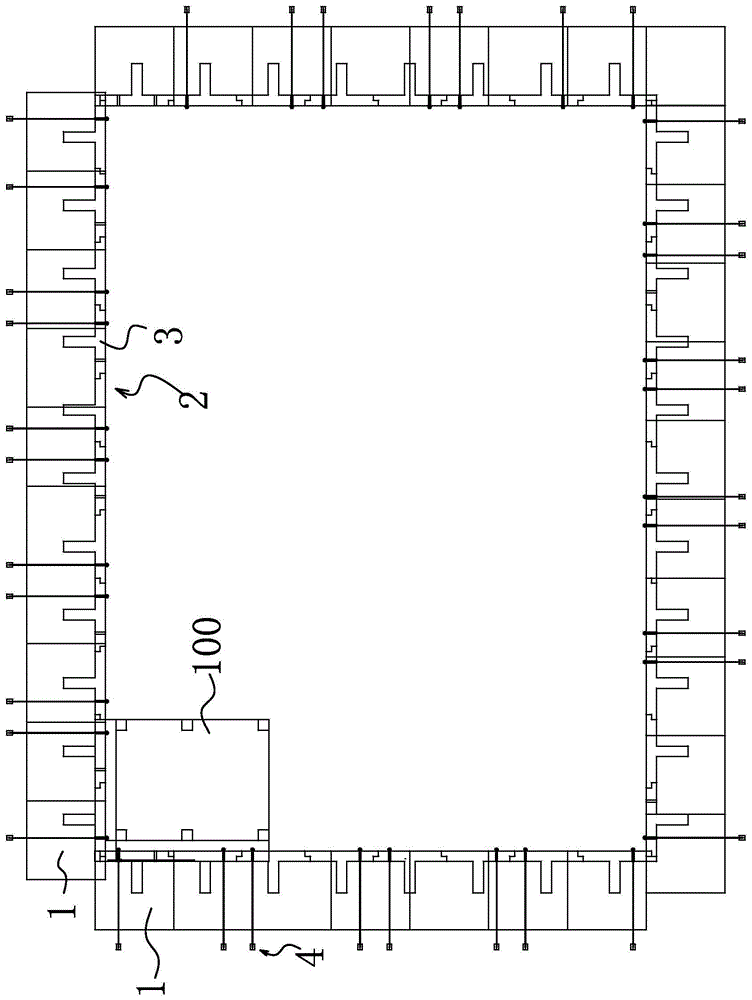

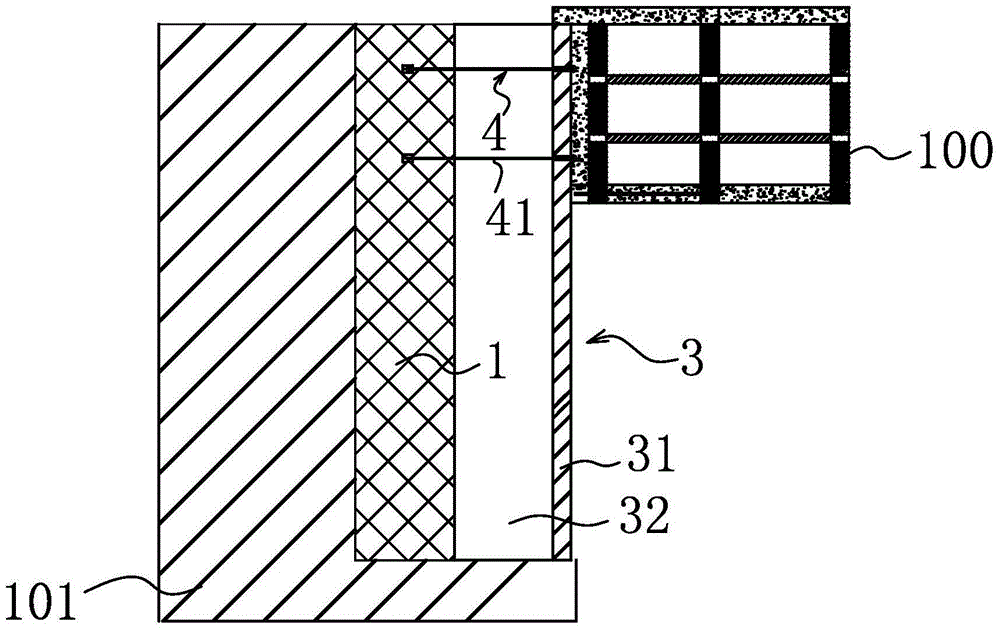

Composite fender pile for building basement

ActiveCN105019472AImprove waterproof performanceImprove sealingArtificial islandsUnderwater structuresBasementStructural engineering

The invention belongs to the technical field of buildings, and relates to a composite fender pile for building a basement. The technical problem that the strength is low in the prior art is solved. The composite fender pile for building the basement comprises composite piles and fender piles. The composite piles are arranged along the circumference of the basement and are connected with one another to form a closed annular structure. The fender piles are surrounded outside the basement and are fixedly connected with the composite piles. The composite fender pile for building the basement has the advantages of being high in strength, good in stability, convenient to manufacture and the like.

Owner:周兆弟

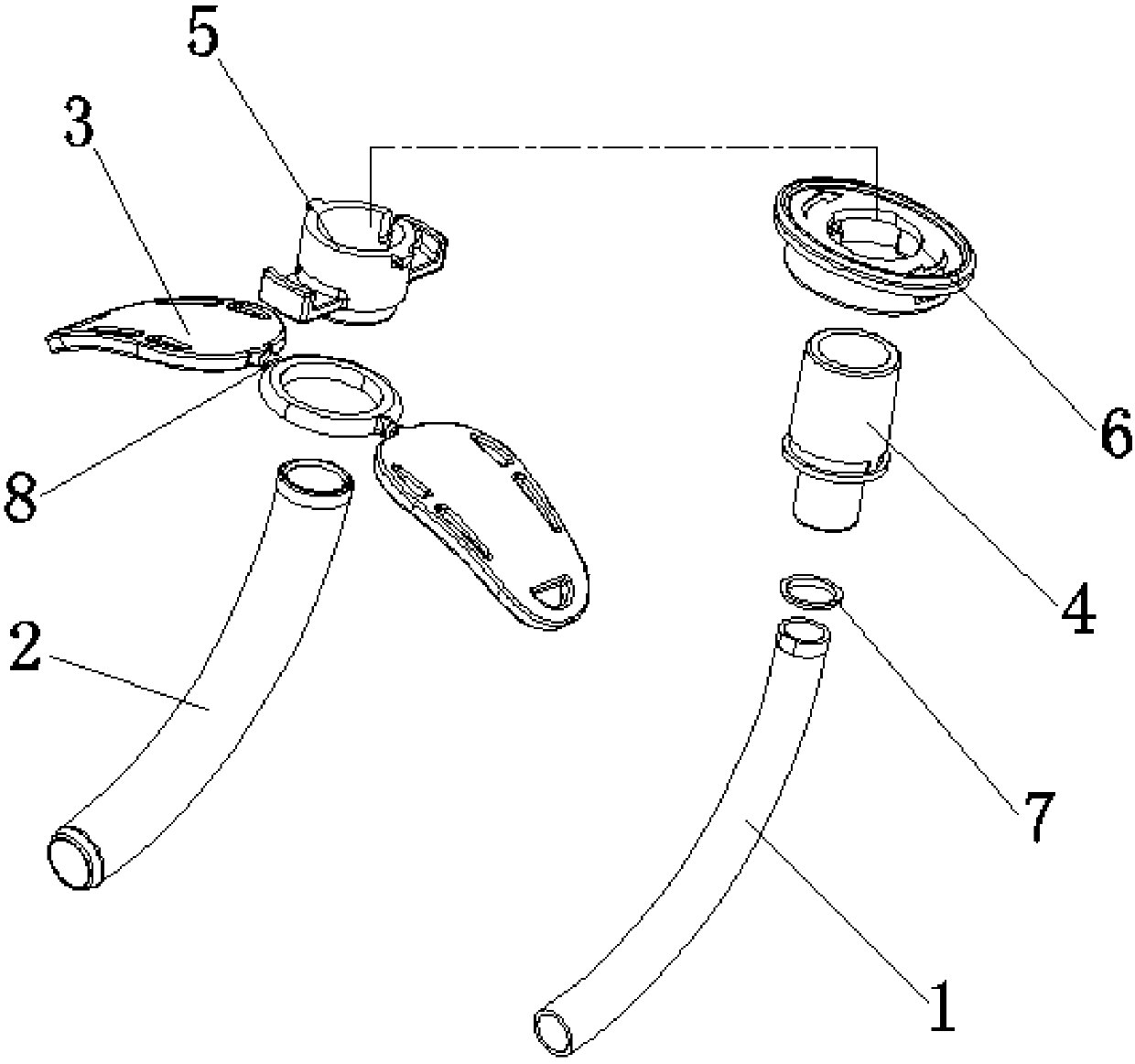

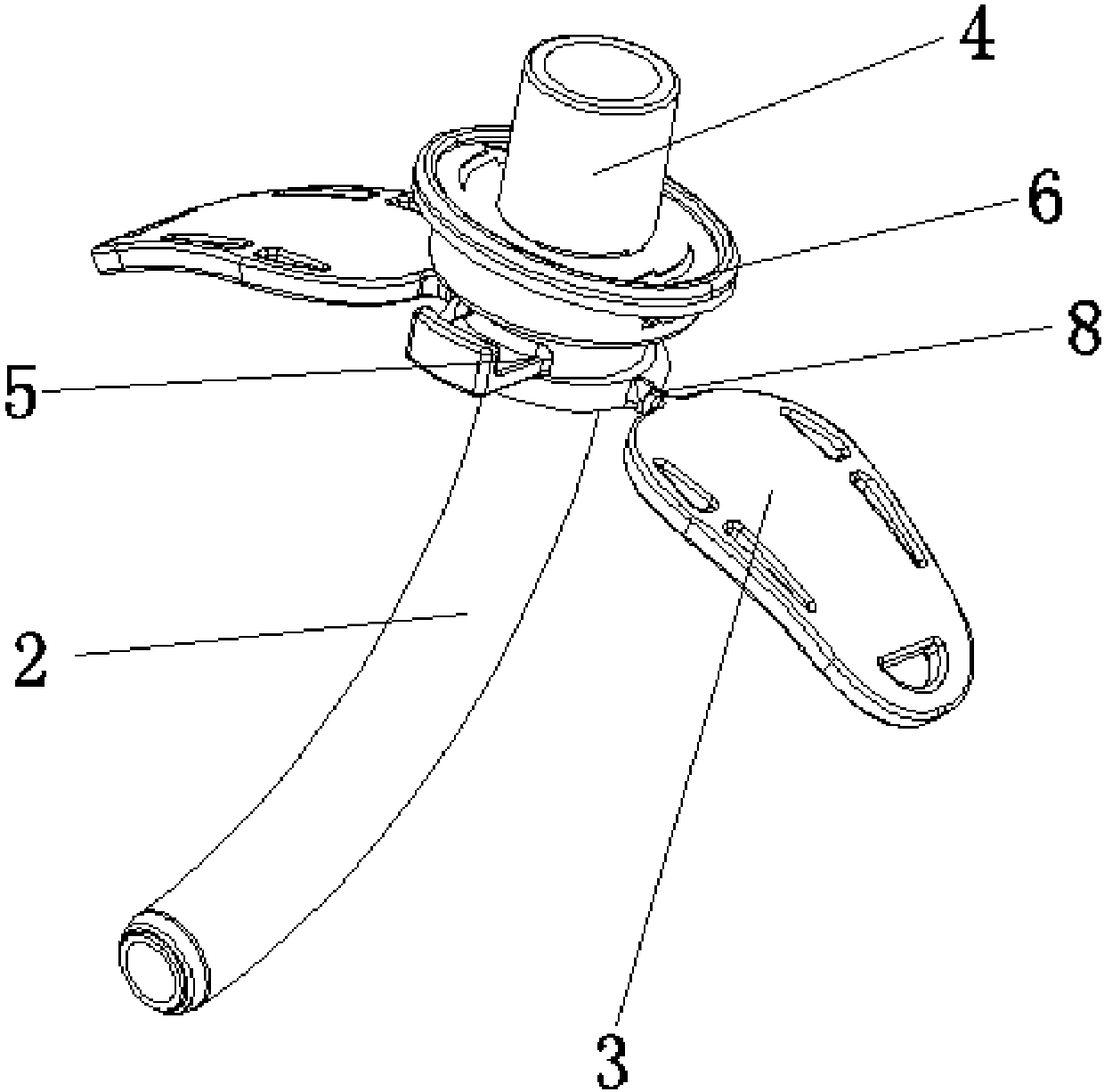

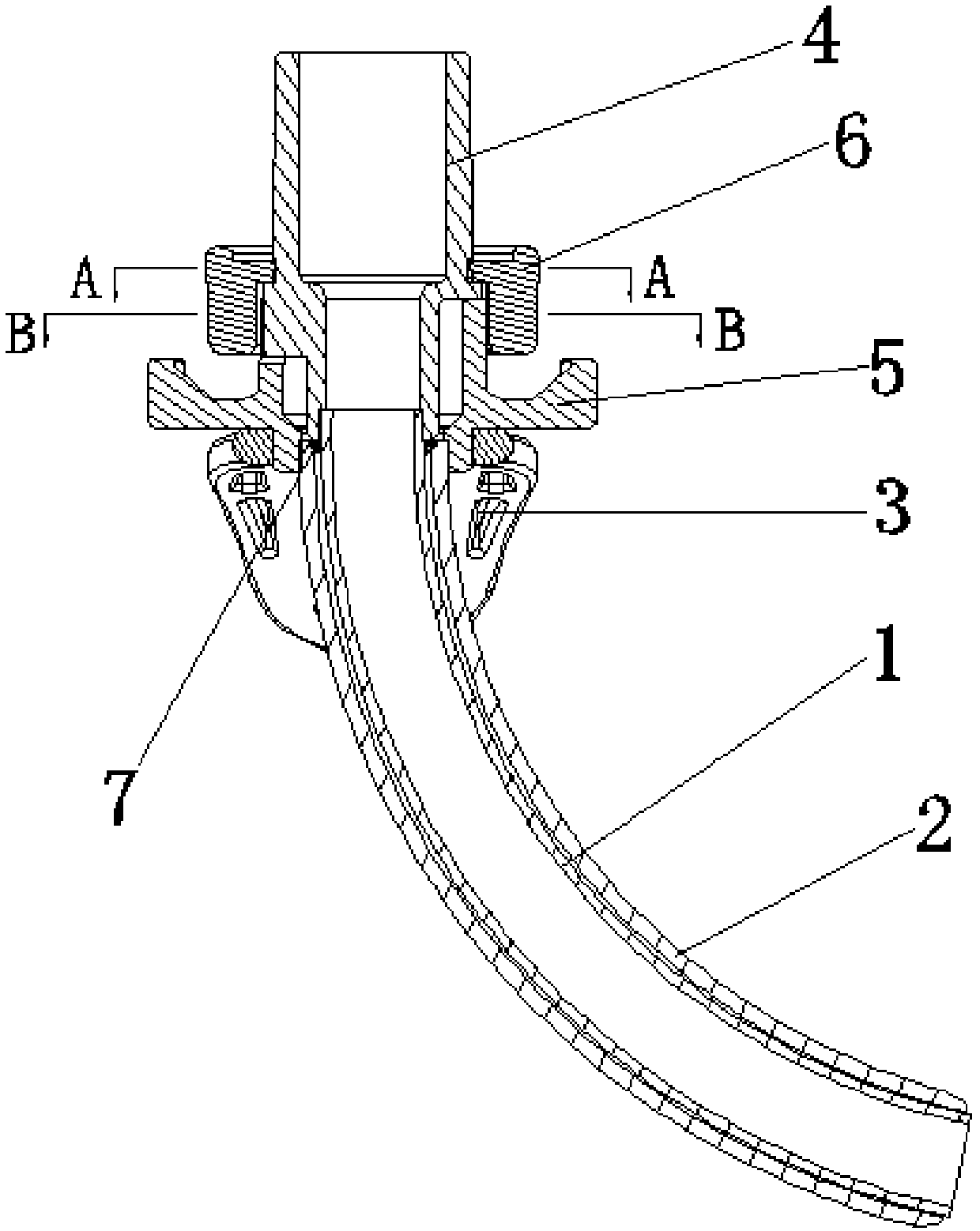

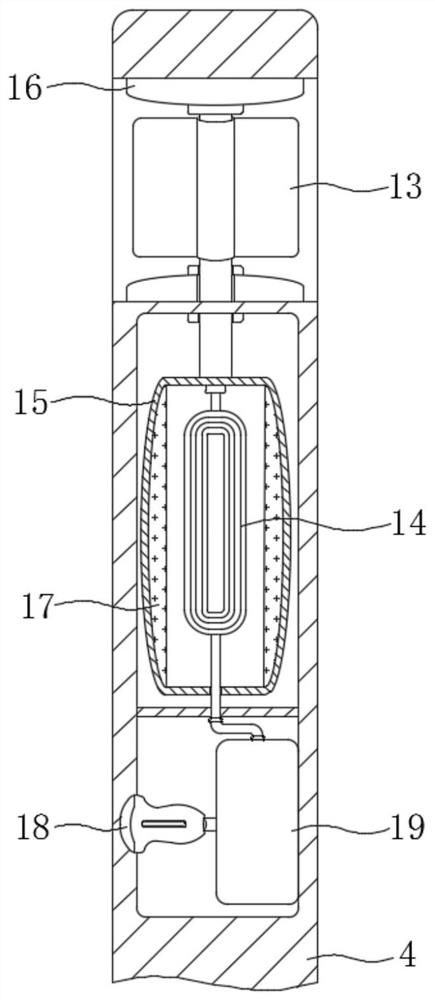

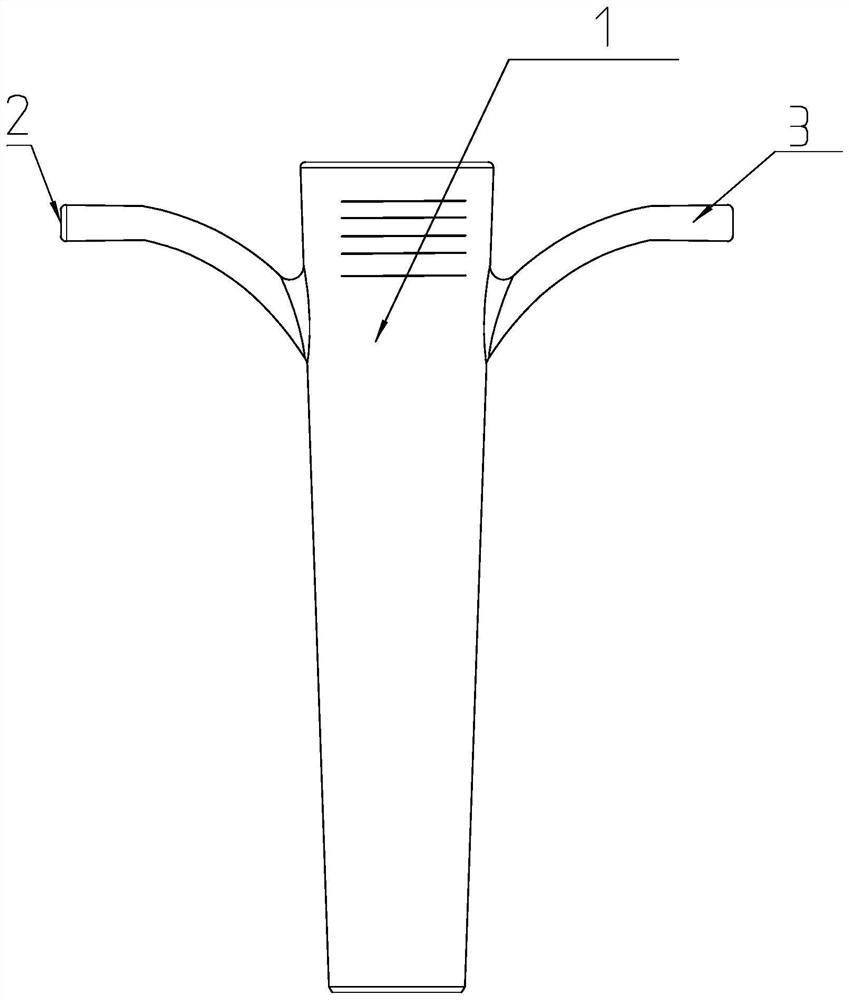

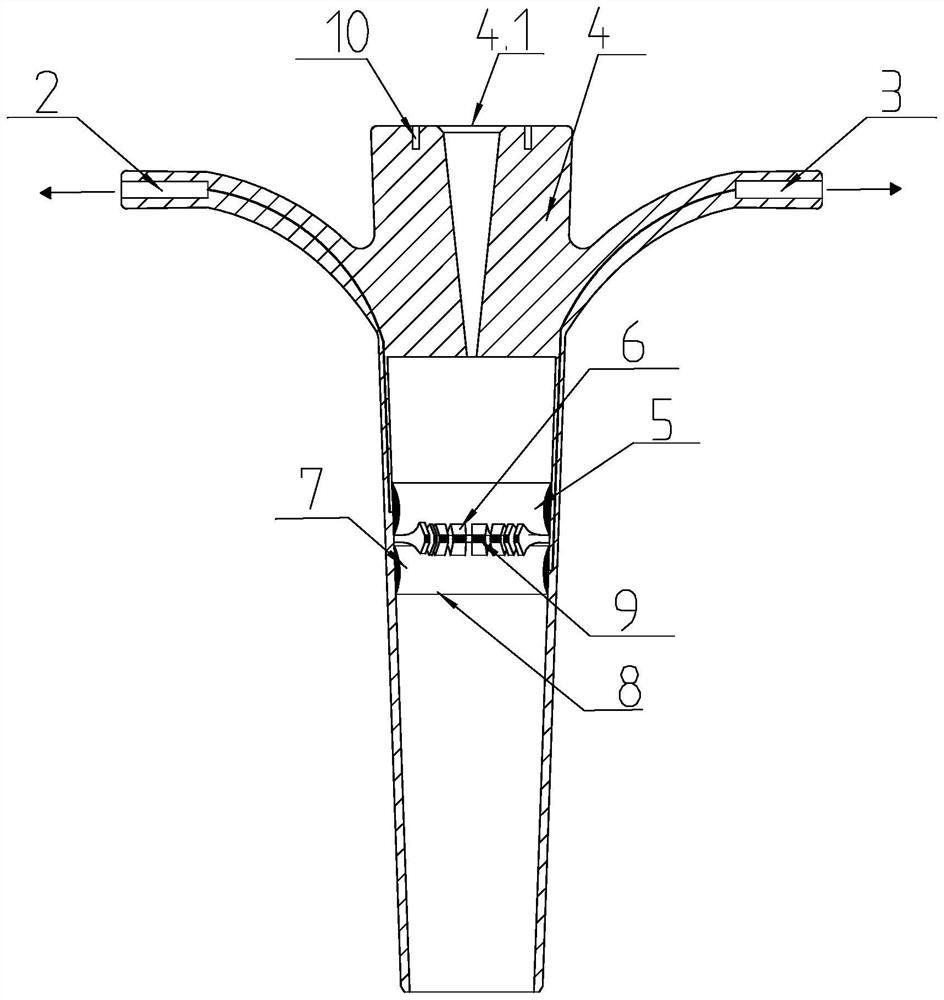

Tracheostomy tube

PendingCN107929904AQuick seal connectionImprove connection reliabilityTracheal tubesMedical devicesTracheostomy tube insertionTracheal cannulation

The invention discloses a tracheostomy tube which comprises an inner cannula, an outer cannula sleeving the periphery of the inner cannula and fixed wings located on the outer side of the outer cannula. A connector is arranged at one end of the inner cannula, a cutting sleeve is arranged at one end of the outer cannula, a rotatable cap capable of locking or loosening the connector and the cuttingsleeve is arranged between the inner cannula and the outer cannula, and a seal gasket for sealing the gap at the linkage position of the inner cannula and the outer cannula is also arranged between inner cannula and the outer cannula. The fixed wings are movably connected with the cutting sleeve through cylindrical blocks. The tracheostomy tube can achieve quick sealed connection of the inner cannula and the outer cannula, is easy to assemble and effectively improves the connecting reliability and sealing performance between the inner cannula and the outer cannula, and the adjustable fixed wings bring convenience to a user for angle adjustment and is very convenient to use.

Owner:GUANGZHOU WELLLEAD MEDICAL EQUIP CO LTD

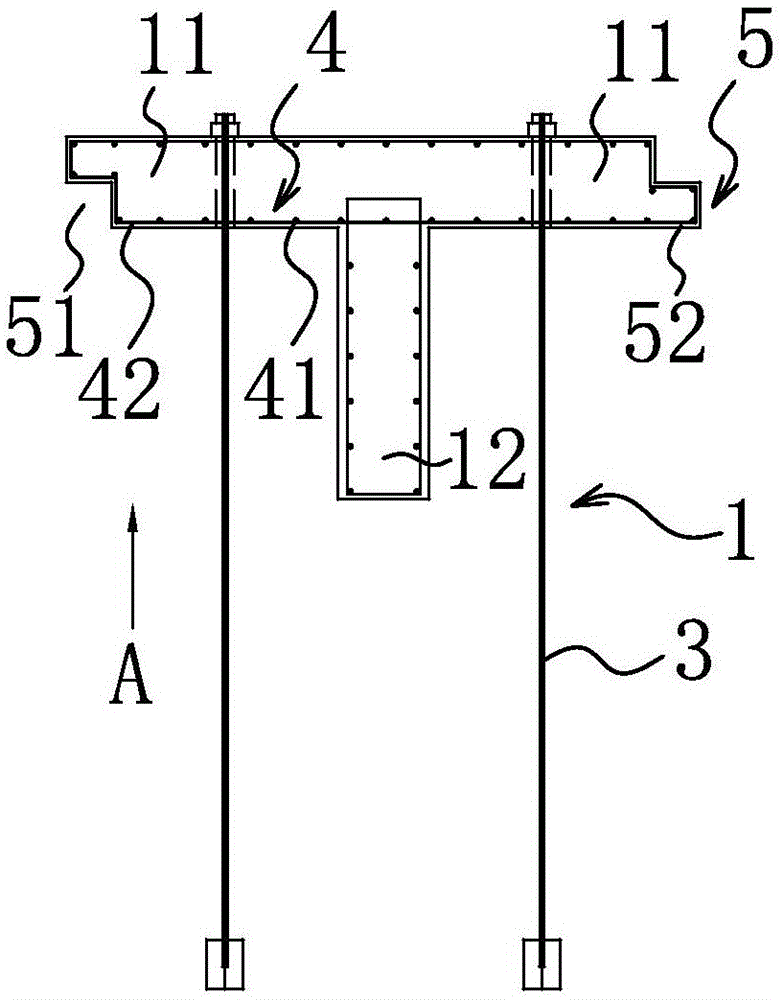

Fender pile structure

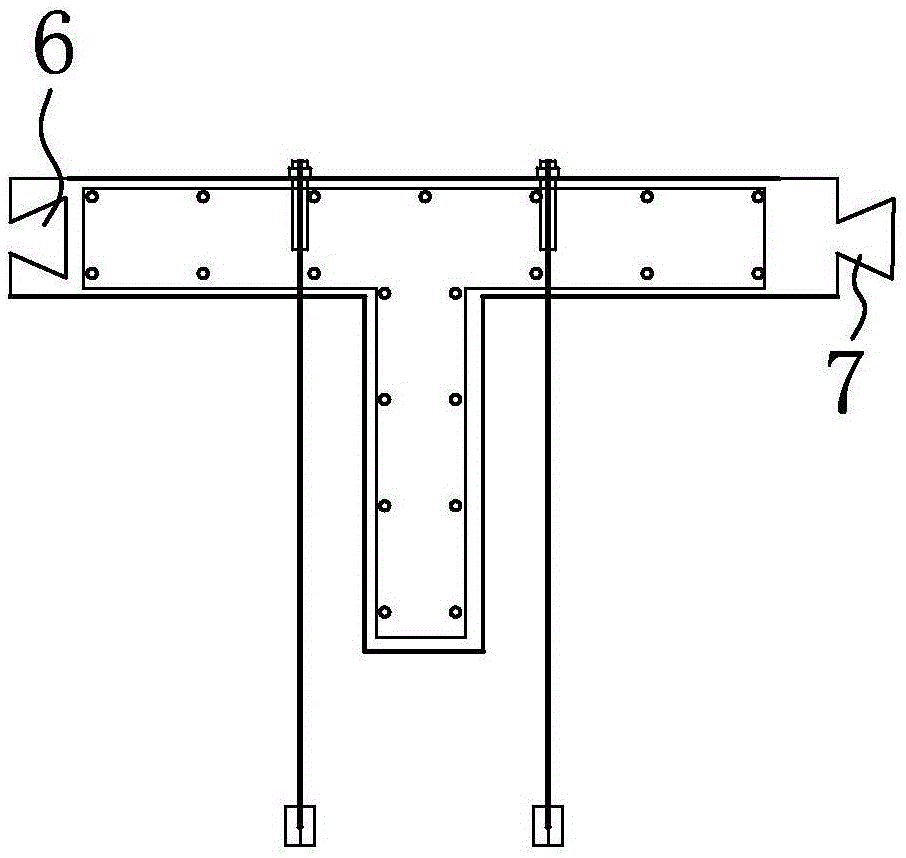

InactiveCN105019401AHigh strengthImprove stabilityCoastlines protectionBulkheads/pilesBasementStructural engineering

The invention belongs to the technical field of buildings, and relates to a fender pile structure. The technical problem that the stability is poor in the prior art is solved. The fender pile structure comprises a first pile body and a second pile body. The cross section of the first pile body and the cross section of the second pile body are in a T shape. A first sealing mechanism is arranged at the end of the first pile body, and a second sealing mechanism matched with the first sealing mechanism is arranged at the end of the second pile body. When the first pile body and the second pile body are close to each other, the first sealing mechanism and the second sealing mechanism can be matched in a clamped mode, so that sealing connection is achieved. According to the fender pile structure, the stability of the T-shaped pile bodies is high; the fender pile structure is suitable for enclosing a basement and also suitable for cement mixing piles or drilling piles, and thus the strength is improved; the piles bodies are stably connected with other parts through an anchor rod assembly, and therefore the strength and the stability of the pile bodies are further improved.

Owner:周兆弟

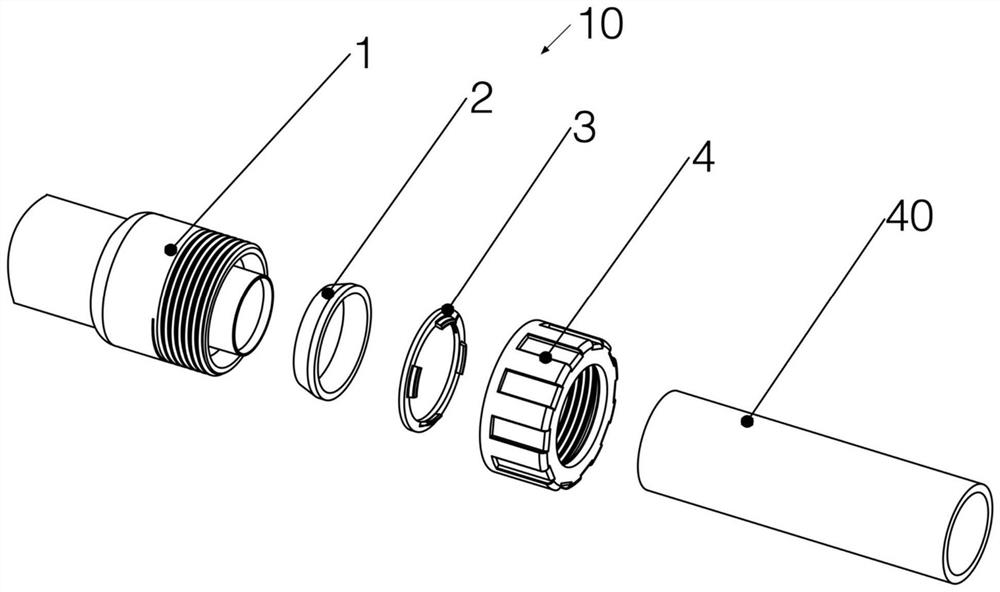

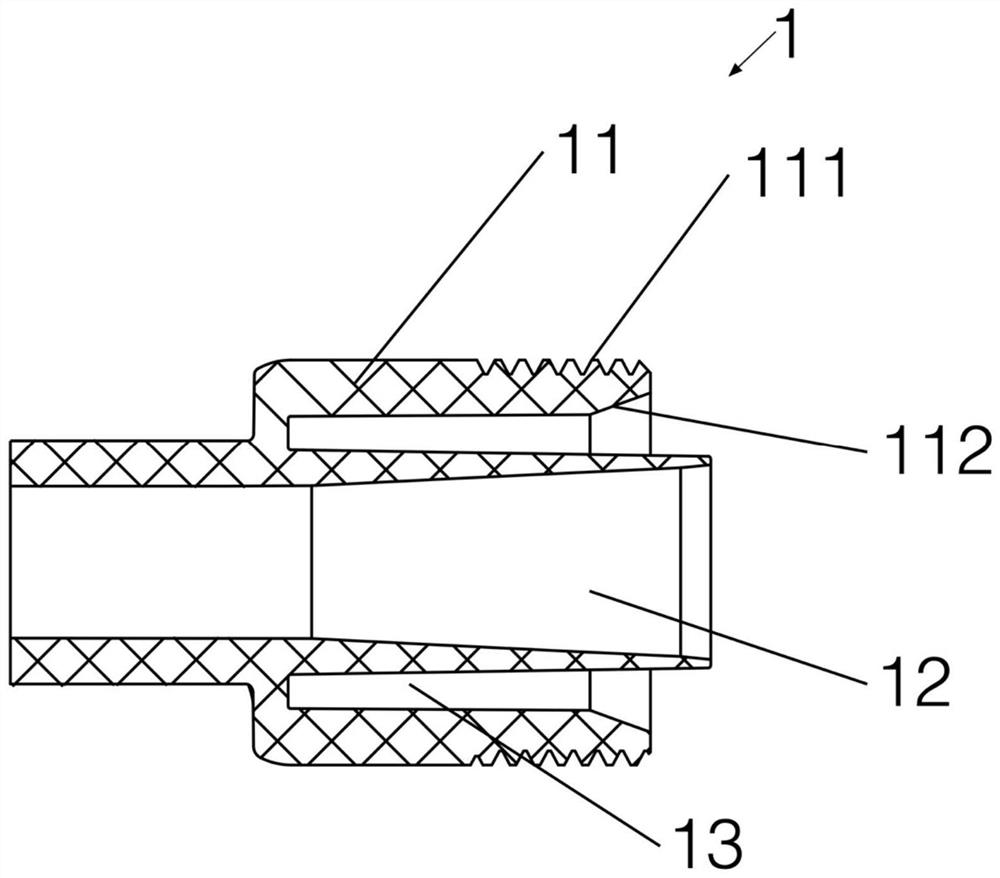

Hose connecting assembly and hose butt joint device

The invention discloses a hose connecting assembly and a hose butt joint device. The hose connecting assembly comprises a pipe joint, a sealing ring, an opening gasket and a cylindrical nut, the pipe joint is provided with a sleeve and an inner pipe extending out of the sleeve, a gap allowing a hose to be inserted is formed between the inner pipe and the sleeve, a first chamfer is arranged at the end part of the inner wall of the sleeve, the sealing ring is connected to a position outside the hose in a sleeving mode, the opening gasket is connected to a position outside the hose in a sleeving mode, the first end face of the opening gasket is abutted with the end part of the sleeve so as to abut against the sealing ring into the first chamfer, a plurality of protrusions which are distributed in the circumferential direction are arranged on the second end face of the opening gasket, the cylindrical nut is in threaded connection with the sleeve, the bottom wall of the cylindrical nut is suitable for abutting against the second end face and is provided with a center hole for the hose to penetrate through, and the hole wall of the center hole is provided with a second chamfer suitable for abutting against the protrusions and enabling the free ends of the protrusions to be inserted into the outer wall of the hose. The hose butt joint device comprises the two hose connecting assemblies, wherein the inner pipes of the hose connecting assemblies are connected into a whole and communicate with each other. By the adoption of the scheme, a silica gel ring can be flat and prevented from losing efficacy, and the hose can be locked and prevented from being disengaged.

Owner:FUJIAN XIHE SANITARY WARE TECH

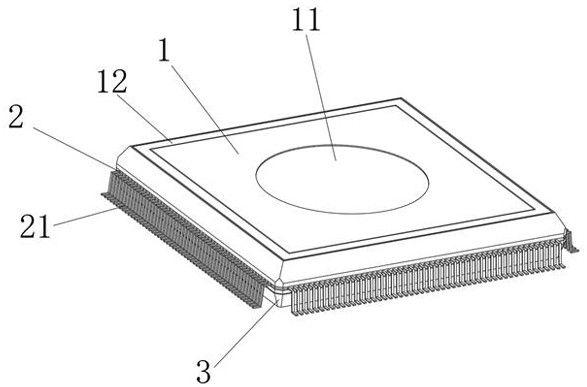

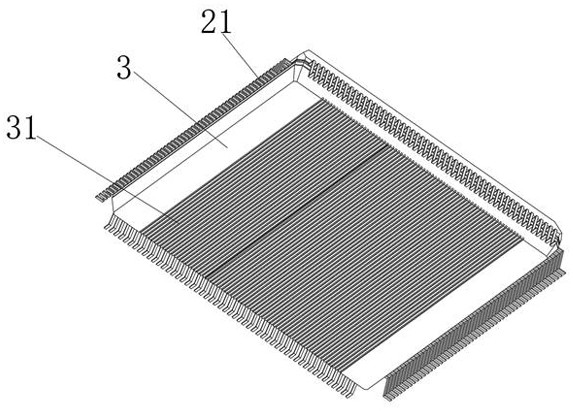

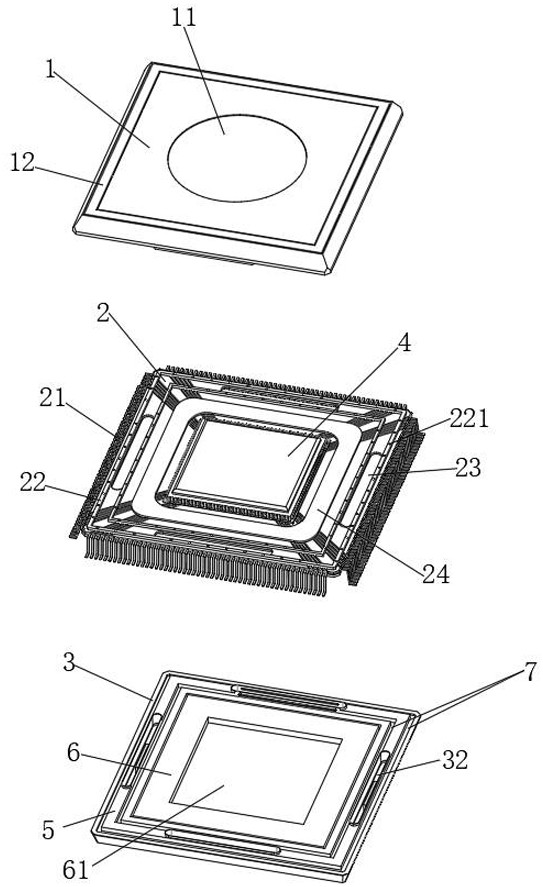

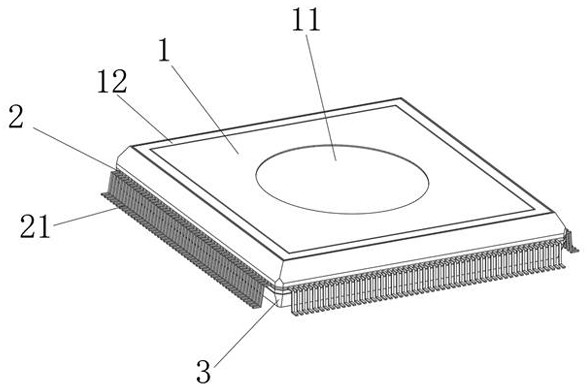

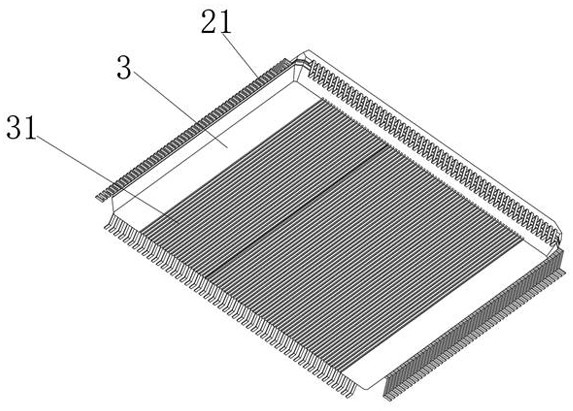

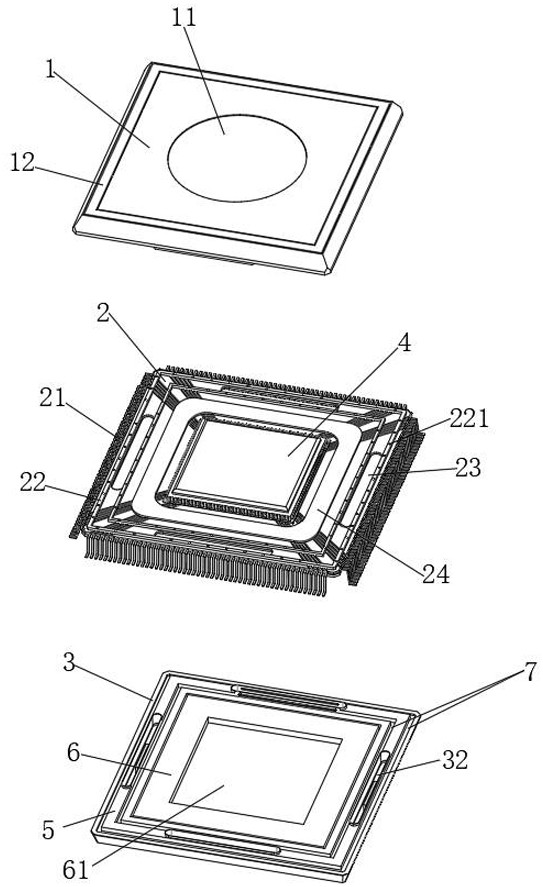

High-precision integrated circuit chip packaging device and packaging process thereof

ActiveCN114220773AQuick seal connectionShorten light curing timeNon-rotating vibration suppressionSemiconductor/solid-state device detailsLight guideMechanical engineering

The high-precision integrated circuit chip packaging device comprises an upper shell, a lower shell and a lining plate, a chip is fixed to the lining plate, the opposite sides of the upper shell and the lower shell are each provided with a second light guide frame, the inner side and the outer side of a frame body of each second light guide frame are each provided with a gluing groove, and the gluing grooves are formed in the inner side and the outer side of the frame body of each second light guide frame. The second light guide frame of the upper shell is provided with four folding blocks, the four folding blocks are evenly distributed at equal angles, the top ends of the folding blocks extend to penetrate through the upper shell and are fixedly provided with a first light guide frame, and the second light guide frame of the lower shell is provided with folding grooves matched with the folding blocks. And the packaging structure can be completely disassembled after being packaged, is convenient to maintain and reuse, is simple in process, effectively reduces the manufacturing cost, has market prospects and is suitable for popularization.

Owner:江苏高格芯微电子有限公司

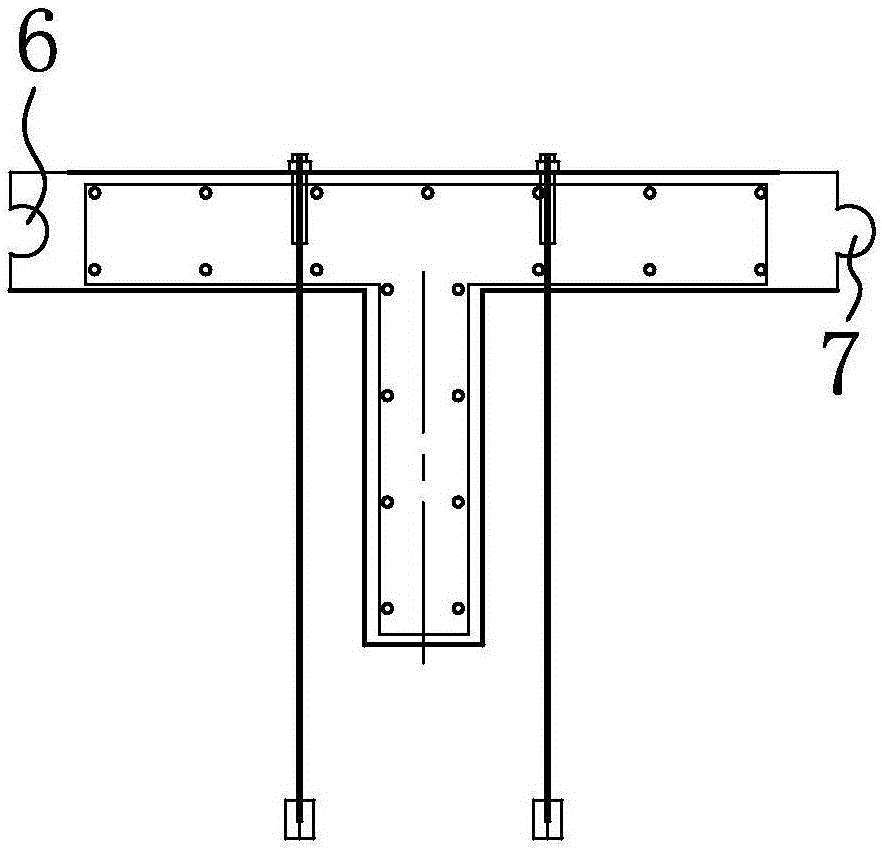

Fender post

The invention belongs to the technical field of building and relates to a fender post. The technical problem of poor stability of the prior art is solved. The fender post comprises a pile body, the cross section of the pile body is T-shaped, the pile body comprises a transverse pile and a longitudinal pile fixedly connected with the transverse pile, sealing mechanisms capable of causing two adjacent piles bodies to be clamped and matched with each other are arranged at two sides of the transverse pile, and at least one anchor rod is fixed on the transverse pile along the radial direction of the transverse pile. The T-shaped pile body is high in stability and suitable for fending basements, concrete stirring piles or drilling piles, so the strength is improved, the pile body and other parts form stable connection due to the anchor rod assembly, and the strength and stability of the pile body are further improved.

Owner:周兆弟

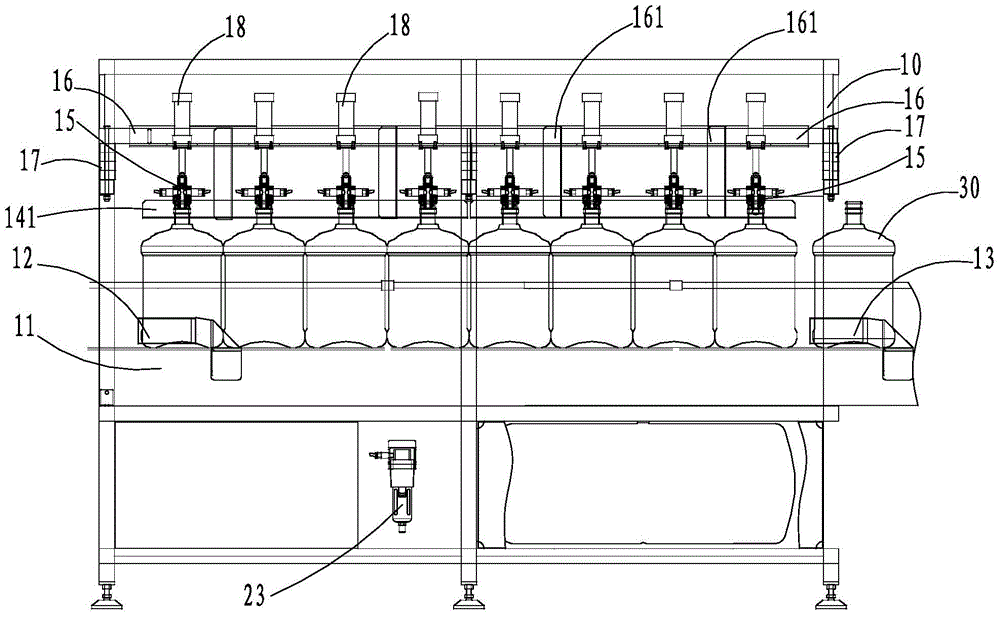

Screening and transporting device and screening and transporting method for containers

The invention relates to a screening and transporting device and a screening and transporting method for containers. The screening and transporting device for the containers comprises a transportation mechanism, a leakage detection mechanism, a rejection mechanism and a controller, wherein the transportation mechanism is used for transporting the containers; the leakage detection mechanism is used for detecting whether the containers have air leakage faults or not; the rejection mechanism is used for rejecting the containers which are detected to have the air leakage faults out of the transportation mechanism; the transportation mechanism, the leakage detection mechanism and the rejection mechanism are respectively connected with the controller. According to the screening and transporting device for the containers, firstly the containers with air leakage are detected by using the leakage detection mechanism, signals of the containers with the air leakage are sent to the controller, and when the containers are transported to a rejection position provided with the rejection mechanism, the controller controls the rejection mechanism to reject the containers with the air leakage out of the transportation mechanism. Thus, the containers transported from the transportation mechanism are all have no air leakage fault. Obviously, the containers which have the air leakage faults can be fast and conveniently rejected, and a whole process is high in automation degree.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

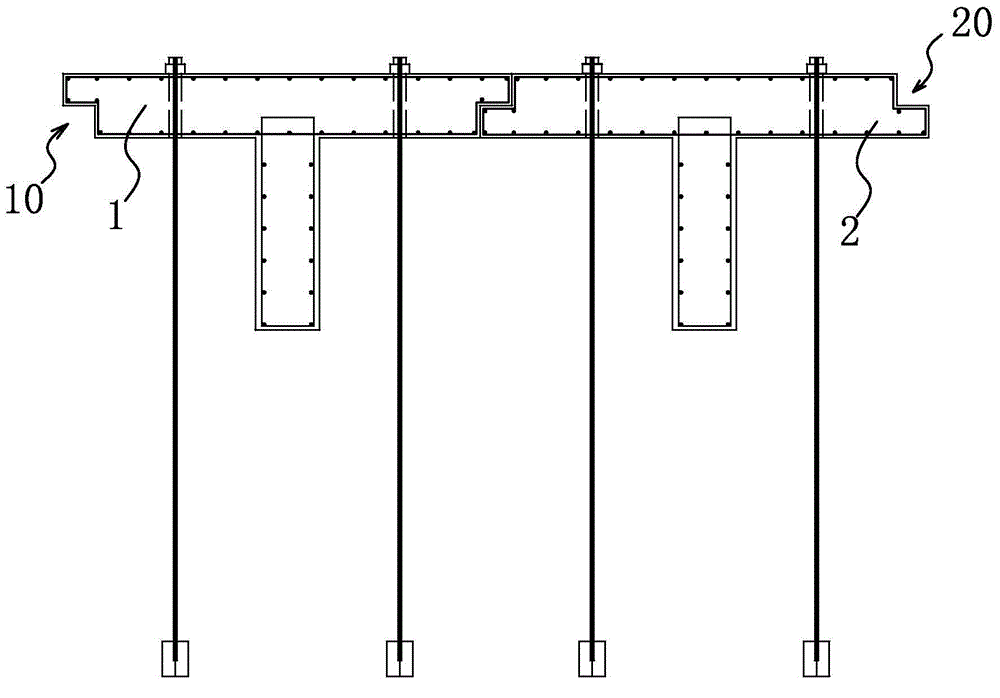

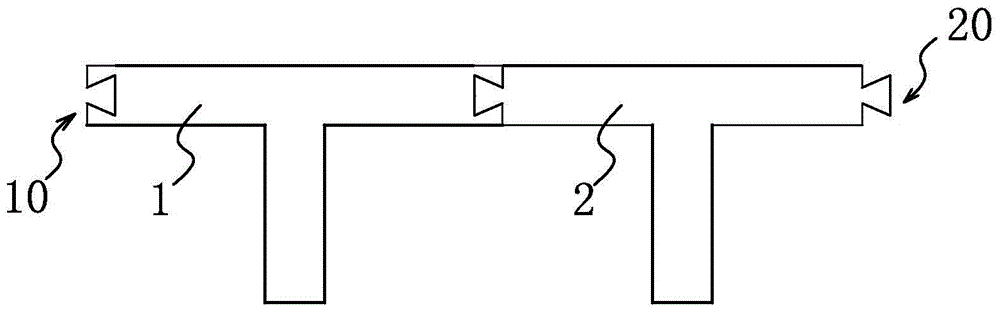

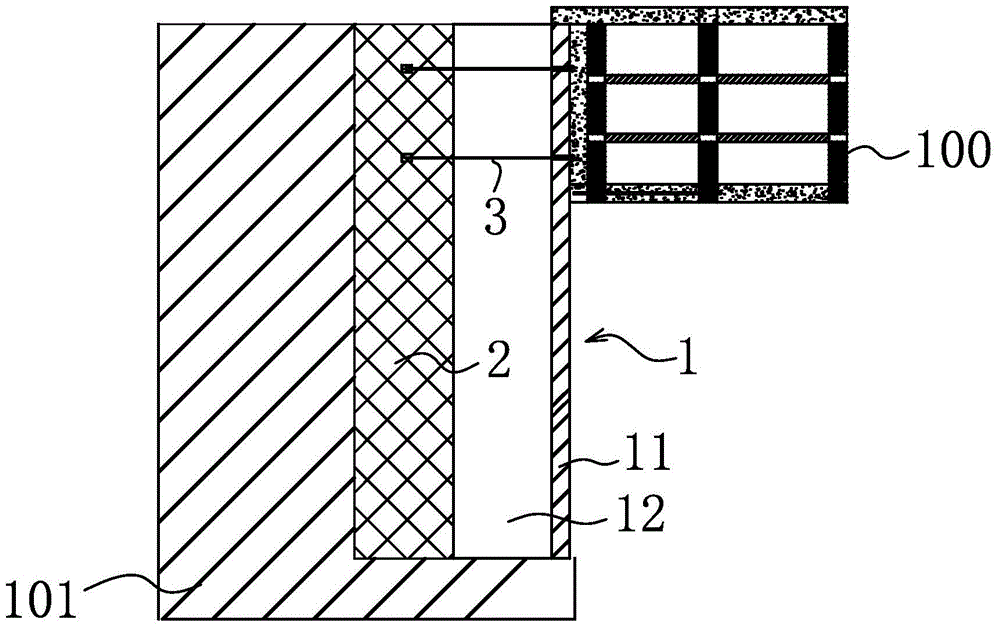

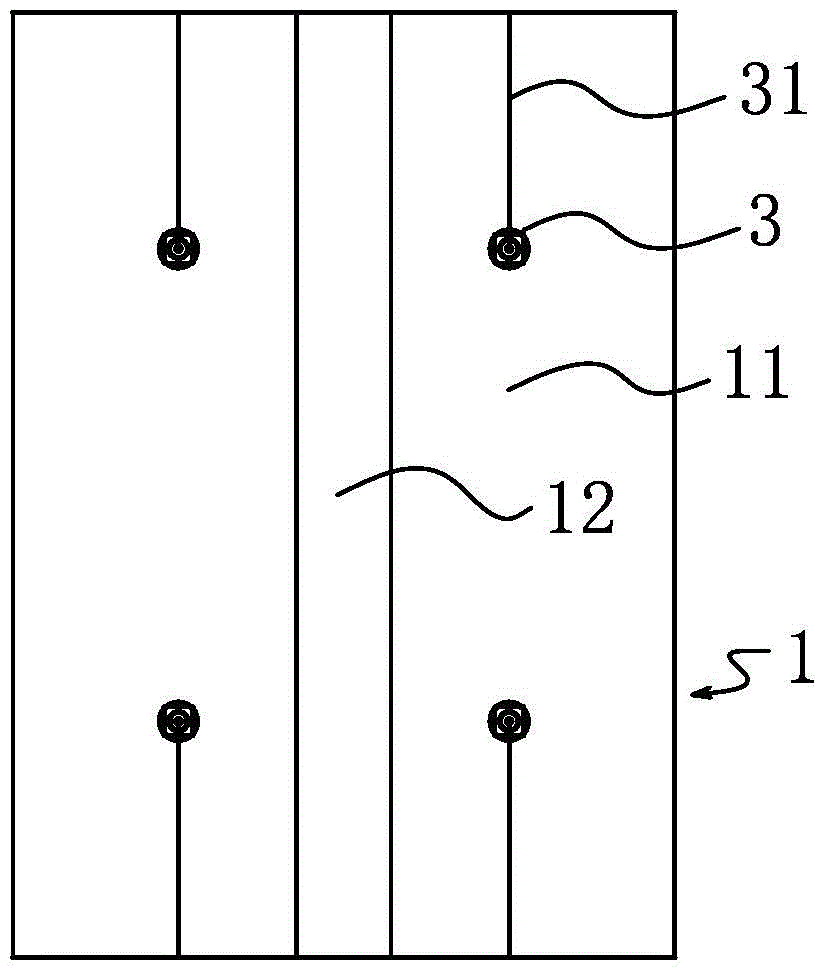

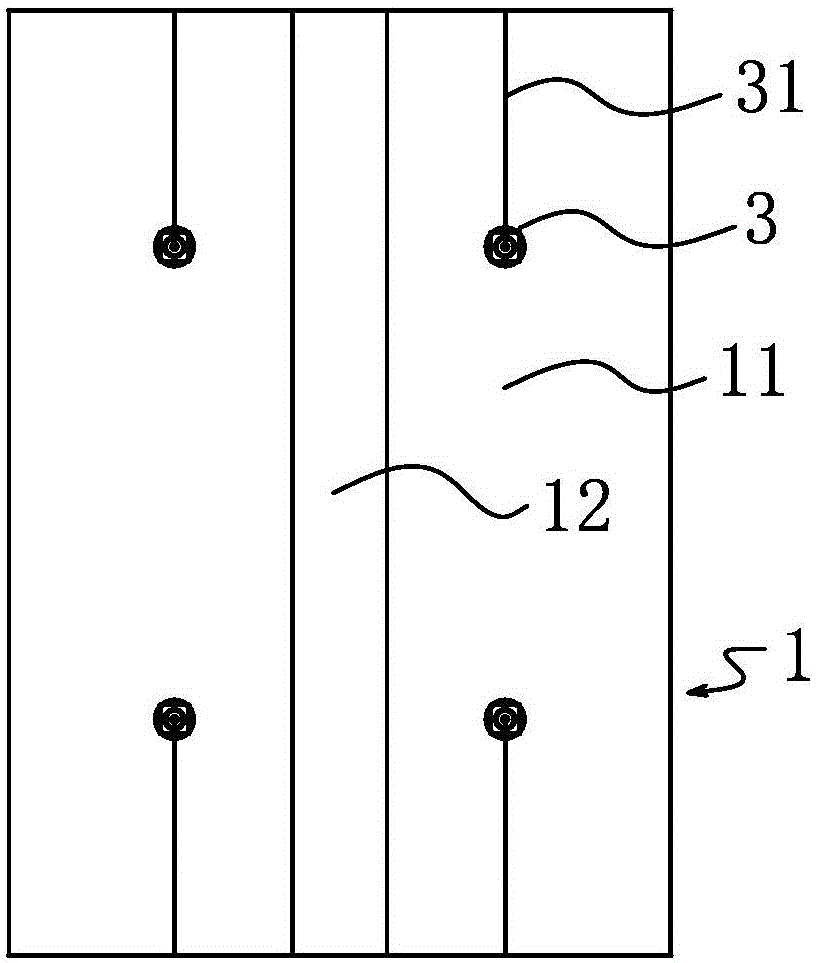

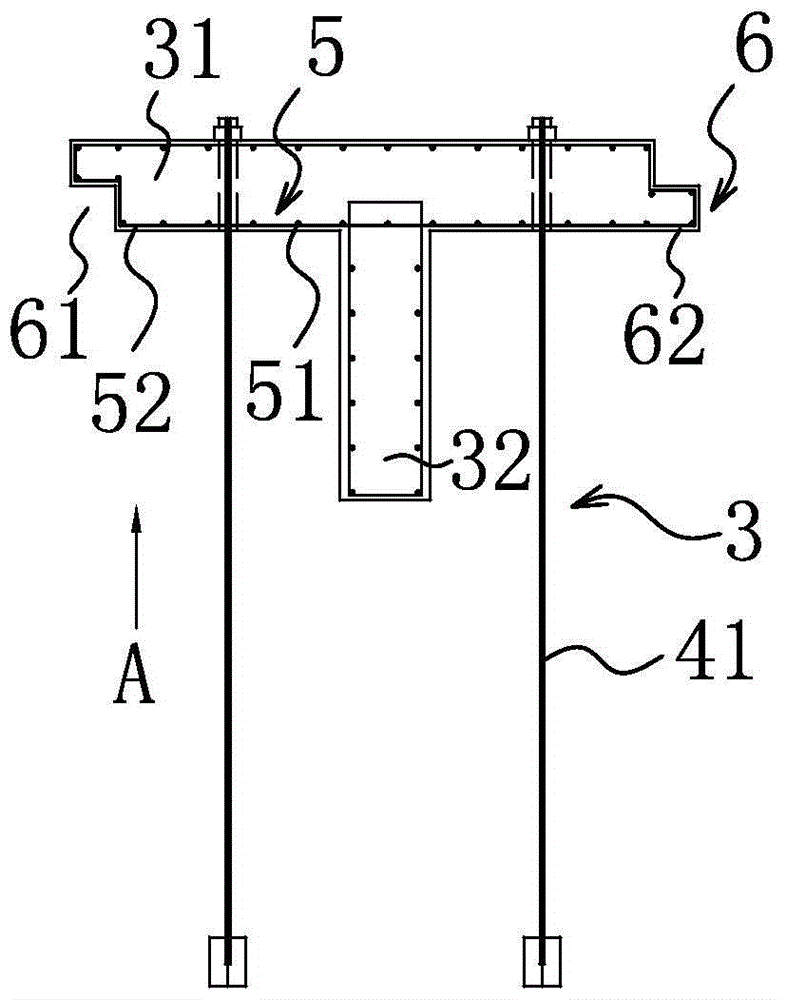

Composite retaining pile structure

ActiveCN105019400BHigh strengthImprove stabilityCoastlines protectionBulkheads/pilesStructural engineeringEngineering

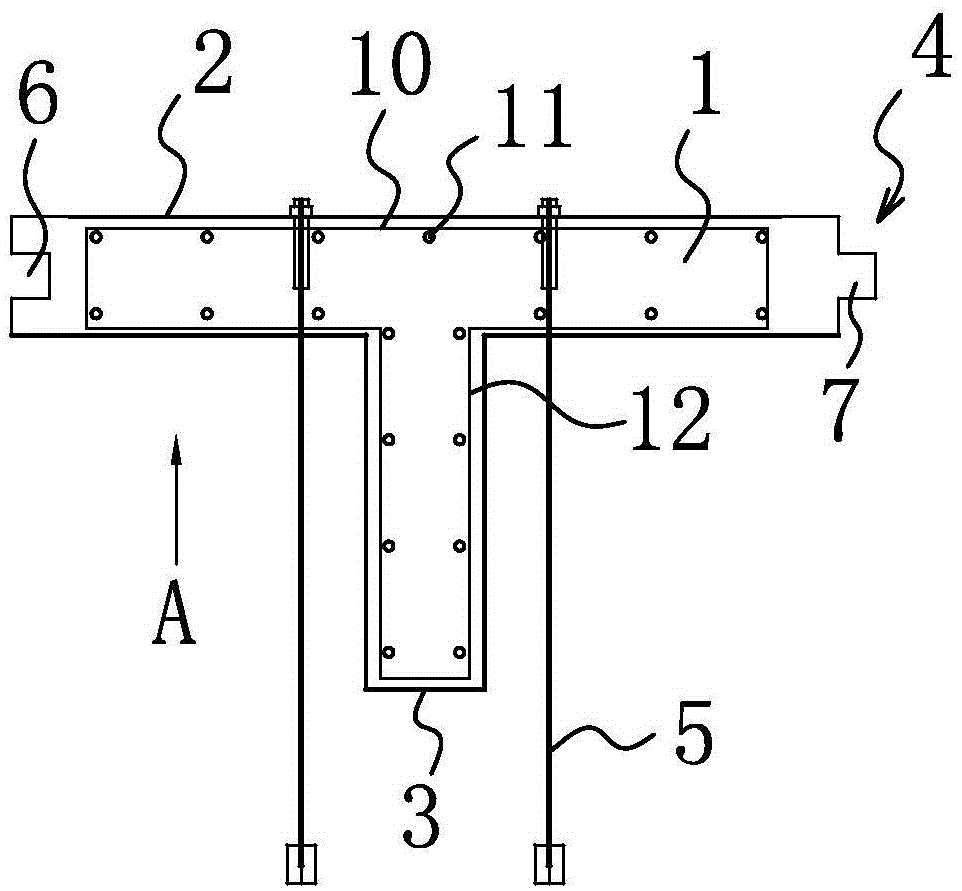

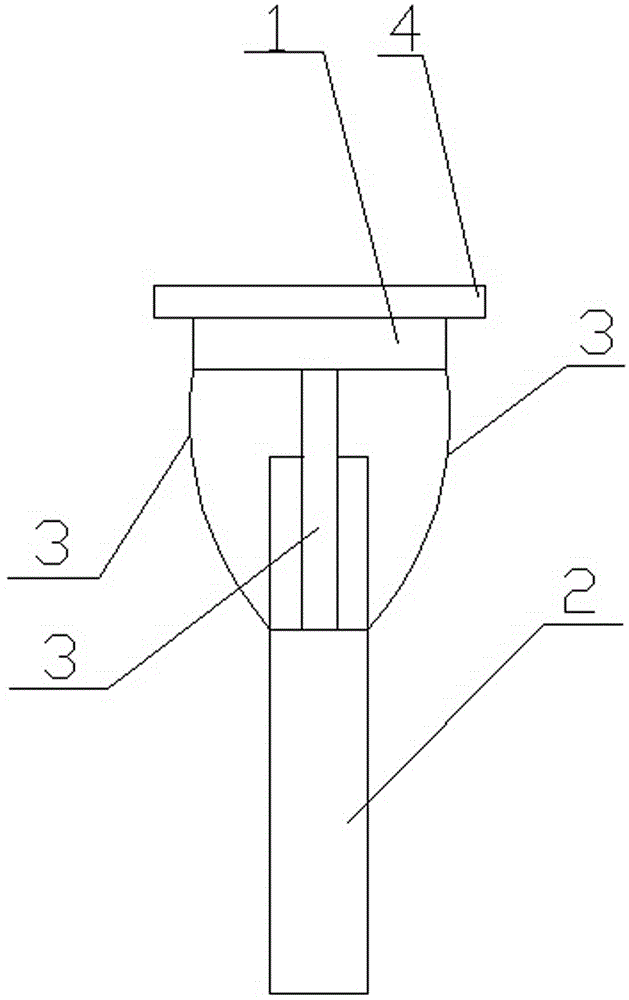

A composite retaining pile structure comprising a T-shaped pile (1) having a T-shaped cross-section, also comprising a composite pile (2) having the axis line thereof parallel to the T-shaped pile (1). Several anchor rods (3) are arranged on the T-shaped pile (1). The anchor rods (3) are fixedly connected at one extremity thereof to the T-shaped pile (1) and inserted at the other extremity into the composite pile (2) and form fixed connections with the composite pile (2).

Owner:周兆弟

Composite fender pile structure

ActiveCN105019400AHigh strengthImprove stabilityCoastlines protectionBulkheads/pilesStructural engineeringUltimate tensile strength

The invention belongs to the technical field of buildings, and relates to a composite fender pile structure. The technical problem that the strength is low in the prior art is solved. The composite fender pile structure comprises a T-shaped pile with the T-shaped cross section, and further comprises a composite pile with the axis being parallel to the T-shaped pile. The T-shaped pile is provided with a plurality of anchor rods. One ends of the anchor rods are fixedly connected with the T-shaped pile, and the other ends of the anchor rods are inserted in the composite pile and are fixedly connected with the composite pile. The composite fender pile structure has the advantages of being high in strength, good in stability, convenient to manufacture and the like.

Owner:周兆弟

Quick connector device

ActiveCN103615617BSolve the problem of difficult hoistingAvoid timeRod connectionsSecuring devicesLight pipeCoupling

The invention relates to a quick clamping and releasing device and a quick connector device with the quick clamping and releasing device. The quick clamping and releasing device comprises a clamping device body, and the body comprises an outer clamping sleeve and more than one clamping rod. The outer clamping sleeve comprises a side wall, and the inner surface of the side wall is a work surface. The clamping rods are evenly and symmetrically distributed along the side wall of the outer clamping sleeve, and the clamping ends of the clamping rods penetrate through the side wall of the outer clamping sleeve and are hinged to the outer clamping sleeve on the side wall of the outer clamping sleeve. Connecting holes are formed in the force application ends of the clamping rods. The rotating track of the contact position of the clamping ends of the clamping rods and a piece to be clamped along a hinge shaft is an involute or an Archimedes helix. Objects of different shapes and sizes can be clamped fast, and the problem that a hoisted piece is hard to hoist due to the fact that a steel wire rope cannot penetrate through the hoisted piece is solved. The quick clamping and releasing device can be used as a light pipe quick connector device and a tool for pipeline pressure testing and climbing, the operation is convenient, the structure is simple, cost is low, the application range is wide, and the application condition is wide.

Owner:DALIAN CONSERVATION SCI & TECH CO LTD

A method of outsourcing waterproof construction that penetrates metal roof panel components

ActiveCN111593887BAchieving a watertight sealIncrease stiffnessRoof covering insulationsBuilding material handlingArchitectural engineeringStructural engineering

Owner:GUANGZHOU XIEAN CONSTR ENG

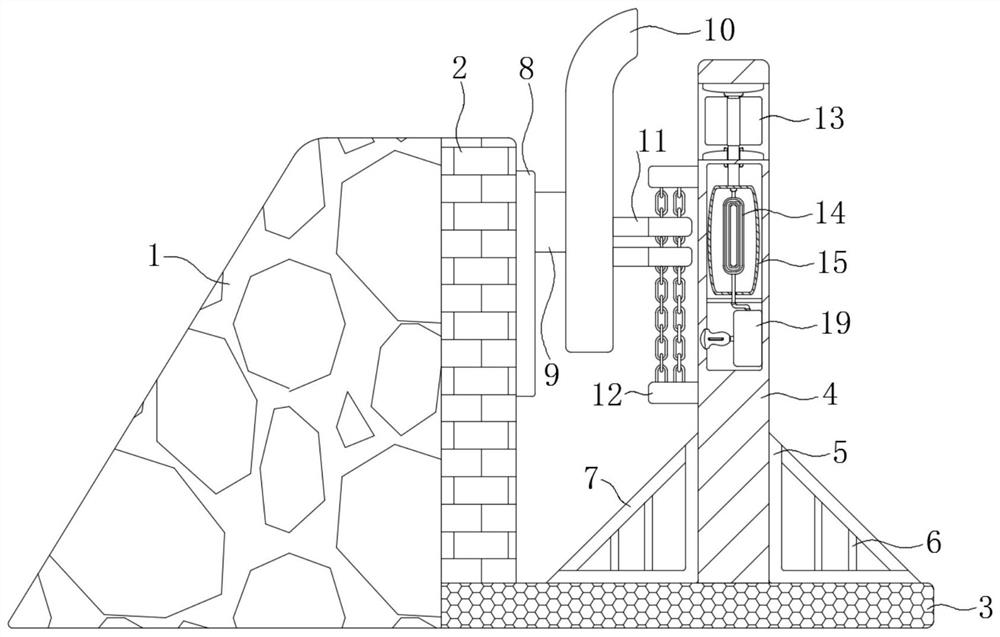

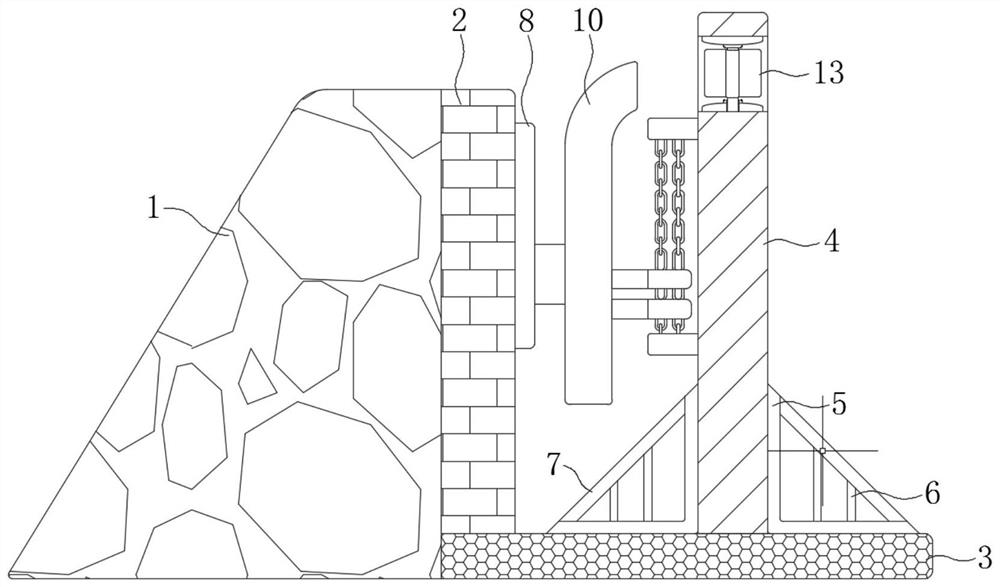

Vertical water-stop structure and construction method thereof for water conservancy projects

ActiveCN110565584BHigh strengthMeet the purpose of temporarily bearing water pressureDamsDykesWater stopArchitectural engineering

The invention discloses a vertical water-stop structure for water conservancy projects, which comprises a roadbed, a wall body, a base and a blocking plate. The base is located at the bottom of the water and connected to the water side of the roadbed. Rails are welded on the side wall of the body opposite to the column, and the base is also provided with a column; the invention also discloses a construction process of a vertical water-stop structure in a water conservancy project, which includes the following steps: S1: prefabricated concrete slab; S2 : Excavation of foundation pit; S3: Formwork; S4: Binding reinforcement cage; S5: Pouring; S6: Formwork removal; S7: Fixing movable parts. The invention has a novel structure and a simple structure. The blocking plate can automatically rise to a certain height according to the water level. When the water level is higher than the wall, the electric mechanism transmits electric energy through sound waves of a specific frequency, so that the sealing connection between the blocking plate and the track can be quickly realized. Thereby, the height of the vertical waterproof structure is increased, and the purpose of automatic flood prevention without manual operation is realized.

Owner:宁夏晋明建设工程有限公司

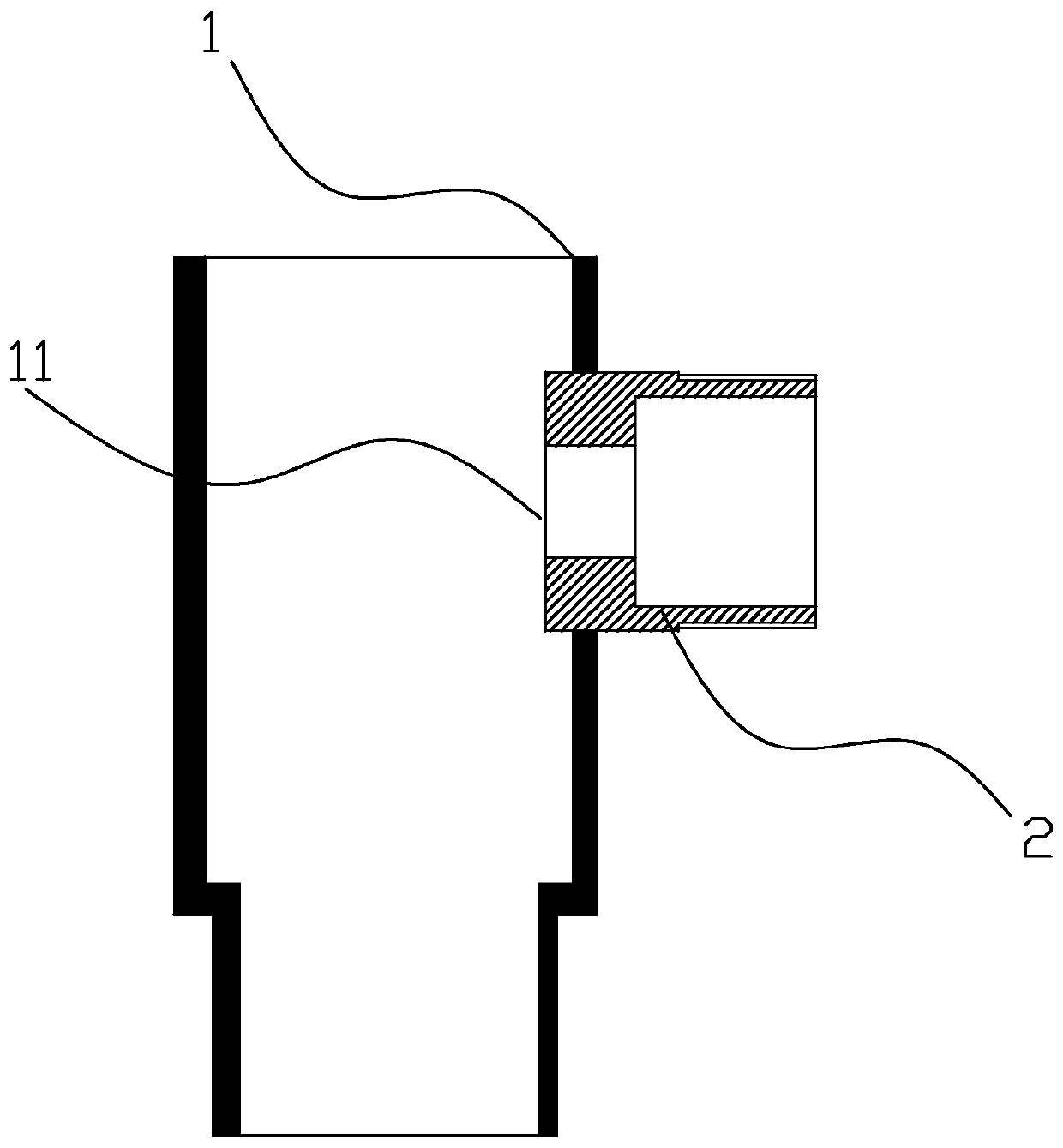

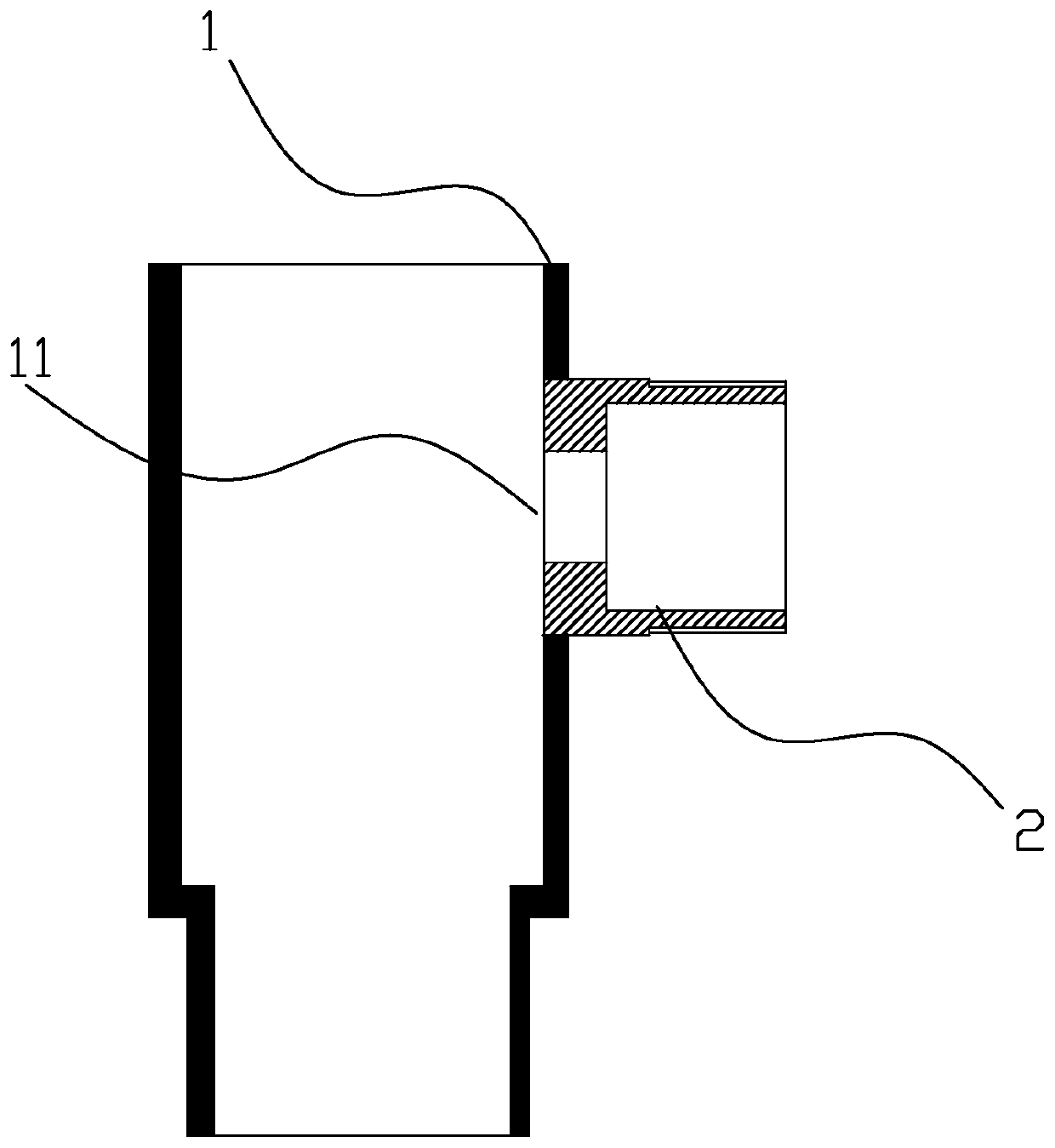

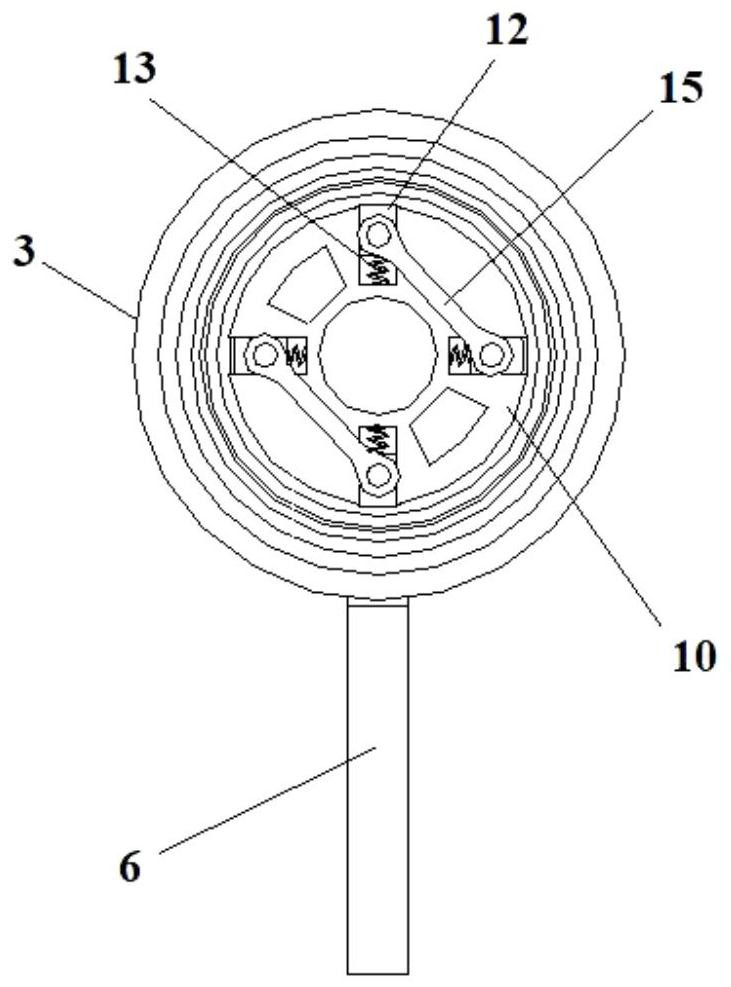

A leak-proof electric contact water level gauge

ActiveCN107588824BQuick seal connectionImprove sealingLevel indicators by physical variable measurementElectricityAutomatic control

The invention relates to the field of gauge detection and automatic control, in particular to a leakproof water level gauge with an electric contact. The water level gauge with the electric contact comprises a water level gauge body, an installation cylinder and a pressing end cover, wherein the water level gauge body is installed in the installation cylinder, the pressing end cover is firmly arranged on the end portion of the water level gauge body in a pressing mode, the water level gauge with the electric contact further comprises a detection structure used for detection, a first installation hole used for installation of the water level gauge body is formed in the installation cylinder, and the first installation hole is provided with a first inclined side surface structure; the waterlevel gauge body comprises a detection part and an installation part connected with each other, and the installation part is provided with a second inclined side surface structure attached to the first inclined side surface structure; the installation part is provided with an installation platform, the pressing end cover is provided with a groove structure, and the installation platform is matchedwith the groove structure. By means of the water level gauge with the electric contact, reliable sealing of the water level gauge body, the installation cylinder and the sealing end cover is achieved, and it is prevented that damage to electrodes in processes of installation area vibration and medium flushing affects continuous production; moreover, additional auxiliary components and parts are not needed for sealing, so that the cost is lowered, the installation speed is improved, and the installation efficiency is increased.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD

Container screening and transportation device and method

The invention relates to a screening and transporting device and a screening and transporting method for containers. The screening and transporting device for the containers comprises a transportation mechanism, a leakage detection mechanism, a rejection mechanism and a controller, wherein the transportation mechanism is used for transporting the containers; the leakage detection mechanism is used for detecting whether the containers have air leakage faults or not; the rejection mechanism is used for rejecting the containers which are detected to have the air leakage faults out of the transportation mechanism; the transportation mechanism, the leakage detection mechanism and the rejection mechanism are respectively connected with the controller. According to the screening and transporting device for the containers, firstly the containers with air leakage are detected by using the leakage detection mechanism, signals of the containers with the air leakage are sent to the controller, and when the containers are transported to a rejection position provided with the rejection mechanism, the controller controls the rejection mechanism to reject the containers with the air leakage out of the transportation mechanism. Thus, the containers transported from the transportation mechanism are all have no air leakage fault. Obviously, the containers which have the air leakage faults can be fast and conveniently rejected, and a whole process is high in automation degree.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

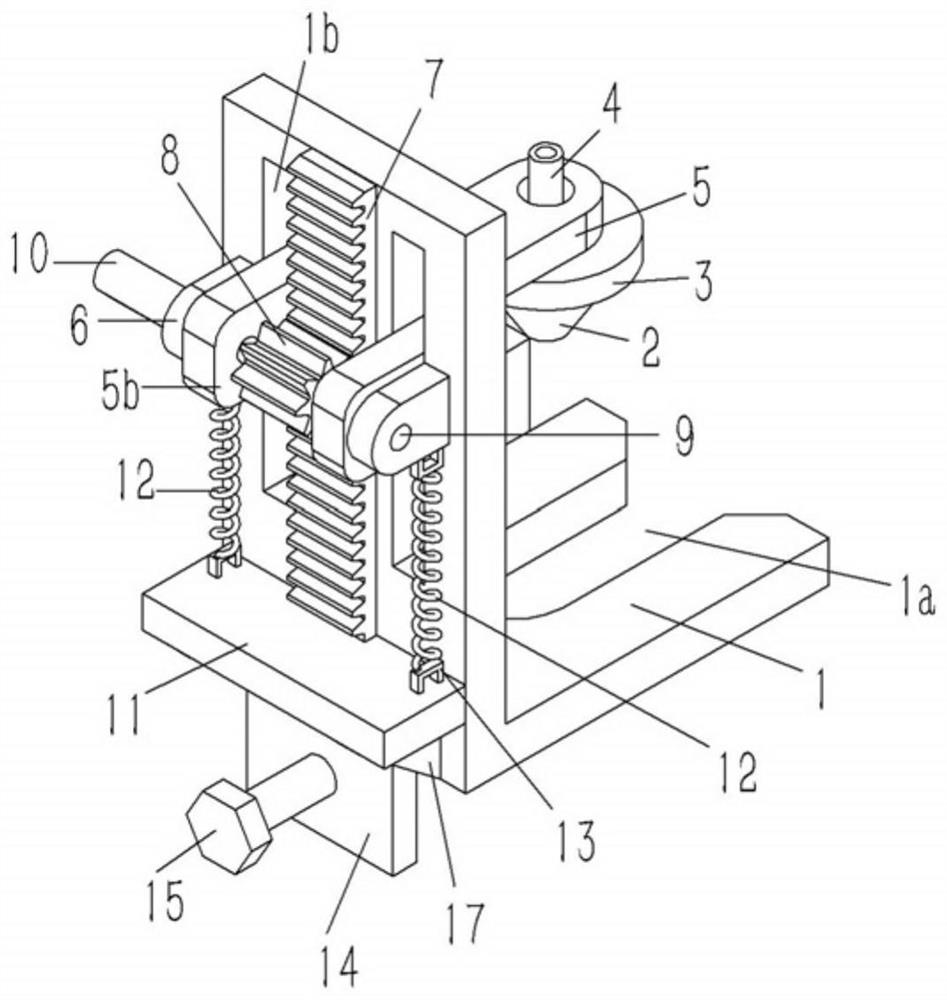

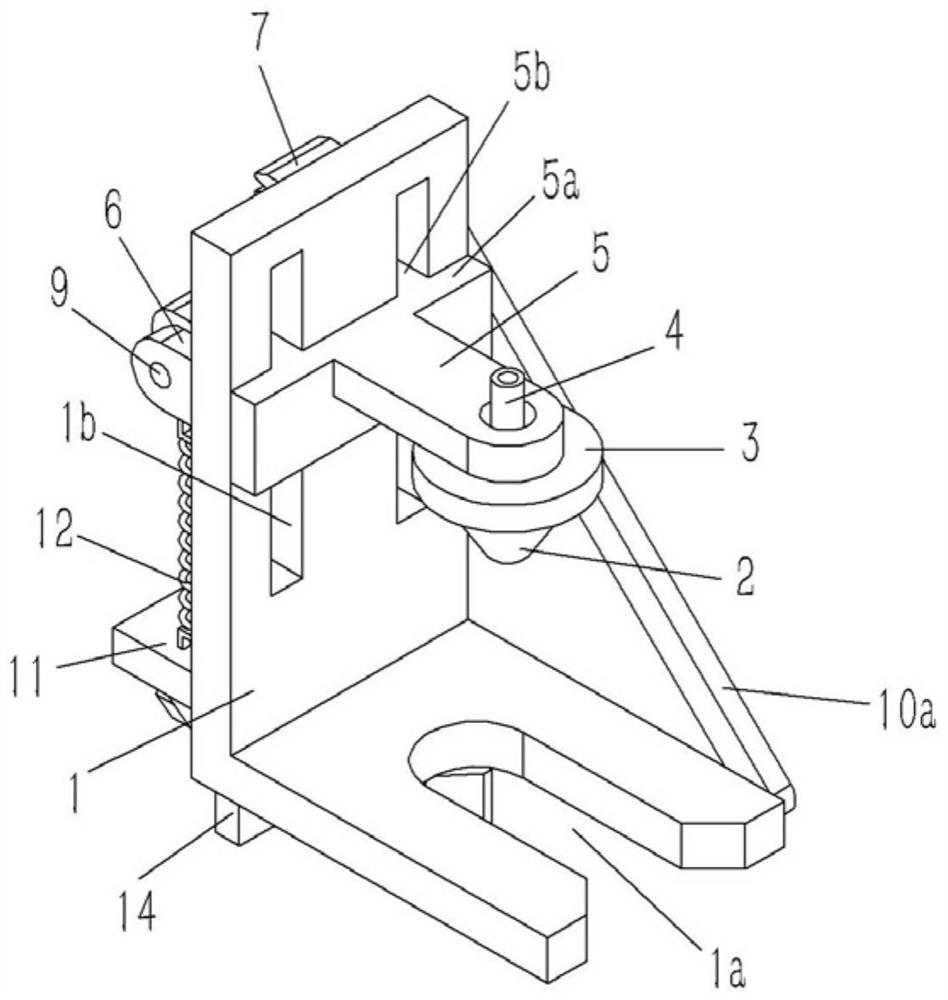

Quick buckling device on air tightness detector

InactiveCN111735572AShorten the timeImprove detection efficiencyFluid-tightness measurement using fluid/vacuumClassical mechanicsStructural engineering

The invention discloses a quick buckling device on an air tightness detector. The quick buckling device comprises a clamping base, and the clamping base is composed of a horizontal part and a verticalpart. A slot penetrating through the front end surface of the horizontal part of the clamping base is formed in the horizontal part of the clamping base, and a plurality of vertical guide grooves areformed in the vertical portion of the clamping base. A conical rubber pressing head is arranged over the slot in the clamping base, a center hole is formed in the rubber pressing head, a ventilationpipe is inserted into the center hole, the upper end of the rubber pressing head is fixedly sleeved with a buckling cover in an inserted mode, the ventilation pipe is fixed to the buckling cover in aninserted mode, and a pressing plate is fixedly connected to the buckling cover. The device adopted by the invention can be quickly connected with a faucet in a sealing manner, and can be convenientlydisassembled from and assembled with the faucet, so that the time consumed by the faucet is shortened, and the detection efficiency of the air tightness detector is improved.

Owner:何陈昌

A high-precision integrated circuit chip packaging device and its packaging process

ActiveCN114220773BQuick seal connectionShorten light curing timeNon-rotating vibration suppressionSemiconductor/solid-state device detailsLight guideShock resistance

The invention discloses a high-precision integrated circuit chip packaging device and its packaging technology, comprising an upper case, a lower case and a liner, a chip is fixed on the liner, and the opposite sides of the upper case and the lower case are There is a second light guide frame, the inner and outer sides of the second light guide frame are provided with glued grooves, and the second light guide frame of the upper shell is provided with a mating block, and the four mating blocks are equiangularly divided. Arrangement, the top of the mating block extends through the upper case and is fixed with the first light guide frame, and the second light guide frame of the lower case is provided with a mating groove that matches the mating block. The structure of the present invention is simple , high packaging efficiency, strong heat dissipation and shock resistance of the packaging structure, and can be completely disassembled after packaging, easy to maintain and reuse, simple process, effectively reducing manufacturing costs, has market prospects, and is suitable for promotion.

Owner:江苏高格芯微电子有限公司

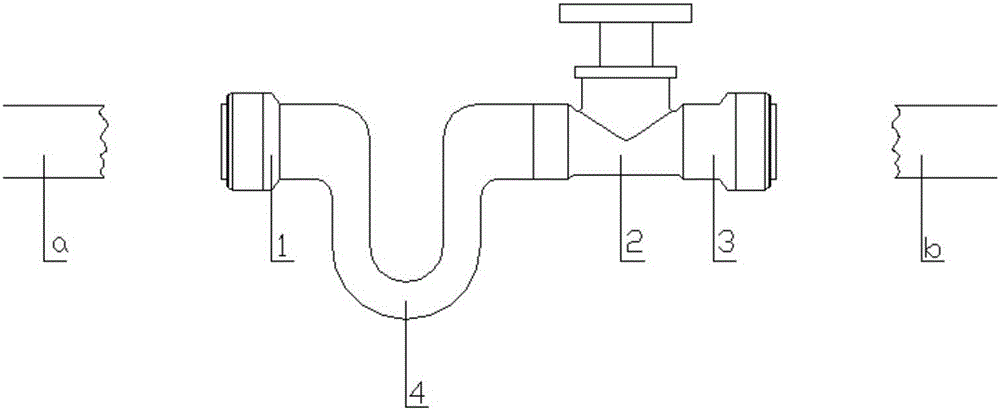

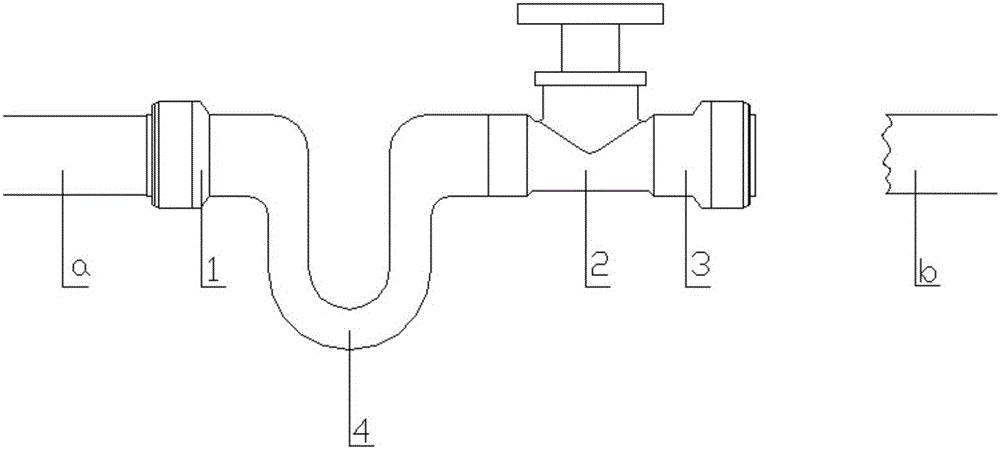

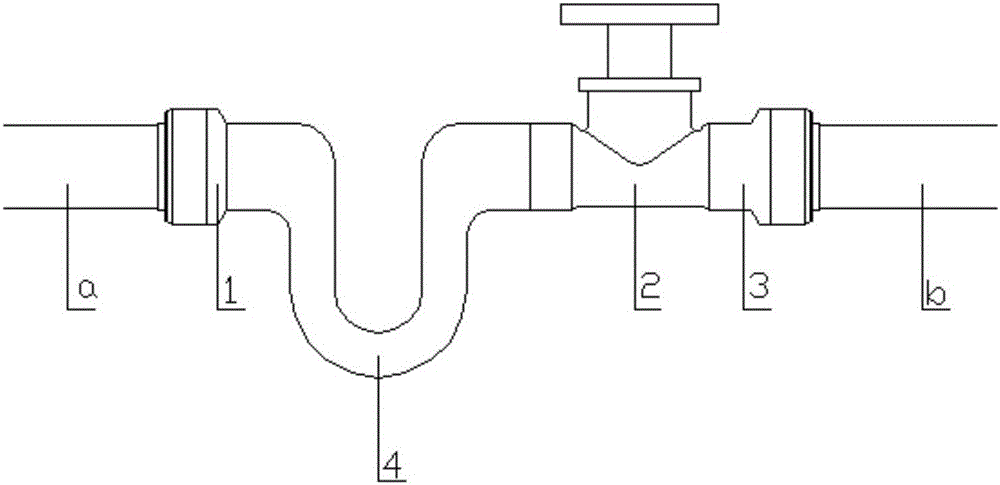

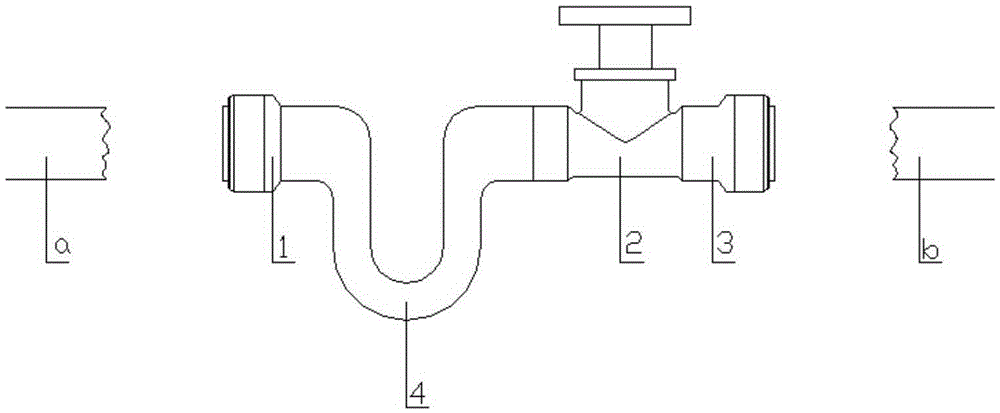

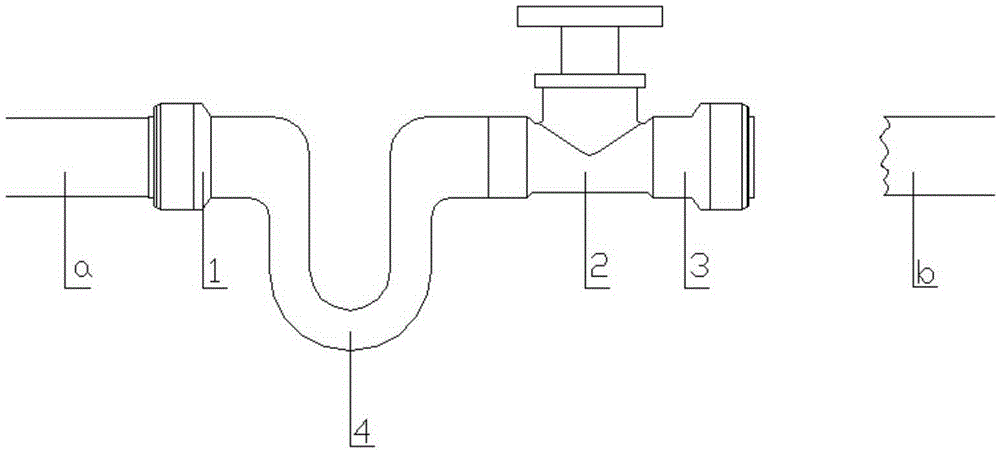

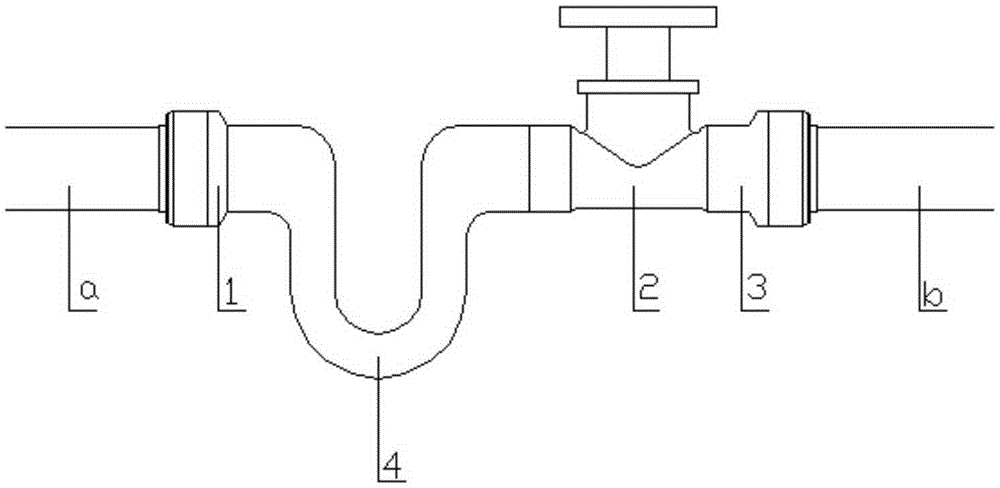

Pipe quick connection device and its realization method

The invention discloses a rapid pipeline connection device and an implementation method thereof. The rapid pipeline connection device comprises a first direct-plugging type automatic locking rapid connector, a high pressure resistant metal net hose, a pipeline valve and a second direct-plugging type automatic locking rapid connector, wherein the first direct-plugging type automatic locking rapid connector is matched with an upper breakage pipeline with pressure in outer diameter, the high pressure resistant metal net hose can adjust the connection space, and the second direct-plugging type automatic locking rapid connector is matched with a lower breakage pipeline with no pressure in outer diameter. The first direct-plugging type automatic locking rapid connector, the high pressure resistant metal net hose, the pipeline valve and the second direct-plugging type automatic locking rapid connector are connected, the pipeline valve is turned on, the first direct-plugging type automatic locking rapid connector is connected with the upper pipeline with pressure, and the pipeline valve is turned off after the connection; and then the second direct-plugging type automatic locking rapid connector is connected with the lower pipeline with no pressure, and the pipeline valve is turned on after the connection, so that the breakage pipeline with pressure is rapidly connected.

Owner:ZHEJIANG YU LONG PIPE TECH CO LTD

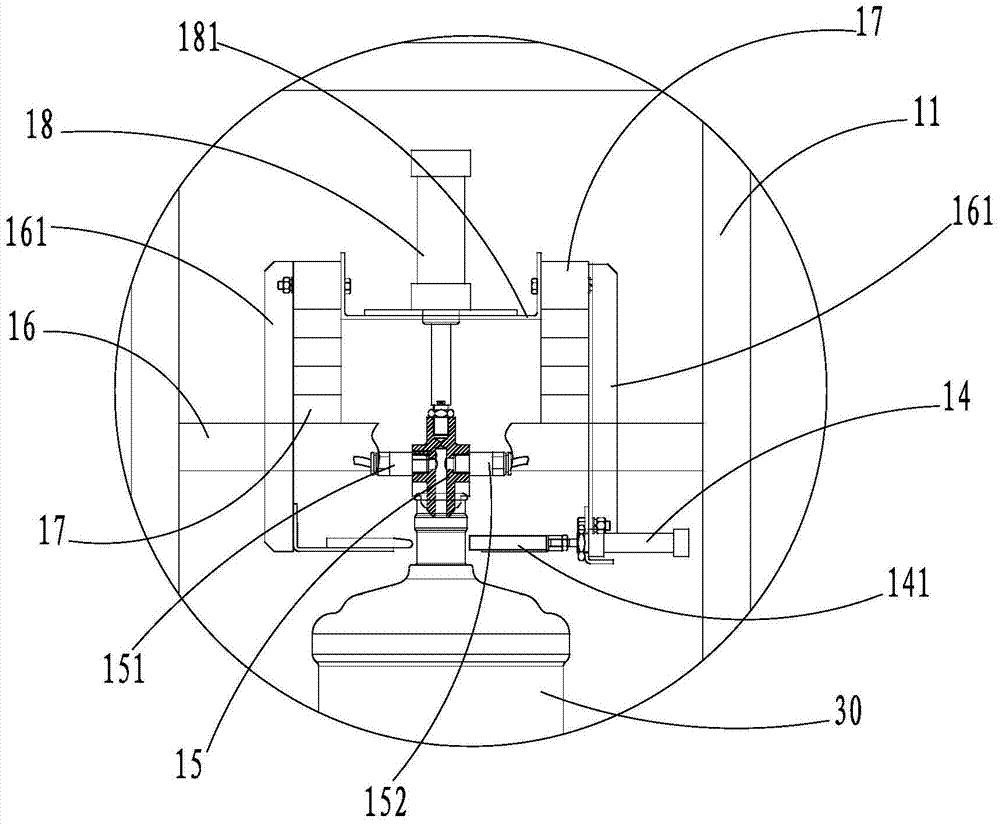

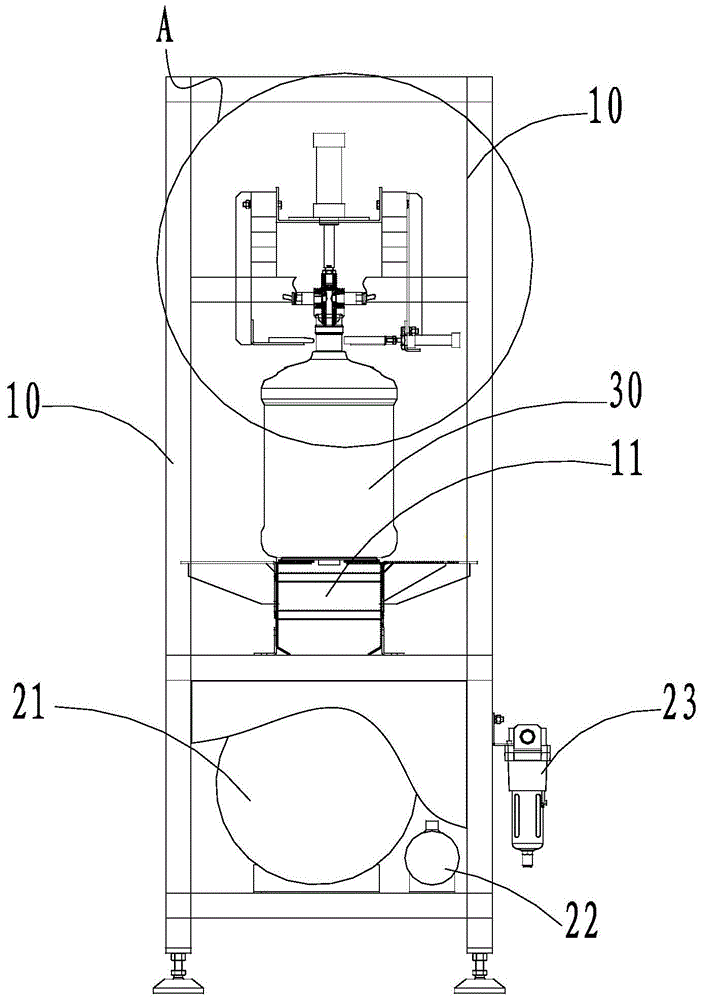

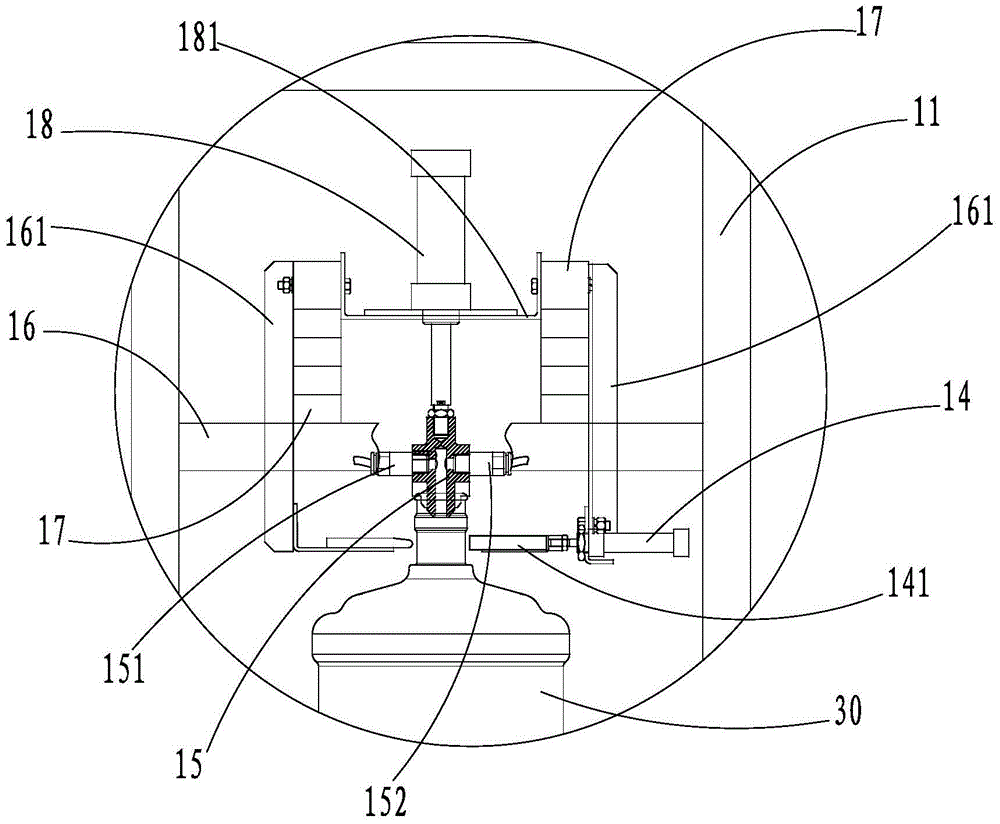

Sealing detection device for air cannon tank body

InactiveCN104828412AQuick sealPromote circulationEngine sealsLarge containersEngineeringMechanical engineering

The invention discloses a sealing detection device for an air cannon tank body. The sealing detection device comprises the air cannon tank body, wherein the air cannon tank body is provided with an air outlet; the air outlet is provided with a detection tube body and a sealing mechanism; the detection tube body comprises an upper tube body and a lower tube body; the upper tube body and the lower tube body are fixedly connected by virtue of a connecting plate, and a gap is reserved between the upper tube body and the lower tube body; the upper tube body is arranged in the air outlet and is fixedly and hermetically connected with the air outlet; the lower end of the lower tube body is hermetically connected with the air cannon tank body; the sealing mechanism comprises a sealing piston and a flange plate; the sealing piston is formed by a lower sealing piston part hermetically matched with the lower tube body and an upper sealing piston part hermetically matched with the upper tube body; one end, positioned outside the air cannon tank body, of the upper tube body is fixedly provided with a flange ring matched with the flange plate. According to the sealing detection device disclosed by the invention, quick and efficient sealing detection for the air cannon tank body can be carried out, and the working efficiency is improved.

Owner:PUYANG CITY HONGYU PRESSURE VESSEL

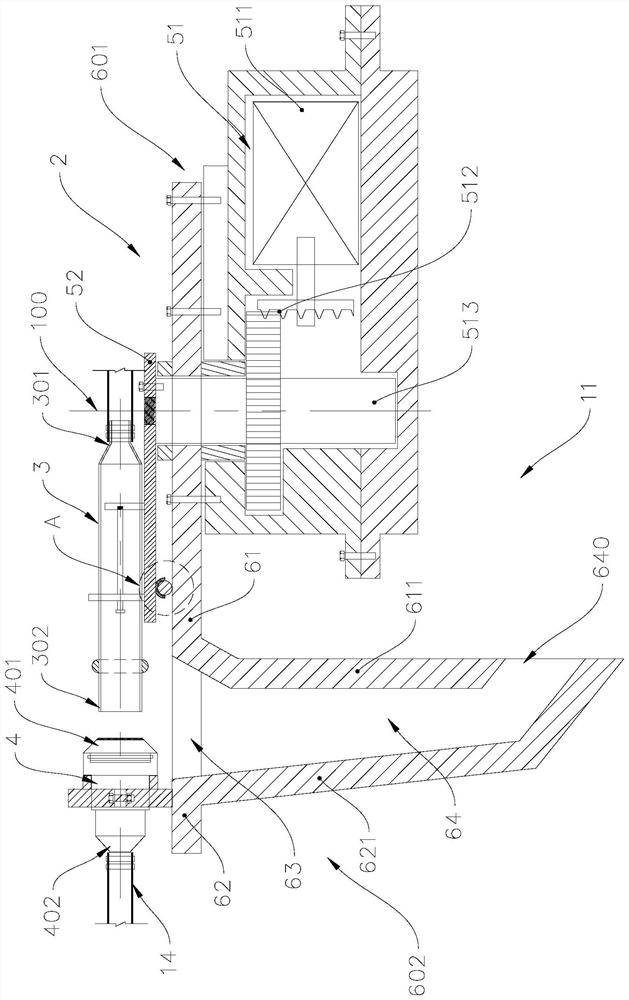

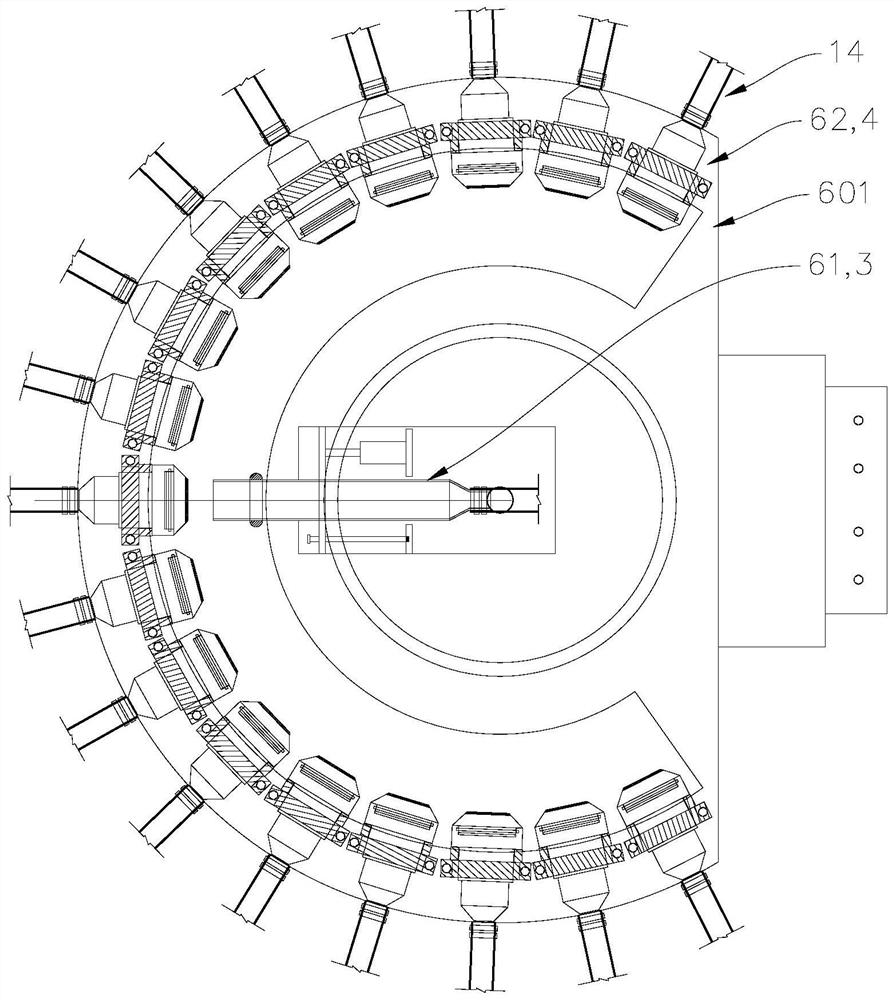

Tunnel multichannel rapid grouting joint device and tunnel grouting system

PendingCN114658457AEfficient groutingQuick seal connectionAnchoring boltsLinear driveGeotechnical engineering

The invention provides a tunnel multi-channel rapid grouting joint device and a tunnel grouting system. The tunnel multi-channel rapid grouting joint device comprises a first grouting hose, a joint, a pushing pipe, a base, a linear driving unit, a rotary driving unit and a second grouting hose. The first grouting hose is in butt joint with the hollow anchor rod; the second grouting hose is communicated with a grout outlet of the grouting machine, and the second grouting hose is communicated with the input end of the pushing pipe; the base can rotate, the pushing pipe is arranged on the base, and the pushing pipe can move between a connection position and a separation position in the radial direction under the driving of the linear driving unit; the multiple connectors are arranged on the periphery of the first axis in the circumferential direction of the first axis. A convex edge is arranged on the periphery of the pipe wall of the output end; the quick connection end of the connector is provided with a rotatable and swingable sealing piece, and when the pushing pipe is located at the connection position, the sealing piece abuts against the pushing pipe. The tunnel grouting system comprises the tunnel multi-channel rapid grouting joint device. According to the invention, multi-channel rapid grouting is realized, and the working efficiency is improved.

Owner:NO 5 ENG OF CHINA RAILWAY 19 BUREAU GRP +1

Rapid pipeline connection device and implementation method thereof

ActiveCN105351655AEasy to connect and operateSmall site impactCouplingsHigh pressureMechanical engineering

The invention discloses a rapid pipeline connection device and an implementation method thereof. The rapid pipeline connection device comprises a first direct-plugging type automatic locking rapid connector, a high pressure resistant metal net hose, a pipeline valve and a second direct-plugging type automatic locking rapid connector, wherein the first direct-plugging type automatic locking rapid connector is matched with an upper breakage pipeline with pressure in outer diameter, the high pressure resistant metal net hose can adjust the connection space, and the second direct-plugging type automatic locking rapid connector is matched with a lower breakage pipeline with no pressure in outer diameter. The first direct-plugging type automatic locking rapid connector, the high pressure resistant metal net hose, the pipeline valve and the second direct-plugging type automatic locking rapid connector are connected, the pipeline valve is turned on, the first direct-plugging type automatic locking rapid connector is connected with the upper pipeline with pressure, and the pipeline valve is turned off after the connection; and then the second direct-plugging type automatic locking rapid connector is connected with the lower pipeline with no pressure, and the pipeline valve is turned on after the connection, so that the breakage pipeline with pressure is rapidly connected.

Owner:ZHEJIANG YU LONG PIPE TECH CO LTD

Flexible connection device of logging-while-drilling instrument

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

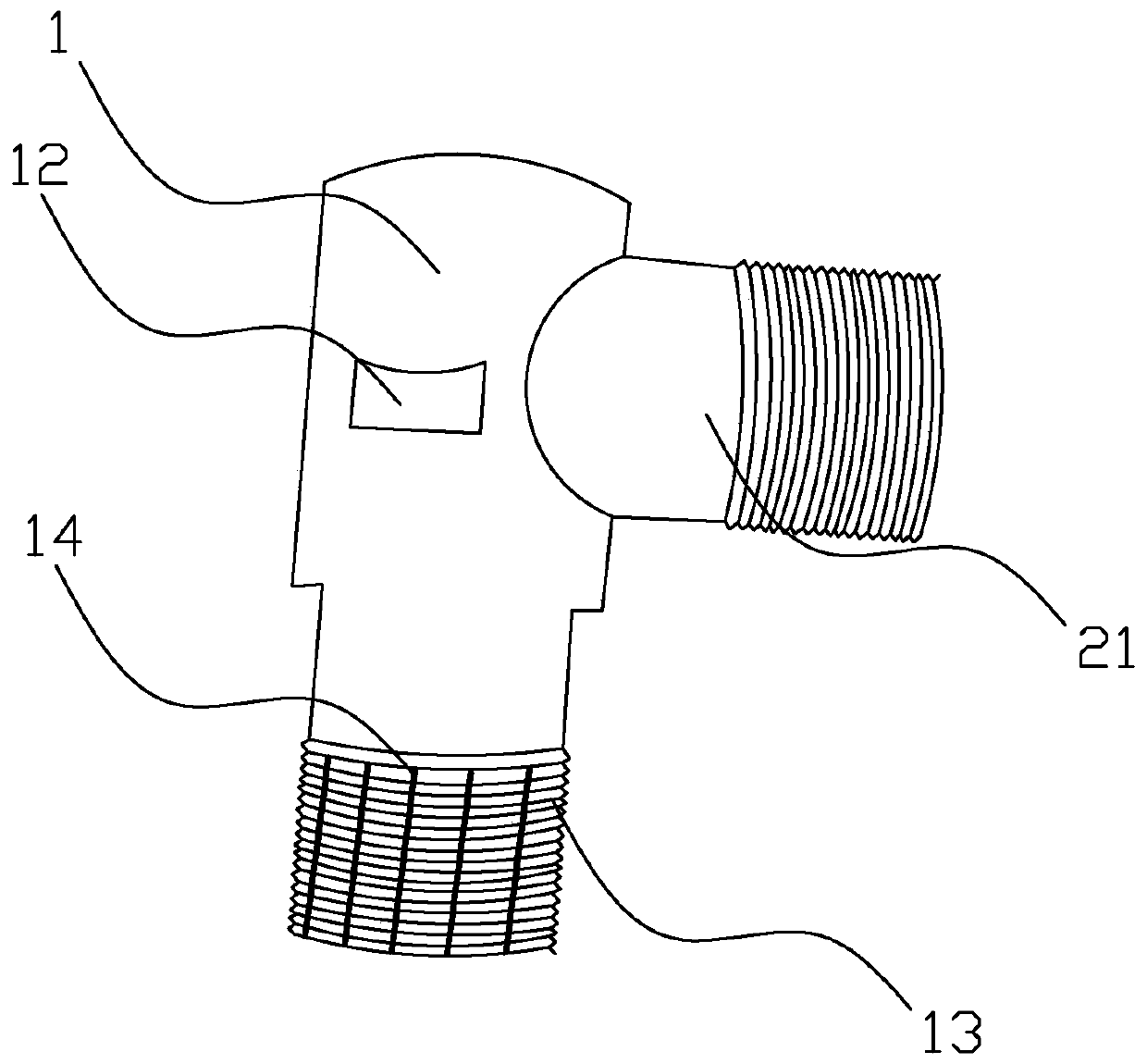

Machining method for stainless steel angle valve body

The invention relates to the technical field of faucets, and provides a machining method for a stainless steel angle valve body. The machining method for the stainless steel angle valve body comprisesthe following steps: a. preparation for an angle valve main body: machining a surface and then drilling a horizontal water outlet hole through a numerically-controlled drilling machine, and carryingout finish machining to obtain the stainless steel angle valve main body; b. preparation for a water outlet connector: machining a surface and then chamfering the periphery of one end which is weldedto the angle valve main body, of a straight pipe connector, and carrying out finish machining to obtain the stainless steel water outlet connector; and c. welding: inserting the chamfered end of the water outlet connector into the horizontal water outlet hole of the angle valve main body to locate, integrally welding the outer surface of the angle valve main body to the periphery of the water outlet connector, and then enabling a drill bit of an oil drilling machine to stretch into the angle valve main body to cut a part which is bulged out of the inner wall of the angle valve main body, of the water outlet connector, so as to obtain the stainless steel angle valve body. According to the machining method for the stainless steel angle valve body, the problem of high overall casting cost foran existing angle valve body is solved.

Owner:泉州市汉雅不锈钢厨卫有限公司

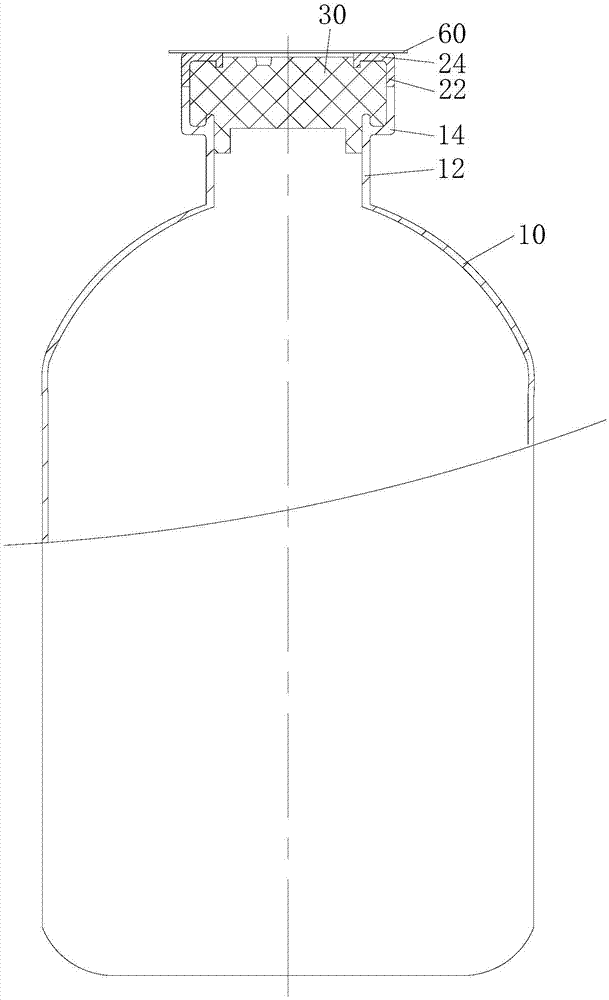

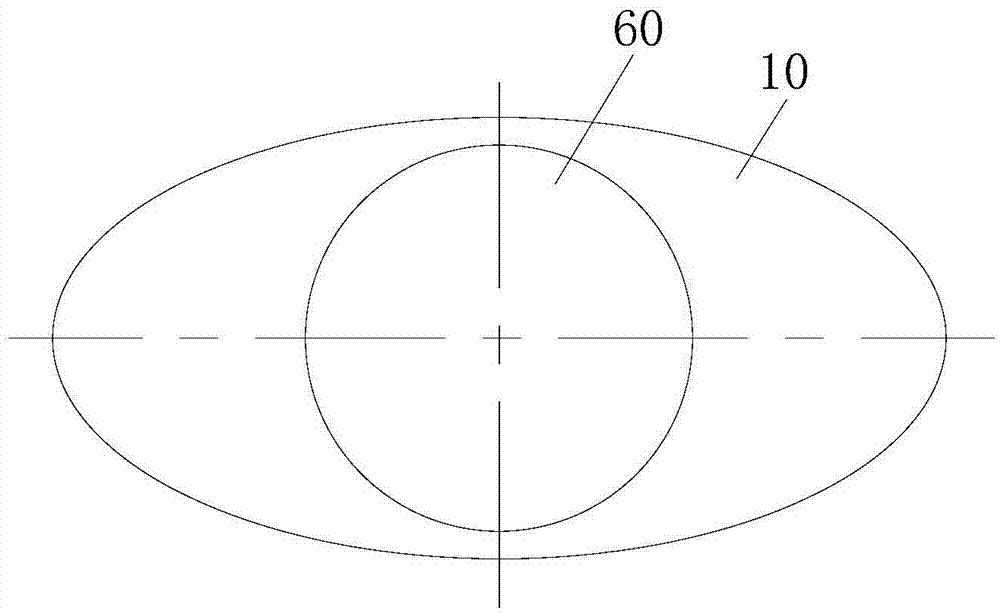

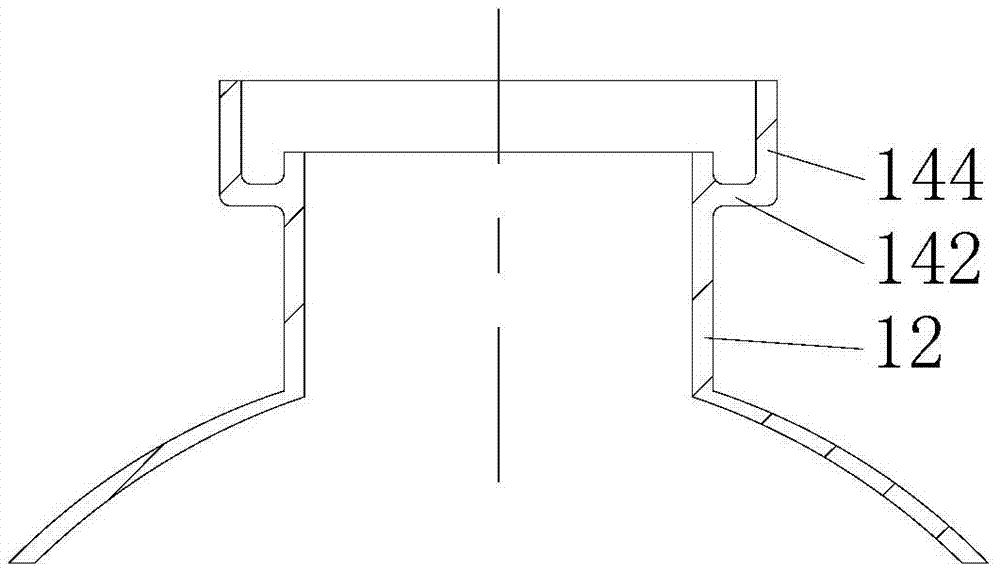

Combined cover and transfusion container with combined cover

PendingCN106963641AReduce in quantitySimple structurePharmaceutical containersMedical packagingStructural engineeringInfusion solution

The invention provides a combined cover and a transfusion container with the combined cover. The combined cover comprises an outer cover and a rubber plug, wherein the outer cover comprises a top wall and an annular side wall which are shaped by integration, one part of the rubber plug is tightly plugged in the outer cover, and the other part extends downwards to form a connecting part which is selected and connected to the inner wall of an interface of the transfusion container; and a hole which can be exposed from the upper surface of the rubber plug is formed in the top wall, and a seal part which can be separated from the outer surface of the top wall easily is sealed and disposed on the hole. The transfusion container comprises a body and the combined cover, wherein an interface is formed in the upper end of the body; a raised annular wall is disposed on the outer side of the upper part of the interface; the extending end of the annular wall is sealed and connected with the outer cover; storage space used to store the rubber plug is formed through enclosing of the outer cover and the annular wall; and the connecting part is sealed and connected to the inner wall of the interface. According to the invention, the structure is simple; welding can be conducted conveniently and rapidly; reliable seal can be formed; and cost can be reduced.

Owner:RENOLIT HENGXUN PACKAGING TECH BEIJING CO LTD

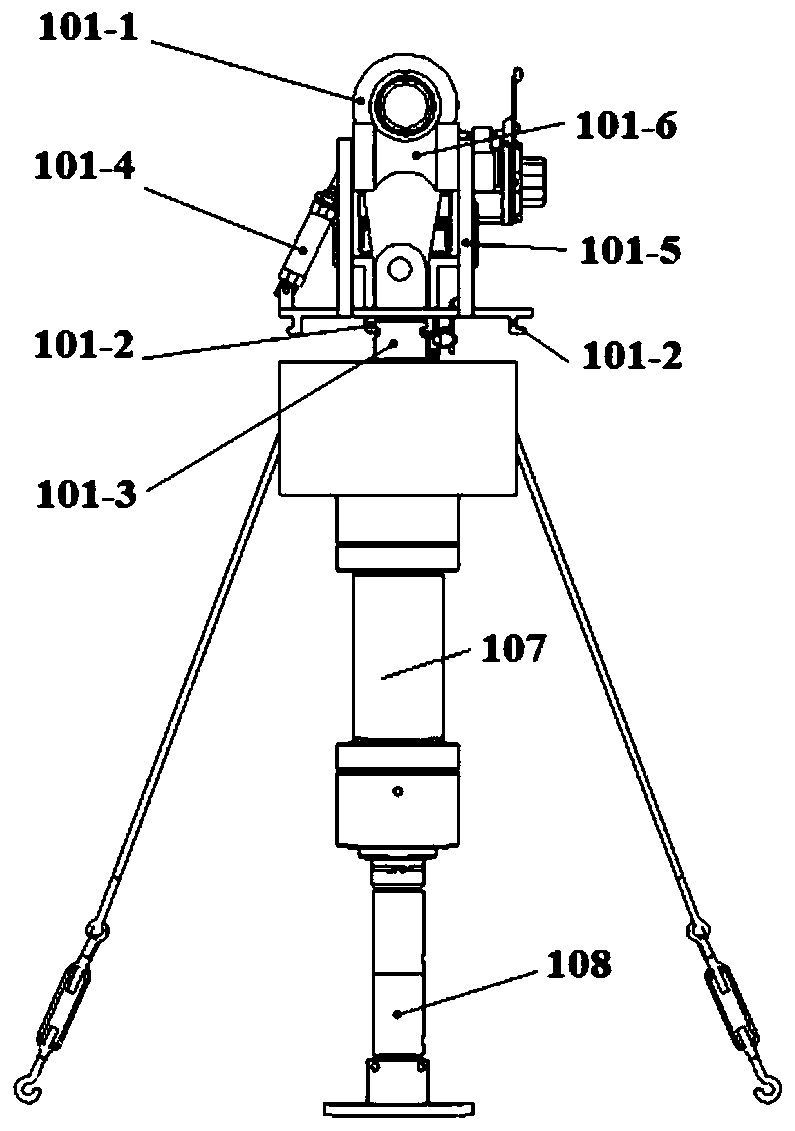

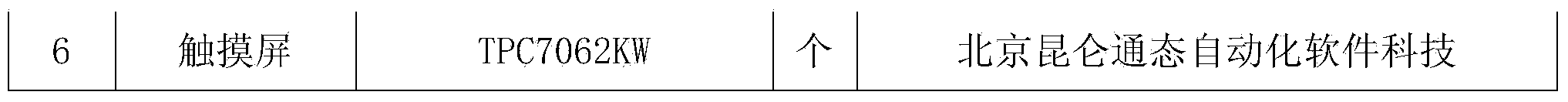

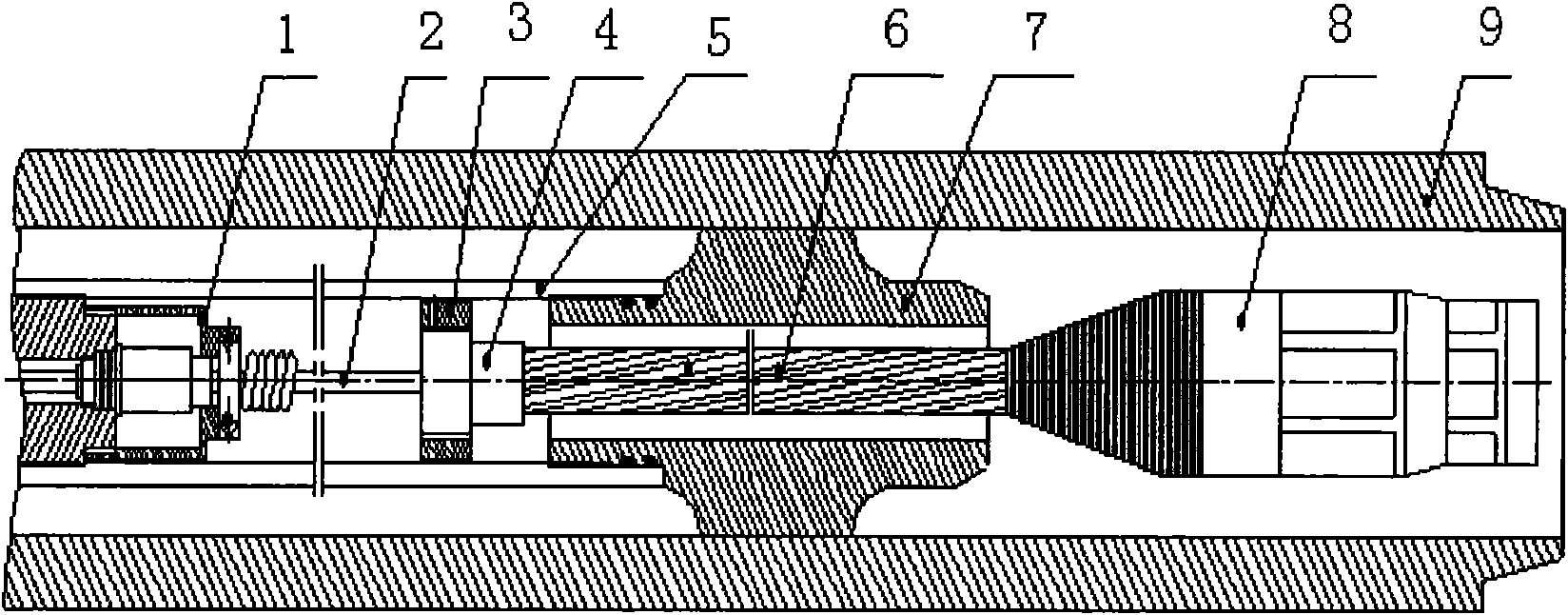

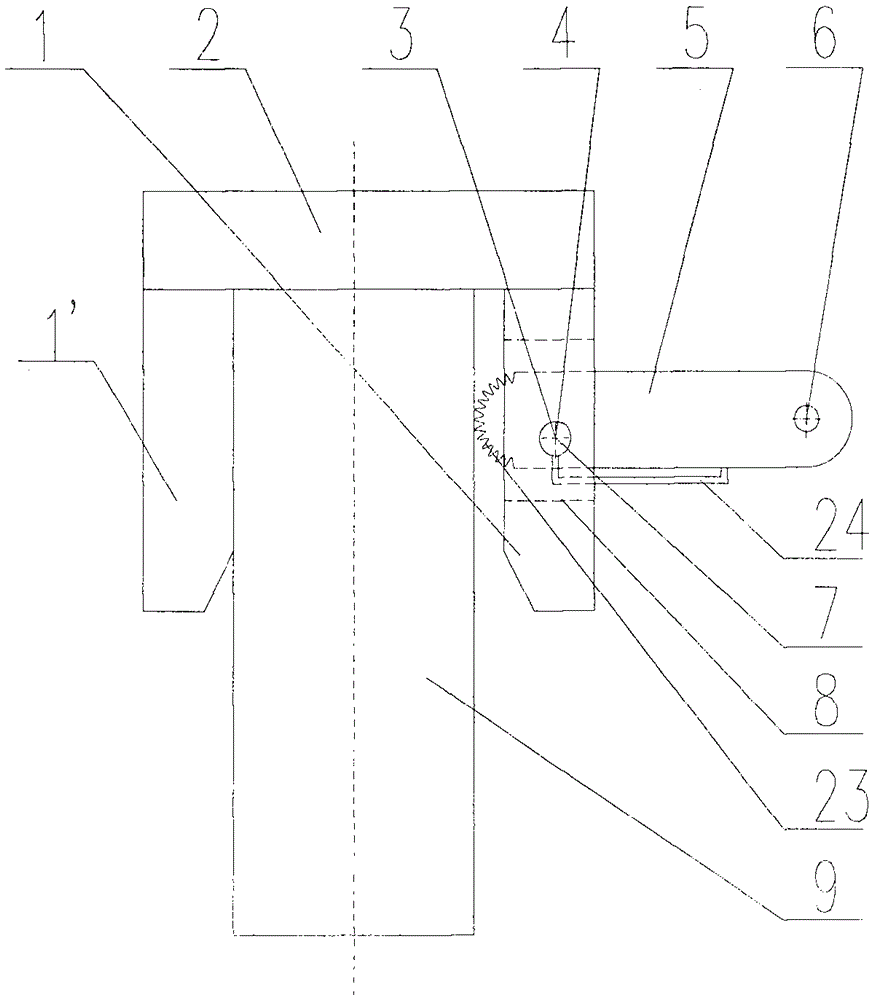

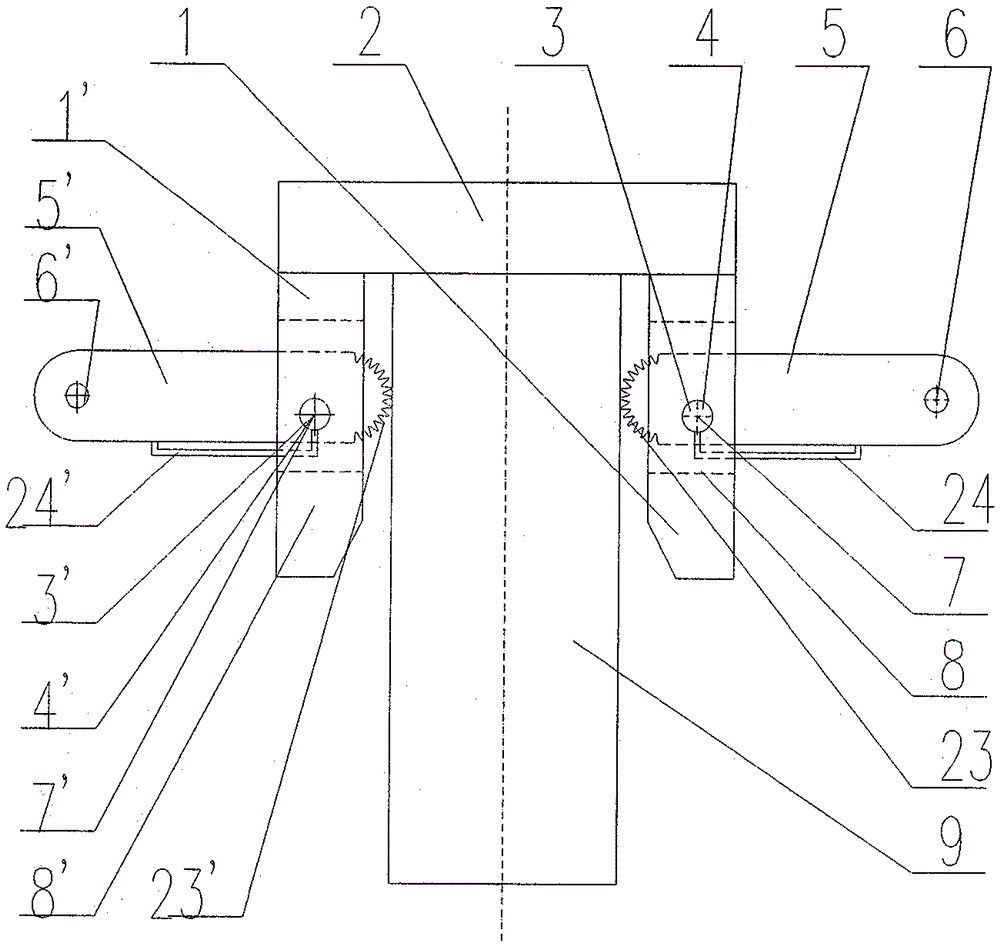

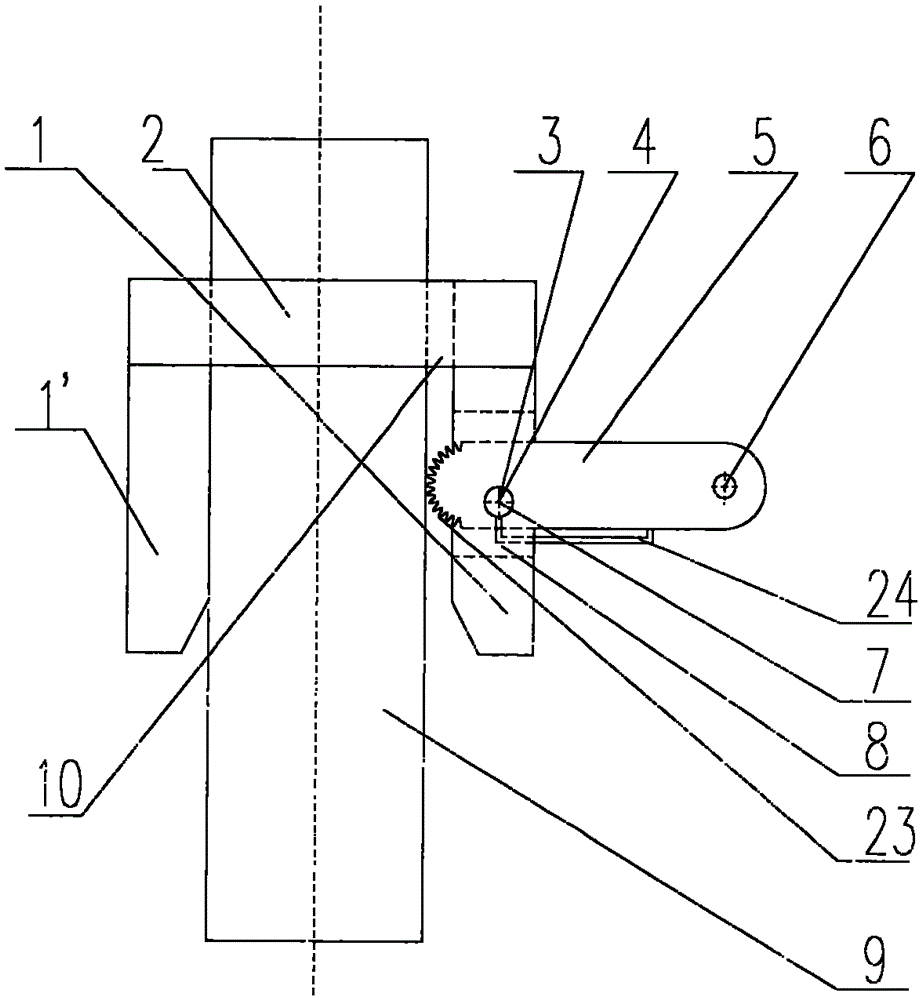

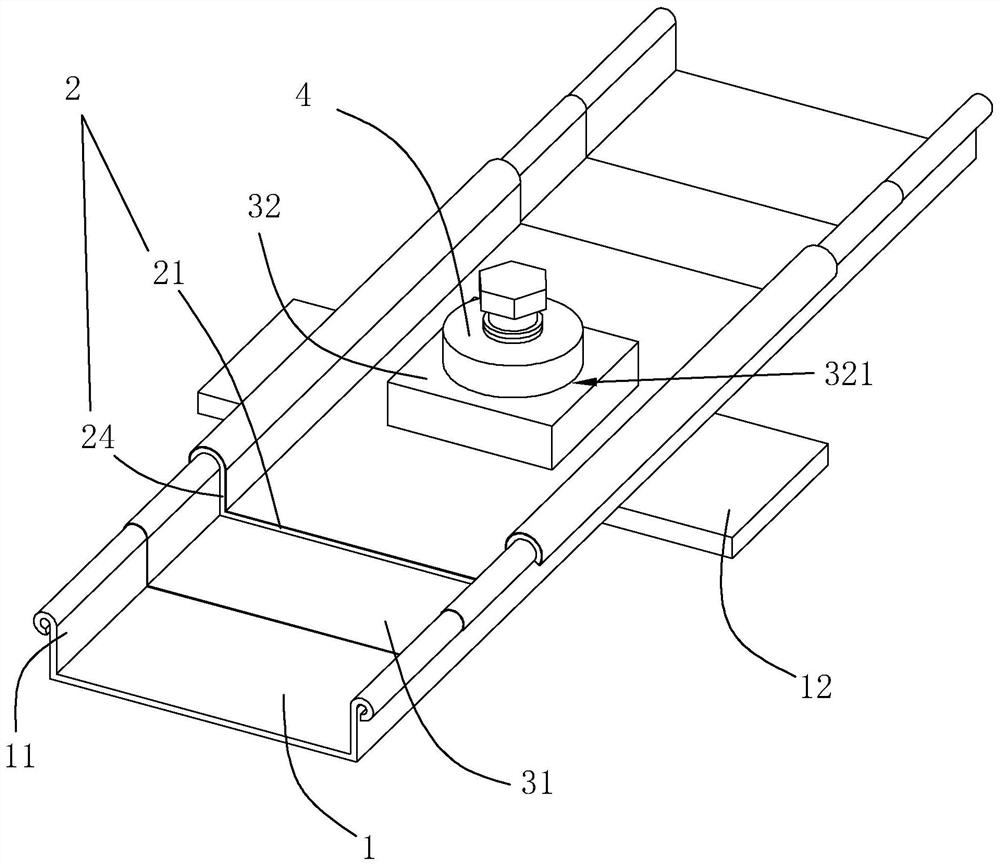

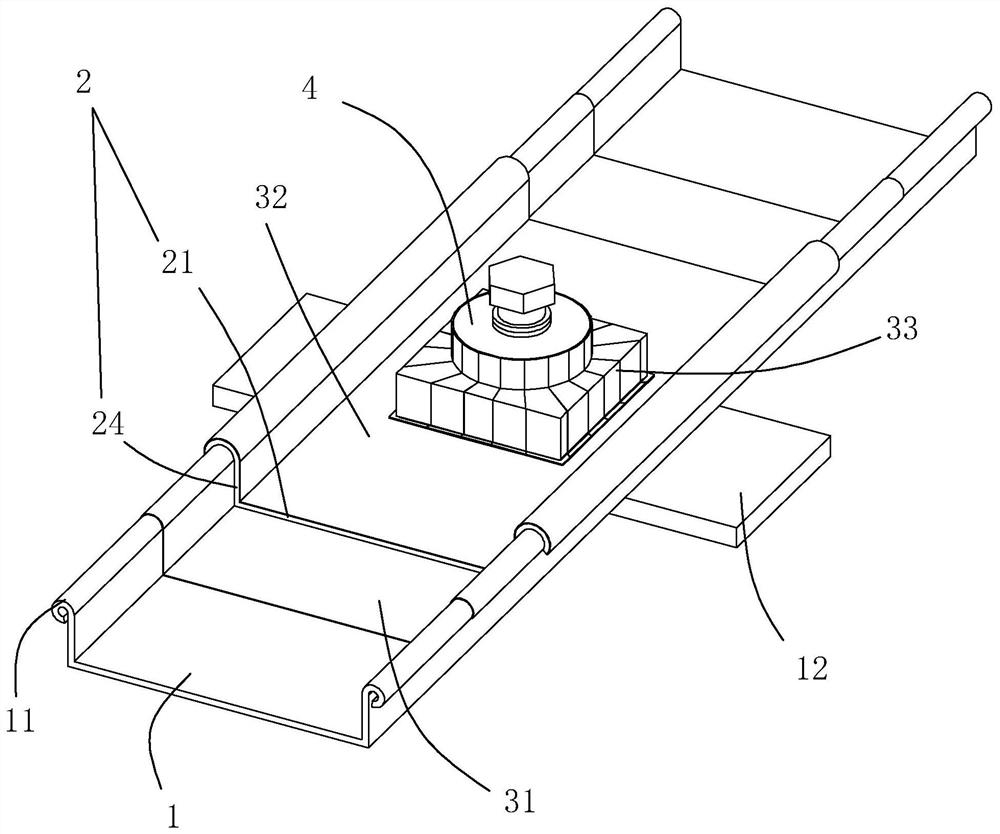

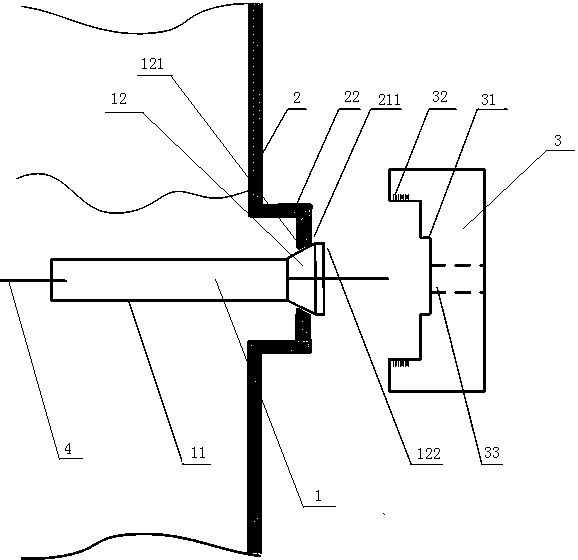

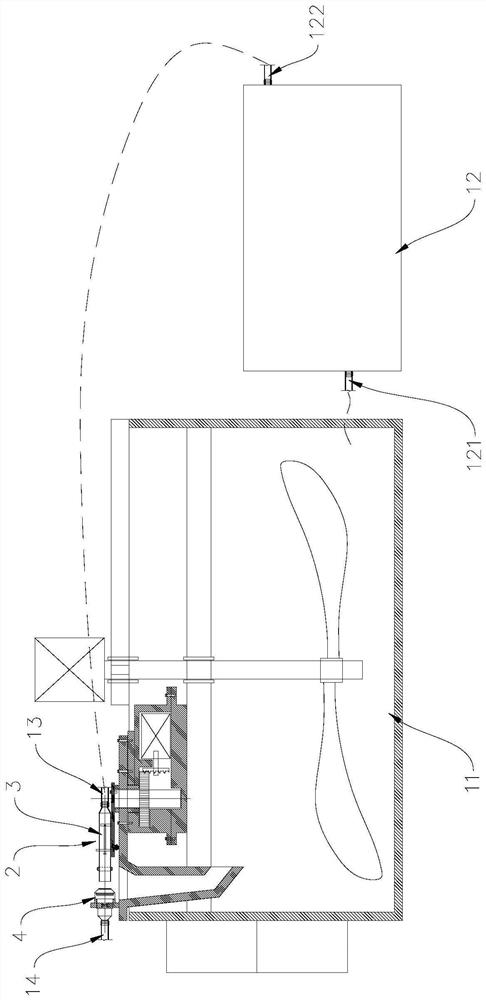

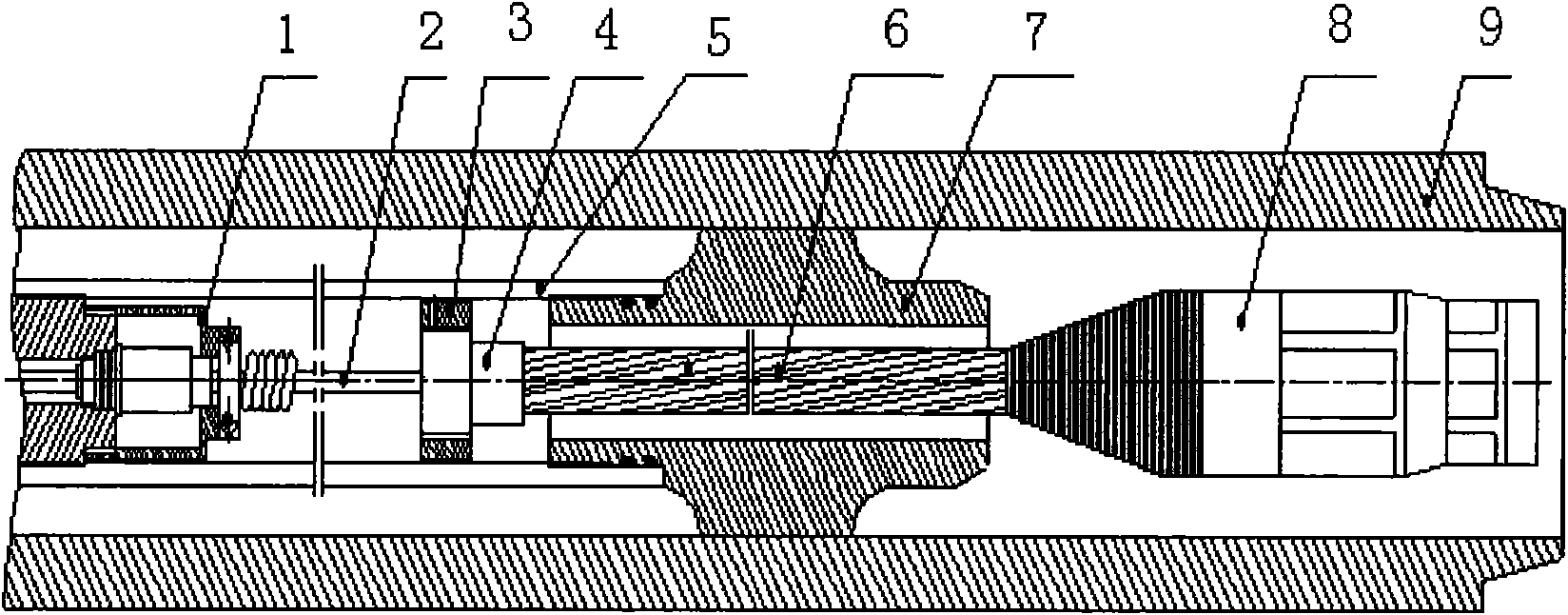

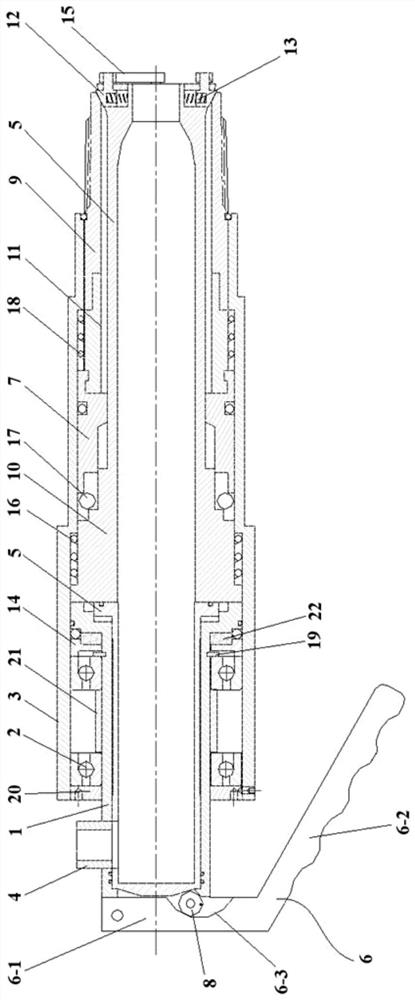

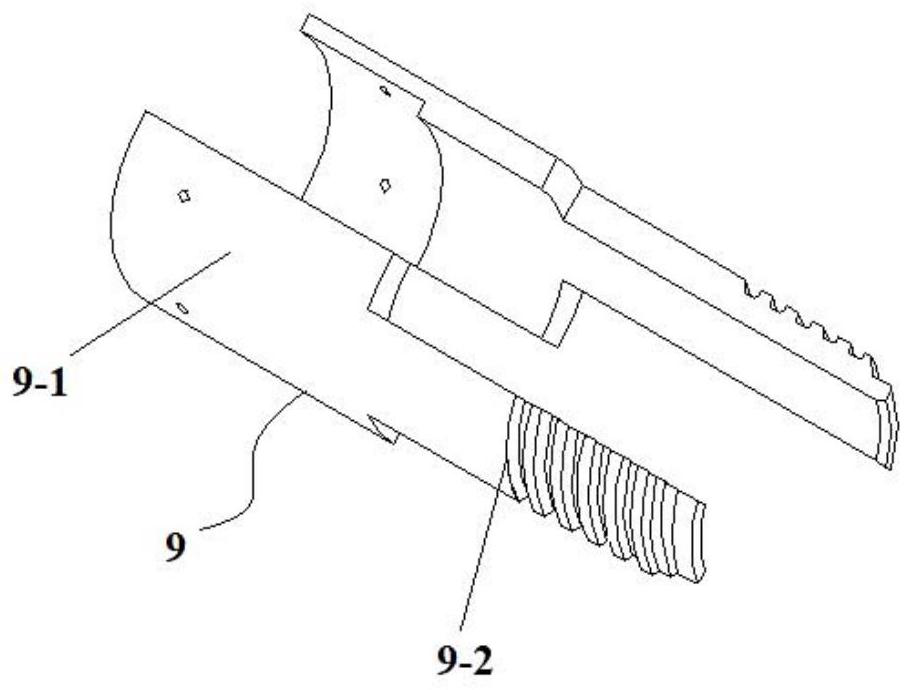

A quick plug-in water feeder and its construction method

ActiveCN109798080BEasy to operateReduce volumeBorehole drivesFlushingStructural engineeringHigh pressure water

The invention discloses a quick plug type water feeder and a construction method thereof. The quick plug type water feeder comprises a mandrel, a bearing and a bearing sleeve in coaxially sequential arrangement from inside to outside, and the side wall of the mandrel is provided with a high-pressure water connection port. The water feeder further comprises a force transmission hollow shaft, and the force transmission hollow shaft sleeves the mandrel internally, coaxially and closely and is capable of moving axially. A closed end of the force transmission hollow shaft is provided with a pressure handle and a rolling element, and a coaxial core rod is arranged at an open end of the force transmission hollow shaft. An annular piston, a clamping jaw push-fastening sleeve and a clamping jaw arecoaxial and arranged between the outer wall of the core rod and the inner wall of the bearing sleeve sequentially. The clamping jaw comprises arc clamping jaw plates in peripheral distribution, and inner walls of ends of the clamping jaw plates are jaw plate wedged faces. A piston block is arranged between the jaw plate wedged faces and the outer wall of the mandrel, and the wall face, close to the jaw plate wedged faces, of the piston block is a wedged outer wall. A first spring along the radial direction of the mandrel is arranged between the piston block and the mandrel. Safety and reliability in quick connection between the water feeder and an internal thread of a drill stem can be realized, drilling efficiency is improved, and requirements of rotary drilling and high-pressure sealingare met.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Sealing cap used for endoscope and ureter or flow guide tube in matched mode

The invention provides a sealing cap for cooperative use of an endoscope and a ureter or a flow guide tube, which comprises a first inflation channel arranged on a sealing cap body and used for inflating a first inflation part, and a first balloon capable of extruding a limiting part to one side to bend the limiting part, and a second inflation channel arranged on the sealing cap body and used for inflating the first inflation part to form a second balloon capable of extruding the limiting part to one side to bend the limiting part. And the second inflation channel is used for inflating the second inflation part, so that the second inflation part can form a second balloon which extrudes the pressure limiting part towards the other side to be bent. The device has the beneficial effects that the air bags capable of being contracted and expanded are arranged on the two sides of the limiting part correspondingly, the setting angle of the end of the limiting part can be restrained through expansion or contraction of the different air bags, and the limiting part is promoted to swing up and down according to the use requirement; therefore, the full fixation of the telescopic freedom degree of the endoscope and the unidirectional freedom degree fixation are realized.

Owner:姜玉雷

Quick plugging device for pipeline and implementation method of quick plugging device

The invention discloses a quick plugging device for a pipeline and an implementation method of the quick plugging device. The quick plugging device comprises a direct-insertion type automatic locking quick connector matched with the outer diameter of the broken pipeline and a pipeline valve matched with the direct-insertion type automatic locking quick connector. One end of the direct-insertion type automatic locking quick connector is connected with the broken pipeline and the other end is connected with the pipeline valve. When the quick plugging device is used for plugging, the direct-insertion type automatic locking quick connector is connected with the pipeline valve, the pipeline valve is opened, the direct-insertion type automatic locking quick connector is connected with the broken pipeline to be plugged, the pipeline valve is closed after connection is finished, and plugging is achieved. Due to the fact that the valve is open in the plugging connection process and pressure of the pipeline with the pressure can be relieved from the valve, no large resistance exists when the direct-insertion type automatic locking quick connector is connected with the pipeline, connection can be achieved easily and quickly, the pipeline valve is closed after connection is finished, and plugging is achieved.

Owner:ZHEJIANG YU LONG PIPE TECH CO LTD

Composite retaining piles for building basements

ActiveCN105019472BImprove waterproof performanceImprove sealingArtificial islandsUnderwater structuresBasementUltimate tensile strength

A composite retaining pile for use in constructing a basement, comprising composite piles (1) and retaining piles (2). The composite piles (1) are arranged in the circumferential direction of a basement (100) and connected with each other to form one closed ring structure. The retaining piles (2) surround the basement (100) and are fixedly connected with the composite piles (1).

Owner:周兆弟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com